Sulfur-nitrogen co-doped porous carbon supported ternary transition metal composite material and preparation method thereof

A technology of transition metals and composite materials, which is applied in the electrolysis process, electrodes, electrolysis components, etc., can solve the problems of complex catalyst preparation methods, use of toxic reagents, long synthesis cycle, etc., to reduce atomic aggregation, improve activity and stability, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

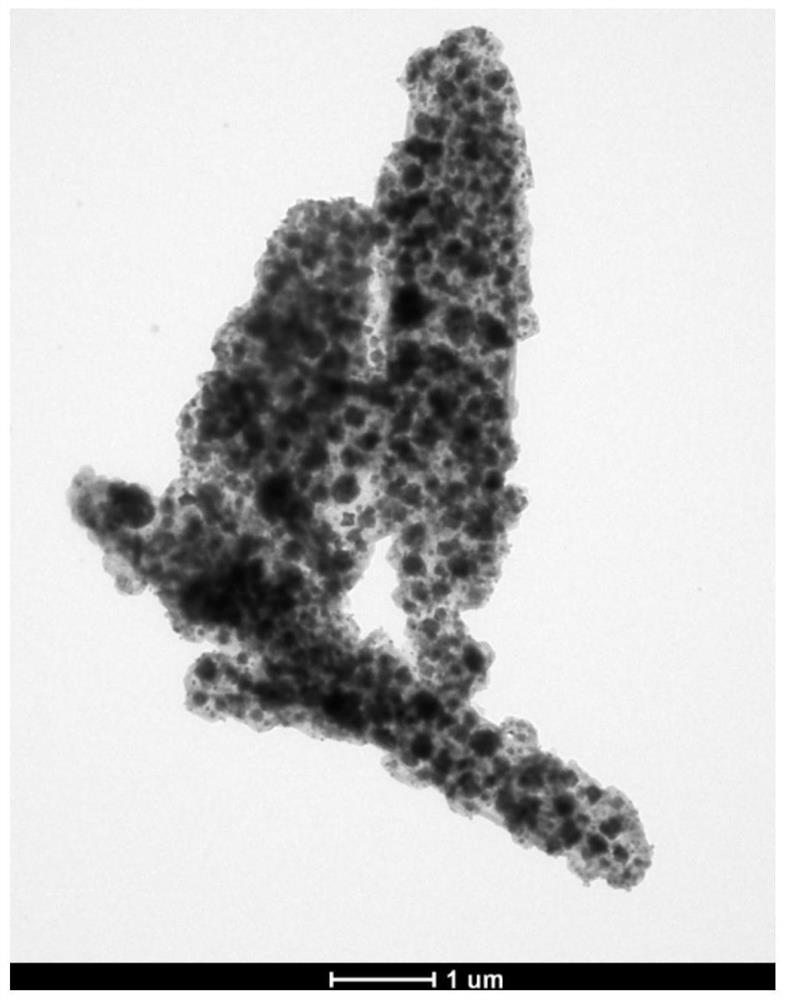

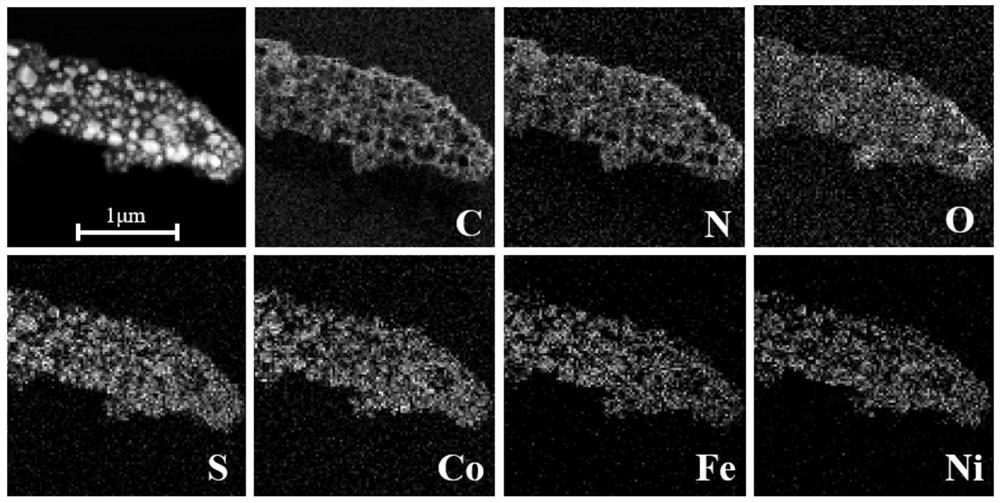

Image

Examples

Embodiment 1

[0032] A method for preparing a sulfur-nitrogen co-doped porous carbon-supported ternary transition metal composite material, comprising the following steps:

[0033] (1) Under the condition of 25℃, 0.15mmol iron tetrafluoroborate Fe(BF 4 ) 2 , 0.15mmol cobalt nitrate Co(NO 3 ) 2 Dissolved in 40mL of methanol and water in a mixed solution with a volume ratio of 1:1 to obtain a mixed solution with iron precursor and cobalt precursor concentrations of 0.00375mol / L as solution A;

[0034] (2) Dissolve 3mmol of surfactant K-29 type polyvinylpyrrolidone (PVP) and 0.3mmol of organic ligand dipyridyl disulfide in 40mL of a mixed solution of methanol and water with a volume ratio of 1:1, and ultrasonicate for 2min to obtain the compound solution. Bulk concentration is the mixed solution of 0.0075mol / L, as solution B;

[0035] (3) Potassium tetracyanonickelate 0.3mmol K 2 [Ni(CN) 4 ] was dissolved in 10mL water to obtain an aqueous solution with a nickel precursor concentration o...

Embodiment 2

[0046] A method for preparing a sulfur-nitrogen co-doped porous carbon-supported ternary transition metal composite material, comprising the following steps:

[0047] (1) Under the condition of 25℃, 0.1mmol iron tetrafluoroborate Fe(BF 4 ) 2 and 0.1mmol cobalt nitrate Co(NO 3 ) 2 Dissolved in 40mL of methanol and water in a mixed solution with a volume ratio of 1:1 to obtain a mixed solution with an iron precursor and a cobalt precursor concentration of 0.0025mol / L as solution A;

[0048] (2) Dissolve 4mmol of surfactant K-29 type polyvinylpyrrolidone (PVP) and 0.2mmol of organic ligand dipyridyl disulfide in 40mL of a mixed solution of methanol and water with a volume ratio of 1:1, and ultrasonicate for 2min to obtain the compound solution. The mixed solution with volume concentration of 0.005mol / L is used as solution B;

[0049] (3) Potassium tetracyanonickelate 0.2mmol K 2 [Ni(CN) 4 ] was dissolved in 10mL water to obtain an aqueous solution with a nickel precursor co...

Embodiment 3

[0056] A method for preparing a sulfur-nitrogen co-doped porous carbon-supported ternary transition metal composite material, comprising the following steps:

[0057] (1) Under the condition of 25℃, 0.2mmol iron tetrafluoroborate Fe(BF 4 ) 2 and 0.2mmol cobalt nitrate Co(NO 3 ) 2 Dissolved in 40mL of methanol and water in a mixed solution with a volume ratio of 1:1 to obtain a mixed solution with an iron precursor and a cobalt precursor concentration of 0.005mol / L as solution A;

[0058] (2) Dissolve 8mmol of surfactant K-29 type polyvinylpyrrolidone (PVP) and 0.4mmol of organic ligand dipyridyl disulfide in 40mL of a mixed solution of methanol and water with a volume ratio of 1:1, and ultrasonicate for 2min to obtain the compound solution. The mixed solution with volume concentration of 0.01mol / L is used as solution B;

[0059] (3) Potassium tetracyanonickelate 0.4mmol K 2 [Ni(CN) 4 ] was dissolved in 10mL water to obtain an aqueous solution with a nickel precursor conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com