Polyethylene glycol-polyethyleneimine modified ferric oxide nanoparticle preparation method

A nanotechnology of polyethyleneimine and iron oxide, which is applied in the field of materials, can solve the problems of limited application, difficulty in storage, difficulty in water, etc., and achieves the effects of strong operability, uniform particle size distribution, and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

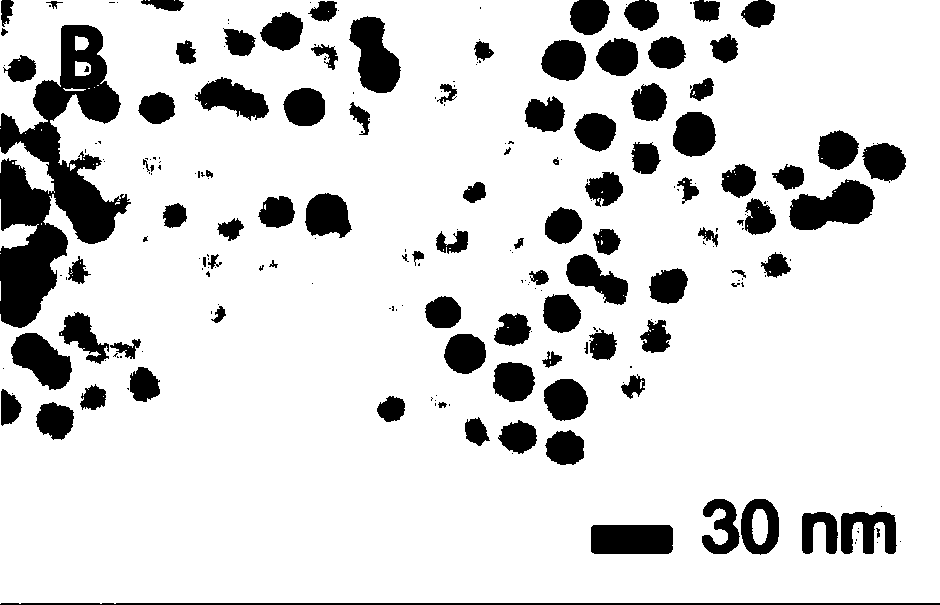

Image

Examples

Embodiment 1

[0030] A preparation method of polyethylene glycol-polyethyleneimine modified iron oxide nanoparticles, comprising the following steps:

[0031] 1) 2g polyethylene glycol (M w =1000) was dissolved in 200ml of dichloromethane, 0.2g of maleic anhydride was added, 0.05g of triethylamine and 0.25g of 4-dimethylaminopyridine were added at the same time, reacted at room temperature for 48h, and more than three times the volume of dichloromethane was added The glacial ether precipitation obtains carboxylated polyethylene glycol; Step 1) in, the mol ratio of described polyethylene glycol and maleic anhydride is 1:1; Triethylamine and 4-dimethylaminopyridine mol ratio are 1: 6.28. The total mass of triethylamine and 4-dimethylaminopyridine added is 1.5 times the mass of maleic anhydride.

[0032] 2) 0.4g of the resulting product was dissolved in 40ml of tetrahydrofuran, and 8g of polyethyleneimine (M w =8,000), add 0.05g dicyclohexylcarbodiimide and 0.15g 4-dimethylaminopyridine, rea...

Embodiment 2

[0037] A preparation method of polyethylene glycol-polyethyleneimine modified iron oxide nanoparticles, comprising the following steps:

[0038] 1) 2g polyethylene glycol (M w =1000) was dissolved in 200ml of dichloromethane, 0.25g of maleic anhydride was added, 0.05g of triethylamine and 0.3g of 4-dimethylaminopyridine were added at the same time, reacted at room temperature for 72h, and the carboxyl group was obtained by precipitation with excess glacial ether polyethylene glycol; in step 1), the mol ratio of polyethylene glycol and maleic anhydride is 1:1.28; the mol ratio of triethylamine and 4-dimethylaminopyridine is 1:7.55, triethylamine and The added total mass of 4-dimethylaminopyridine is 1.4 times of the mass of maleic anhydride.

[0039] 2) 0.115g of the resulting product was dissolved in 11.5ml of tetrahydrofuran, and 8g of polyethyleneimine (M w =8,000), add 0.06g dicyclohexylcarbodiimide and 0.17g 4-dimethylaminopyridine, react 72h under room temperature, remo...

Embodiment 3

[0044] A preparation method of polyethylene glycol-polyethyleneimine modified iron oxide nanoparticles, comprising the following steps:

[0045] 1) 2g polyethylene glycol (M w =1000) was dissolved in 200ml of dichloromethane, 0.3g of maleic anhydride was added, 0.1g of triethylamine and 0.4g of 4-dimethylaminopyridine were added at the same time, reacted at room temperature for 60h, and precipitated with excess glacial ether to obtain carboxyl polyethylene glycol; in step 1), the mol ratio of polyethylene glycol and maleic anhydride is 1:1.53; the mol ratio of triethylamine and 4-dimethylaminopyridine is 1:5.03, triethylamine and The total mass added of 4-dimethylaminopyridine is 1.67 times of the mass of maleic anhydride.

[0046] 2) 0.2g of the resulting product was dissolved in 10ml of tetrahydrofuran, and 8g of polyethyleneimine (M w =8,000), add 0.05g dicyclohexylcarbodiimide and 0.15g 4-dimethylaminopyridine, react 96h under room temperature, remove solvent by rotary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com