Vermicelli block or noodle block automatic box-removing device and box-removing method

A noodle block and noodle block technology, which is applied in the field of automatic unboxing device, can solve problems such as increased waste rate of noodle block or noodle block, reduced quality of noodle block or noodle block, easy deformation and damage of drying box, etc., and achieves beautiful shape , Low breakage rate, avoiding the effect of easy deformation and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

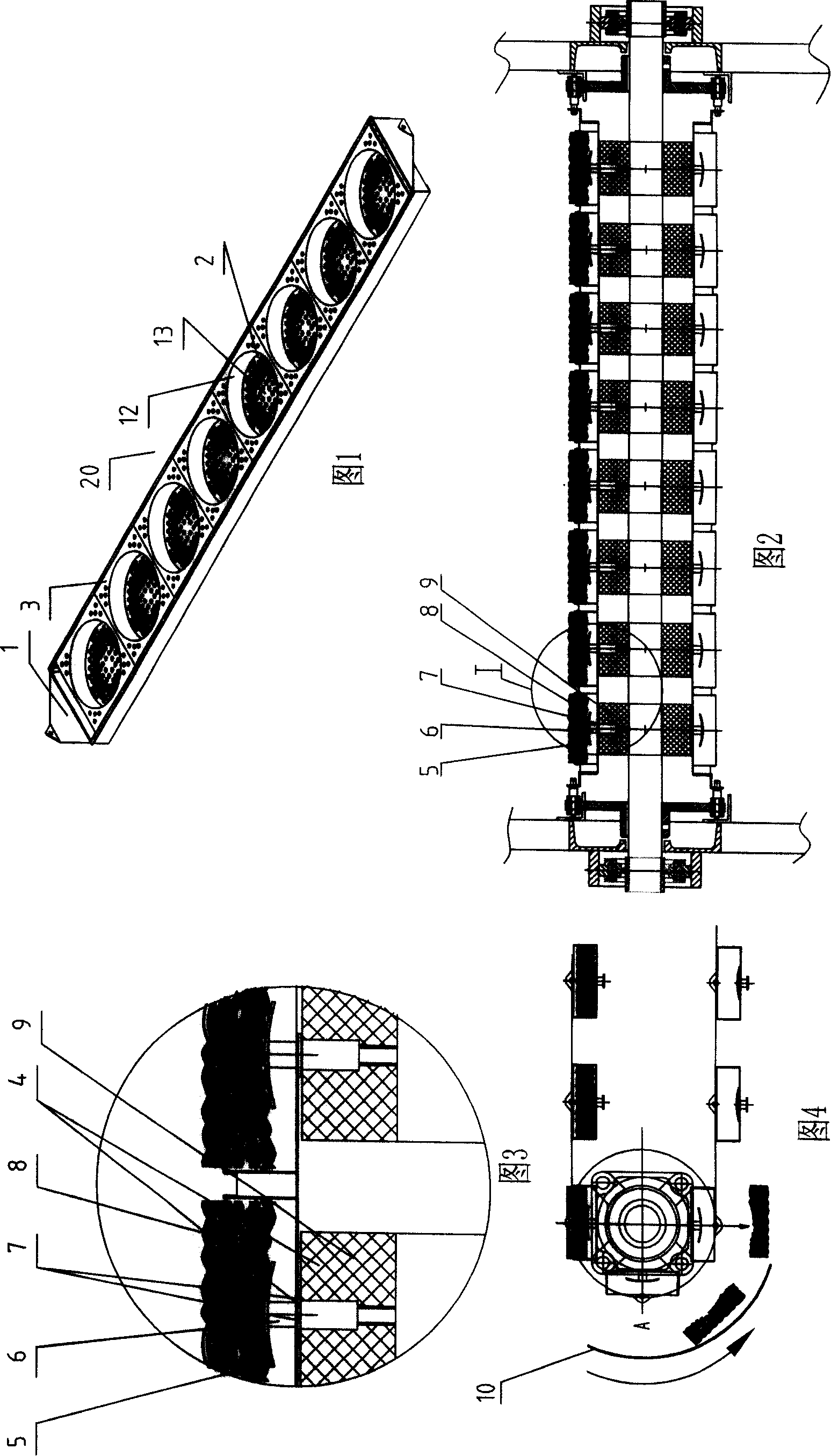

[0014] An automatic box-removing device for powder blocks or noodle blocks, comprising a sliding hole 4 arranged on the bottom plate 2 of the drying box 20, a sliding top piece installed in the sliding hole 4 and capable of sliding back and forth, and a The tubular nylon top pulley 9 of 11 on the rotating shaft. The sliding hole 9 is placed at the center of the powder box 12 . Sliding top piece 13 comprises upper top board 5, lower top board 7 and the sliding shaft 6 that connects upper top board 5 and lower top board 7, and sliding shaft 6 is installed in the sliding hole 4 on the base plate 2; Upper top board 5, sliding shaft 6 and lower Top plate 7 is fixed together, and the periphery of upper top plate 5 and lower top plate 7 is circular, and the upper surface of upper top plate 5 is spherical, and the top surface projected area of upper top plate 5 is 1 / 3rd of powder box area. The positions and the number of the sliding holes 4 and the nylon top rollers 9 are in one-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com