Device and method for detecting leak rate of O type rubber sealing ring used for spaceflight

The technology of a rubber sealing ring and a detection device is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problems of high detection cost, complicated operation and long detection period, etc. Achieve high detection efficiency, high detection sensitivity, and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

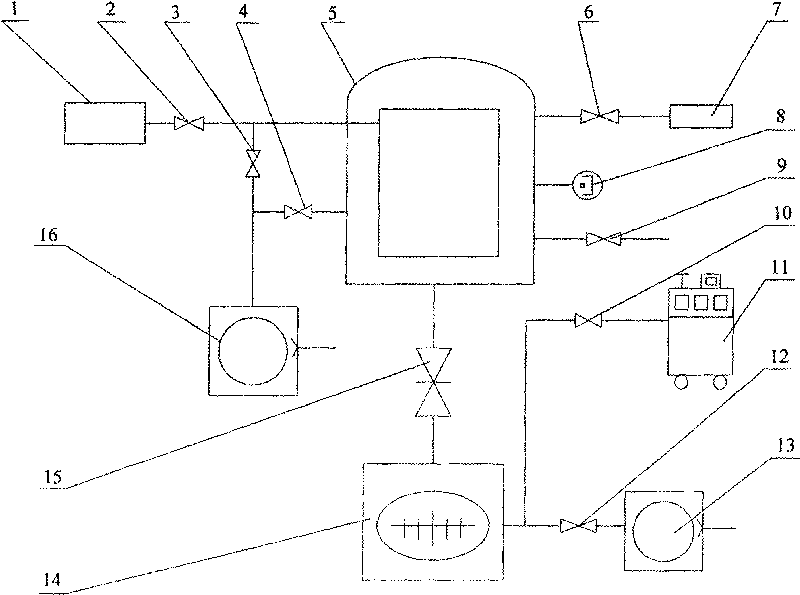

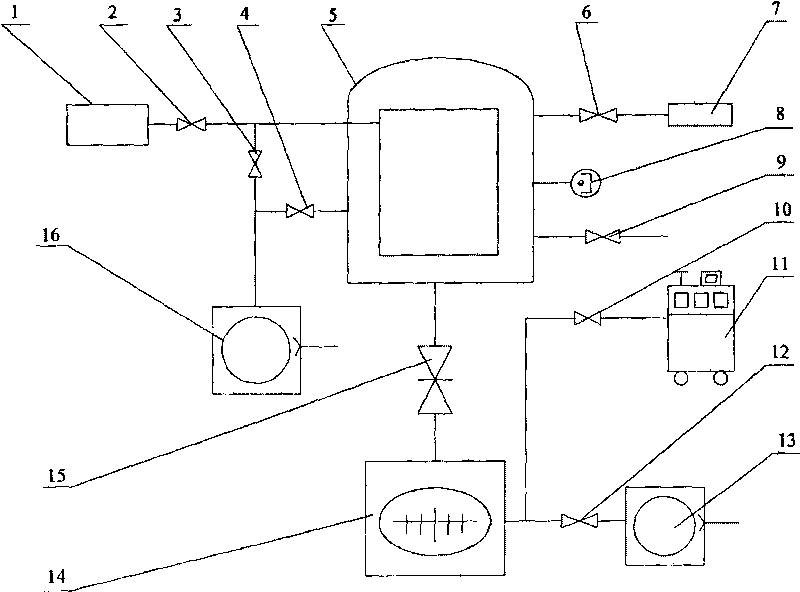

[0024] A leak rate detection device for an O-shaped rubber sealing ring for aerospace, its structure is as follows figure 1 As shown, it includes a helium bag 1 (that is, a gas storage device), an inflation valve 2, a first pre-exhaust valve 3, a second pre-exhaust valve 4, a leak detection tool 5, a standard leak valve 6, a standard leak hole 7, and a vacuum gauge 8. Air release valve 9, leak detection valve 10, leak detector 11, fore-stage angle valve 12, fore-stage pump 13, molecular pump 14, ultra-high vacuum gate valve 15 and pre-vacuum pump 16.

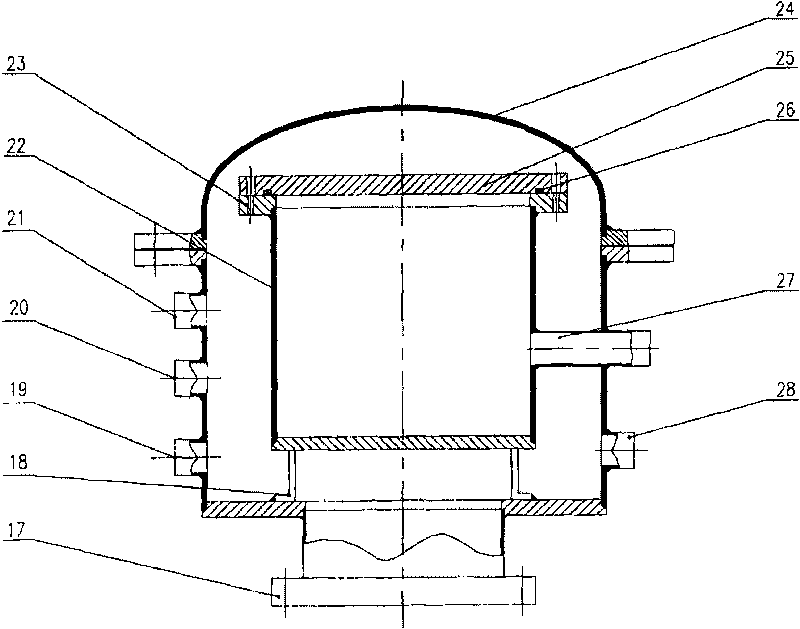

[0025] Wherein, the structural composition of leak detection frock 5 is as follows: figure 2 As shown, it includes an ultra-high vacuum flange 17, a bracket 18, an air release pipe 19, a vacuum gauge connecting pipe 20, a standard leakage connecting pipe 21, a simulation cabin 22, a sealing flange 23, a testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com