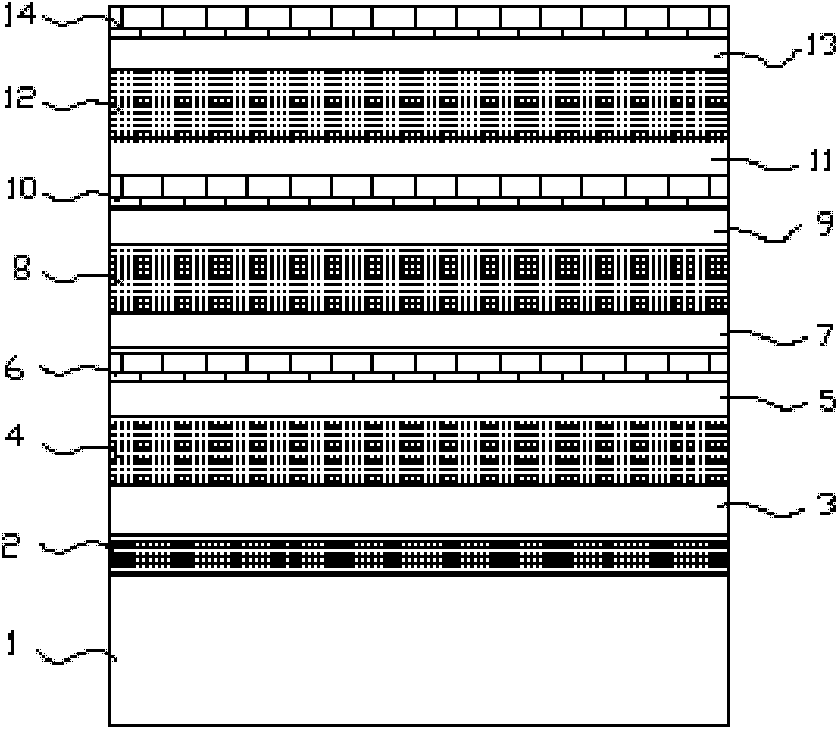

Method for growing InGaP/GaAs/Ge three-junction solar cell on silicon substrate

A technology for solar cells and silicon substrates, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as surface topography fluctuations, lower solar cell efficiency, and increased dislocations, and achieve a wide growth process window, The effect of strong controllability and repeatability of the growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

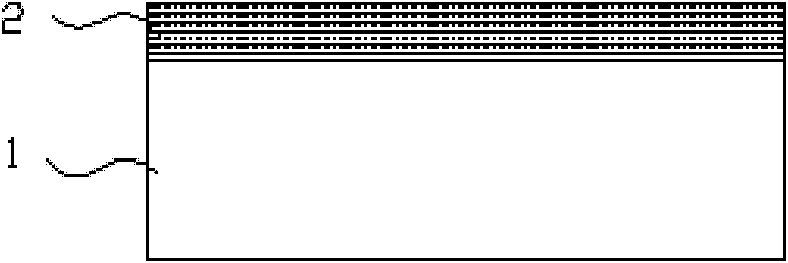

[0022] 1) Growth of Ge by high vacuum chemical vapor deposition x Si 1-x Stress transition layer: choose SiH 4 and GeH 4 as the source of the reaction. The (001) plane Si substrate 1 was cleaned, put into a high-vacuum chemical vapor deposition reaction chamber, and firstly baked at 1000° C. for 10 minutes. Then, the temperature was lowered to 600°C to grow Ge with Ge composition gradually changing from 0 to 1. x Si 1-x Stress transition layer 2 (such as figure 2 shown). During the growth process, the SiH 4 The flow rate is fixed, and then slowly increase the GeH 4 traffic. The growth temperature is 600° C., the growth pressure is 50 mTorr, the change rate of Ge content is 5% / μm, and the change mode is continuous change.

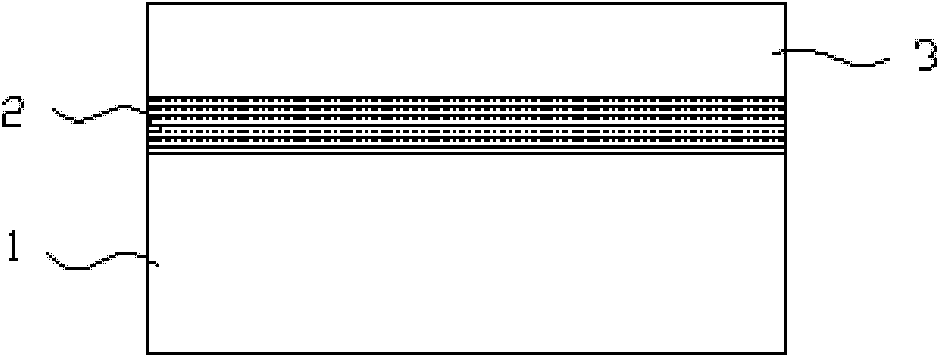

[0023] 2) in Ge x Si 1-x A Ge film layer 3 with a thickness of 2 μm is deposited on the stress transition layer (such as image 3 shown). The dislocation density of the Ge thin film layer 3 grown at this time is 5×10 6 cm -2 .

[0024] 3) F...

Embodiment 2

[0029] 1) Growth of Ge by high vacuum chemical vapor deposition x Si 1-x Stress transition layer: choose Si 2 h 6 and GeH 4 as the source of the reaction. The (001) plane Si substrate 1 was cleaned, put into a high-vacuum chemical vapor deposition reaction chamber, and firstly baked at 1000° C. for 10 minutes. Then, the temperature was lowered to 750°C, and Ge with Ge composition gradually changed from 0 to 1 was grown. x Si 1-x Stress transition layer 2 (such as figure 2 shown). During the growth process, the Si 2 h 6 The flow rate is fixed, and then slowly increase the GeH 4traffic. The growth temperature is 750°C, the growth pressure is 100mTorr, the change rate of Ge content is 8% / μm, and the change mode is a step change, and every growth of 0.5 μm is a step.

[0030] 2) in Ge x Si 1-x A Ge film layer 3 with a thickness of 2 μm is deposited on the stress transition layer (such as image 3 shown). The dislocation density of the Ge thin film layer 3 grown at...

Embodiment 3

[0036] 1) Growth of Ge by high vacuum chemical vapor deposition x Si 1-x Stress transition layer: choose Si 2 h 6 and GeH 4 as the source of the reaction. The (001) plane Si substrate 1 was cleaned, put into a high-vacuum chemical vapor deposition reaction chamber, and firstly baked at 1000° C. for 10 minutes. Then, the temperature was lowered to 800°C to grow Ge with Ge composition gradually changing from 0 to 1. x Si 1-x Stress transition layer 2 (such as figure 2 shown). During the growth process, the Si 2 h 6 The flow rate is fixed, and then slowly increase the GeH 4 traffic. The growth temperature is 800°C, the growth pressure is 300mTorr, the change rate of Ge content is 10% / μm, and the change method is a step change, and every 0.5 μm of growth is a step.

[0037] 2) in Ge x Si 1-x A Ge film layer 3 with a thickness of 2 μm is deposited on the stress transition layer (such as image 3 shown). The Ge thin film layer 3 grown at this time has a dislocation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com