Patents

Literature

30results about How to "Improve profile quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

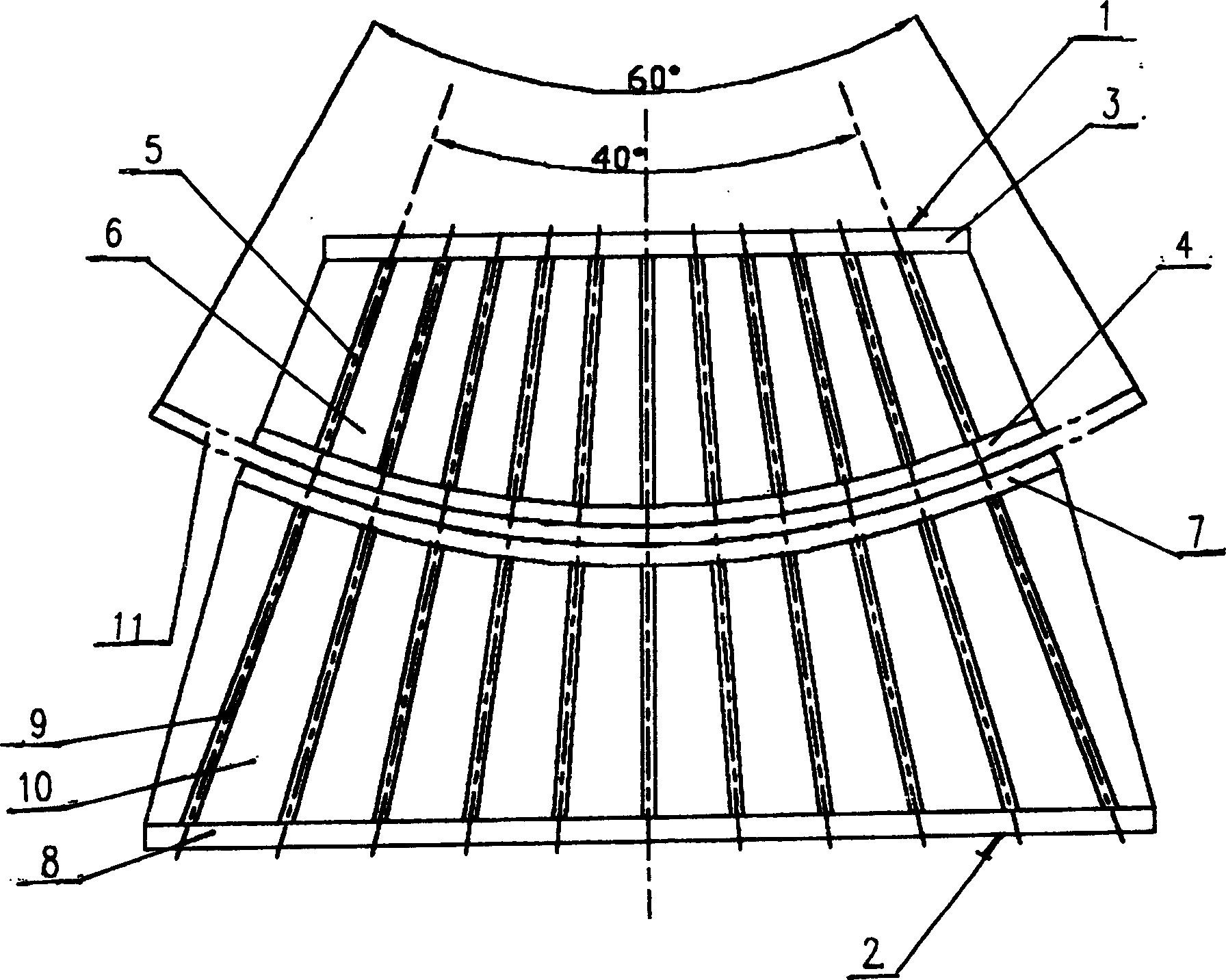

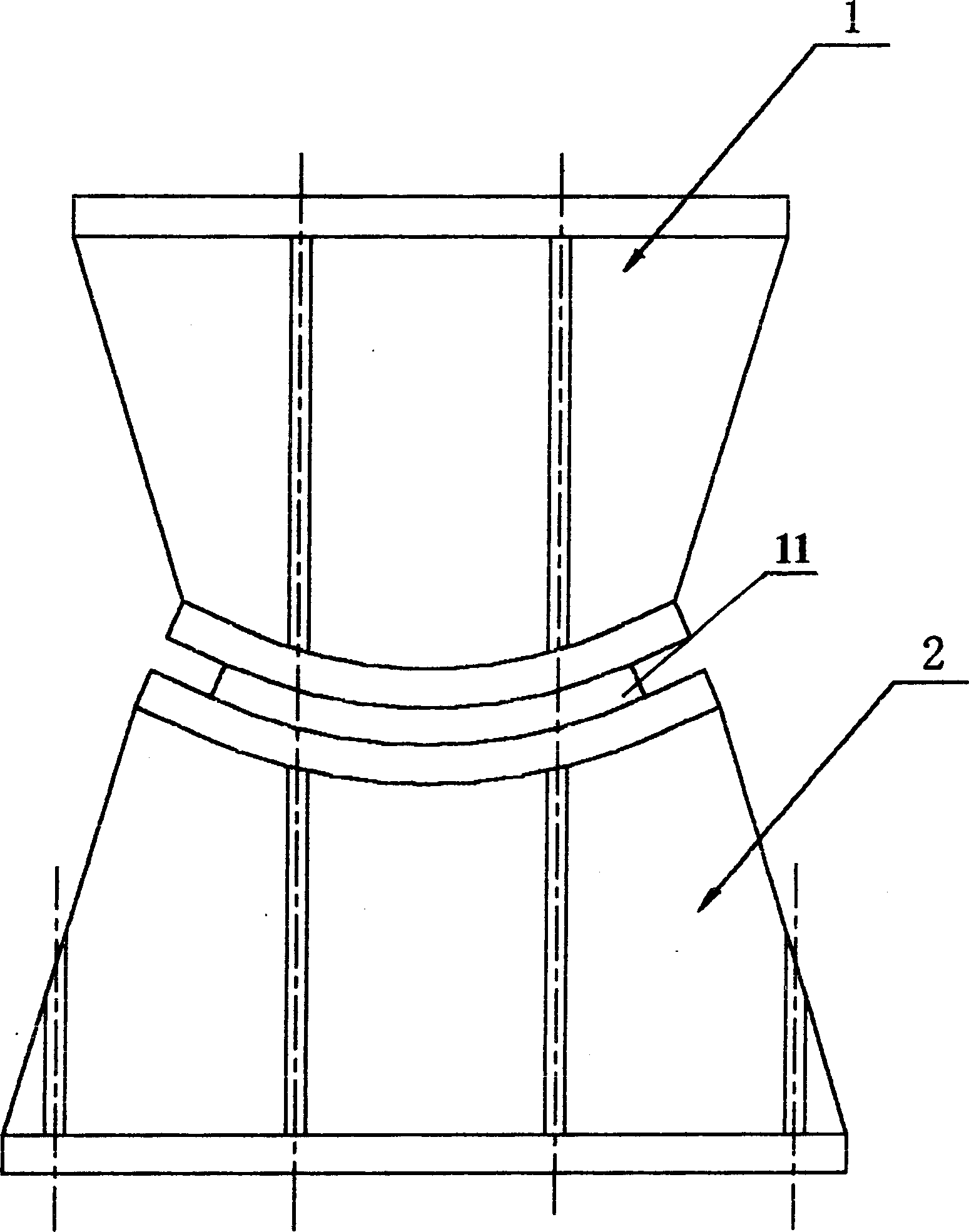

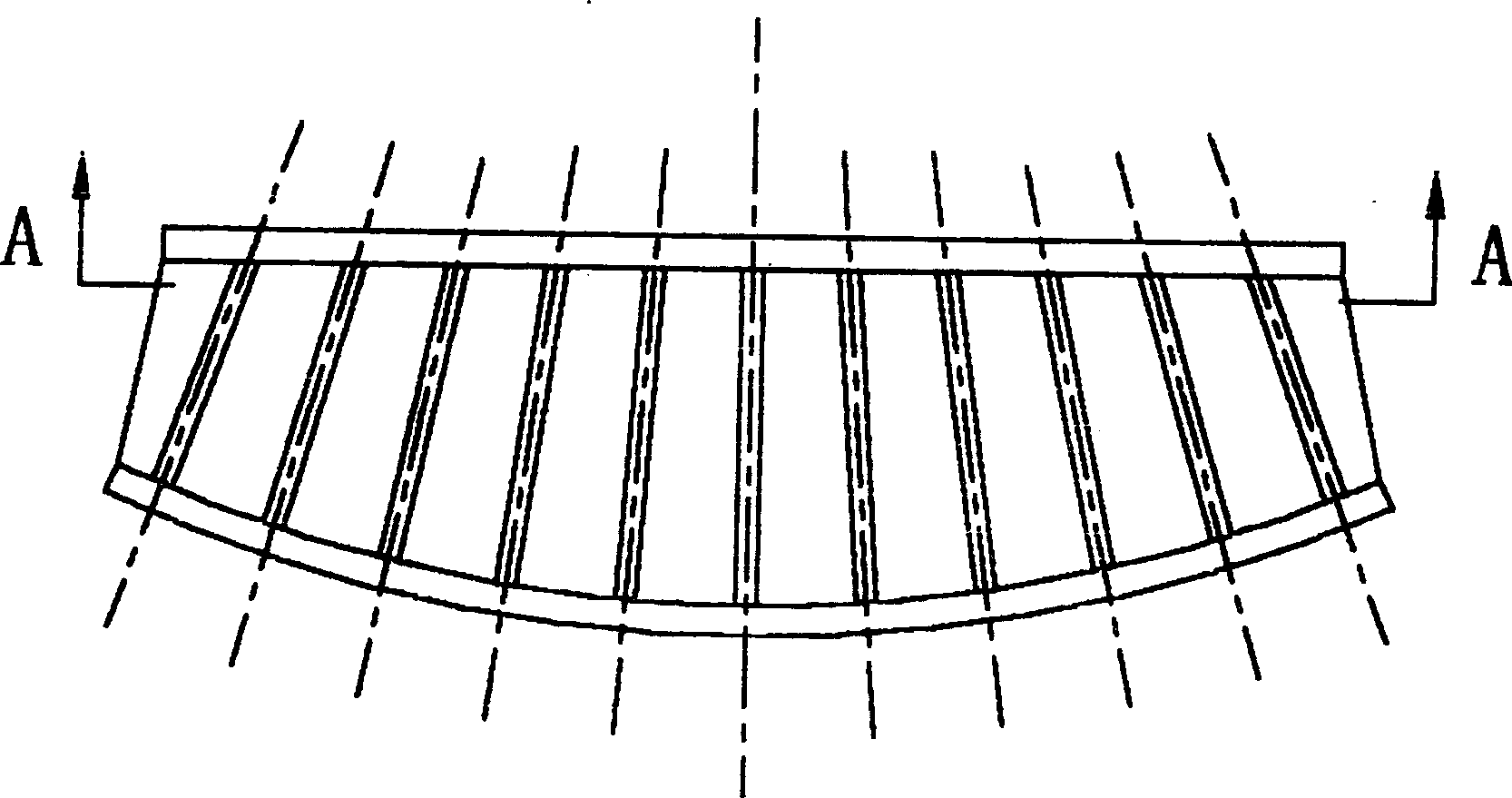

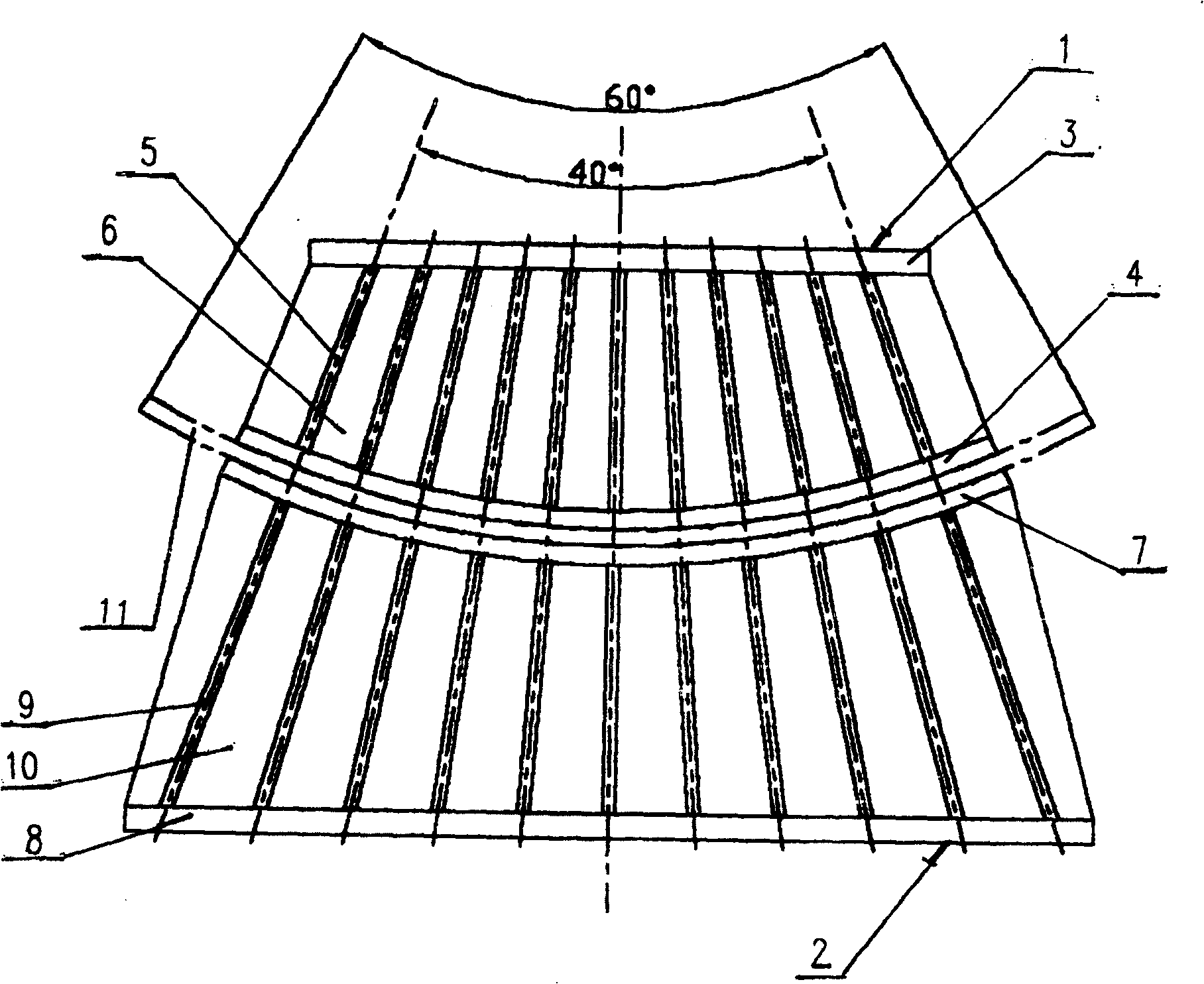

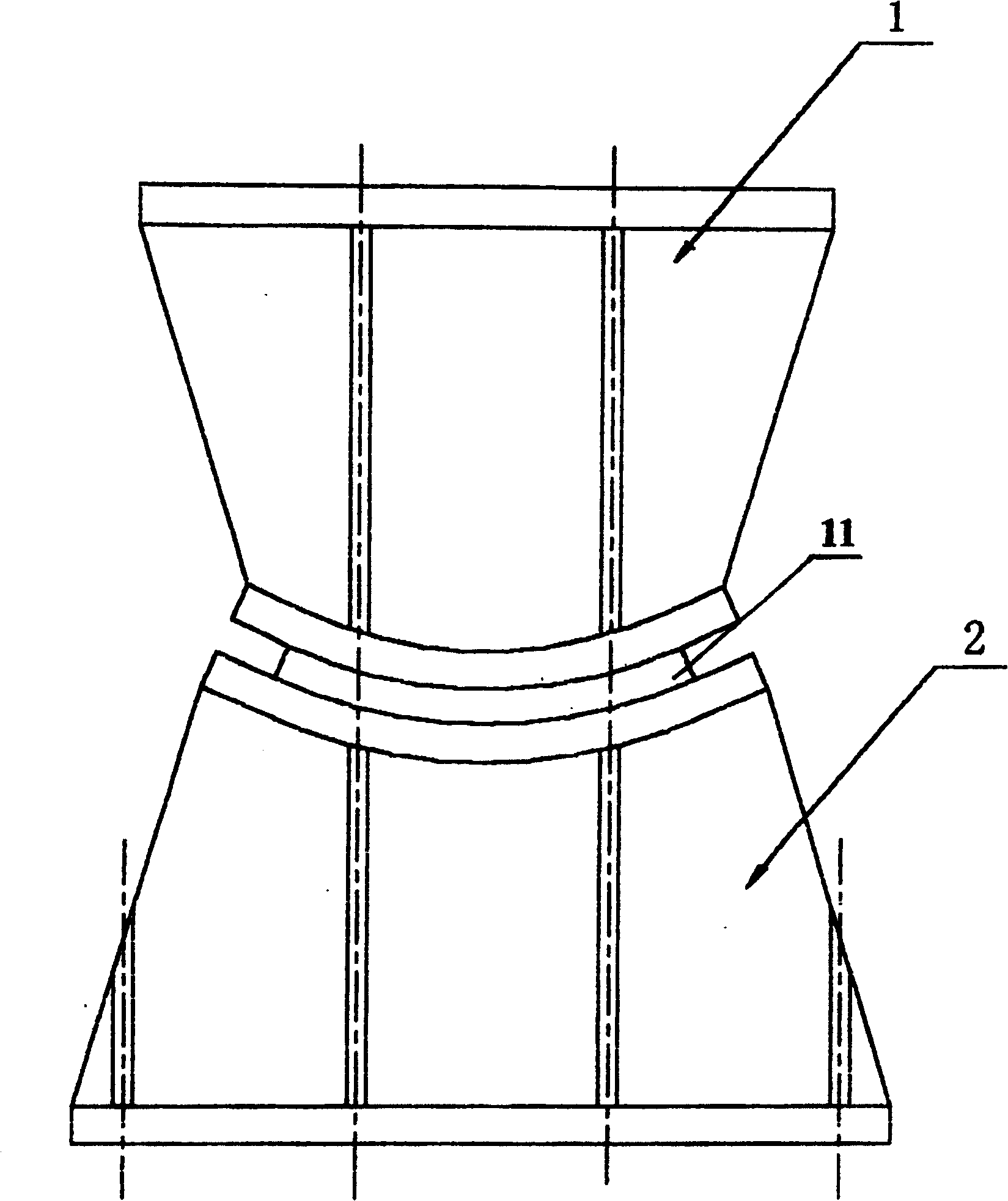

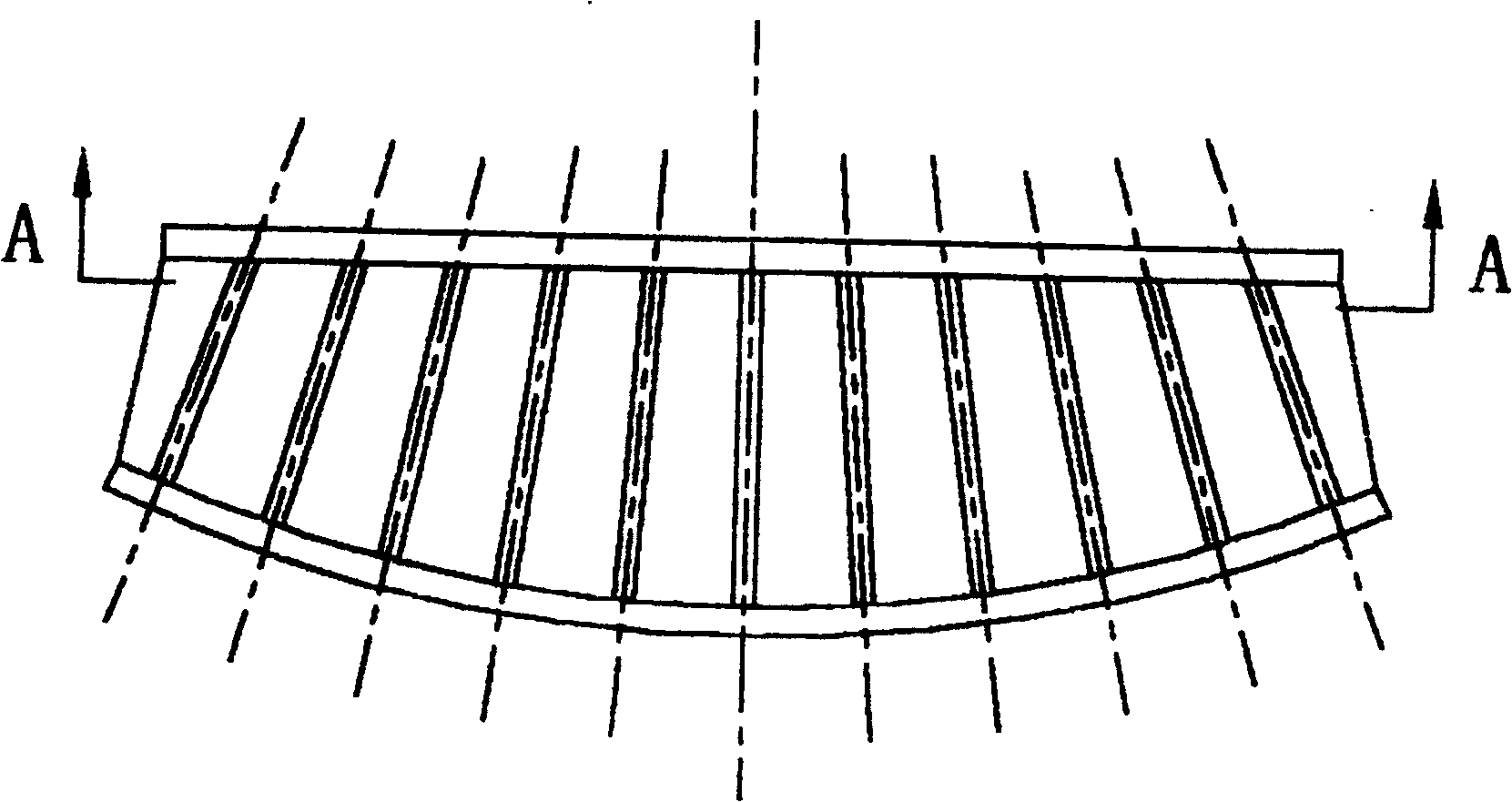

Double curvature plate cold press forming method and equipment thereof

The present invention relates to double curvature plate cold pressing formation method and apparatus. The formation process includes the following steps: determining the rebound elasticity of cold pressed steel plate, determining the curvature radius and size of upper and lower working plates, setting plate material, cutting, pressing, etc. The formation apparatus includes upper pressing mold, lower pressing mold, reinforcing ribbed plates welded onto the top plate, upper working plate, lower working plate and bottom plate, and oil press. The present invention makes it possible to produce high quality double curvature plate with smooth surface.

Owner:中国船舶集团渤海造船有限公司

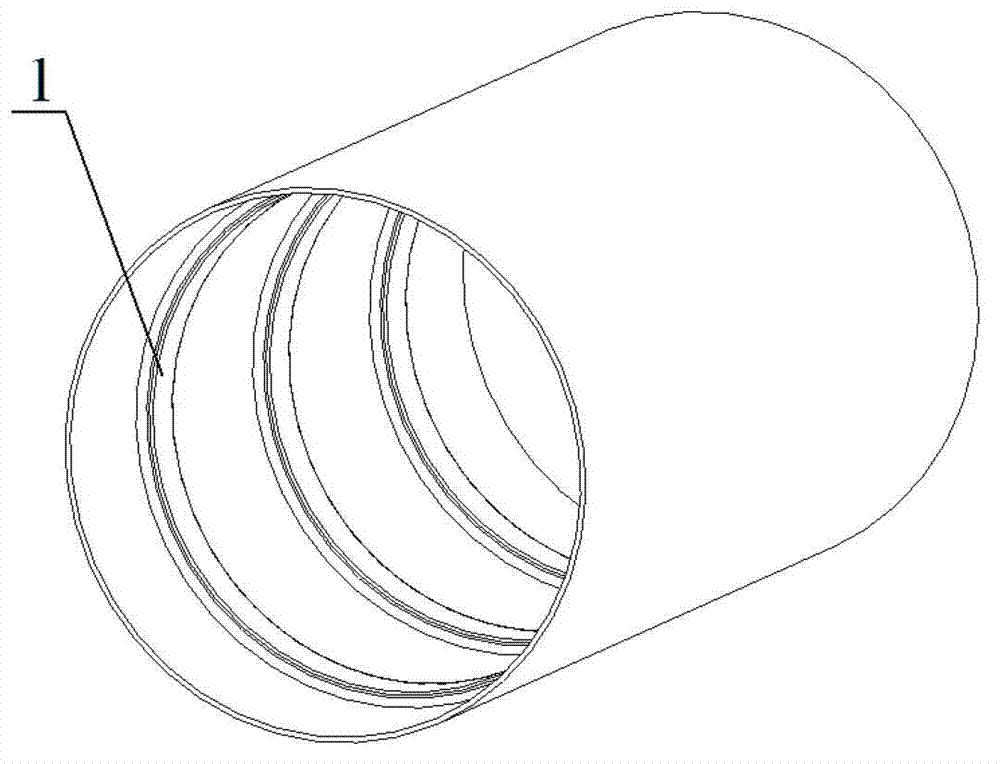

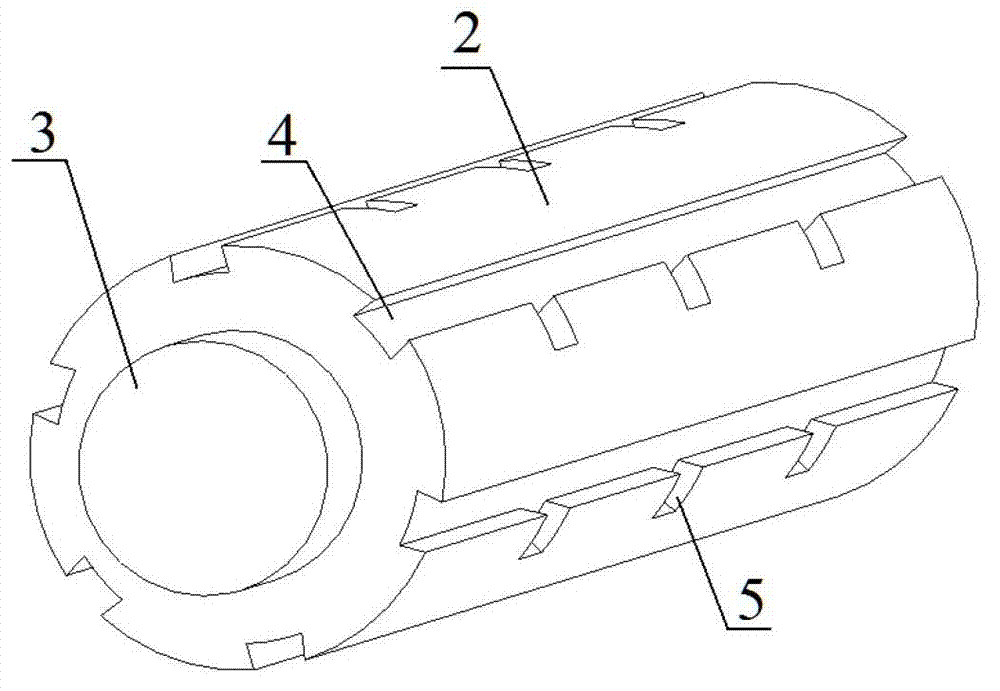

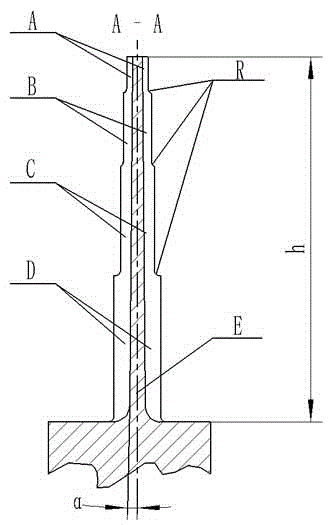

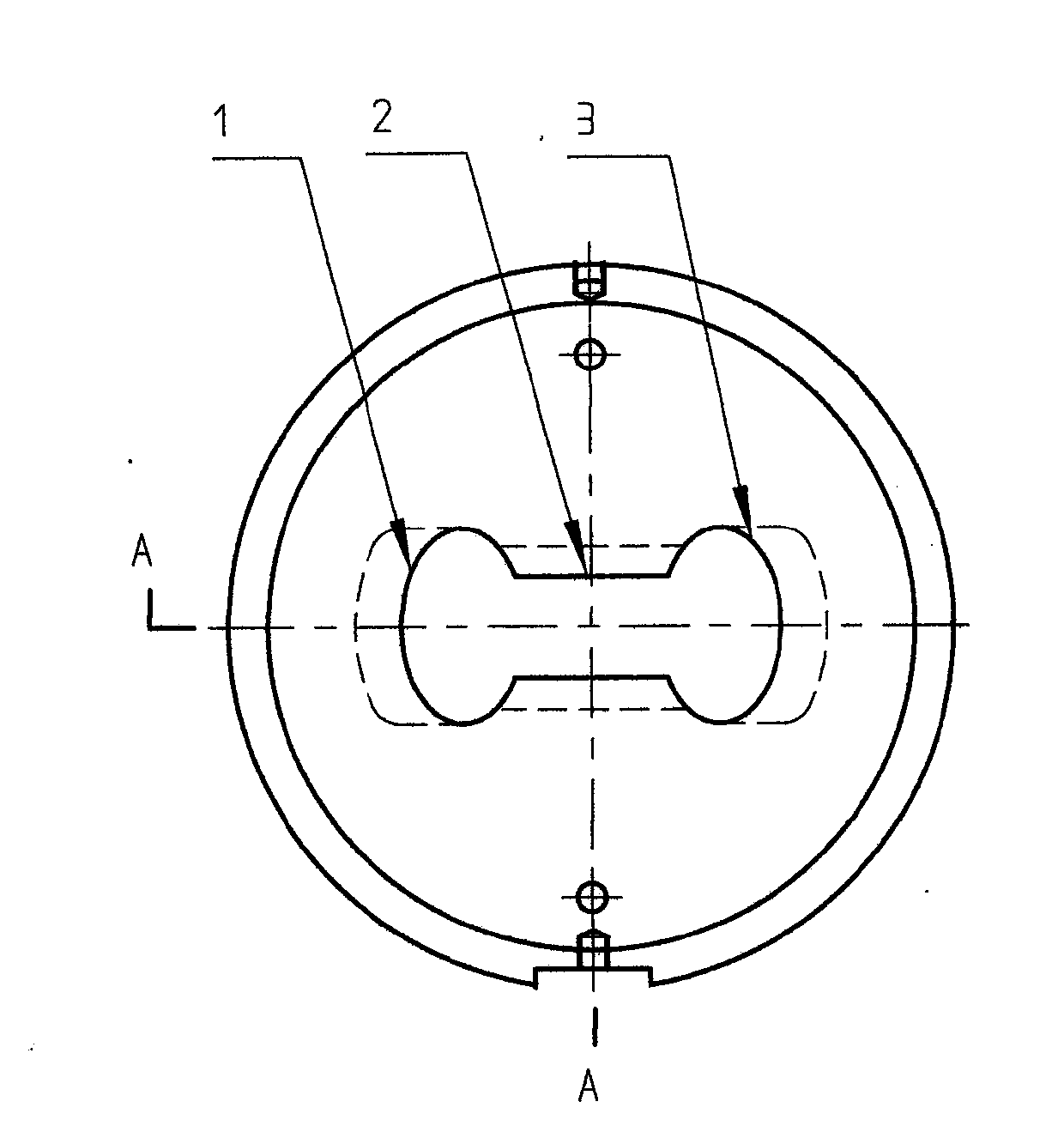

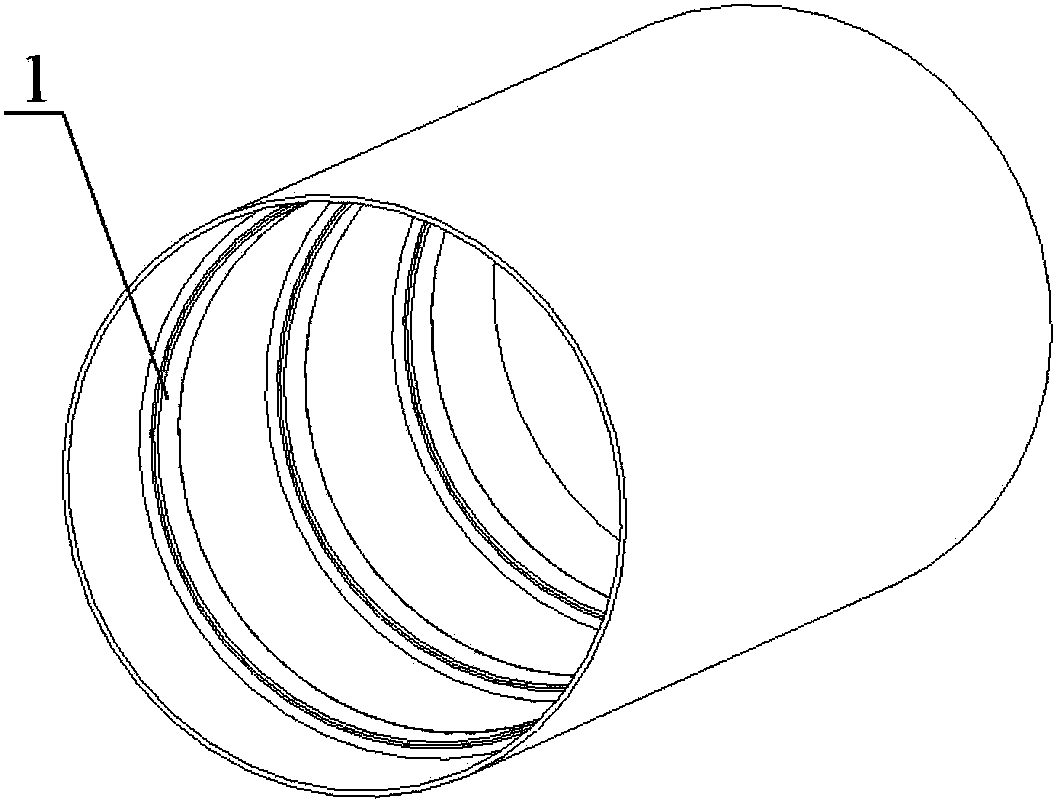

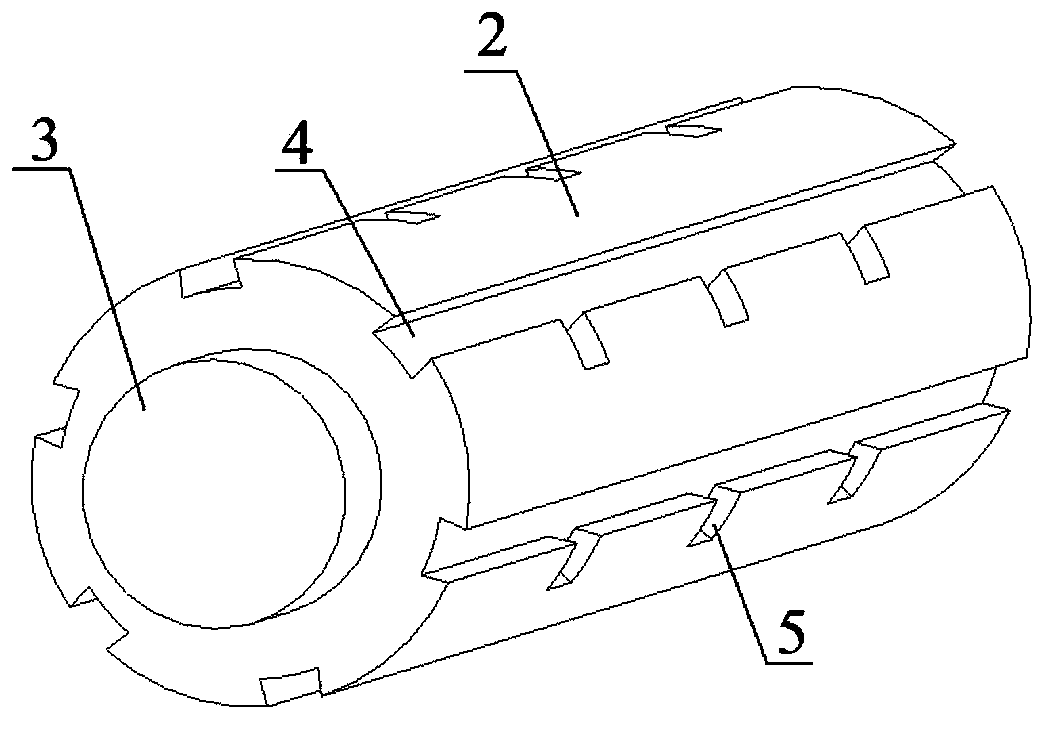

Core mold and shaping method for shaping strip annular internal reinforced rib rotary body thin-wall part

InactiveCN102764841APrevent movementHigh forming precisionForging/hammering/pressing machinesMetallic materialsUltimate tensile strength

The invention relates to a core mold and a shaping method for a shaping strip annular internal reinforced rib rotary body thin-wall part, wherein a base mold is composed of a base mold main body and a mold withdrawing end; a swallow tail groove and a positioning groove are formed on the base mold main body; a shape mold is wholly of an annular structure; the shape mold is uniformly divided into a plurality of split molds of same shapes; shaping arc grooves for annular internal reinforced ribs are formed on the shaping plane of the split molds; swallow tail tenons matched with the wallow tail groove and the positioning groove are formed on the inner surfaces of the split molds. By adopting the mode of combined core mold, the problem of hard demolding during the shaping process of the rotary body thin-wall part internal reinforced rib is solved. By virtue of the positioning on the base mold swallow tail groove, the movement of the shaping mold is prevented effectively; and the shaping precision of the rotary body thin-wall part internal reinforced rib is improved. The base mold, the shaping mold and the fixing pin of the core mold can be made of different metal materials according to respective strength requirements; only the mold needs to be replaced for rotary body thin-wall pieces of which the inner diameters are the same and the internal reinforcing ribs are different, so that the cost of the mold is reduced greatly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

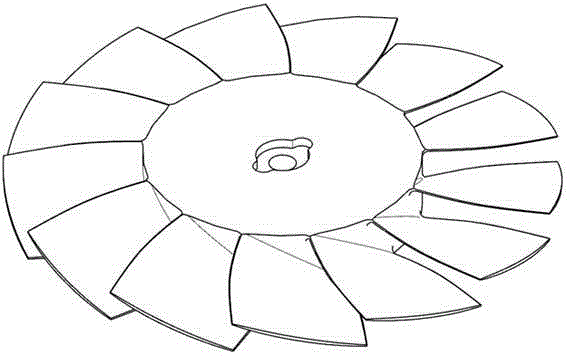

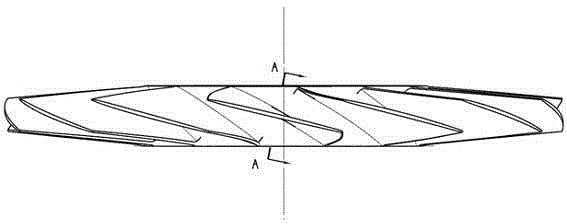

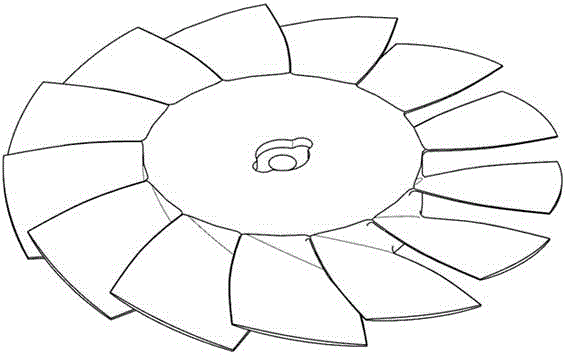

Process for strengthening milling rigidity of aluminum-alloy ultrathin-blade integral impeller

The invention discloses a process for strengthening the milling rigidity of an aluminum-alloy ultrathin-blade integral impeller. The process comprises the following steps: firstly layering the ultrathin blade of the integral impeller; reserving rough machining allowance; and carrying out layered finish machining on the ultrathin blade. According to the invention, resonance of the whole blade is reduced via non-uniform allowance and transition fillets between each layer, so vibration of the ultrathin-blade integral impeller caused by influence of cutting force in cutting can be effectively reduced, the molded surface quality and curved surface precision of the blade milled by a cutter and dimensional stability of the impeller are improved, and cutting efficiency is significantly enhanced.

Owner:SHANGHAI INST OF TECH

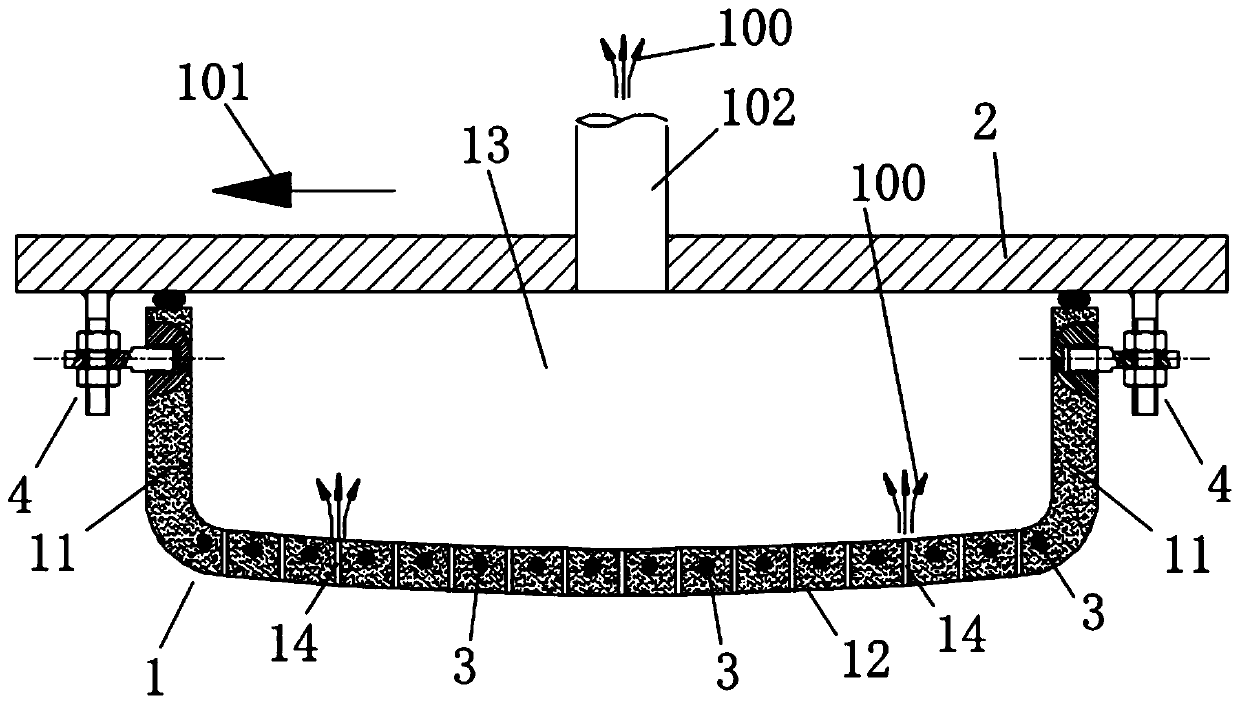

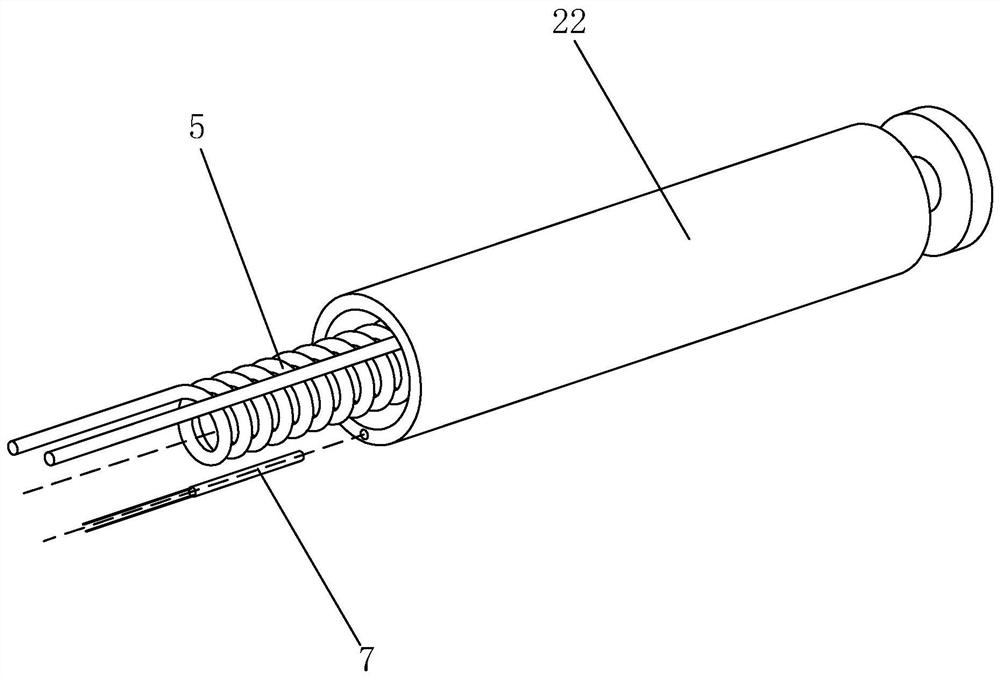

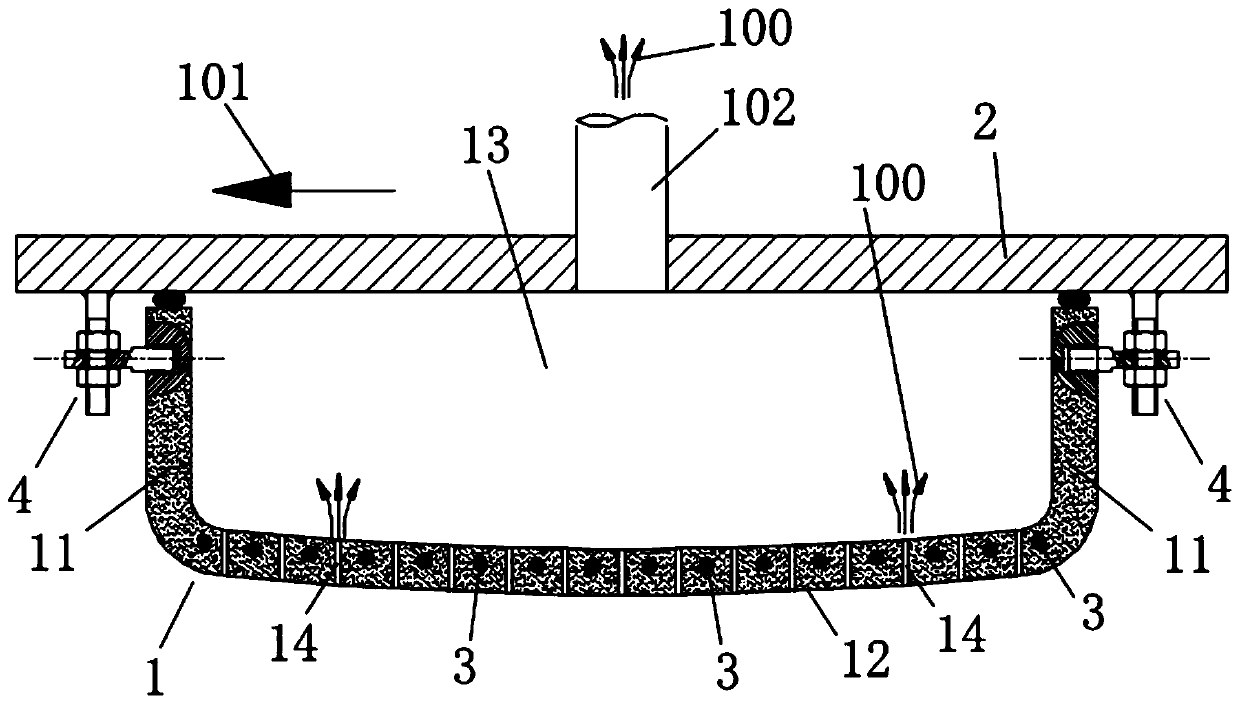

Control method for heat-insulating layer structural uniformity

ActiveCN104848002ASwell evenlyAvoid displacementThermal insulationPipe protection by thermal insulationEngineeringRocket engine

A control method for heat-insulating layer structural uniformity belongs to the technical field of solid rocket motor heat-insulating layer manufacturing, The method sequentially includes the steps: preparation, evacuation, inflation and exhausting, inflation and rotation. The structural uniformity of the heat-insulating layer can be improved through the above steps. Due to the conversion between the inflation and the exhausting of a rubber air bag and the speed controlling of the inflation and exhausting, uniform bulge of each portion of the rubber air bag can be ensured, and the displacement of a sinker arranged on the upper portion of the rubber air bag can be avoided. After the basic bulge of the rubber air bag, rotation and adjustment are conducted, the influence on the thickness of the heat-insulating layer sinker by the gravity can be solved, and thus the purpose of the complete structure and the uniform thickness of the heat-insulating layer can be achieved. The control method for the heat-insulating layer structural uniformity is applied to products in various models, remarkably improves the profile quality of the heat-insulating layer, solves the quality problem that the thickness of the heat-insulating layer is not uniform, and passes the ground test of motors.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

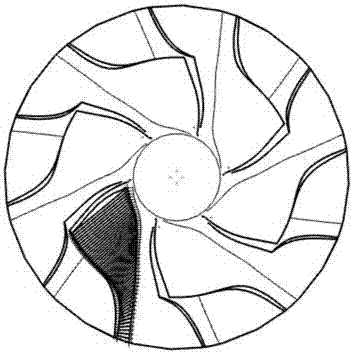

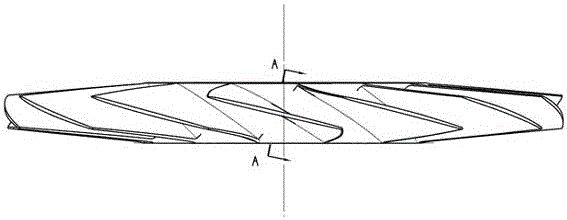

Milling method of diffuser

InactiveCN104227098AExtend your lifeLow costMilling equipment detailsEngineeringMechanical engineering

The invention relates to a milling method of a diffuser. The milling method comprises the following steps: a. with a route from an outlet blade-less section to an inlet blade-less section between two adjacent blades as a first milling route, roughly milling the blades in a layering manner according to the first milling route, and sequentially milling the outlet blade-less sections and the inlet blade-less sections between every two adjacent blades; and b. with a route at the periphery of the blades as a second milling route, milling the margins of the blades in one step according to the second milling route, thus sequentially milling all the blades. By adopting the milling method, the milling quality and milling efficiency of the diffuser can be improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

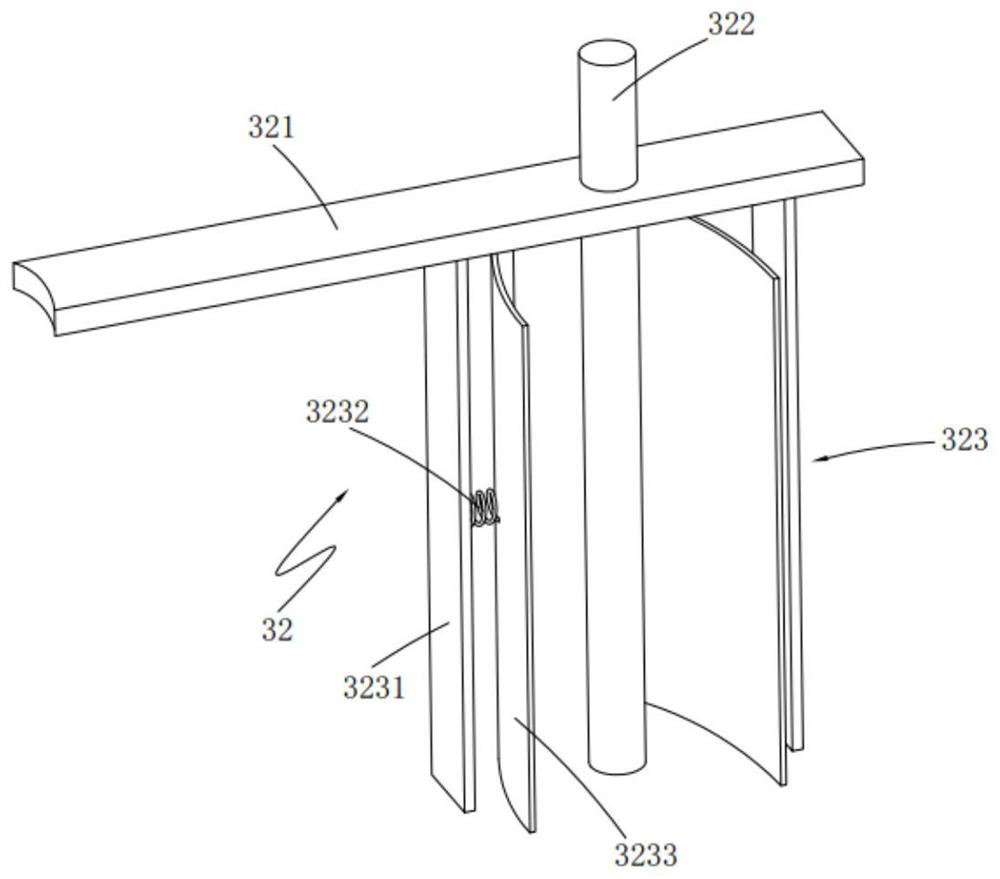

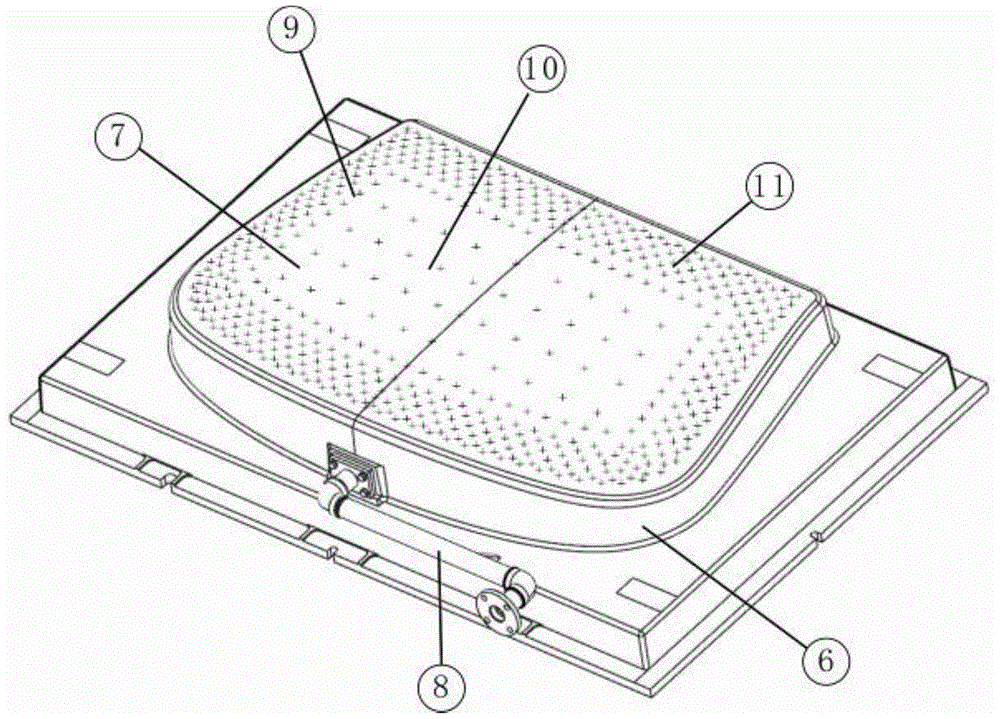

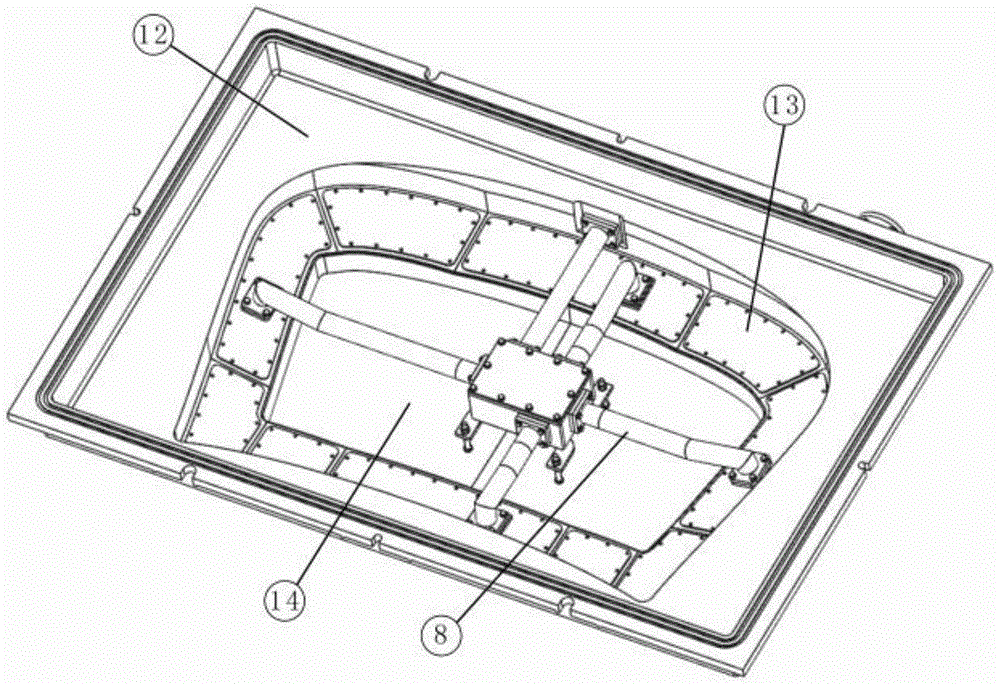

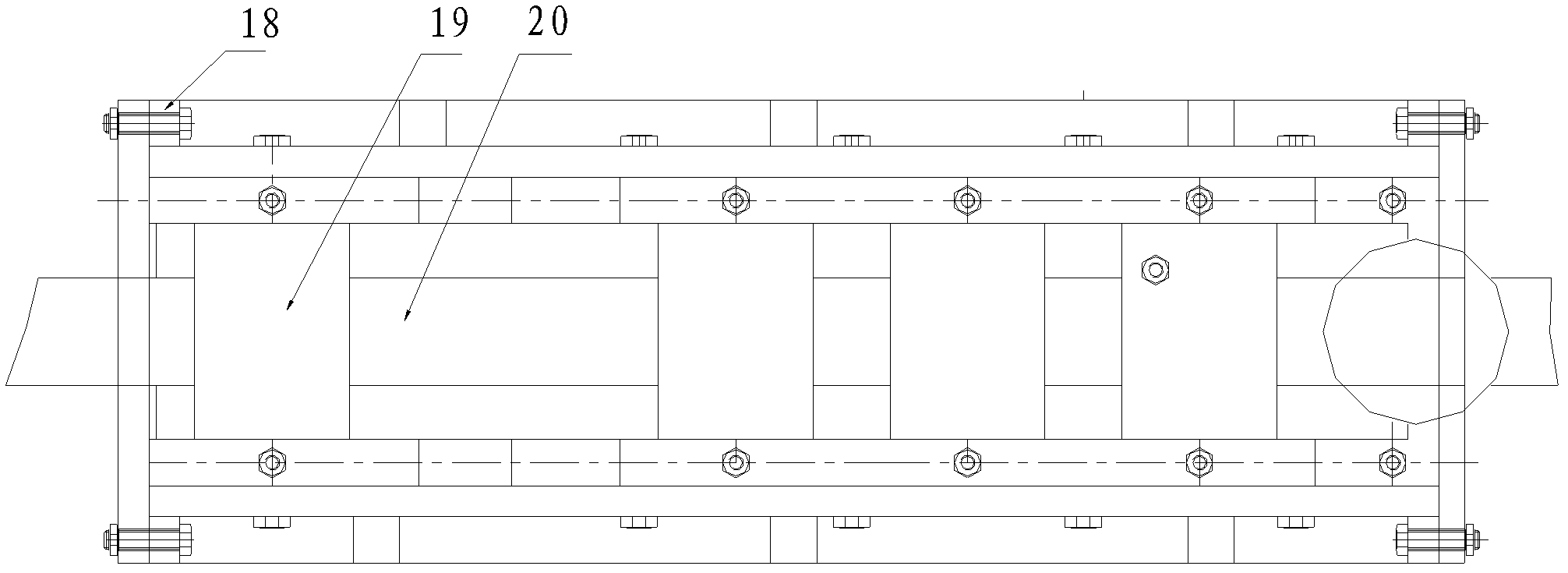

Improved mold for out-of-furnace press forming of automobile laminated glass

InactiveCN104193154AReduce molding movementGuaranteed accuracyGlass reforming apparatusOptical propertyEngineering

The invention relates to an improved mould for out-of-furnace press forming of an automobile laminated glass. The improved mold comprises a convex mold (6) and a concave mold (20). The mold is characterized in that the concave mold (20) is provided with a side pre-press forming mechanism (21) and a glass following positioning mechanism (22), the side pre-press forming mechanism (21) comprises a side pre-press cylinder (31), a pre-press rotating shaft structure (32) and a concave mold side structure (18), and the glass following positioning mechanism (22) comprises a positioner rotating shaft (24), a positioning servo motor (25), a positioning speed reducer (26), a positioning coupler (27), a transmission gear (28), a rack (29), a positioner bracket (30), a positioning cylinder (33) and a positioning stop (34). Compared with the prior art, the mold has the advantages of meeting the quality and property requirements for the molded surface, goodness of fit, optical properties of glass products with a large spherical surface, a large span, high large arch rise and great side contour curvature change, improving the yield and the like.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

Ceramic die for bending molding of glass panel

ActiveCN110316944AImprove profile qualityMeet bending and forming needsGlass reforming apparatusWindshieldElectric heating

The invention relates to the technical field of glass molding, in particular to equipment for bending of a glass panel, and particularly provides a ceramic die for bending molding of the glass panel.The ceramic die comprises a ceramic terrace die and multiple electric heating elements, the ceramic terrace die is provided with side walls and a bottom wall, the electric heating elements are arranged in the bottom wall, the outer surface of the bottom wall is provided with a convex molded surface, a vacuum cavity is formed in the ceramic terrace die, and negative pressure can be generated in thevacuum cavity; at least one partition vacuum mechanism is further additionally arranged in the vacuum cavity, each partition vacuum mechanism is provided with a partition vacuum cavity, and partitionnegative pressure can be generated in the partition vacuum cavities. The ceramic die can meet the requirement of front windshields with HUD areas, installing areas of rainwater sensors or light sensors or other optical elements and installing areas of cameras bending molding, and can lower the glass molded surface fluctuation, and finally, the glass panel with higher-quality molded surfaces is obtained; moreover, the bending molding quality of peripheral sides with higher molding difficulty can be guaranteed.

Owner:FUYAO GLASS IND GROUP CO LTD

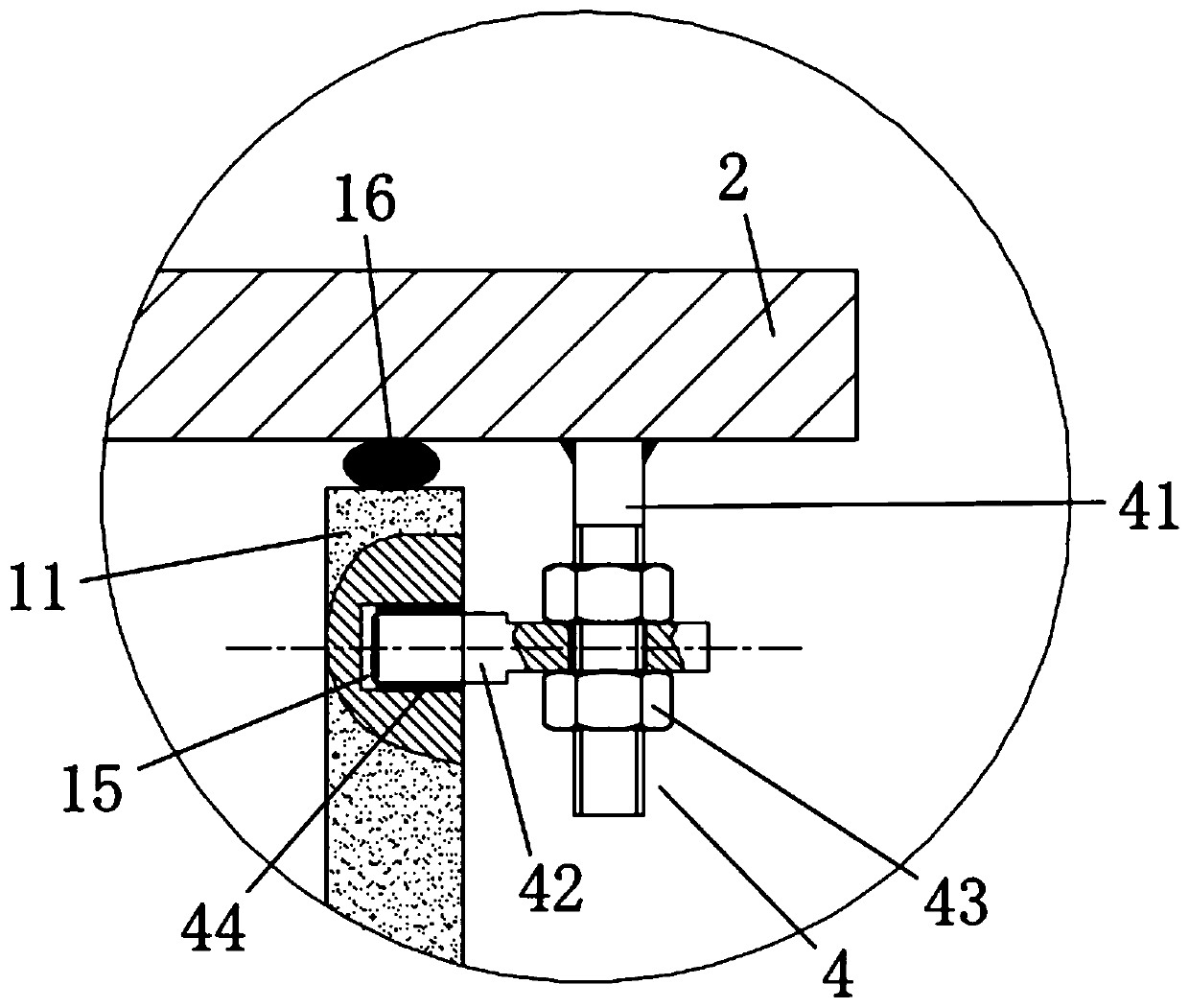

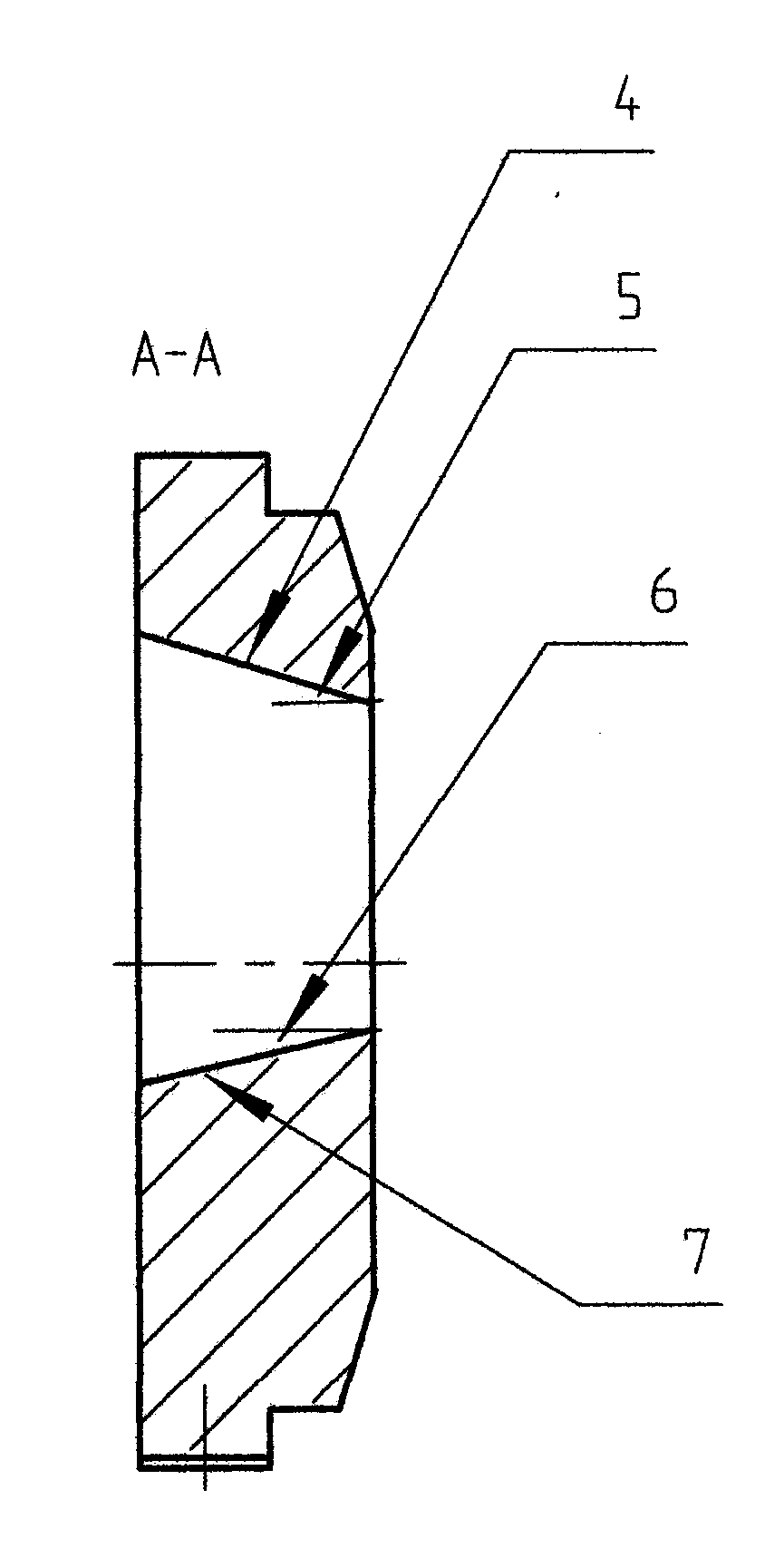

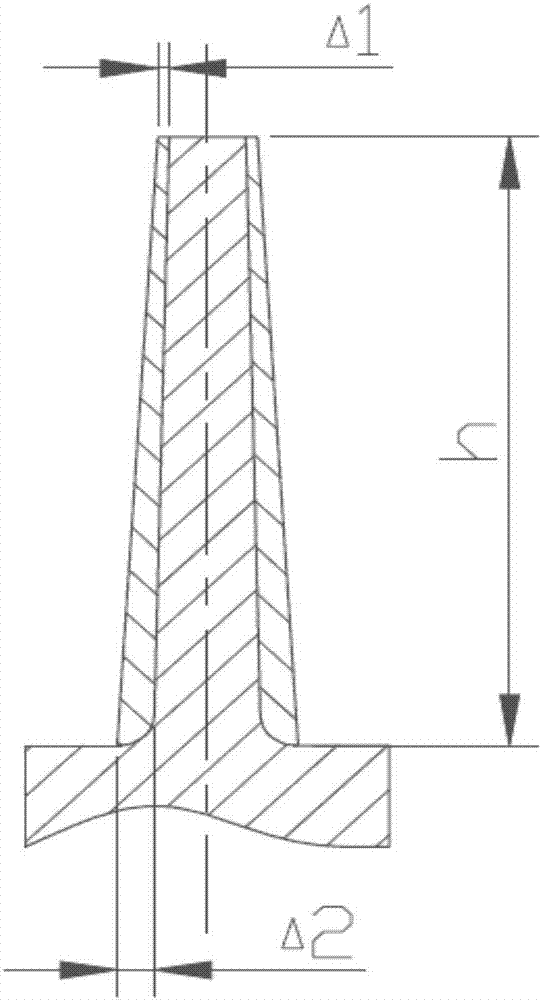

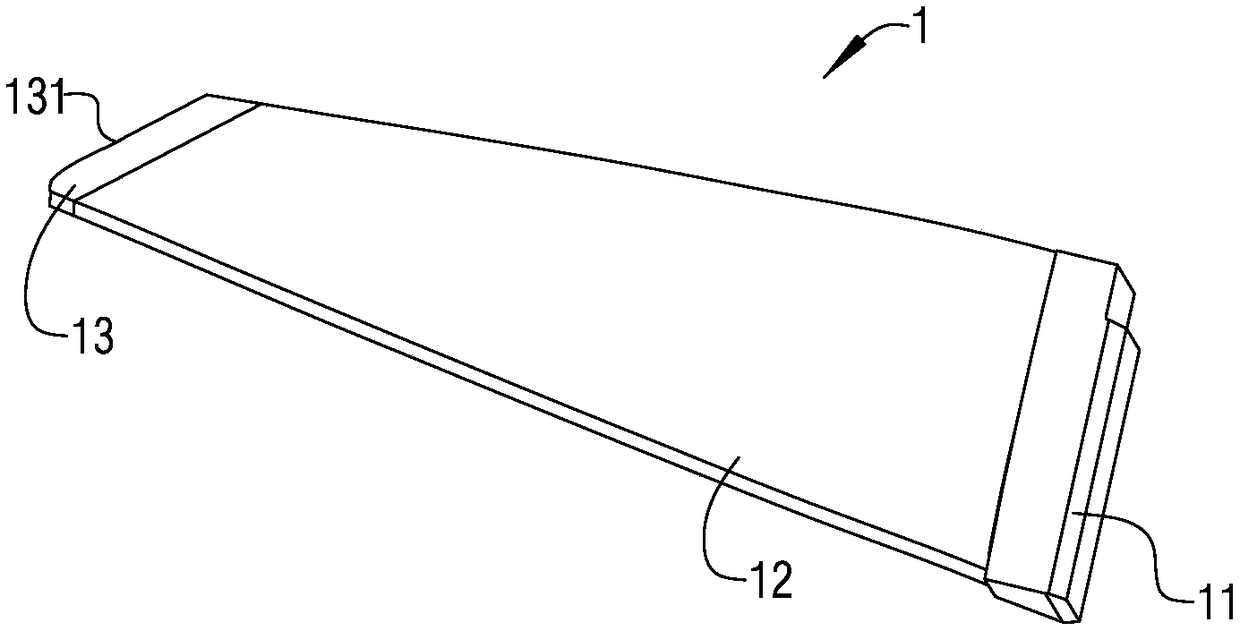

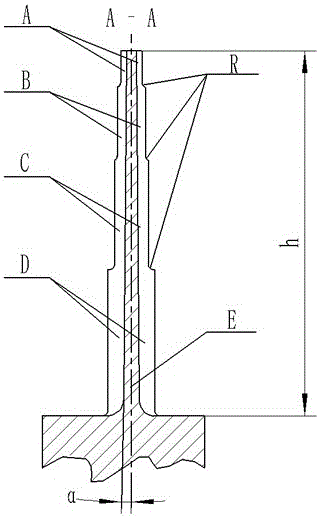

Front-mounted broadened aluminum profile extruding die

InactiveCN103464500AGood stretching effectImprove profile qualityExtrusion diesPhysicsConical surface

The invention relates to a front-mounted broadened aluminum profile extruding die. The front-mounted broadened aluminum profile extruding die comprises a round extruding cylinder, a broadening die and a forming die, wherein the broadening die is arranged between the forming die and the round extruding cylinder, and the middle part of a die cavity of the broadening die is narrower than the left and right end parts of the die cavity by 25-40%; an extending angle formed by an upper conical surface of the die cavity and the axis is 18-25 degrees; a pressure relief angle formed by a lower conical surface of the die cavity and the axis is 10-20 degrees. According to the front-mounted broadened aluminum profile extruding die, a flat extruding cylinder is saved, the broadening effect of an ingot blank is good during the extruding, and the quality of a profile is improved; by utilizing the structure, the extrusion force can be reduced, the service life of the die can be prolonged, and the production cost can be lowered.

Owner:磐石市飞跃模具有限公司

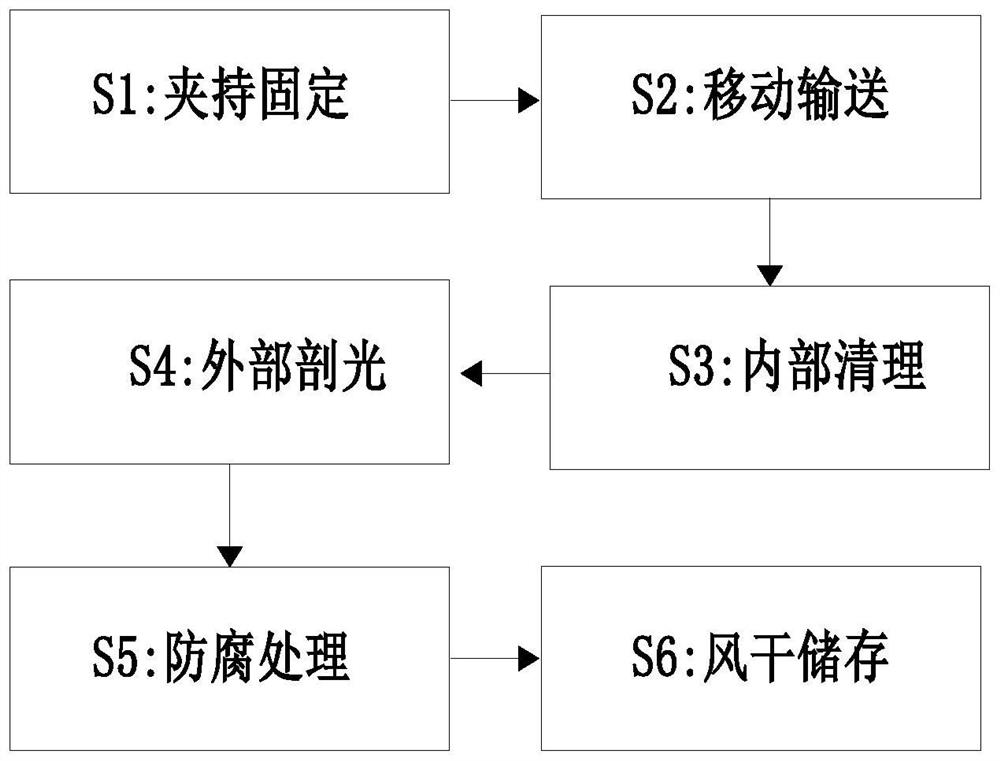

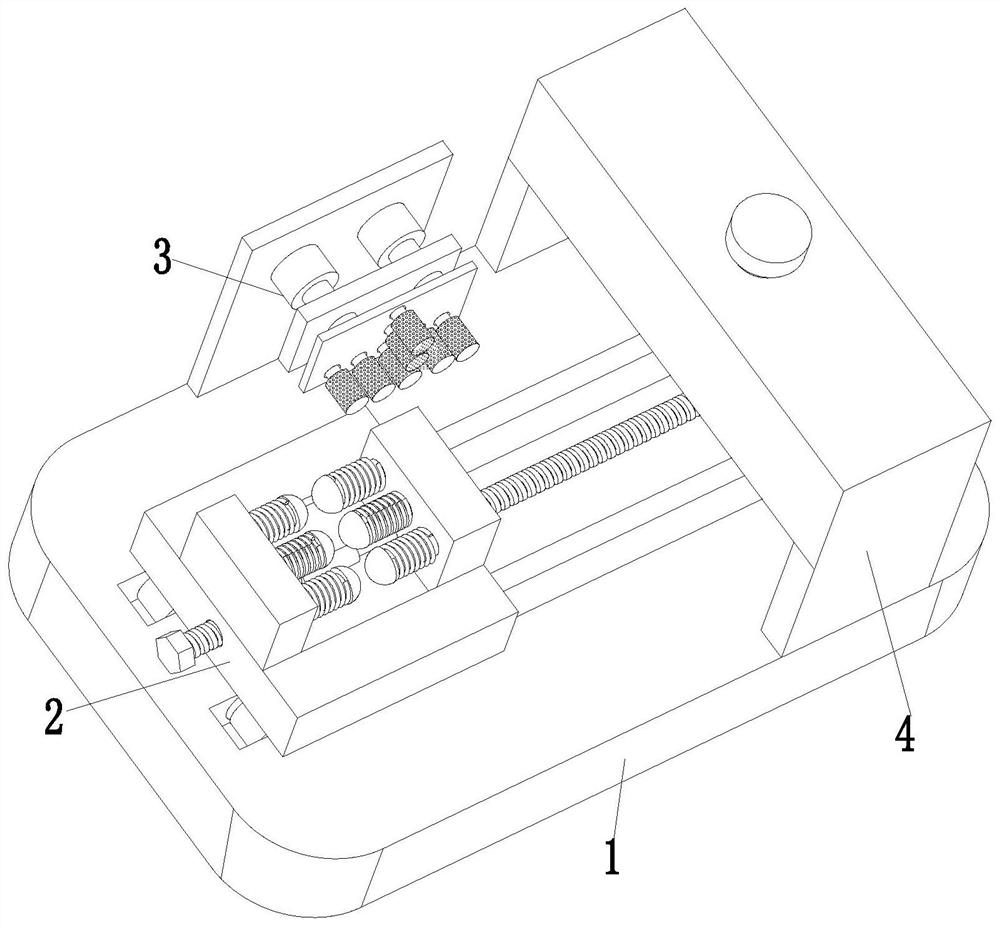

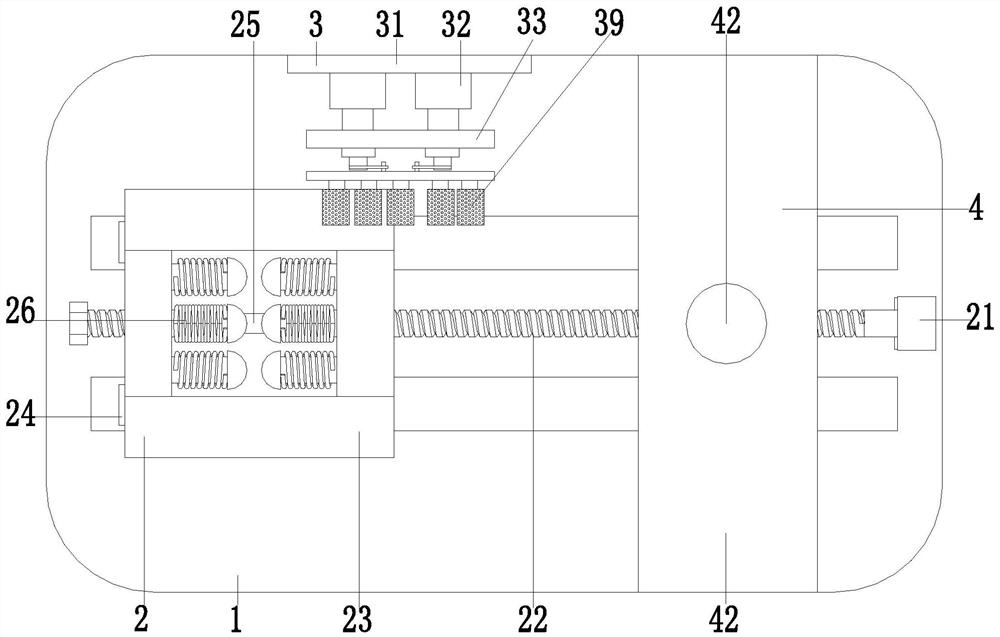

Bathroom pipeline joint forming finish machining treatment process

InactiveCN111941188AEasy to useStable profileEdge grinding machinesGrinding carriagesPolishingStructural engineering

The invention relates to a bathroom pipeline joint forming finish machining treatment process, in particular to bathroom pipeline joint forming finish machining treatment equipment. The equipment comprises a bottom plate, a movable clamping device, a polishing device and an anti-corrosion device, a sliding groove is formed in the middle of the bottom plate, and the movable clamping device is installed on the bottom plate in a sliding fit manner. The polishing device is installed in the middle of the bottom plate, and the anti-corrosion device is installed at the right side of the bottom plateand located on the right side of the polishing device. The equipment can solve the problems that when an existing device clamps a pipeline joint, the pipeline joint cannot be stably clamped, consequently, the pipeline joint is unstable during polishing, the polishing quality of the pipeline joint is affected, residues in the pipeline joint cannot be cleaned up, the spraying anti-corrosion effect is affected, residual rust on the polished surface cannot be cleaned up in time, and burrs are still adhered to the surface of the pipeline joint due to over-high temperature of the surface of the pipeline joint.

Owner:谢祥松

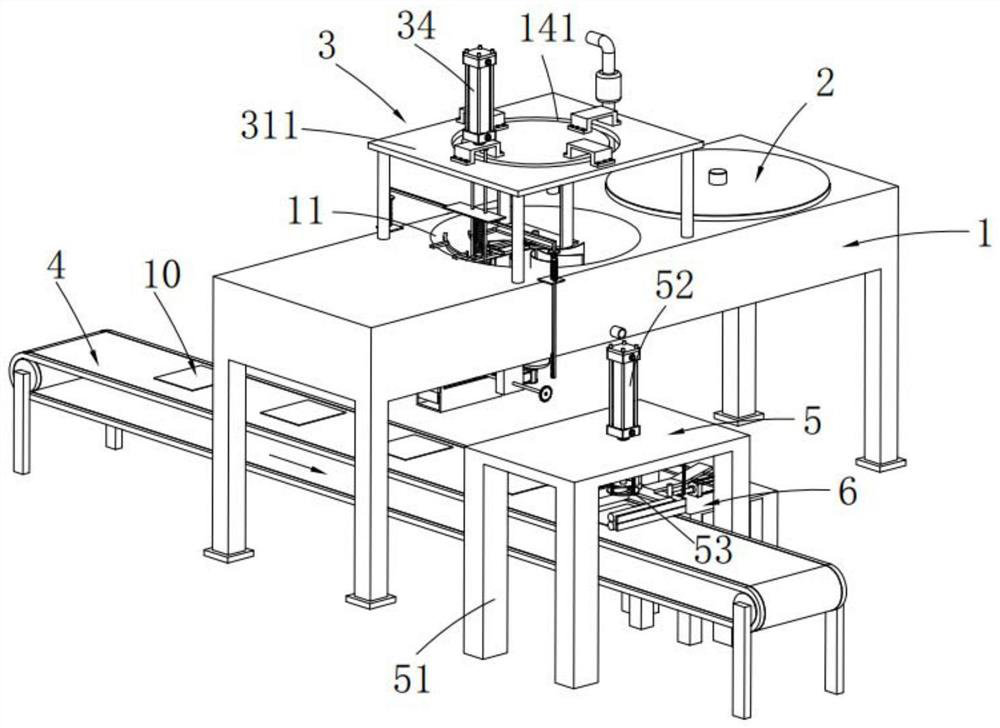

Automatic traditional Chinese medicine patch forming equipment

ActiveCN112274427AGuaranteed flatnessImprove flatnessPharmaceutical product form changeMetal working apparatusPoulticeMechanical engineering

The invention relates to the technical field of traditional Chinese medicine production, in particular to automatic traditional Chinese medicine patch forming equipment. The equipment comprises a first base and decocting equipment arranged on the first base, and a forming mechanism comprises a stirring assembly, a gathering assembly, a discharging assembly and a first driving part; a first conveying mechanism evenly conveys base cloth in the conveying direction of the first conveying mechanism; and a profiling mechanism comprises a second base, a first air cylinder and a profiling assembly. After plaster slurry is subjected to fire toxin removal and gathering in a water cooling tank through cooperation of the gathering assembly and the stirring assembly, the plaster slurry is cut into small parts through cutters acting at intervals, the small parts are conveyed to base cloth on a second conveying mechanism, a thin film is conveyed to a pressing station through a film conveying mechanism, when the base cloth, the plaster slurry and the thin film are pressed and formed by a pressing mechanism, the flatness of the thin film is guaranteed by a film feeding mechanism, automatic formingof a traditional Chinese medicine patch is achieved, the flatness of the thin film is improved, and therefore the forming quality of the traditional Chinese medicine patch is improved.

Owner:安徽美邸康药业有限公司

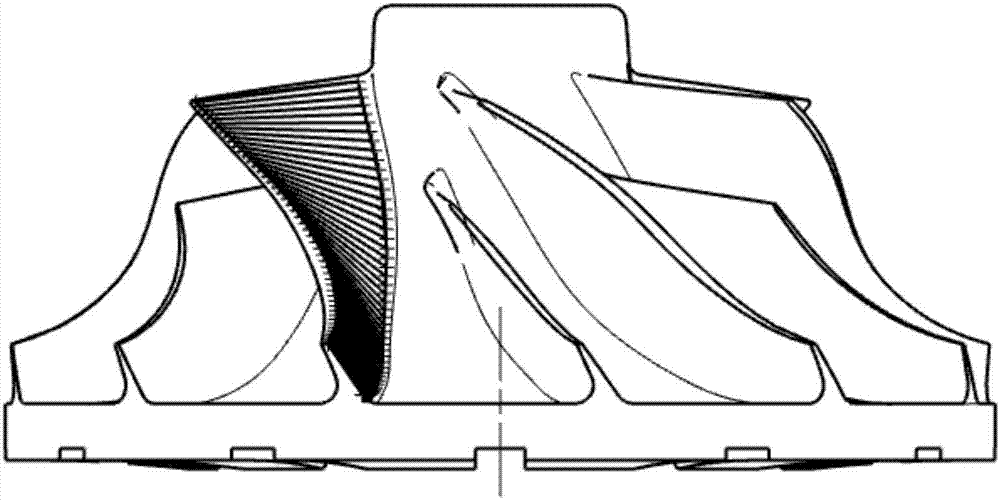

Process method for reducing impeller blade side milling machining deformation errors

InactiveCN107052420AIncrease stiffnessEffective control of processing deformationMilling equipment detailsImpellerMilling cutter

The invention discloses a process method for reducing the deformation error of the side milling of the impeller blade; firstly, a rough machining allowance is reserved, and then, along the impeller root curve with the reserved excess allowance and another curve opposite to the impeller root Take equal enough points respectively, connect the corresponding points taken on the two curves, use NX secondary development to program to form tool positions and perform rough machining; finally, use conical milling cutter side milling for semi-finishing and finishing Machined to the required size. The side milling process according to the method can effectively control the machining deformation of the impeller blade, reduce the machining error, improve the rigidity of the impeller blade, improve the quality of the blade surface, and improve the processing efficiency. Compared with the traditional method, the error of side milling deformation is effectively reduced.

Owner:SHANGHAI INST OF TECH

A ceramic mold for bending and forming glass plates

ActiveCN110316944BImprove profile qualityMeet bending and forming needsGlass reforming apparatusGlass sheetWindshield

The invention relates to the technical field of glass molding, in particular to equipment for bending of a glass panel, and particularly provides a ceramic die for bending molding of the glass panel.The ceramic die comprises a ceramic terrace die and multiple electric heating elements, the ceramic terrace die is provided with side walls and a bottom wall, the electric heating elements are arranged in the bottom wall, the outer surface of the bottom wall is provided with a convex molded surface, a vacuum cavity is formed in the ceramic terrace die, and negative pressure can be generated in thevacuum cavity; at least one partition vacuum mechanism is further additionally arranged in the vacuum cavity, each partition vacuum mechanism is provided with a partition vacuum cavity, and partitionnegative pressure can be generated in the partition vacuum cavities. The ceramic die can meet the requirement of front windshields with HUD areas, installing areas of rainwater sensors or light sensors or other optical elements and installing areas of cameras bending molding, and can lower the glass molded surface fluctuation, and finally, the glass panel with higher-quality molded surfaces is obtained; moreover, the bending molding quality of peripheral sides with higher molding difficulty can be guaranteed.

Owner:FUYAO GLASS IND GROUP CO LTD

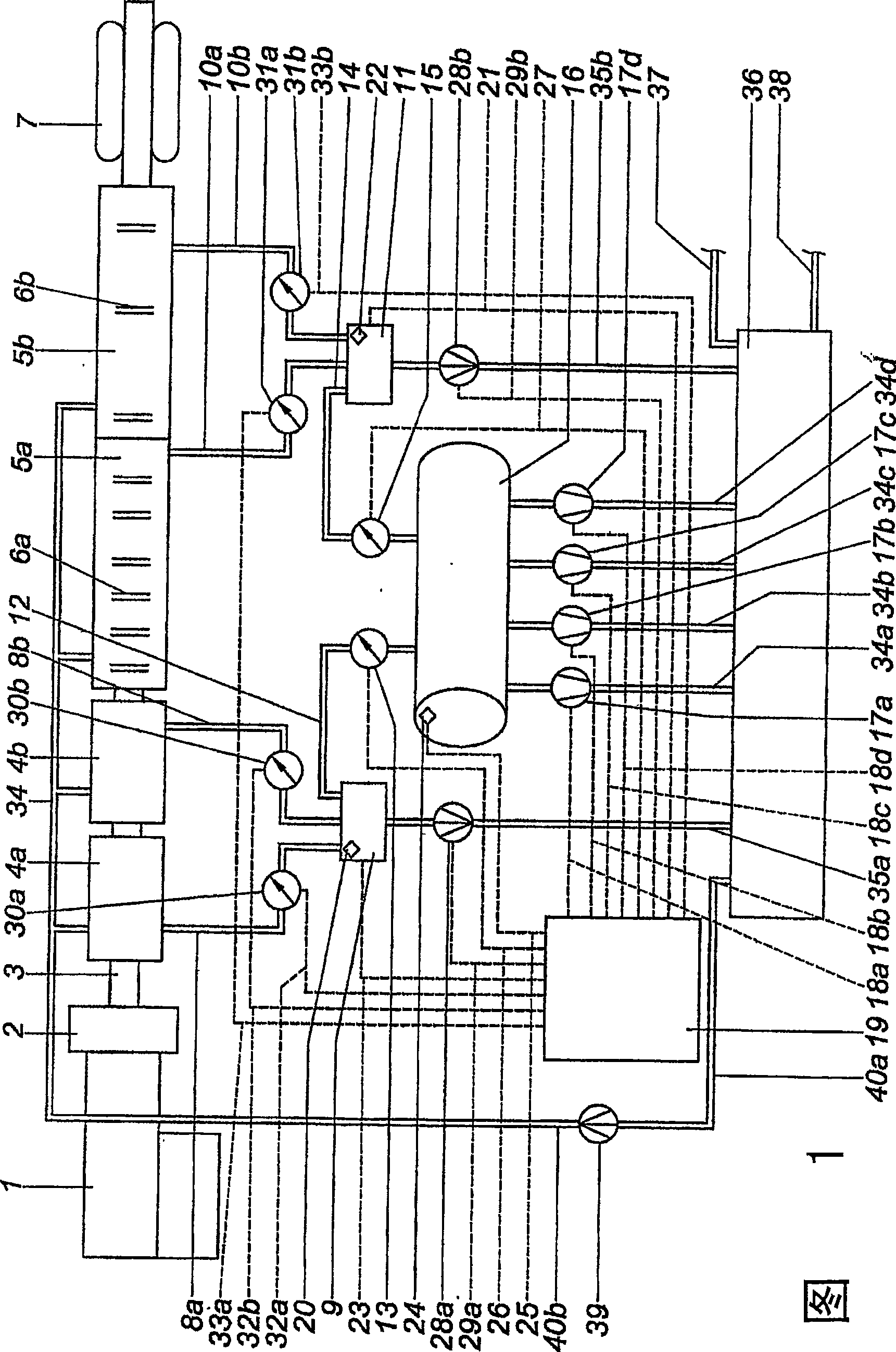

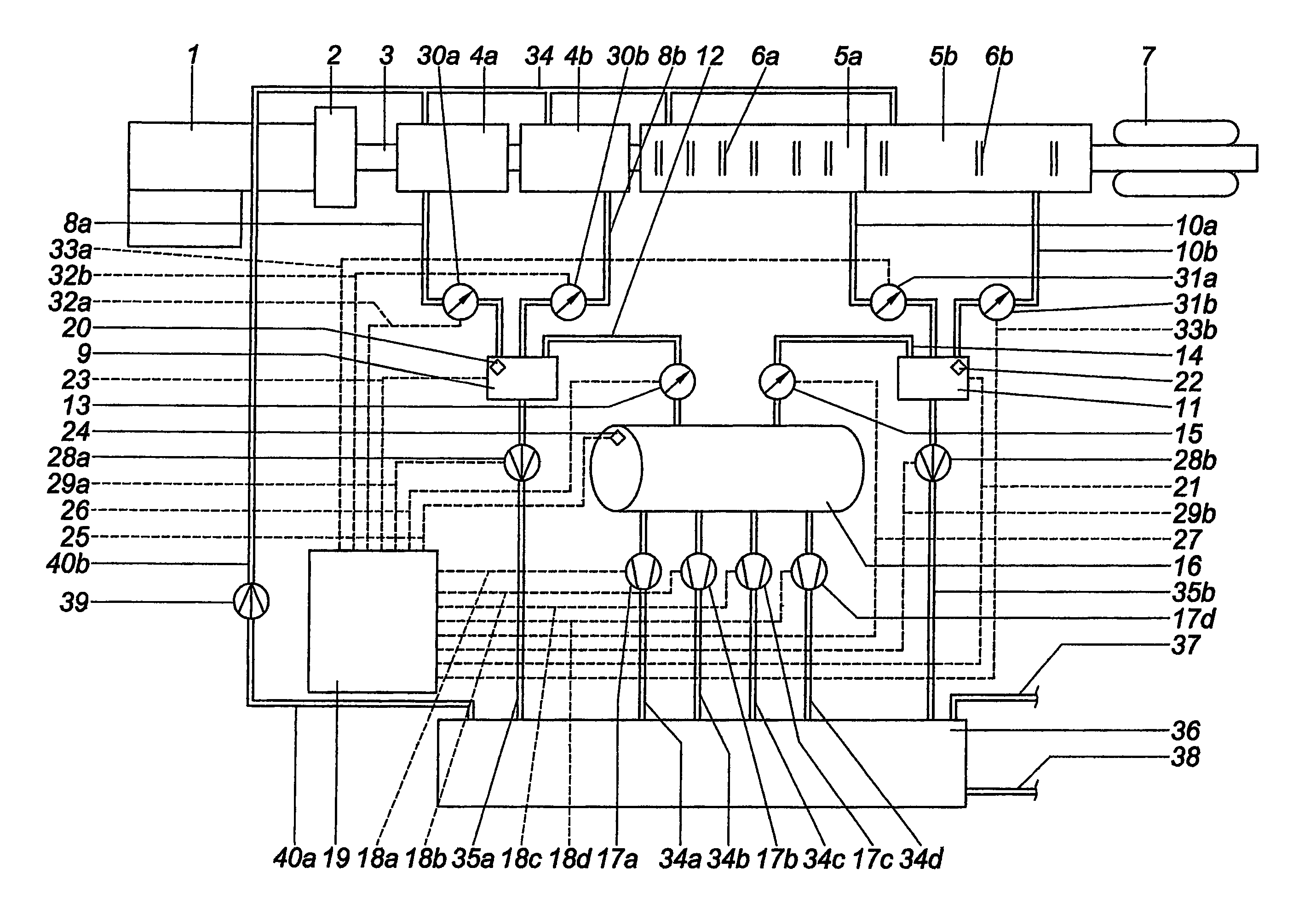

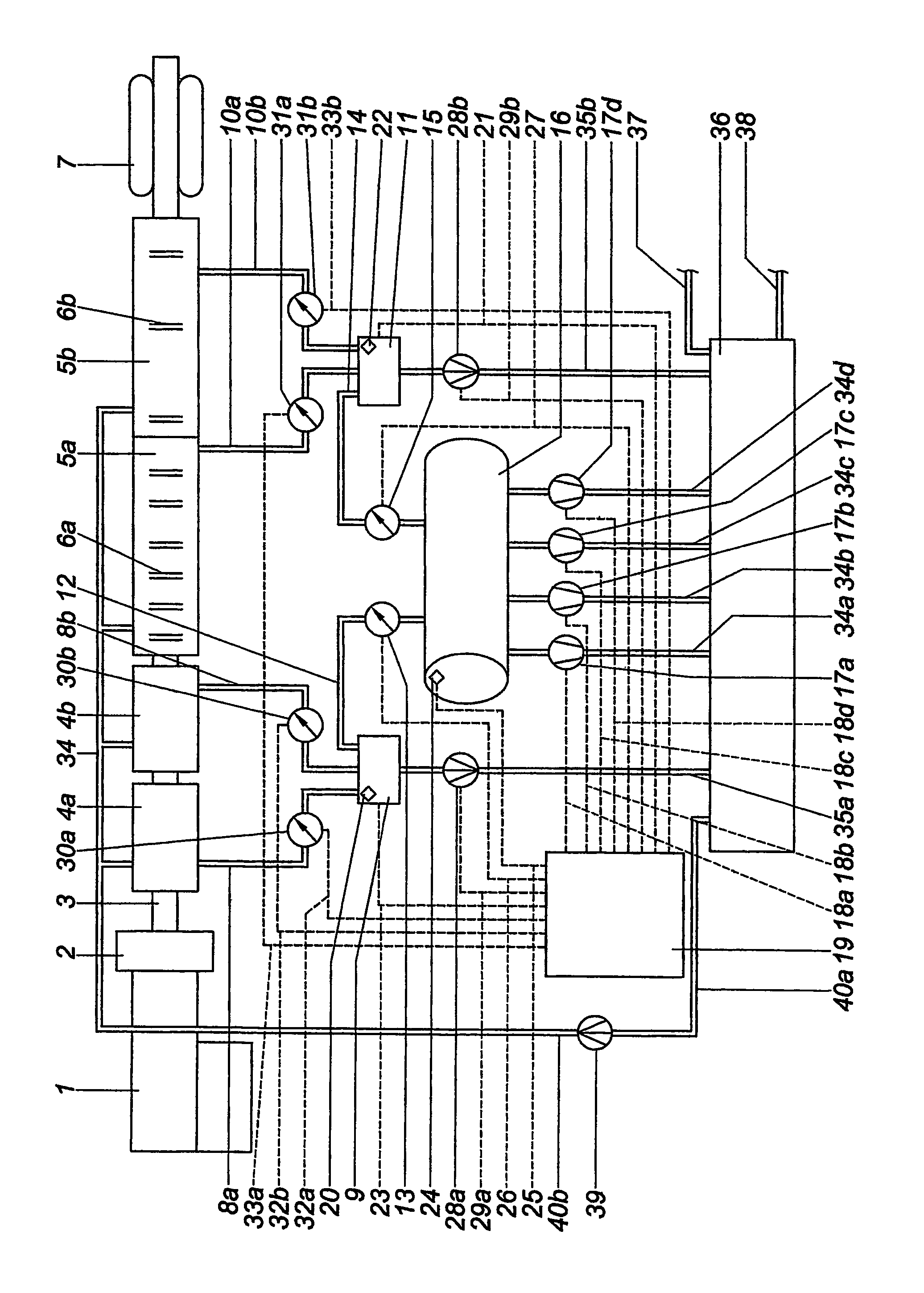

Method and device for regulating the vacuum supply of calibration tools

InactiveCN100498630CImprove profile qualityPressure Priority AdjustmentFluid pressure control using electric meansEngineeringBiology

The invention relates to a method for vacuum supply of a calibration tool (4a, 4b; 5a, 5b), comprising at least one dry calibration tool (4a, 4b) and at least one calibration tank (5a, 5b). According to the method described, at least one vacuum pump (17a, 17b, 17c, 17d) is required to be connected to the calibration tool (4a, 4b; 5a, 5b) in order to extract air from the calibration tool (4a, 4b; 5a, 5b), Adjust the pressure in the calibration tool (4a, 4b; 5a, 5b) to the nominal value through the regulating valve (13, 15). The purpose of the invention is to reduce energy consumption and improve the quality of produced profiles. In order to achieve this purpose, a plurality of vacuum pumps (17a, 17b, 17c, 17d) extract air from a common pressure vessel (16) and draw air from at least one dry in said common pressure vessel (16) through a first regulating valve (13). The calibration tool (4a, 4b) extracts air and, in addition, air is extracted from at least one calibration tank (5a, 5b) in the common pressure vessel (16) via a second regulating valve (15). Furthermore, the invention relates to a device for carrying out said method.

Owner:TECHNOPLAST KUNST GES

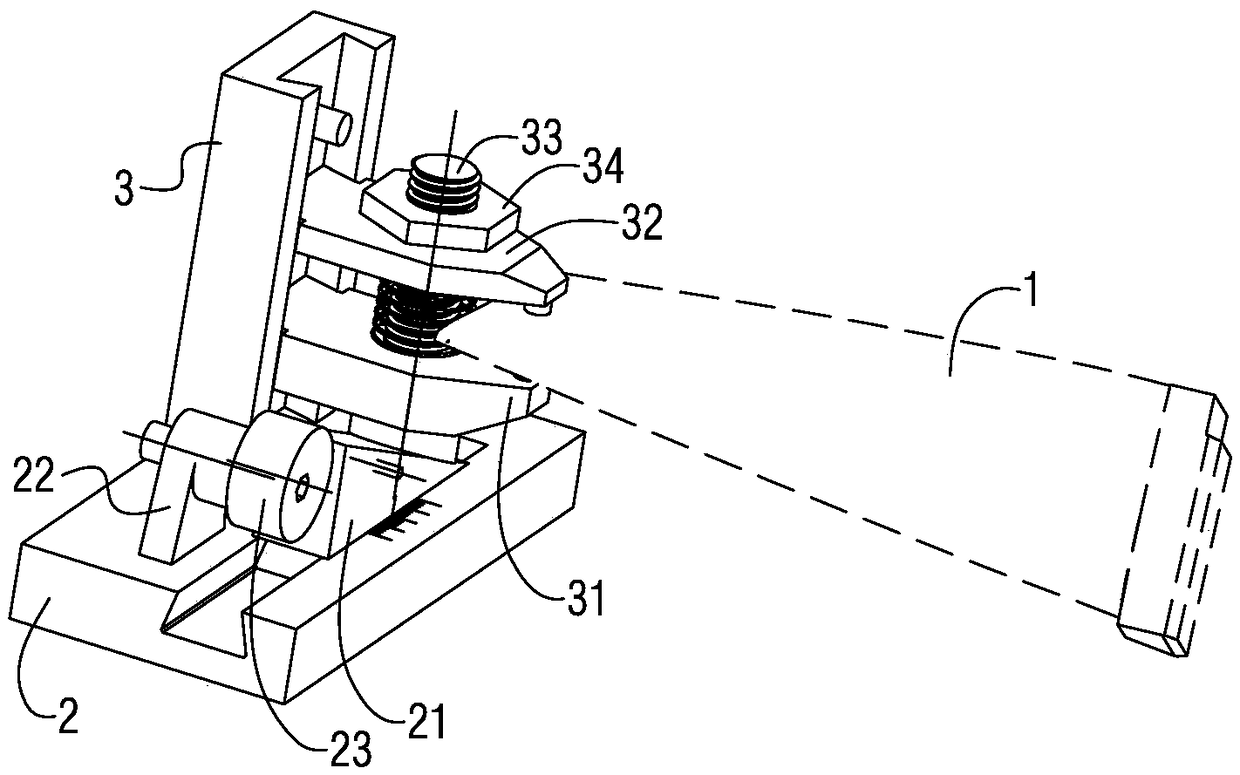

A kind of clamping method of compressor blade and used clamp

ActiveCN106392714BReduce lossReduce processing deformationPositioning apparatusMetal-working holdersMachining deformationWaste product

The invention provides an air compressor blade clamping method. The air compressor blade clamping method comprises the following steps: step A. ensuring that the length of the tip of the blade is 6-8mm in a forged piece forming process; and step B. providing the clamp to ensure that the tip of the blade is located between a locating plate and a pressing plate, causing the locating plate to contact with the tip of the blade by rotating an eccentric wheel, and causing the pressing plate to clamp the tip of the blade by rotating a nut, thereby completing the clamping of an air compressor blade blank. The air compressor blade clamping method has the beneficial effects that the accurate positioning and clamping of variable positioning surfaces of parts can be realized; the machining deformation is reduced; the quality of molded surfaces of the parts is improved; the loss of waste products is reduced; in addition, the margin range of the molded surfaces can be monitored to explore the machining quality of the part blanks. The invention also provides the clamp for the air compressor blade clamping method.

Owner:CHINA HANGFA SOUTH IND CO LTD

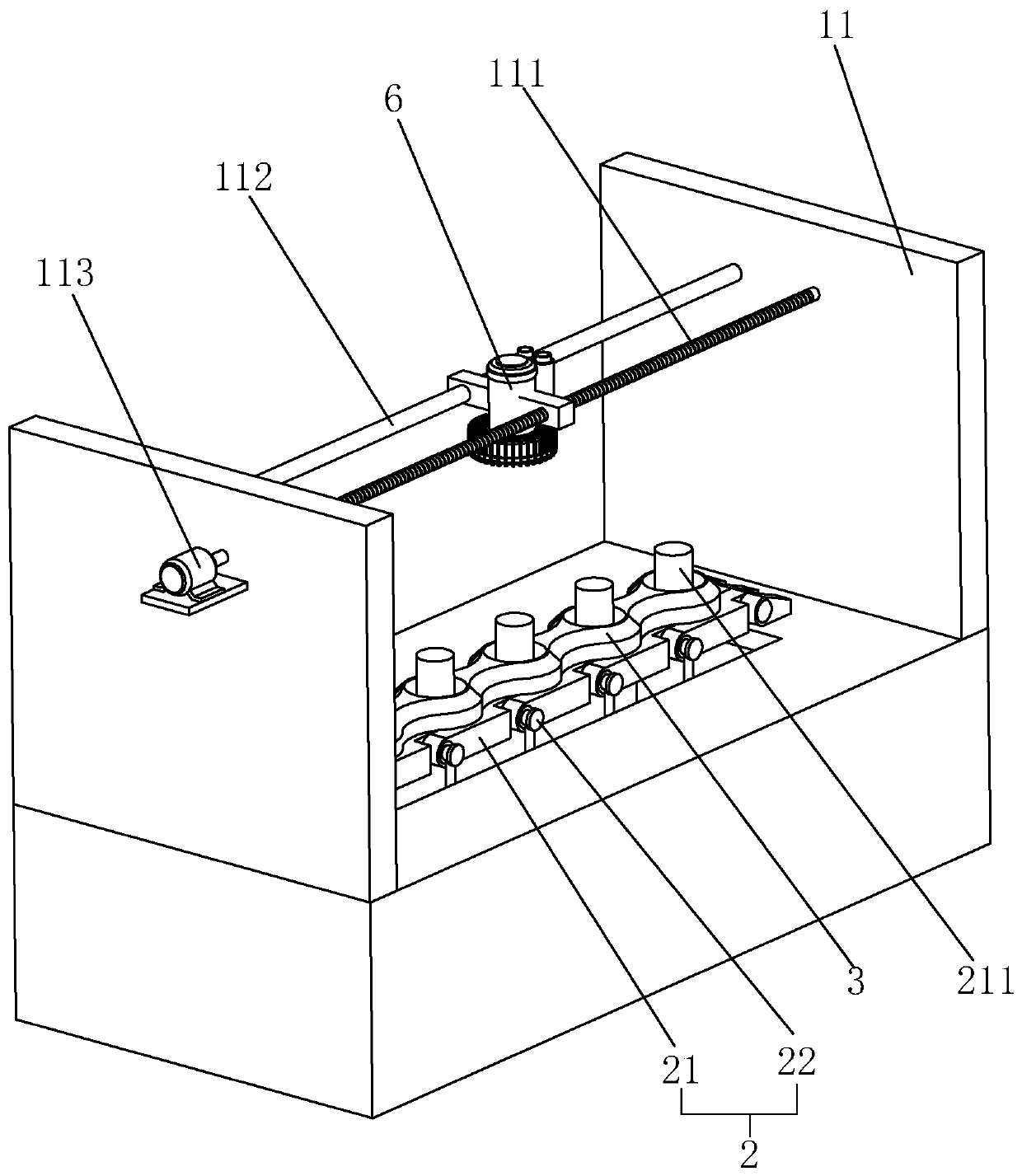

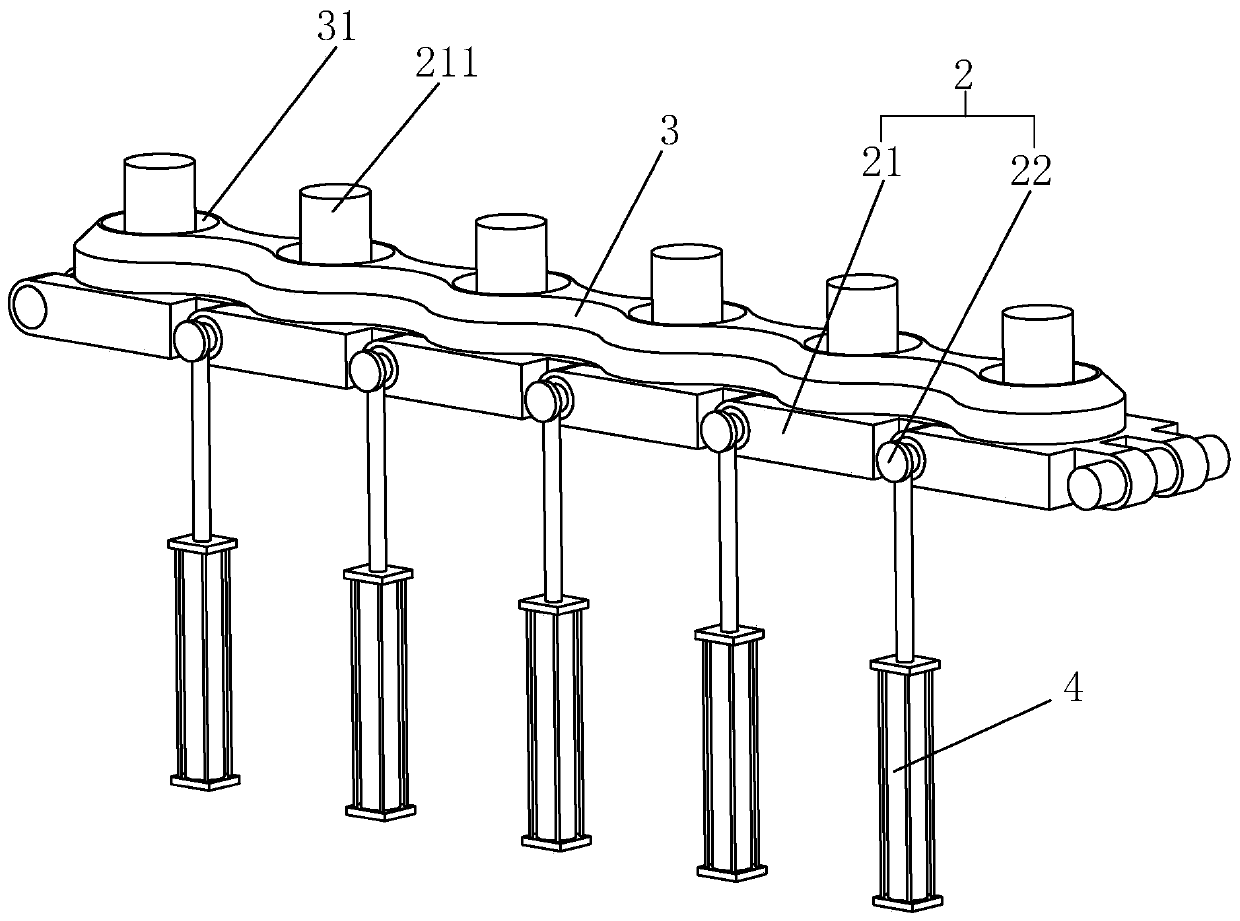

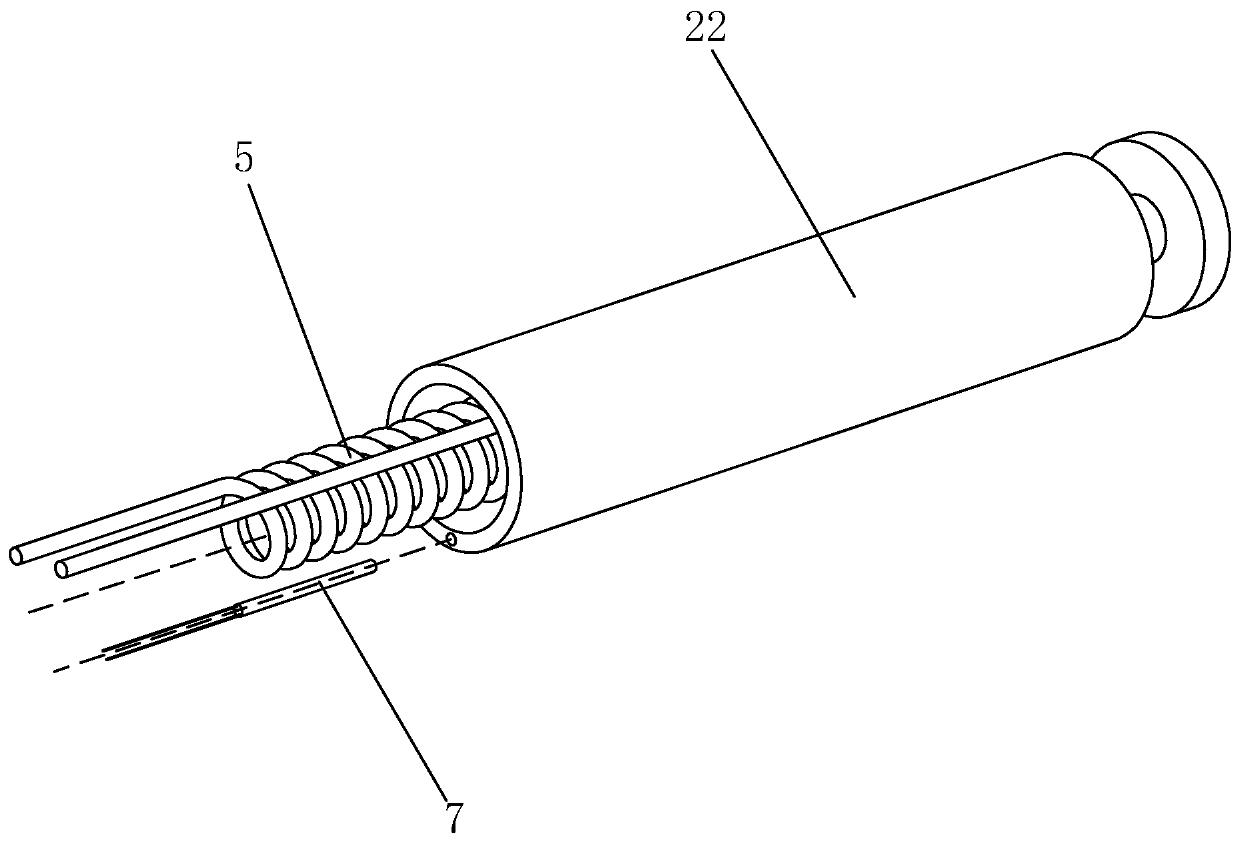

Absorbable bone plate profiling shaping structure and method thereof

The invention relates to an absorbable bone plate profiling shaping structure and a method thereof, which belong to the technical field of absorbable bone plates. The plate fixing jig includes a plurality of jig joint units connected end to end and a connecting shaft arranged between every two adjacent jig joint units, and every two adjacent jig joint units are hingedly connected by the connecting shaft, and the bone plate fixing jig The body of the absorbable bone plate is relatively fixed on the top, and the frame is fixed with a plurality of driving parts. Each driving part is fixed to one end of the corresponding connecting shaft to drive the connecting shaft to move upward. A heating device is installed inside the connecting shaft, which can A cooling system for cooling is installed on the upper part of the absorbable bone plate to overcome the limitations of the absorbable bone plate in the curved surface environment of the fracture site, greatly reduce or eliminate the internal stress of the absorbable bone plate, and improve the performance of the absorbable bone plate. strength and longevity.

Owner:ZHEJIANG BOSHUOBEI BIOLOGICAL TECH

Process method for enhancing the milling rigidity of aluminum alloy ultra-thin blade overall impeller

Owner:SHANGHAI INST OF TECH

Hot drawing-air bulking composite forming method for high-temperature titanium alloy skin

PendingCN113996711AHigh precisionReduce lossesAircraft componentsShaping toolsMetallurgyTitanium alloy

The invention relates to a hot drawing-air bulking composite forming method for high-temperature titanium alloy skin, belonging to the technical field of hot forming of high-temperature titanium alloy. The invention aims to solve the problem of poor forming quality of high-temperature titanium alloy complex profile parts in the aerospace field in the prior art. According to the method, a high-temperature titanium alloy blank is subjected to hot drawing in a one-time hot forming process, the high-temperature titanium alloy blank is preliminarily attached to a die, and then the high-temperature titanium alloy blank is completely attached to the mold through air bulking forming. According to the method, a composite forming process combining hot drawing and air bulking is adopted, so the skin blank is preliminarily attached to the convex-concave die during hot drawing and completely attached to the convex-concave die under an air bulking condition, the profile precision of the part is improved, and the loss of mechanical properties is reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Absorbable bone plate profiling shaping structure and method thereof

The invention relates to an absorbable bone plate profiling shaping structure and a method thereof, and belongs to the technical field of absorbable bone plate. The structure includes a rack; the upper surface of the rack is provided with a bone plate fixing fixture; the bone plate fixing fixture includes a plurality of end-to-end clamp joint units and connecting shafts arranged between each two adjacent clamp joint units, and each two adjacent fixture joint units are hinged and connected through the connecting shaft. The bone plate fixing fixture is relatively fixedly provided with an absorbable bone plate body. The rack is fixedly provided with a plurality of driving parts. Each driving part is fixed with one end of the corresponding connecting shaft to drive the corresponding connectingshaft to move upward. The connecting shafts are each internally provided with a heating device, and the upper part of the absorbable bone plate body is provided with a cooling system for cooling, sothe effects of overcoming the limitation of the absorbable bone plate when being applied in a curved surface environment of a fracture part, greatly reducing or eliminating the internal stress of theabsorbable bone plate, and improving the strength and life of the absorbable bone plate are achieved.

Owner:ZHEJIANG BOSHUOBEI BIOLOGICAL TECH

An improved automobile laminated glass furnace outer pressing mold

InactiveCN104193154BReduce molding movementGuaranteed accuracyGlass reforming apparatusOptical propertyGlass furnace

The invention relates to an improved mould for out-of-furnace press forming of an automobile laminated glass. The improved mold comprises a convex mold (6) and a concave mold (20). The mold is characterized in that the concave mold (20) is provided with a side pre-press forming mechanism (21) and a glass following positioning mechanism (22), the side pre-press forming mechanism (21) comprises a side pre-press cylinder (31), a pre-press rotating shaft structure (32) and a concave mold side structure (18), and the glass following positioning mechanism (22) comprises a positioner rotating shaft (24), a positioning servo motor (25), a positioning speed reducer (26), a positioning coupler (27), a transmission gear (28), a rack (29), a positioner bracket (30), a positioning cylinder (33) and a positioning stop (34). Compared with the prior art, the mold has the advantages of meeting the quality and property requirements for the molded surface, goodness of fit, optical properties of glass products with a large spherical surface, a large span, high large arch rise and great side contour curvature change, improving the yield and the like.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

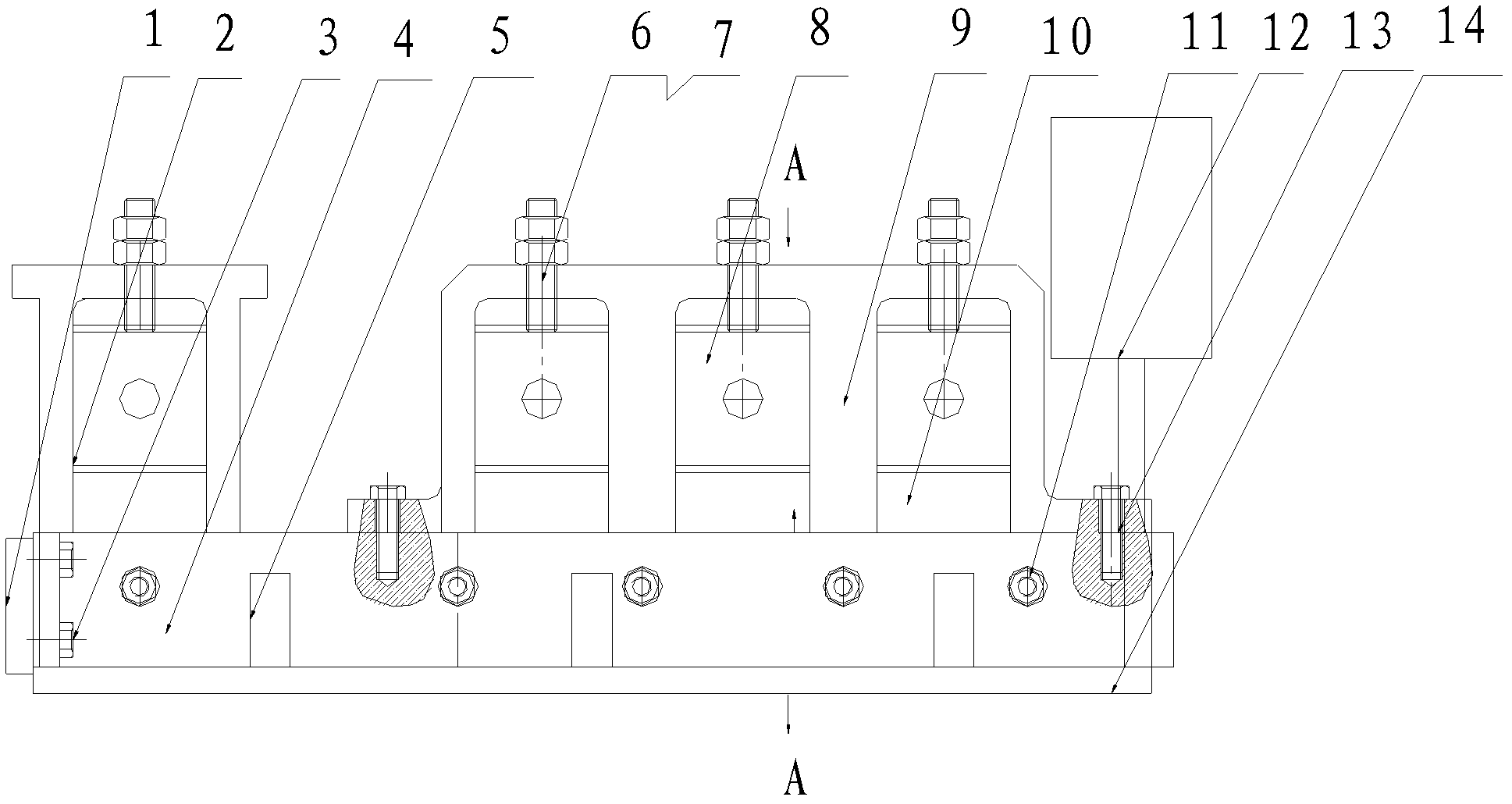

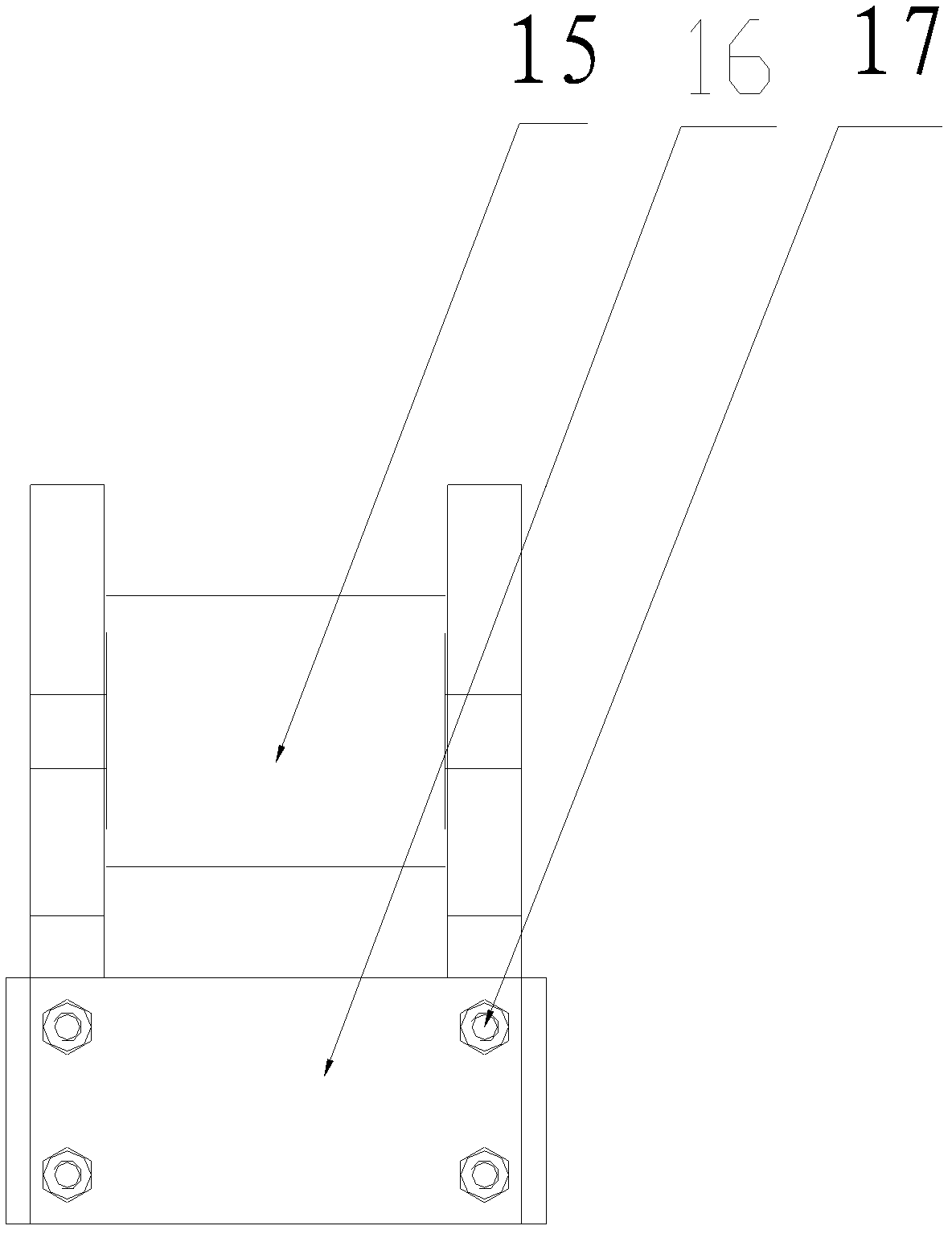

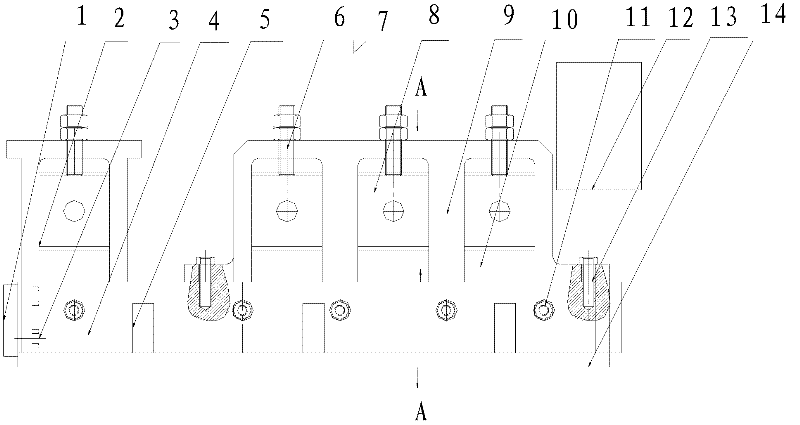

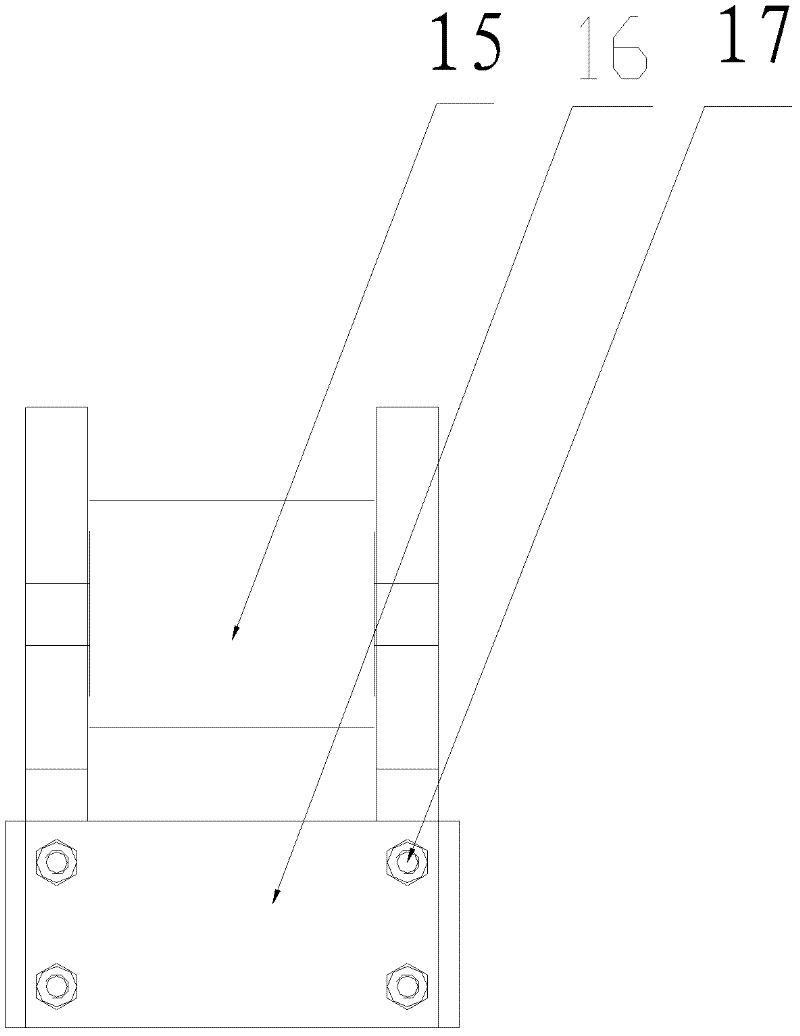

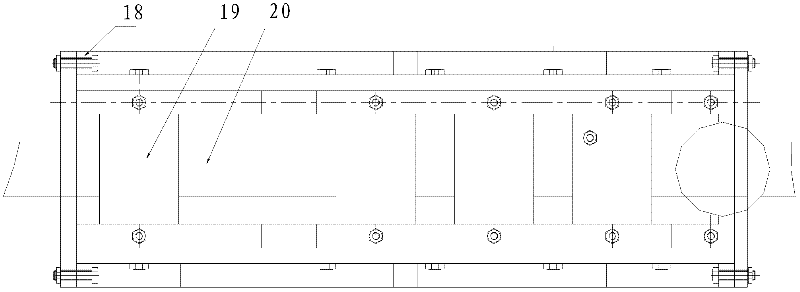

Copper bar roller alignment device for motor rotor coil edgewise-winding machine

ActiveCN102364838BExpand the scope of workUniform force distributionManufacturing dynamo-electric machinesWinding machineSingle support

The invention relates to a copper bar roller alignment device for a motor rotor coil edgewise-winding machine, and belongs to the technical field of generator rotor coil edgewise-winding. The copper bar roller alignment device for the motor rotor coil edgewise-winding machine is characterized by comprising a bottom plate, baffle plates, a single support, an integrated support, side pressure plates, positioning plates, support plates, floating pressure blocks and roller rotating shafts, wherein the single support and the integrated support are provided with adjustable notches and the floating pressure blocks which are connected together with the roller rotating shafts, and are fastened on a working platform by bolts; the side pressure plates are fastened on the two sides of each of the single support and the integrated support by the bolts; and the baffle plates, the positioning plates and the support plates are arranged at left and right ends by the bolts. The device has the advantages of saving cost, reducing consumption and widening the working range of the edgewise-winding machine, along with simple structure, high processibility, convenience of manufacture, copper bar stressing uniformity, high profiling quality and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

A Method for Controlling the Uniformity of Thermal Insulation Layer Structure

ActiveCN104848002BSwell evenlyAvoid displacementThermal insulationPipe protection by thermal insulationEngineeringGravitation

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

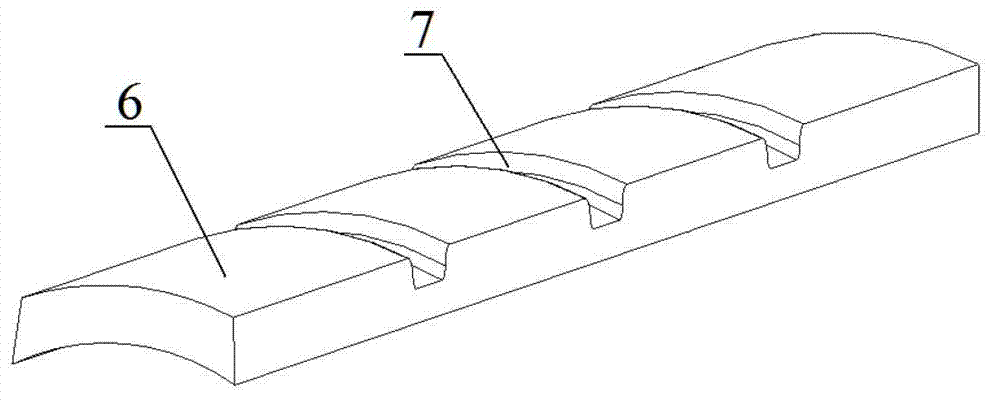

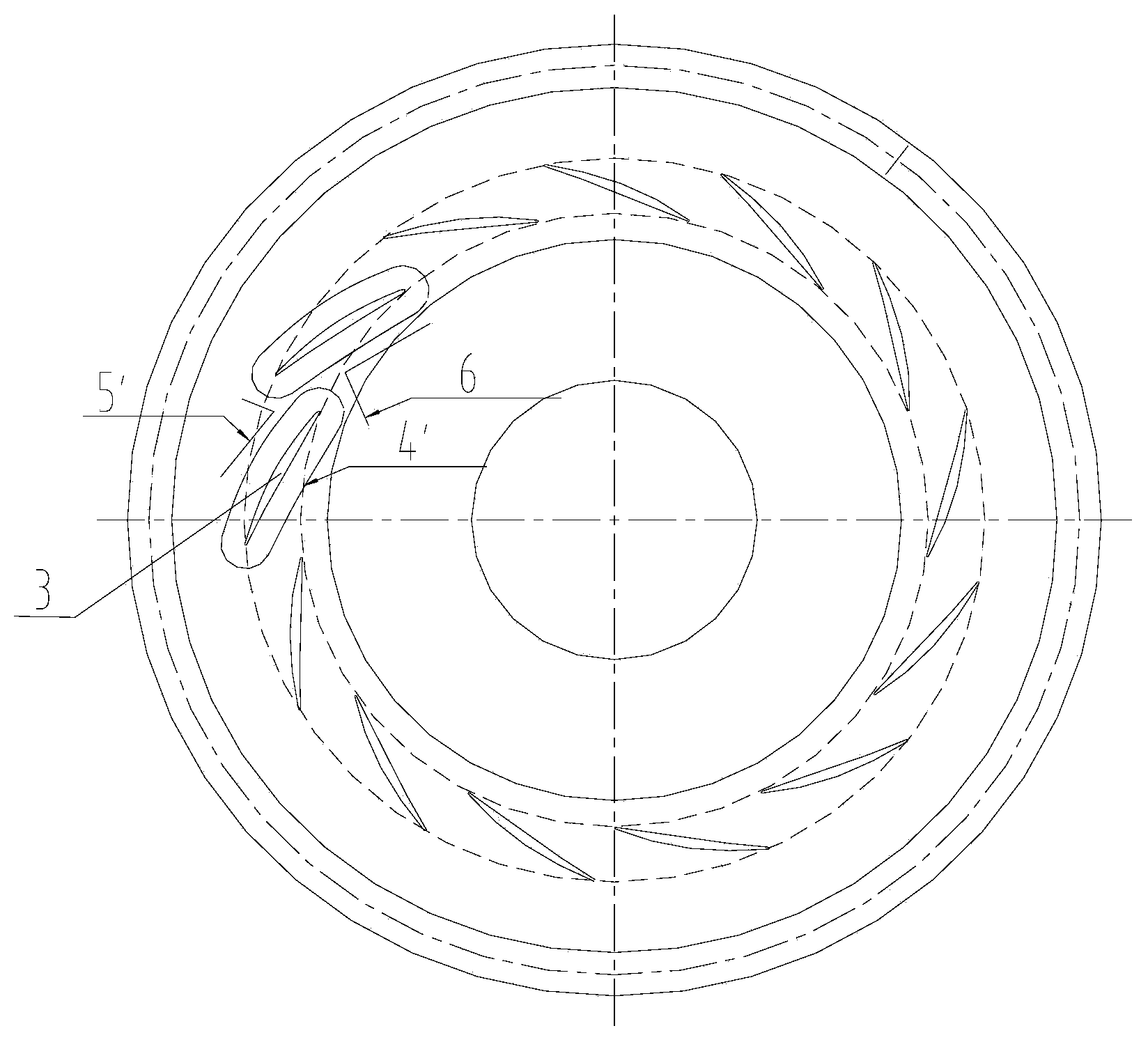

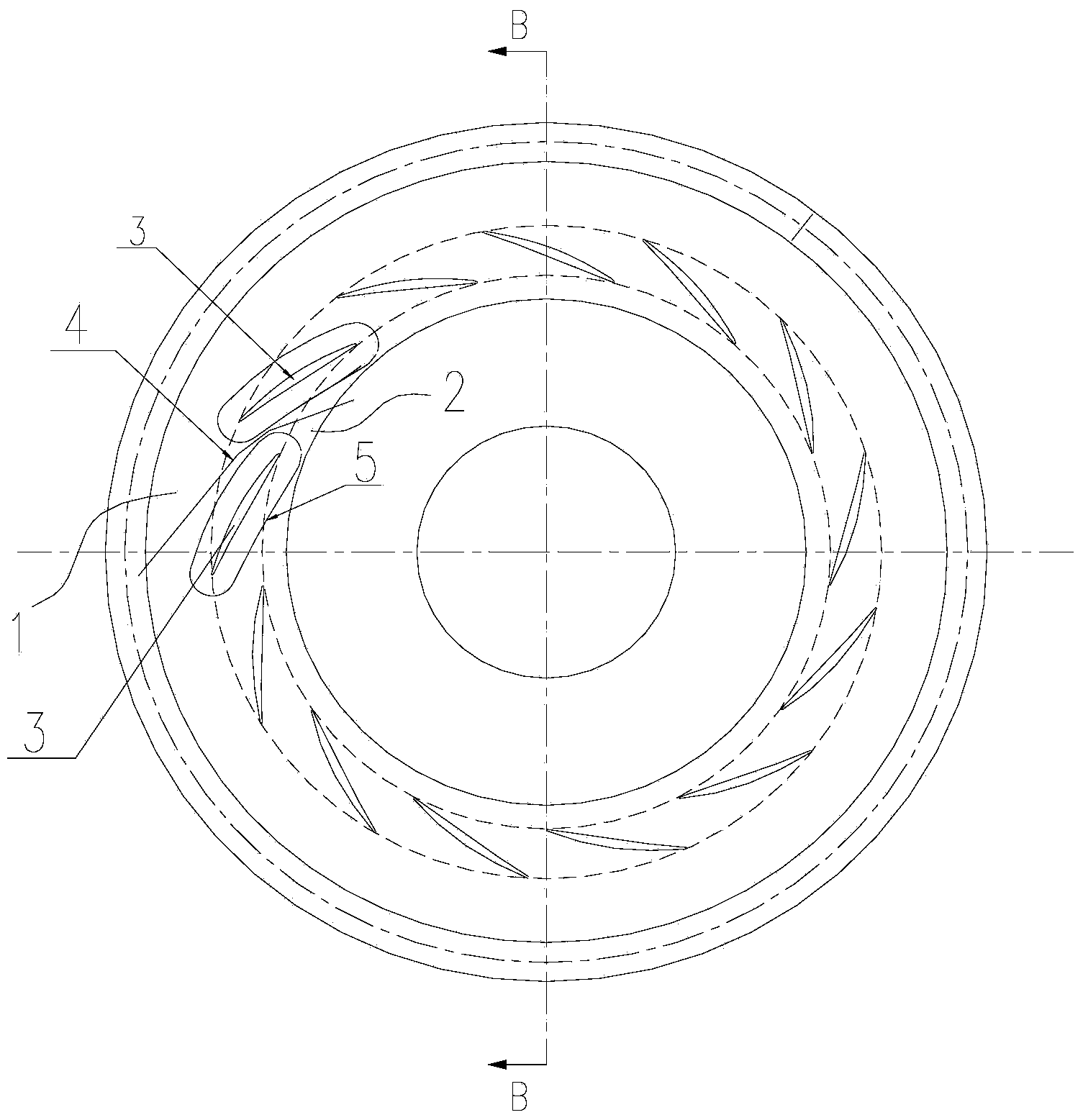

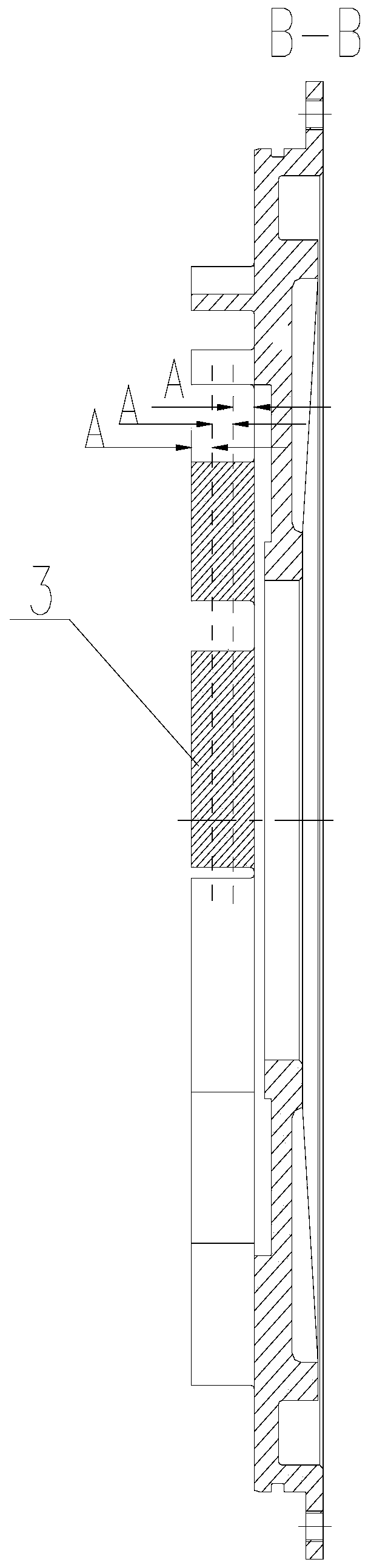

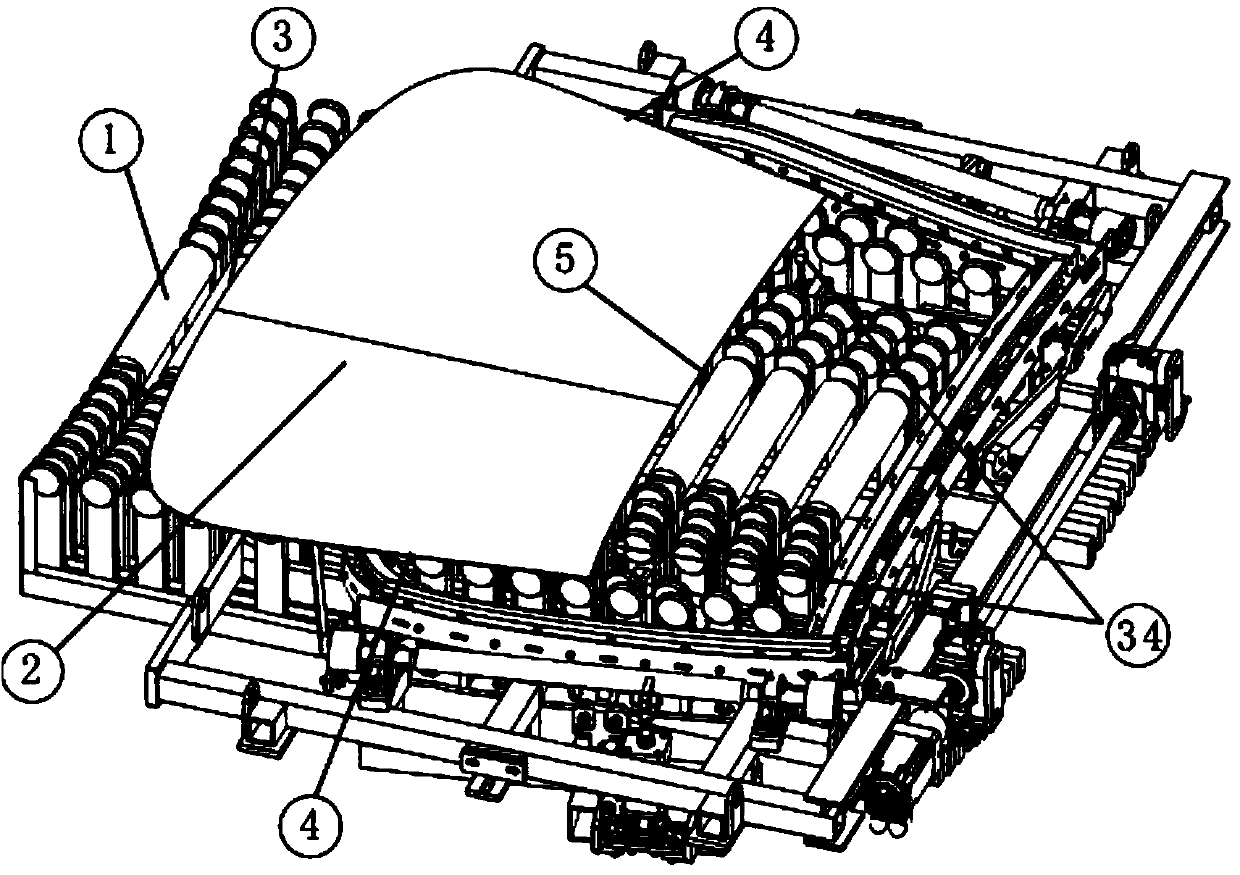

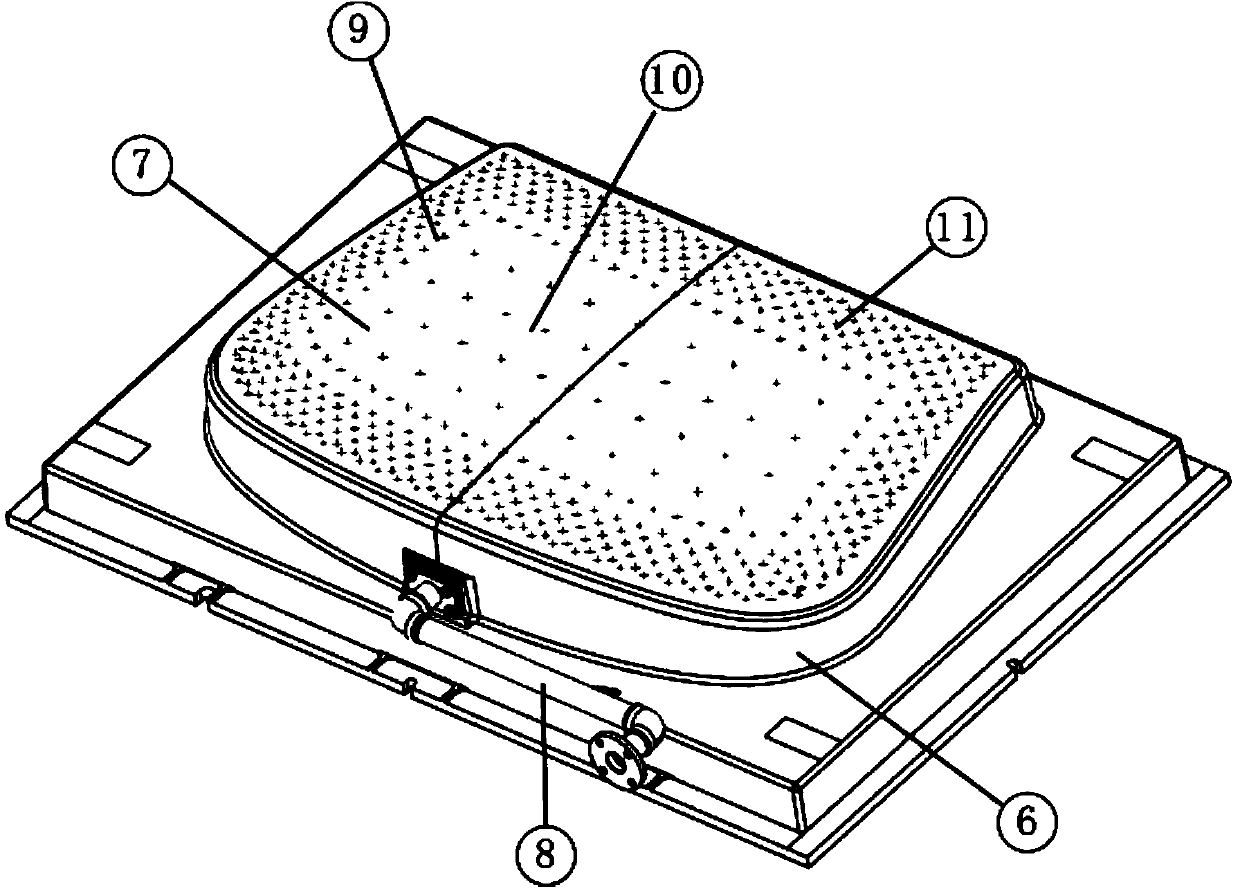

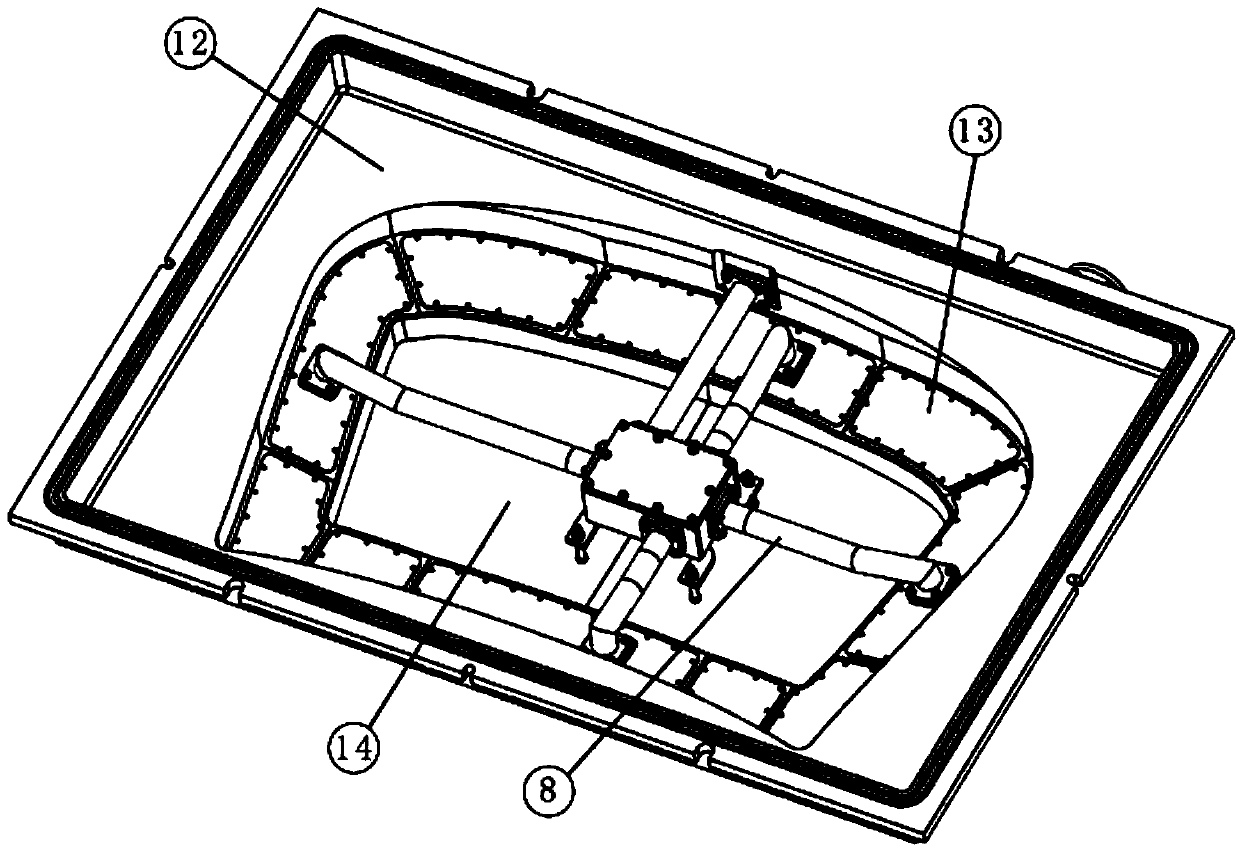

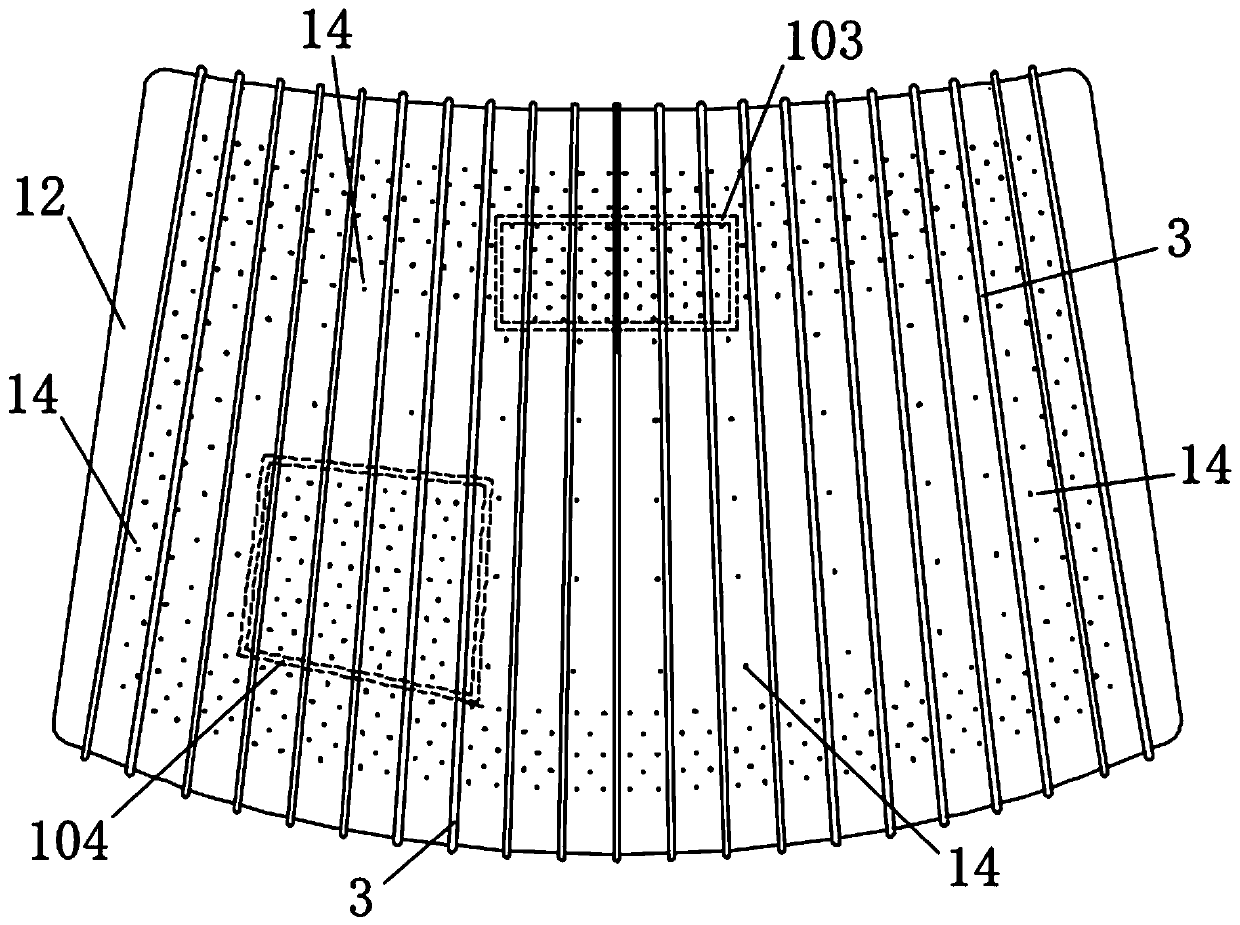

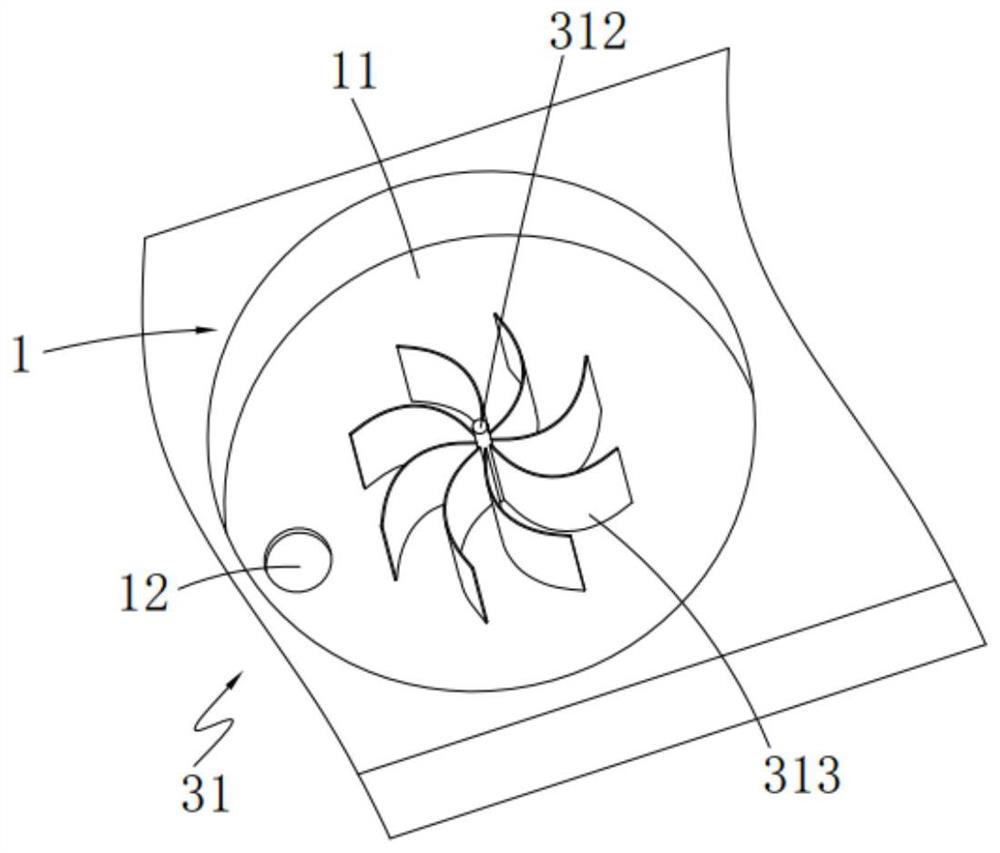

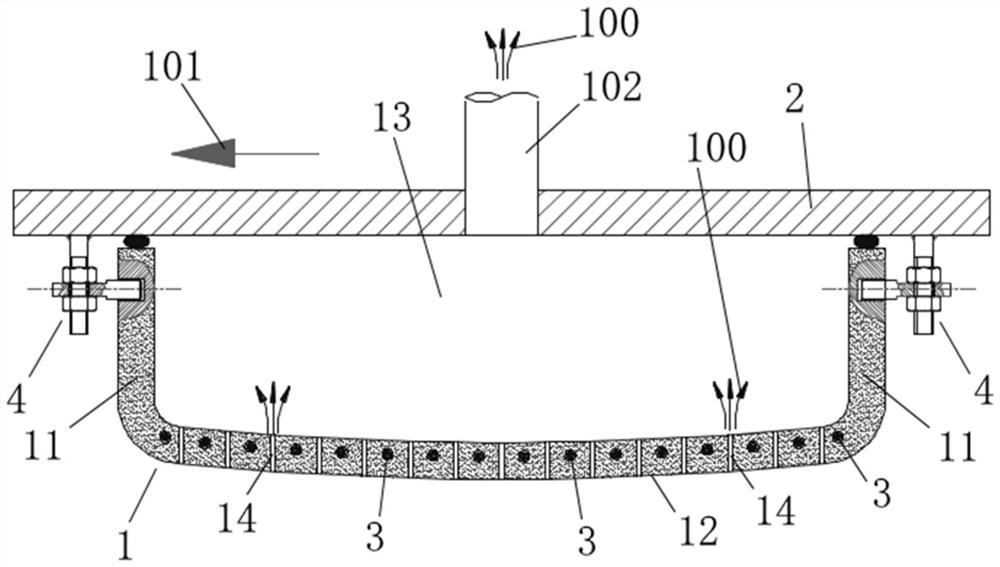

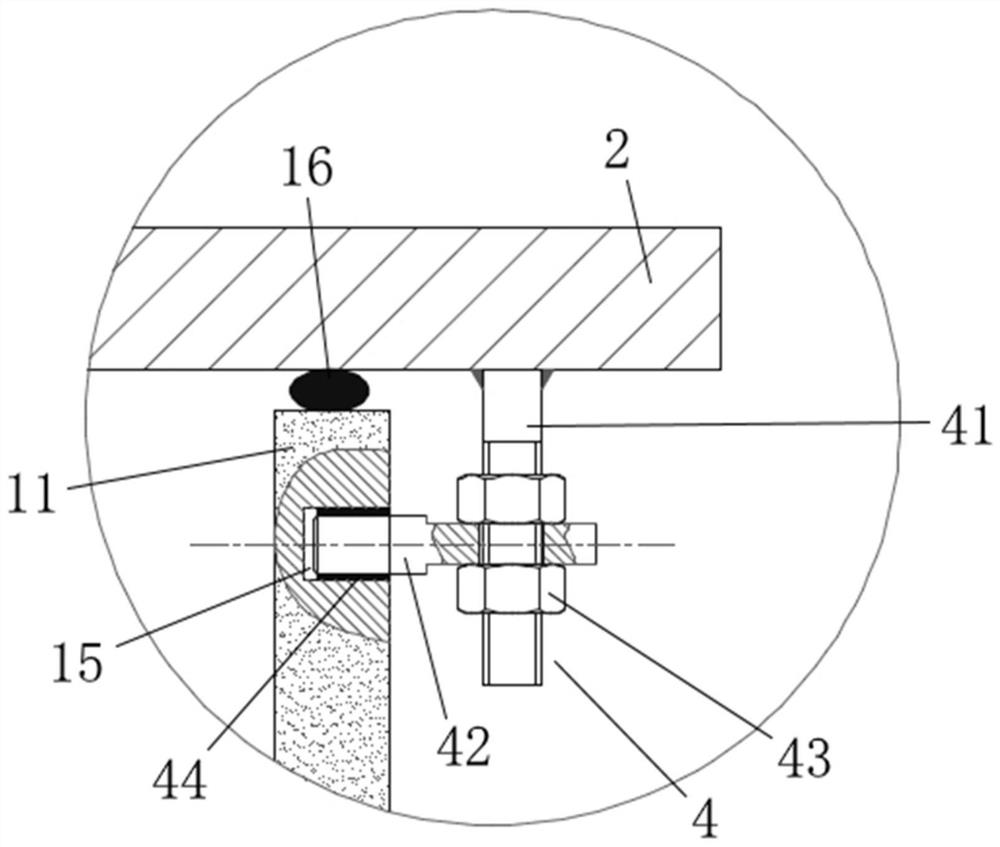

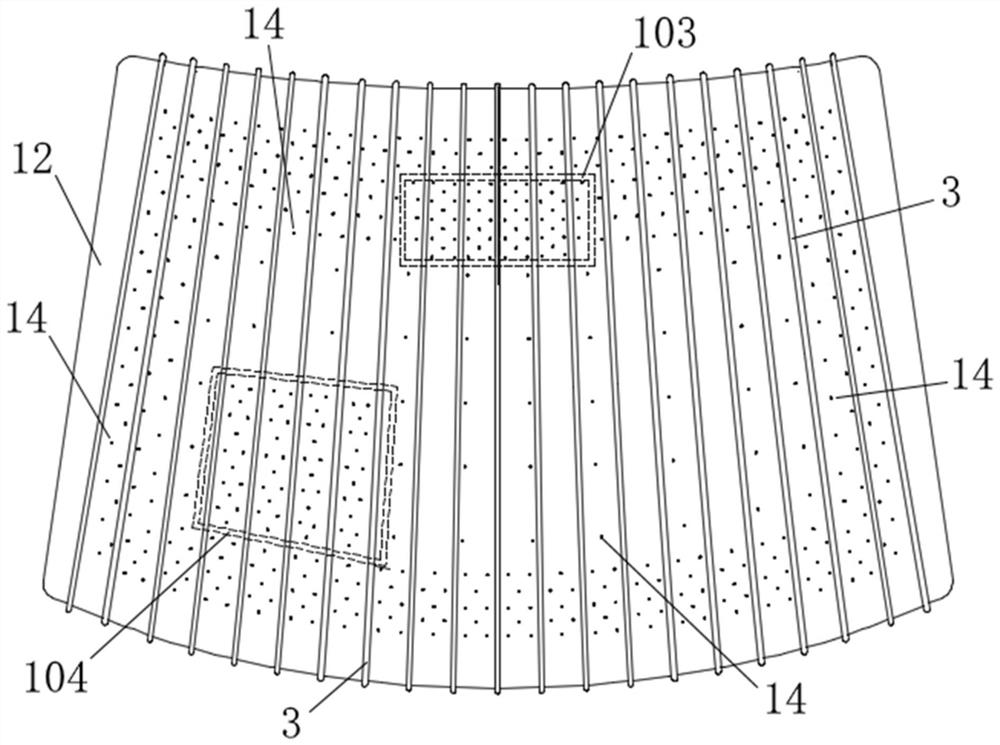

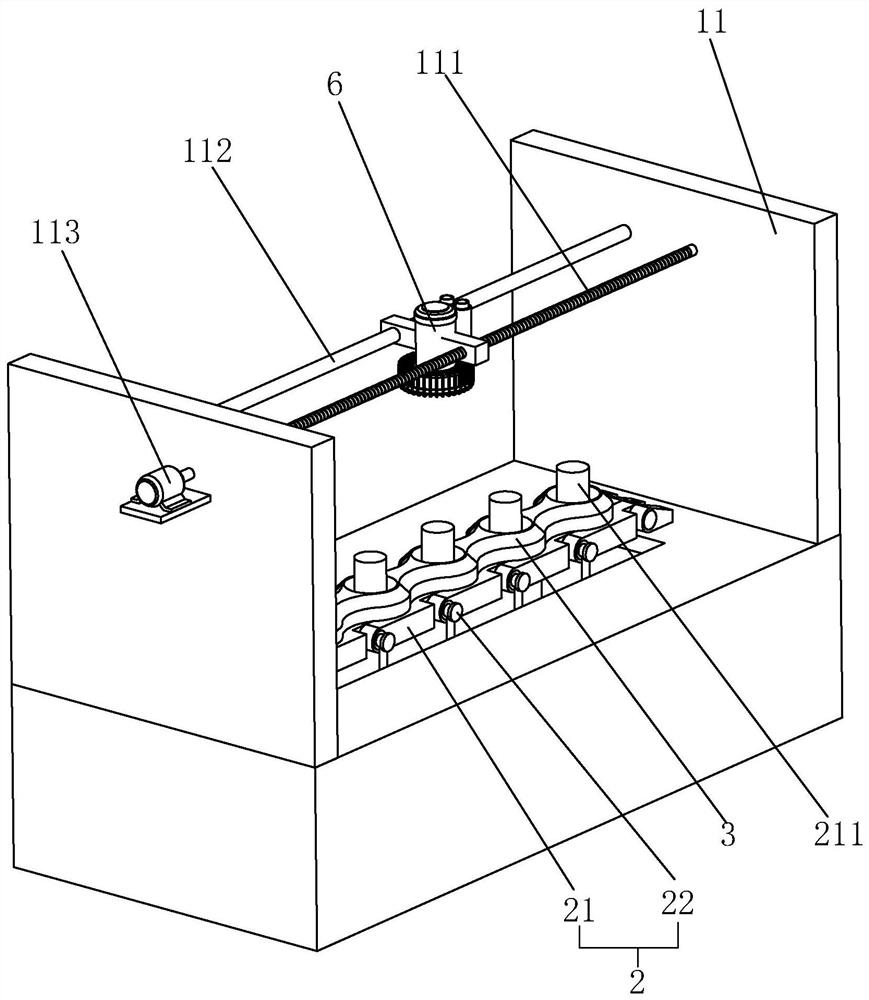

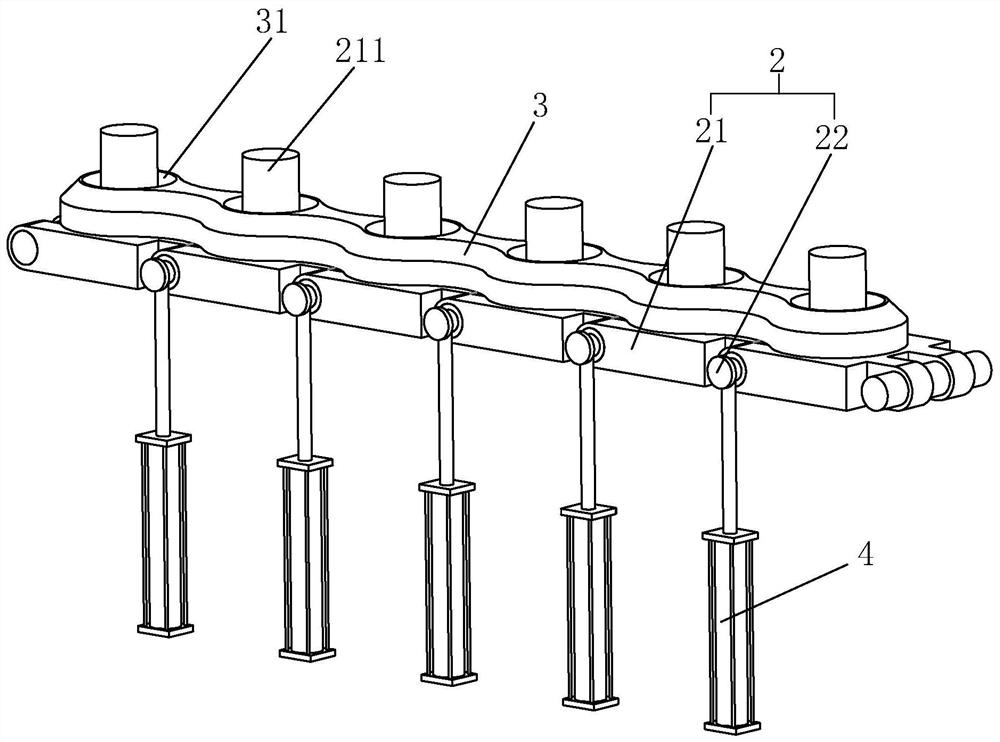

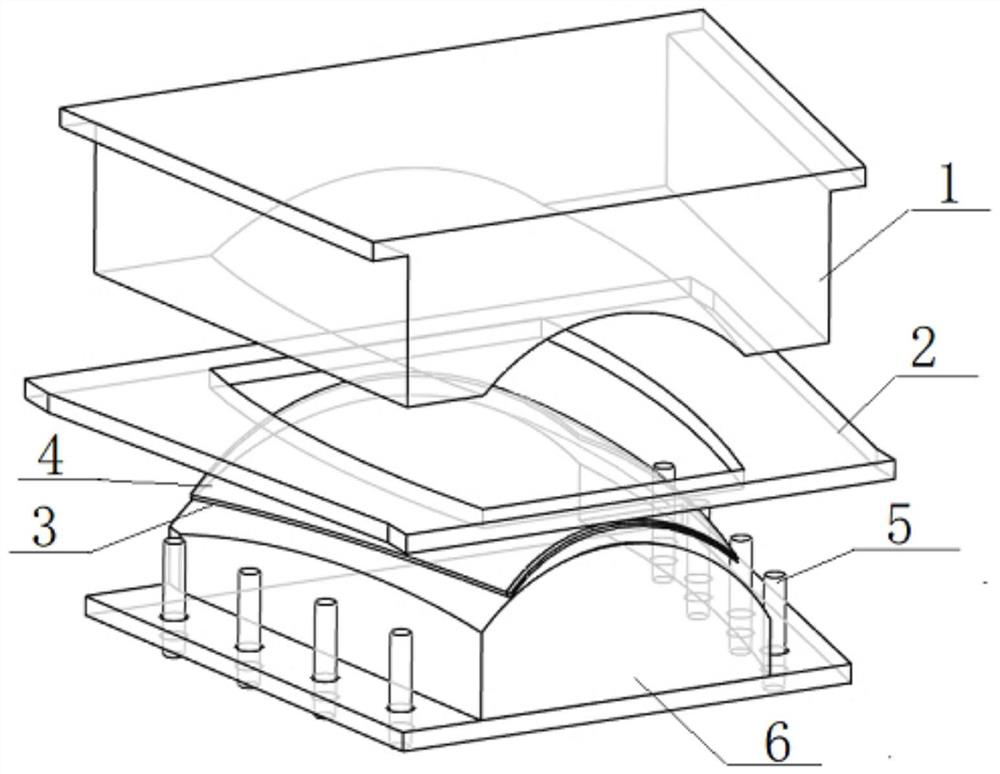

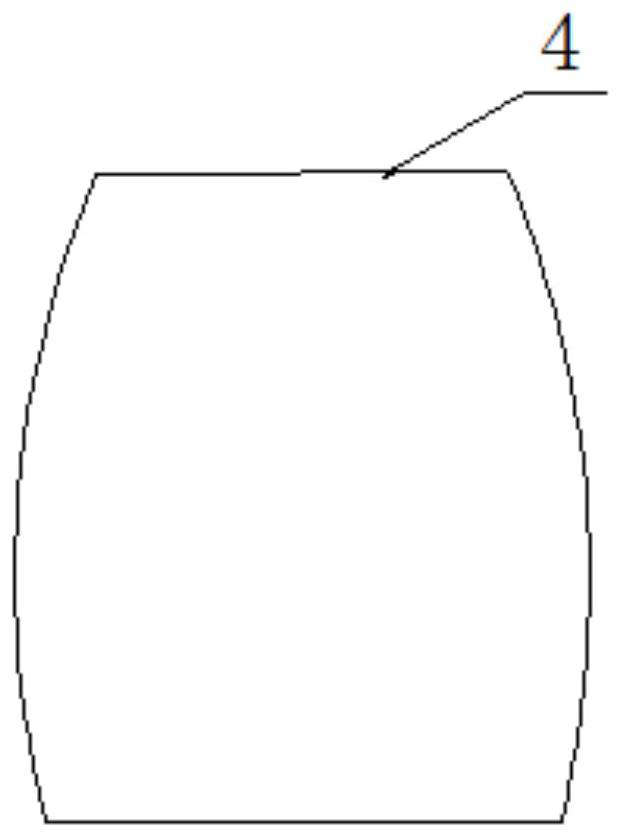

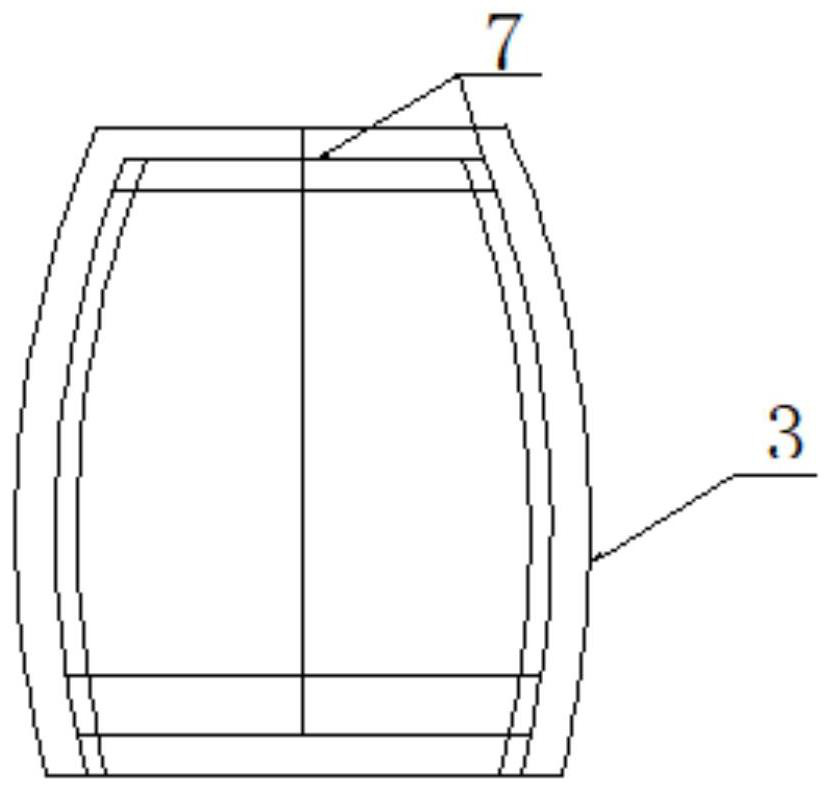

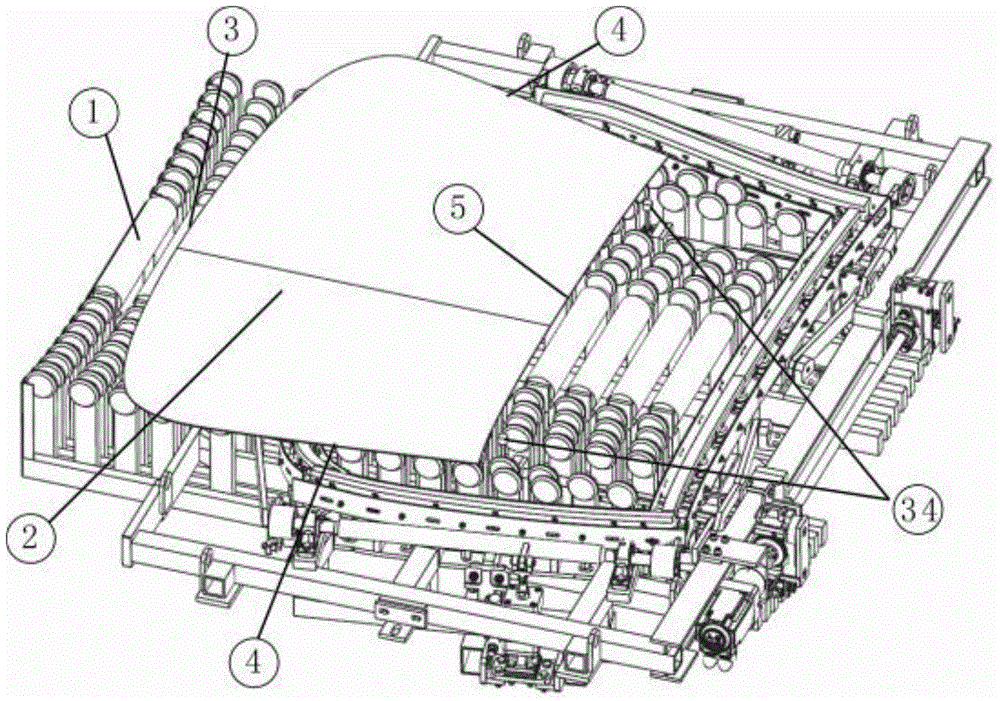

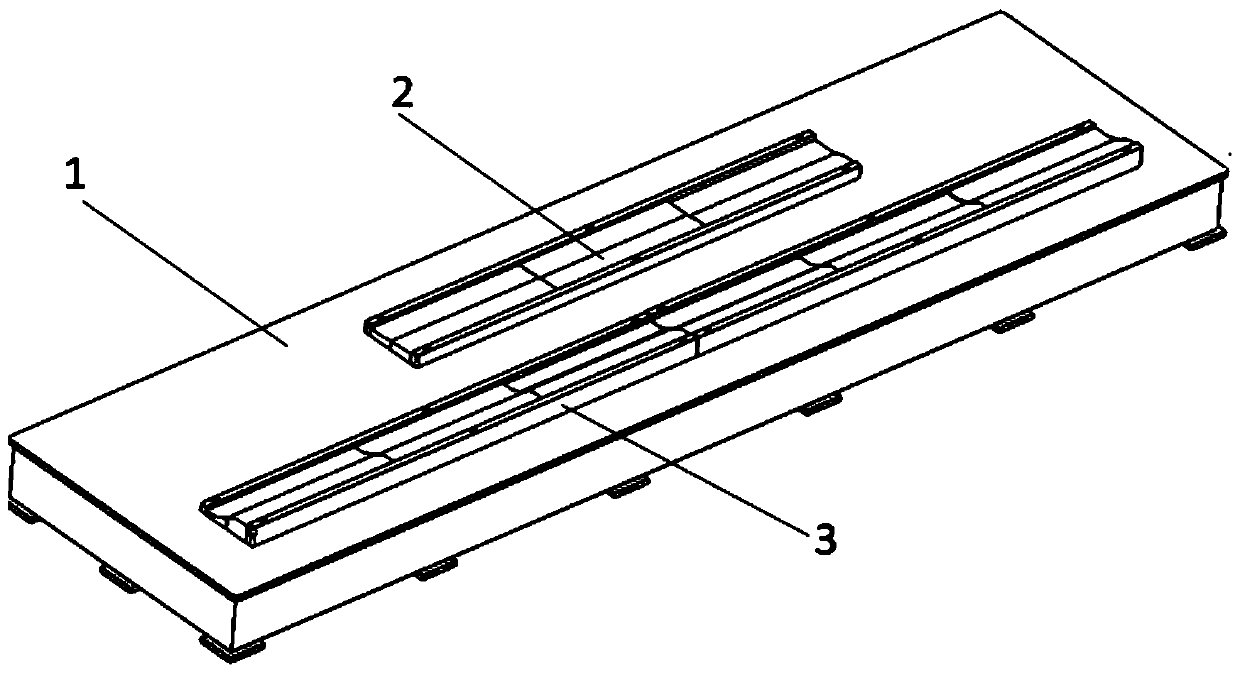

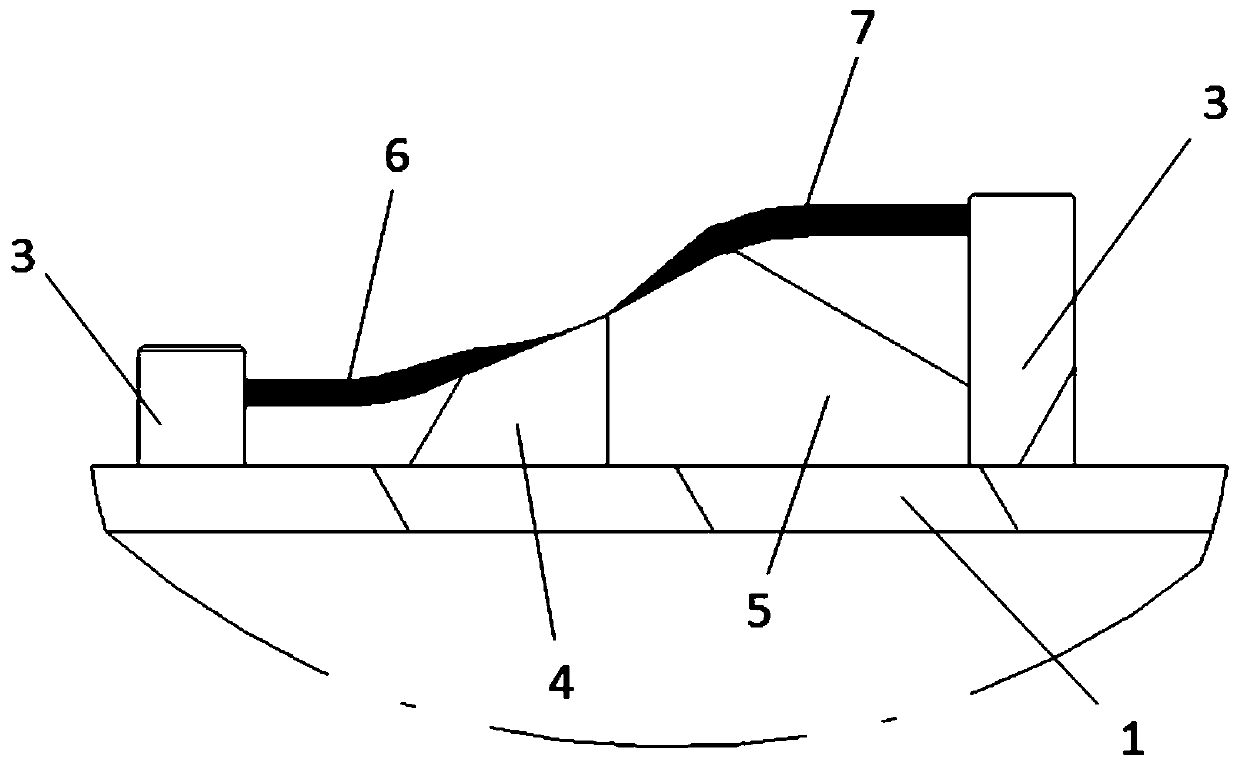

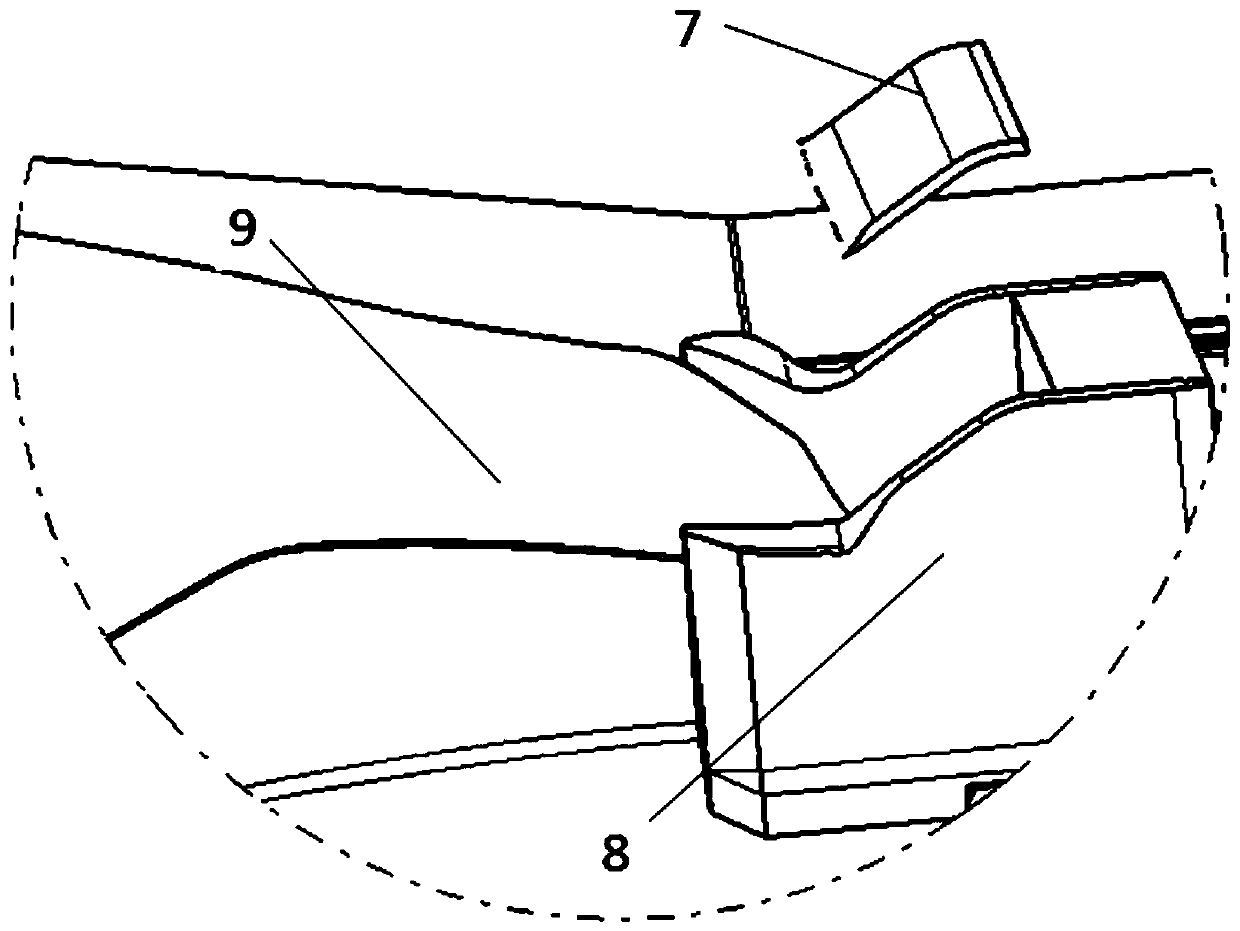

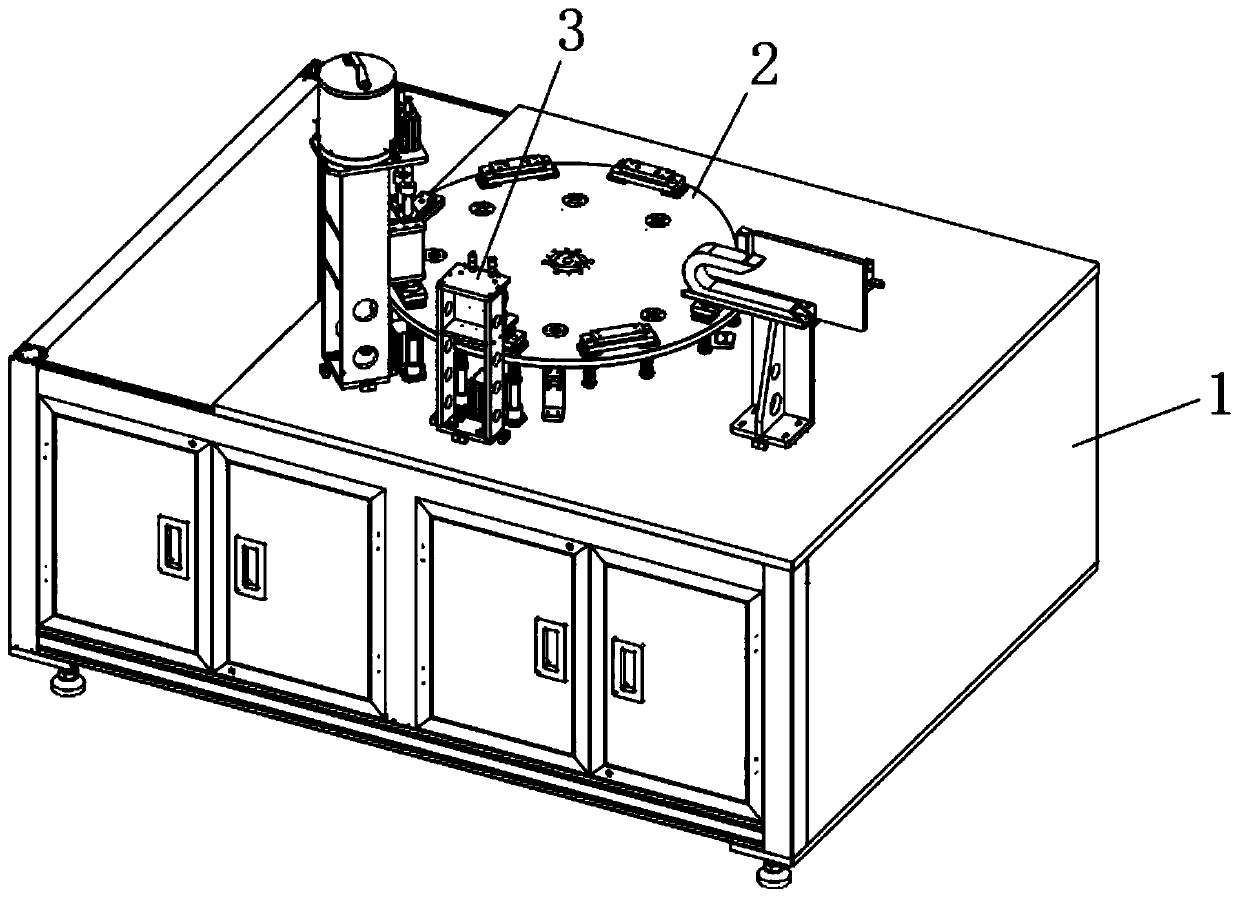

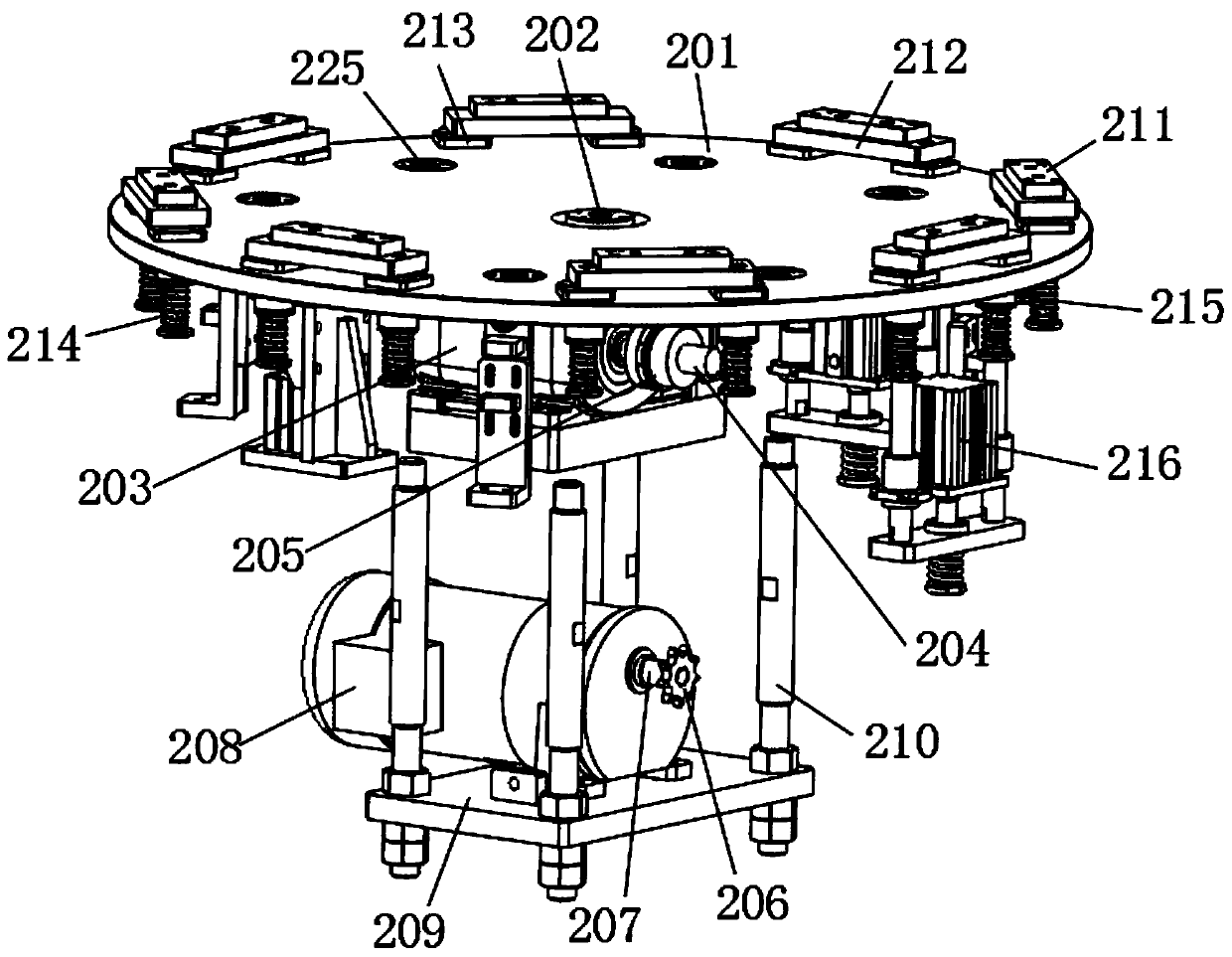

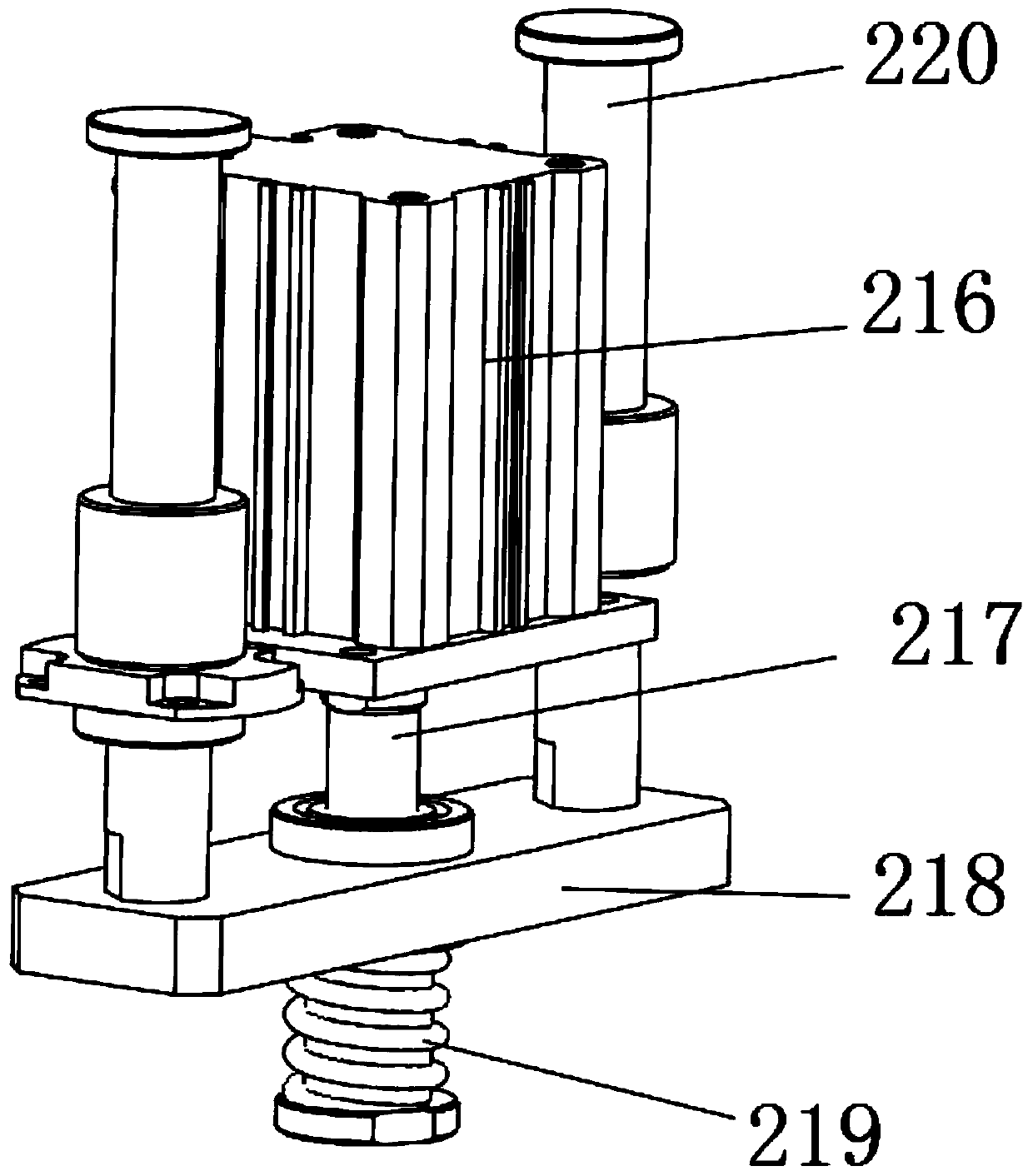

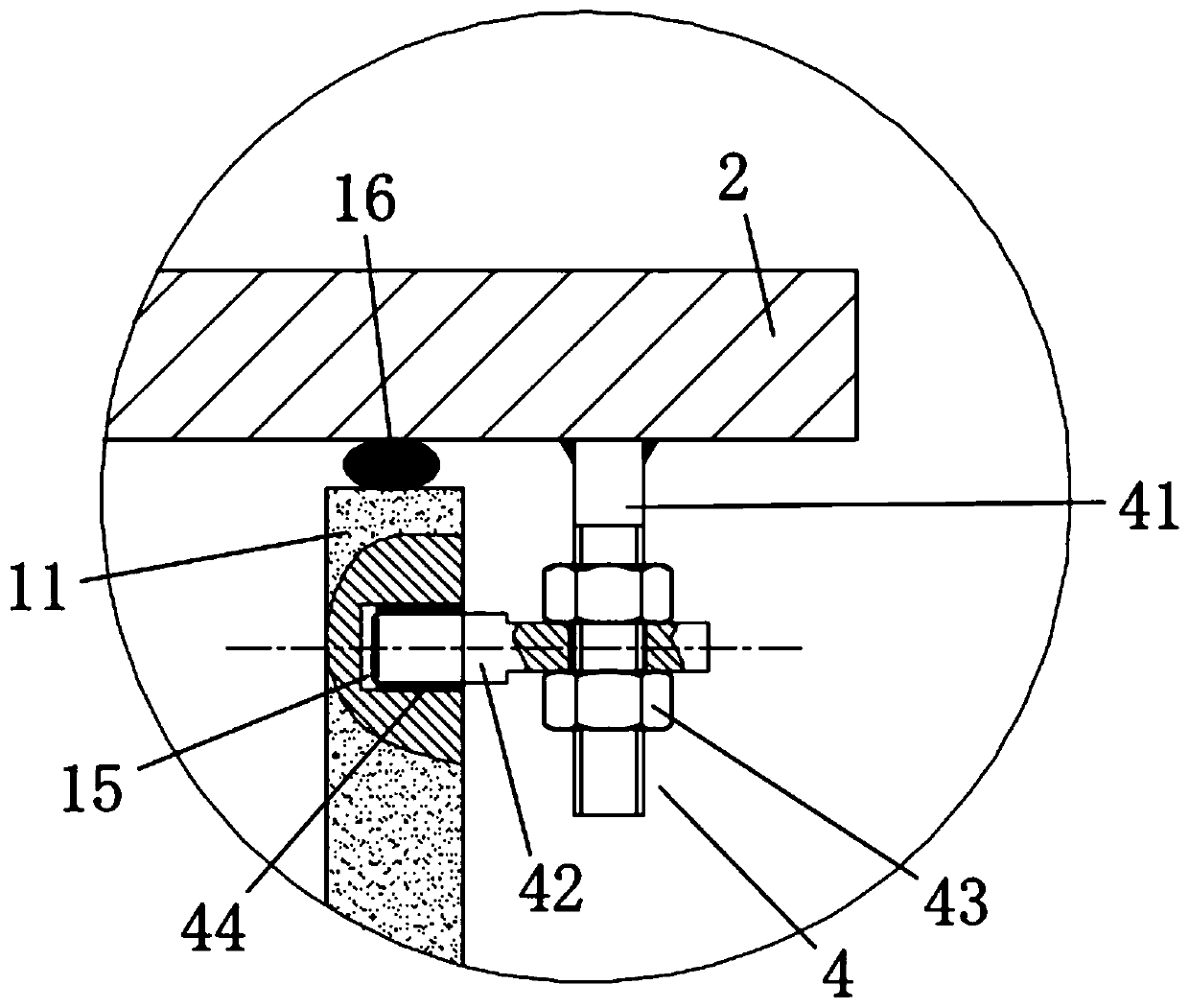

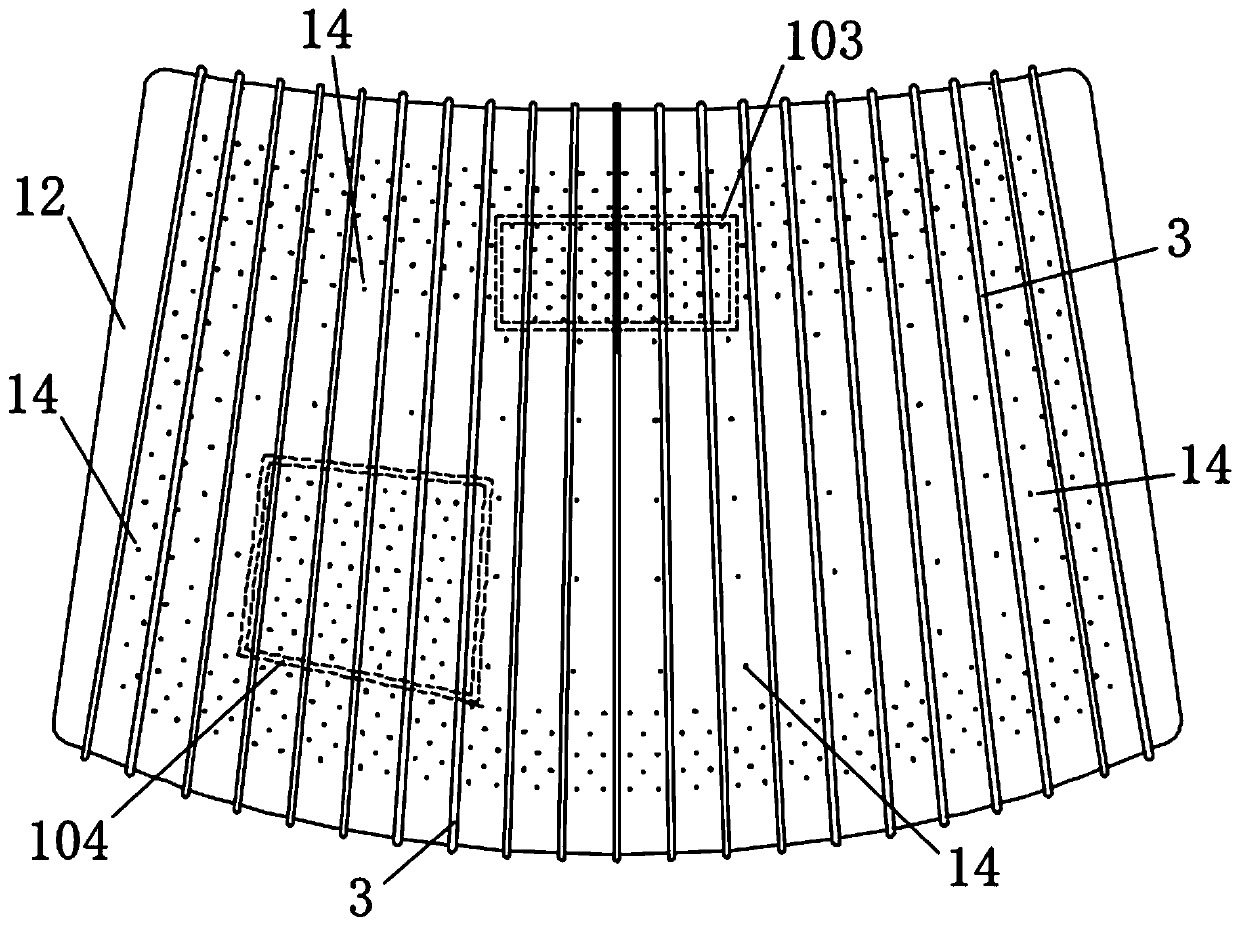

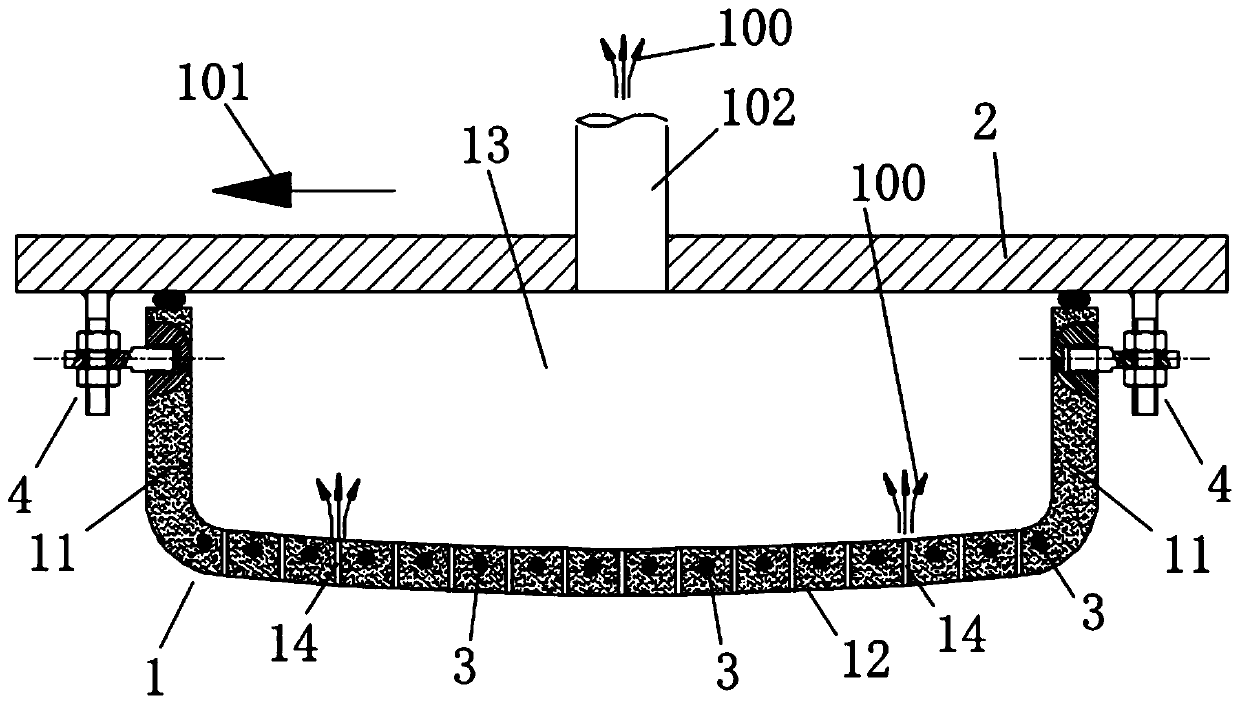

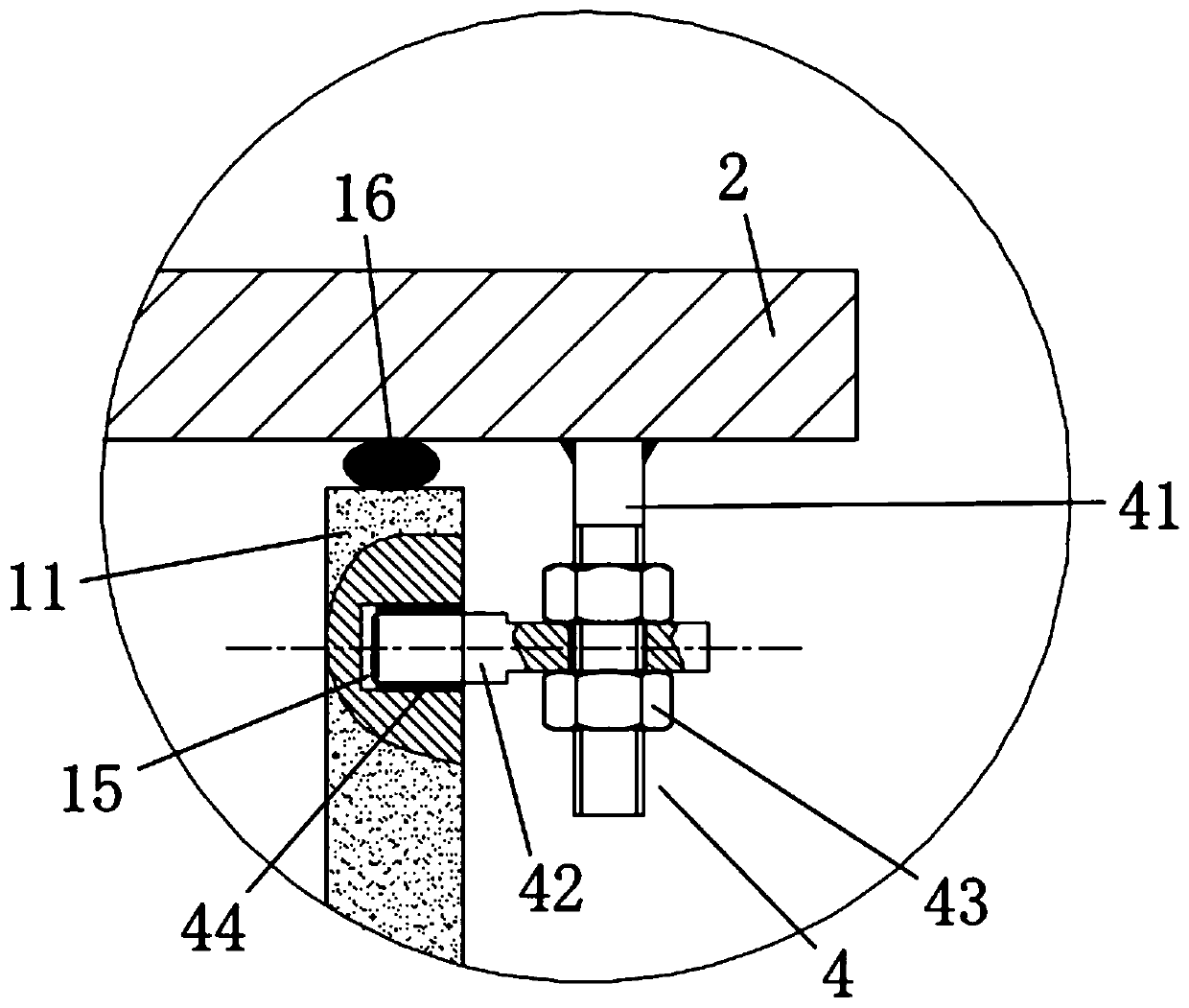

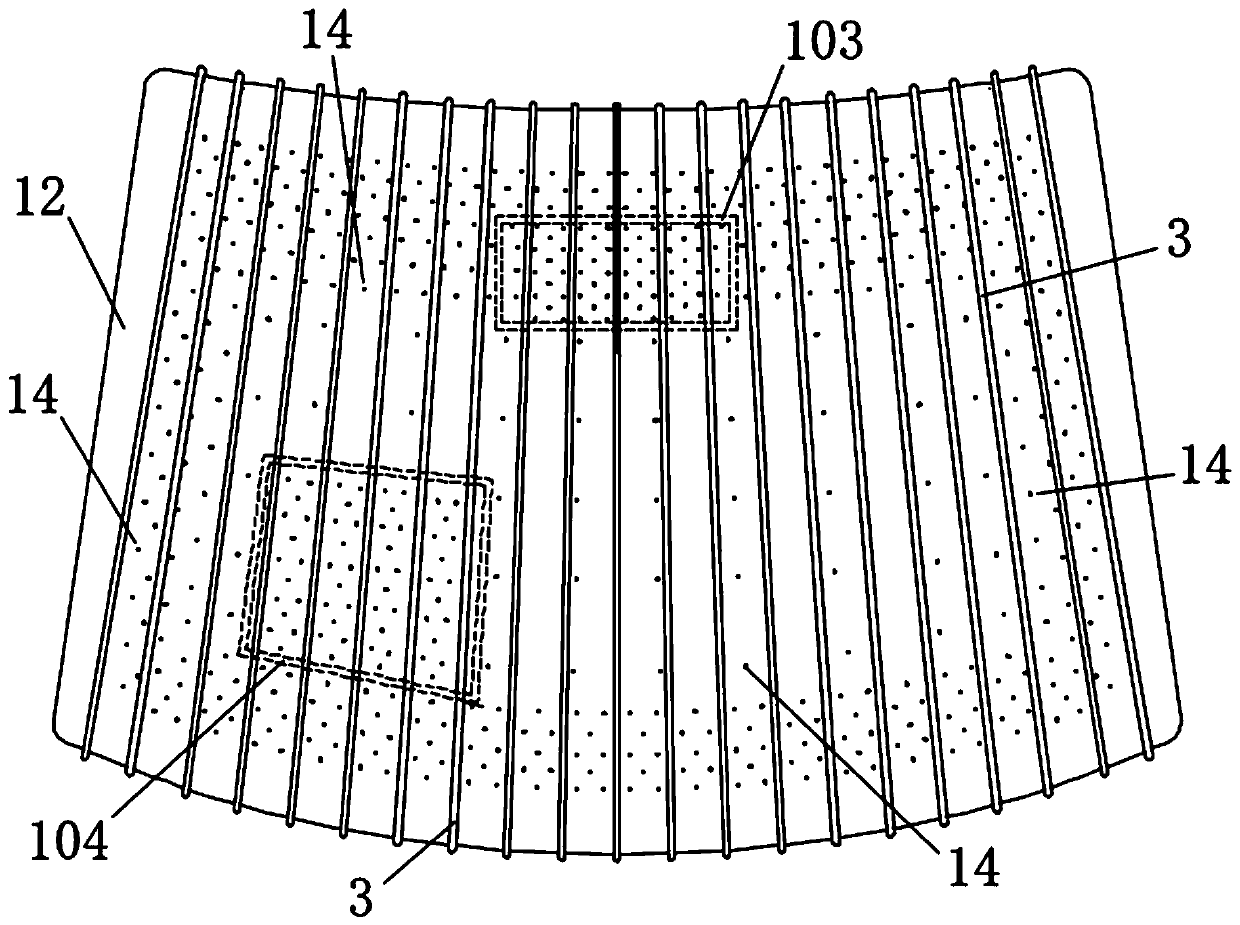

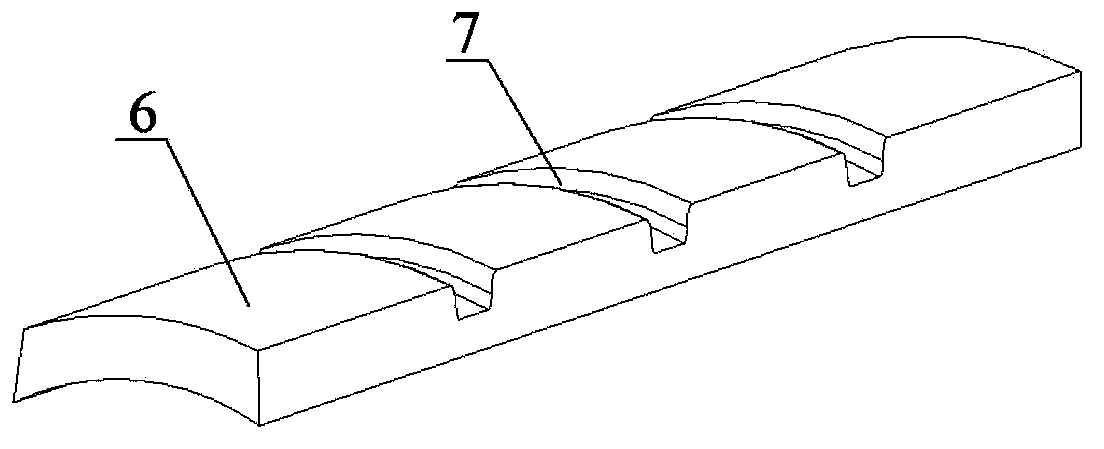

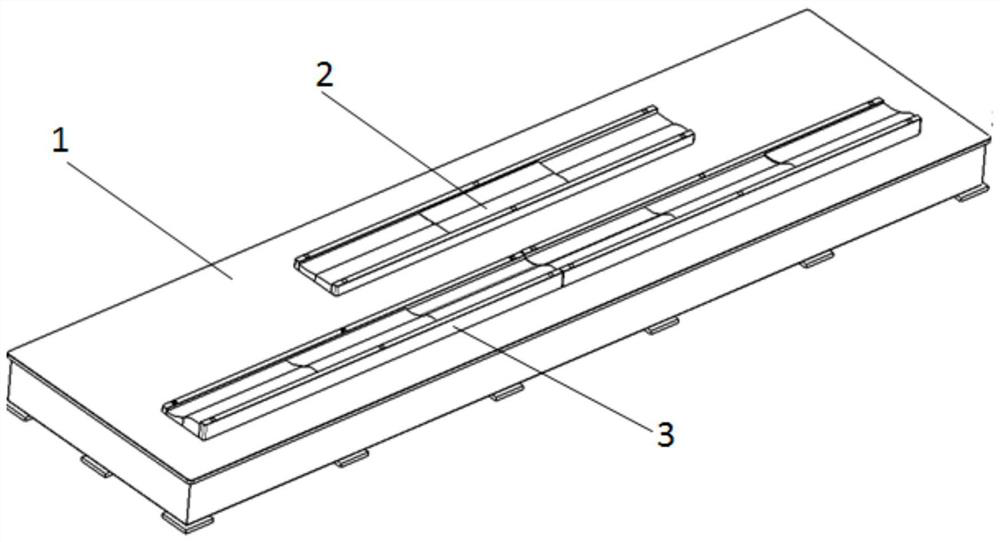

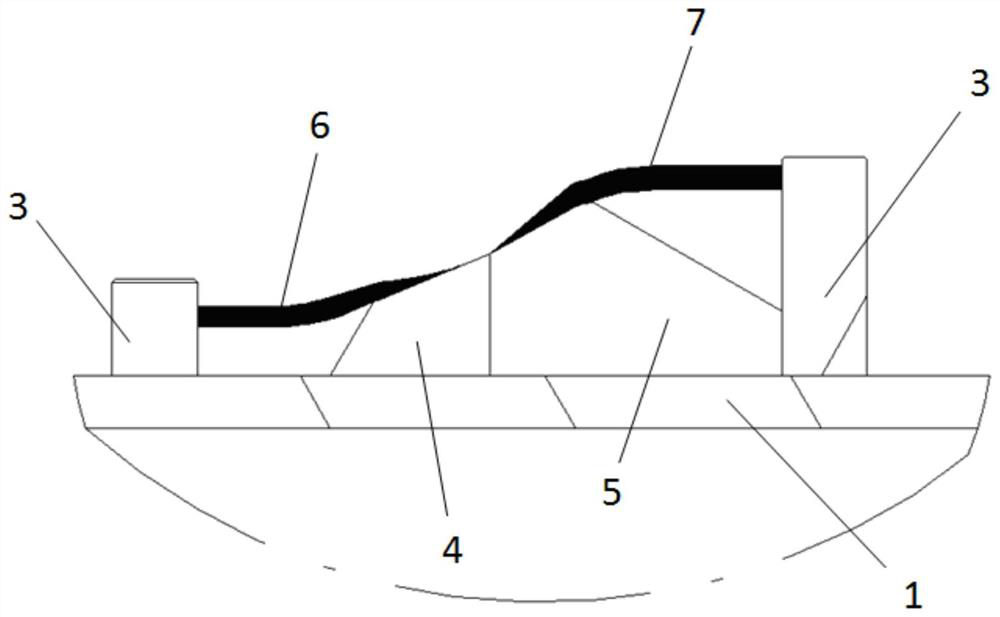

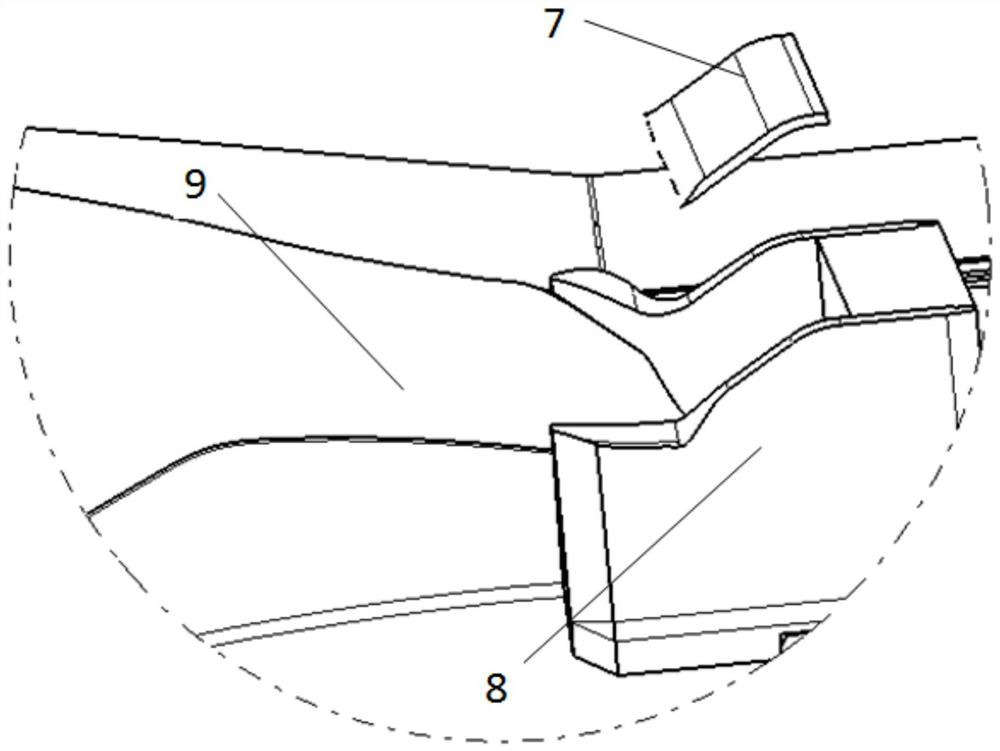

Forming tool for composite fan blade laying layer units

ActiveCN111231365AIncrease productivityImprove profile qualityDomestic articlesStructural engineeringFan blade

The invention discloses a forming tool for composite fan blade laying layer units. The forming tool comprises an overlapping platform (1) and overlapping work surfaces (2) arranged on the overlappingplatform (1); the two sides of the overlapping work surfaces (2) are provided with overlapping reference blocks (3) to serve as an overlapping reference; and the overlapping work surfaces (2) and laying layer units in composite fan blade tenons are the same in quantity. By adopting the forming tool, batch forming of the laying layer units can be achieved in advance, meanwhile, during laying layerunit overlapping, it can be achieved that symmetrical concave and convex units are formed at a time on the same forming mold surface, and the profile quality of the units is improved; then, in the composite fan blade overlapping and laying process, the preformed laying layer units serve as an integrated overlapped layer block to be placed on the blade forming tool; and on the premise that the profile precision of the laying layer units is ensured, the operation time for blade laying layer overlapping can be greatly shortened, and the blade production efficiency is improved.

Owner:AVIC COMPOSITES

Copper bar roller alignment device for motor rotor coil edgewise-winding machine

ActiveCN102364838AExpand the scope of workUniform force distributionManufacturing dynamo-electric machinesWinding machineSingle support

The invention relates to a copper bar roller alignment device for a motor rotor coil edgewise-winding machine, and belongs to the technical field of generator rotor coil edgewise-winding. The copper bar roller alignment device for the motor rotor coil edgewise-winding machine is characterized by comprising a bottom plate, baffle plates, a single support, an integrated support, side pressure plates, positioning plates, support plates, floating pressure blocks and roller rotating shafts, wherein the single support and the integrated support are provided with adjustable notches and the floating pressure blocks which are connected together with the roller rotating shafts, and are fastened on a working platform by bolts; the side pressure plates are fastened on the two sides of each of the single support and the integrated support by the bolts; and the baffle plates, the positioning plates and the support plates are arranged at left and right ends by the bolts. The device has the advantages of saving cost, reducing consumption and widening the working range of the edgewise-winding machine, along with simple structure, high processibility, convenience of manufacture, copper bar stressing uniformity, high profiling quality and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Double curvature plate cold press forming method and equipment thereof

Owner:中国船舶集团渤海造船有限公司

Method for regulating the vacuum supply of calibration tools

InactiveUS7513751B2Negative pressureLess variationPositive displacement pump componentsConfectioneryEngineeringControl valves

A method and apparatus for regulating the vacuum supply to calibration tools which include at least one dry calibration tool and at least one calibration bath, wherein at least one vacuum pump is brought into contact with a calibration tool in order to extract air from the calibration tool, the pressure in the tool being regulated to a target value by means of a control valve. Several vacuum pumps extract air from a common pressurized container, and the air is extracted from at least one dry calibration tool by a first control valve in the common pressurized container and in addition the air is extracted from at least one calibration bath by a second control valve in the common pressurized container.

Owner:TECHNOPLAST KUNST GES

Preparation method of pressed finishing powder

The invention discloses a preparation method of pressed finishing powder, comprising preparation of materials, mixing, and shaping by pressing. Since talcum powder, mica powder, titanium dioxide and zinc stearate are mixed and dispersed, the pressed finishing powder is much smooth and safer in use; particularly, the talcum powder, mica powder, titanium dioxide and zinc stearate are dispersed separately and fully, so that the powder has smooth particles; besides, under control, grape seed oil, hyaluronic acid concentrate and sodium hyaluronate are mixed more easily and more uniformly at a hightemperature; since essences are added and mixed at a low temperature, the essences are not easy to volatilize at the high temperature, and odor of the essences is remained further; the pressed finishing powder has a good moisturizing effect.

Owner:王娟

Glass plate bending ceramic die

ActiveCN110255869AImprove profile qualityPrevent burstGlass reforming apparatusElectric heatingGlass forming

The invention relates to the technical field of glass forming, particularly to glass plate bending equipment and provides a glass plate bending ceramic die. The glass plate bending ceramic die comprises a ceramic terrace die, a cover plate and a plurality of electric heating elements, wherein the ceramic terrace die comprises a side wall and a bottom wall; the glass plate bending ceramic die also comprises at least three hanging devices, the outer surface of the side wall is provided with at least three positioning blind holes, every hanging mechanism comprises a fixing device and an inserting device, the top end of the fixing device is fixedly connected to the lower surface of the cover plate, the outer end of the inserting device is fixed onto the fixing device, and the inner end of the inserting device can be inserted into the corresponding positioning blind hole. The glass plate bending ceramic die can avoid the problems of expansion, breakage and the like in local connected parts during application and reduce fluctuation of low glass profiles to produce finished glass plates with higher profile quality and meanwhile to ensure the bending quality of circumferential edges which are higher in forming difficulty.

Owner:FUYAO GLASS IND GROUP CO LTD

A ceramic mold for bending and forming glass plates

ActiveCN110255869BImprove profile qualityPrevent burstGlass reforming apparatusGlass sheetGlass forming

The invention relates to the technical field of glass forming, particularly to glass plate bending equipment and provides a glass plate bending ceramic die. The glass plate bending ceramic die comprises a ceramic terrace die, a cover plate and a plurality of electric heating elements, wherein the ceramic terrace die comprises a side wall and a bottom wall; the glass plate bending ceramic die also comprises at least three hanging devices, the outer surface of the side wall is provided with at least three positioning blind holes, every hanging mechanism comprises a fixing device and an inserting device, the top end of the fixing device is fixedly connected to the lower surface of the cover plate, the outer end of the inserting device is fixed onto the fixing device, and the inner end of the inserting device can be inserted into the corresponding positioning blind hole. The glass plate bending ceramic die can avoid the problems of expansion, breakage and the like in local connected parts during application and reduce fluctuation of low glass profiles to produce finished glass plates with higher profile quality and meanwhile to ensure the bending quality of circumferential edges which are higher in forming difficulty.

Owner:FUYAO GLASS IND GROUP CO LTD

Core mold and shaping method for shaping strip annular internal reinforced rib rotary body thin-wall part

InactiveCN102764841BPrevent movementHigh forming precisionForging/hammering/pressing machinesMetallic materialsUltimate tensile strength

The invention relates to a core mold and a shaping method for a shaping strip annular internal reinforced rib rotary body thin-wall part, wherein a base mold is composed of a base mold main body and a mold withdrawing end; a swallow tail groove and a positioning groove are formed on the base mold main body; a shape mold is wholly of an annular structure; the shape mold is uniformly divided into a plurality of split molds of same shapes; shaping arc grooves for annular internal reinforced ribs are formed on the shaping plane of the split molds; swallow tail tenons matched with the wallow tail groove and the positioning groove are formed on the inner surfaces of the split molds. By adopting the mode of combined core mold, the problem of hard demolding during the shaping process of the rotary body thin-wall part internal reinforced rib is solved. By virtue of the positioning on the base mold swallow tail groove, the movement of the shaping mold is prevented effectively; and the shaping precision of the rotary body thin-wall part internal reinforced rib is improved. The base mold, the shaping mold and the fixing pin of the core mold can be made of different metal materials according to respective strength requirements; only the mold needs to be replaced for rotary body thin-wall pieces of which the inner diameters are the same and the internal reinforcing ribs are different, so that the cost of the mold is reduced greatly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Forming tooling for a laminated unit body of a composite fan blade

The invention relates to a forming tool for a composite fan blade laminate unit body, the forming tool includes a laying platform (1) and a laying working surface (2) arranged on the laying platform (1), during the laying work Both sides of the surface (2) are provided with lay-up reference blocks (3) as lay-up references, and the number of lay-up working faces (2) is the same as the number of lay-up units in the tenons of composite fan blades. Adopting the tooling described in the present invention can use the ply unit body to form in batches in advance, and at the same time, when laying up the ply unit body, the symmetrical concave surface and convex surface unit body can be formed on the same molding die surface at one time, which improves the profile of the unit body quality. The pre-formed ply units are then placed on the blade forming tooling as integral laminate blocks during the composite fan blade layup process. Under the premise of ensuring the accuracy of the surface of the ply unit, the operation time of blade ply laying can be greatly shortened, and the production efficiency of the blade can be improved.

Owner:AVIC COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com