Thermoplastic polyurethane film and preparing method thereof

The technology of thermoplastic polyurethane and plastic polyurethane is applied in the field of waterproof and moisture-permeable thermoplastic polyurethane film and its preparation, which can solve the problems of poor corrosion resistance and weather resistance, and achieve good corrosion resistance and weather resistance, and good waterproof and moisture permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

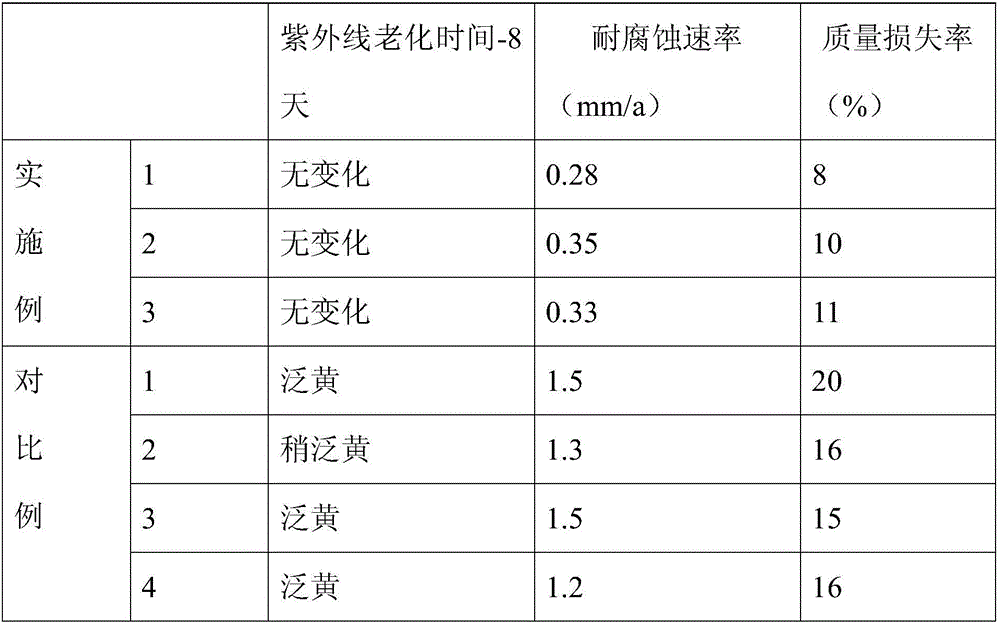

Examples

Embodiment 1

[0022] First, select the raw materials for the preparation of thermoplastic polyurethane film: 83 parts of thermoplastic polyurethane, 9 parts of smooth agent and 8 parts of fogging agent; wherein, 45 parts of polytetramethylene ether glycol, 27 parts of composite diisocyanate (the It is a composition of toluene diisocyanate and isophorone diisocyanate, the mass ratio of toluene diisocyanate and isophorone diisocyanate is 1:3), 6 parts of ethylene glycol ethyl ether acetate and 2 parts of dibutyltin diacetate And 7 parts of styrene-acrylonitrile-glycidyl methacrylate;

[0023] Then, the above-mentioned raw materials are stirred evenly in the feed bucket;

[0024] Then, dry through a dehumidifier to control the moisture content of the above-mentioned raw materials to be less than or equal to 0.02%;

[0025] Next, after being plasticized by the screw of the extruder, it is extruded through the die opening; the temperature of the screw of the extruder is controlled in five stage...

Embodiment 2

[0029] First, select the raw materials for preparing thermoplastic polyurethane film: 80 parts of thermoplastic polyurethane, 8 parts of smoothing agent and 7 parts of fogging agent; wherein, 40 parts of polytetramethylene ether glycol, 25 parts of composite diisocyanate (the It is a composition of toluene diisocyanate and isophorone diisocyanate, the mass ratio of toluene diisocyanate and isophorone diisocyanate is 1:2), 5 parts of ethylene glycol ethyl ether acetate and 1 part of dibutyltin diacetate And 5 parts of styrene-acrylonitrile-glycidyl methacrylate;

[0030] Then, the above-mentioned raw materials are stirred evenly in the feed bucket;

[0031] Then, dry through a dehumidifier to control the moisture content of the above-mentioned raw materials to be less than or equal to 0.02%;

[0032] Next, after being plasticized by the screw of the extruder, it is extruded through the die opening; the temperature of the screw of the extruder is controlled in five stages durin...

Embodiment 3

[0036] Except that the preparation raw materials of thermoplastic polyurethane film are 85 parts of thermoplastic polyurethane, 10 parts of slippery agent and 10 parts of fogging agent; wherein, 50 parts of polytetramethylene ether glycol, 30 parts of composite diisocyanate (it is toluene The composition of diisocyanate and isophorone diisocyanate, the mass ratio of toluene diisocyanate and isophorone diisocyanate is 1:4), 8 parts of ethylene glycol ethyl ether acetate and, 3 parts of dibutyltin diacetate and benzene Except for 8 parts of ethylene-acrylonitrile-glycidyl methacrylate, other preparation methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com