Electrostatic spinning method and device of fiber-based waterproof moisture-permeable film high in moisture-permeable flux

A waterproof and moisture-permeable film, electrospinning technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of inter-fiber adhesion and low porosity, difficult to control, etc., to improve waterproof and moisture-permeable performance, reduce adhesion degree, the effect of increasing diffusion and exchange rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

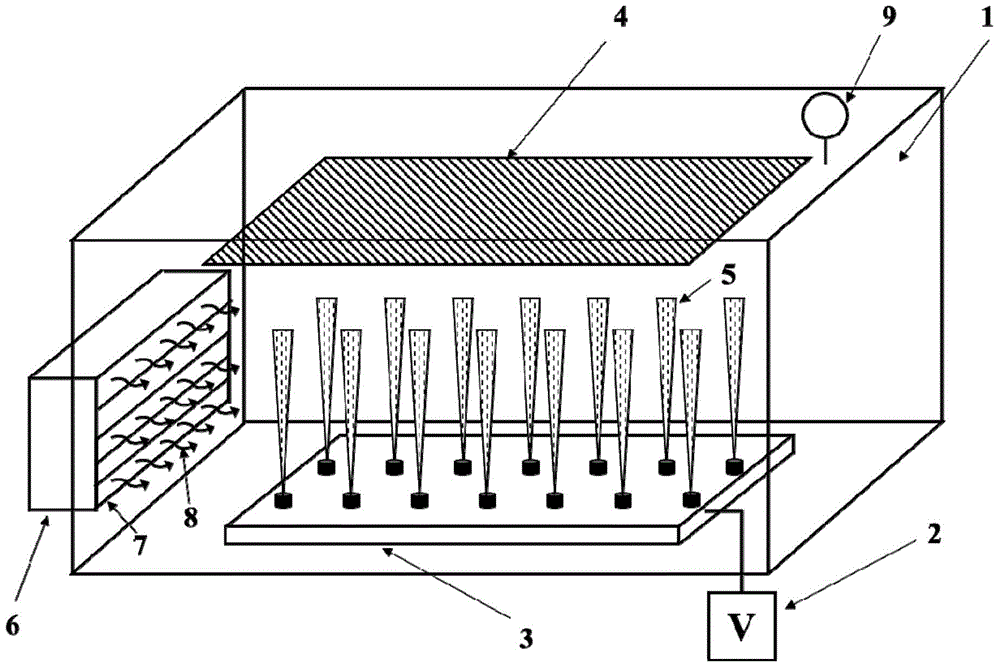

[0058] An electrospinning method of a fiber-based waterproof and moisture-permeable membrane with high moisture permeability, the specific steps are:

[0059] Step 1: After drying the polyvinylidene fluoride powder in a vacuum oven at 130°C for 2.5 hours, dissolve it in acetone to prepare a solution with a concentration of 25%;

[0060] The second step: pour the solution into the nozzle through the liquid supply system, the liquid supply speed is 10mL / h, the textile is used as the receiving substrate, the distance from the receiving substrate to the spinneret is 50cm, and the applied voltage is 100kV for electrostatic Spinning; at the same time, the polymer solution jet is sprayed at an angle of 45° with a mixed side airflow of air and formic acid vapor, and the spray speed is 10m / s. The volume fraction of formic acid vapor in the mixed side airflow is 80%, and the temperature of the airflow is 30°C.

[0061] The obtained fiber-based waterproof and moisture-permeable membrane...

Embodiment 2

[0065] An electrospinning method of a fiber-based waterproof and moisture-permeable membrane with high moisture permeability, the specific steps are:

[0066] Step 1: After drying the polyvinylidene fluoride-hexafluoropropylene powder in a vacuum oven at 120°C for 1.5 hours, dissolve it in N,N-dimethylformamide to prepare a solution with a concentration of 25%;

[0067] The second step: pour the solution into the nozzle through the liquid supply system, the liquid supply speed is 0.1mL / h, the aluminum foil is used as the receiving substrate, the distance from the receiving substrate to the spinneret is 25cm, and the applied voltage is 75kV. Electrospinning; at the same time, the polymer solution jet was sprayed at an angle of 90° with a mixed lateral airflow of air and ethyl acetate vapor, and the spray speed was 0.1m / s. Wherein the ethyl acetate vapor accounts for 50% of the volume fraction of the mixed side airflow, and the temperature of the airflow is 45°C.

[0068] The o...

Embodiment 3

[0072] An electrospinning method of a fiber-based waterproof and moisture-permeable membrane with high moisture permeability, the specific steps are:

[0073] The first step: After drying the polyvinylidene fluoride-tetrafluoroethylene-perfluoromethyl vinyl ether particles in a vacuum oven at 120°C for 1.5 hours, they were dissolved in N-methylpyrrolidone and prepared with a concentration of 15%. solution;

[0074] The second step: pour the solution into the nozzle through the liquid supply system, the liquid supply speed is 2mL / h, the non-woven fabric is used as the receiving substrate, the distance from the receiving substrate to the spinneret is 15cm, and the applied voltage is 50kV Electrospinning is carried out; at the same time, the mixed side air flow of air and ethanol vapor is used to blow the polymer solution jet at an angle of 45°, and the blowing speed is 50m / s. The ethanol vapor accounts for 40% of the volume fraction of the mixed lateral airflow, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com