Tin-based oxide negative electrode material and preparation method and application thereof

A negative electrode material and oxide technology, applied in the field of tin-based oxide negative electrode material and its preparation, can solve the problems of weakening the advantages of high capacity, large irreversible capacity, and reducing specific capacity, and achieve long service life, high safety, specific capacity and so on. High volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

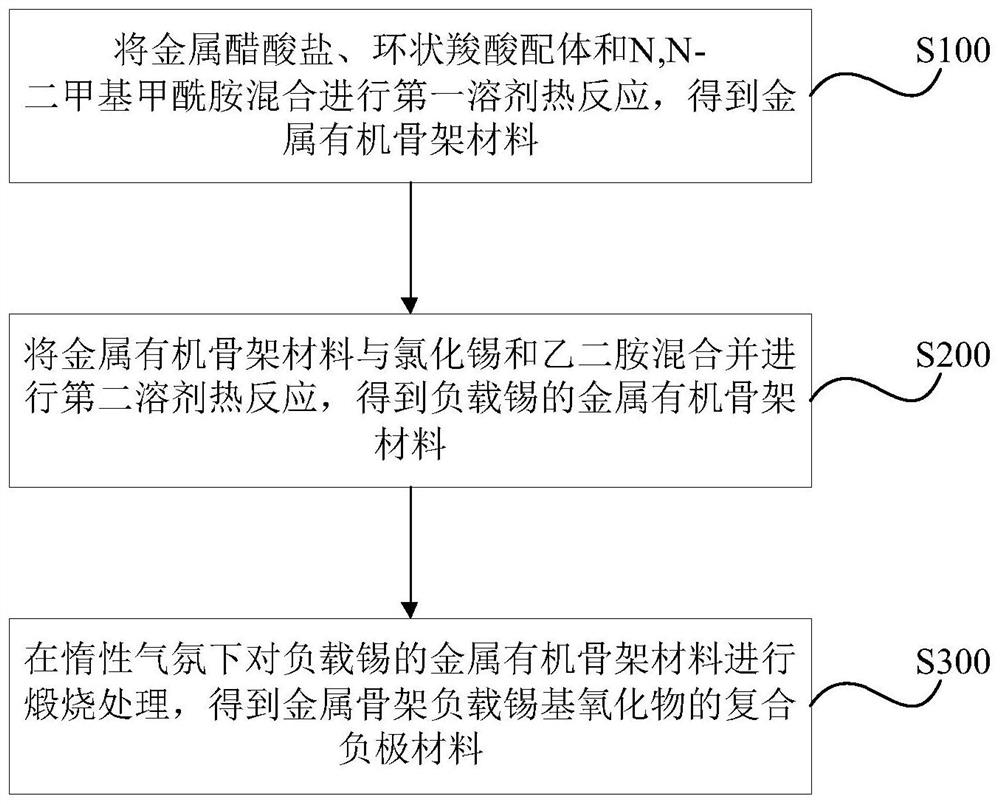

[0046] 1) Prepare a 0.01mol / mL zinc acetate solution with DMF as a solvent, then add phthalic acid with a molar ratio of 1:1 to zinc acetate, and heat at 80°C for 10 hours for solvothermal reaction to synthesize metal-organic framework materials.

[0047] 2) Using ethylenediamine as a solvent, fully dissolve the metal-organic framework material and tin chloride with a molar ratio of 0.1:1 by ultrasonic and magnetic stirring, wherein the solid-liquid ratio of tin chloride to ethylenediamine is 0.5mol / mL . Then, the solvothermal reaction was carried out at 80° C. and kept for 10 h to prepare the metal-organic framework material loaded with tin.

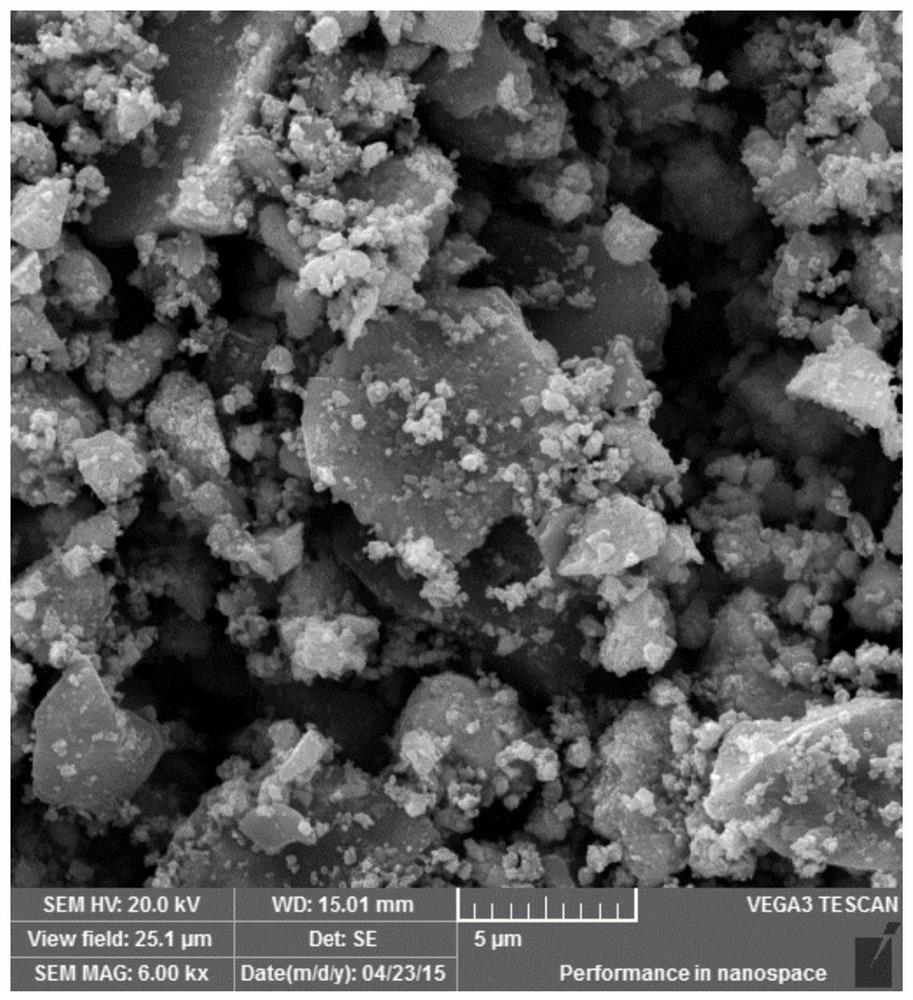

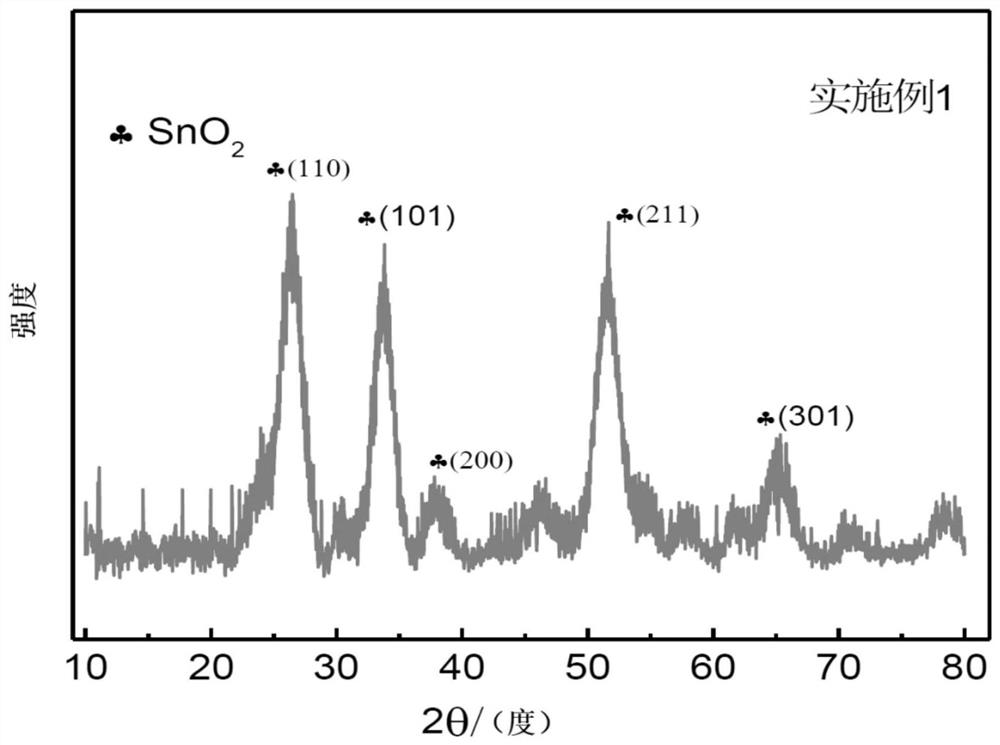

[0048] 3) Calcining the metal-organic framework material loaded with tin in an inert atmosphere at 800° C. for 0.5 h to obtain a composite negative electrode material with tin-based oxide loaded on the metal framework.

Embodiment 2

[0050] 1) Prepare a 0.01mol / mL zinc acetate solution with DMF as a solvent, then add phthalic acid with a molar ratio of 2:1 to zinc acetate, and heat at 80°C for 15 hours for solvothermal reaction to synthesize metal-organic framework materials.

[0051] 2) Using ethylenediamine as a solvent, fully dissolve the metal-organic framework material and tin chloride with a molar ratio of 0.1:1 by ultrasonic and magnetic stirring, wherein the solid-liquid ratio of tin chloride to ethylenediamine is 0.5mol / mL . Then, the solvothermal reaction was carried out at 80° C. and kept for 15 hours to prepare the metal-organic framework material loaded with tin.

[0052] 3) Calcining the metal-organic framework material loaded with tin in an inert atmosphere at 700° C. for 1 h to obtain a composite negative electrode material with tin-based oxide loaded on the metal framework.

Embodiment 3

[0054] 1) Prepare a 0.02mol / mL zinc acetate solution with DMF as a solvent, then add phthalic acid with a molar ratio of 2:1 to zinc acetate, and heat at 100°C for 8 hours for solvothermal reaction to synthesize metal-organic framework materials.

[0055] 2) Using ethylenediamine as a solvent, fully dissolve the metal-organic framework material and tin chloride with a molar ratio of 1:1 by ultrasonic and magnetic stirring, wherein the solid-liquid ratio of tin chloride to ethylenediamine is 0.5mol / mL . Then, the solvothermal reaction was carried out at 80° C. and kept for 15 hours to prepare the metal-organic framework material loaded with tin.

[0056] 3) Calcining the metal-organic framework material loaded with tin in an inert atmosphere at 700° C. for 1.5 h to obtain a composite negative electrode material with tin-based oxide loaded on the metal framework.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com