Method for processing garlic granule through vacuum freezing and microwave vacuum serial combined drying

A technology of vacuum freeze-drying and microwave vacuum, which is applied in food science, food preservation, application, etc., can solve the problems of long production cycle and large energy consumption, and achieve the goals of improving sensory and nutrition, saving energy consumption, and reducing energy consumption costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

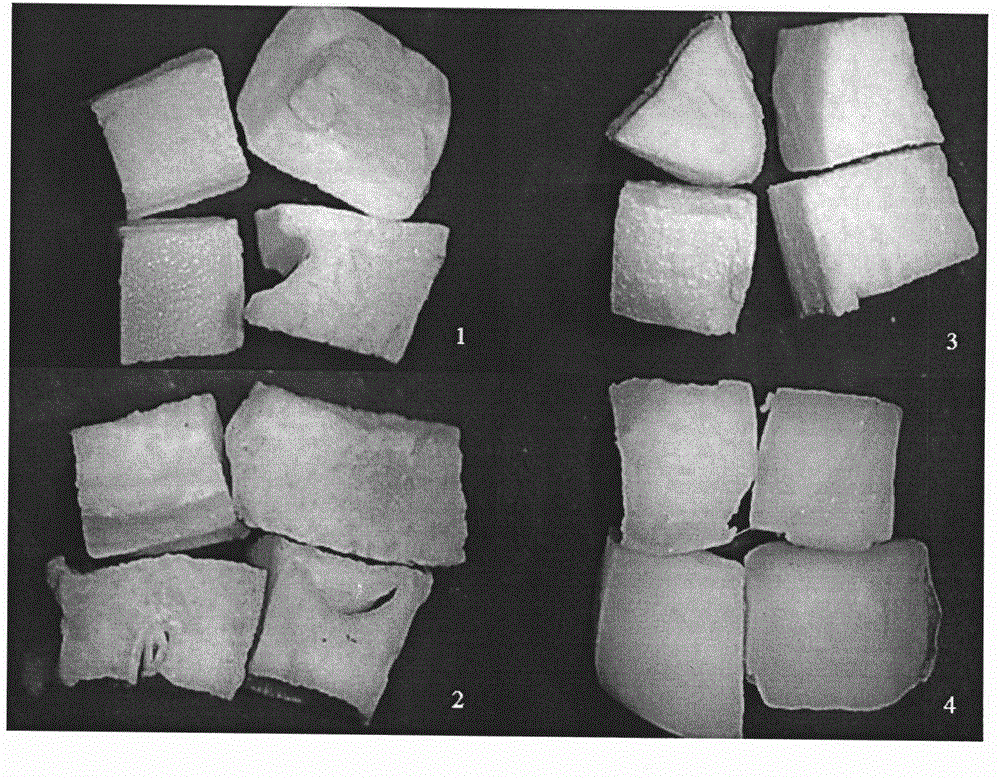

Image

Examples

Embodiment 1

[0023] (1) Garlic pretreatment: Pour the garlic on the garlic selection table, remove the moth-eaten, mildewed, and undersized garlic, then use a cutting machine to cut the garlic, pour the chopped garlic cloves on the elevator, and The conveyor belt is sent to the splitter for splitting. After the split garlic is dried off-line, the outer coat and transparent film of the garlic cloves are removed, and the unremoved garlic skins are manually picked out. Finally, cut into cube garlic grains with a side length of 5mm with a multi-kinetic dicing machine.

[0024] (2) Plate loading: Take three material plates, each plate is covered with 2 layers of material, the material in the middle of the plate is slightly thinner, and the periphery is slightly thicker.

[0025] (3) Pre-freezing: put the material into the freezer after packing, let the material pre-freeze at a temperature of -30°C, keep it at this temperature for 4 hours, and reduce the temperature of the material to the eutec...

Embodiment 2

[0030] (1) Garlic pretreatment: Pour the garlic on the garlic selection table, remove the moth-eaten, mildewed, and undersized garlic, then use a cutting machine to cut the garlic, pour the chopped garlic cloves on the elevator, and The conveyor belt is sent to the splitter for splitting. After the split garlic is dried off-line, the outer coat and transparent film of the garlic cloves are removed, and the unremoved garlic skins are manually picked out. Finally, cut into cube garlic grains with a side length of 5mm with a multi-kinetic dicing machine.

[0031] (2) Plate loading: Take three material plates, each plate is covered with 2 layers of material, the material in the middle of the plate is slightly thinner, and the periphery is slightly thicker.

[0032] (3) Pre-freezing: put the material into the freezer after packing, let the material pre-freeze at a temperature of -25°C, keep it at this temperature for 4 hours, and reduce the temperature of the material to the eutec...

Embodiment 3

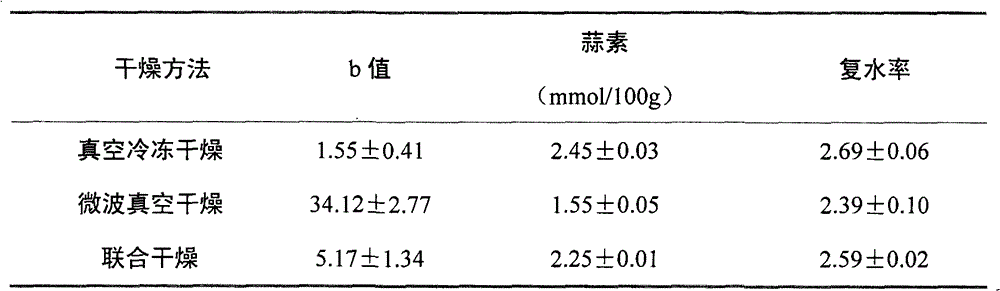

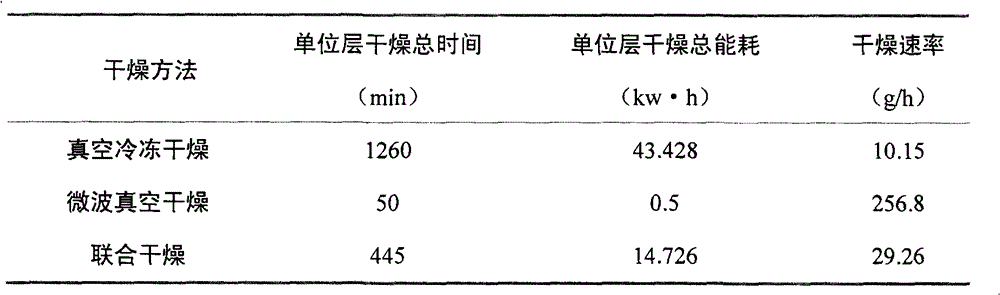

[0037] Garlic granules processed in different ways were compared.

[0038] The processing flow of garlic granules in the vacuum freeze-drying group is through material selection, stalk cutting, peeling, and dicing machine to cut garlic granules into cubes with a side length of 5mm, and then put them on a plate with 2 layers. The loaded material is put into the freezer, and the material is pre-frozen at a temperature of -30°C, and kept at this temperature for 4 hours, and the temperature of the material is lowered to the eutectic point. Lower the temperature of the cold trap to -45°C in advance, put the material into the freeze-drying bin, vacuumize to 10Pa, and then carry out vacuum freeze-drying. After reaching the safe moisture with a moisture content of 6% or less, the drying ends.

[0039] The processing process of garlic granules in the microwave vacuum drying group is through material selection, stalk cutting, peeling, and dicing machine to cut garlic granules into cube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com