Large-scale prepared particle size-controllable nitrogen and oxygen doped carbon microsphere and preparation method and application thereof

A technology for large-scale preparation and carbon microspheres, which is applied in the preparation/purification of carbon, nanotechnology for materials and surface science, nanotechnology, etc. It can solve the problems of difficult large-scale preparation, complicated steps, and high cost. The preparation method is simple and easy, the mesopore volume is increased, and the yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

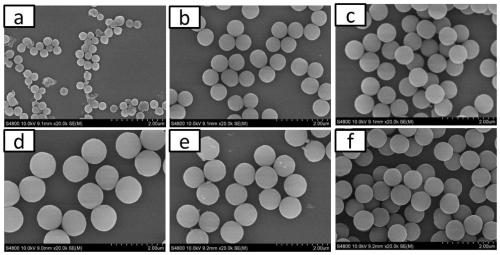

[0030] A Synthesis of precursor polymer microspheres (controlling the particle size of microspheres by adjusting the solvent composition)

[0031] Add 5g of diallyl phthalate, 7g of divinylbenzene, 5g of acrylonitrile and 80g of solvent into a 250ml three-neck flask. The three-necked flask was placed in an oil bath at 70°C with an electric digital display constant-speed stirring device, and condensed and refluxed. After stirring evenly, it was filled with nitrogen atmosphere for protection. Then, 0.2 g of azobisisobutyronitrile was added to start the polymerization reaction. After 3 hours, the reaction was completed, and the solid product was separated by centrifugation, washed and dried to obtain the precursor polymer microspheres. The rotating speed of the electric digital display constant speed stirring device is 900r / min, and the mass ratios of absolute ethanol and deionized water in the solvent are 2:3, 1:1, 3:2, 7:3, 4:1, 9: 1. According to formula 1, the average yiel...

Embodiment 2

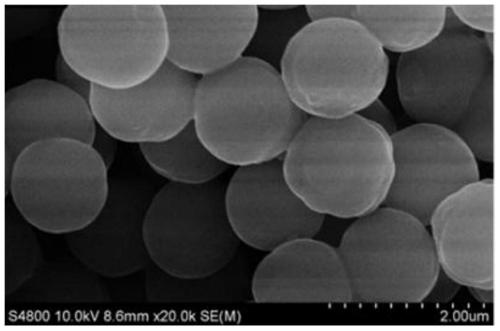

[0040] A. Synthesis of precursor polymer microspheres (control the particle size of the microspheres by adjusting the stirring rate composition during the synthesis)

[0041] Add 7g of diallyl phthalate, 5g of divinylbenzene, 5g of acrylonitrile, and 80g of solvent into a 250ml three-necked flask. The three-necked flask was placed in an oil bath at 70°C with an electric digital display constant-speed stirring device, and condensed and refluxed. After stirring evenly, it was filled with nitrogen atmosphere for protection. Then, 0.2 g of azobisisobutyronitrile was added to start the polymerization reaction. After 3 hours, the reaction was completed, and the solid product was separated by centrifugation, washed and dried to obtain the precursor polymer microspheres. The mass ratio of ethanol to deionized water in the solvent is 9:1, and the stirring speeds of the electric digital display constant speed stirring device are 300, 600, 900, 1200 r / min respectively. Calculated accor...

Embodiment 3

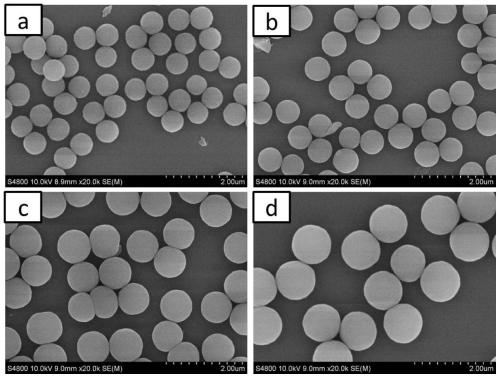

[0048] A. Synthesis of precursor polymer microspheres

[0049] Take two 250ml three-necked flasks, numbered A and B respectively. Add 7g diallyl phthalate, 2g methyl acrylate, 3g ethyl acrylate, 5g acrylonitrile to bottle A; add 7g diallyl phthalate, 2g styrene, 3g methacrylic acid to bottle B Methyl ester, 5g acrylonitrile. Then 80 g of solvent were added separately. The three-necked flask was placed in an oil bath at 70°C with an electric digital display constant-speed stirring device, and condensed and refluxed. After stirring evenly, it was filled with nitrogen atmosphere for protection. Then, 0.2 g of azobisisobutyronitrile was added to start the polymerization reaction. After 3 hours, the reaction was completed, and the solid product was separated by centrifugation, washed and dried to obtain the precursor polymer microspheres. The mass ratio of ethanol to deionized water in the solvent is 9:1, and the stirring rate of the electric digital display constant speed stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com