Patents

Literature

152results about How to "Fast rehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

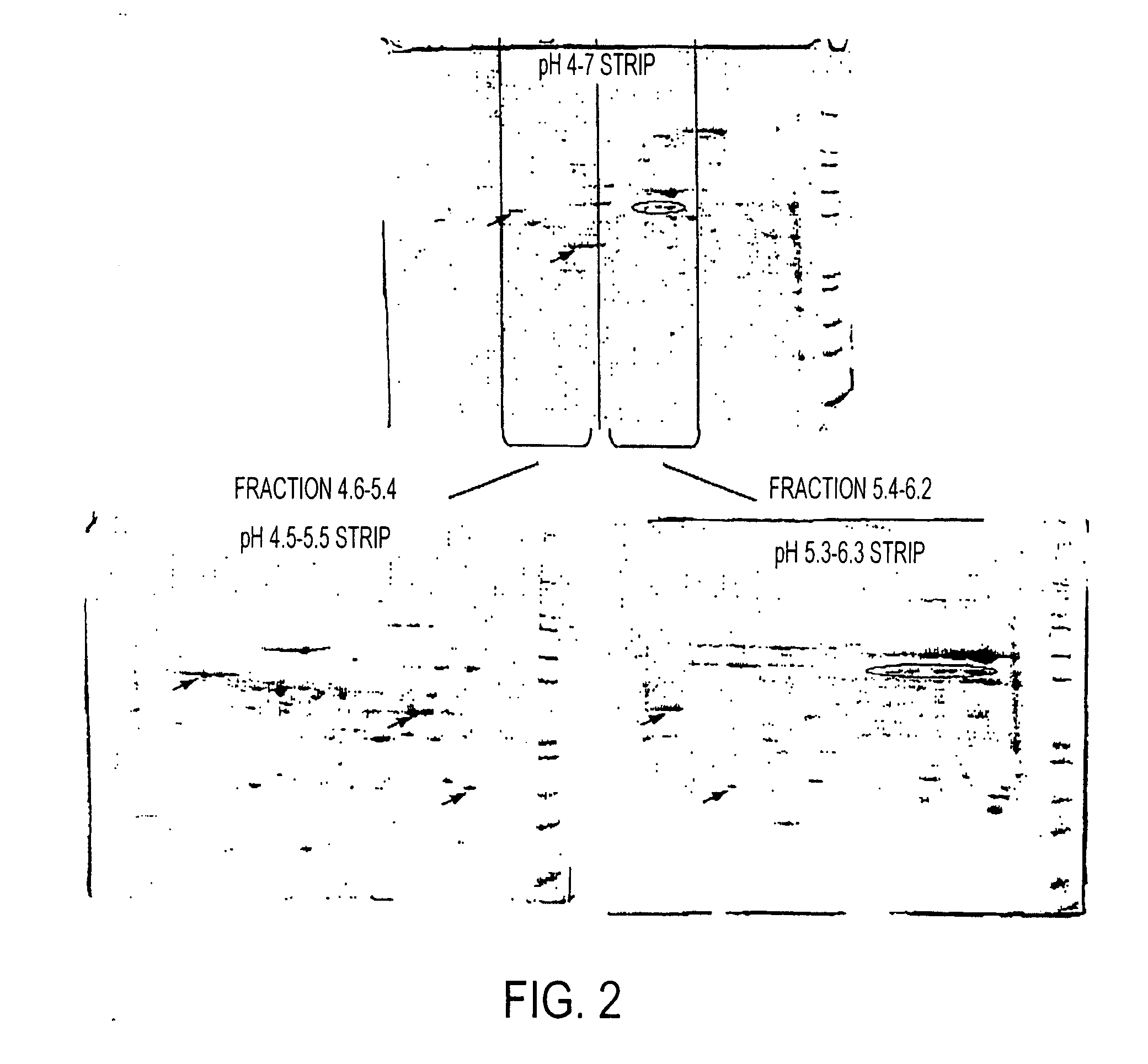

Method for enhancing taste of rice noodles by taking fresh rice as raw material

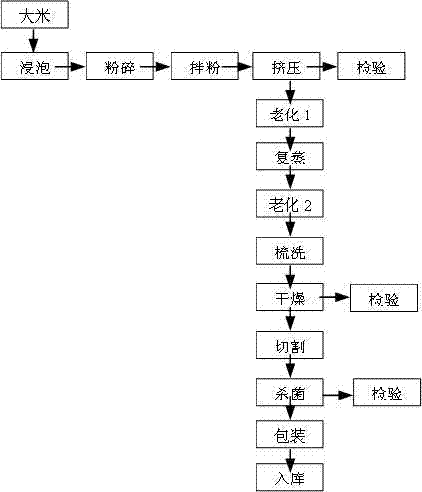

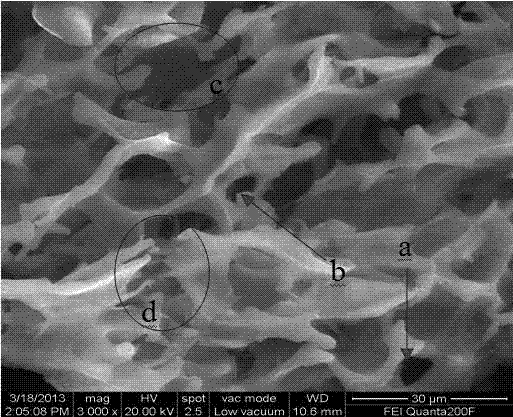

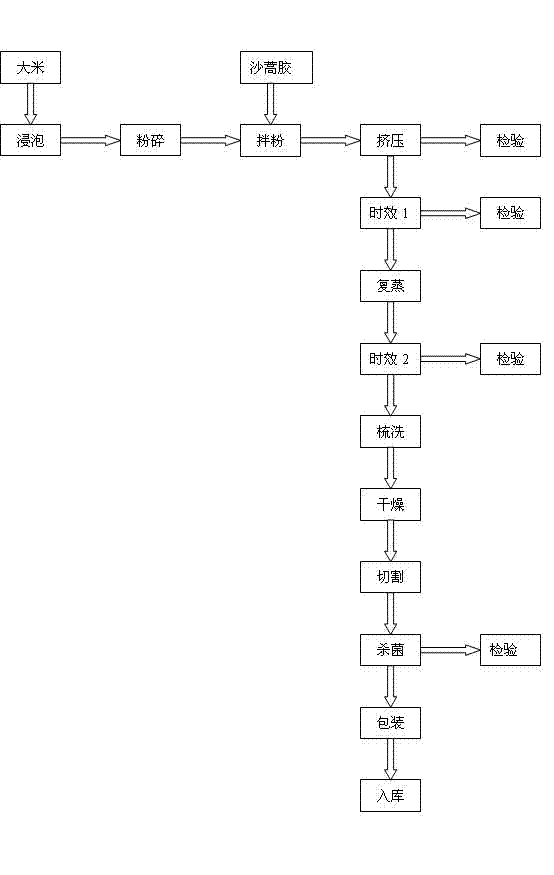

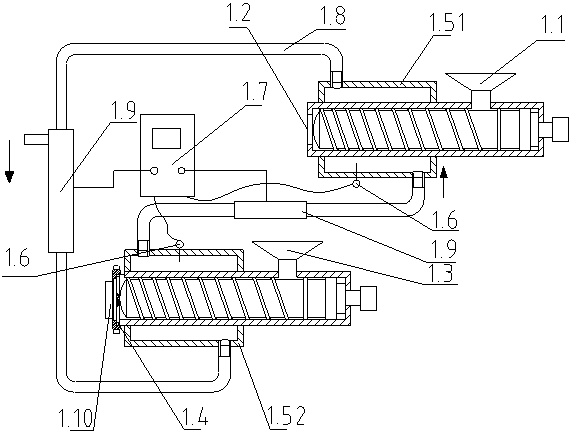

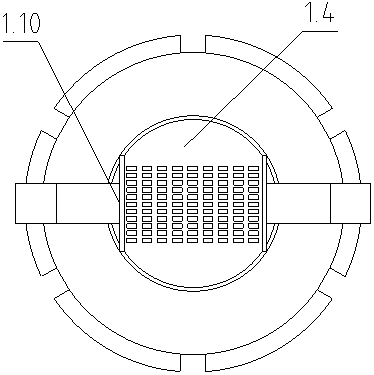

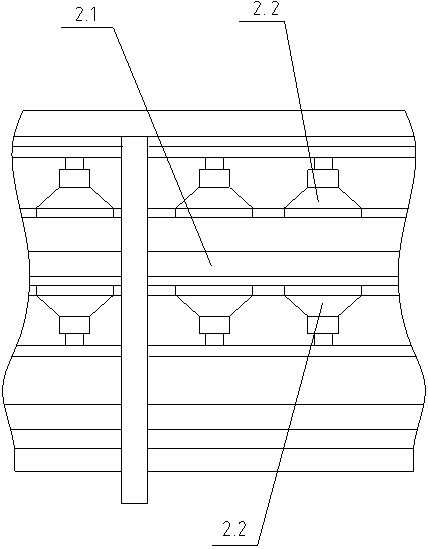

The invention discloses a method for enhancing the taste of rice noodles by taking fresh rice as raw material. The method adopts a common production process of the rice noodles and comprises the following steps: soaking and smashing, then adding dietary fiber and rice protein in a certain ratio into the process of stirring, and adjusting water content; then performing processes of twin-screw extrusion, aging 1, steaming again, aging 2, washing and the like; finally, drying, cutting, sterilizing and packaging to obtain the rice noodles. In the rice noodles prepared by the method, the selection requirements of the raw materials are greatly reduced; various fresh early indica rice, late indica rice, mixed rice of early indica rice and late indica rice and broken rice are applicable. The rice noodles prepared by the method are less in pulp output amount and low in rice bar broken rate; meanwhile, the rice noodles have porous structures which are easily tasted and strong in reconstitution properties. In addition, the added dietary fiber and rice protein are capable of well making up the defect of relatively single nutrition of original rice noodles, so that the requirements of consumers on mouth feel, flavor and nutrition are met.

Owner:NANCHANG UNIV

Ready-to-eat instant fruit-nut combined food and production method thereof

InactiveCN102217746AFood nutrition retention is goodFast rehydrationFood preparationFreeze dryPectin

The invention discloses a ready-to-eat instant fruit-nut combined food and a production method thereof, belonging to the technical field of food processing. The mass percentages of the product components of the combined food before being freeze-dried are as follows: 40-50% of fruits, 4-10% of nuts, 5-10% of sugars, 5-10% of starches, 0.5-1% of pectin, 0.5-0.8% of fruity powder, and 30-40% of water; and after being freeze-dried, the mass percentages of the product components are as follows: 15-25% of fruits, 20-30% of nuts, 15-30% of sugars, 15-30% of starches, 3-5% of pectin, 2-5% of fruity powder, and of 1-5% water. The production process of the combined food comprises pre-treatment of nuts and fruits, gelatinization, mixed dishing up and shaping, quick freezing, vacuum freeze drying andinspection and package. The perfect combination of nuts and fruits in the combined food is unique, so that the comprehensive utilization value and the economic benefit of the fruits, the nuts and thelike can be improved; therefore, excellent social benefit is indirectly produced; and the combined food is a good example in fine and further processing of agricultural products.

Owner:马鞍山沁玖洲食品有限公司

Production method of straight rice noodle made of broken rice

The invention relates to a production method of a straight rice noodle made of broken rice, which belongs to the field of agricultural product processing. The production method comprises the following steps that integral rice and a certain percentage of broken rice are used as main raw materials, the raw materials are soaked and pulverized, a small amount of artemisia sphaerocephala krasch gum is added in the process of breading, and then procedures such as twin-screw extrusion, aging 1, repeated evaporation, aging 2, smoothing and washing, and drying are performed. The straight rice noodle prepared by using the production method has the advantages of little syrup amount, low broken rate and good taste, and the production cost is greatly reduced.

Owner:NANCHANG UNIV

Preparation method of peanut wire-drawing protein

ActiveCN101999512AReasonable compositionMeet nutritional intake needsProtein composition from vegetable seedsFiberBiotechnology

The invention relates to a preparation method of peanut wire-drawing protein. The preparation method comprises the following steps: 1) preparing low-denaturalization peanut protein powder; 2) mixing uniformly; 3) hardening and tempering; 4) extruding and swelling; and 5) discharging. The product of the invention is pure white and has specific peanut aroma and rapid rehydration; when the product is torn, a structure as thin as hair can be formed; and moreover, the product has an obvious fibrous tissue, high fiber toughness, tensile force and elasticity, forms a ball without breakage when kneaded by hands, and disperses like fiber immediately after rehydration. The peanut wire-drawing protein ensures that the nutrition level of people is improved without increasing cholesterol, has a uniqueflavor without beany flavor or flatulence factor of soy protein, and is a high-quality resource of vegetable protein. Meanwhile, a proper amount of soy protein and wheat protein is added, and the three high-quality vegetable proteins are combined so that the allocation of essential amino acids for human contained in the peanut wire-drawing protein is more reasonable and better conforms to the nutrition requirements of the human.

Owner:QINGDAO CHANGSHOU FOOD

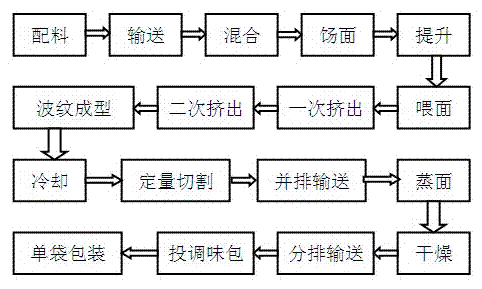

Non-fried miscellaneous grain instant noodle and production method thereof

ActiveCN103125843ABalanced and reasonable nutritionResistance to tumor immunityFood preparationCorn starchEssential nutrient

The invention discloses a non-fried miscellaneous grain instant noodle and a production method thereof. The non-fried miscellaneous grain instant noodle comprises, by weight, 1-8% of food additives, 1.0-1.25% of gluten fortifier, 25-50% of water, 0.2-1.0% of edible oil, 5-30% of wheat flour, 5-30% of corn flour, 1-10% of corn starch, 10-30% of potato starch, 5-20% of mashed potato, 25-50% of tartary buckwheat flour, 5-25% of common buckwheat flour, 5-15% of modified starch, 2-10% of sweet potato starch, 2-10% of sweet potato powder, and 2-10% of cassava starch. The production method includes raw material weighing, mixing, paste curing and extrusion forming, long strip noodle block cooling and slicing, cooking, drying and packaging. Miscellaneous grains are adopted to serve as raw materials of the instant noodle, various human body essential nutrient substances and trace elements are contained, nutrition is reasonable and balanced, and a healthy diet idea of contemporary people is fitted; and continuous production is carried out through the adoption of a production line, work intensity of working staff is reduced, and production efficiency is promoted.

Owner:SICHUAN JIUJIUAI FOOD

Concentrated food having rehydration characteristics and the processing method

InactiveCN101061815AImprove food acceptanceHas rehydrating propertiesBakery productsFood preparationIsomaltooligosaccharideInverted sugar syrup

The invention discloses a compressed foodstuff which is prepared mainly from bread flour 40-60 weight parts, instant cereal powder 5-10 weight parts, syrup 15-20 weight parts, plant oil 10-20 weight parts and right amount of other auxiliary materials, wherein the syrup is selected from barley syrup, isomaltose hypgather, fructose syrupand inverted syrup or their combination.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Method for drying traditional Chinese medicine materials in mixing mode through microwave vacuum and hot air

InactiveCN102445055AMaintain physical integrityFast rehydrationDrying using combination processesMicrowave powerEngineering

A method for drying traditional Chinese medicine materials in mixing mode through microwave vacuum and hot air comprises placing the traditional Chinese medicine materials in a microwave vacuum drying stove, drying the traditional Chinese medicine materials for 3 to 5 minutes under the condition that the vacuum ranges from 0.07Mpa to 0.09Mpa and the unit microwave power ranges from 3W to 5W, delivering the traditional Chinese medicine materials into a hot air dryer, drying the traditional Chinese medicine materials for 1 to 3 hours under the temperature ranging from 70 DEG C to 90 DEG C, and finally delivering the traditional Chinese medicine materials to the microwave vacuum drying stove again for drying under the condition of the first step till the end. The method adopts mixing of the microwave vacuum drying and the hot air drying, enables the internal structure of the traditional Chinese medicine materials to achieve the effect of swelling, loosening and cracking, improves exudation ratio of decoction of liquid medicine and shortens decoction time without damaging contents of the traditional Chinese medicine materials. Further the method can keep intrinsic body integrity of the traditional Chinese medicine materials, reduces contractibility rate of the traditional Chinese medicine materials, accelerates rehydration of the traditional Chinese medicine materials, improves product quality and reduces energy consumption.

Owner:HENAN UNIV OF SCI & TECH

Microwave vacuum freeze-drying method for rhizoma gastrodiae

InactiveCN107308350ANutrients are not destroyedAppearance color is not damagedDrying solid materials with heatDrying solid materials without heatFreeze-dryingAdditive ingredient

The invention discloses a microwave vacuum freeze-drying method for rhizoma gastrodiae. The microwave vacuum freeze-drying method comprises the following steps: firstly, cleaning and draining fresh rhizoma gastrodiae; secondly, pre-freezing the rhizoma gastrodiae at the temperature of 10 DEG C below zero to 30 DEG C below zero for 1 hour to 1 year; thirdly, slicing and pricking the rhizoma gastrodiae obtained in the second step; fourthly, putting the pricked rhizoma gastrodiae into a microwave freezing dryer, and freezing at the pressure of 5 to 20 Pa and the temperature of 35 DEG C below zero to 40 DEG C below zero for 1 to 3 hours; introducing nitrogen, controlling the pressure at 20 to 100 Pa, controlling microwave power at 100 to 300 w / kg when the time reaches 0 to 3 hours, controlling the microwave power at 300 to 500 w / kg when the time reaches 3 to 6 hours, controlling the microwave power at 100 to 200 w / kg when the time reaches 6 to 8 hours, and warehousing to obtain freeze-dried rhizoma gastrodiae slices. The method disclosed by the invention has the advantages of short production period and low energy consumption and cost for freeze drying; in addition, effective ingredients, nutritional ingredients, appearance, color and luster of the fresh rhizoma gastrodiae are sufficiently protected from being damaged, original shapes of crude products are maintained, and the rhizoma gastrodiae slices are crisp and tasty in mouthfeel.

Owner:ZHEJIANG JIANFENG HEALTH TECH

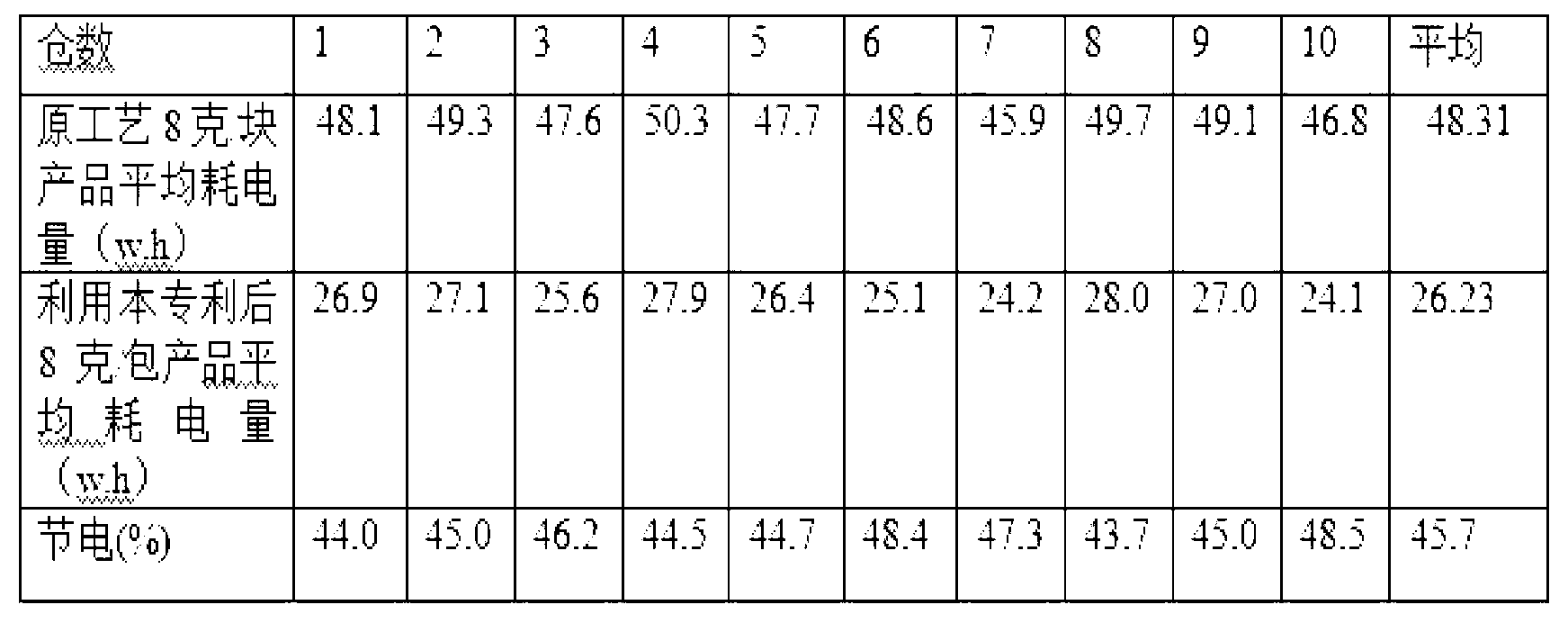

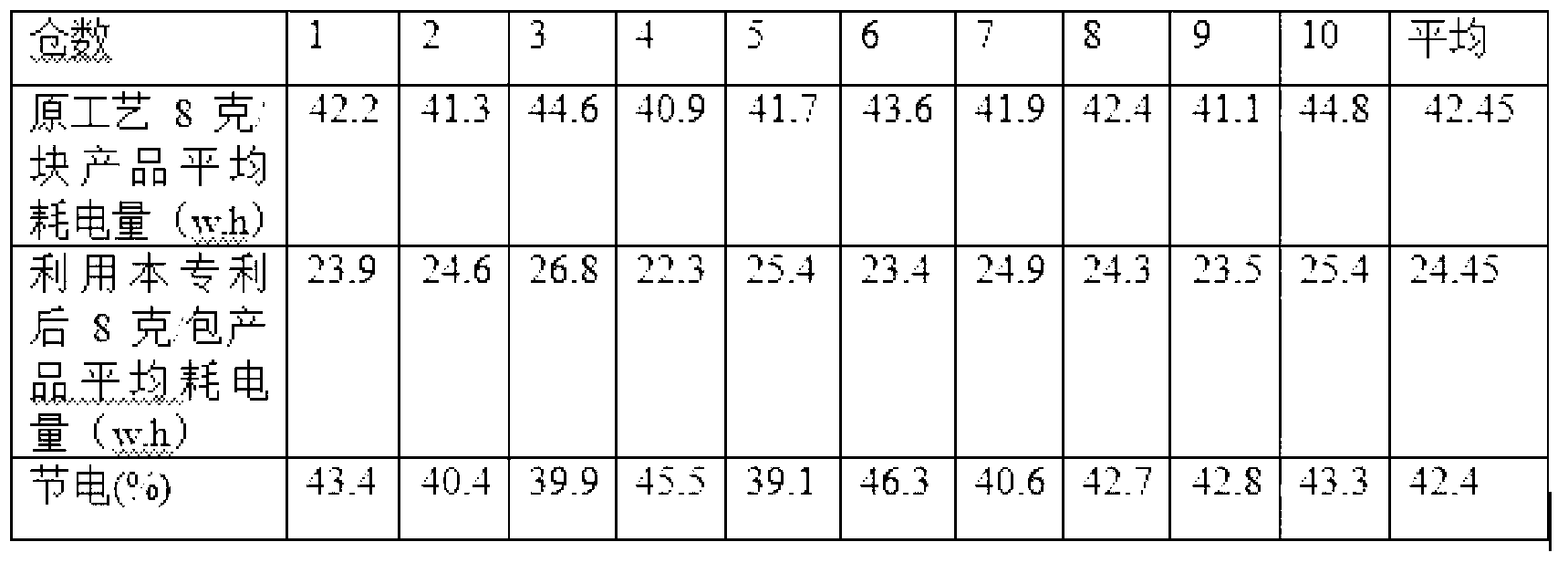

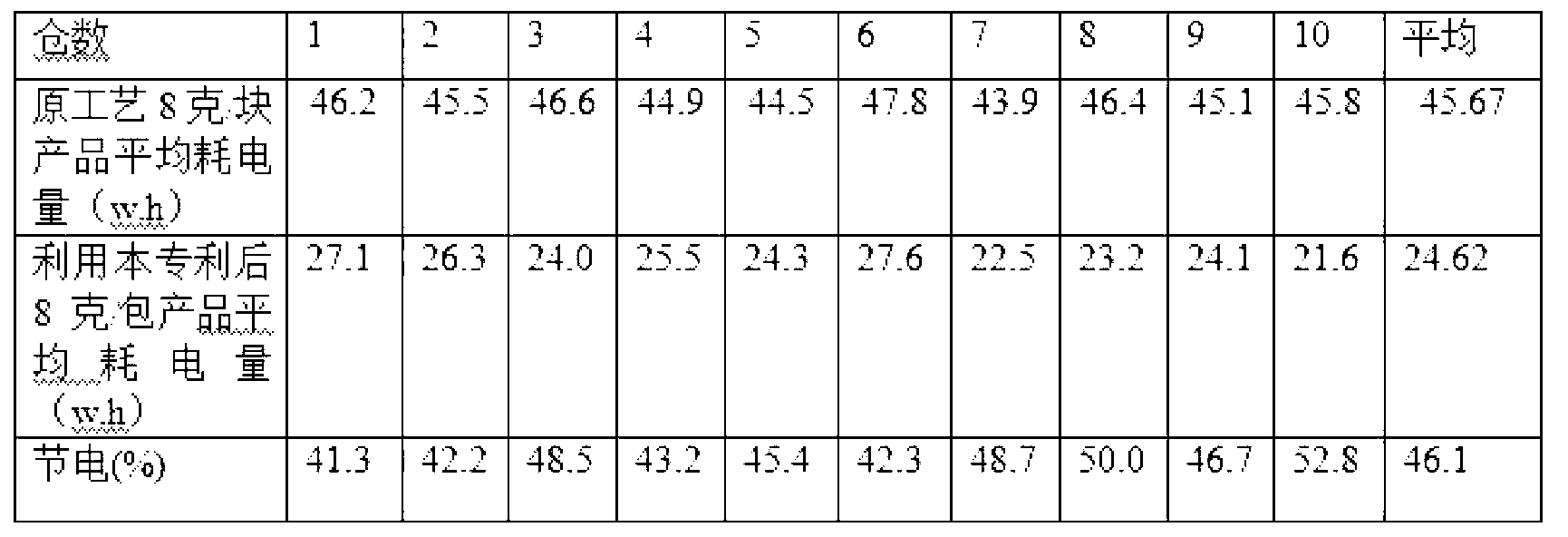

Freeze-dry process preparation method of bulk vegetable egg flower soup base

The invention discloses a freeze-dry process preparation method of a bulk vegetable egg flower soup base, and belongs to the technical field of vacuum freeze-dry processing of the vegetable egg flower soup base. Various vegetables and egg flower needed by the freeze-dried soup base disclosed by the invention are independently freeze-dried according to respective freeze-dry process curves, the seasonings which do not need to be freeze-dried are added according to the formulation of the soup base, and the mixture of the vegetables, the egg flower and the seasonings is packaged to obtain the bulk vegetable egg flower soup base, which is different from an original block type soup base. The vegetables are fresh in color and luster, and the egg flower and the seasonings are rewatered rapidly and more delicious in taste after the soup base prepared by using the method disclosed by the invention is brewed by using hot water; and simultaneously, experimental data and practical application data in large-scale production prove that at least 40% of energy consumption is reduced.

Owner:马鞍山沁玖洲食品有限公司

Production method of instant potato rice noodles

InactiveCN107212254ARich in nutrientsImprove toughnessFood preservationFood shapingInstant potatoInstant noodle

The invention discloses a production method of instant potato rice noodles. According to the invention, whole potato flour is added into rice as a raw material for preparation. Prepared by a specific method, the instant potato rice noodles have rich nutrients, good toughness, fast rehydration, a low broken rate, and higher contents of protein, total sugar, insoluble dietary fibers and minerals of K and Ca than those of common instant rice noodles. The production method enriches nutrients of the instant rice noodles, and improves a sensual quality of the instant rice noodles at the same time. The instant potato rice noodles can not only enrich varieties of instant foods, but also increase varieties of potato staple food production so as to meet demands of modern metropolitan fast-paced people for health and fast food. The instant potato rice noodles prepared by the invention have better toughness, short time of rehydration and a low cooked broken rate. The production method enriches the nutrients of the instant rice noodles, and improves the sensual quality of the instant rice noodles at the same time.

Owner:贵州省生物技术研究所

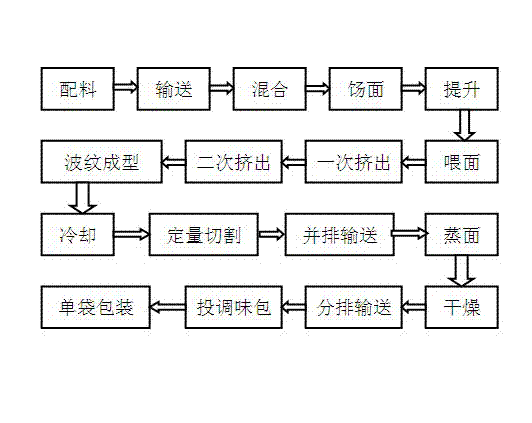

Preparation method for coarse cereal food

InactiveCN102334634AReduce adverse effectsTo achieve the effect of disinfection and sterilizationFood preparationHuman healthConvenience food

The invention relates to a preparation method for a coarse cereal food. The coarse cereal food is produced by extrusion and cooking processes, mixture is directly fed into the barrel of an extruder, and is extruded by a pushing screw, the mixture is cooked under the effect of appropriate temperature and pressure, and thereby is disinfected and sterilized but not puffed, non-fried and highly cooked convenient food is produced after a series of processes, such as corrugation, cooling, quantitative cutting, recooking and drying, and thereby the coarse cereal convenient food which is cooked without being rolled and fried is produced. The invention prevents the adverse affection of fried food on human health.

Owner:ANHUI YANZHIFANG FOOD

Preloaded biological heart valve capable of rapidly rehydrating and preparation method thereof

ActiveCN109172867AEasy to useFast rehydrationPharmaceutical delivery mechanismTissue regenerationChemistryAqueous solution

The invention discloses a preloaded biological heart valve capable of rapidly rehydrating and a preparation method thereof. The preparation method comprises the following steps: crosslinking treatment, immersing a biofilm sheet in glutaraldehyde aqueous solution for crosslinking reaction; Hydrophilic treatment, wherein the biofilm sheet is immersed in a solution containing hydrophilic molecules and a condensing agent, and the hydrophilic molecules are immobilized on the biofilm sheet by a chemical grafting method; and drying, drying the biofilm sheets which have been treated by hydrophilic treatment and cross-linking treatment, so as to obtain a preloaded biological heart valve which can be quickly rehydrated. The pre-loaded biological heart valve prepared by the preparation method of theinvention can realize rapid rehydration, and the creases after rehydration can be quickly flattened and convenient to use.

Owner:VENUS MEDTECH (HANGZHOU) INC +1

Freeze drying preparation method of fruit and vegetable crisp slices

InactiveCN104222261AAccelerated sublimationSpeed up the drying processFruit and vegetables preservationFreeze-dryingProcess engineering

The invention discloses a preparation method for freeze-drying fruit and vegetable crisp slices. The preparation method comprises the following steps: blanching cleaned and split raw materials for enzyme deactivation, rapidly placing the raw materials after enzyme deactivation into a pre-cooling color-protecting liquid for cooling, pulping, homogenizing, paving material layers with thickness of 5-10mm in a metal material plate, inserting to an integrated metal grid mould, precooling at temperature of -30 DEG C, performing vacuum freeze drying according to the following process: when the temperature is lower than 10 DEG C, increasing temperature at the rate of 3-5 DEG C per hour, when the temperature reaches 10 DEG C, keeping the temperature for 1 hour, increasing temperature at the rate of 5-7 DEG C per hour, when the temperature reaches 40 DEG C, keeping for 2 hours, and then finishing the vacuum freeze drying. According to the invention, a proper amount of water is added into the raw materials for pulping and homogenizing, then curing is carried out, the integrated metal grid mould is used for accelerating the process that heat is conducted inside the material layers, the whole material plate is divided into a plurality of independent evaporation units, so that sublimation of water is greatly accelerated, obtained fruit and vegetable crisp slices are crisp and porous, good in reconstitution property, and the defect that the traditional freeze-drying fruit and vegetable crisp slices are poor in reconstitution property so as to stick teeth is overcome.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Cold air drying technique of vegetable and edible fungus

InactiveCN101301001ABright appearanceImprove textureFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingBiotechnologyDrying time

The present invention relates to a cold-wind drying technique of vegetable and edible fungus. The method comprises the steps of a preprocessing step, a enzymes-deactivating step, a cooling step and a cold-wind drying step which are executed in sequence. The invention is characterized in that in the cold-wind drying step, the raw material of vegetable or domestic fungus is placed into a cold-wind drying chamber with a temperature of 25-30DEG C, a moisture of 5%-8%, and a wind speed of 3-5m / s. The drying time lasts for 1.5-2hours. Furthermore after the step of cold-wind drying, the raw materials of vegetable or domestic fungus are executed with the freezing step to make that the central temperature of the frozen raw material obtains a temperature lower than -18DEG C and the finished product is obtained. The invention uses a low-temperature dewatering and cold-wind drying method for processing the vegetable or domestic fungus. The appropriate temperature, moisture, wind speed and time are controlled, therefore the color, incense, flavor and brittleness of the product are guaranteed to more approximate to those of the original product. Besides, as the product is frozen after the step of cold-wind drying, the storage period of the product is prolonged to about 2 years.

Owner:福州富水综合食品有限公司

Snakegourd fruit flesh powder and preparing process thereof

InactiveCN102613501AThe serial process is tightSplit fluidity is excellentFood preparationAntioxidantSlurry

The invention discloses a process for preparing snakegourd fruit flesh powder, which comprises the steps of separating fresh snakegourd fruit flesh from snakegourd fruits and seeds; grinding the flesh into liquid; controlling the temperature to fix color; removing gas in the liquid; homogenizing; spray drying and the like; and obtaining the dried snakegourd fruit flesh powder. The process is catenated and compact and omits measures such as adding synthetic antioxidants, preservatives and the like in traditional processing of biologics, so that formulated vegetable protein polysaccharide and vegetable gelatine have functions such as improving effects and resisting oxidation. The obtained flesh powder is characterized in that the color is natural pale orange-yellow, the powder is fine, smooth and slightly scented, the pectin content is 65% - 70%, the water content is 6% - 7%, powder mobility and dispersibility are good, rehydration is quick, and the rehydration property is strong. The powder is convenient to store and transport and can be used as main and assisting materials to formulate other biologics. The powder contains bioactive substances including lots of the pectin, the vegetable protein polysaccharide and the like, and has multiple biological functions such as enhancing immunity, resisting radiation, resisting tumors, delaying senescence and the like.

Owner:何家庆

A kind of straight dry rice flour processing method

The invention relates to a processing method of straight stripped dry rice noodles. The processing method comprises the following steps: 1, pretreating a raw material; 2, immersing; 3, burdening, and crushing; 4, pregelatinizing; 5, extrusion molding; 6, scattering through twisting, and spreading and airing; and 7, drying and packaging. The straight stripped dry rice noodles produced with the processing method of the invention, which have the advantages of fast rehydration, good taste, moderate toughness, and no burnt soup occurring, can be rehydrated when the straight stripped dry rice noodles are immersed for 10-15min at about 25DEG C, and not more than 30min at a low temperature in winter.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

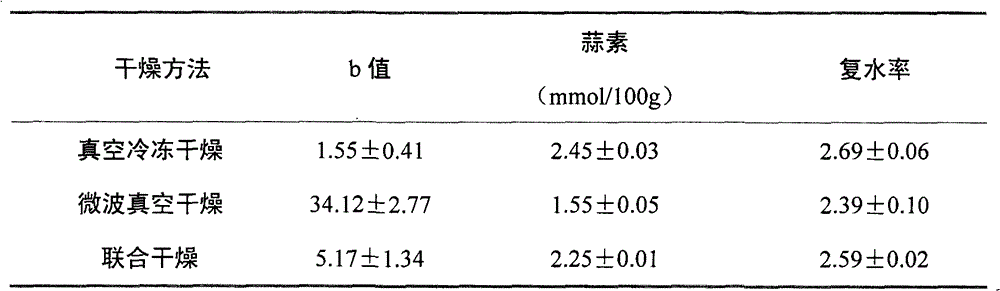

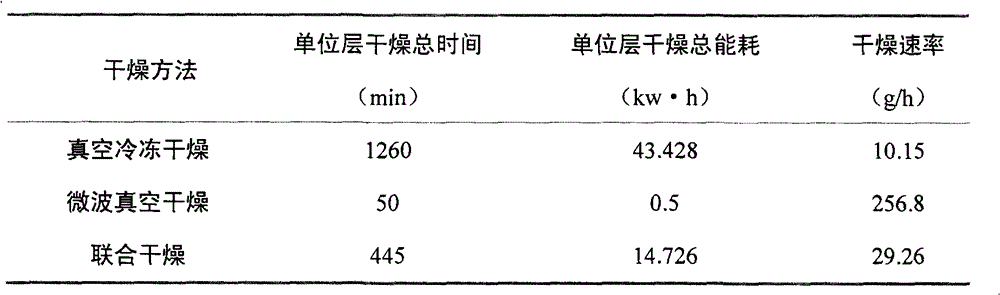

Method for processing garlic granule through vacuum freezing and microwave vacuum serial combined drying

The invention discloses a method for processing garlic granules through vacuum freezing and microwave vacuum serial combined drying, belonging to the key technical field of garlic deep processing. The method comprises the steps of selecting raw materials, cutting off bases, removing skins, cutting the raw materials into cubic garlic granules with length of side being 5mm by using a dicer and containing the diced materials in trays at two layers; after the diced materials are contained in the trays, pre-freezing at negative 20DEG C for 4 hours; after pre-freezing is finished, reducing the temperature of a cold trap to negative 45DEG C to negative 35DEG C in advance, placing the materials in a freeze-drying chamber, vacuumizing the freeze-drying chamber to be below 12Pa for vacuum freeze-drying, and stopping vacuum freeze-drying after approximate 7 hours till the water content is 30 percent; taking out the trays, immediately placing the trays in a microwave vacuum drying machine, starting up a vacuum pump, starting microwave when vacuum degree reaches 90KPa to 120KPa for drying 15-20 minutes under the condition of power being 420W, and stopping drying after the safe water content isbelow 6 percent. Not only can the garlic granules obtained by adopting the drying process reserve the excellent quality of common vacuum freeze-dried garlic granules, but also the time of vacuum freeze-drying process is shorted and the energy consumption is reduced.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

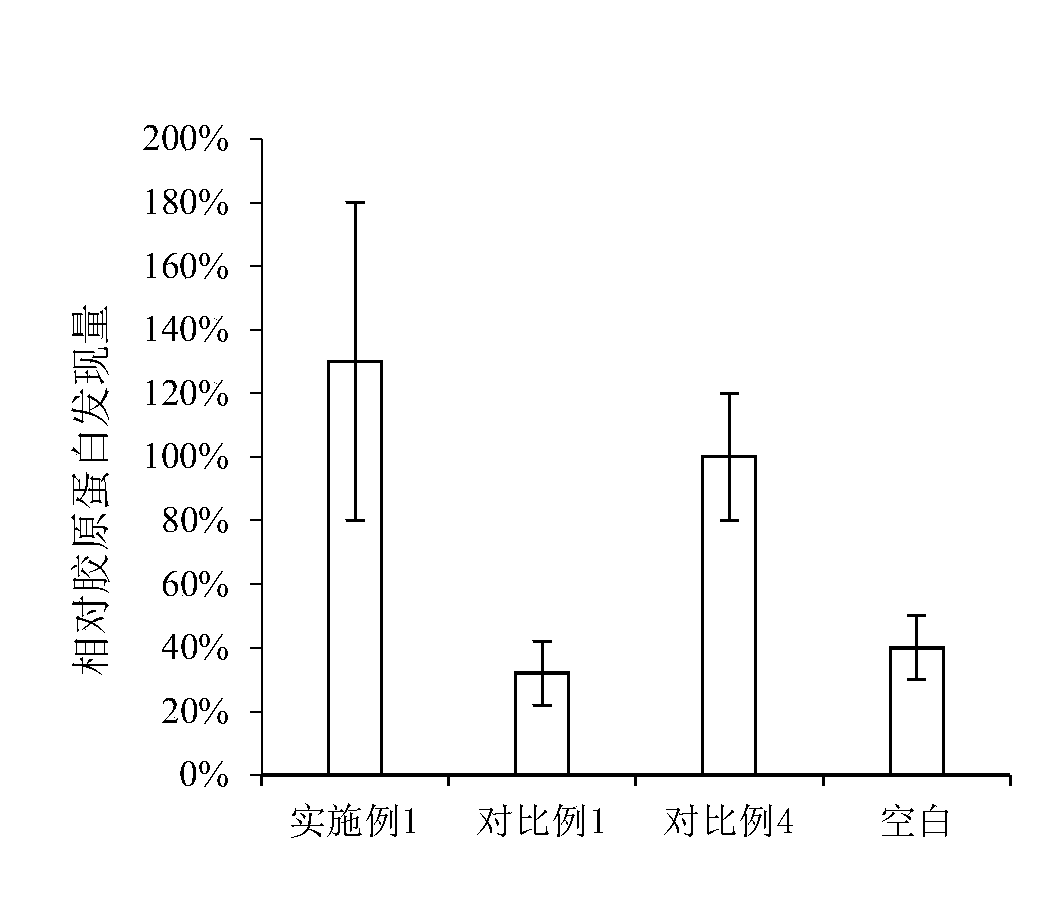

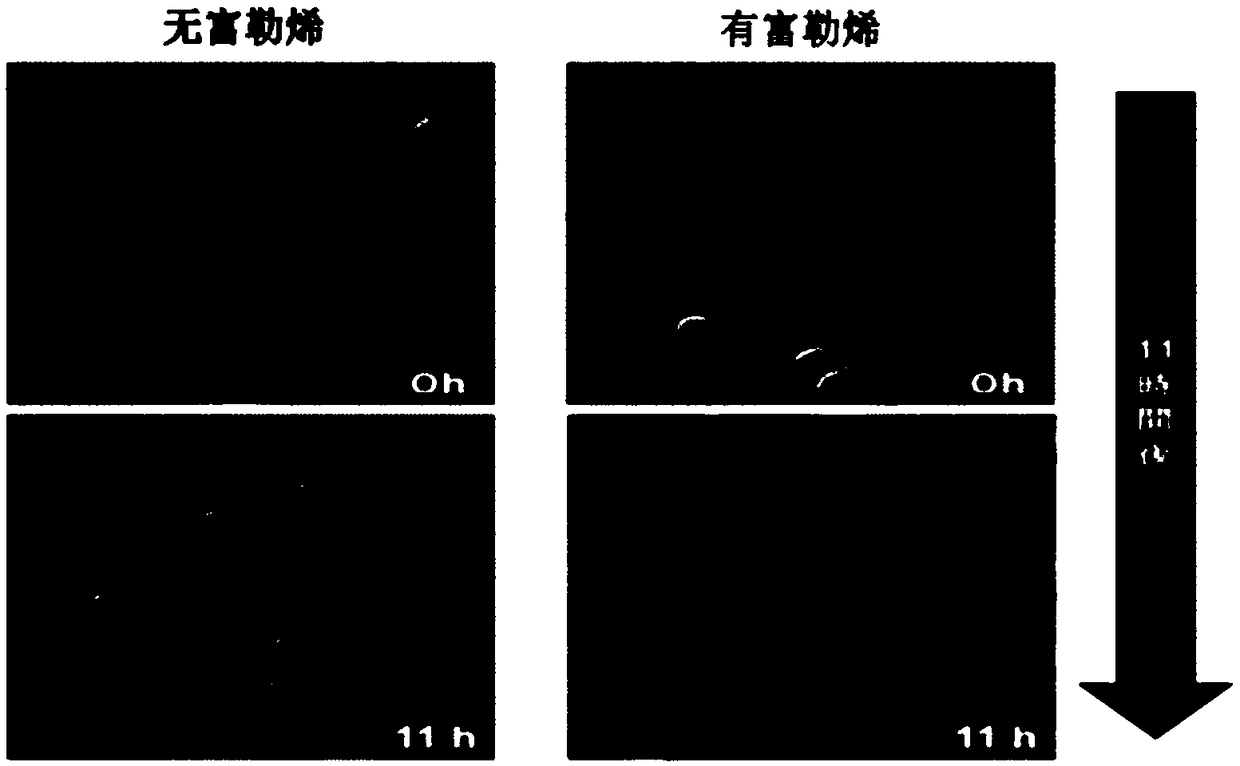

Fullerene skin cleaning skin care product and use method thereof

ActiveCN108743415ARetain activityLong storage timeCosmetic preparationsToilet preparationsFreeze-dryingSolvent

The invention relates to the field of skin care products, provides a fullerene skin cleaning skin care product and a use method thereof and aims at solving the problem of easiness in oxidation of VC derivatives. The invention provides the fullerene skin cleaning skin care product and the use method thereof. The fullerene skin cleaning skin care product is prepared from a freeze-dried powder and asolvent; the freeze-dried powder is prepared from the following components in parts by mass: 2-5 parts of water-soluble fullerene, 3-8 parts of the VC derivative, 0.5-1 part of trehalose and 75-90 parts of water; and the solvent is prepared from the following components in parts by mass: 0.1-0.5 part of carnosine, 6-12 parts of promoter, 1-3 parts of revertose skin brightening agent and 80-99 parts of water. The VC derivative can inhibit melanin pigmentation, but is very easily oxidized and is difficultly absorbed by skin, so that the VC derivative needs to be modified to be improved in oxidation resistance; the fullerene has efficient oxidation resistance, the VC derivative and the fullerene are compounded, the trehalose or the revertose skin brightening agent are added to improve the moisturizing effect, and the promoter is added to improve the effect of production of melanin; and the carnosine can strengthen the antioxidant effect of the fullerene and is reacted with a part of freeradicals.

Owner:广州宝莱生物科技有限公司

Moisture loss prevention method during cut flower vacuum precooling course

InactiveCN1602658AShort cooling timeUniform coolingFlower preserving apparatusWater depletionCut flowers

This invention provides a way to preserve water from the flowers un the process of vacuum pro-coldness when cut flowers. The factory is put the tidied flowers stem into the container with enough liquor. Ensure that the stem is under liquor. Put the probe into the liquor in the same time, and then put the container with flowers into the vacuum jug. Start the vacuum pump to depress the air pressure, accommodate the temperature to the required standard, close the vacuum pump, and then recover to normal pressure. This way can decrease the depletion of flowers in transport decreased water depletion, solved the problem of long distance transport. Promote the development of flowers commerce in our nation and other nations.

Owner:CHINA AGRI UNIV

Processing method of fresh-keeping instant rice noodles

ActiveCN110037241ALow gelatinization temperatureGood gelatinization temperatureFood ingredient as emulsifierRetrogradationFermentation

The invention provides a processing method of fresh-keeping instant rice noodles, and relates to the technical field of food processing. The processing method of the fresh-keeping instant rice noodlescomprises the following steps of (1) preparing the raw materials; (2) performing fermentation; (3) performing milling to obtain pulp; (4) performing blending; (5) performing enzymolysis; (6) performing twin-screw extruding and shaping; (7) performing ageing; (8) performing cooking once again; (9) performing noodle washing, and performing cutting off; (10) performing metering and packing; (11) performing post-sterilizing; and (12) performing cooling. According to the fresh-keeping instant rice noodles, the compounding ratio of the materials is adjusted and controlled, and secondary fermentation is combined with optimization treatment with diastase, noodle cooking, cooking, recooking, post-sterilizing and quick cooling, so that the problems that rice noodles are subjected to beta configuration (namely retrogradation) and cannot be stored for a long term can be solved, the rice starch can maintain alpha state, and the instant rice noodles being rapid in rehydration, good in mouth feel and edible after being brewed for a short time, can be made.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

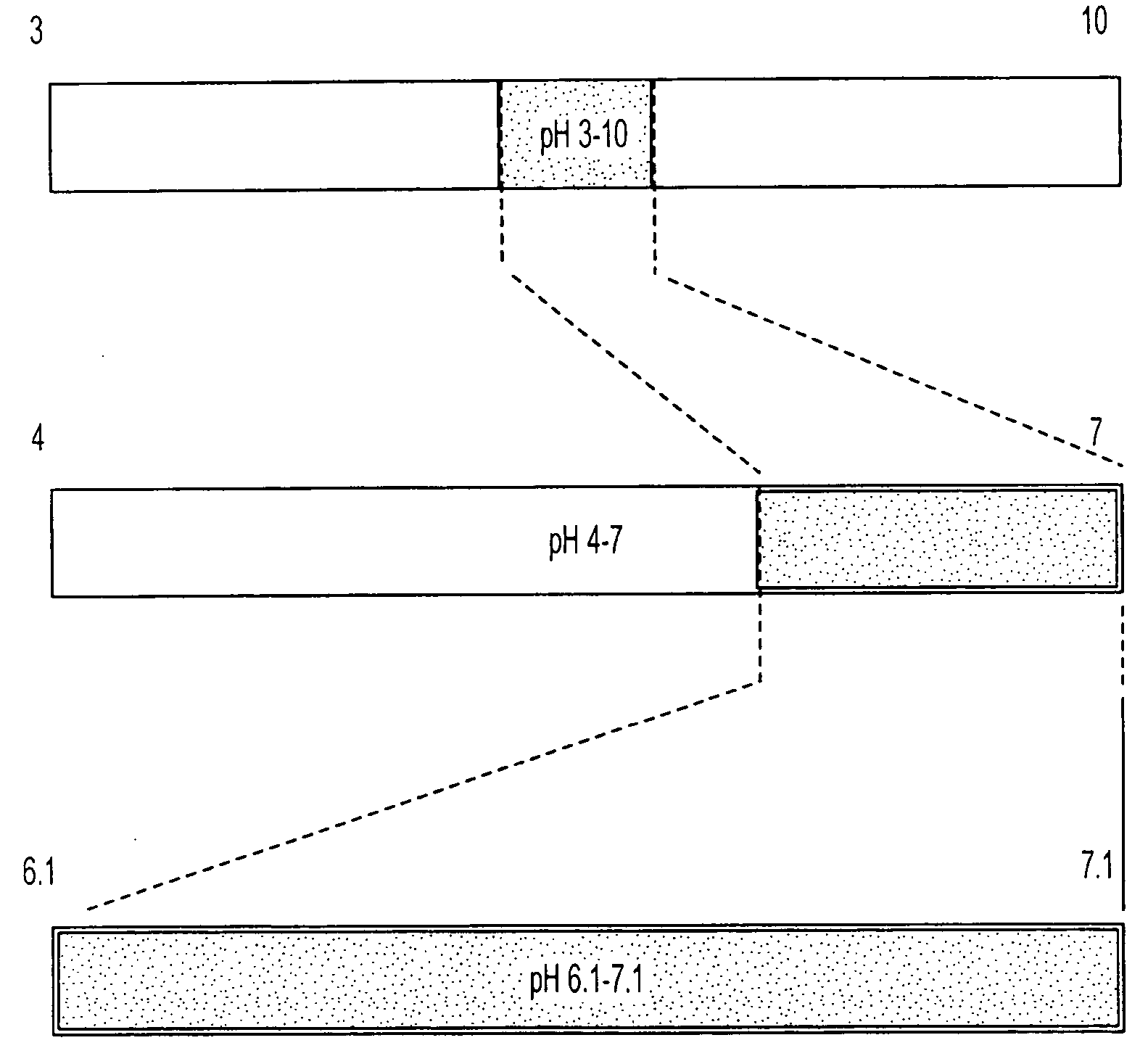

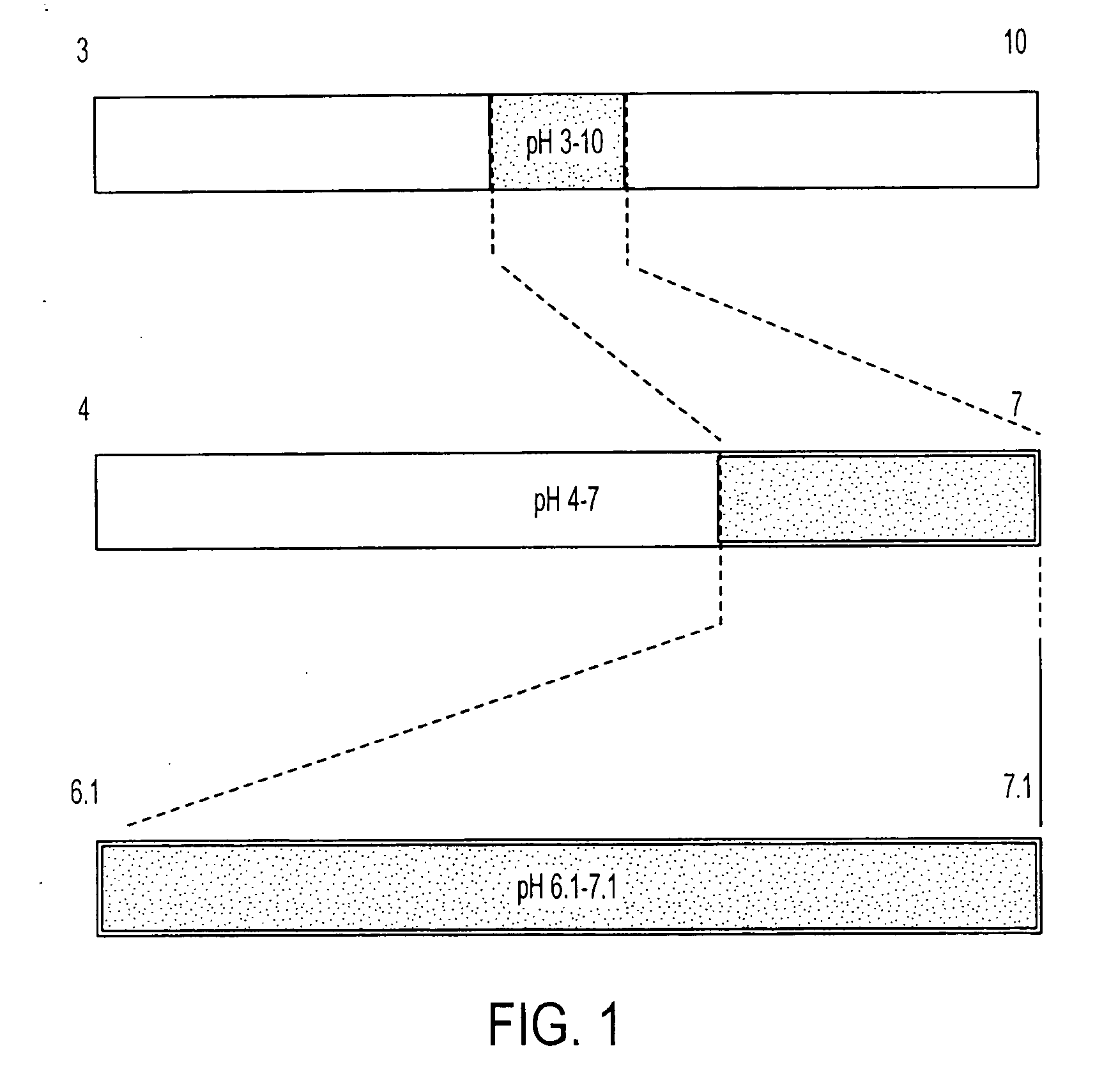

Isoelectric focusing gels and methods of use thereof

InactiveUS20050103629A1Facilitate access and removalFast rehydrationElectrolysis componentsVolume/mass flow measurementIEF - Isoelectric focusingElectrophoresis

Provided herein are rapidly-rehydratable prior-cast, dehydrated, electrophoresis separation media particularly useful for isoelectric focusing, including methods of making, and methods of use thereof.

Owner:LIFE TECH CORP

Method for manufacturing freeze-dried shii-take egg drop soup

InactiveCN102648773AReduce lossesWith color and flavorFood preparationAdditive ingredientFreeze-drying

The invention provides a method for manufacturing freeze-dried shii-take egg drop soup. The scheme is that material and seasonings are processed through pretreatment, curing, precooling, quick freezing and vacuum drying and then are take out from a bin, sorted and packed to be put in storage; curing is performed for 3 to 10 minutes under the pressure of 0.5 to 0.6 MPa; precooling is performed for 2 to 3 hours under the temperature of minus 15 DEG C to minus 20 DEG C; freeze-drying is performed for 4 to 6 hours under the temperature of minus 35 DEG C to minus 45 DEG C; and drying is performed for 5 to 6 hours under the conditions that the degree of vacuum is 100 to 200 Pa and the temperature is 70 DEG C to 80 DEG C. The method has the benefits that the egg drop soup manufactured through the method can be eaten as soon as being brewed for 5 minutes with water with the temperature of 95 DEG C, so that the loss of nutritional ingredients and active ingredients is small, the nutritional value is high, the reconstitution property is good, the reconstitution speed is high, and reconstituted material has the indigenous color and taste.

Owner:HENAN IFOOD

Technique for preparing natural pine needle powder

The invention relates to a process for preparing natural pine needle powder, which uses a freeze-drying method and a micronization method. The process comprises the steps of screening and cleaning fresh pine needles obtained through yearly pruning, freezing the fresh pine needles in a freeze dryer, drying the fresh pine needles, cutting the dried pine needles into small segments 1 to 2 centimeters long, putting the small segments of the pine needles into a micronization machine, grinding the small segments into fine powder or ultrafine powder or even nanometer-sized ultrafine powder according to need, sterilizing and packing ground pine needle powder. The process makes the pine needles into a product easier to absorb by human body by performing scientific reasonable deep processing treatment, fully preserves the nutrient components of the pine needles from being destroyed, improves the absorptivity of the nutrient components of the pine needles, and realizes optimum cell-wall breaking effects. As the ground pine needle powder is sterilized and packed, maximum efficacy is obtained with a minimum taking dose, so that the bioavailability of the pine needles is greatly improved.

Owner:蒋月秋

Cooked instant noodles and making method thereof

InactiveCN109363082ATaste is smooth and strongGreat tasteFood ingredient as mouthfeel improving agentPhosphateDeep frying

The invention relates to cooked instant noodles. The cooked instant noodles comprise the components in parts by weight of 45-65 parts of wheat flour, 15-30 parts of acetate modified starch, 3-10 partsof vital wheat gluten, 0.2-0.5 part of sodium alginate, 1-2 parts of table salt, 0.1-0.25 part of sodium carbonate, 0.3-0.6 part of composite phosphate, 0.1-0.2 part of propylene glycol alginate, 20-30 parts of water, and 0.0005-0.0015 part of edible pigment. The noodles disclosed by the invention are nutritive, healthy, free from deep frying, and smooth and chewy in mouth feel, and have the mouth feel of cooked noodles, after being soaked. Common instant noodles are large in differences in the eating manner of soaking and cooking due to secondary gelatinizing in the cooking process. A steaming manner and a cooking manner are combined for use, and the cooking process is favorable for absorption of moisture by wrappers, so that the gelatinizing degree is increased. The technique breaks through and reduces the mouth feel differences between different eating methods. The instant noodles disclosed by the invention have the advantages of being convenient, quick, and good in mouth feel.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

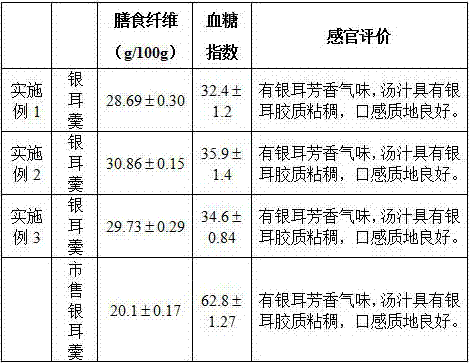

Instant white fungus thick soup with high dietary fibers and low GI value and processing method of instant white fungus thick soup

The invention belongs to the technical field of processing of white fungus thick soup, and particularly relates to instant white fungus thick soup with high dietary fibers and low GI value and a processing method of the instant white fungus thick soup. The white fungus thick soup is made from the following raw materials in parts by weight: 2-5 parts of chia seeds, 0.5 part of basil seeds, 1 part of dried red dates, 0.5 part of dried Chinese wolfberry fruits, 0.01-0.04 part of sucralose, 50-80 parts of fresh white funguses and 100-150 parts of pure water. The fresh white funguses are combined with natural plant raw materials of the chia seeds, the basil seeds and the like containing high dietary fibers, and a vacuum freeze drying technique is adopted, so that an instant product which is high in dietary fibers, low in glycemic index, balanced in nutrients, good in flavor and eating mouth feel, good in rehydration properties and easy to store and carry is prepared. The dietary fibers of the instant white fungus thick soup product are greater than or equal to 28g / 100g, the GI value is smaller than 55, after being brewed, the instant white fungus thick soup has fresh, smooth and viscous sense of the white funguses, the serum cholesterol can be reduced, the satiety can be improved, the control on blood sugar and the weight can be facilitated, and the white fungus thick soup is suitable for fat people and diabetics to eat.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Frozen dry jujube and preparation thereof

InactiveCN1423950AAvoid breaking downReduce lossesFruit and vegetables preservationAdditive ingredientFreeze-drying

A freeze dried jujube is prepared from fresh jujube through removing kernel, pre-freezing and freeze drying in vacuum freeze drier where water is directly sublimated. Its advantages are less loss of nutrients, and original color and taste.

Owner:FOOD INST LULIANG DISTRICT SHANXI PROV

Production process of sugar-free non-fried instant noodles

The invention relates to a production process of instant noodles, in particular to a production process of sugar-free non-fired instant noodles. The production process of the sugar-free non-fried instant noodles provided by the invention is characterized by comprising the following steps of: preprocessing raw materials: preprocessing wheat bran, bean dreg and corn; kneading dough: weighing 1-300 parts by weight of plant noodle material, 0.001-0.05 part by weight of xanthomonas polysaccharide corn flour or 2-6 parts by weight of xanthan gum and 1-300 parts by weight of water and stirring to be uniform to make a flour dough, wherein the plant noodle material is one or more than one of wheat bran noodle material, bean dreg noodle material and corn noodle material; cutting into blocks; curing; and packaging. The sugar-free non-fired instant noodles produced by adopting the process contains abundant vitamins, crude cellulose, protein and minerals, has comprehensive nutrient components and are easy to be absorbed by human body; and the processability is enhanced when the process is adopted to produce the sugar-free instant noodles.

Owner:刘建青

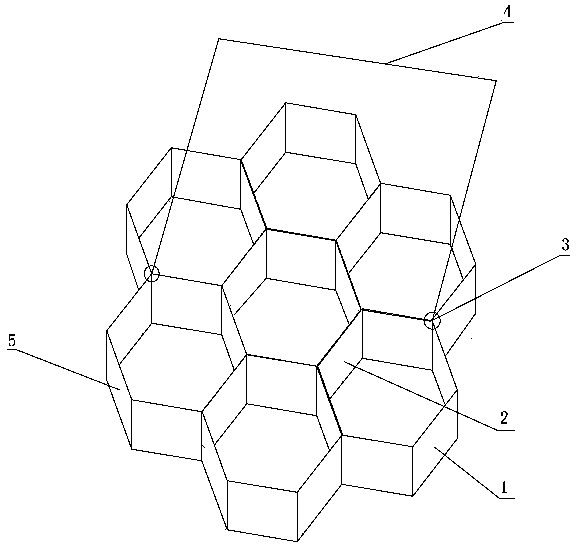

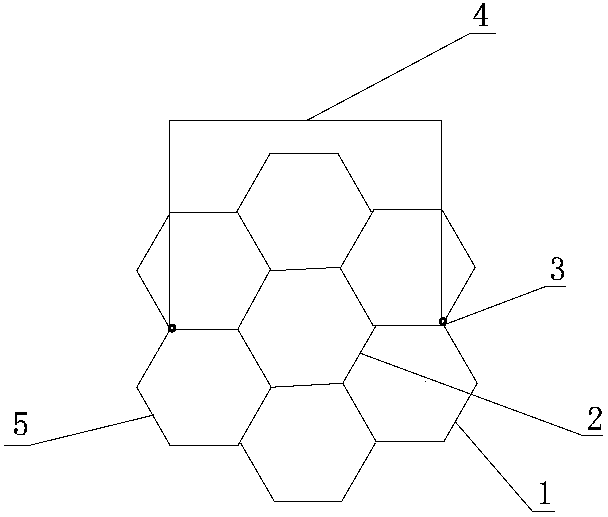

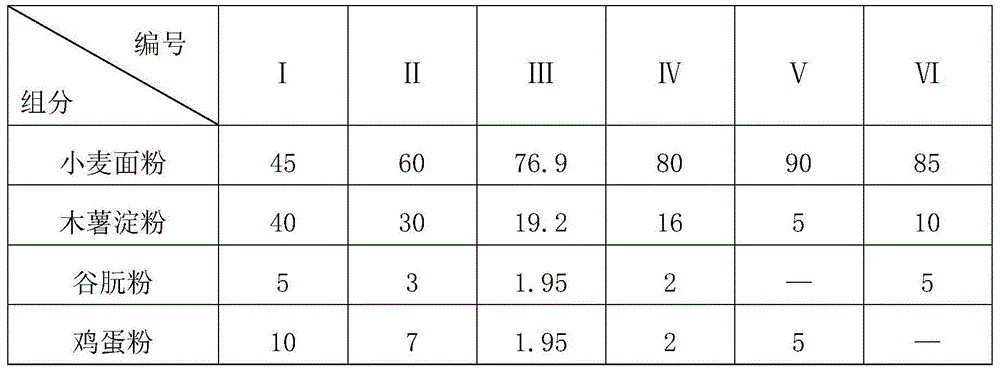

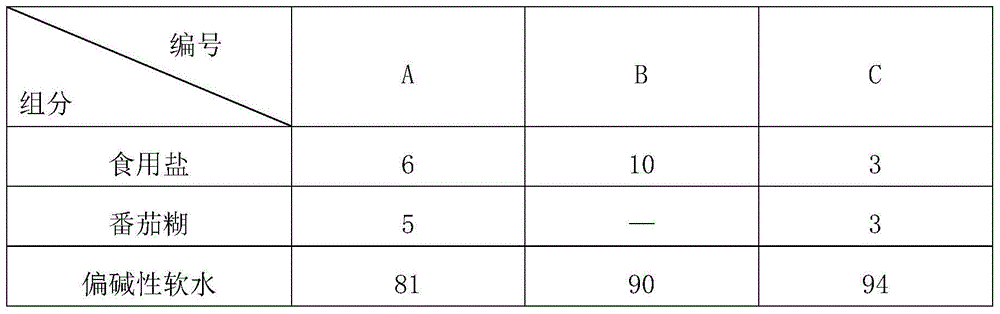

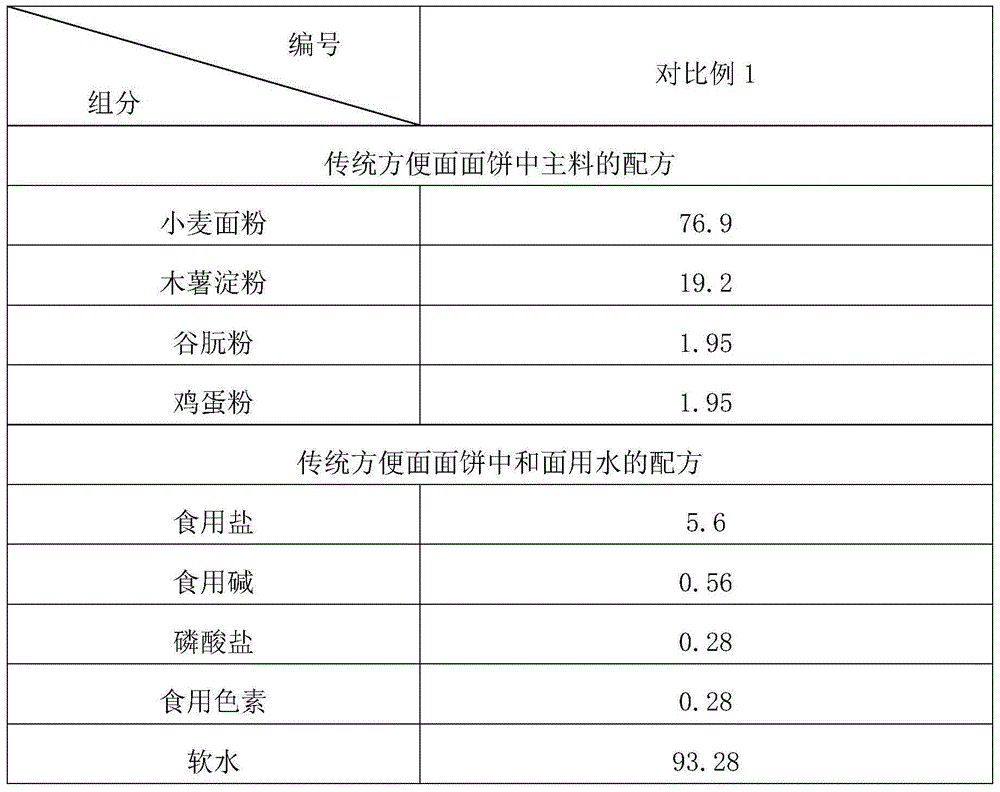

Additive-free instant noodle cake and industrial production method thereof

The invention discloses an additive-free instant noodle cake and an industrial production method thereof. The additive-free instant noodle cake comprises main materials and flour-mixing water, wherein the main materials comprise the following components in percentage by weight: 40-95% of flour, 5-45% of starch, 0-5% of vital gluten and 0-10% of an egg raw material; the flour-mixing water comprises the following components in percentage by weight: 0-5% of a natural coloring raw material, 1-10% of edible salt and the balance of weakly-alkaline soft water; the mixing ratio of the main materials to the flour-mixing water is 1:(0.25-0.45). As the raw material formula is optimized and is optimally innovated by using an industrial production method, including processes such as stable control on the temperature of dough, control on dough piece pressing and extension operation, low-pressure steam boiling and immersion dispersion, the quality of the instant noodle cake is well improved, and the instant noodle cake has very good taste and reconstitution properties under the condition that no additive is added.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Making method of instant rice

InactiveCN103478601AImprove water retentionEasy to cook throughMulti-step food processesFood preparationGradual increaseRice grain

The invention discloses a making method of instant rice. The making method is characterized by comprising the steps of 1. cleaning rice; 2. cooking the rice; 3. loosening rice grains; 4. drying the rice grains; and 5. discharging and packaging. In a process of cooling the rice, the rice is cooked through a gradual increasing temperature, smooth pores can be kept in the rice grains so that the water retention capability of the rice grains is good and the rice grains are easily cooked; in a process of drying the rice grains, through a series of steps of pre-drying, constant-temperature moisturizing, drying, preheating and insulating, and cooling, the rice grains are dried thoroughly, and the mouthfeel of the rice can not be damaged. The instant rice made by adopting the making method is high in rehydrating speed of the rice grains, complete in rice grains after rehydrating, and good in mouthfeel.

Owner:湖南龙窖山生态农业股份有限公司

Preparation method of corn noodles

The invention discloses a preparation method of corn noodles. The corn noodles are prepared with a method including smashing or soaking and smashing, mixing, ultrasonic treatment, puffing curing, pressing, drying or ageing and the like, the obtained corn noodles have pure corn flavor and do not contain any gluten fortifier, thickening colloid, enzymic preparations or preservative, no chemical reagents are used, the edible safety of the product is guaranteed, and the production process is simple, convenient to operate and applicable to large-scale industrial production.

Owner:延边阿拉里机械设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com