Ultrafast hydrogen ion composite electrode material and preparation method thereof

A composite electrode and hydrogen ion technology, applied in the field of materials, can solve the problems of low capacitance, poor conductivity and stability, and limit application development, and achieve the effect of simple preparation process and good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of ultrafast hydrogen ion composite material includes the following steps:

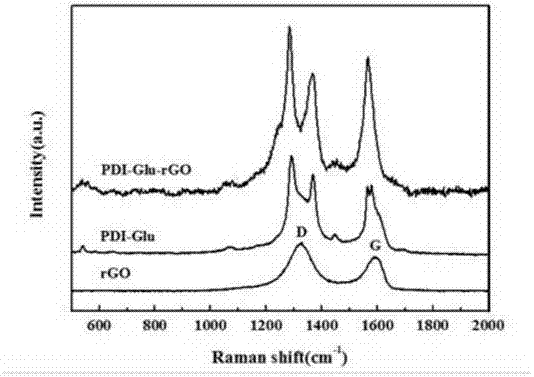

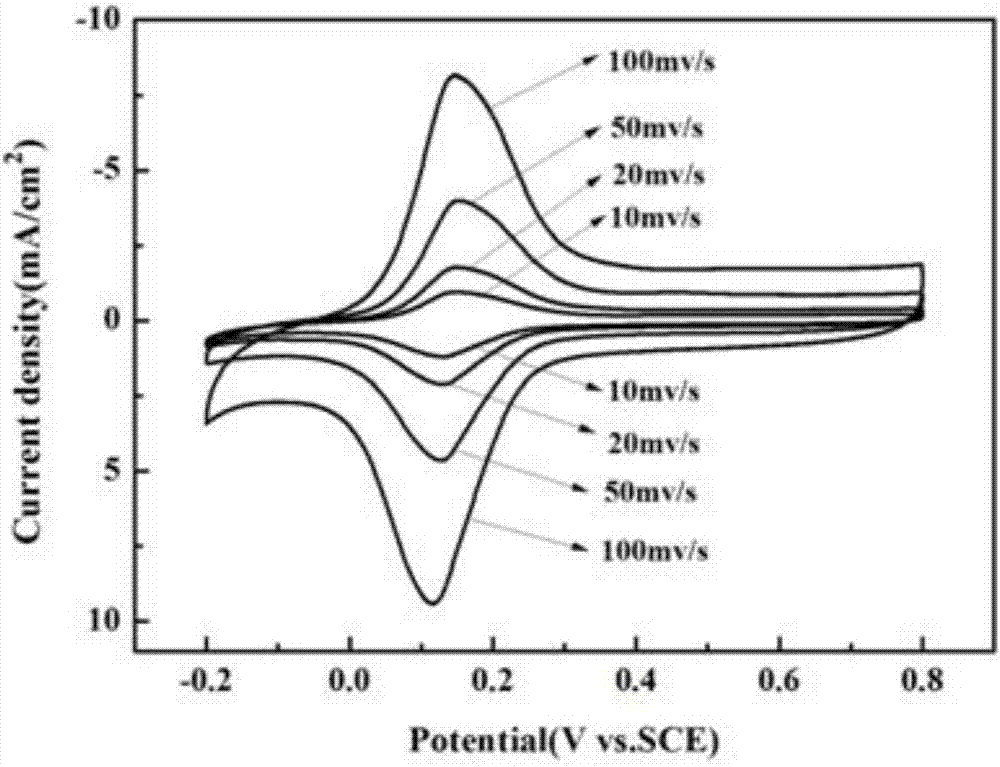

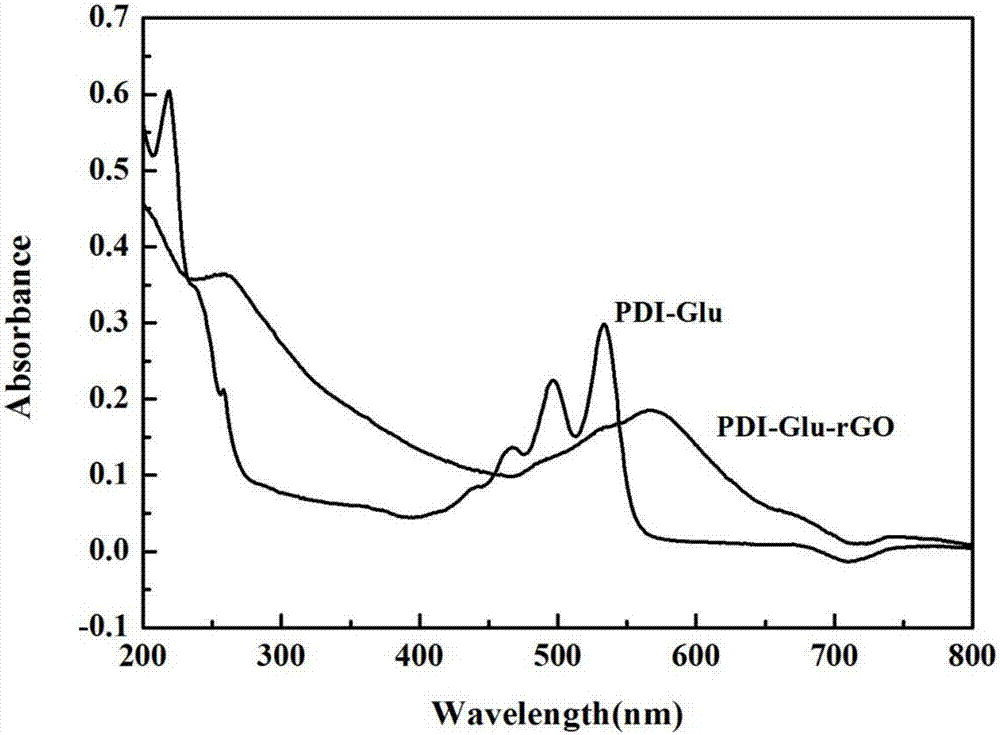

[0026] A. Put 0.5 g of perylene tetracarboxylic acid anhydride glutamic acid and 50 ml of 2 mg / ml graphite oxide suspension into a 100 ml round bottom flask and stir at a certain speed to form a uniform mixed solution, and react at 95°C. 4 Within hours, the perylene tetracarboxylic anhydride glutamic acid / graphite oxide composite was obtained.

[0027] B. Add 0.7 ml of ammonia and 1.0 ml of hydrazine hydrate to the mixed solution obtained in step A to reduce graphite oxide, the mass fraction of ammonia water is 15%, the mass fraction of hydrazine hydrate is 25%, and react at 95°C for 1 hour. After the completion, the product is cooled to room temperature, centrifuged and washed with deionized water and absolute ethanol for 4 times, after drying, the perylenetetracarboxylic anhydride amino acid / reduced graphite oxide ultrafast hydrogen ion composite material can be prepared.

[00...

Embodiment 2

[0032] A preparation method of ultrafast hydrogen ion composite material includes the following steps:

[0033] A. Put 0.5 g of perylenetetracarboxylic anhydride-based aspartic acid and 40 ml of 3 mg / ml graphite oxide suspension into a 100 ml round-bottom flask and stir at a certain speed to form a uniform mixed solution, and react at 80°C After 3 hours, a perylene tetracarboxylic anhydride-based aspartic acid / graphite oxide composite was obtained.

[0034] B. Add 0.5 ml of ammonia water and 1.2 ml of hydrazine hydrate to the mixed solution obtained in step A to reduce graphite oxide, the mass fraction of ammonia water is 10%, the mass fraction of hydrazine hydrate is 20%, and the reaction is carried out at 90°C for 2 hours. After the end, the product was cooled to room temperature, and washed with deionized water and absolute ethanol for 4 times by centrifugation. After drying, the perylenetetracarboxylic anhydride based aspartic acid / reduced graphite oxide ultra-fast hydrogen ion...

Embodiment 3

[0036] A preparation method of ultrafast hydrogen ion composite material includes the following steps:

[0037] A. Put 0.5 g of perylene tetracarboxylic acid anhydride glycine and 40 ml of the 3.5 mg / ml graphite oxide suspension into a 100 ml round bottom flask and stir at a certain speed to form a uniform mixed solution, and react at 90°C for 5 hours. The perylene tetracarboxylic acid anhydride glycine / graphite oxide composite was obtained.

[0038] B. Add 1.0 ml of ammonia and 0.8 ml of hydrazine hydrate to the mixed solution obtained in step A to reduce graphite oxide, the mass fraction of ammonia water is 25%, the mass fraction of hydrazine hydrate is 15%, and the reaction is carried out at 85°C for 3 hours. After the end, the product is cooled to room temperature, centrifuged and washed 4 times with deionized water and absolute ethanol, and dried to prepare perylenetetracarboxylic anhydride glycine / reduced graphite oxide ultra-fast hydrogen ion composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com