Petroleum resin ball granule and its production equipment and manufacturing method

A technology for petroleum resin and spherical particles, which is applied in the fields of petroleum resin spherical particles and their production equipment and manufacturing, can solve the problems of adjusting the output, difficult production needs, large installation sites, etc., to achieve good fluidity and particle strength, production operation Simple, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

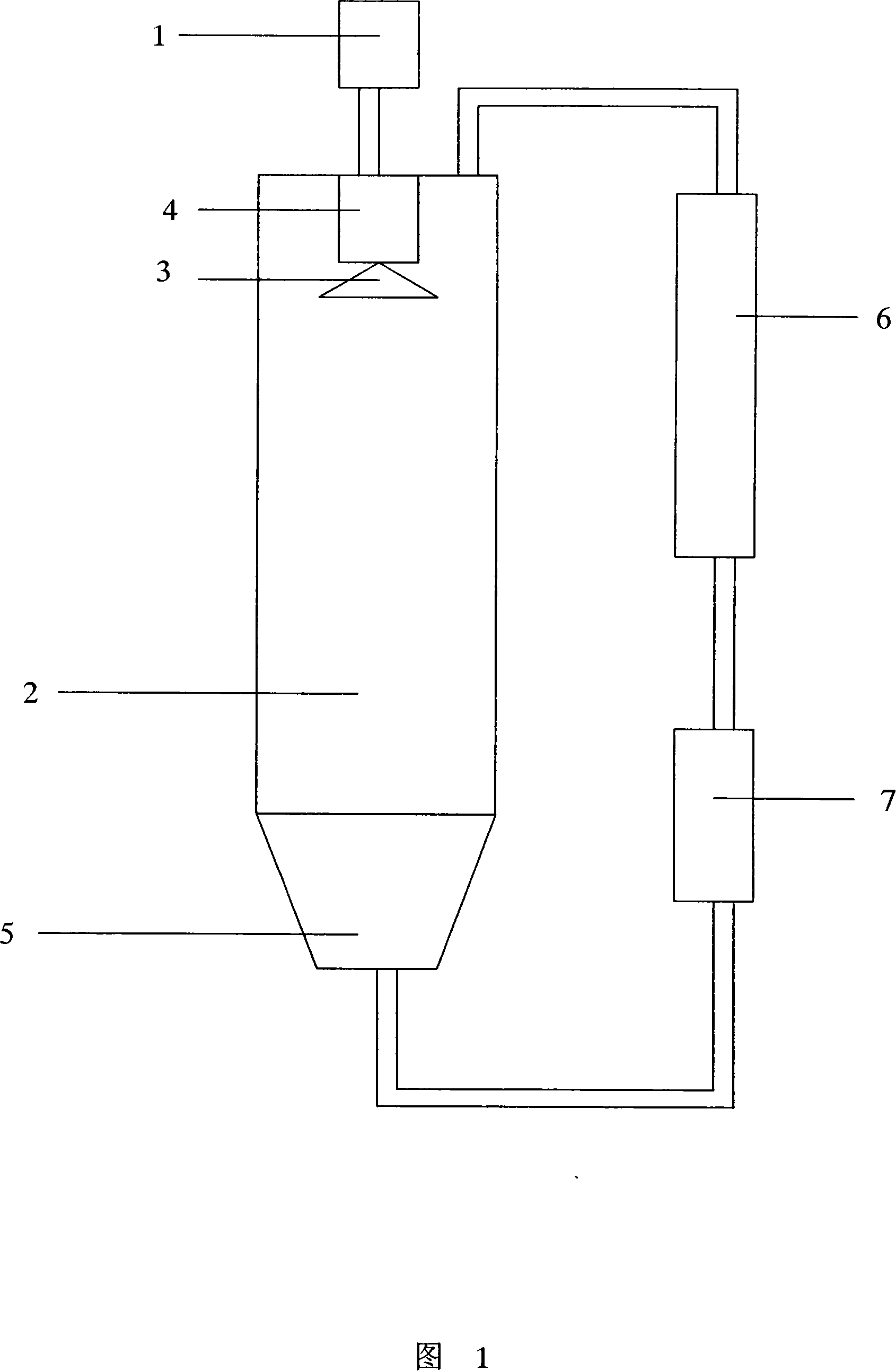

[0024] The refined liquid C5 petroleum resin enters the nozzle from the silo and sprays downward. When spraying out, the nozzle is in the vibration movement driven by the vibration mechanism. The vibration frequency is 200 times per second and the amplitude is 3mm. Droplets become spherical droplets, and exchange heat with the rising inert gas in the prilling tower, and condense into spherical solid particles with an average particle diameter of 3 mm; the spherical solid particles fall into the fluidized bed at the bottom of the prilling tower for further cooling, Leave the prilling tower and enter the packaging process. The fluidization drive of the fluidized bed at the bottom of the prilling tower comes from the inert gas flowing upward from the bottom of the tower. The inert gas leaving the fluidized bed continues to move upwards in the prilling tower and interacts with the downward petroleum resin particles. Heat exchange, leaving the prilling tower from the top of the tow...

Embodiment 2

[0026] The refined liquid C5 petroleum resin enters the nozzle from the silo and sprays downward. When spraying out, the nozzle is in the rotating motion driven by the rotating mechanism at a speed of 20 rpm. The petroleum resin leaving the nozzle becomes spherical droplets driven by the movement of the nozzle. , and conduct heat exchange with the rising inert gas in the prilling tower, and condense into spherical solid particles with an average particle diameter of 1.5 mm; the spherical solid particles fall into the fluidized bed at the bottom of the prilling tower for further cooling, and leave the prilling tower to enter Packaging process. The fluidization drive of the fluidized bed at the bottom of the prilling tower comes from the inert gas flowing upward from the bottom of the tower. The inert gas leaving the fluidized bed continues to move upwards in the prilling tower and interacts with the downward petroleum resin particles. Heat exchange, leaving the prilling tower f...

Embodiment 3

[0028] The refined liquid C9 petroleum resin enters the nozzle from the silo and sprays downward. When spraying, the nozzle is in the vibration movement driven by the vibration mechanism. The vibration frequency is 500 times per second and the amplitude is 1mm. Droplets become spherical droplets, and exchange heat with the rising inert gas in the prilling tower, and condense into spherical solid particles with an average particle size of 1mm; the spherical solid particles fall into the fluidized bed at the bottom of the prilling tower for further cooling, Leave the prilling tower and enter the packaging process. The fluidization drive of the fluidized bed at the bottom of the prilling tower comes from the inert gas flowing upward from the bottom of the tower. The inert gas leaving the fluidized bed continues to move upwards in the prilling tower and interacts with the downward petroleum resin particles. Heat exchange, leaving the prilling tower from the top of the tower, enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com