Wheel-sticking prevention mortar injecting system and method

A kind of mortar and anti-sticking technology, which is applied in the direction of earth cube drilling, wellbore/well parts, earth mover/shovel, etc. It can solve the problem of increased mud adhesion area of mud scraper, change of mud flow characteristics, and ineffective mud block. Removal and other problems, to solve the sticky wheel problem, reduce the concentration, increase the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

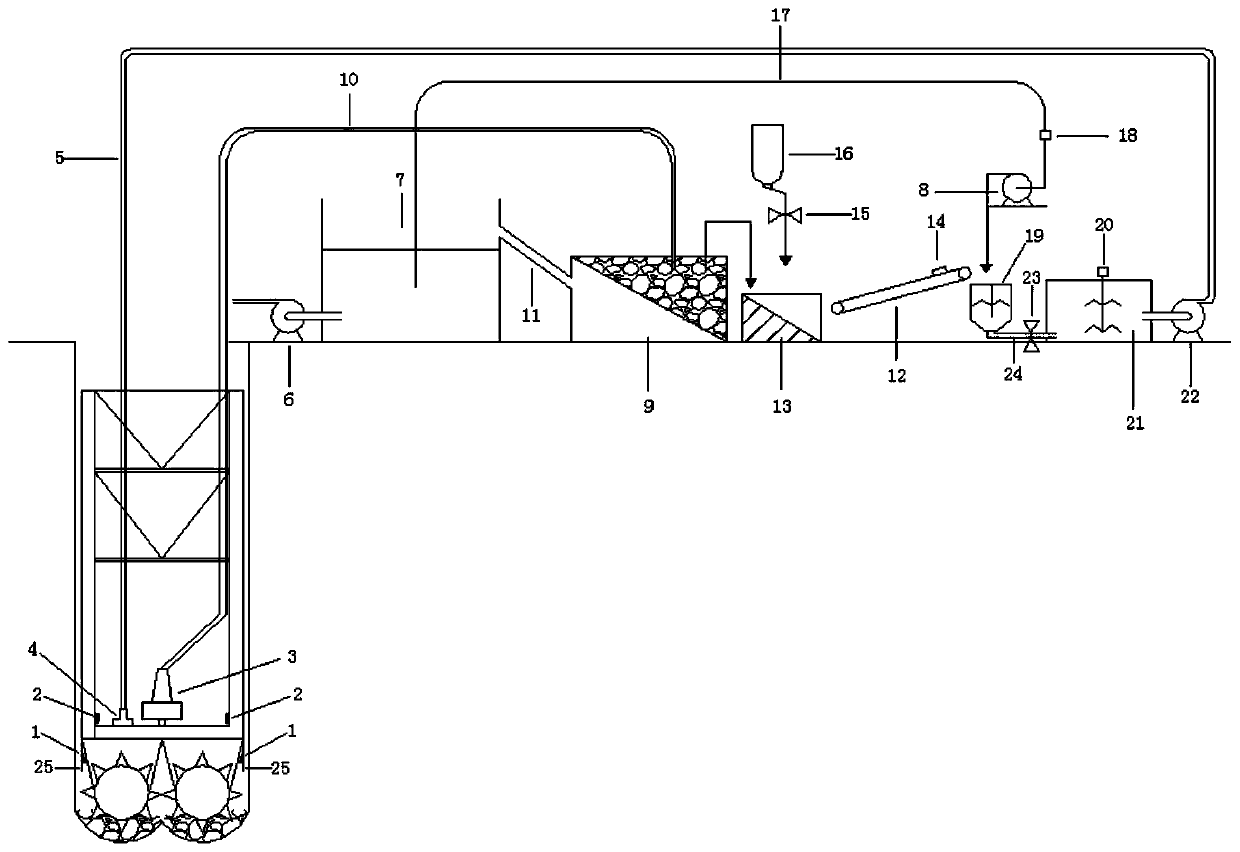

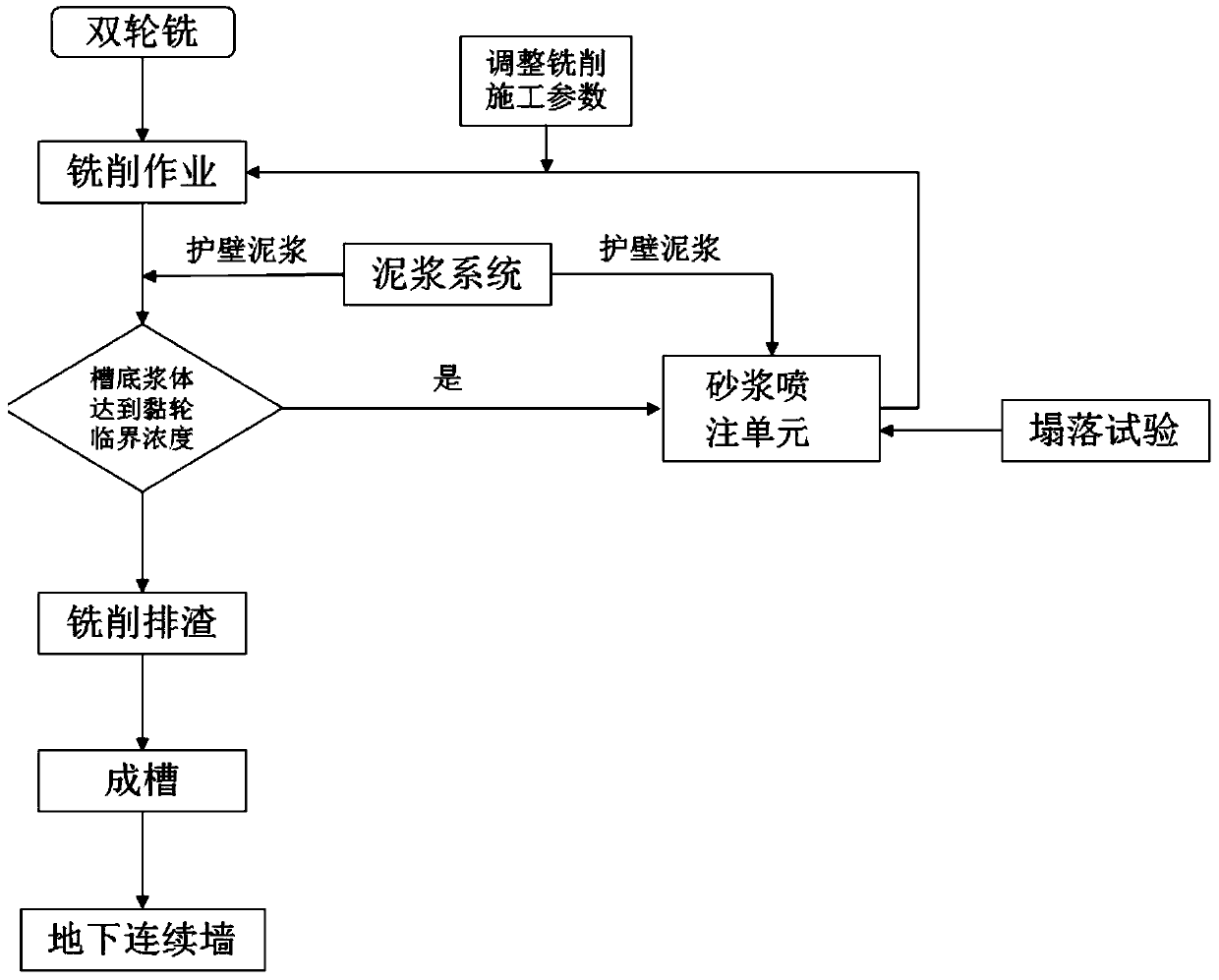

[0034] like figure 1As shown, an anti-sticking wheel mortar injection system is provided in an embodiment of the present invention, including: a concentration sensor 2 and a mortar injection unit;

[0035] When the concentration sensor 2 detects that the slurry concentration in the working area is greater than the set threshold, the mortar injection unit is started, and the mortar injection unit injects mortar into the working area to reduce the slurry concentration in the working area. body concentration.

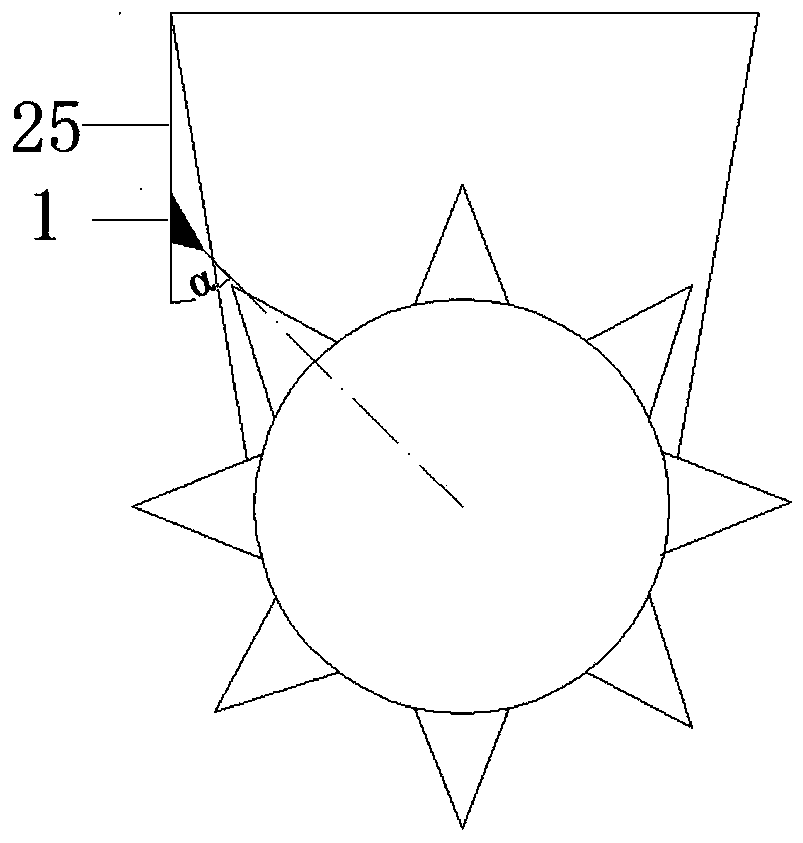

[0036] The concentration sensor 2 is generally located near the milling wheel; the working area refers to the deep area at the bottom of the groove; Determine the slump test and ensure that the slump height of the mixed mortar is greater than 200mm, and the particle size of the sand in the mortar is selected to be 0.5mm to 3mm.

[0037] The anti-adhesive wheel mortar injection system in the embodiment of the present invention can be applied to the suction and slag discha...

specific Embodiment approach

[0039] Further, based on the first specific implementation, in the second specific implementation of the embodiment of the present invention, the mortar injection unit further includes a transfer tank 21 and a first pump 22, the transfer tank 21 The inlet is connected to the outlet of the first control valve 23 through the mixer mortar pipe 24 , the inlet of the first pump 22 is connected to the outlet of the transfer tank 21 , and its outlet is connected to the working area through the mortar injection pipe 5 . In order to improve the uniformity of the mortar, the mortar injection unit also includes an agitator 20, and the agitator 20 is arranged in the transfer tank 21;

Embodiment 2

[0042] Based on Example 1, in the embodiment of the present invention, wall protection mud is used as the conveying medium of sand particles. On the premise of ensuring the wall protection effect of milling grooves, the mortar is sprayed into the deep area of the bottom of the groove to reduce the adhesion of the slurry at the bottom of the groove and realize automatic Control the proportion of sand particles and wall protection mud, milling wheel injection mortar, and mortar suction and discharge cycle.

[0043] Specifically, the difference between the embodiment of the present invention and embodiment 1 is:

[0044] The mortar injection unit further includes a sand module and a mud module, the outlets of the sand module and the mud module are both connected to the inlet of the mixer 19 for providing sand and mud to the mixer 19 respectively.

[0045] The mud module includes a slag suction port 3, a third pump 6, a separator 9, a mud pool 7, a second pump 8, and a flow mete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com