Patents

Literature

60 results about "Disintegration Rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The number of radioactive transformations per unit time and expressed as disintegrations per minute or disintegrations per second. It is the unit of measure for quantities of radionuclide.

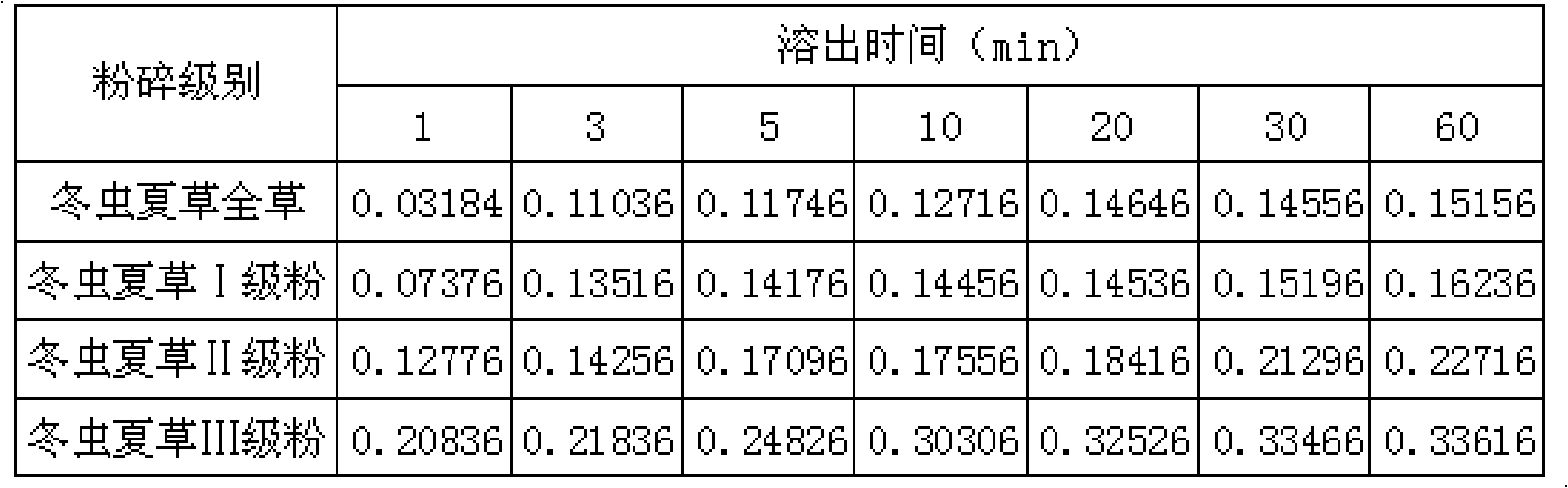

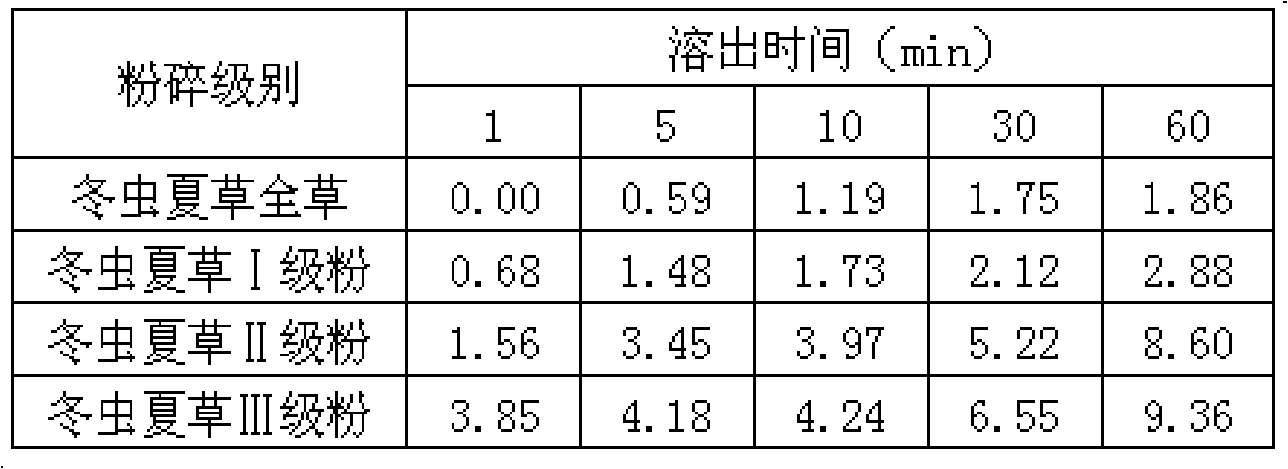

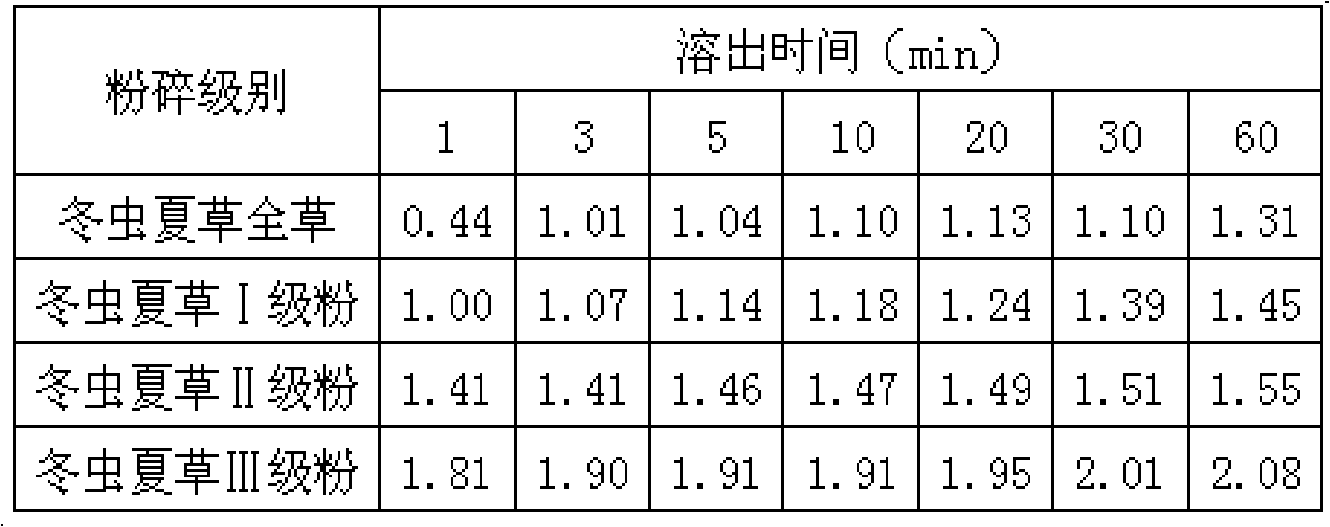

Aweto micropowder tablet and preparation method thereof

ActiveCN101332212AIncrease concentrationFully activePill deliveryImmunological disordersMedicineTableting

The present invention relates to a cordyceps sinensis powder tablet and a preparation method thereof, which pertains to the field of medicines and health products. The technical problem the present invention aims at providing a tablet containing cordyceps sinensis medicinal powder and no auxiliary material; the appearance, shape and harness of the tablet is consistent with the tablet quality standard. The cordyceps sinensis powder tablet only adopts cordyceps sinensis powder with the water content of 8 to 18 percent and the granule diameter of 1 to 150mum; no auxiliary material is added in the preparation process and the cordyceps sinensis powder is the only component. The aim of direct tablet forming can be achieved by controlling the water of the powder or by the process of second tabletting or dry granule tabletting. The process ensures that the tablet appearance is good; pockmark surface rate and fracture rate are low; tablet harness, disintegration rate and friability are consistent with the tablet quality requirement; the harness can also ensure that the tablet can not fracture in the preparation process when coating and film covering is carried out in the later stage.

Owner:QINGHAI SPRING MEDICINAL RESOURCES TECHNOLOGY CO LTD

Method for preparing photo-catalytic cement-based material and method for preparing photocatalyst

ActiveCN102153318AImprove photocatalytic efficiencyHigh specific surface areaSolid waste managementMetal/metal-oxides/metal-hydroxide catalystsUltraviolet lightsNitric oxide

The embodiment of the invention discloses a method for preparing a photo-catalytic cement-based material and a method for preparing a photocatalyst. The method comprises the steps of mixing nanometer titanium dioxide and coal ash to obtain coal ash loaded nanometer titanium dioxide; compounding an up-conversion material with the coal ash loaded nanometer titanium dioxide; then heating and calcining to obtain a photocatalyst; and mixing the photocatalyst with cement to obtain a photo-catalytic cement-based material. Because a visible light can be converted to an ultraviolet light by the up-conversion material, the up-conversion material is compounded with the nanometer titanium dioxide to increase the photocatalysis efficiency of the photo-catalytic cement-based material. In addition, the specific surface area of the titanium dioxide can be increased by the coal ash so that the TiO2 is preferably dispersed in the cement, and thereby the photocatalysis efficiency of the photo-catalytic cement-based material is increased. Proved by experimental results, the photo-catalytic cement-based material prepared by using the preparation method disclosed by the invention obtains a disintegration rate of more than 80% to substances such as nitric oxide, benzene, formaldehyde and the like.

Owner:安徽海螺材料科技股份有限公司

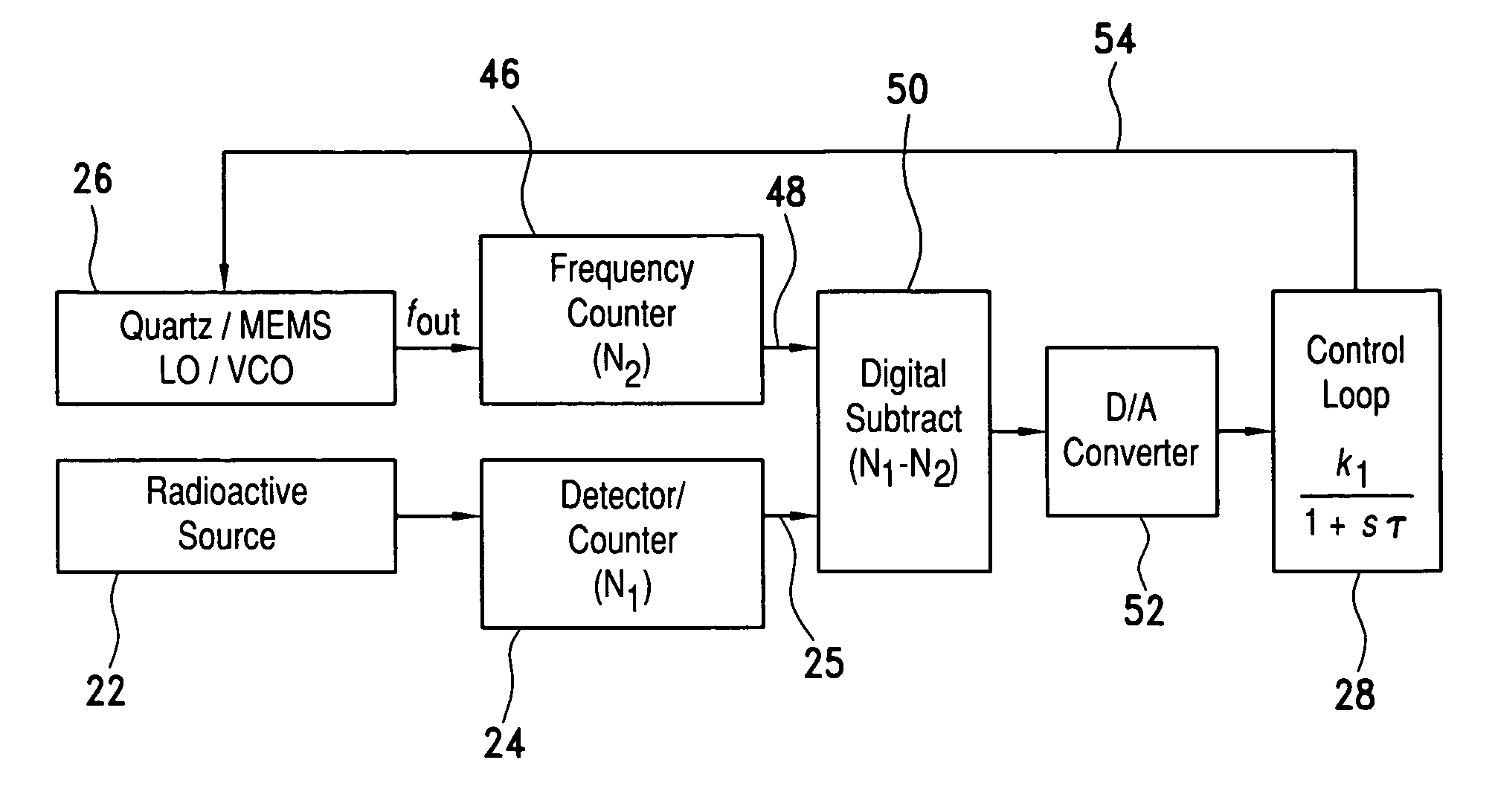

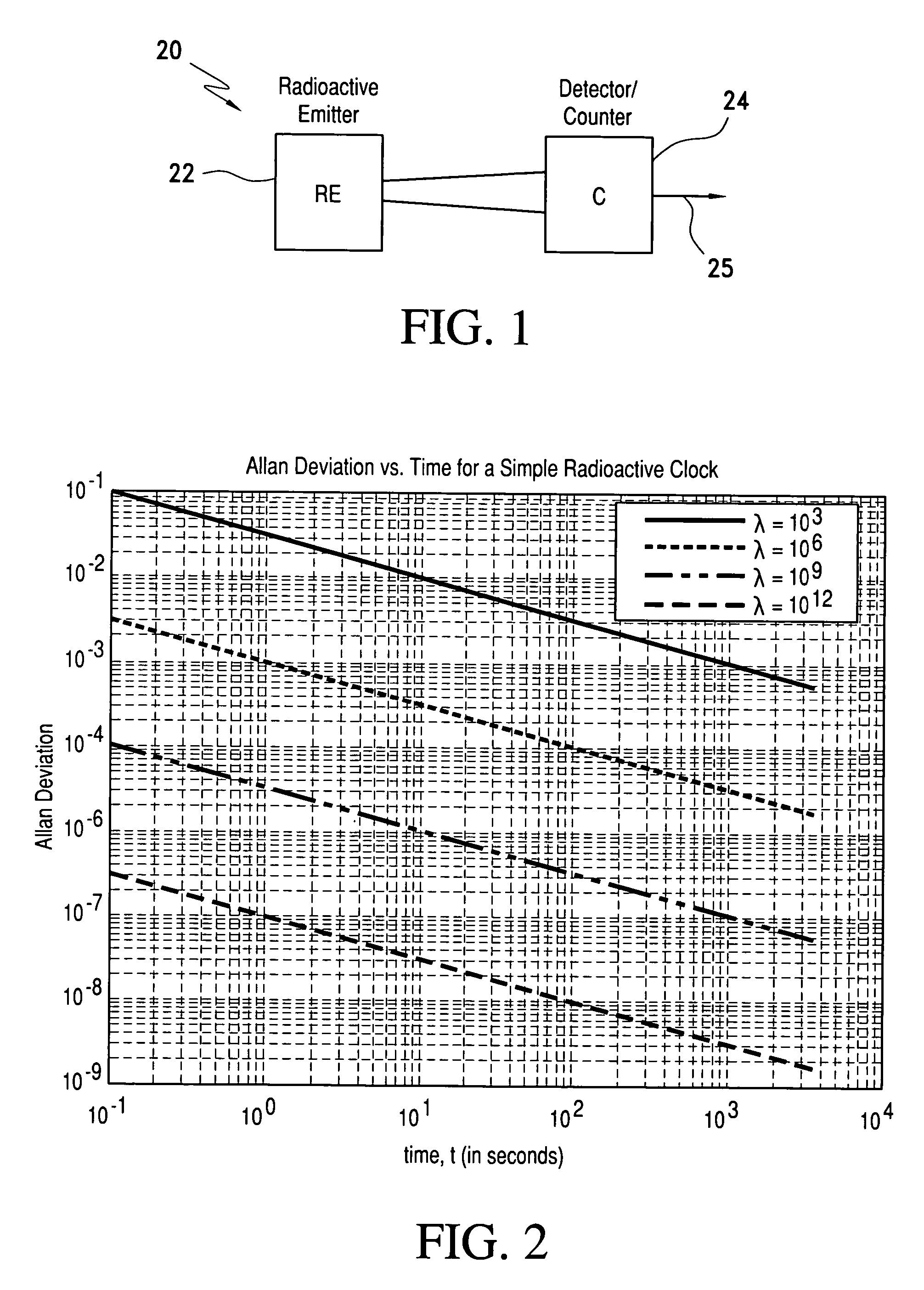

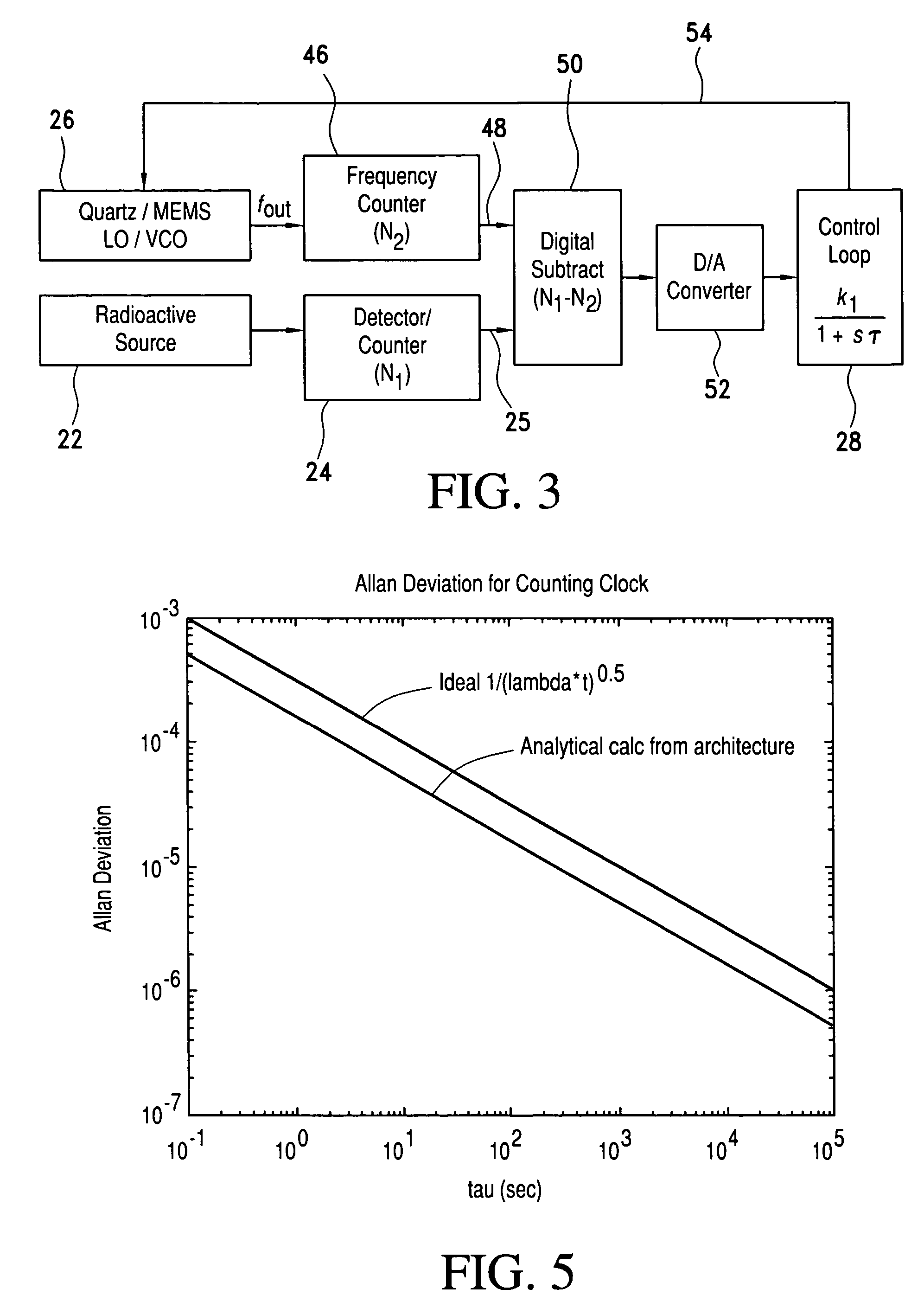

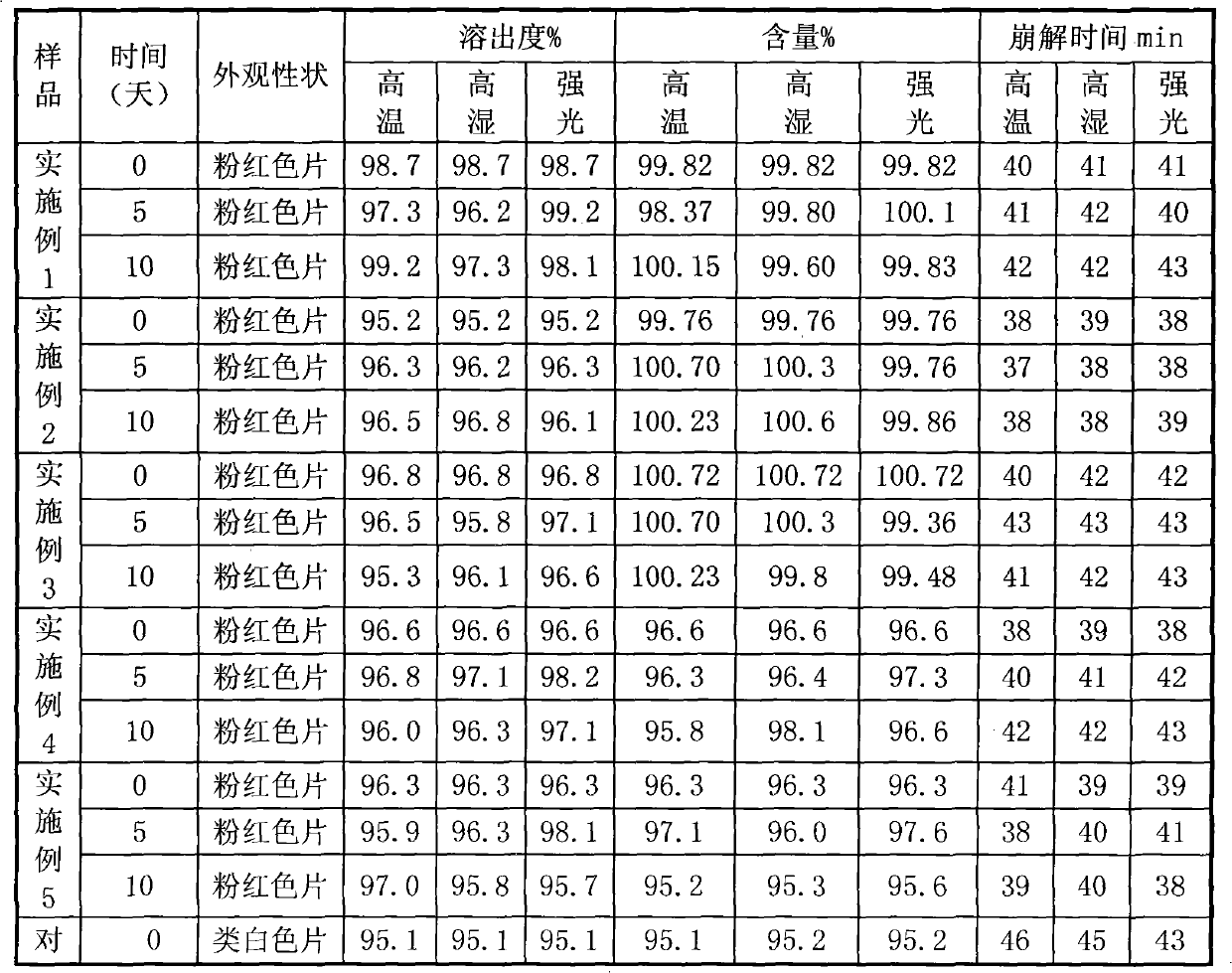

Radioactive decay based stable time or frequency reference signal source

InactiveUS20060255281A1Energy efficient and stable and preciseStable and precise and referenceApparatus using radioisotope pulsesSynchronous motors for clocksDead timeRadioactive agent

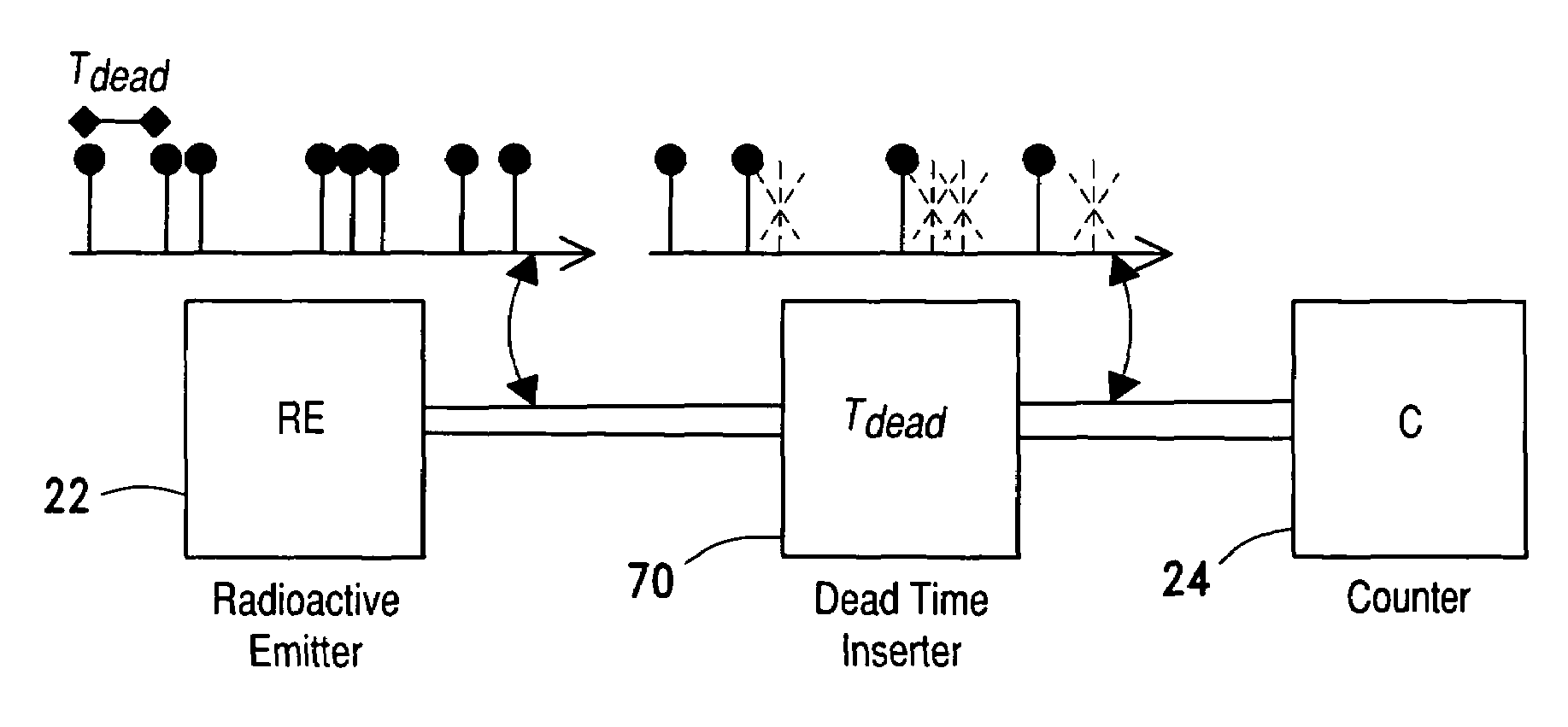

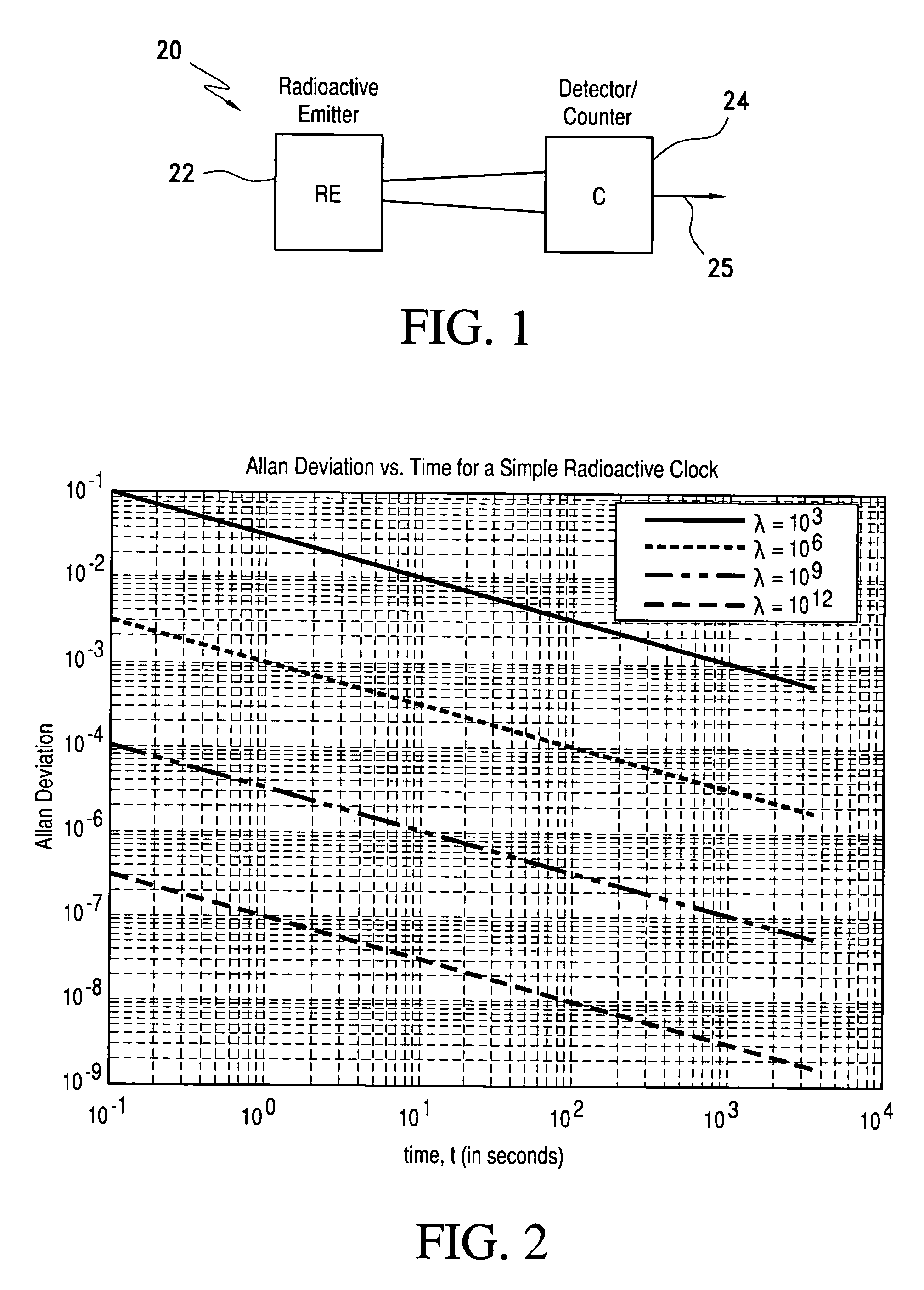

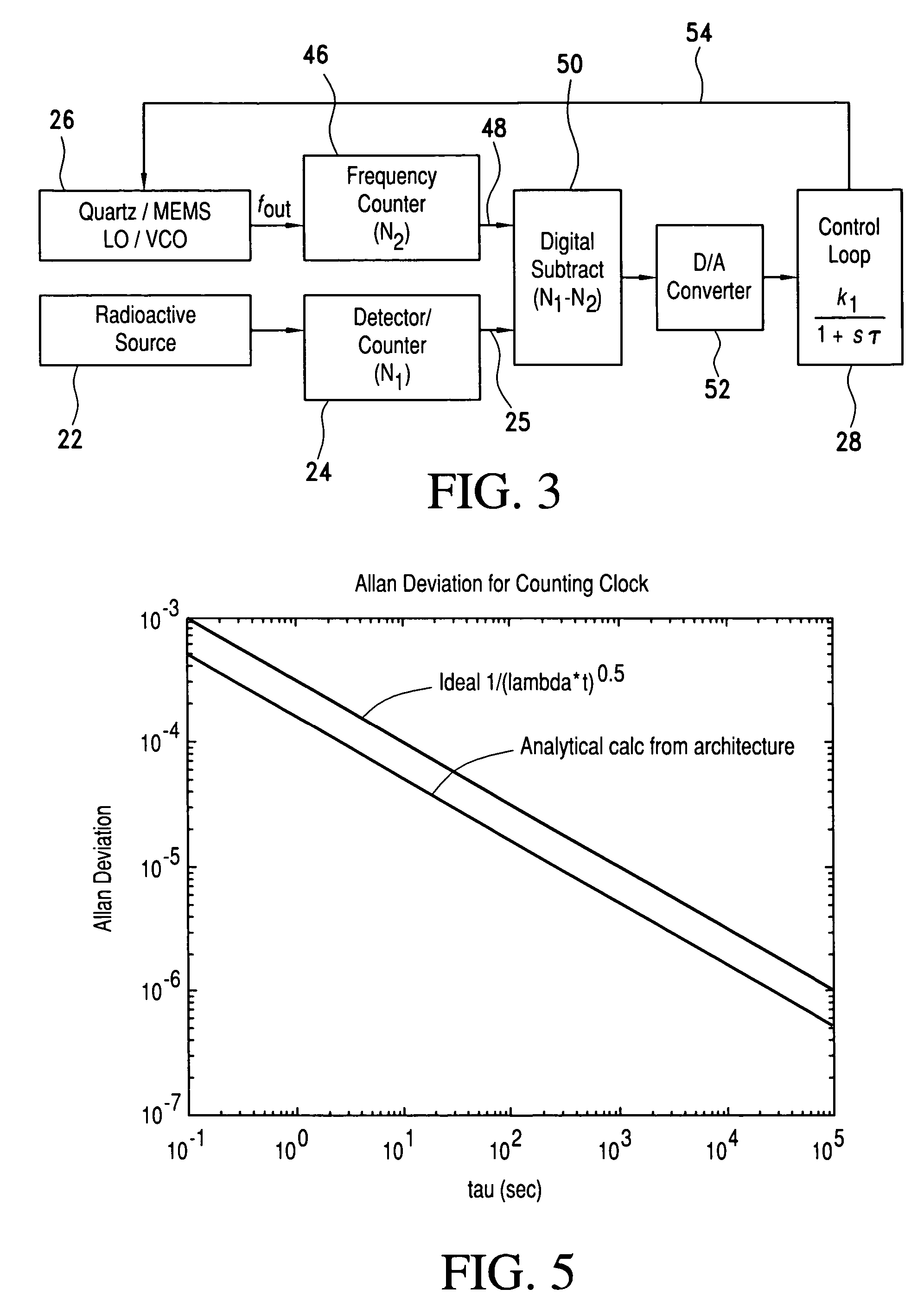

A signal source for use as a frequency source or time keeping signal source includes a radioactive emission source generating a substantially periodic signal corresponding to a radioactive material's disintegration rate. A radioactive emission detector generates a radioactive emission detection signal and, to stabilize the detected periodic signal, a dead time controlling attenuator blanks or shuts off the radioactive emission detection signal for a selected dead time interval in response to each detected radioactive emission (i.e., a detected signal pulse or signal component) generated by the source. The dead time controlling attenuator output provides a long-term and short-term a stable periodic signal.

Owner:CORNELL RES FOUNDATION INC

Brucite granular fertilizer and its preparation method

InactiveCN1785914AReduce pollutionNo wasteMagnesium fertilisersFertiliser formsSpherical granuleWater soluble

The present invention relates to a brucite granule fertilizer and its preparation method. Said preparation method includes the following steps: mixing brucite, natural magnesium sulfate and light calcined magnesium, using water or 5% (mass) of citric acid solution as binding agent, mixing all the materials, granulating drying and packaging so as to obtain spherical granules whose diameter is 2-4mm, in which water content is less than or equal to 1%, hardness is 1.5-4kg / sq.cm, disintegration rate is greater than or equal to 90%, citric-soluble MgO mass content is 53-62% and water-soluble MgO mass content is 3-5%.

Owner:大连爱思凯矿产有限公司

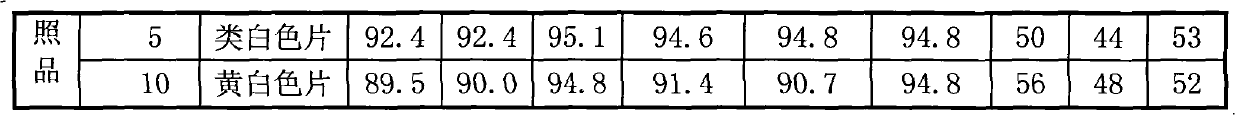

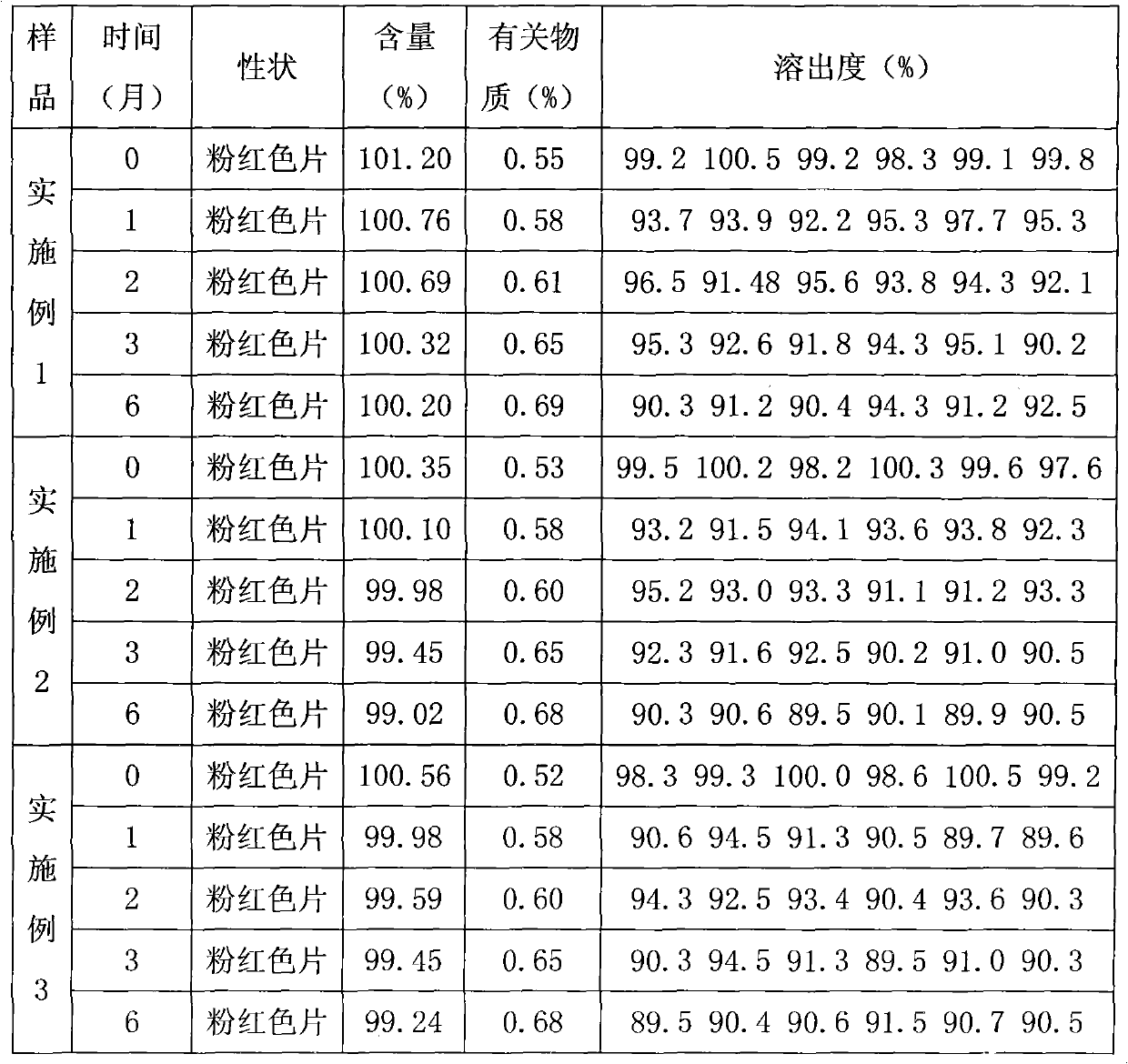

Tablet containing Rosuvastatin calcium and preparation process thereof

ActiveCN101766578AImprove quality stabilityHigh dissolution rateOrganic active ingredientsMetabolism disorderCyclodextrinLactose

The invention belongs to the filed of medicine, in particular to a tablet containing Rosuvastatin calcium and a preparation process thereof. As for the tablet containing the Rosuvastatin calcium of the invention, lactose and hydroxypropyl cyclodextrin with the ratio ranging from 1:1 to 2.5:1 are selected to serve as fillers, and opacifier medicinal iron oxide red is added in production process. In the invention, a direct powder tabletting method is utilized for taletting, and the prepared tablet containing the Rosuvastatin calcium has the characteristics of stable long-term preservation, rapid disintegration rate, high dissolution and high bioavailability.

Owner:LUNAN BETTER PHARMA

Disintegratable round-granule sulfur magnesium fertilizer and preparation method thereof

InactiveCN102775220AHigh granulation rateHigh in magnesiumFertiliser formsFertilizer mixturesBruciteWater content

The invention belongs to the field of agricultural fertilizers, and relates to a disintegratable round-granule sulfur magnesium fertilizer. Powdery brucite and sulfur powder are used as main raw materials, and a magnesium sulfate heptahydrate solution is used as a binding agent. The disintegratable round-granule sulfur magnesium fertilizer is prepared by granulating the following components in parts by mass: mixture of 90-95 parts of powdery brucite and 5-10 parts of sulfur as the dry material, and magnesium sulfate heptahydrate solution as the binding agent. After drying the round granules, the water content is less than or equal to 3%, the strength is greater than or equal to 2Kg / cm<2>, and the disintegration rate is greater than or equal to 95%. The magnesium sulfate heptahydrate solution is used as the binding agent to enhance the granulation rate; the 60-120 mesh powdery brucite and sulfur powder are mixed as the dry material; and granulation, screening, drying, cooling and packaging are carried out to prepare the spherical granules with the granular size of 2-4mm. The invention has the advantages of low cost, high magnesium content and high disintegration speed. The product is spherical granules, has the advantages of favorable disintegratability, uniform granularity and high strength, and can be conveniently mixed with other nitrogen-phosphorus-potassium fertilizers.

Owner:张浩

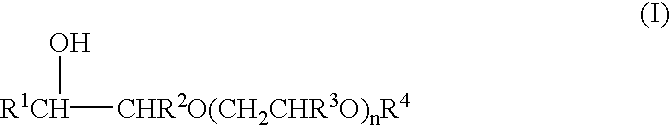

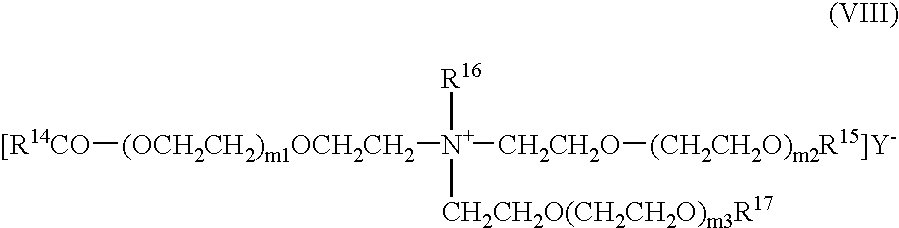

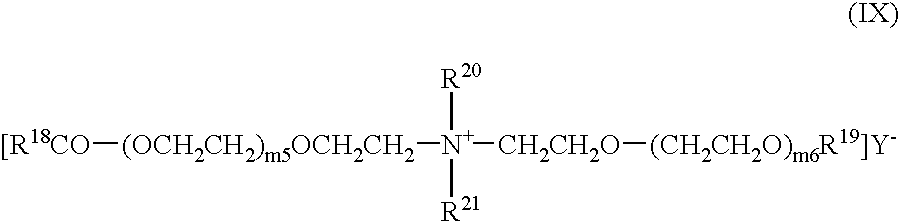

Tenside granules with improved disintegration rate

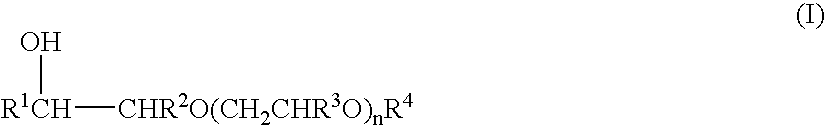

InactiveUS20030144172A1Easy to cleanHigh dissolution rateNon-ionic surface-active compoundsOrganic detergent compounding agentsEtherSurface-active agents

The invention relates to tenside granules with an improved disintegration rate that are obtained by granulating nonionic tensides of the hydroxy mixed ether type in the presence of disintegrants and compacting the products obtained.

Owner:COGNIS DEUT GMBH & CO KG

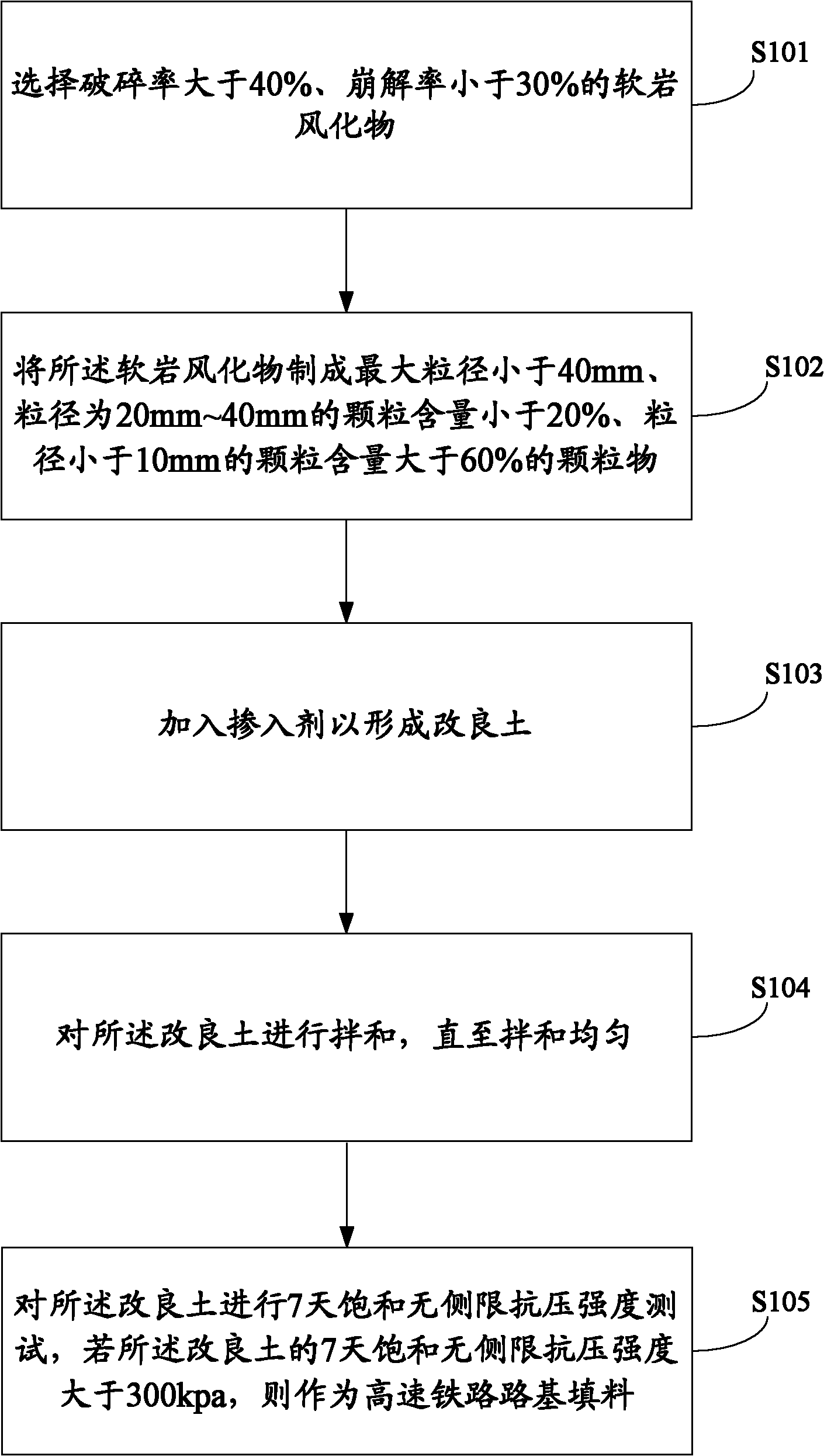

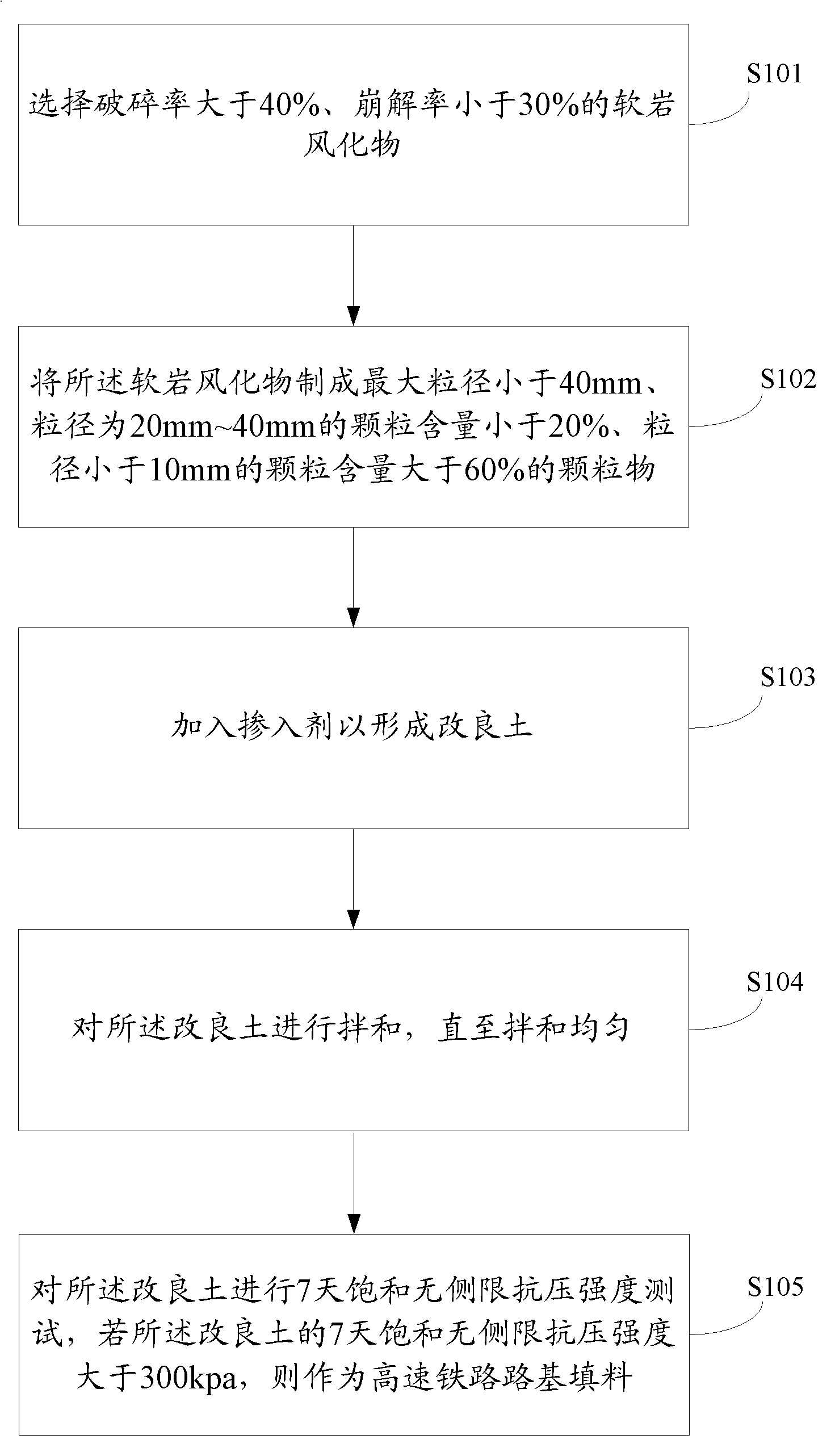

Chemical improving method using soft rock weathered material as high-speed railway subgrade filler

InactiveCN102153303AReduce engineering costsReduce wasteSolid waste managementSocial benefitsWaste material

The invention discloses a chemical improving method using a soft rock weathered material as a high-speed railway subgrade filler, comprising the following steps of: (1) selecting a soft rock weathered material with crushing rate of more than 40% and disintegration rate of less than 30%; (2) making a filler with maximum particle size of less than 40 mm by the soft rock weathered material, wherein the content of particles with particle sizes of 20-40 mm in the filler is less than 20% while the content of the particles with particle sizes of less than 10 mm is more than 60%; (3) adding a doping agent to form improved soil; (4) blending the improved soil until the improved soil is uniformly blended; and (5) carrying out saturated unconfined compressive strength testing on the improved soil for seven days, and if the seven-day saturated unconfined compressive strength of the improved soil is more than 300 kpa, using the improved soil as the high-speed railway subgrade filler. The soft rock weathered material can reach the standard of the high-speed railway subgrade filler after improved by the chemical improving method, and then the engineering cost can be largely reduced, waste materials are reduced, the environment is protected, and finally, good economic, technological, environmental and social benefits are obtained.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Disintegrating magnesium-containing granular fertilizer and preparation method thereof

ActiveCN108046903AParticles are smoothUniform particlesMagnesium fertilisersOrganic fertilisersOrganic acidPrill

The invention relates to the technical field of agricultural fertilizer, and particularly provides disintegrating magnesium-containing granular fertilizer and a preparation method thereof. The magnesium-containing granular fertilizer is prepared from the following raw materials in parts by mass: 60-90 parts of a magnesium-containing raw material, 10-40 parts of a ball forming aid, 12-20 parts of an organic acid solution with mass concentration of 5%-20%. The provided disintegrating magnesium-containing granular fertilizer has the characteristics of short disintegration time limit, high disintegration rate, smooth and uniform granules and high hardness and can be disintegrated or dissolved rapidly when in water due to good disintegration performance, the utilization rate of nutrients in soil by crops is increased, and the growth promoting effect is good; a production process of the disintegrating magnesium-containing granular fertilizer is simple and low in cost, mechanical fertilization is convenient, and environmental pollution is reduced.

Owner:营口菱镁化工集团有限公司

Radioactive decay based stable time or frequency reference signal source

InactiveUS7476865B2Energy stable and preciseStable and precise referenceApparatus using atomic clocksApparatus using radioisotope pulsesDead timeRadioactive agent

A signal source for use as a frequency source or time keeping signal source includes a radioactive emission source generating a substantially periodic signal corresponding to a radioactive material's disintegration rate. A radioactive emission detector generates a radioactive emission detection signal and, to stabilize the detected periodic signal, a dead time controlling attenuator blanks or shuts off the radioactive emission detection signal for a selected dead time interval in response to each detected radioactive emission (i.e., a detected signal pulse or signal component) generated by the source. The dead time controlling attenuator output provides a long-term and short-term a stable periodic signal.

Owner:CORNELL RES FOUNDATION INC

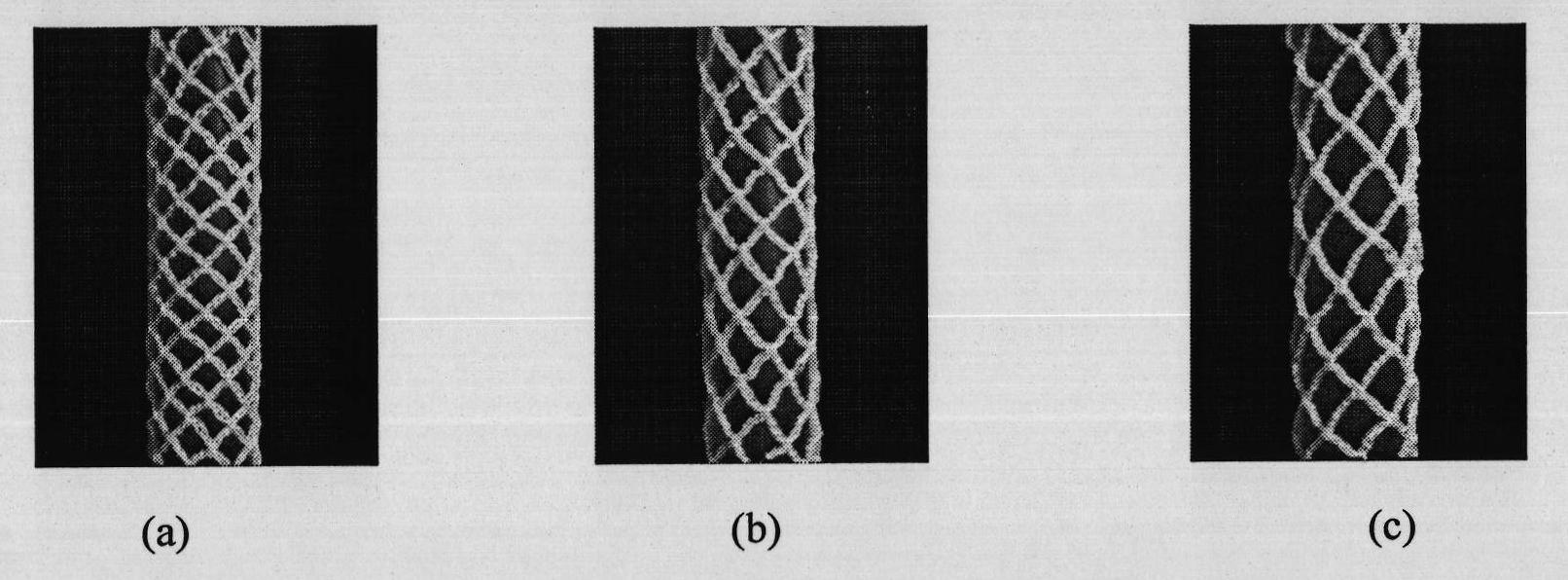

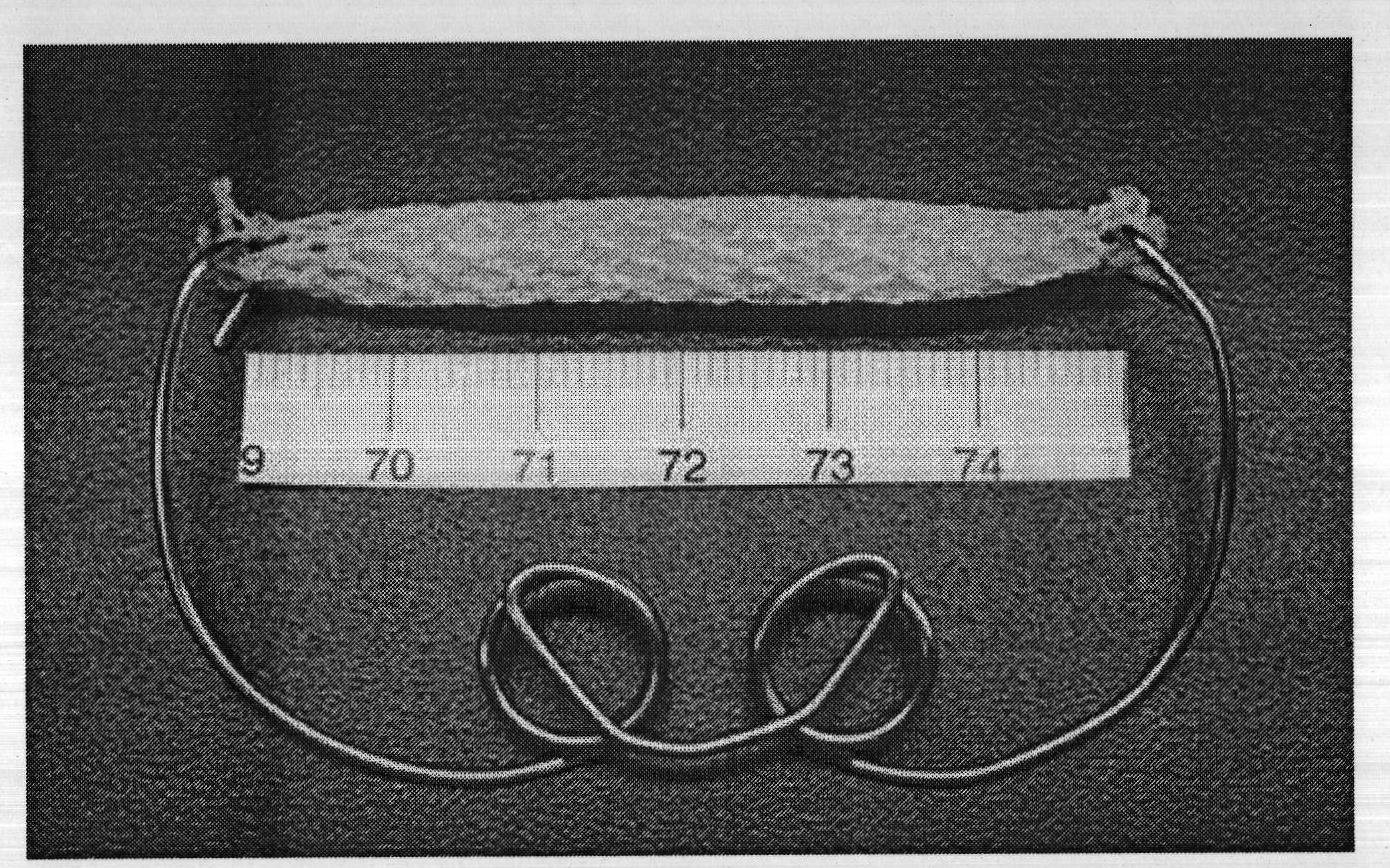

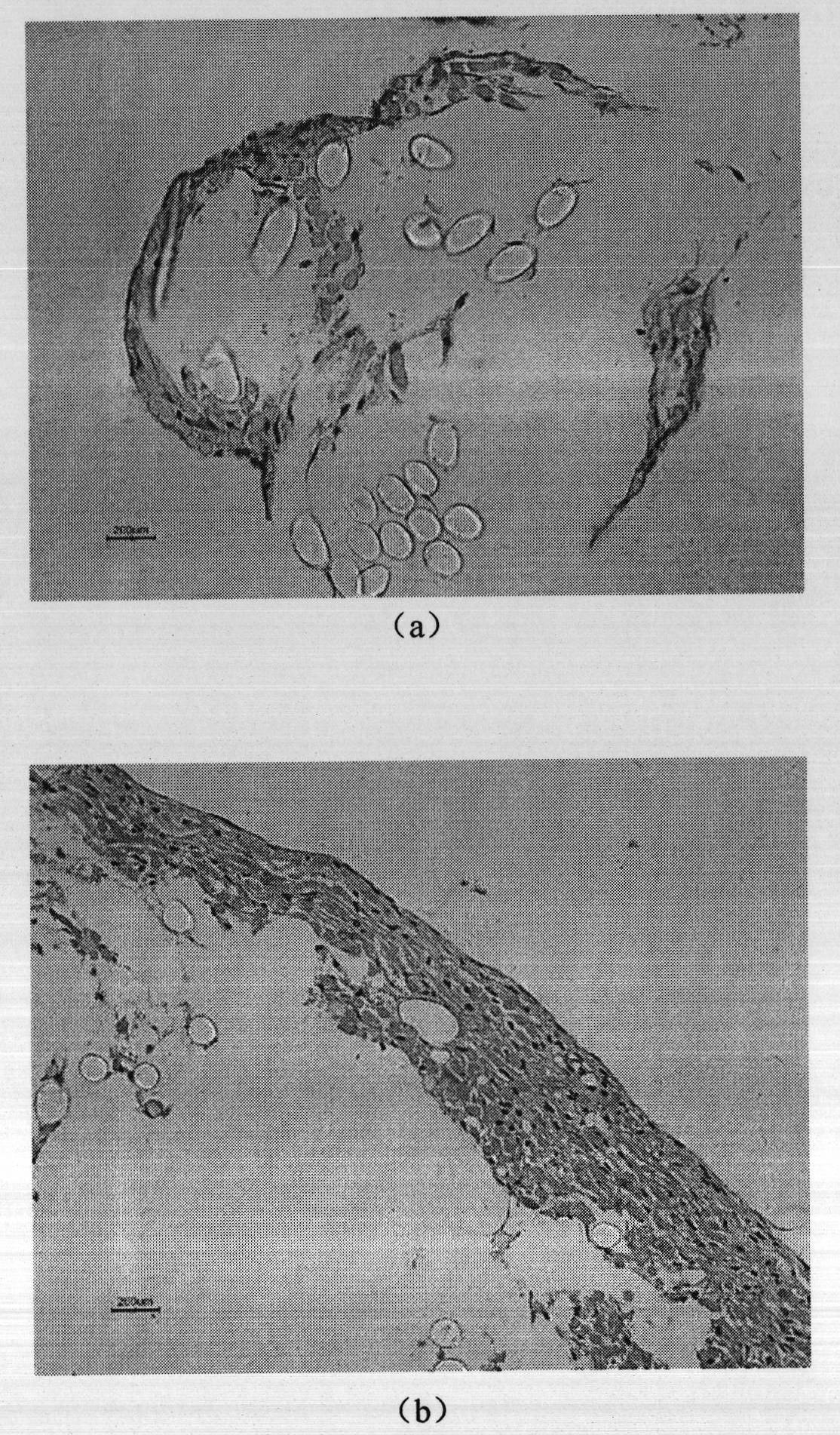

Tissue engineering artificial tendon scaffold enhanced body and preparation method thereof

InactiveCN101829356AGood biomechanical propertiesChange tensile strengthYarnProsthesisGlycollic acidMechanical property

The invention relates to a tissue engineering artificial tendon scaffold enhanced body which comprises tube-shaped fabrics. The tube-shaped fabrics are braided by interweaving PGA (Polyglycolic Acid) fiber flaments and PLA (Polylactic Acid) fiber flaments or PGLA (Poly (Lactic-glycolic Acid)) fiber flaments on a spindle machine to form braided wires or combining the fiber flaments to cord yarns and are in a hollow circular reticular tissure structure. A preparation method of the tissue engineering artificial tendon scaffold enhanced body comprises the following steps of braiding the PGA (Polyglycolic Acid) fiber flaments and the PLA (Polylactic Acid) fiber flaments or the PGLA (Poly (Lactic-glycolic Acid)) fiber flaments into wires or the cord yarns, braiding the wires or the cord yarns into a ring by withdrawing a braiding needle, braiding edges of the reticular structure by the braiding needle, and connecting the edges by short needles. The enhanced body can enable cells to grow in an attaching mode, has the advantage of controllable degradation rate of a scaffold, simple and rapid preparation method and the like, particularly and still has higher mechanical property in the degradation process of the scaffold and has favorable application prospect, wherein the mechanical disintegration rate is matched with the tendon tissue growth rate, and the length of the scaffold can be arbitrarily shorn as required. The invention has favorable application prospect.

Owner:DONGHUA UNIV

High-efficiency high-disintegration rate novel low-toxicity cell element herbicide and preparation method thereof

ActiveCN107251897AHigh suspension rateEfficient and high disintegration rateBiocideAnimal repellantsBiotechnologyDispersion stability

The invention discloses a high-efficiency high-disintegration rate novel low-toxicity cell element herbicide and a preparation method of the high-efficiency high-disintegration rate novel low-toxicity cell element herbicide. The high-efficiency high-disintegration rate novel low-toxicity cell element herbicide is small in average grain size, good in dispersion stability and high in suspending rate, and has the advantages of high efficiency, high disintegration rate, low toxicity, evaporation resistance, drifting resistance, and evener fogdrop size. In addition, the preparation process is easy to control, the stability of the performances of a prepared dry suspending agent is effectively guaranteed, the production efficiency is improved effectively, and the production cost is lowered. The high-efficiency high-disintegration rate novel low-toxicity cell element herbicide is prepared from the following raw materials by weight: 770-810 parts of clopyralid, 100-120 parts of special dry suspending dispersing aid, 40-60 parts of special dry suspending wetting aid, 40-60 parts of special dry suspending disintegration aid, and 1500-2500 parts of water.

Owner:ANHUI YINONG CHEM

Preparation process of decoloring-free alkyl glucoside

ActiveCN108358980ASolve the problem of time-consuming and labor-intensive decolorization processInhibit side effectsSugar derivativesSugar derivatives preparationFatty alcoholSide reaction

The invention belongs to the technical field of surfactant development, and discloses a preparation method of decoloring-free alkyl glucoside. The method comprises the following steps: homogeneously dispersing high amylose in short-chain alcohol, then adding a catalyst, heating and stirring, carrying out first-step glycosylation, carrying out heat preservation after the end of the reaction, and adding fatty alcohol, carrying out second-step transglycoside reaction, and thus obtaining the colorless or milky white alkyl glucoside product after the end of the reaction. Compared with ordinary starch, the high amylose has denser starch granules, so the disintegration rate is slow, starch molecular chains cannot be accumulated in a high-temperature system, the occurrence of side reactions is reduced, the product is milky white in color and has no need of decolorization, moreover, the utilization rate of the raw materials is higher, the surface tension of the product is low, and the surface activity is higher.

Owner:GUANGZHOU UNIVERSITY

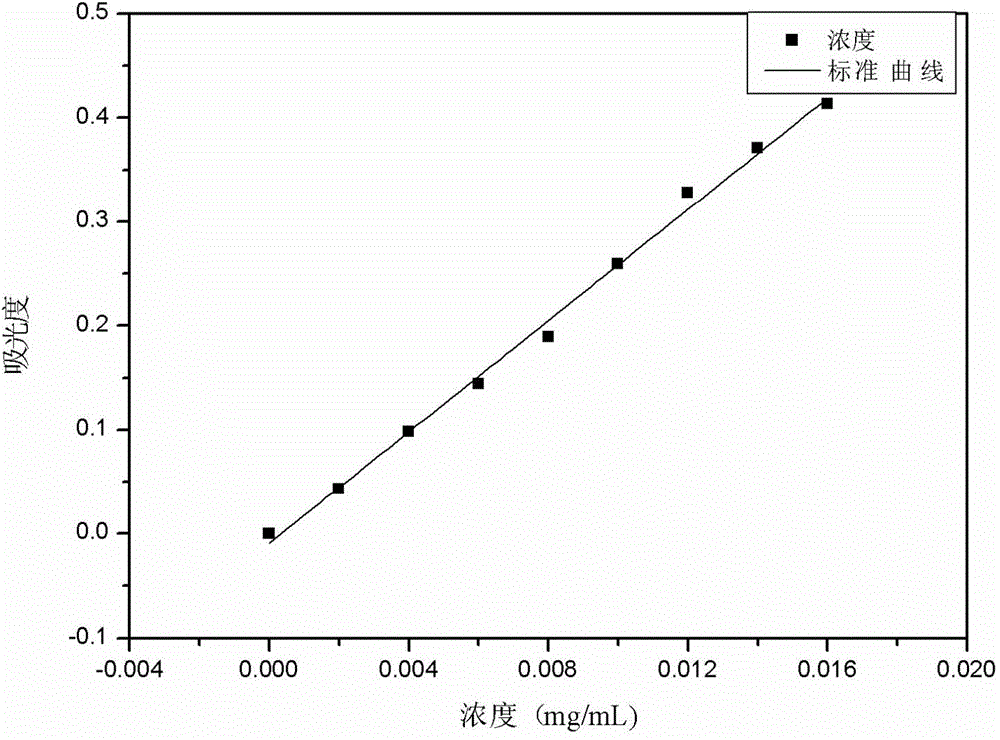

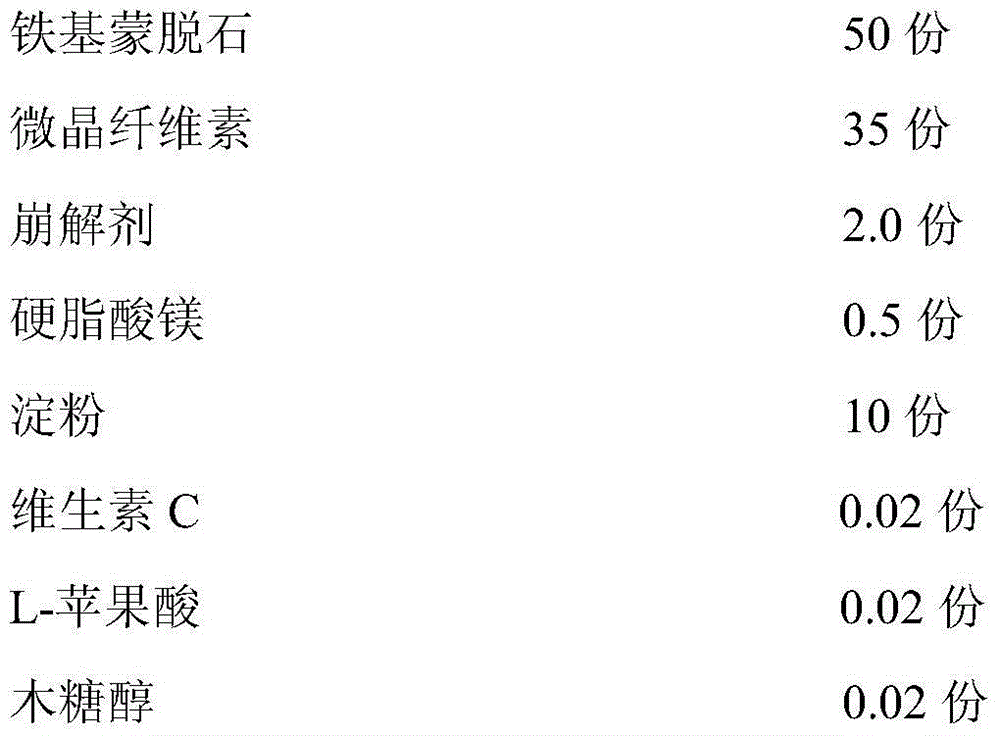

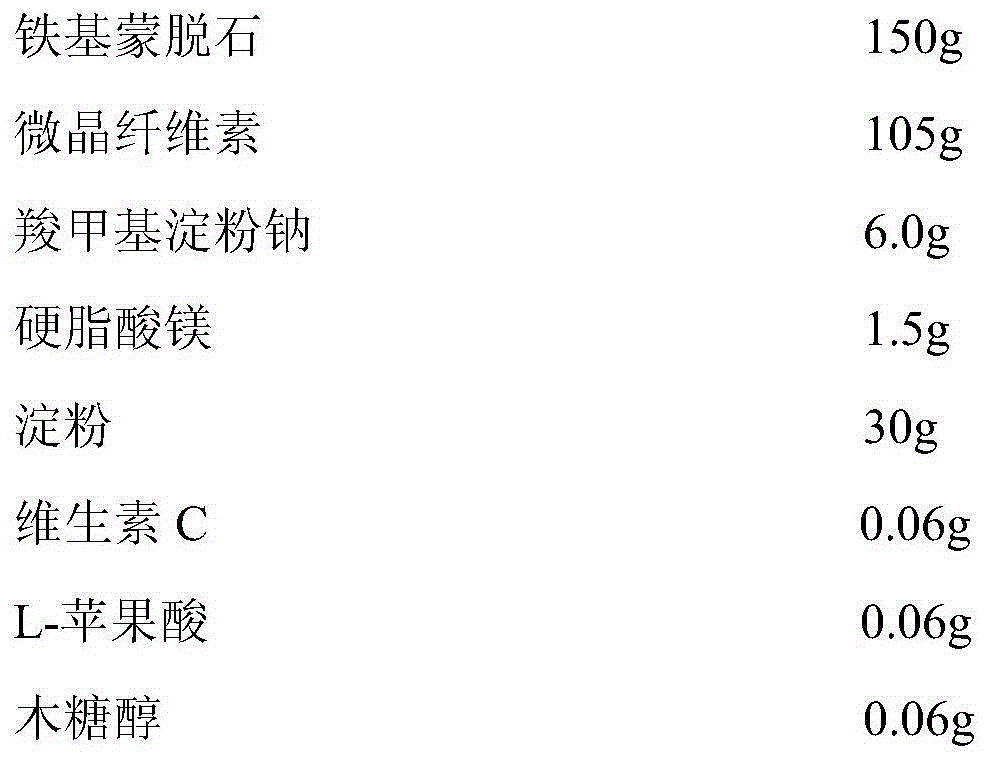

Iron-based smectite dispersible tablets and preparation method thereof

InactiveCN104055793ALow costImprove liquidityHeavy metal active ingredientsMetabolism disorderAntioxidantPharmacology

The invention discloses iron-based smectite dispersible tablets and a preparation method thereof, and relates to a medicinal preparation of the iron-based smectite. The iron-based smectite dispersible tablets are composed of an iron-based smectite medicine and accessories mainly including a filler, a disintegrant, a lubricant and a binder; in addition, an antioxidant is added to achieve an anti-oxidization effect. The preparation method of the tablets comprises the steps of mixing the pretreated iron-based smectite with the accessories in a certain ratio, forming the mixture into dispersible tablets by virtue of wet granulation and tabletting, and covering the dispersible tablets with sugar coatings. The iron-based smectite dispersible tablets are used for treating chronic renal failure hyperphosphatemia and iron-deficiency anemia. The iron-based smectite dispersible tablets are high in disintegration rate, and capable of quickly bonding with phosphates and effectively preventing the incidence of hyperphosphatemia.

Owner:SHANDONG SBOND PHARMA

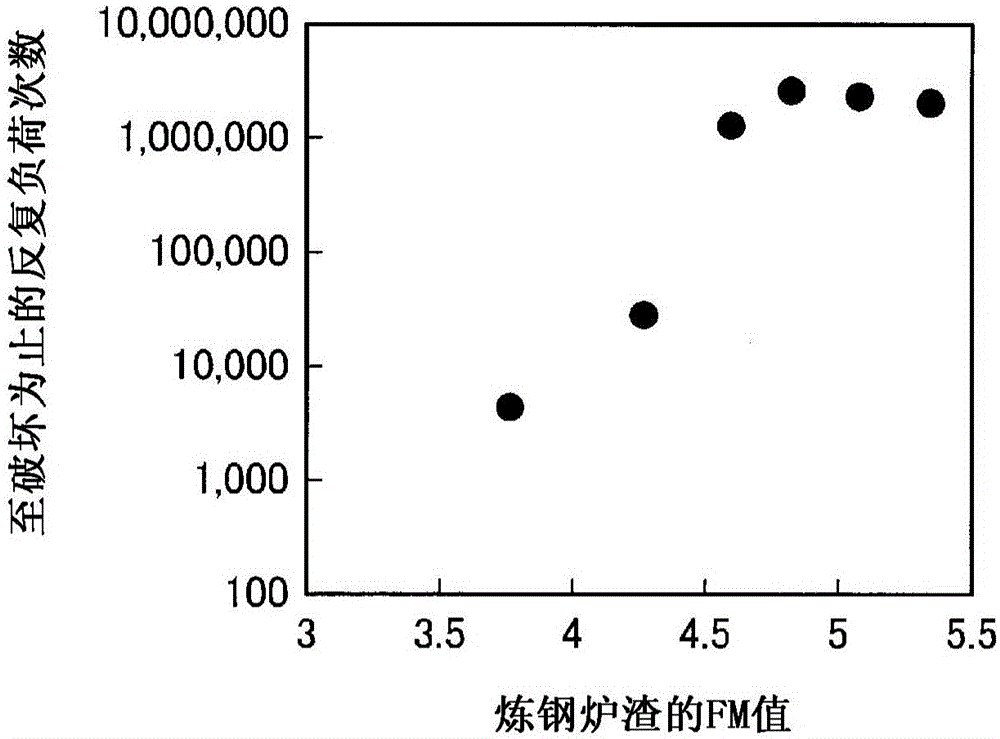

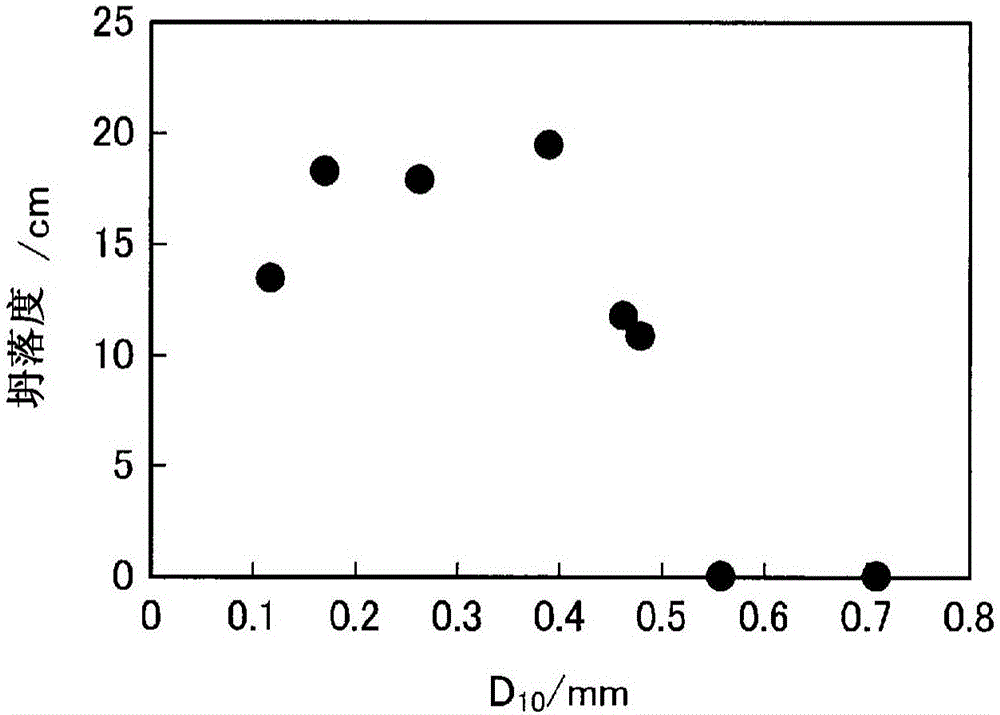

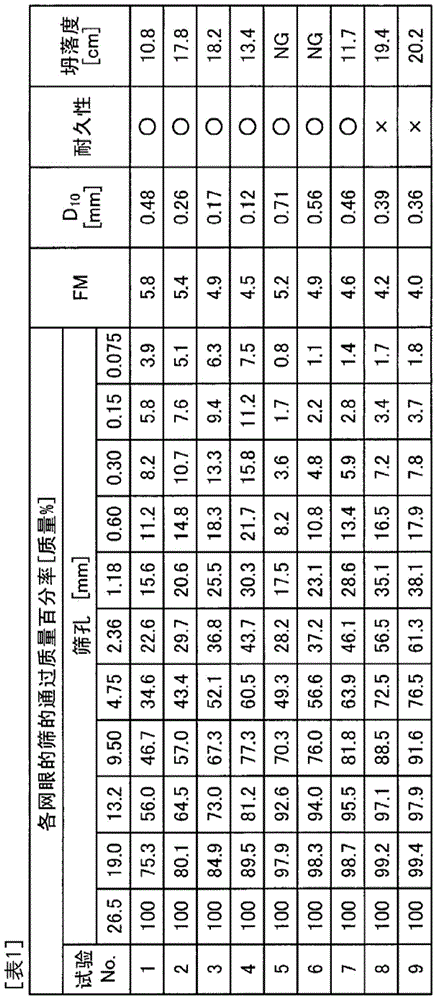

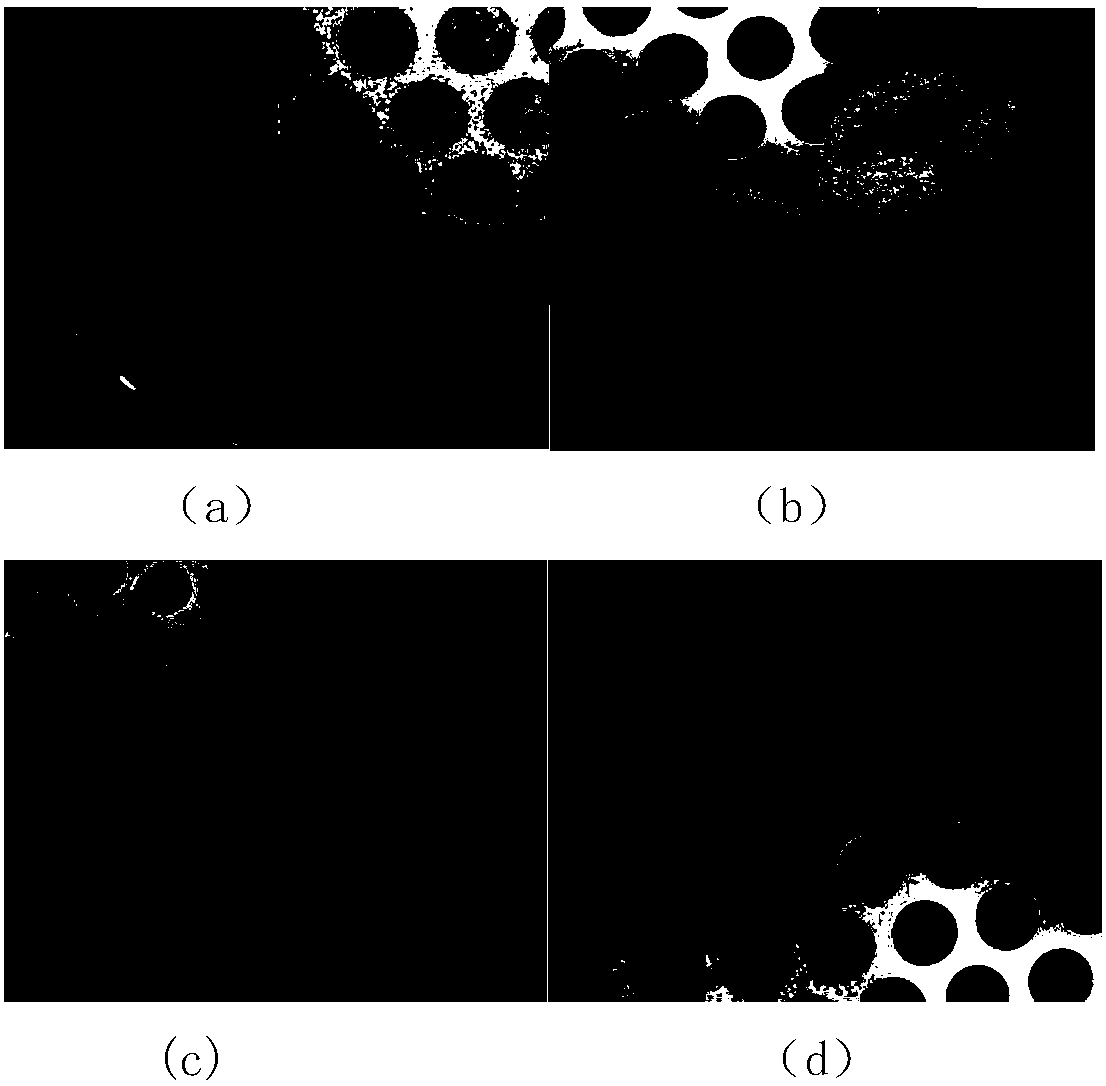

Method for producing hydrated solidified body, and hydrated solidified body

A method for producing a hydrated solidified body is a method for producing a hydrated solidified body by kneading a granular steel-making slag and a SiO2-containing substance together with water. The method is characterized in that the steel-making slag to be used is one that can have a disintegration rate of 2.5 mass% or less after being immersed in warm water having a temperature of 80˚C for 10 days and has a coarse granule ratio of 4.5 or more, and the SiO2-containing substance to be used is a blast furnace slag fine powder or a mixture of a blast furnace slag fine powder and fly ash.

Owner:JFE STEEL CORP

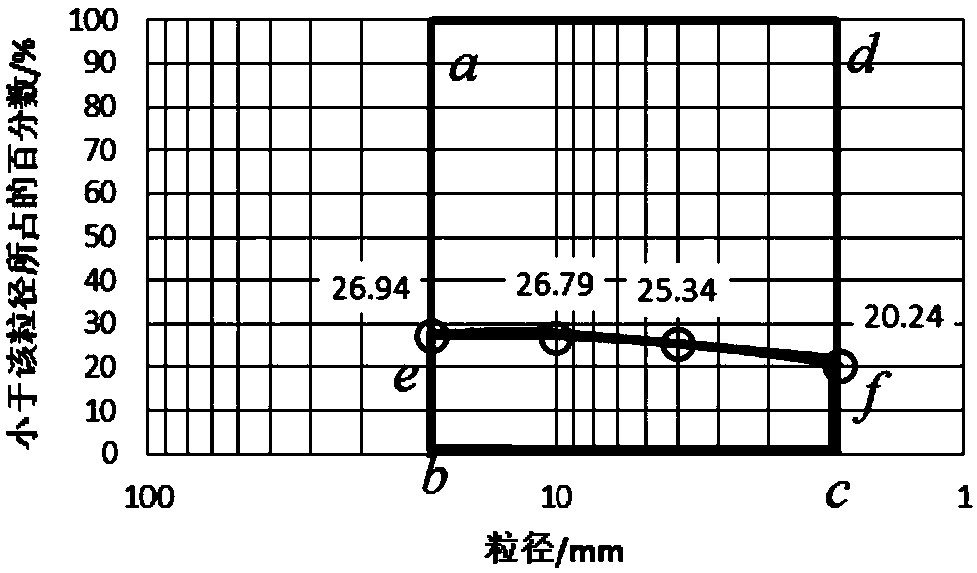

Description method of disintegration characteristics based on soft rock site state

ActiveCN108153947AEnrich the evaluation index information of disintegration resistanceSpecial data processing applicationsDistribution characteristicPhases of clinical research

The invention provides a description method of disintegration characteristics based on a soft rock site state. Based on a disintegration evolution process of a site argillaceous rock state, the disintegration characteristics are described from various angles, specifically four aspects such as a influence depth, fracture rate, particle distribution characteristics and disintegration rate. The influence depth is a one-dimensional linear variable for describing a one-way influence range of disintegration; the fracture rate is a two-dimensional plane variable for describing a boundary feature index of plane disintegration particles and can indirectly reflect particle sizes and distribution; the particle distribution characteristic are three-dimensional variables, and the particle sizes and distribution in the disintegration depth are described; the disintegration rate is a particle distribution value comprehensively determined of a disintegration object. Therefore, the influence depth, theplane fracture rate, the disintegration object particle size distribution and the disintegration rate are comprehensive descriptions of the disintegration characteristics corresponding to developmentstages of disintegration. Compared with the prior art, the method has the advantages that various indexes of the disintegration process of extremely soft rocks can be systematically reflected, and description parameters are closer to actual rock slope disintegration phenomenons.

Owner:HOHAI UNIV

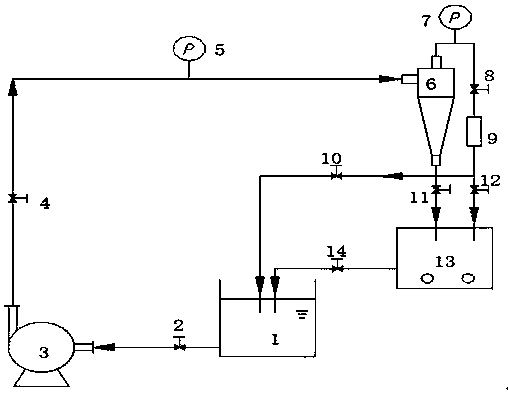

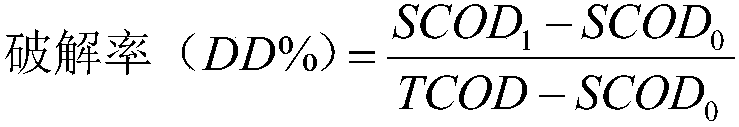

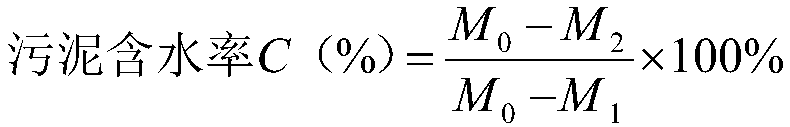

Combined ultrasonic whirl and disintegration process for surplus sludge

InactiveCN108046550AReduce moisture contentDelayed cracking timeSludge treatment by de-watering/drying/thickeningUltrasonic cavitationShear flow

The invention relates to the technical field of municipal domestic wastewater and sludge treatment and specifically discloses a combined ultrasonic whirl and disintegration process for surplus sludge.The process comprises the following steps: after carrying out gravity sedimentation and concentration on surplus sludge generated by a secondary sedimentation tank of a municipal sewage treatment plant, disintegrating the surplus sludge under the action of a strong whirl shear flow field to form small flocs; then, realizing the crushing of microorganism cell walls under the action of ultrasonic cavitation; and releasing intercellular and extracellular polymers and intercellular organic matters into a water body to facilitate the subsequent recycle of a carbon source, so that the reduction ofthe surplus sludge is realized. By using the combined ultrasonic whirl and disintegration process, the disintegration rate of the sludge is increased, the disintegration time of the surplus sludge isshortened, the problem that the overmuch surplus sludge is difficult to treat is effectively solved, the transportation cost of the sludge is reduced, the operation costs of sludge treatment and sewage treatment are reduced as a whole, and the combined ultrasonic whirl and disintegration process has high environmental and economic benefits.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

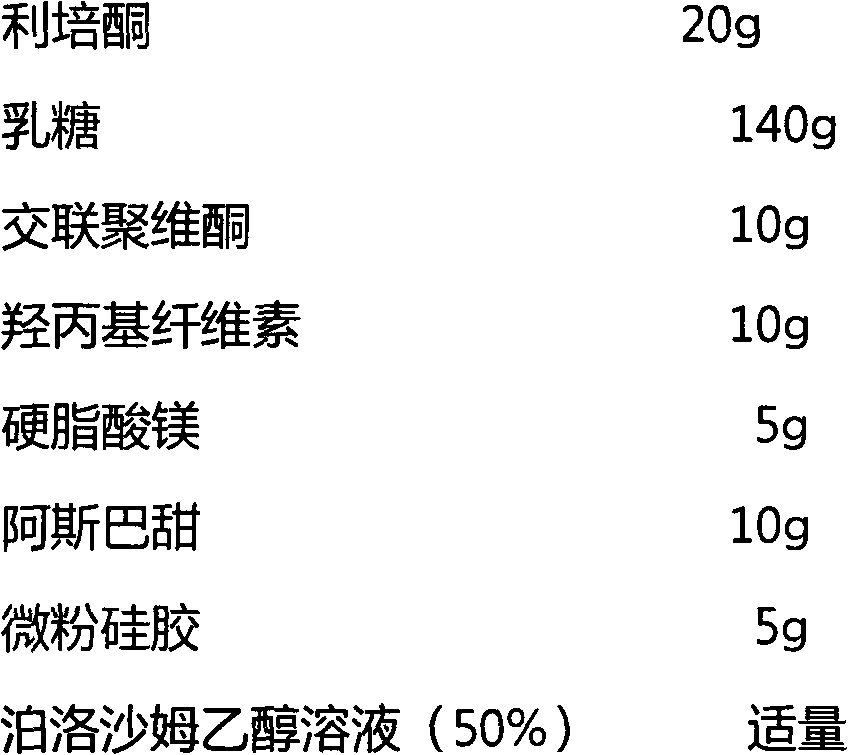

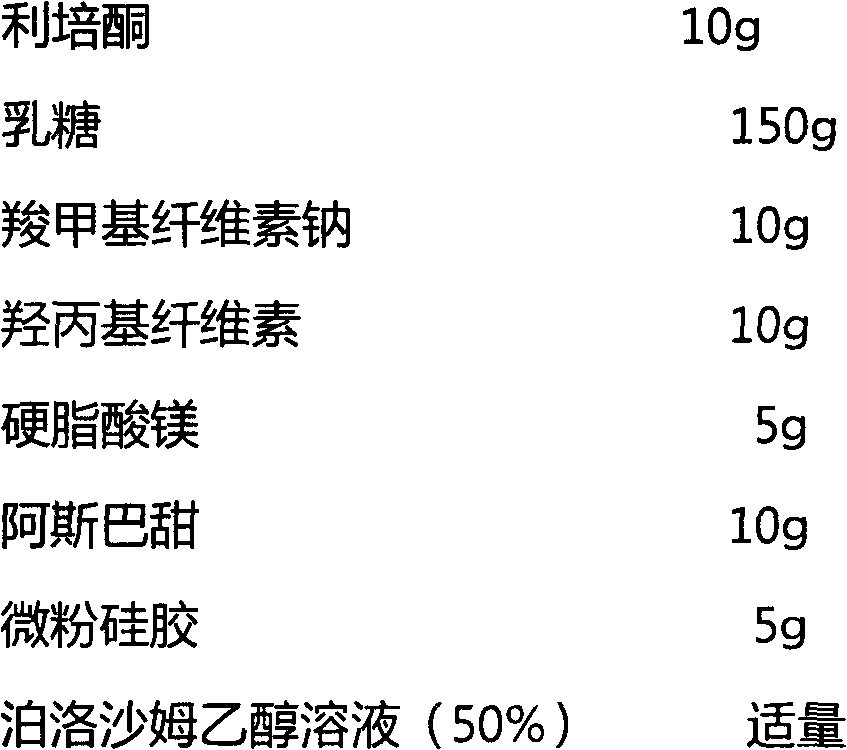

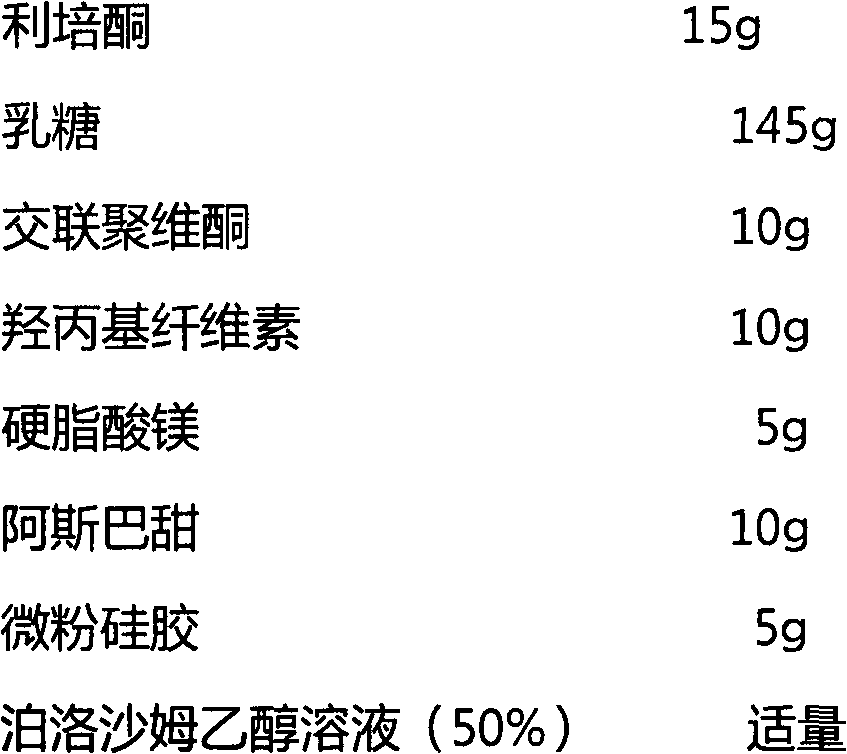

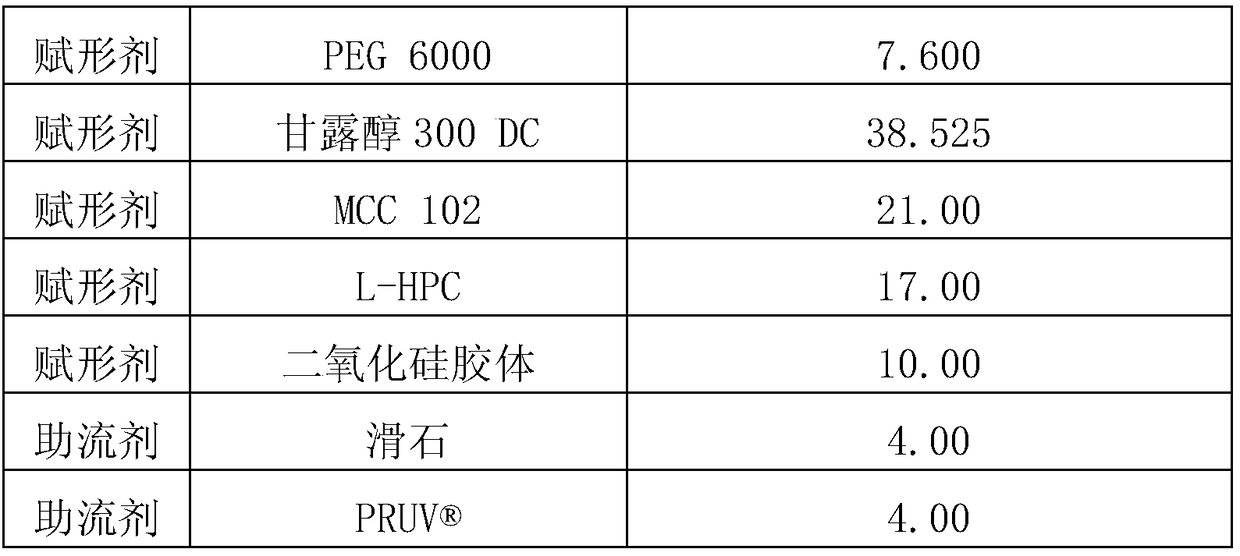

Risperidone orally-disintegrating tablet

InactiveCN103751134AProcess stabilityOrganic active ingredientsNervous disorderPatient complianceOrally disintegrating tablet

The invention provides a risperidone orally-disintegrating tablet. The risperidone orally-disintegrating tablet contains a physiologically effective amount of risperidone and a necessary pharmaceutically-suitable excipient. The risperidone orally-disintegrating tablet has content of 5-10wt%. The pharmaceutically-suitable excipient is a mixture comprising a filler, an odor mask agent, a disintegrating agent, a surfactant, a binder, a lubricant and a flow promoter. The risperidone orally-disintegrating tablet has the advantages of fast disintegration rate, excellent taste, stable quality and reliable curative effects and can improve patient compliance.

Owner:SHANGHAI TIANLONG PHARMA

Tenside granules with improved disintegration rate

InactiveUS20060079432A1Non-ionic surface-active compoundsOrganic detergent compounding agentsEtherDissolution

Owner:COGNIS DEUT GMBH & CO KG

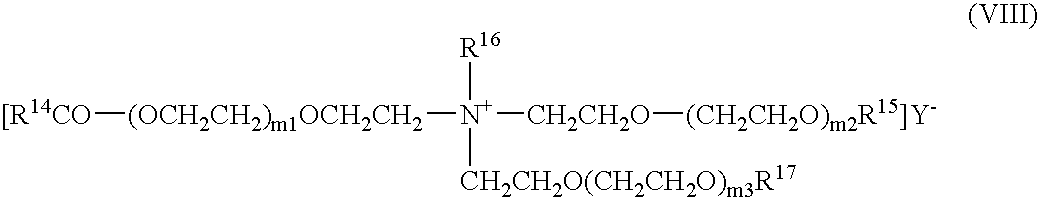

Vermicelli block or noodle block automatic box-removing device and box-removing method

A powder agglomerate or flour agglomerate automatic de-box device comprises a slide opening opened one the bottom board of a drying box, a sliding ejector arranged inside the slide opening and an ejecting mechanism arranged on a turning cylinder which is arranged on the outlet of the drying machine. The sliding ejecting piece comprises an upper ejecting board, a sliding shaft and a lower ejecting board. A de-box process is that the ejecting mechanism jacks upwards the lower ejecting board, the upper ejecting board also moves upwards when the lower ejecting board moves upwards, and the upper ejecting board upwards pushes powder agglomerates or flour agglomerates and is pushed away from a flour box. When the drying box moves to position of a rotation shaft and rotates 90 degrees, the powder agglomerate or the flour agglomerate falls down and slips to the next procedure along a guide strip, thereby completing the automatic de-box process. The powder agglomerate or flour agglomerate automatic de-box device of the invention has the advantages of automatic de-box, de-box rate of 100%, harmonious and fluent movements, low manufacturing cost and saved labor force. The powder agglomerate or the flour agglomerate has the advantages of trim and uniform appearance, elegant shape, low disintegration rate of powder agglomerate or flour agglomerate vermicelli and the like, which simultaneously avoids easily deforming and destroying the drying box for the reason of strong force beating.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

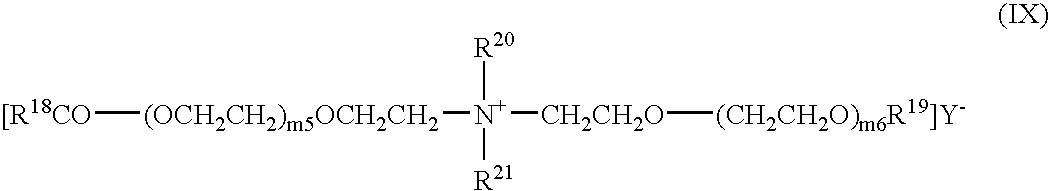

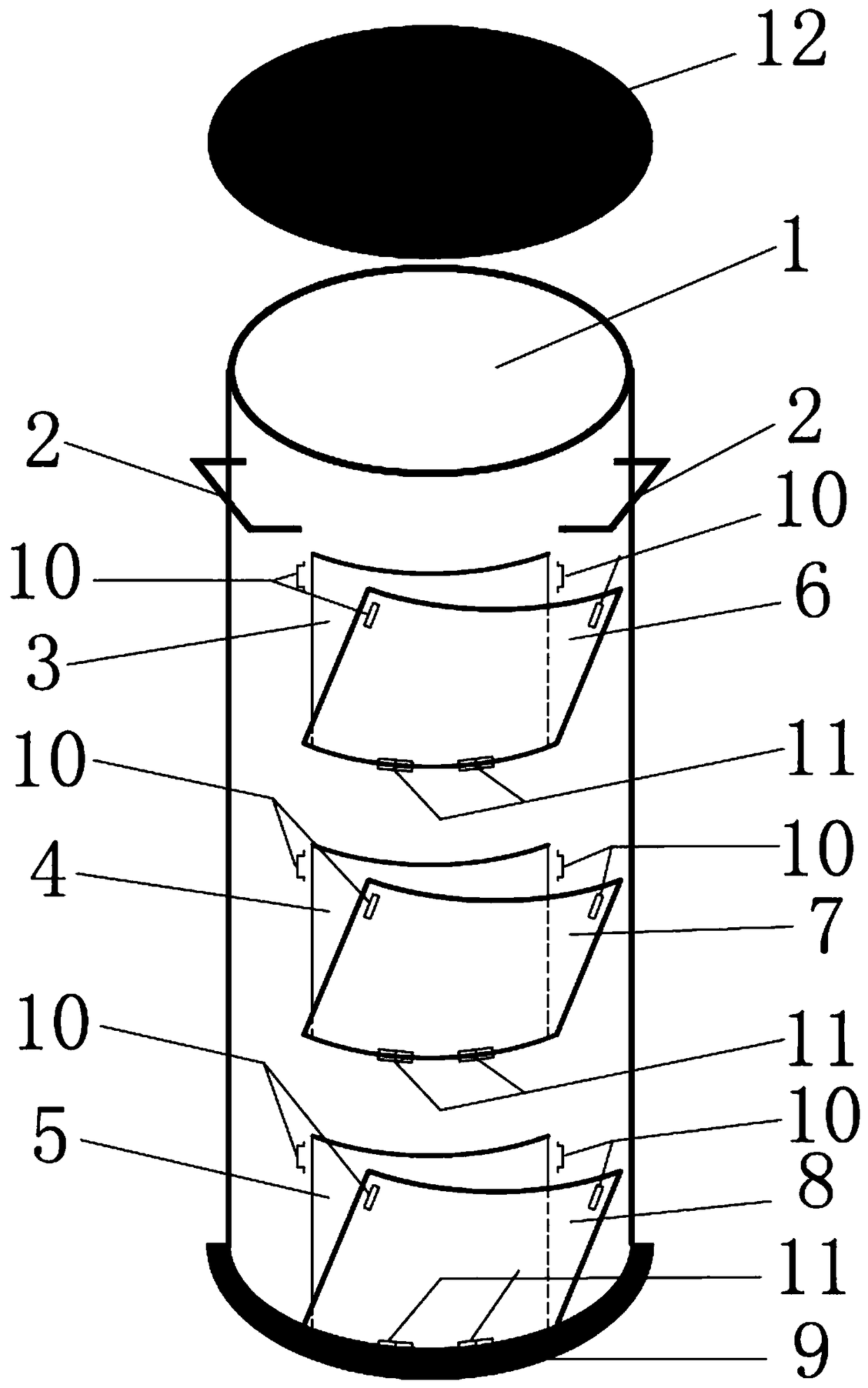

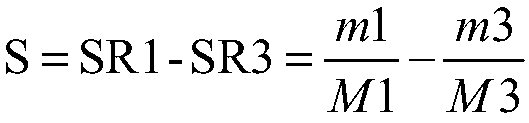

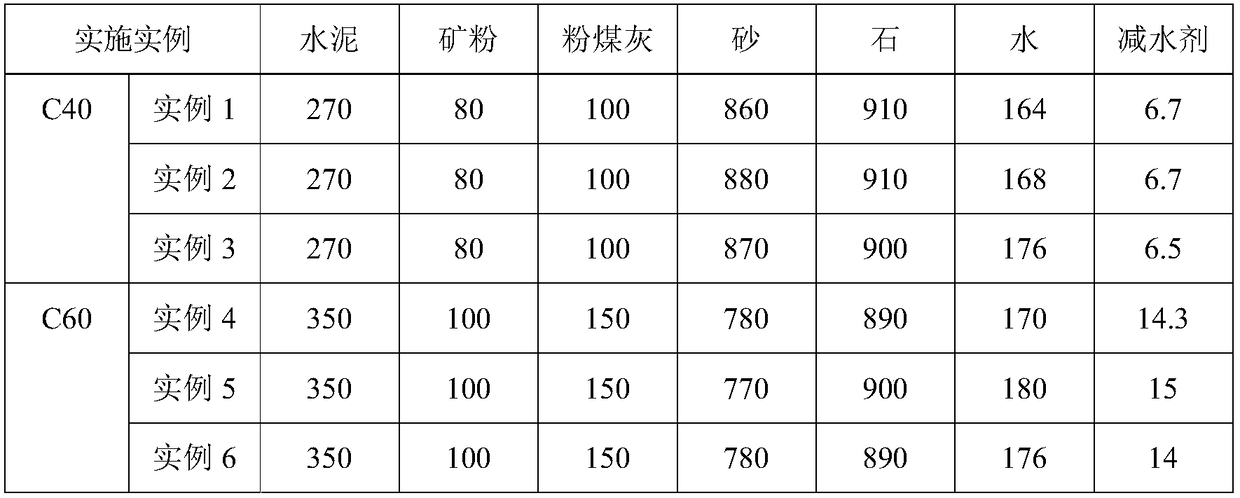

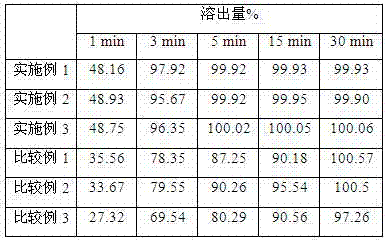

Device and method for detecting disintegration rate and stability of concrete on construction site

InactiveCN108982820AReliable resultsReflect stabilityMaterial testing goodsArchitectural engineeringDisintegration Rate

The invention discloses a device and method for detecting the disintegration rate and the stability of concrete on a construction site. The device comprises a material container, openings and baffles,wherein the top, the middle and the bottom of the material container are provided with the openings and the baffles; the baffles are connected to the bottoms of the openings through connecting bolts;and fixing devices are arranged on the two sides of the baffles and are arranged on the two sides of the openings and the two sides of the corresponding baffles separately and are used for fixing thebaffles so as to seal the openings. According to the device and the method, the disintegration rate and the stability of the concrete can be accurately tested, meanwhile, the stability of the concrete in the pumping process can be quantitatively predicted, and the pumpability of the concrete can be evaluated.

Owner:BEIJING UNIV OF TECH

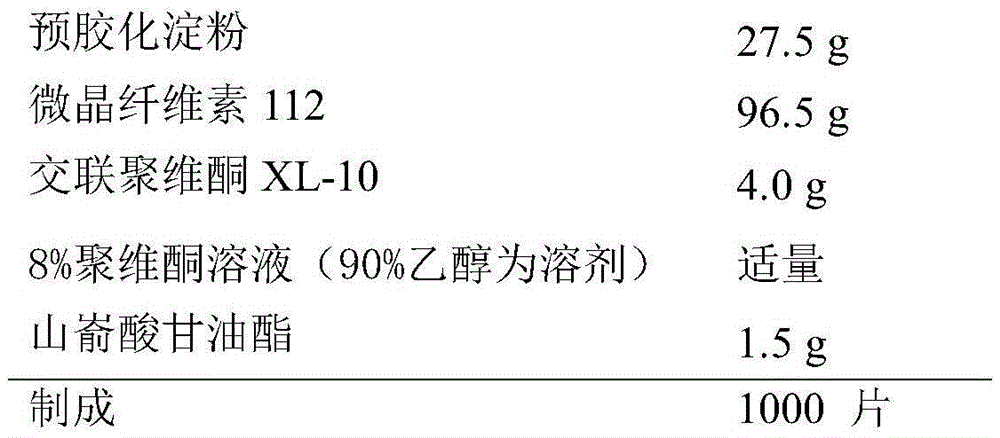

Ulipristal acetate dispersible tablet and preparation method thereof

InactiveCN107982230ADisintegrates quicklyHigh dissolution rateOrganic active ingredientsPharmaceutical non-active ingredientsDissolutionSURFACTANT BLEND

The invention discloses a ulipristal acetate dispersible tablet, which consists of the following components in percentage by weight: 3-15% of ulipristal acetate, 60-90% of a filler, 5-30% of povidone,2-7.5% of a surfactant, 2-5% of a disintegrant and 0.05-2% of a lubricant. The invention also discloses a preparation method of the ulipristal acetate dispersible tablet, wherein the preparation method comprises the following steps: dissolving the povidone in an ethanol solution, and then sequentially adding the surfactant and the ulipristal acetate, so that a prepared material is obtained; and uniformly mixing the filler and the disintegrant, adding the prepared material, implementing granulating and drying, straightening particles, adding the lubricant, uniformly mixing the materials and conducting tabletting, so that the dispersible tablet is obtained. The dispersible tablet prepared by the invention is high in disintegration rate, high in dissolution rate, good in dispersion uniformity and high in ulipristal acetate content; and the dispersible tablet is convenient to take and convenient to carry, and the compliance of clinical administration is greatly improved.

Owner:ZHENGZHOU TAIFENG PHARMA CO LTD

Preparation method of carbon-containing polymer for preparing graphene three-dimensional structure powder material

The invention discloses a preparation method of a carbon-containing polymer for preparing a graphene three-dimensional structure powder material, and belongs to the field of polymer synthesis. The preparation method comprises: (1) adding a cross-linking agent monomer and an initiator monomer to a polymerization monomer to obtain a monomer mixing phase, and adding a pore forming agent; (2) adding an aqueous solution to a reaction kettle, adding a dispersant, adding the monomer mixing phase to the reaction kettle in a dropwise manner, and carrying out a reaction; (3) cooling, washing and carrying out other operations to obtain a copolymer; and (4) removing the pore forming agent by using an extractant, and carrying out hydrolysis on the copolymer to obtain the carbon-containing polymer for preparing the graphene three-dimensional structure powder material. According to the present invention, the carbon-containing polymer has the following advantages that transition metal ions are easily incorporated so as to be subjected to low temperature graphitization, the three-dimensional graphene powder having the three-dimensional structure can be formed after the high temperature graphitization treatment, and the disintegration rate is more than 98%; and the method has advantages of high product purity, stable product quality, and easy operation.

Owner:GUANGXI UNIV

Compound compound paracetamol and zincgluconate dispersible tablet and method of preparing the same

InactiveCN101249119ASimplify the taking procedureImprove cold symptomsAntipyreticAnalgesicsAdditive ingredientBULK ACTIVE INGREDIENT

The invention provides a compound paracetamol and zinc gluconate dispersion tablet which can be crumbled and a preparation method thereof. A single separating granulation method is adopted on the traditional Chinese medicine of compound indigowood root extract powder, thereby avoiding the infections on the whole tablet moulding capability and the disintegration rate because the traditional Chinese medicine ingredient absorbs moisture during the preparation process. The problems that the crumbling and the dissolving out of active ingredient of a common tablet are slow to lead to the result that western medicine ingredient in the medical prescription improves influenza symptom to take effect slowly, and the action is too assuasive. Surface active agent can be further added in cementing substance to accelerate the crumbling; the dosage of the cementing substance is reduced at the same time, thereby further increasing the disintegrative characteristic of the tablet. In addition, the tablet is dispersed more evenly after being crumbled in the water by adding with the surface active agent, thus forming uniform suspension solution, and the medicine dosage for a patient is more accurate. Correctives with bitter taste masking effect can also be further added in the medical prescription to give the prepared dispersion tablet a nice taste, so that the medicine taking compliance of the patient is increased.

Owner:HONGGUAN BIO PHARMA CO LTD

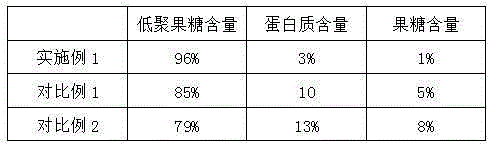

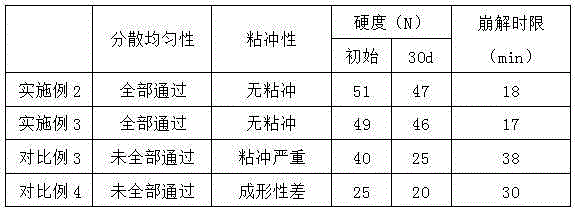

Black garlic fructo-oligosaccharide tablet and preparation method thereof

ActiveCN105053773ASpeed up fermentationReduce dwell timeFood ingredient functionsFood preparationSolubilityGlycoside

The present invention belongs to the technical field of medicines and relates to a tablet with health-care functions, and particularly to a black garlic fructo-oligosaccharide tablet and a preparation method thereof. The black garlic fructo-oligosaccharide tablet includes the following raw materials in parts by weight: black garlic fructo-oligosaccharide powder 100-200 parts, konjac powder 20-30 parts, calcium acetate 5-10 parts, magnesium stearate 1-2 parts, crospolyvinylpyrrolidone 3-4 parts, and 50wt% alkyl glucosides 2-3 parts. The prepared black garlic fructo-oligosaccharide tablet has a high purity of fructo-oligosaccharide, good solubility, faster disintegration rate, long storage time, and stable performance.

Owner:菏泽天鸿果蔬股份有限公司

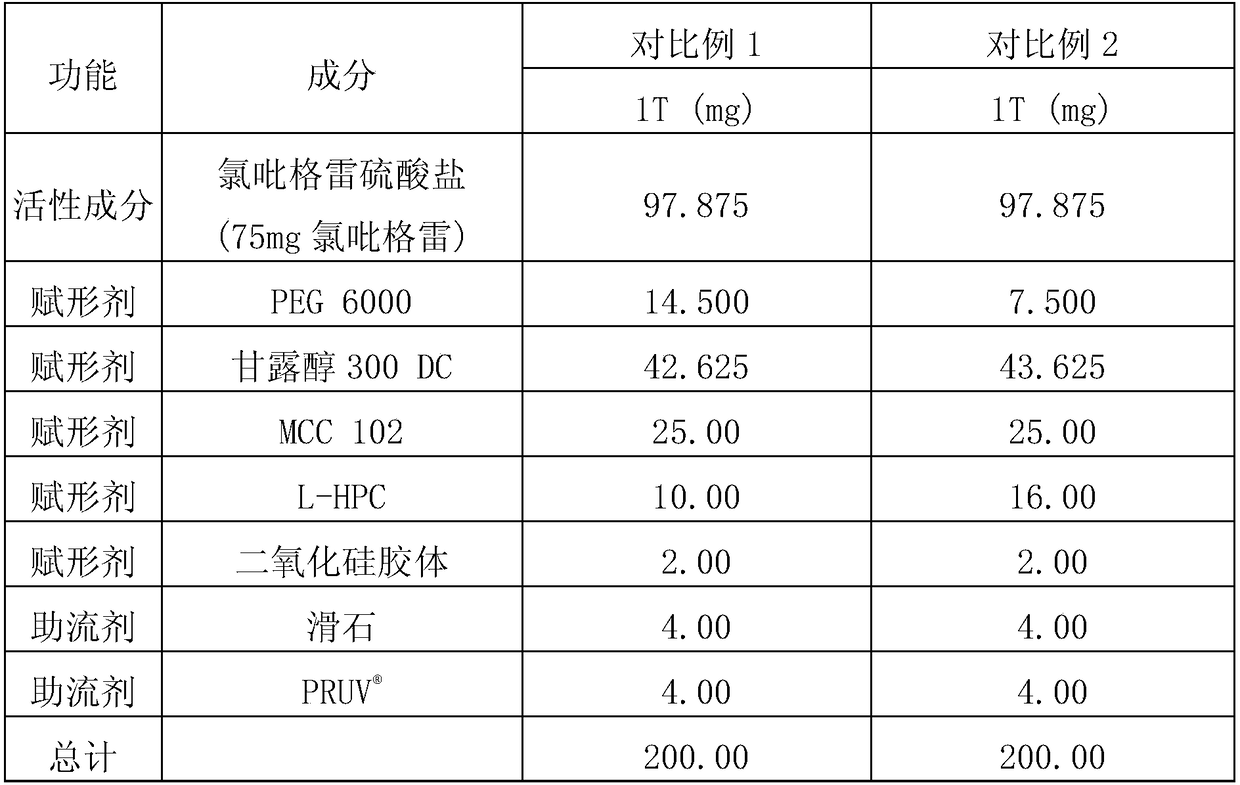

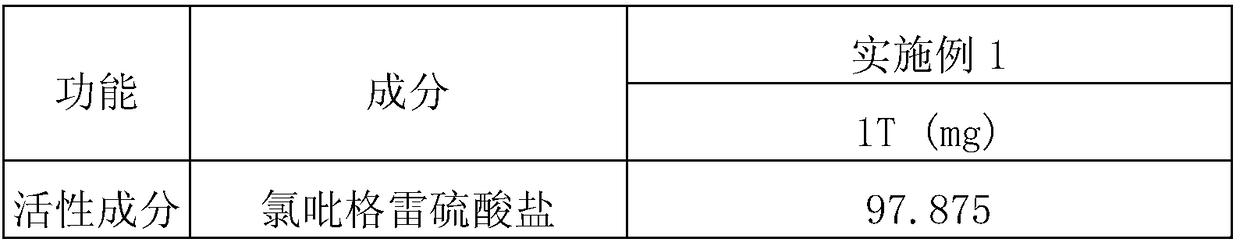

Composite preparation containing clopidogrel and aspirin

PendingCN109069436APrevent release delayIncrease disintegration rateSalicyclic acid active ingredientsCapsule deliveryMedicineClopidogrel

The present invention relates to a composite preparation containing clopidogrel and aspirin and to a method for preparing the same, wherein the composite preparation has stability maintained even during storage and distribution and shows a fast clopidogrel tablet disintegration rate.

Owner:KOREA UNITED PHARMA

Disintegratable round-grain boron magnesium fertilizer and preparation method thereof

InactiveCN102775221AOvercome deficienciesReduce manufacturing costFertilizer mixturesCalciteMass content

The invention belongs to the field of agricultural fertilizers, and particularly relates to a disintegratable round-grain boron magnesium fertilizer which is prepared from the following raw materials in parts by mass: 51-55 parts of brucite powder, 35-43.5 parts of boromagnesite powder, 0-5.5 parts of borax pentahydrate, 2-3 parts of boric acid and 1.5-4 parts of calcite. Water is used as a binding agent. The prepared round-grain boron magnesium fertilizer is 2-4mm spherical grains, of which the 2-4mm throughput rate is greater than or equal to 95%, the strength is greater than or equal to 2Kg / cm<2>, the disintegration rate is greater than or equal to 90%, the MgO mass content is greater than or equal to 40%, and the B2O3 mass content is 9-11%. By using the water as the granulating liquid phase and the mixture powder of brucite powder, boromagnesite powder, borax pentahydrate, boric acid and calcite as the dry material, the round-grain boron magnesium fertilizer has the advantages of cheap and accessible raw materials and reasonable formula. The mixture is granulated, screened, dried, cooled and packaged to obtain the 2-4mm spherical grains. The product is pure natural spherical grains, and has the advantages of high uniformity, smooth surface and high strength; the disintegration rate is greater than or equal to 90%; the boron magnesium fertilizer can be quickly disintegrated, is long-acting, and is convenient for mechanical spreading and mixing with other fertilizers.

Owner:张浩

Slow-release fertilizer for sunflower prepared from micro nano dual-channel coating material and preparation method thereof

InactiveCN105294299ADelayed disintegration rateIncrease profitFertilizer mixturesMicro nanoMesoporous silica

The invention belongs to the slow-release fertilizer field, and specifically discloses a slow-release fertilizer for sunflower prepared from micro nano dual-channel coating material. The slow-release fertilizer is characterized by including the following components by weight: 5-6 parts of alkyl chloride, 50-52 parts of straight chain starch, 8-9 parts of mesoporous silica nanoparticles, 8-9 parts of micron spherical carbon, 40-43 parts of peanut bran, 50-52 parts of Camellia shell ferment powder, 50-52 parts of bagasse ferment powder, 20-22 parts of dry ginger submicron powder, 23-25 parts of drying seaweed powder, 3-4 parts of proline, 3-4 parts of cysteine and 2-2.2 parts of polymeric boron. The crosslinking modified amyloseh is supplemented with two sizes of substances in micron size and nano size to construct a dual-channel slow-release coating material, so as to increase the slow-release regulation and control effect and delay the disintegration rate of the slow-release coating material to certain degree. The fertilizer improves regulation and control effect and realizes respective utilization of different nutrients in different growth stages of sunflower.

Owner:HEFEI YONGSHENG CULTIVATION CO LTD

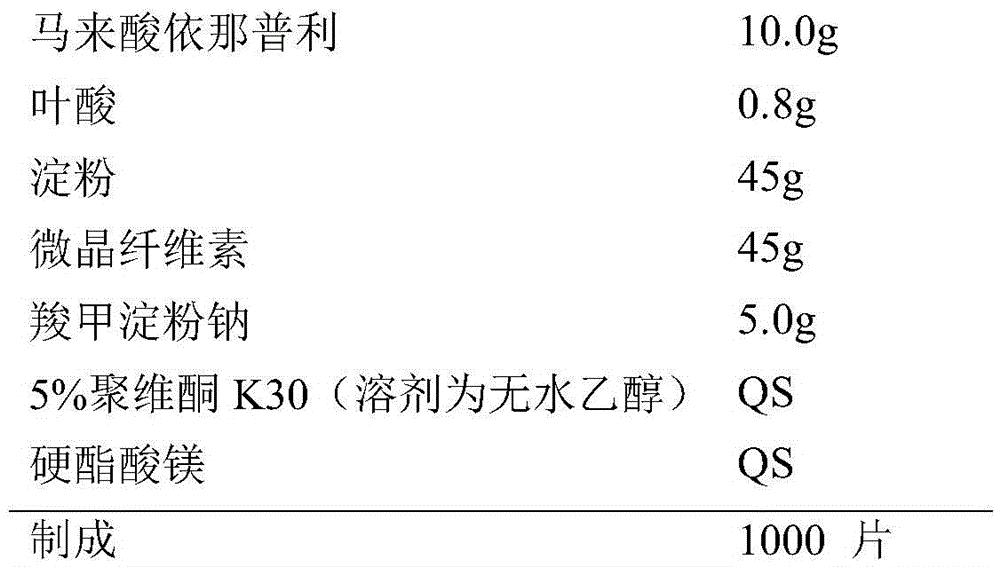

Tablet composition containing enalapril and folic acid and preparation method thereof

ActiveCN106310218ASlow down the dissolution rateProtection from destructionOrganic active ingredientsDipeptide ingredientsCurative effectTherapeutic effect

The invention relates to a tablet composition containing enalapril and folic acid and a preparation method thereof. The tablets prepared by the preparation method are capable of effectively reducing the degradation of active ingredients of a medicine while improving the stability and safety of a compound solid preparation as well as the disintegration rate and timeliness of the medicine in the stomach and intestines; the composition meets the dosage requirements for accurate absorption, and the therapeutic effect of the medicine is remarkably improved.

Owner:SHENZHEN AUSA PHARM CO LTD +1

Dual-channel coated material regulated efficient slow-release fertilizer for tomato and preparation method thereof

InactiveCN105294295ADelayed disintegration rateIncrease profitClimate change adaptationAgriculture gas emission reductionChelated zincMicrosphere

The invention belongs to the field of slow-release fertilizer, and specifically discloses a dual-channel coated material regulated efficient slow-release fertilizer for tomato. The fertilizer is characterized by including the following components by weight: micron magnetic biomass charcoal composite microspheres, modified high film-forming guar flour, guar gum, glutaraldehyde, mesoporous silica nanoparticles, veratridine, lycopene, amino acid chelated zinc, ferric citrate, nitrogen phosphorus potassium microelement fertilizer, Trichoderma viride, metamorphic glucose powder, silicon humate fertilizer, plant ash, a milk coagulant and a proper amount of water. The crosslinking modified high film-forming guar flour is supplemented with two sizes of substances including mesoporous silica nanoparticles and micron magnetic biomass charcoal composite microspheres to construct a dual-channel slow-release coated material with slow-release regulation and control effect, so as to delay disintegration rate of the slow-release coated material, improve regulation and control effect. The slow-release fertilizer realizes utilizes of different nutrients in different growth stages of tomato, and promotes the efficient cultivation of tomato.

Owner:HEFEI YONGSHENG CULTIVATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com