Device and method for detecting disintegration rate and stability of concrete on construction site

A construction site and concrete technology, which is applied to the field of devices for detecting concrete segregation rate and stability at the construction site, can solve problems such as insufficient representation of concrete stability, inconvenience for construction site tests, and complicated operation of segregation rate jumping table tests, and achieves structural Simple, reliable results and easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

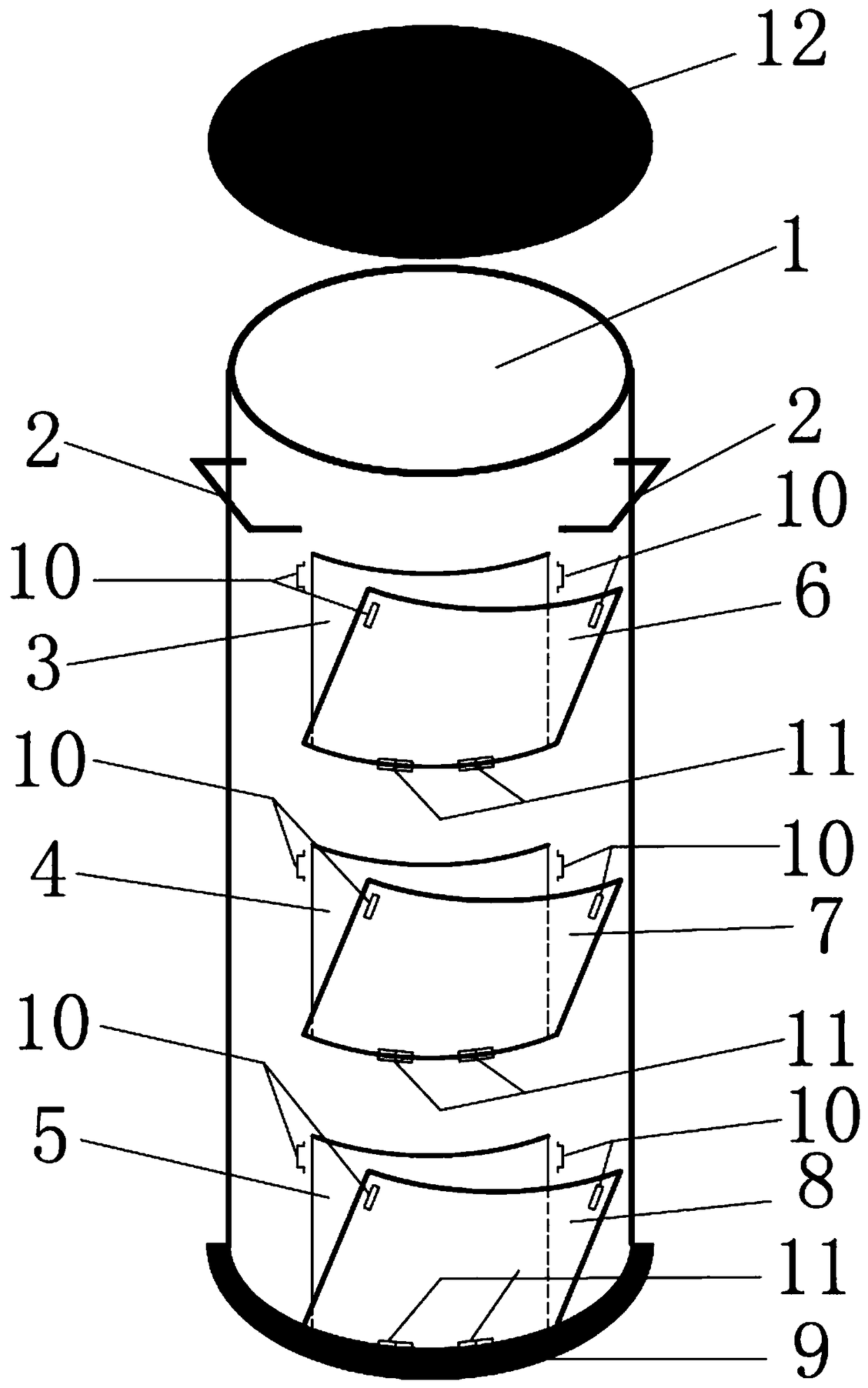

[0026] Such as figure 1 A device for detecting the segregation rate and stability of concrete at a construction site is shown, including a container 1, a first opening 3, a second opening 4, a third opening 5, a first baffle 6, a second baffle 7, The third baffle plate 8, the bottom plate 9, the fixing device 10, the connecting bolt 11, the container 1 is provided with a bung 12, the top is provided with a handle 2, and the bottom is provided with a bottom plate 9.

[0027] Working process of the present invention is as follows:

[0028] When the present invention is used, the first opening 3, the second opening 4, and the third opening 5 are closed with the first baffle plate 6, the second baffle plate 7, and the third baffle plate 8, and then the concrete mixture is packed into In the container 1, fill the back and cover the bucke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com