A preparation method of metal oxide/activated carbon fiber composite electrode material with controllable morphology

A technology of activated carbon fiber and composite electrode, which is applied in the fields of hybrid capacitor electrode, hybrid/electric double layer capacitor manufacturing, fiber processing, etc., can solve the problem that the metal oxide/activated carbon fiber composite electrode material cannot improve the specific capacitance value of the composite material, etc. Achieve the effect of no attenuation of specific capacitance value, strong controllability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

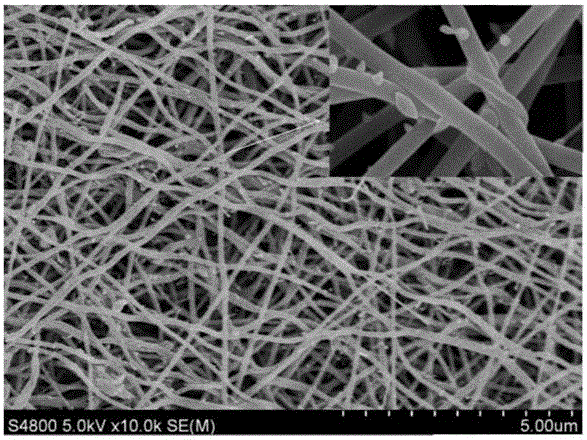

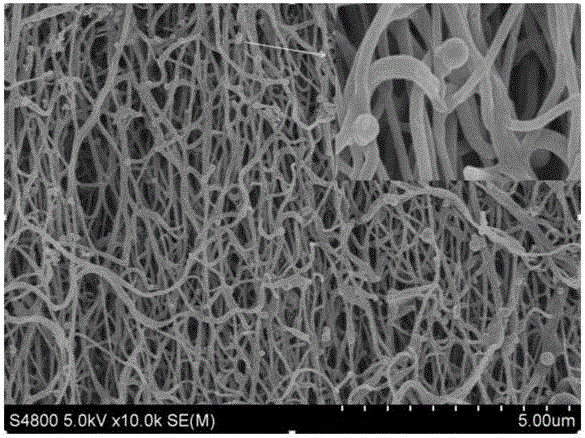

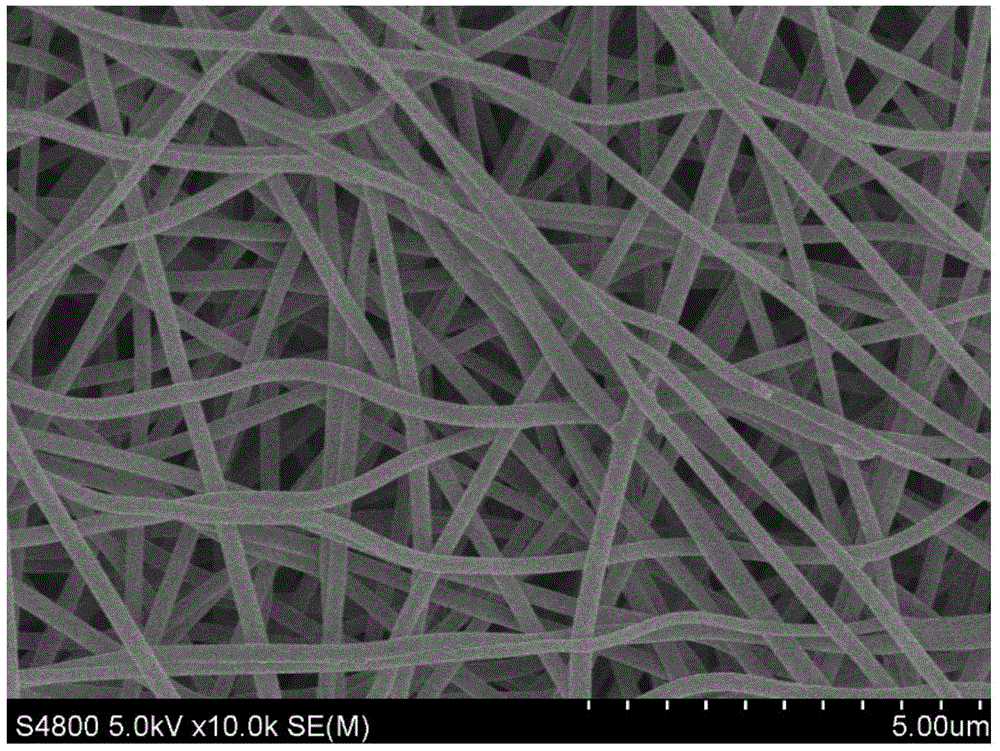

[0017] Specific Embodiment 1: In this embodiment, a method for preparing a metal oxide / activated carbon fiber composite electrode material with controllable morphology is carried out according to the following steps:

[0018] 1. Preparation of polyacrylonitrile fiber: Add nitrate to N,N-dimethylformamide, sonicate until the nitrate is dissolved, then add polyacrylonitrile to the reaction system, and stir at room temperature for 6d~ 12d, obtain the polyacrylonitrile spinning solution; use the electrospinning device, take 5mL-20mL polyacrylonitrile spinning solution, control the end pressure of the micro-injection pump to 80mmHg-100mmHg, and the flow rate of the spinning solution to be 1mL / h-1.5mL / h h, with aluminum foil as the receiving screen, electrospinning is carried out under the conditions that the receiving distance is 20cm-25cm, the output voltage is 18kV-22kV, the air humidity is 0-40%, and the spinneret aperture is 0.4mm-0.6mm, to obtain Polyacrylonitrile fiber; the n...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the nitrate described in step one is nickel nitrate hexahydrate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the nitrate described in step one is cobalt nitrate hexahydrate. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com