Low Leakage Electrolytic Capacitors

An electrolytic capacitor, low leakage technology, applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., can solve the problems of dielectric film damage, low equivalent series resistance, leakage current increase, etc., to increase conductivity, improve Conductivity, the effect of increasing the conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

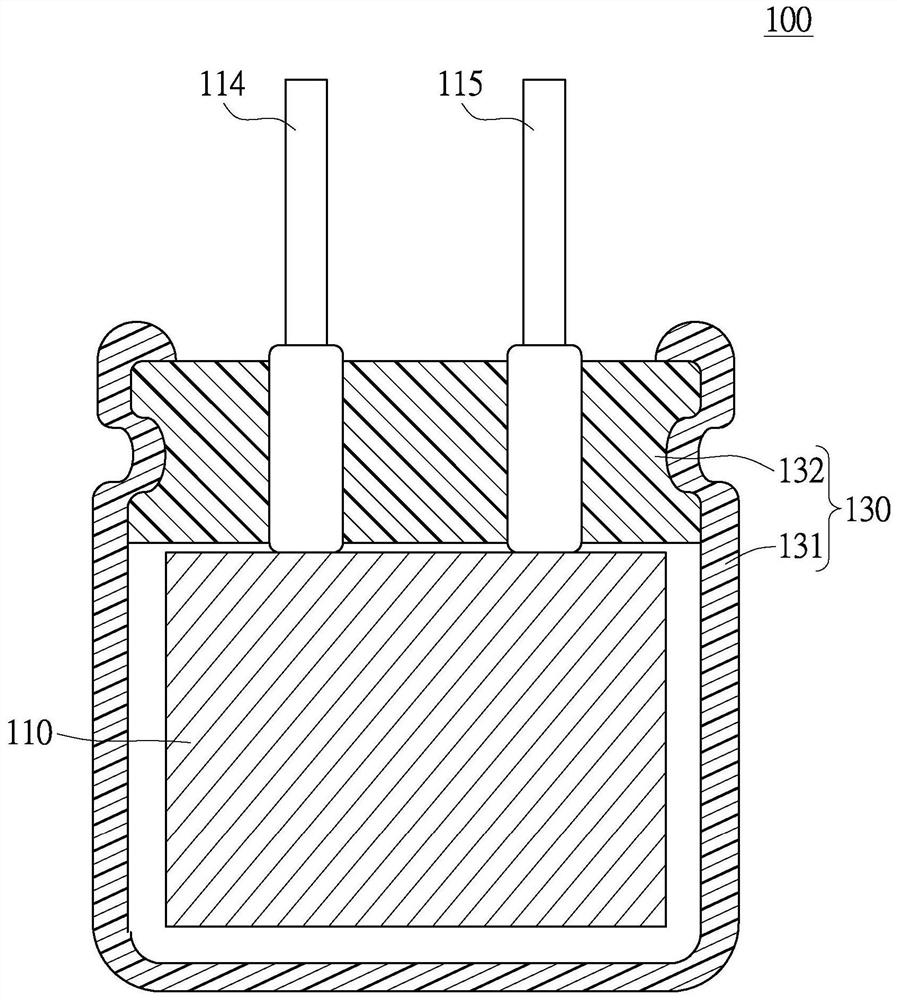

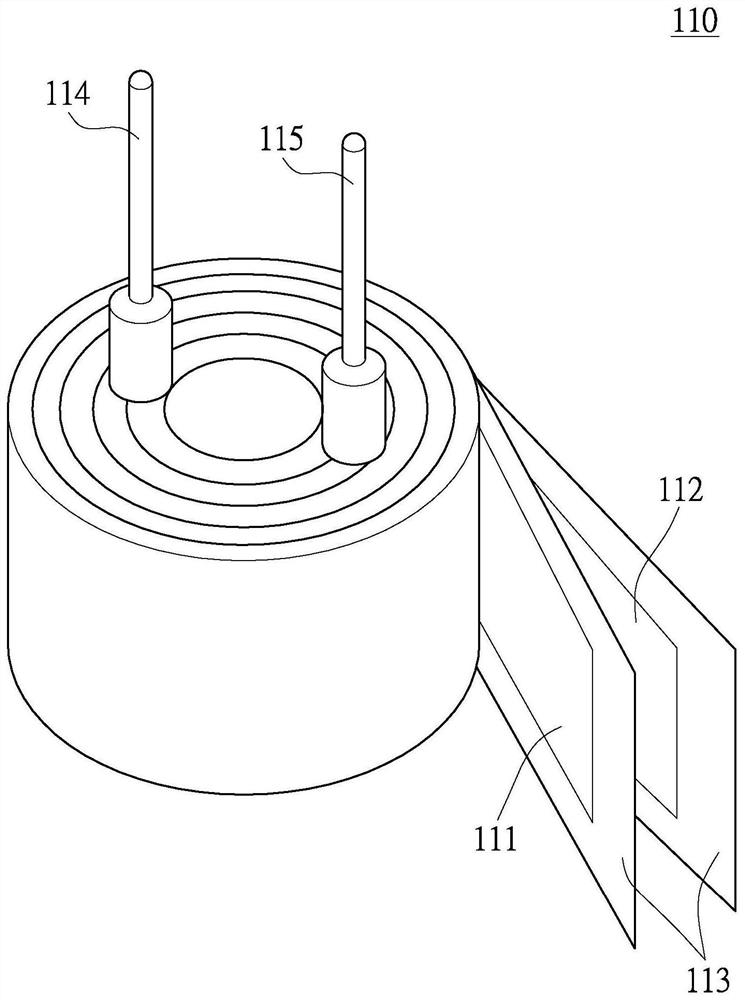

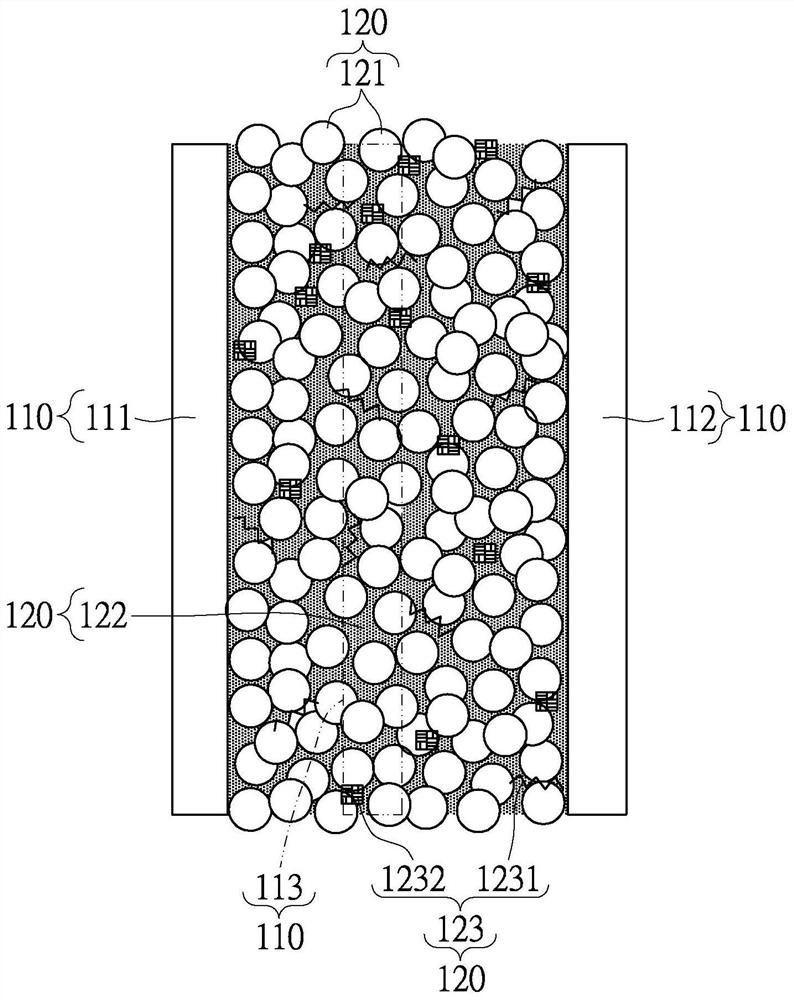

[0038] Please also refer to figure 1 and figure 2 , figure 1 is a cross-sectional view of a low-leakage electrolytic capacitor according to the first embodiment of the present invention, figure 2It is a cross-sectional view of the wound capacitor assembly of the low leakage electrolytic capacitor. As shown in the figure, this embodiment provides a low-leakage wound electrolytic capacitor 100, which mainly includes a wound capacitor assembly 110, a hybrid conductive medium 120, and a package body 130. The wound capacitor assembly 110 The main body is wound by an anode foil 111, a cathode foil 112 and a separator 113 arranged between the anode foil 111 and the cathode foil 112, and the hybrid conductive medium 120 is impregnated in the wound capacitor assembly 110, The packaging body 130 is used to completely cover the wound capacitor assembly 110 and the hybrid conductive medium 120 .

[0039] Specifically, an anode guide pin 114 is installed on the anode foil 111, and a ...

no. 2 example

[0066] Please refer to Figure 4 , is a schematic diagram of a low-leakage electrolytic capacitor according to the second embodiment of the present invention. As shown in the figure, this embodiment provides a low-leakage chip-type electrolytic capacitor 200, which mainly includes a base material layer 210, an annular insulating layer 220 and a conductive layer 230, and the annular insulating layer 220 surrounds the base material layer. 210 , thereby defining an anode portion 211 and a cathode portion 212 on the substrate layer 210 , and the conductive layer 230 covers the surface of the cathode portion 212 .

[0067] Specifically, the material of the substrate layer 210 can be a valve function metal (such as aluminum, tantalum, niobium, titanium, etc.). The surface of the anode part 211 and the surface of the cathode part 212 is roughened by etching, and a dielectric film (not shown) is formed on the surface of the anode part 211 and the surface of the cathode part 212 by ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com