Glass plate bending ceramic die

A ceramic mold and bending forming technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of safety hazards, failure to meet the bending and forming requirements of glass plates, and shortened service life, so as to avoid swelling and cracking or fracture, ensure the quality of bending forming, and reduce the effect of surface fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

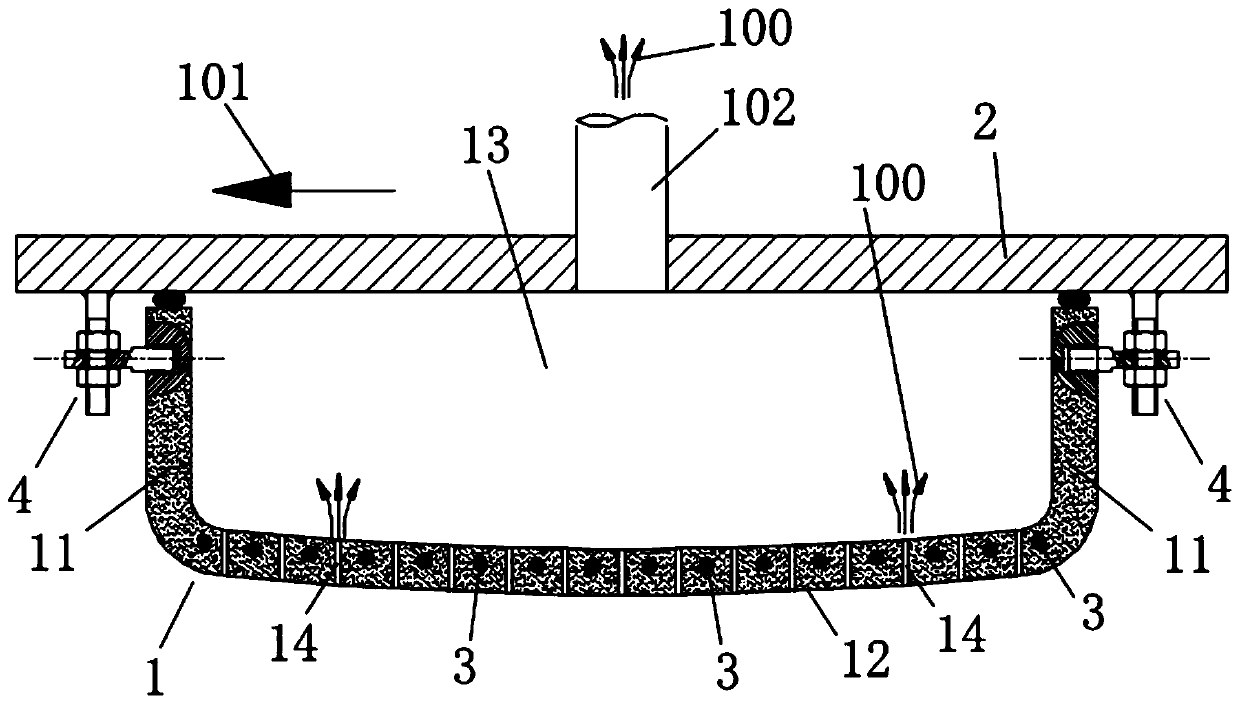

[0027] The content of the present invention will be further described below in conjunction with the accompanying drawings.

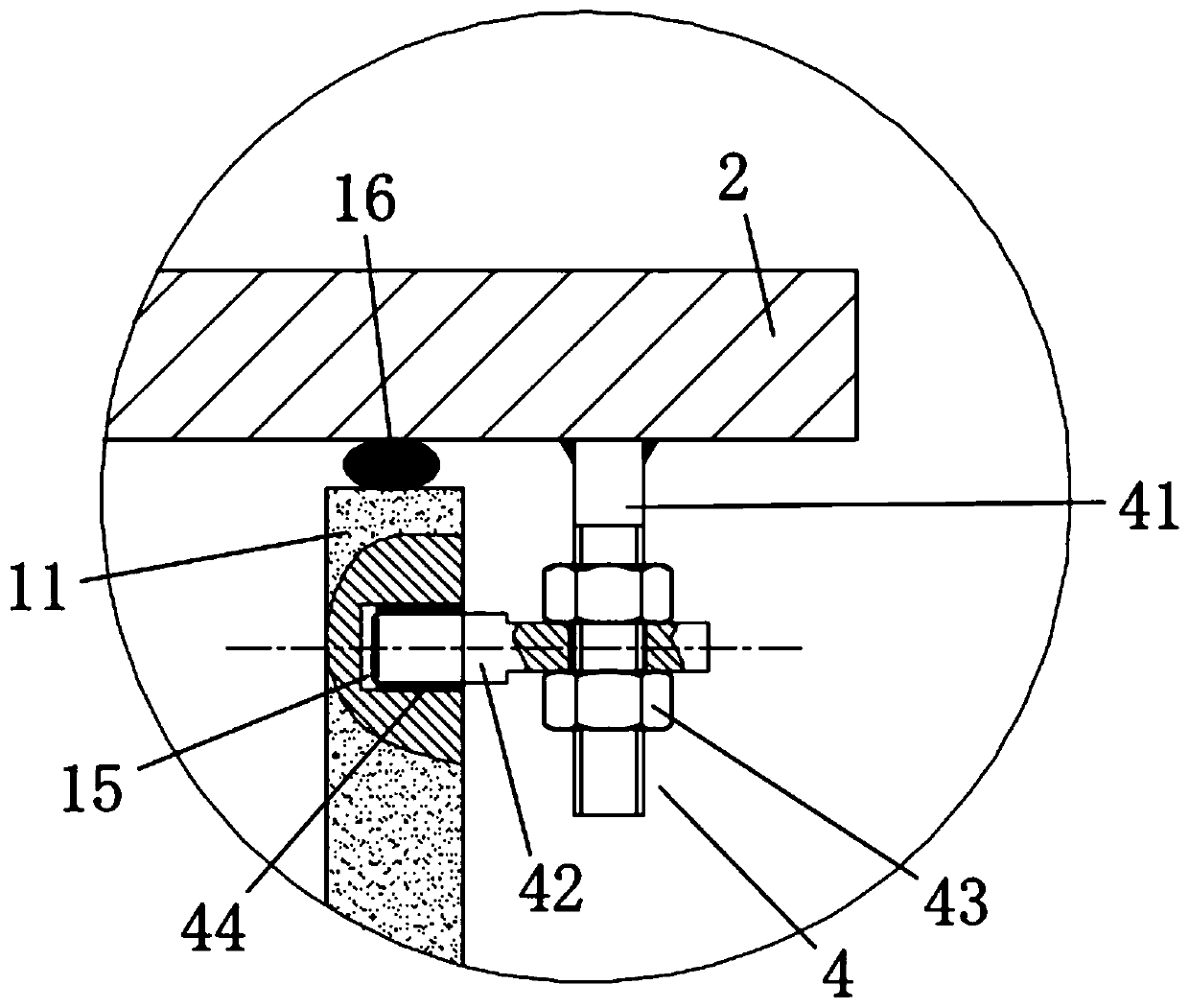

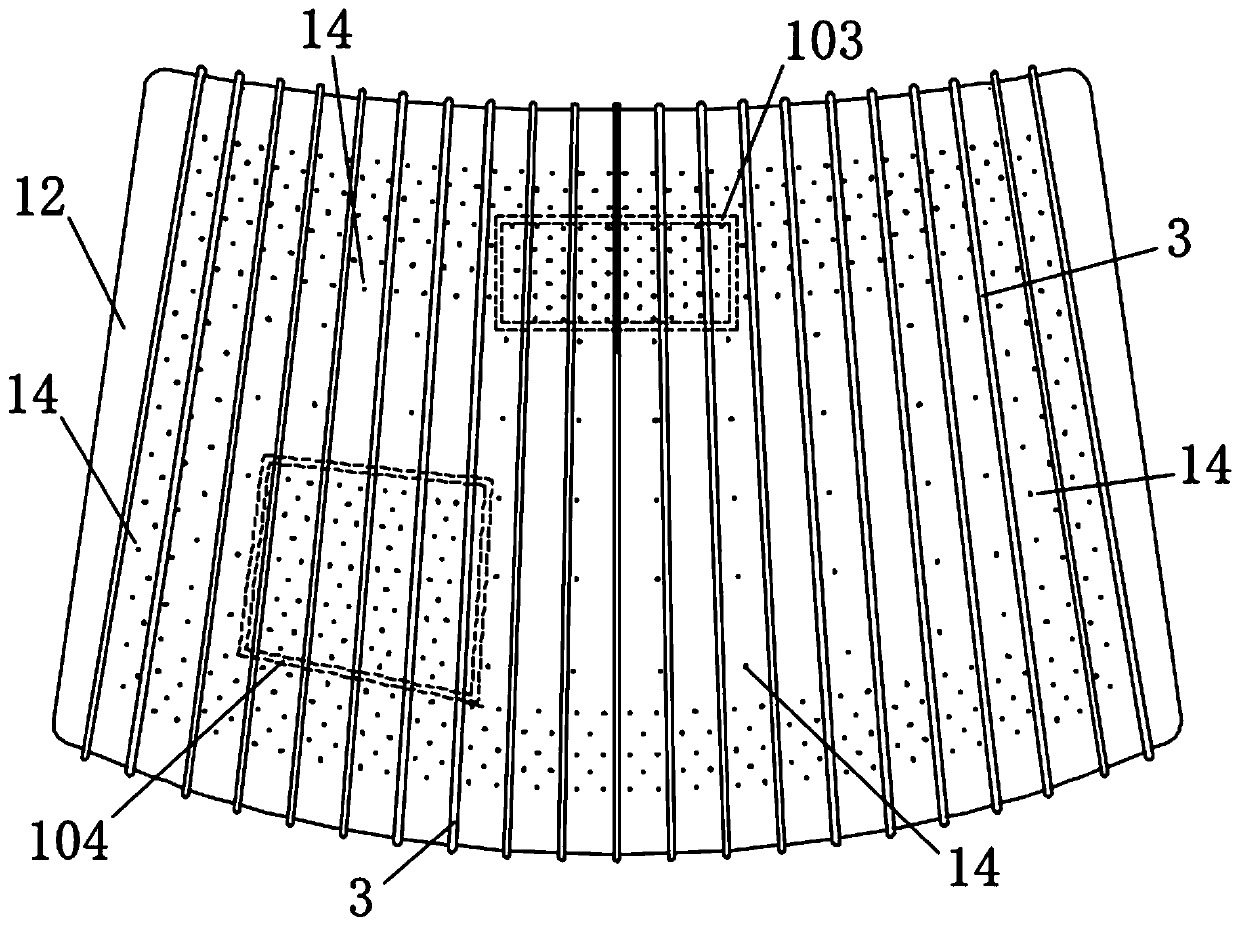

[0028] Such as figure 1 and figure 2 As shown, a ceramic mold for bending and forming a glass plate according to the present invention includes a ceramic punch 1, a cover plate 2 and a plurality of electric heating elements 3, and the ceramic punch 1 is fixed on the cover plate 2 The lower surface of the ceramic punch 1 has a side wall 11 and a bottom wall 12, the electric heating element 3 is arranged in the bottom wall 12, and the outer surface of the bottom wall 12 has a The concave surface matches the convex molding surface. The cover plate 2, the side wall 11 and the bottom wall 12 enclose a vacuum chamber 13. In the bottom wall 12, there are also a plurality of holes that pass through the bottom wall 12 and are connected to the bottom wall 12. The vacuum hole 14 that the vacuum chamber 13 communicates; the cover plate 2 is used to fix the cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com