Patents

Literature

75results about How to "Avoid problems such as breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of heat-resistant titanium alloy wires

ActiveCN109355530ADifferent tensile strength matchingPlastic different matchingTitanium alloyHeat treated

The invention provides a machining and manufacturing method and application of heat-resistant titanium alloy Ti60 wires. The method comprises the steps that Ti60 titanium alloy ingot castings are smelted by adopting a vacuum consumable smelting technology; the smelted Ti60 titanium alloy ingot castings are forged into rods by adopting a free forging technology; the Ti60 titanium alloy rods are finish-forged into thick rod blanks by adopting a finish forging technology; the Ti60 titanium alloy thick rod blanks are rolled into straight strip wire blanks by adopting a hot rolling technology; surface treatment is conducted on Ti60 titanium alloy annealing wire blanks, and pre-oxidation oxidation film hanging treatment is conducted after defects on the surfaces of the wire blanks are removed; continuous high-temperature drawing deformation is conducted on the Ti60 titanium alloy wire blanks obtained after surface treatment by adopting a straight wire drawing machine; the drawn wires are straightened by adopting electric heating tension; and annealing heat treatment is conducted on the straightened wires, and finally centerless grinding is conducted. According to the machining and manufacturing method and application of the heat-resistant titanium alloy Ti60 wires, through combination of different heat machining and heat treating technologies, different matching combinations of the tensile strength, the plasticity and the shearing strength can be obtained, and the heat-resistant titanium alloy Ti60 wires can be used for manufacturing advanced aerospace fasteners such as rivets, bolts and nuts and are used in the temperature range of 600-650 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

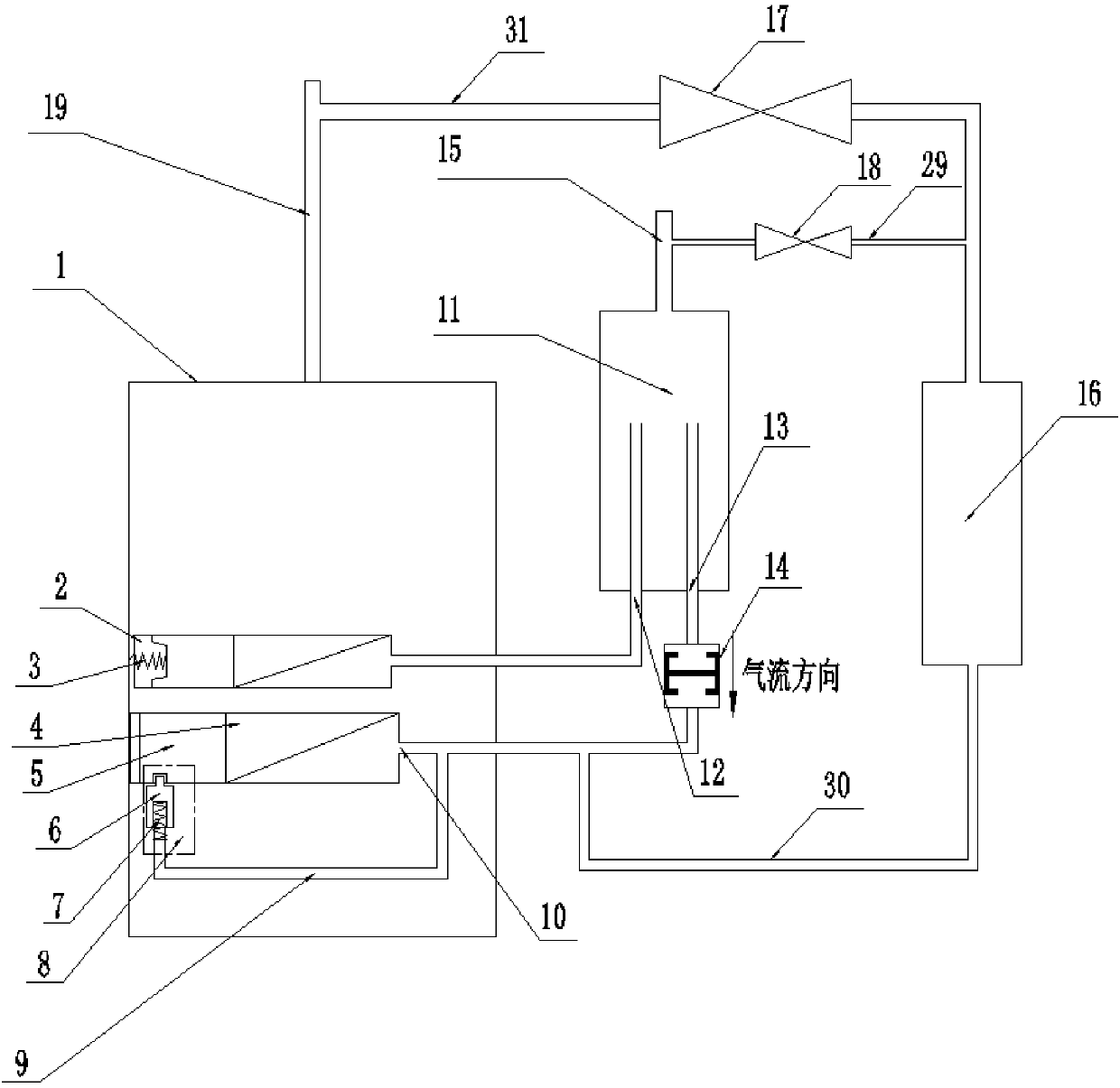

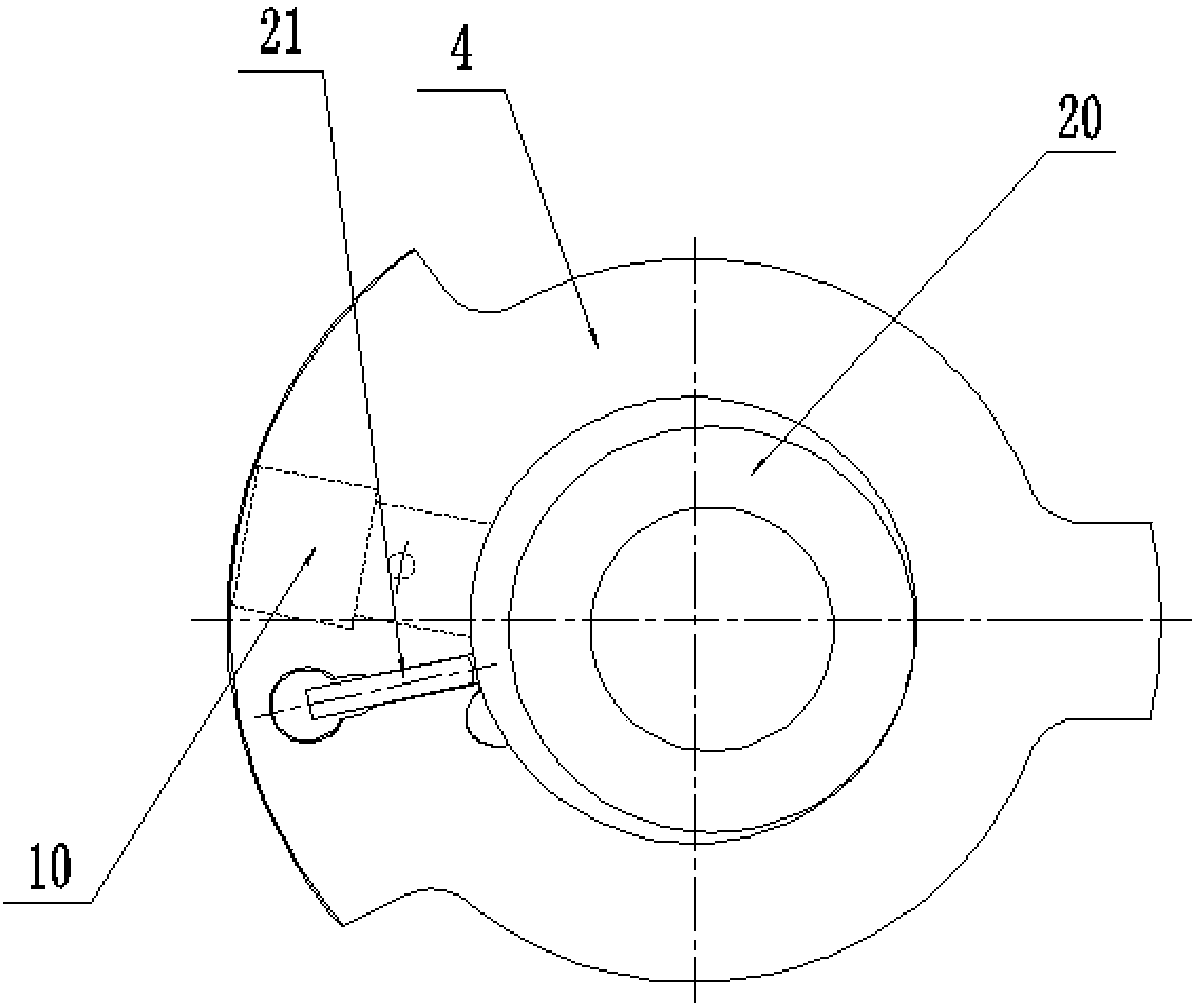

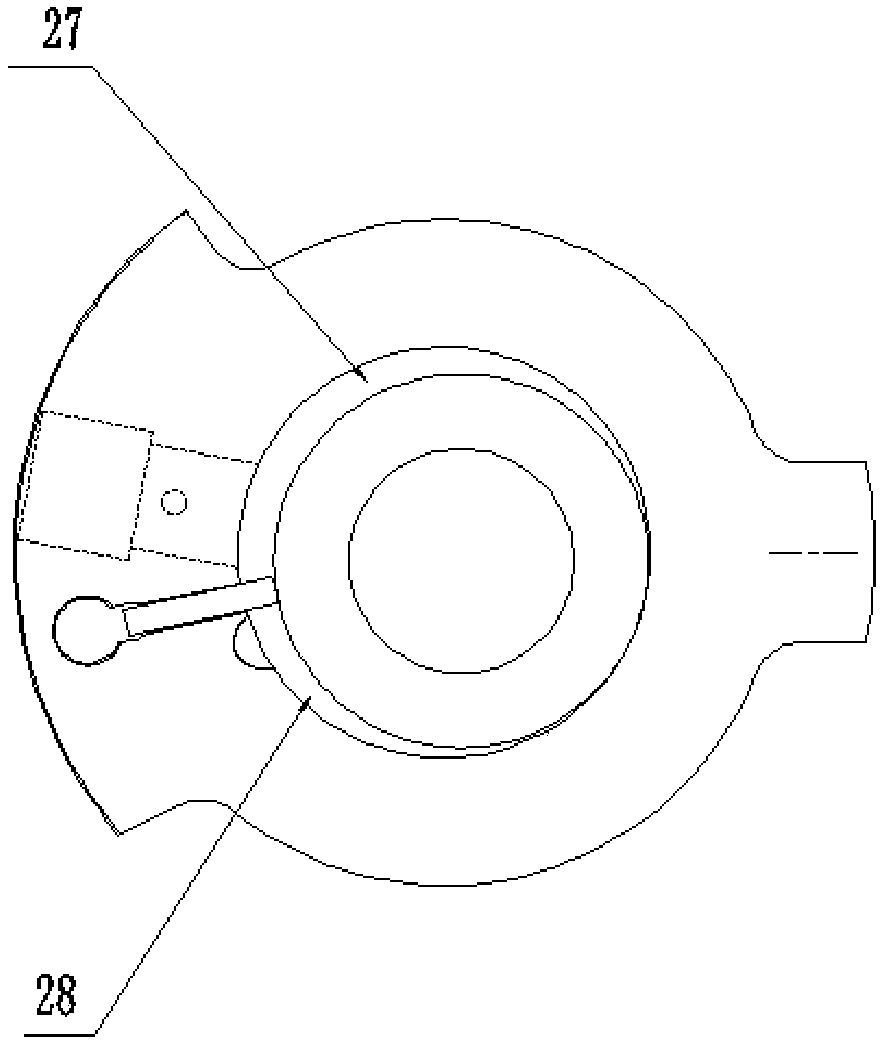

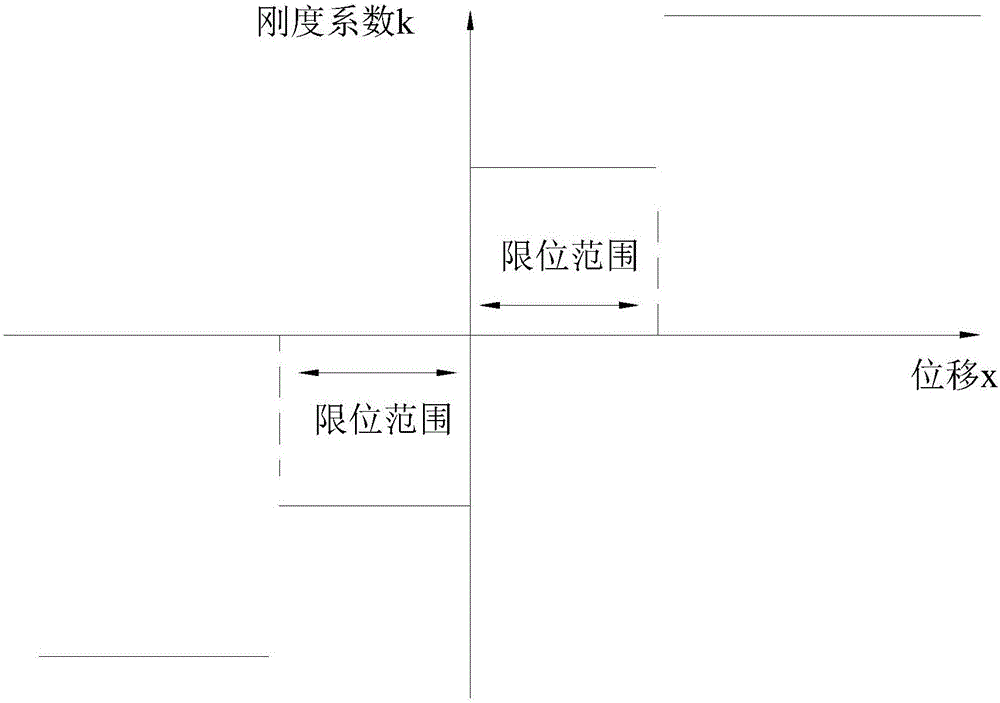

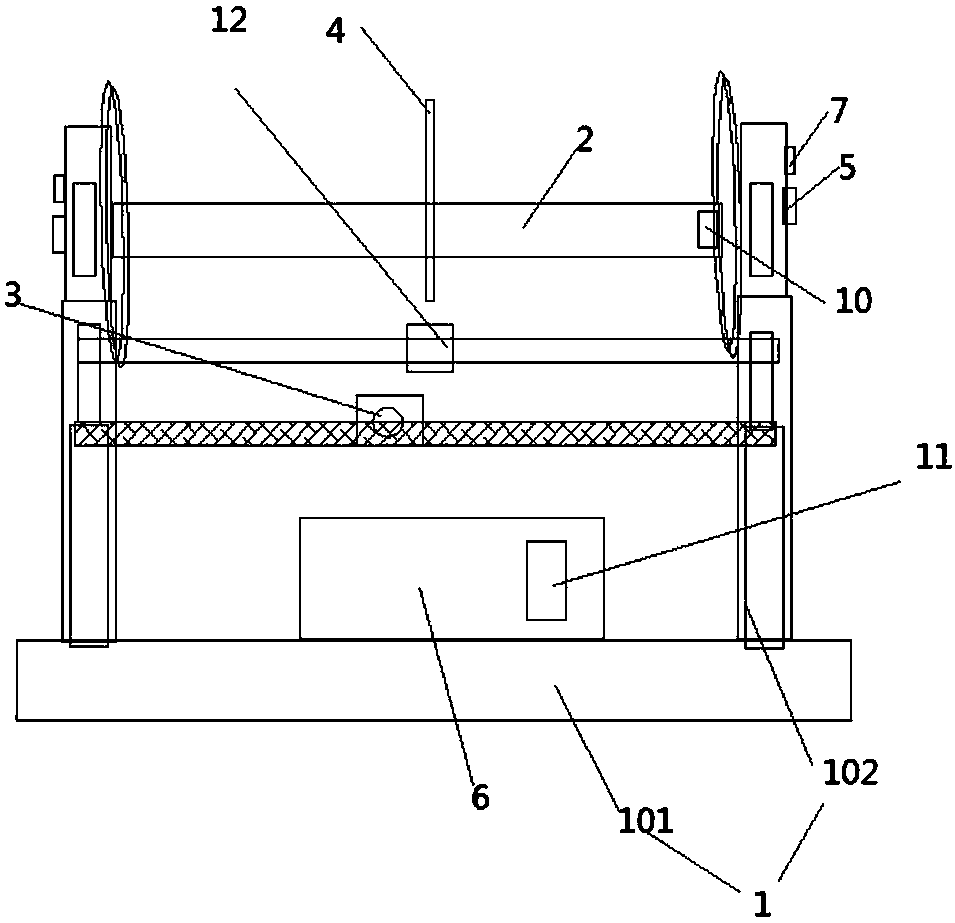

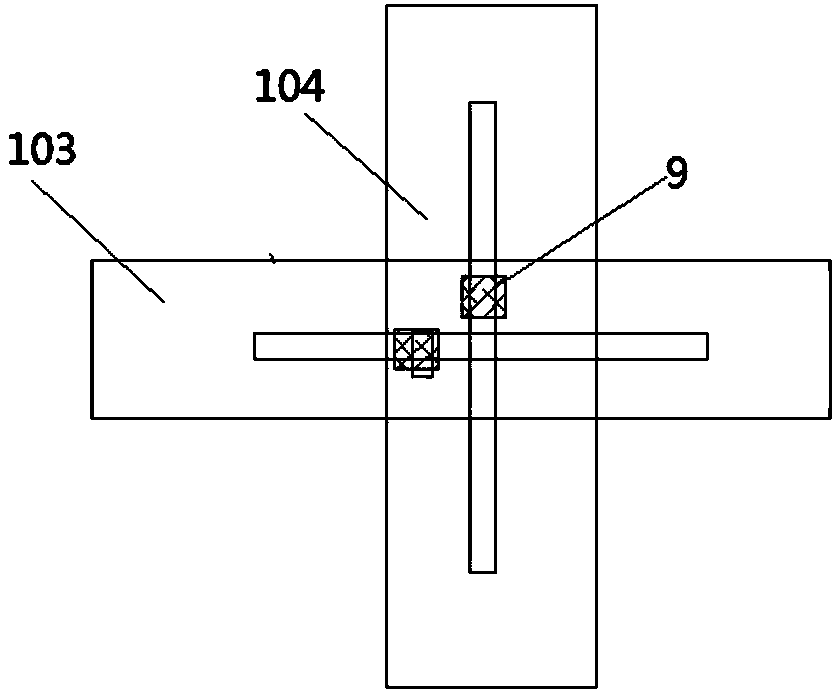

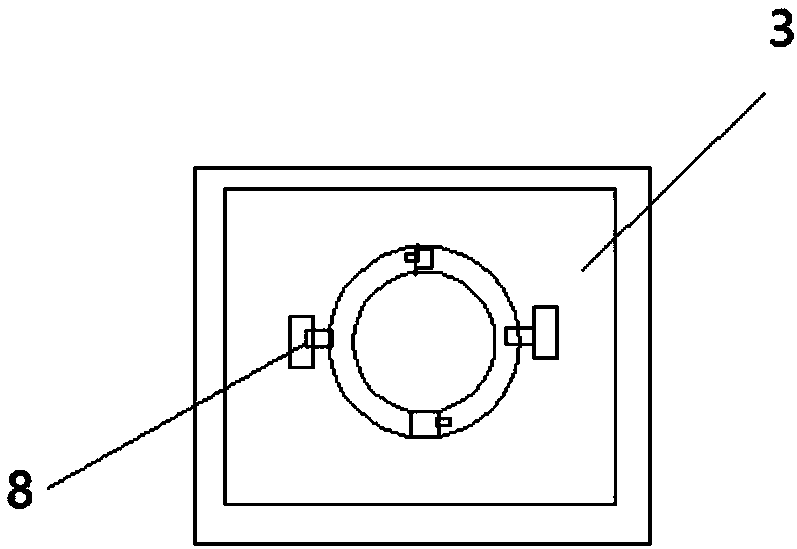

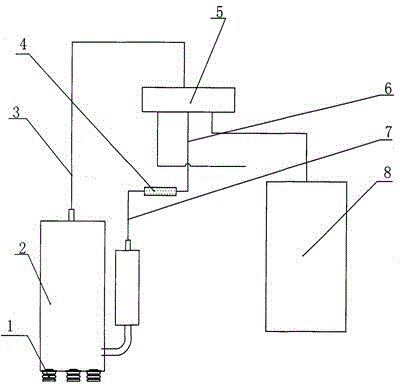

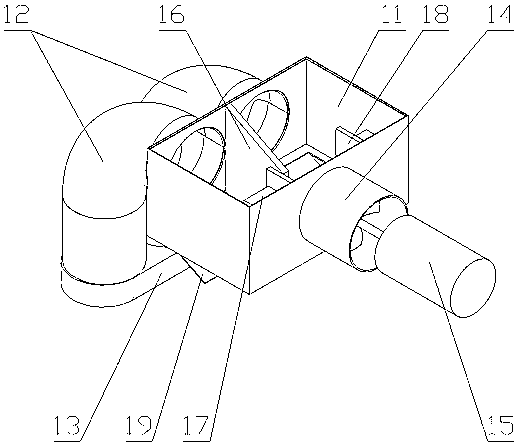

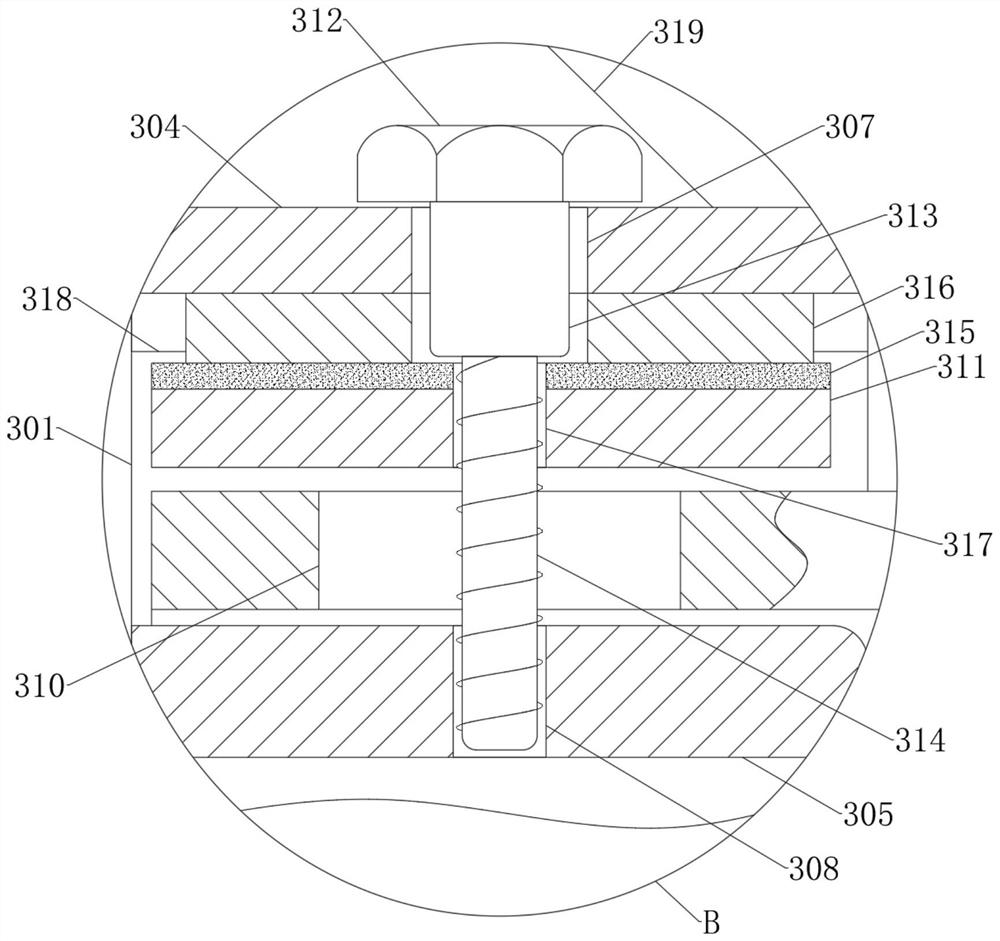

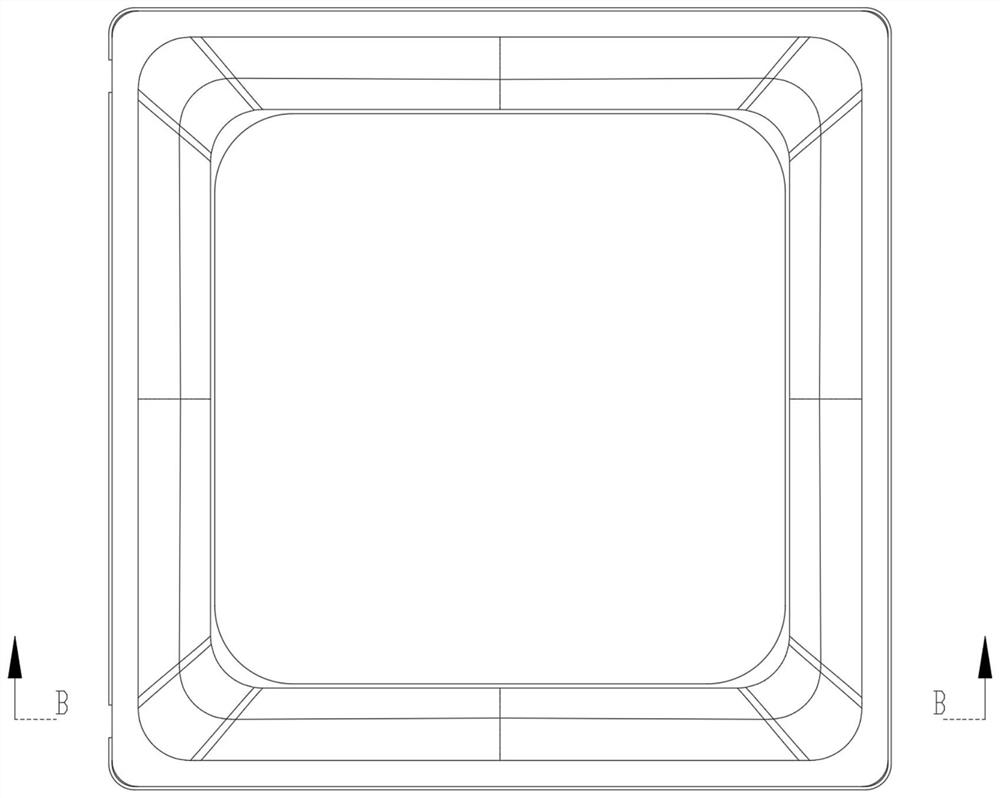

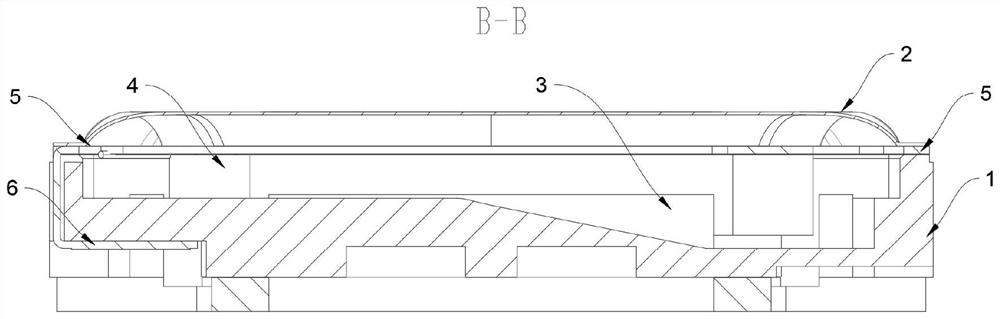

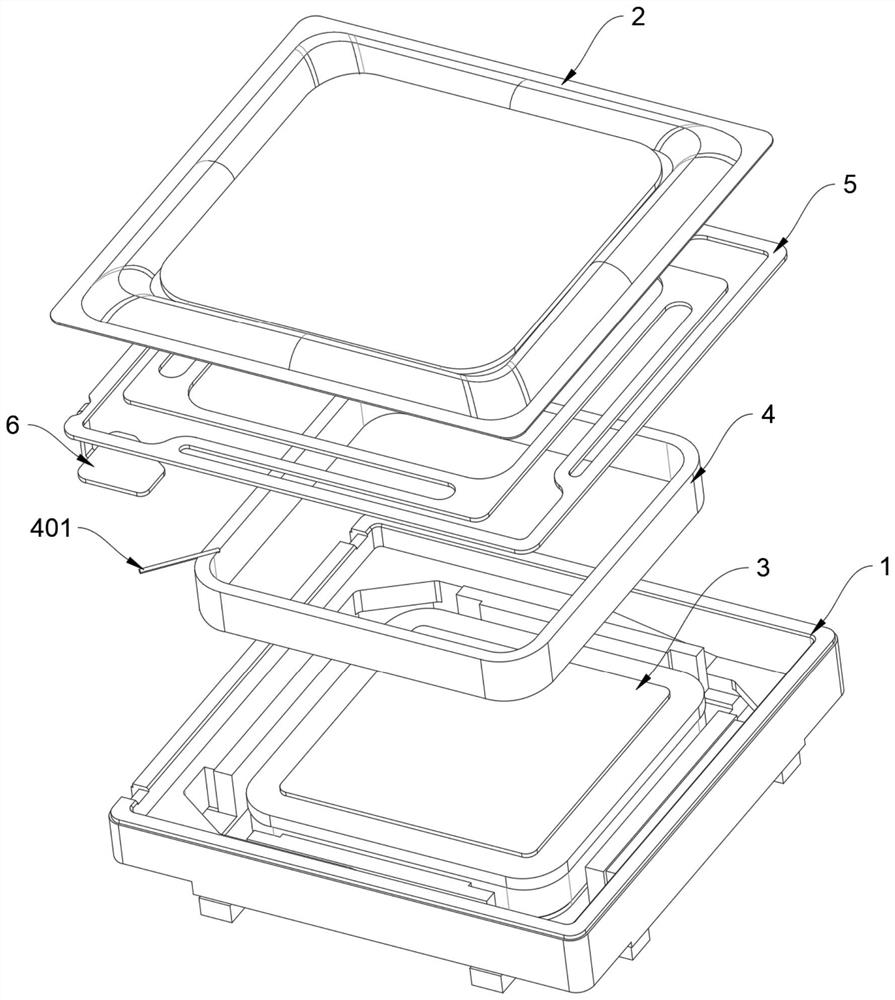

Capacitance-variable control structure, compressor and capacitance-variable control method thereof

PendingCN107917078AReduce jitterAvoid problems such as breakageRotary piston pumpsRotary piston liquid enginesCapacitanceEngineering

The invention discloses a capacitance-variable control structure, a compressor and a capacitance-variable control method thereof. The structure comprises a capacitance-variable assembly and a slidingvane restraint unit (8), wherein the capacitance-variable assembly is arranged on the outer part of a shell (1) of the compressor to which the capacitance-variable control structure belongs, and is used for acting according to a setting sequence; and the sliding vane restraint unit (8) is arranged in a pump body of the compressor, and is used for enabling a capacitance-variable cylinder assembly in the compressor to be at a working state or an idling state under the control of acting of the capacitance-variable assembly according to the setting sequence. According to the technical scheme provided by the invention, the defects such as violent shaking, easiness in machine halt and easiness in breaking a pipeline in the prior art can be overcome, and the beneficial effects on reducing shaking, preventing machine halt, and preventing the pipeline from being broken are achieved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Double-glass assembly manufacturing method

InactiveCN105895739AAvoid prone to air bubblesAvoid displacement of cells on both sidesFinal product manufacturePhotovoltaic energy generationAdhesiveEngineering

The invention discloses a double-glass assembly manufacturing method, and the method comprises the steps: double-glass assembly laying, appearance inspection, EL testing, hot melting laminating, junction box installation, secondary EL testing, power testing, and finished product examination. The double-glass assembly laying specifically comprises the steps: firstly enabling a cut EVA glue film to be laid on bottom toughened glass; secondly enabling a required number of solar cells to be laid on the EVA glue film; thirdly enabling the plurality of cells to be connected in series through a bus bar to form a body; fourthly sequentially laying the EVA glue film and surface roughened glass on the solar cell string, and forming a solar double-glass assembly; and finally carrying out edge sealing through a high-temperature adhesive tape, and drilling. According to the invention, the high-temperature adhesive tape is used for fully pasting and sealing the periphery of the laid double-glass assembly, thereby effectively controlling the overflow quantity. The method greatly shortens the laminating time, and improves the production efficiency.

Owner:JIANGSU LINYANG PHOTOVOLTAIC TECH

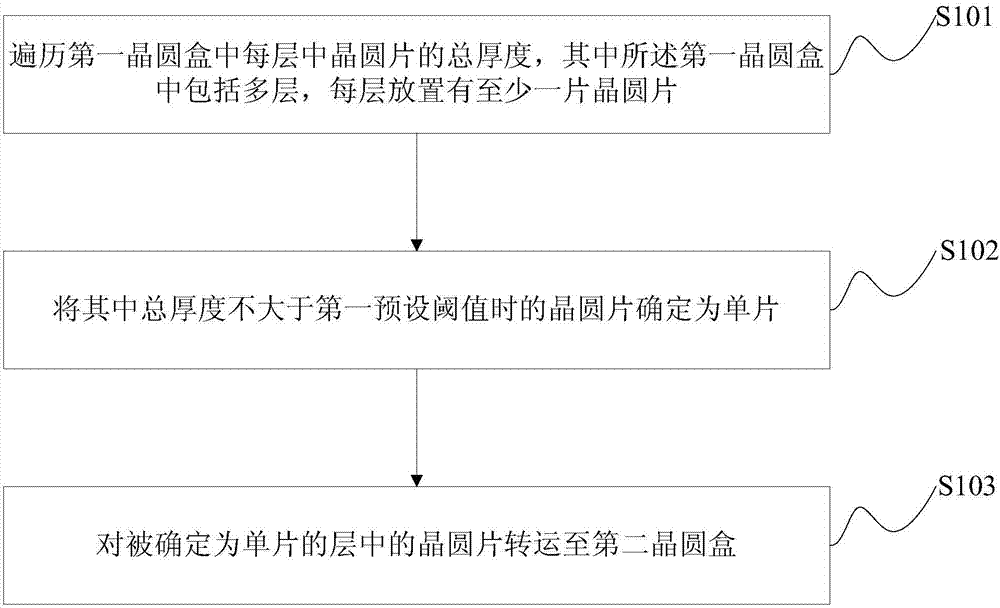

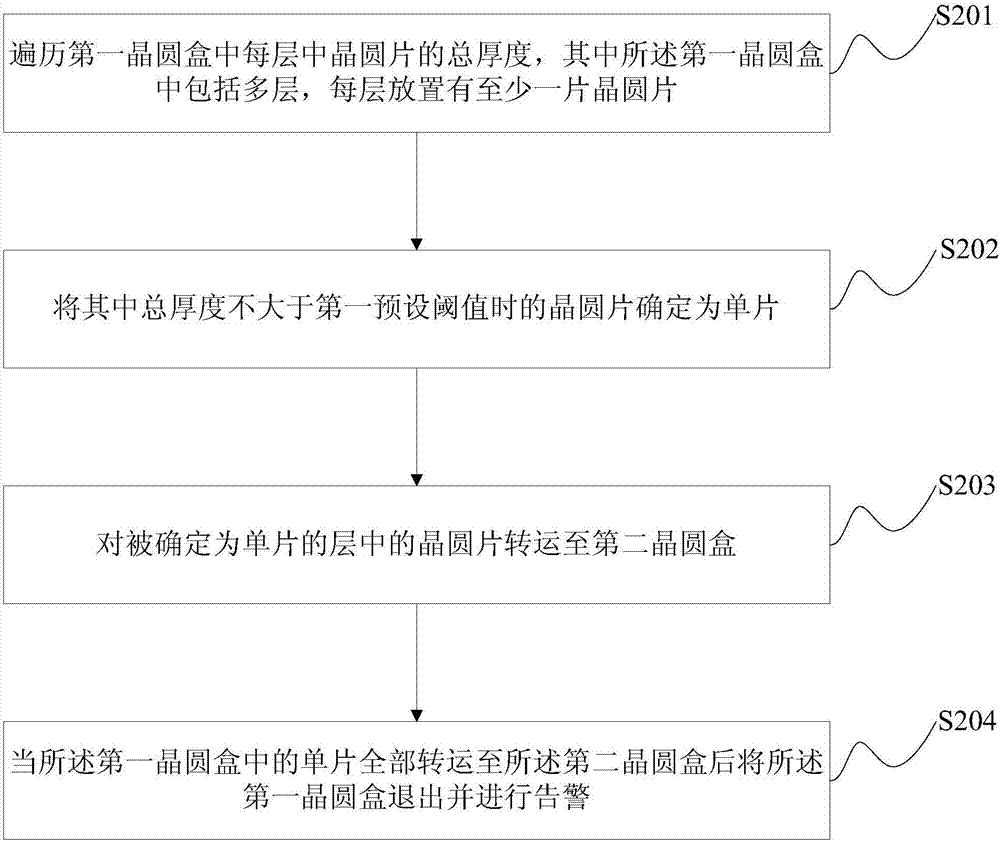

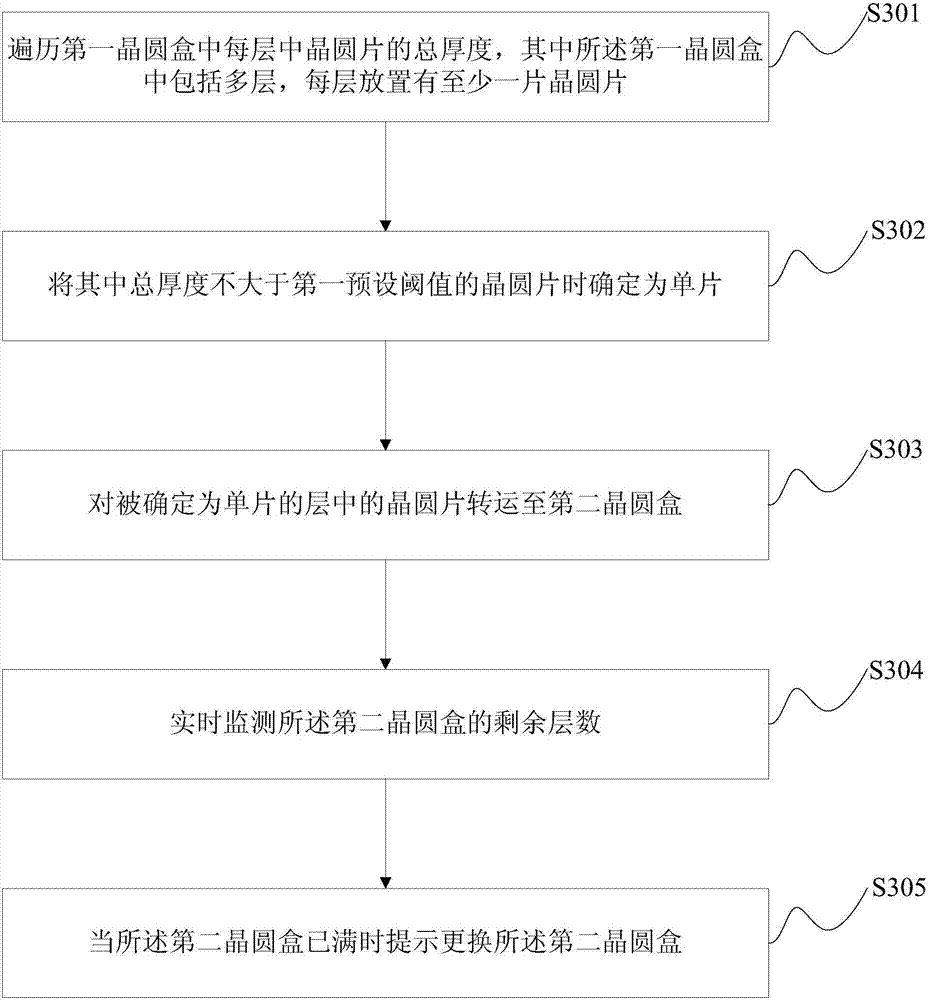

Wafer transportation method, wafer transportation device and wafer transportation system

The invention discloses a wafer transportation method, which comprises the steps of traversing the total thickness of wafers at each layer in a first wafer box, wherein the first wafer box comprises multiple layers, and at least one wafer is placed at each layer; determining a wafer with the total thickness being not greater than a first preset threshold to be a single wafer; and transferring thewafer at the layer determined to have a single wafer to a second wafer box. In addition, the invention further discloses a wafer transportation device and a wafer transportation system. According to the wafer transportation method disclosed by the invention, a code disc value of a motor is acquired through a position sensor, state information of a wafer is obtained before a grabbing arm of a manipulator, the detection time is short, the success rate is high, and problems such as wafer damages occurred during grabbing of the manipulator due to dislocation of wafers in the wafer box are avoided.Compared with a wafer transmission detection device in the past, the wafer transportation device performs judgment on the wafer state before transmission, greatly improves the transmission efficiencyof the wafers and greatly reduces the number of broken wafers.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

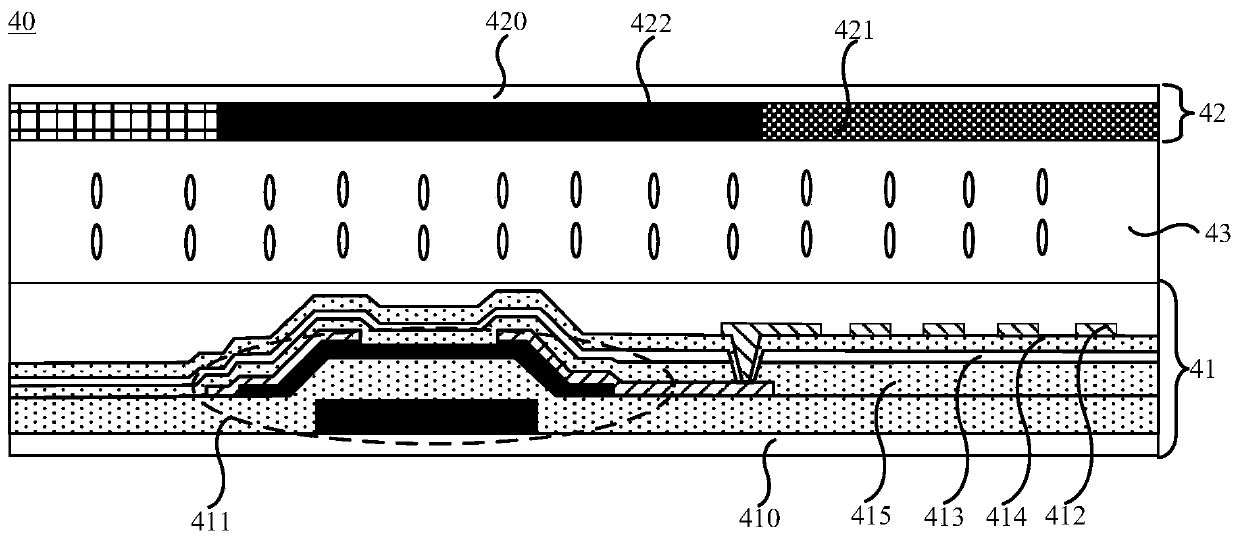

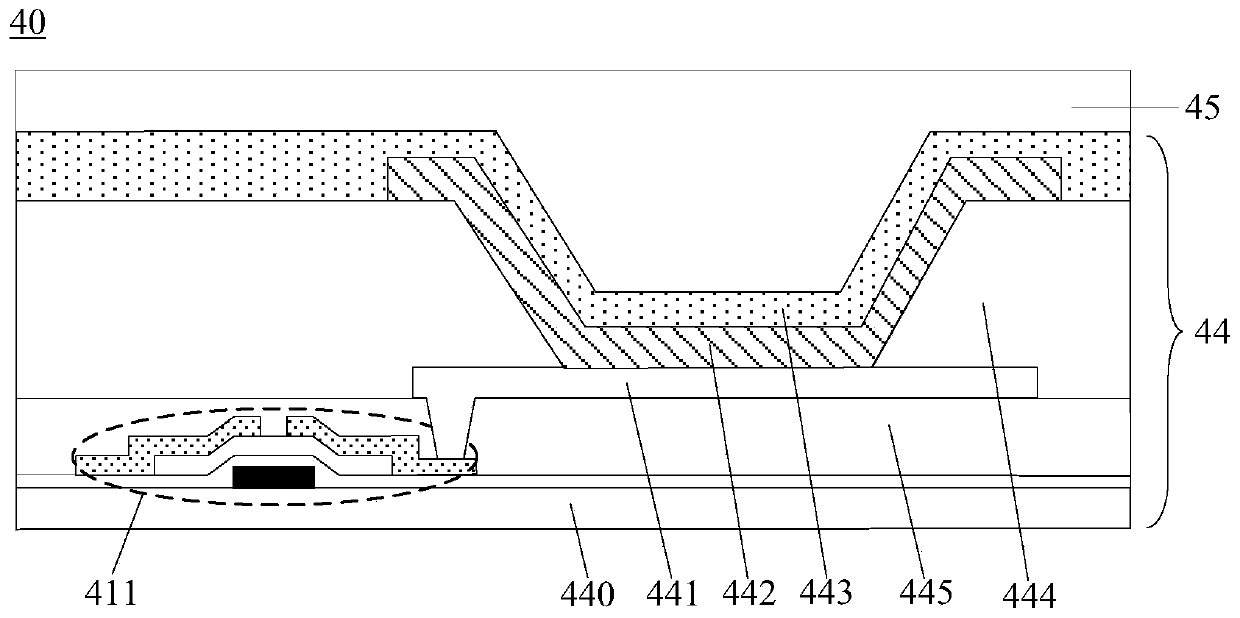

Microelement capable of being tested and micro-transferred, manufacturing, testing and transferring method of microelement and display device

PendingCN111933627AAchieving current extensionImprove light extraction efficiencySemiconductor/solid-state device testing/measurementSolid-state devicesDisplay devicePhysics

The invention provides a microelement capable of being tested and micro-transferred, a manufacturing, testing and transferring method of the microelement and a display device. A first electrode and asecond electrode of a LED chip extend to the surface of a bonding layer corresponding to a groove through the side wall of the LED chip respectively, so that the first electrode and the second electrode are exposed above the groove and play a role in supporting the LED chip in an inverted suspended state. And meanwhile, the first test electrode and the second test electrode can be used for carrying out an electrical test before the LED core particles are transferred, so that the yield screening of the LED core particles is realized, the LED core particles with abnormal electrical properties are prevented from being transferred to the substrate, and the repair cost is further reduced. And then, in a subsequent transfer process, metal of the first electrode and the second electrode exposed above the groove can be used as a chain for mass transfer, an exposed bonding layer is used as an anchor, and the micro-element is positioned to each anchor through transfer equipment, so that mass transfer of the micro-element can be realized.

Owner:XIAMEN QIANZHAO SEMICON TECH CO LTD

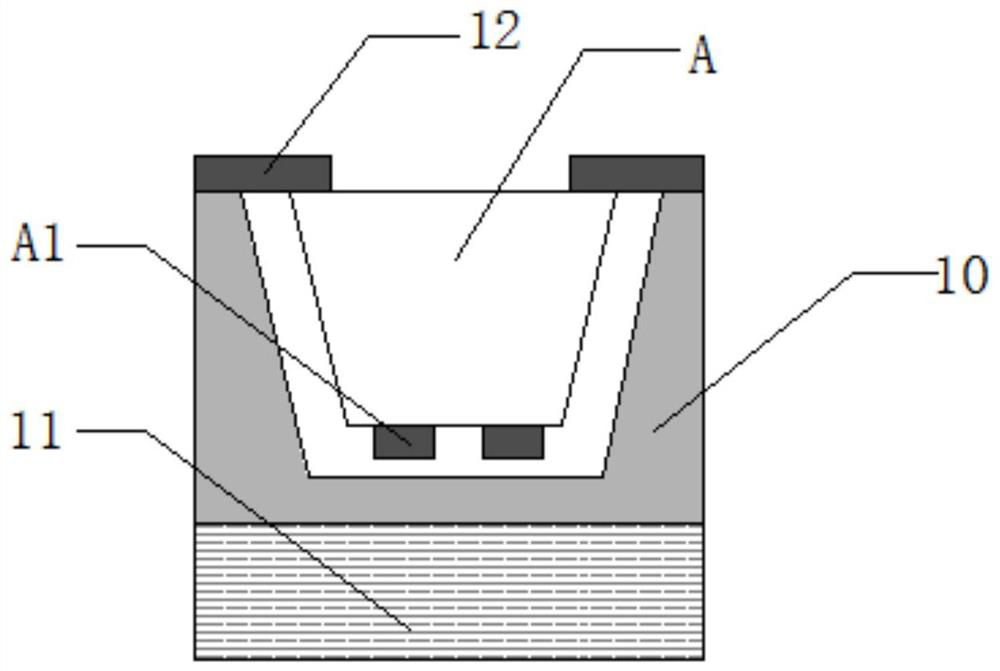

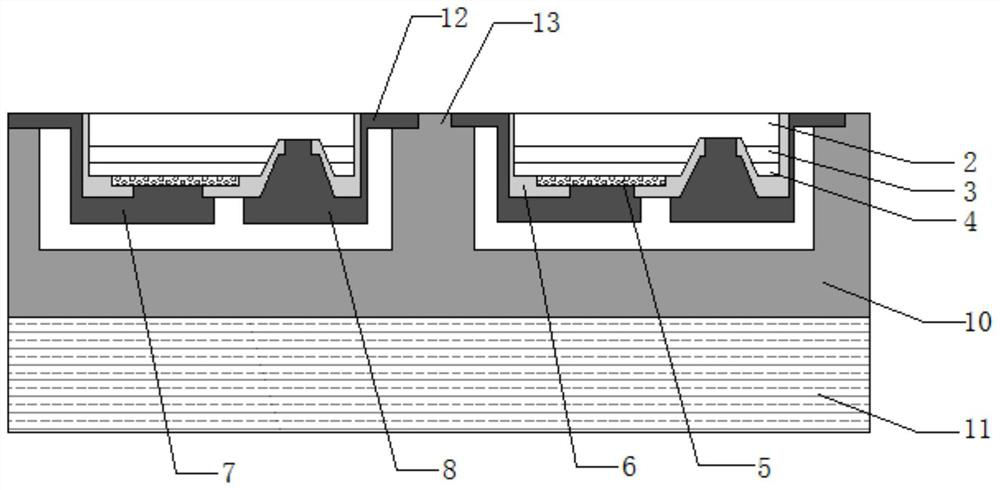

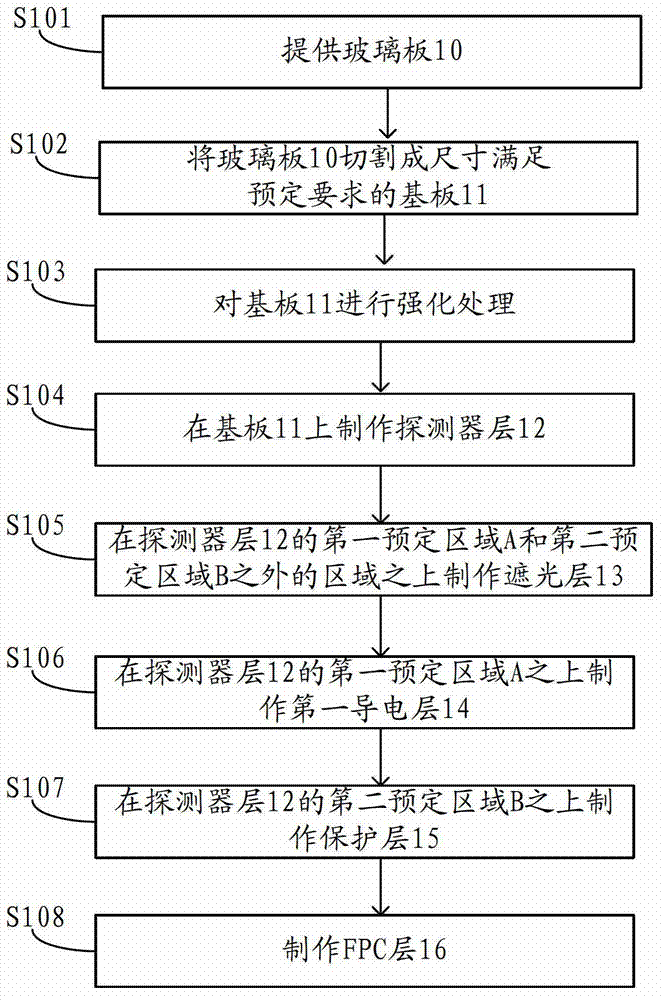

Touch screen and manufacturing method thereof

ActiveCN102866807AAvoid the problem of cutting hard to achieveEasy to implementInput/output processes for data processingEngineeringGlass sheet

An embodiment of the invention provides a touch screen and a manufacturing method thereof. The manufacturing method includes providing a glass board; cutting the glass board into a substrate with the size meeting predetermined requirements; strengthening the substrate; manufacturing a detector layer on the strengthened substrate; manufacturing shading layers on regions outside a first predetermined region and a second predetermined region on the detector layer; manufacturing a first conductive layer on the first predetermined region of the detector layer; manufacturing a protective layer on the second predetermined region of the detector layer and enabling the protective layer to cover the parts of the shading layer; and manufacturing an FPC (flexible printed circuit) layer, enabling the FPC layer to cover the first conductive layer and electrically connecting the FPC layer with the detector layer via the first conductive layer. Compared with the prior art, the touch screen and the manufacturing method thereof are easy to implement.

Owner:TRULY OPTO ELECTRONICS

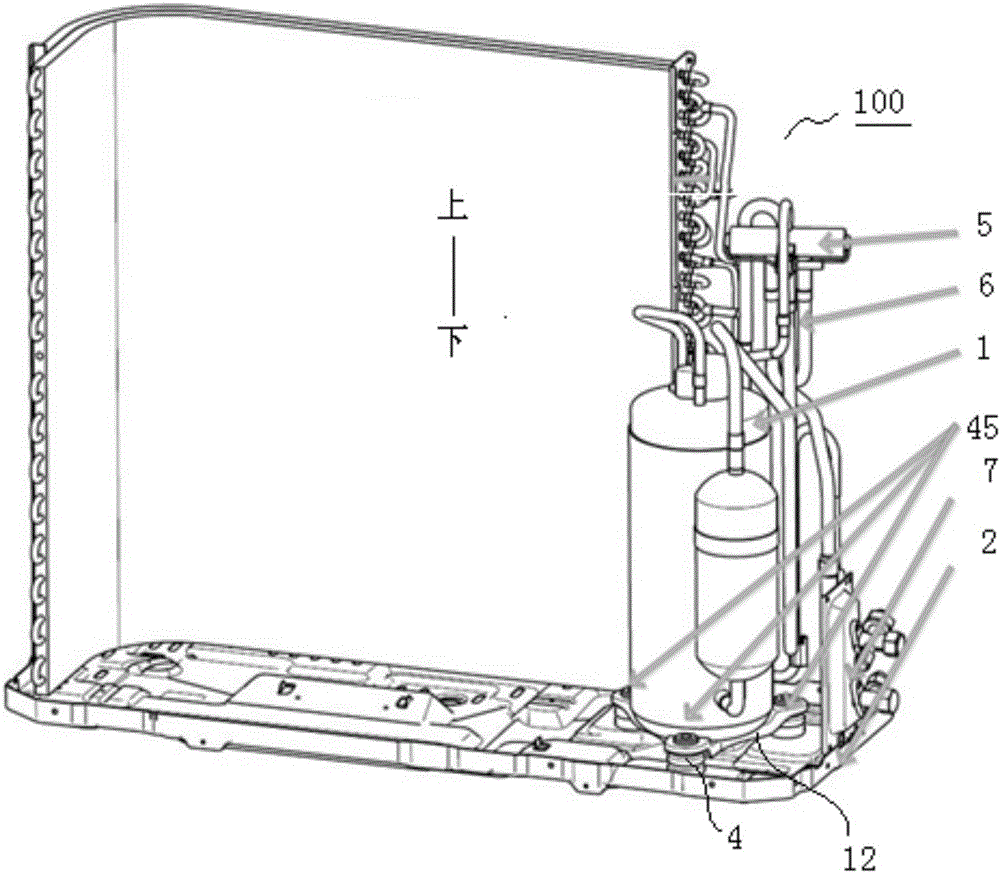

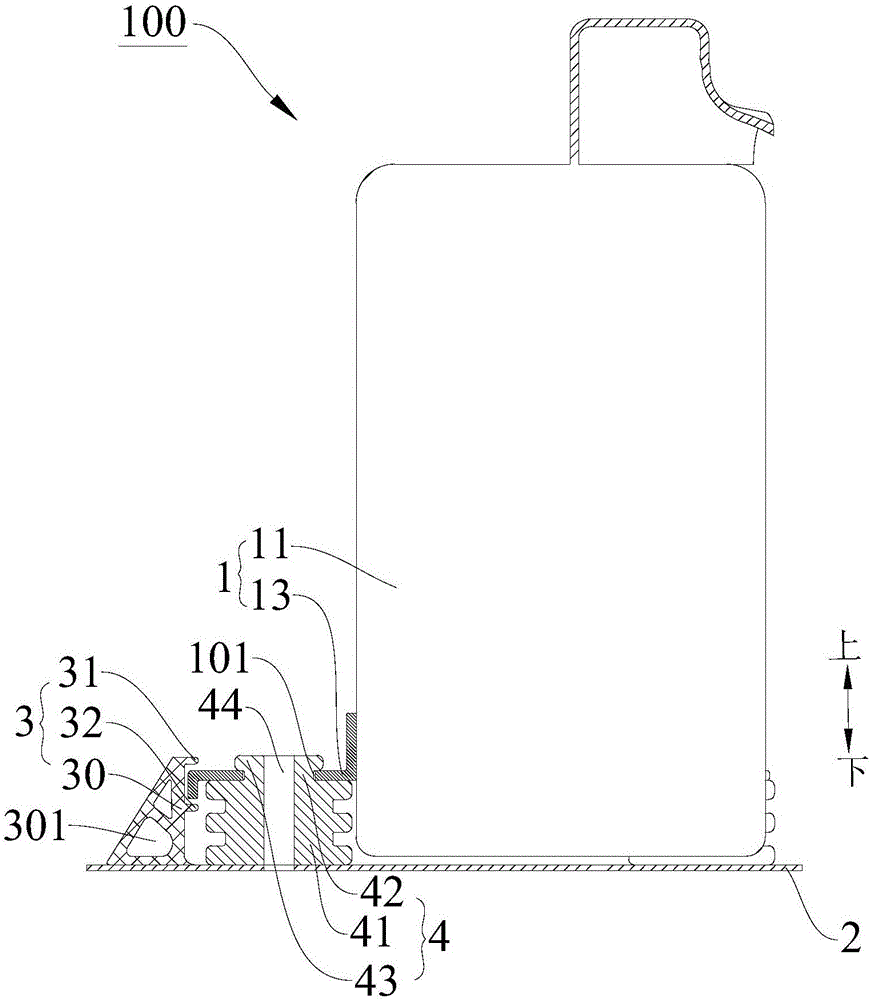

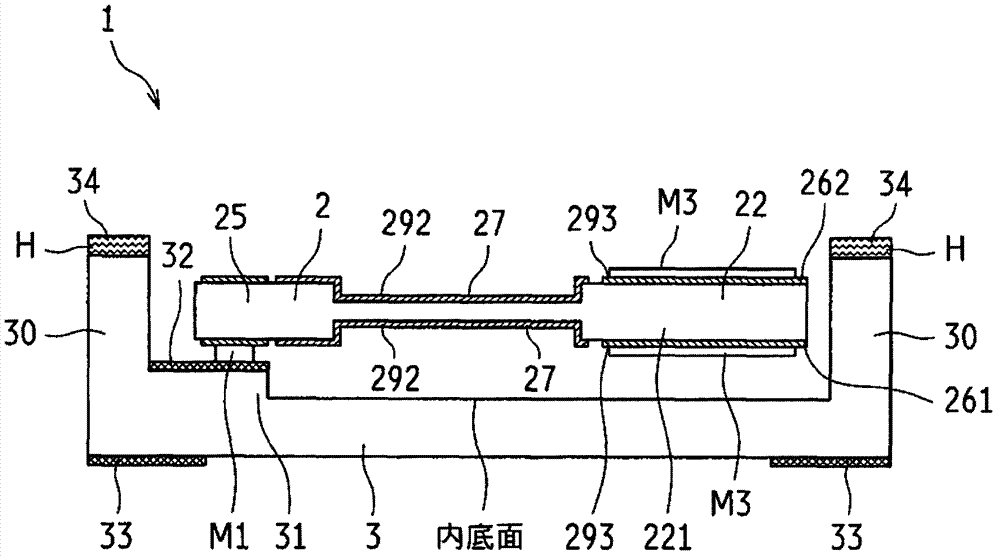

Refrigerating device

The invention discloses a refrigerating device. The refrigerating device comprises a box body base plate, a compressor and a limiting support, wherein the compressor is arranged on the box body base plate; and an upper limiting block for limiting the upward vibration amplitude of the compressor is arranged on the limiting support. According to the refrigerating device in the embodiment of the invention, the limiting support and the box body base plate are matched to limit the up-down vibration amplitude of the compressor, realize vibration attenuation of the compressor in the operating, transporting and falling processes, avoid excessive stress of a pipeline, and also avoid excessive stress of a connected part between the compressor and the box body base plate, thereby avoiding the phenomena of pipeline breaking, and tearing or deformation and separation and the like of the connected part between the compressor and the box body base plate due to impact load or fatigue load.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Yarn finishing device for textile machinery

The invention relates to the technical field of textile production, and specifically discloses a yarn finishing device for a textile machinery. The yarn finishing device for the textile machinery comprises a pedestal, a support frame is fixedly mounted at a left side of the pedestal through a bolt, moreover, at least three guide blocks arranged at equal distance are integrally formed on the support frame, a centering column is integrally formed on an upper end of each guide block, and a yarn cone for winding yarns is mounted on the centering column through sleeving connection. Beneficial effects: the yarn finishing device designed by the invention is convenient to use, can effectively sorting and ordering the yarns through ring-shaped yarn grooves on a traction roller and an adhesive roller, also can realize tensioning for the yarns through cooperation of a tensioning spring and the adhesive roller, and thus, can effectively avoid problems, such as breaking of the yarns caused by intertwining and friction among the yarns; moreover, the device also can effectively remove redundant fibers on the yarns through a vacuum pump and the adhesive roller, and consequently can effectively avoid interference on follow-up textile processing caused by the redundant fibers.

Owner:CHANGLE LITIAN KNITTING TEXTILE CO LTD

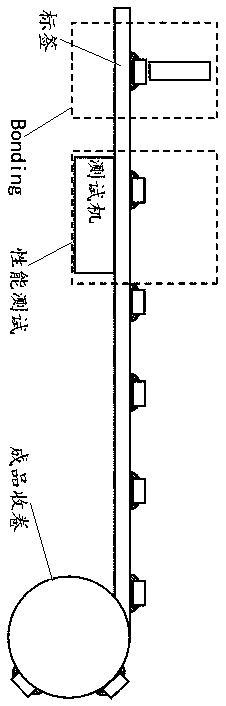

Online coating mechanism of RFID tag bonding machine and using method of online coating mechanism

InactiveCN109018499AImprove impact resistanceImprove reliability and longevityWrapping material feeding apparatusRecord carriers used with machinesEngineeringImpact resistance

The invention discloses an online coating mechanism of a RFID tag bonding machine and a using method of the online coating mechanism, and belongs to the technical field of RFID tags. According to theonline coating mechanism of the RFID tag bonding machine and the using method of the online coating mechanism, after chip bonding is completed, a protective film is additionally arranged on the surface of the chip to improve the impact resistance of the chip, so that the service life of existing products is prolonged, and the reliability of the products is improved. The coating mechanism is designed on an existing Bonding machine and is improved, so that the coating function is achieved without affecting the Bonding efficiency, and the mechanism with the coating function is obtained; and the position of the coating mechanism and the position of a performance testing or winding process device can be exchanged freely, so that the coating function is achieved in the Bonding process, and accordingly, the reliability of the chip is greatly improved while the cost is effectively controlled.

Owner:ARIZON RFID TECH YANGZHOU

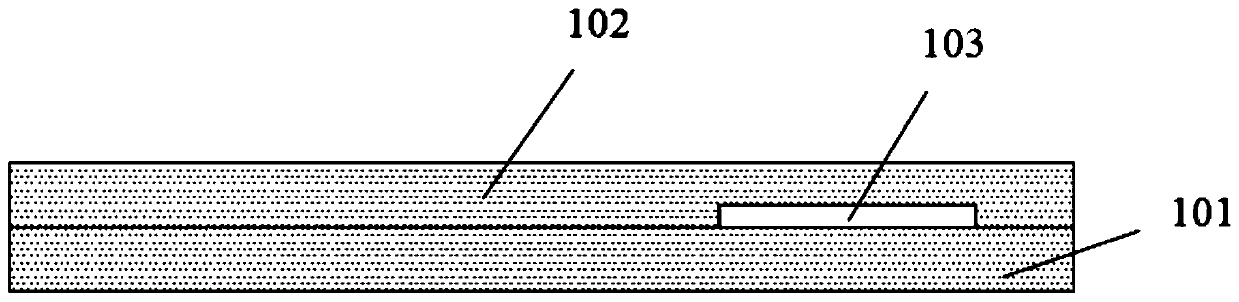

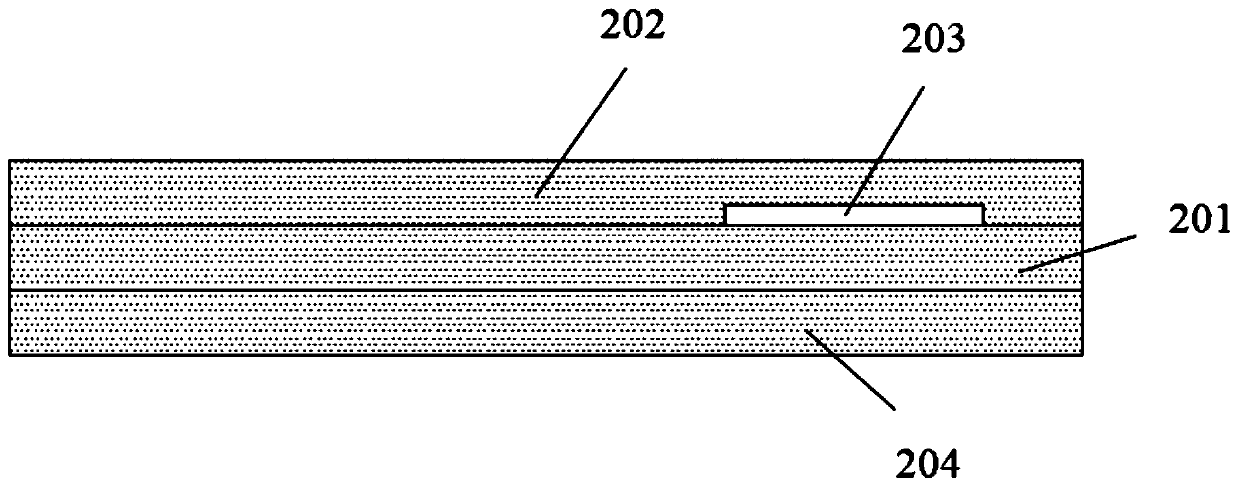

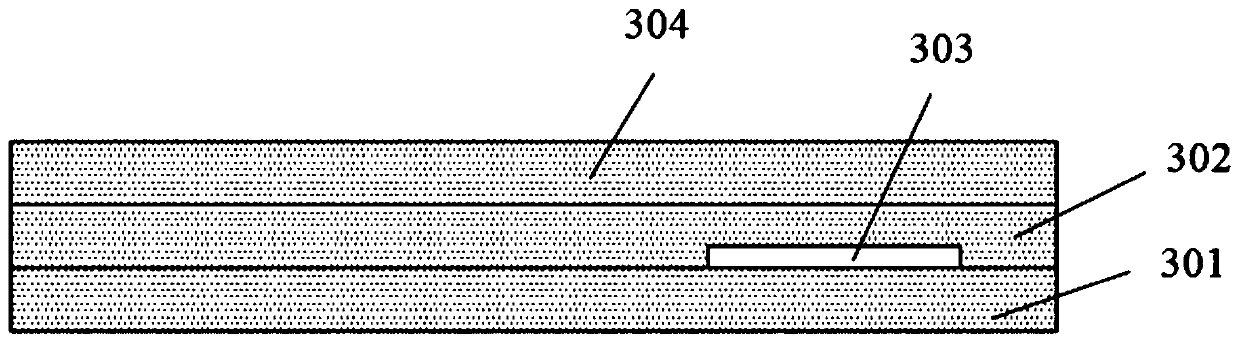

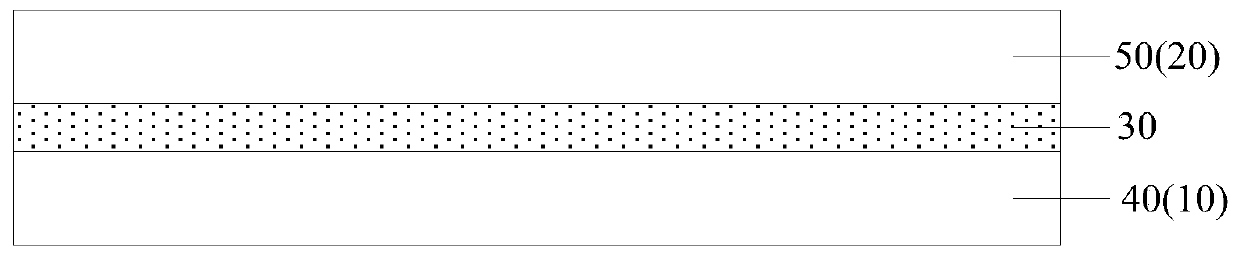

Flexible thin film substrate, preparation method thereof, display panel and display device

InactiveCN110854130AImprove bending performanceReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingHeat resistanceDisplay device

The present invention provides a flexible thin film substrate including a flexible substrate. The flexible substrate including a first substrate layer and a second substrate layer that are stacked. The second substrate layer is disposed over the first substrate layer. The bending region of the second substrate layer is provided with at least one groove. In the present invention, the groove is formed in the bending region of the flexible substrate to reduce the thickness of the substrate in the bending region so that the stress neutral line in the bending region approaches a metal wiring layer,thereby improving the bending resistance of the flexible thin film substrate, and avoiding problems such as an increase internal stress and film breakage in the bending region. The flexible thin filmsubstrate structure of the present invention includes at least two stacked substrate layers to meet the requirements for high flexibility, heat resistance, high water and oxygen resistance.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

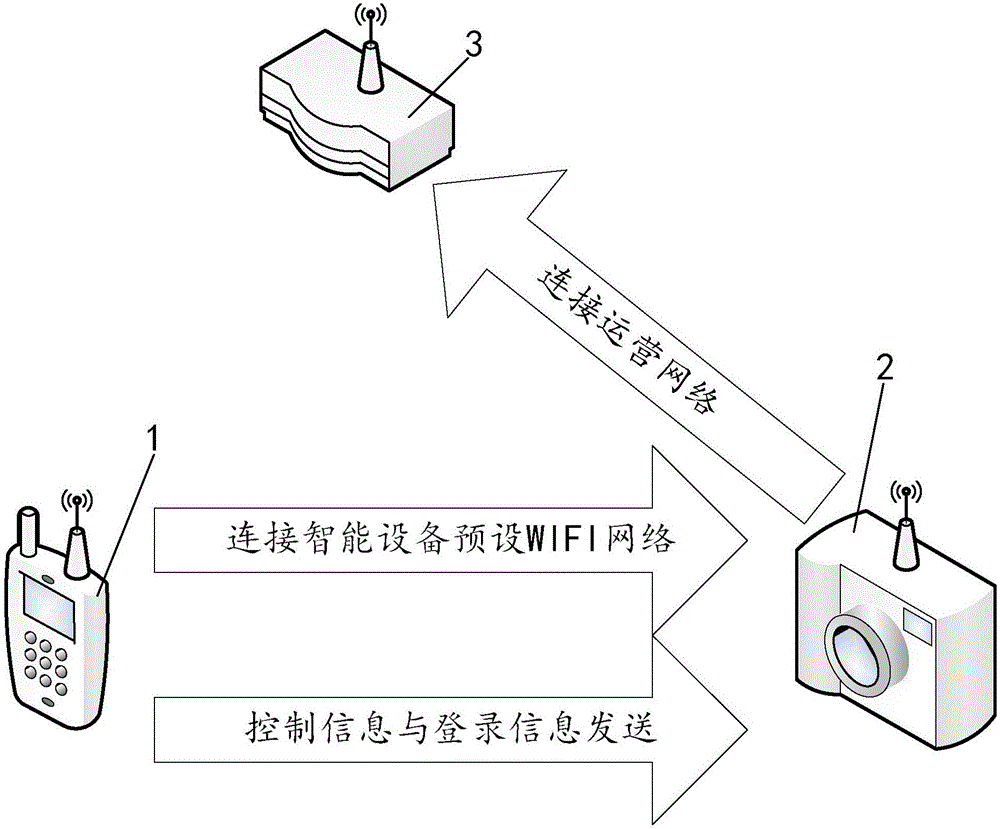

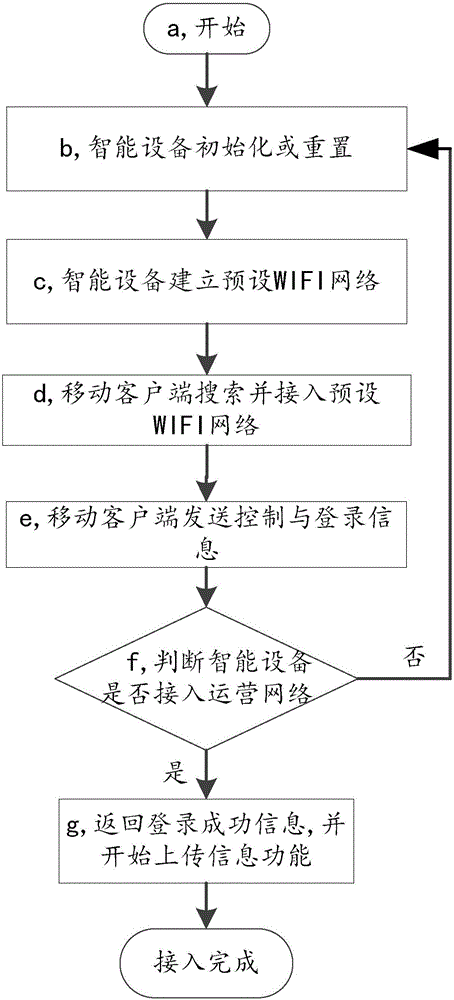

Method for intelligent equipment to obtain operation network configuration by using access point function

InactiveCN105722082AReduce complexityReduce manufacturing costAssess restrictionTransmissionNetwork intelligenceDisplay device

The invention discloses a method for intelligent equipment to obtain operation network configuration by using an access point function. An operation network, the intelligent equipment and a mobile client side are included. The method comprises the following steps that: (1), the intelligent equipment radiates a WIFI signal with a preset security protocol; and the mobile client side automatically searches and is connected to the WIFI signal with the preset security protocol through a pre-set algorithm; and (2), login information of the operation network is set in the mobile client side; and the intelligent equipment is accessed to the operation network according to the login information of the operation network. According to the method for the intelligent equipment to obtain the operation network configuration by using the access point function provided by the invention, the intelligent equipment is unnecessary to manually operate; troubles when the intelligent equipment is operated can be reduced; the intelligent equipment is unnecessary to be provided with an input device and a display device; the complex degree of the intelligent equipment is reduced; the cost is saved; and the intelligent equipment is accessed to a local area network wirelessly, such that the problems of network line winding, breakage and the like can be avoided.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

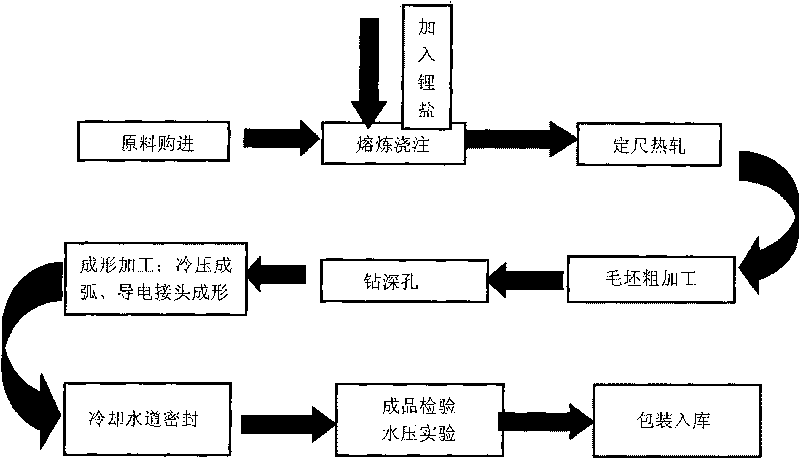

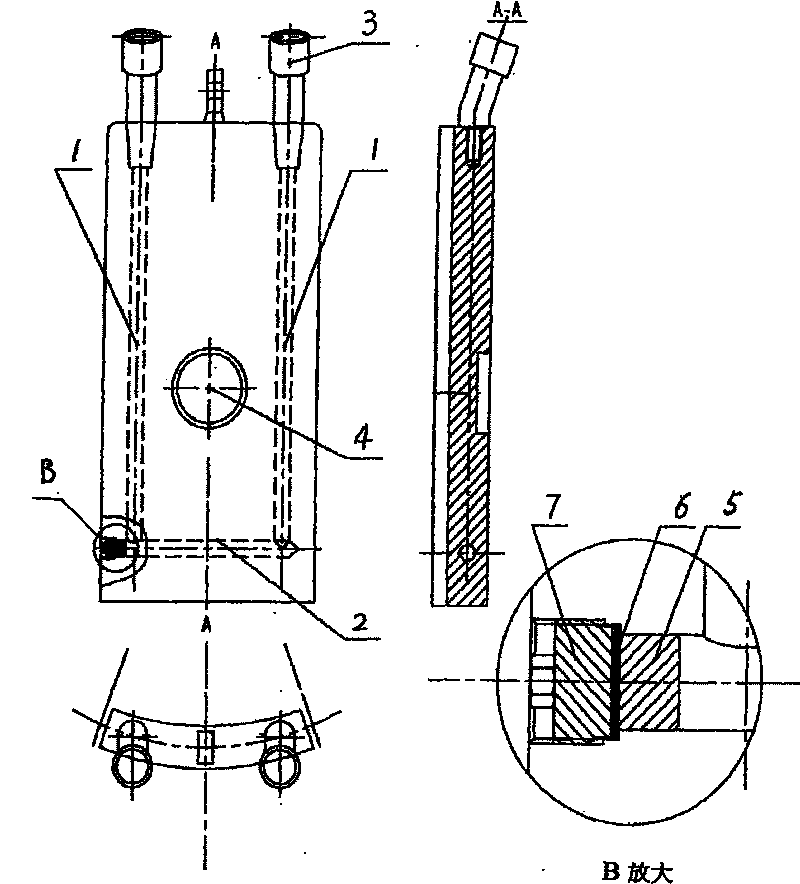

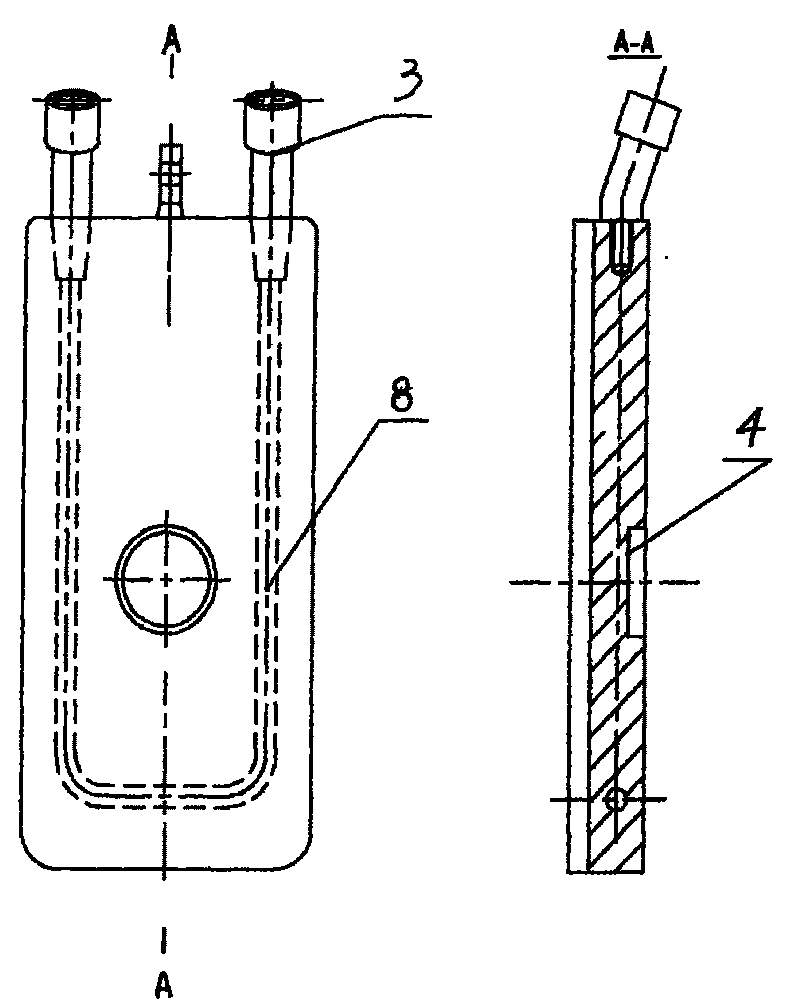

Red copper brass new technique used by ore-smelting electric furnace

ActiveCN101704176AImprove high temperature resistanceImprove corrosion resistanceElectric discharge heatingTemperature resistanceMechanical property

The invention relates to a method for manufacturing brass widely used as conductive element in ore-smelting electric furnace equipment in enterprises producing metallic silicon, ferrosilicon, calcium carbide and the like. The whole production technique mainly comprises the steps of adding trace lithium salt in red copper in melting and casting semicontinuously, hot rolling in set dimension, rough processing the blanks, drilling cooling deep holes, cold pressing and shaping, assembling into a whole, testing the finished product, etc. Cathode pure copper is selected as raw material compulsorily; deoxidation is carried out in melting to ensure the casting blank to be anaerobic copper ingot, and trace lithium salt is added, after casting and crystallizing, the compactness, corrosion resistance, high temperature resistance, abrasion resistance, impact resistance, hardness, electrical conductivity and thermal conductivity of the copper product are improved; the hot rolling process smashes bulky arborization crystal to cause crystalline grains to be thin, the fiber structure is continuous with being cut off the mechanical property, electrical conductivity and thermal conductivity are vastly enhanced; water holes are cooled by deep hole drilling machine processing; a press is used for performing cold pressing to roll the blank into arc shape; a boring machine and other equipments are used for boring out required cambered surface radius, electrical conduction joint parts and brass propping parts; and finally the parts are assembled into a whole, and the product is warehoused after passing the test.

Owner:GANSU MINGWANG ALUMINUM MATERIAL

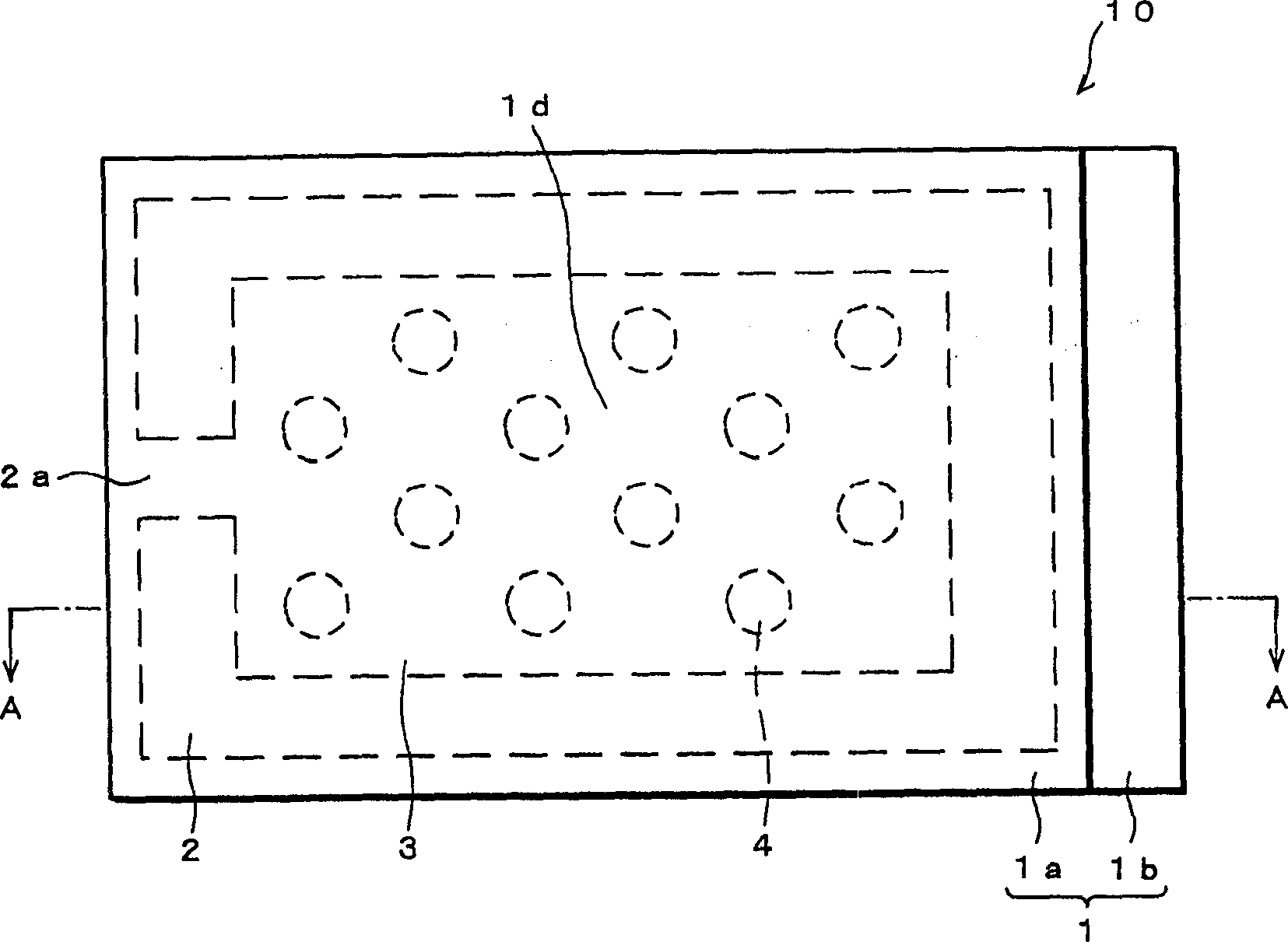

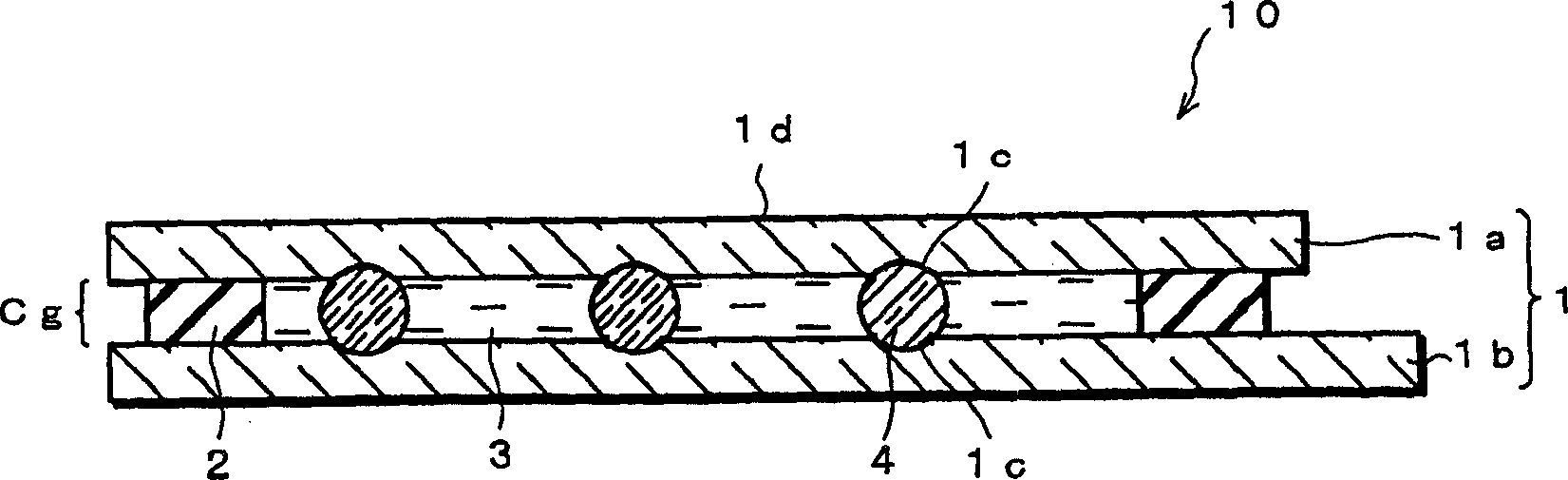

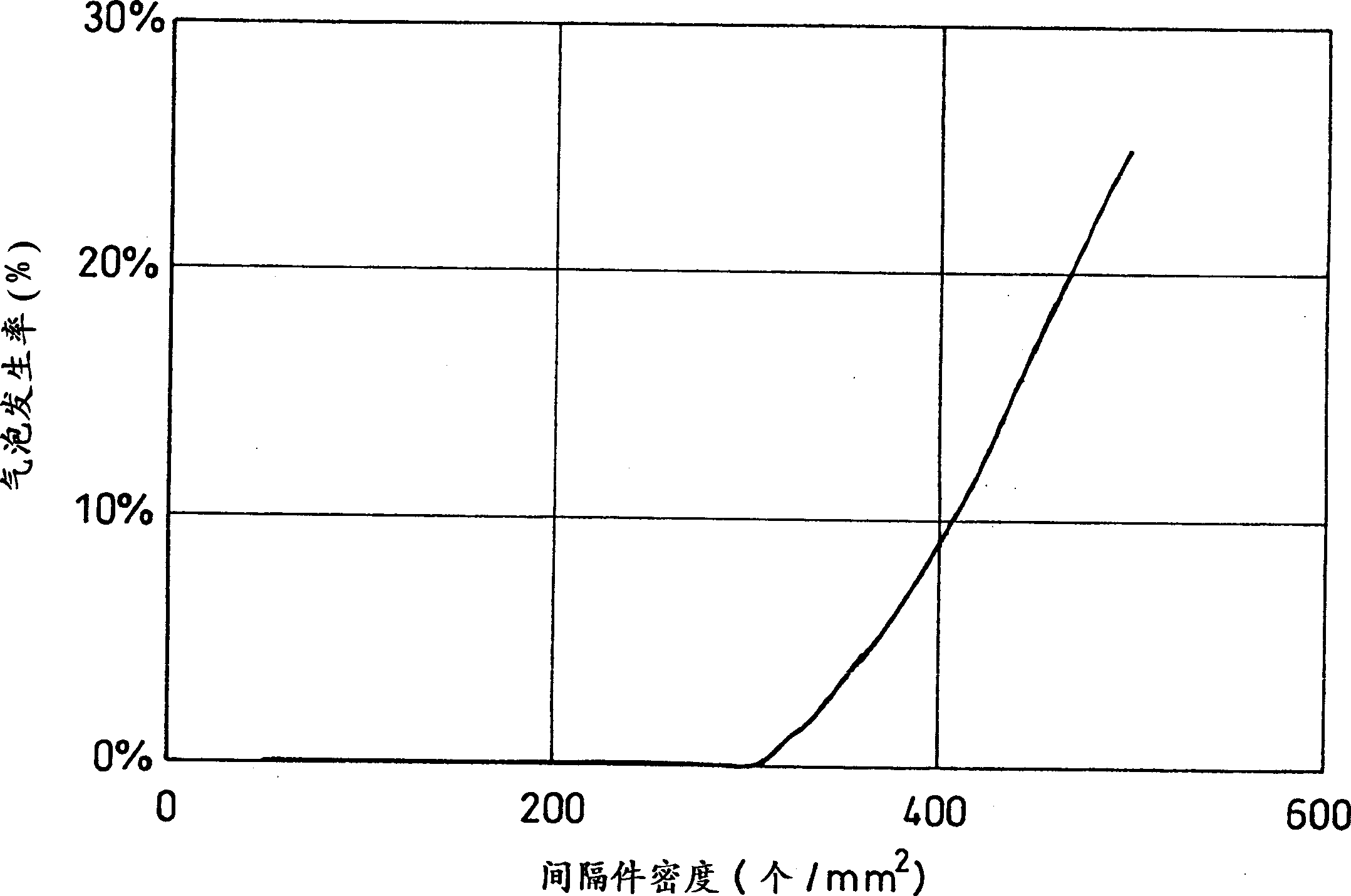

LCD element and its making process

InactiveCN1146751CReally fixedAvoid problems such as complication of manufacturing stepsNon-linear opticsIdentification meansLiquid-crystal displayEngineering

A liquid crystal display element includes a pair of substrates made of plastic, a liquid crystal sandwiched between the pair of substrates, and a plurality of spacers for maintaining a gap d between the pair of substrates, and when x is an average value of thickness of the plurality of spacers in a state without a load in such a direction that the plurality of spacers are sandwiched between the pair of substrates, d and not more than 300 pieces / mm<2>. Further, in the liquid crystal display element, an elastic modulus of the spacers is set to be larger than that of the pair of substrates. Thereby, the movement of the spacers is suppressed and the rigidity of the substrates is improved. As a result, in the liquid crystal display element, color shading is suppressed while suppressing generation of bubbles in a vacuum region and reduction in contrast, thus obtaining desirable display quality of a display image.

Owner:SHARP KK

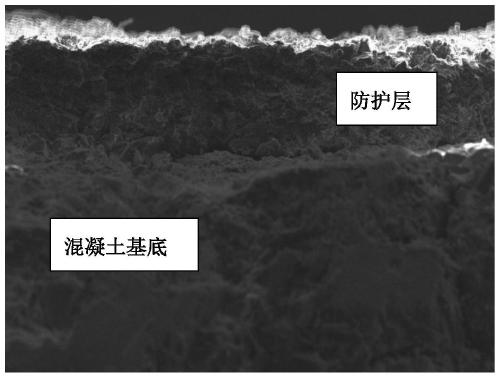

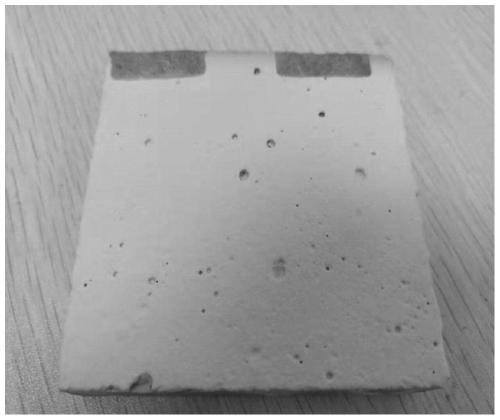

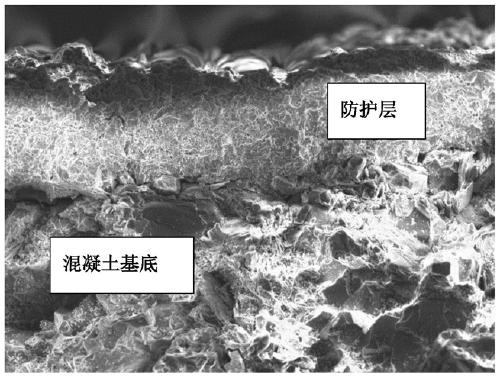

Concrete surface protection treatment method based on plasma hot-spraying technology

ActiveCN111575630AImprove frost resistanceImprove impermeability and durabilityMolten spray coatingWeather resistanceInorganic materials

The invention provides a concrete surface protection treatment method based on a plasma hot-spraying technology. According to the treatment method, firstly, high-pressure air at the temperature of 80DEG C to 100 DEG C is utilized to dry the surface of concrete; next, the high-pressure air is utilized to wrap and carry particles to roughen the surface of the concrete; then, high-pressure air at the temperature of 100 DEG C to 150 DEG C is utilized to flush and preheat the surface of the concrete; and finally, by the aid of plasma hot-spray equipment, a powdery inorganic non-metallic raw material with the particle size of 20 microns to 120 microns is used for hot-spraying an inorganic material protection layer on the surface of the concrete by adjusting the powder feeding rate, plasma power, the airflow rate, the moving velocity, the spraying distance and other parameters. Through the treatment method, the anti-freezing and anti-permeating abilities of the concrete are improved, the defects of poor weather fastness and short service life in traditional organic material protection coating brushing are overcome, and the method can be widely applied to surface protection on concrete prefabricated parts and cast-in-place concrete structures.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Preparation method of bamboo weaving handicraft surface spot cleaning agent

ActiveCN106398907AAvoid problems such as moldy interface breakageNo harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDistillationCleansing Agents

The invention provides a preparation method of a bamboo weaving handicraft surface spot cleaning agent. The method mainly comprises the following steps: pueraria root powder is prepared, an organic silane coupling agent is prepared, and nanometer silicon dioxide, zinc stearate, an octadecanol mixture, and 50% of the pueraria root powder are mixed; distillation is carried out, and distilled fluid is collected; auxiliary liquid is prepared in an agitator tank, the auxiliary liquid and distilled fluid are mixed, the rest 50% of the powder is added, and the cleaning agent is obtained. The method has the beneficial effects that the cleaning agent is sprayed on the handicraft, and dust on the handicraft can be cleaned; at the same time, the cleaning agent does not have viscosity and is not attached to the handicraft, the cleaning agent flows rapidly and does not damage the material of the handicraft, and the problems such as mildewing of the handicraft and connector fracture due to wetting and the like are avoided.

Owner:FUNAN COUNTY TIANYI CRAFTS

Efficient intelligent winder and working method thereof

The invention discloses a working method of an efficient intelligent winder. The efficient intelligent winder comprises a machine frame, at least one group of wire winding rollers, a group of wire feeders and a control device; a separation plate is arranged on each wire winding roller, a driving mechanism used for driving the wire winding rollers and a control mechanism are arranged in the controldevice, the wire winding rollers are arranged on the machine frame, and the wire feeders are arranged on the machine frame; a wire feeding hole is formed in each wire feeder, and the wire winding rollers, the wire feeders and the driving mechanism are all connected with the control mechanism. According to the working method of the efficient intelligent winder, a plurality of the wire winding rollers can be combined to be used and the separation plates can also be arranged on the wire winding rollers so that the winding requirements of a variety of electric wires and cables can be met at the same time, the effect that one wire winding roller is wound with the various wires can be realized, a lot of convenience is brought to construction and production, and the carrying problem of a plurality of the wire winding rollers is well solved.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

Household air conditioner outdoor unit vibration damping pipeline

InactiveCN105737273AEliminate vibrationImprove stabilityLighting and heating apparatusNoise suppressionFour-way valveEngineering

Owner:CHANGZHOU COLIN HUAXIN REFRIGERATION EQUIP CO LTD

Electronic wire connecting device with anti-falling function

InactiveCN111262092AEasy to operateImprove the fixed effectCoupling device detailsElectric machineryStructural engineering

Owner:章军伟

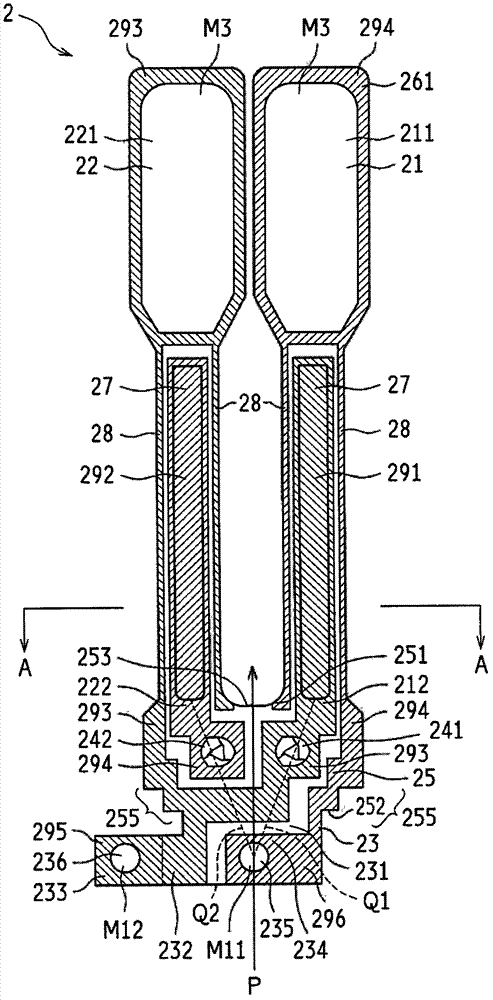

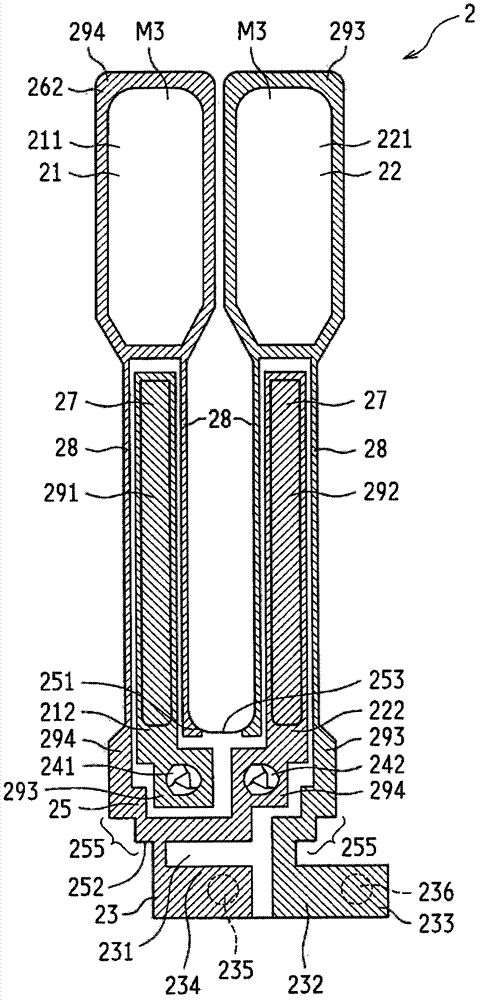

Tuning-fork type piezoelectric vibrating reed and tuning-ork type piezoelectric vibrator

ActiveCN103250349AAvoid problems such as breakagePrevent acoustic leaksImpedence networksPiezoelectric/electrostrictive device material selectionTuning forkMiddle line

A tuning fork-type piezoelectric resonator plate has a resonator blank comprising a pair of vibrating leg portions and a base portion from which the leg portions protrude. The pair of leg portions are arranged in parallel protrudingly from one end face of the base portion, and a pronged portion is formed between the pair of leg portions in an intermediate position in a width direction of the one end face of the base portion. The base portion has a pair of through holes along the one end face of the base portion, and on another end face side opposite to the one end face of the base portion, a joining region that joins to an external portion. The pair of through holes are specially positioned and have special wall surface configurations.

Owner:DAISHINKU CORP

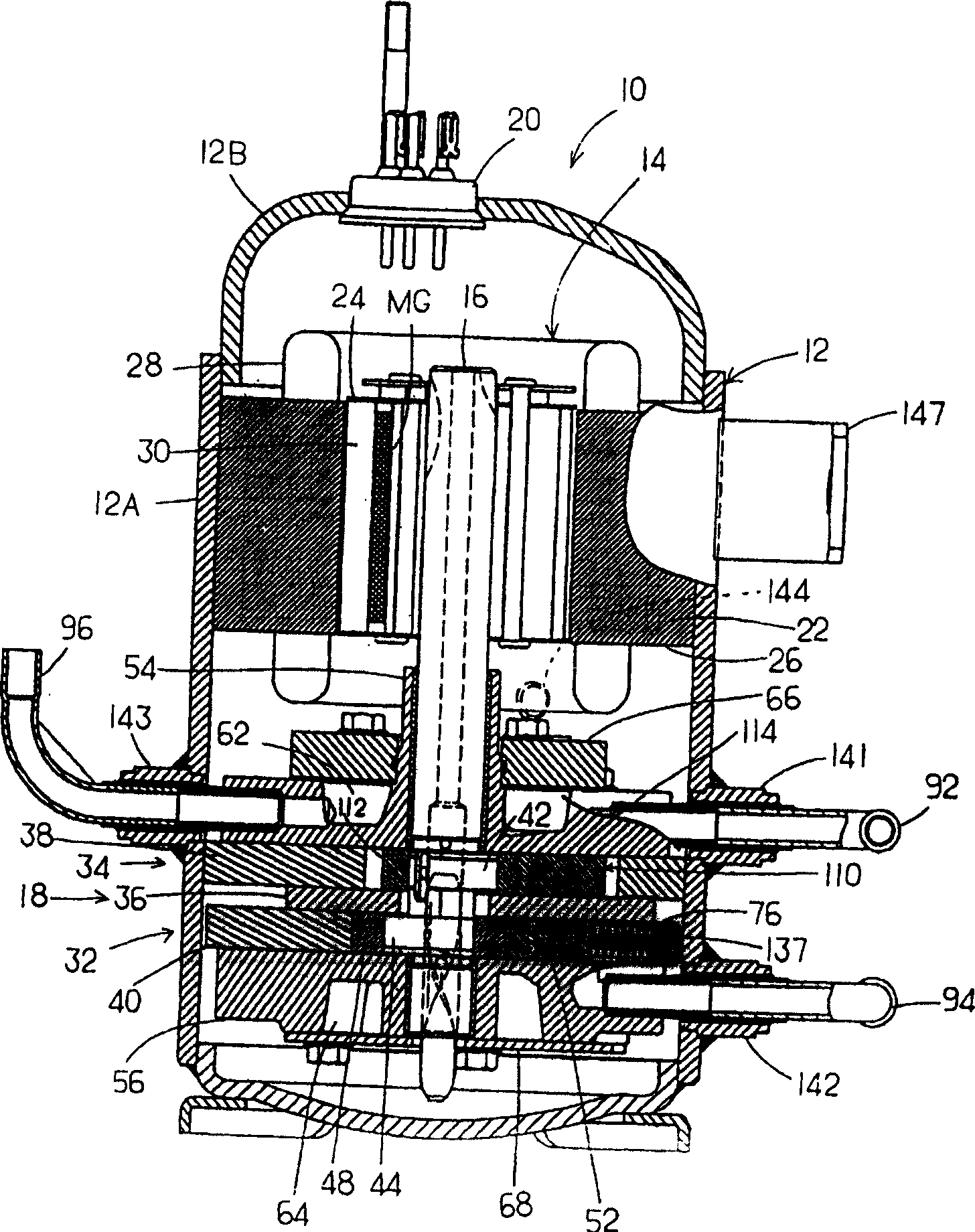

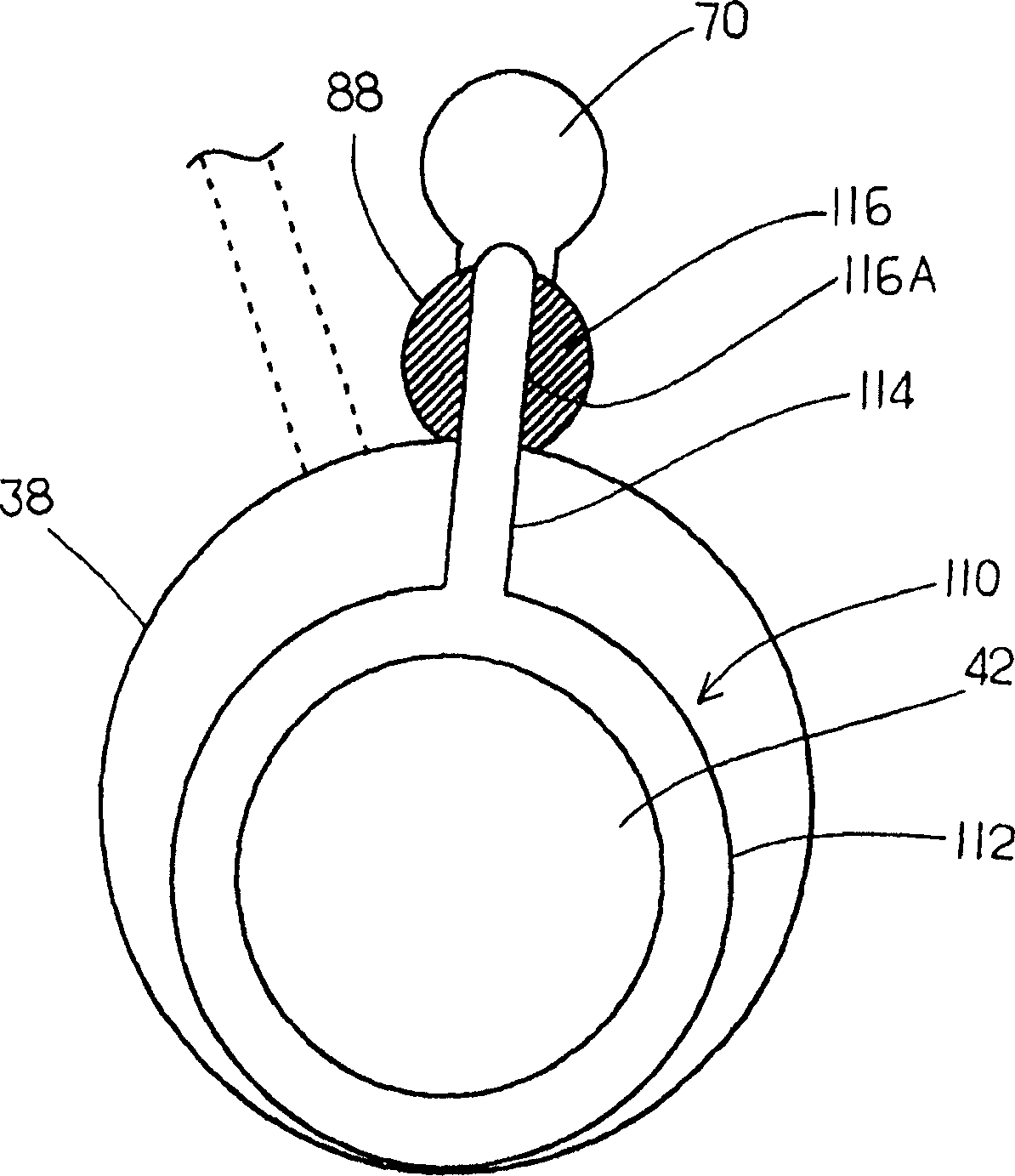

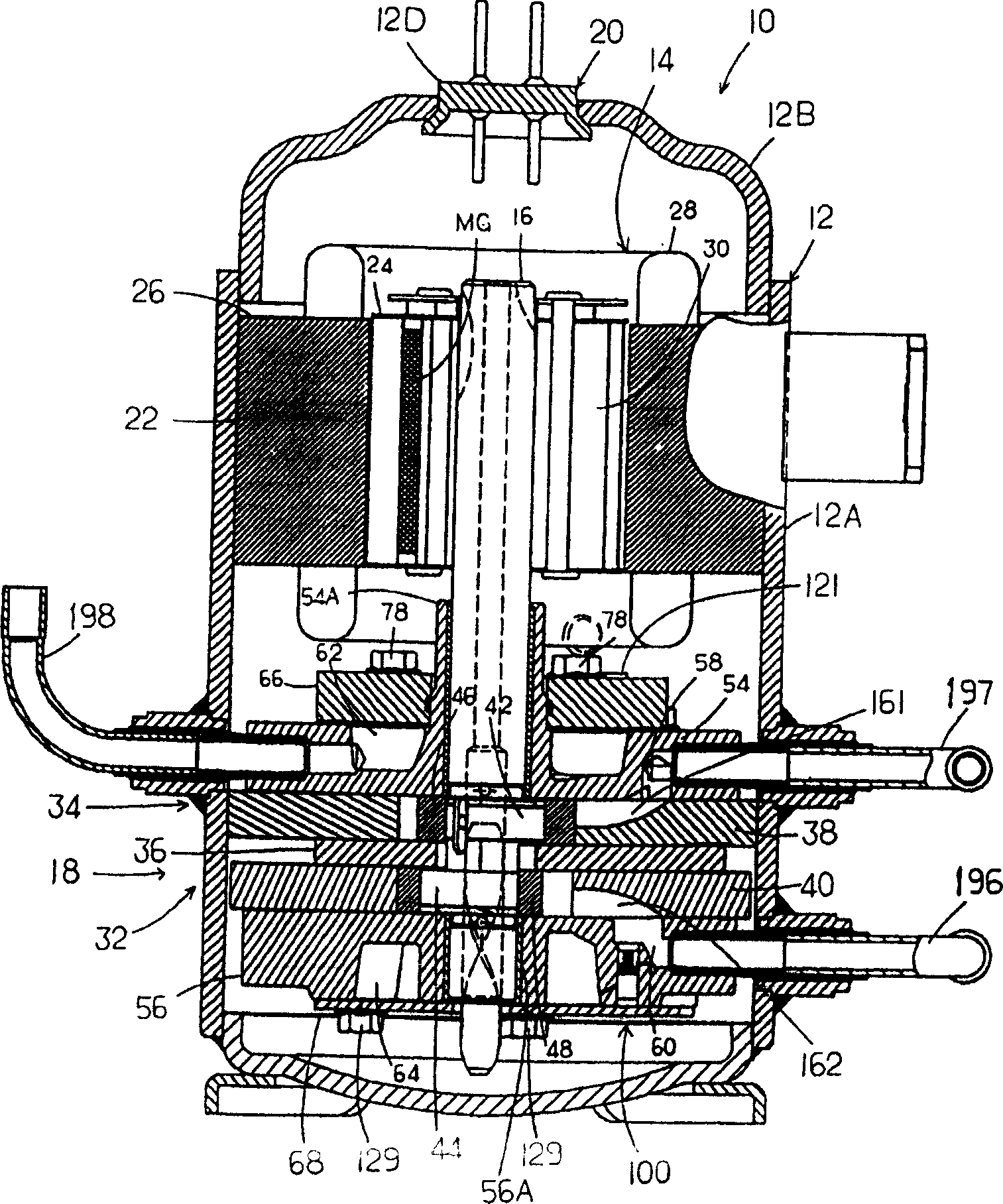

Rotary compressor, method for manufacturing the same, and defroster for refrigerant circuit

InactiveCN1807896AIncreased durabilityImprove reliabilityRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleEngineeringHigh pressure chamber

The invention provides a rotary compressor used to structurally simplify a laminae which divides a cylinder into a low-pressure chamber and a high-pressure chamber; in addition, the invention provides a multi-stage rotary compressor, the manufacturing method thereof and a defrosting device used in a coolant loop. The rotary compressor(10)comprises a first and a second rotary compressing units(32,34) which are driven via an electromotor(14) arranged in a sealed container(12). The first rotary compressing unit(32)is composed of an upper cylinder(38), a swinging piston(110) for a roller(112)which is connected with an eccentric unit(42)on the rotary shaft(16)of the electromotor(14) and eccentrically moves inside the upper cylinder(38), and a laminae(114) which is molded on the swinging piston(110) and protrudes in the radial direction from the roller(112)to divide the upper cylinder(38)into a low-pressure chamber and a high-pressure chamber. A retaining member is arranged to retain the laminae(114) of the swinging piston(110)in a sliding and swingy mode.

Owner:SANYO ELECTRIC CO LTD

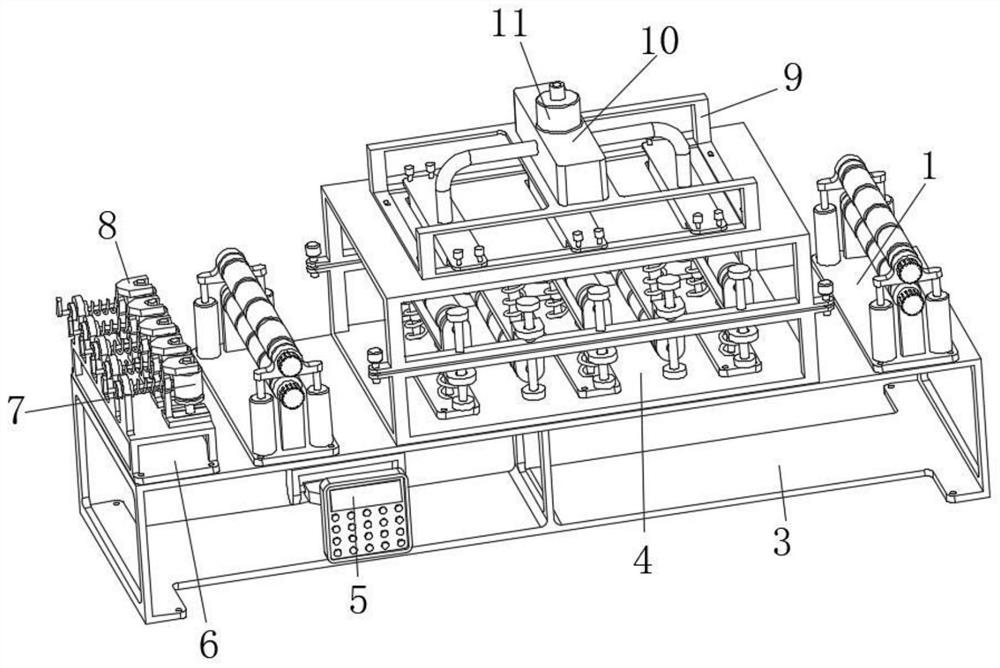

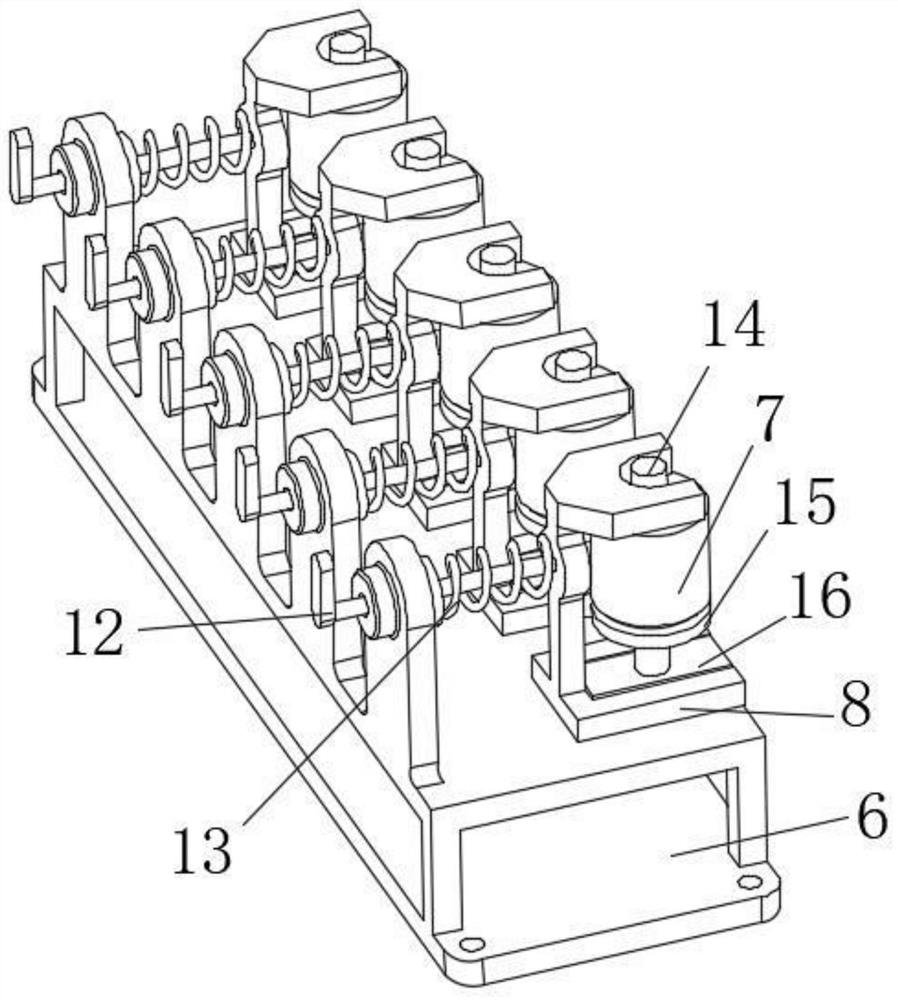

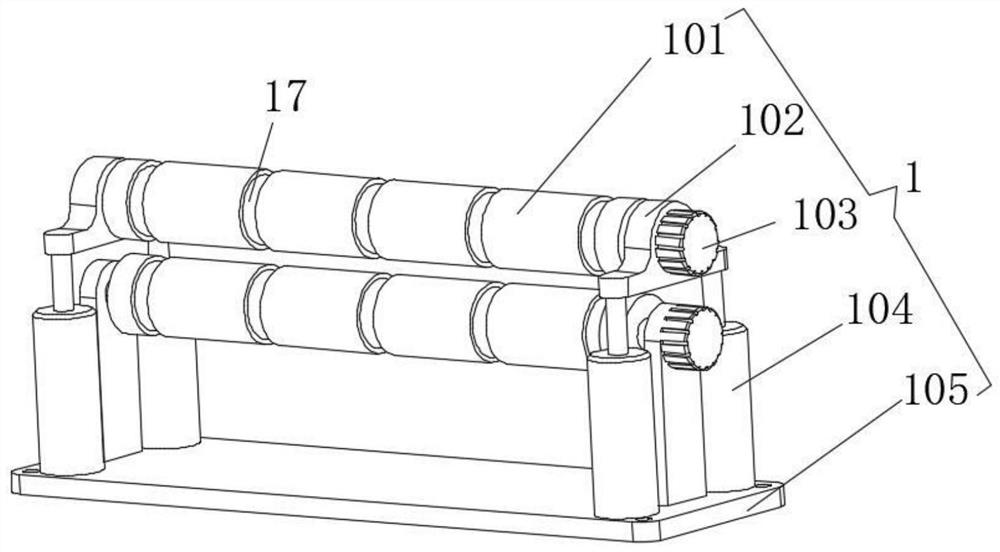

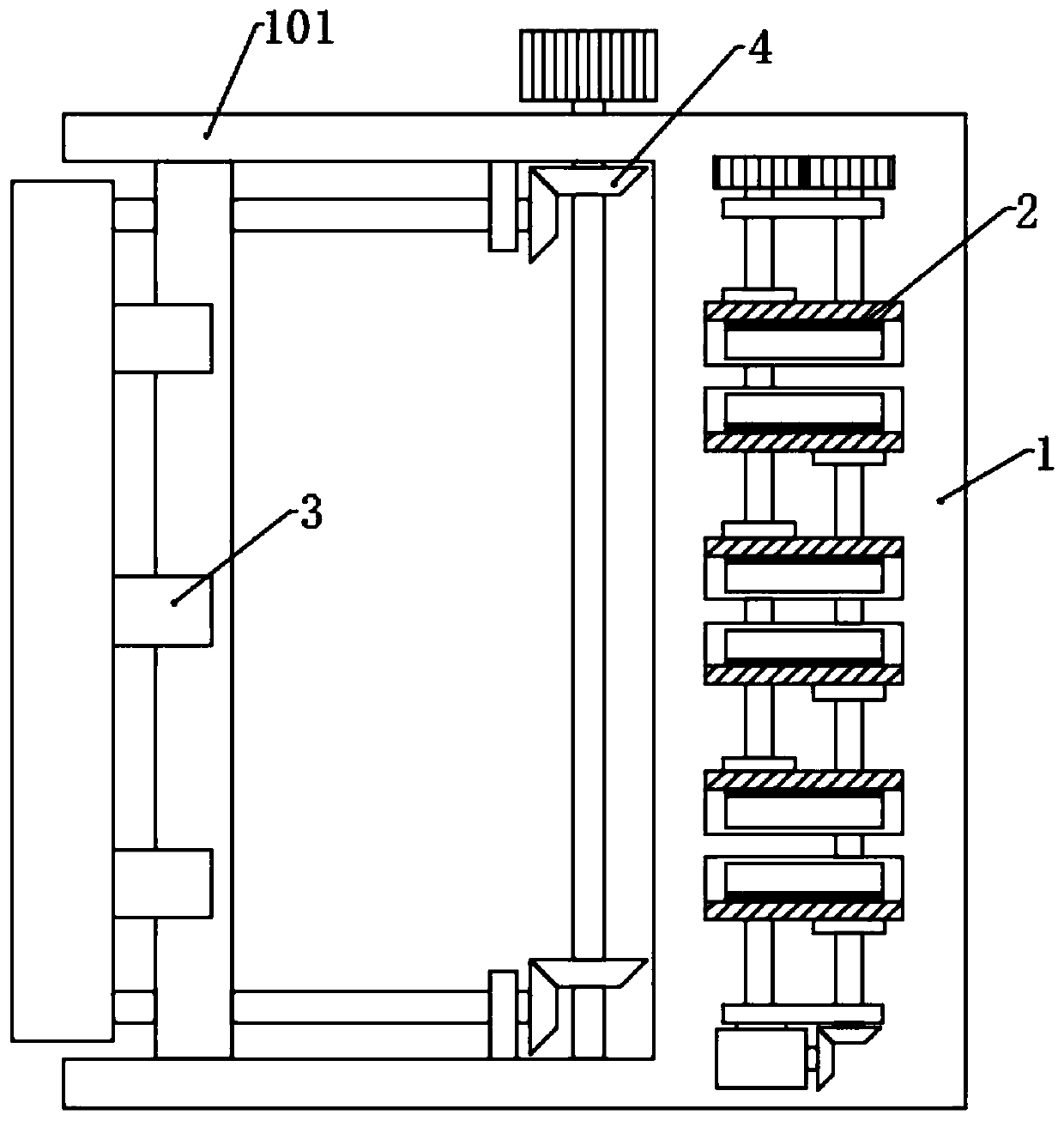

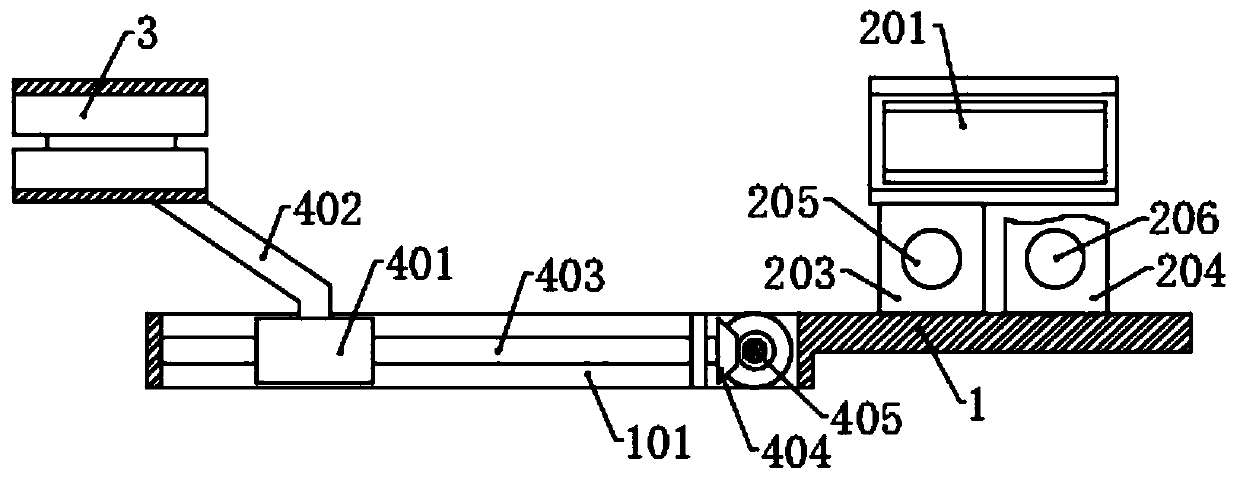

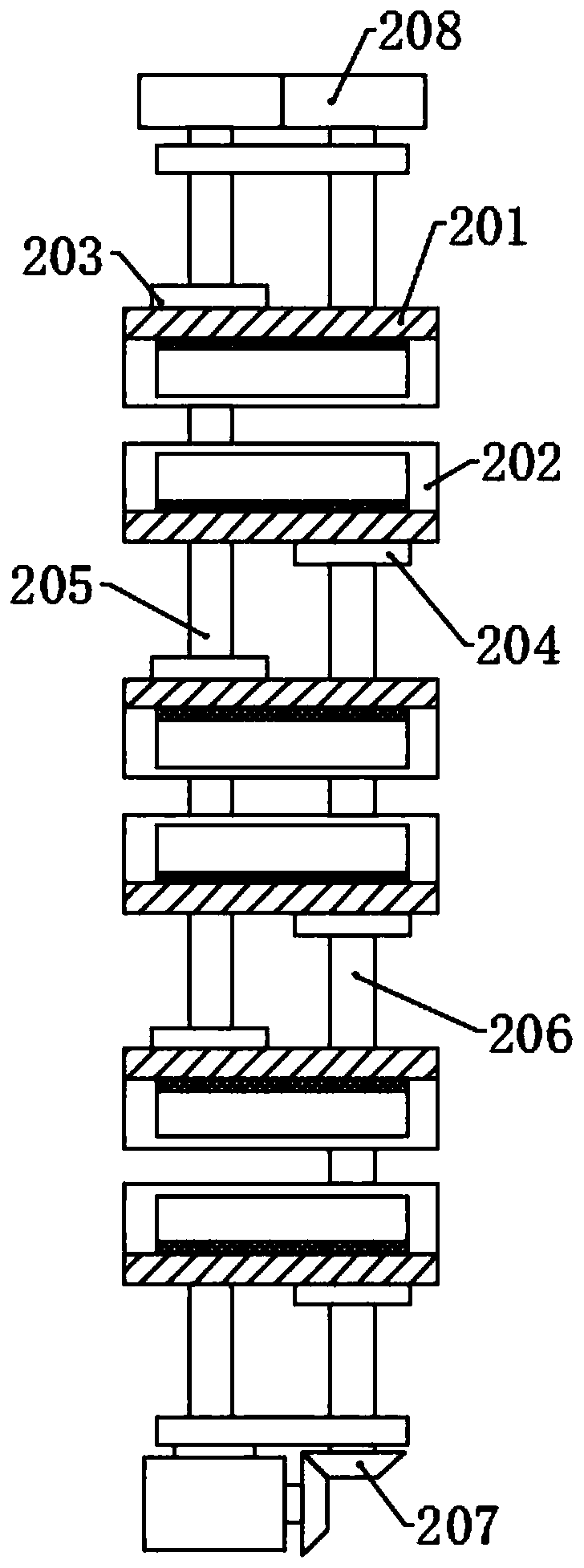

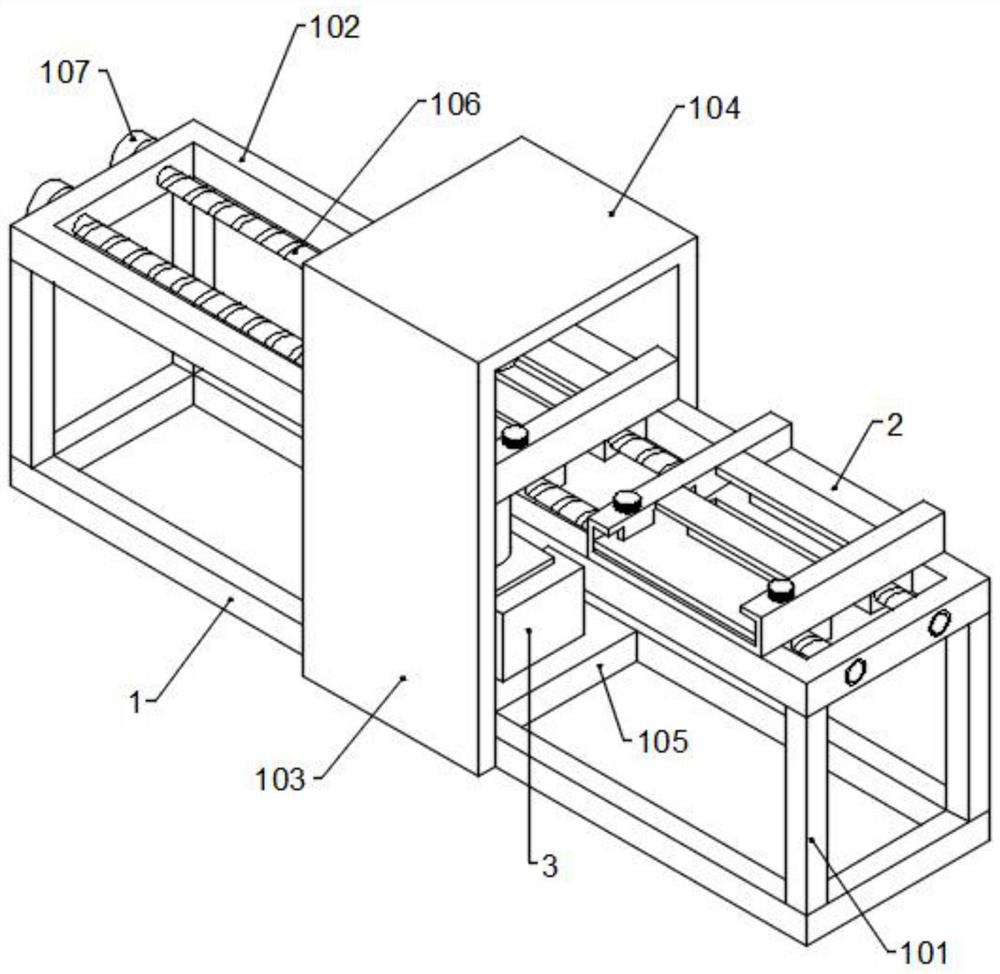

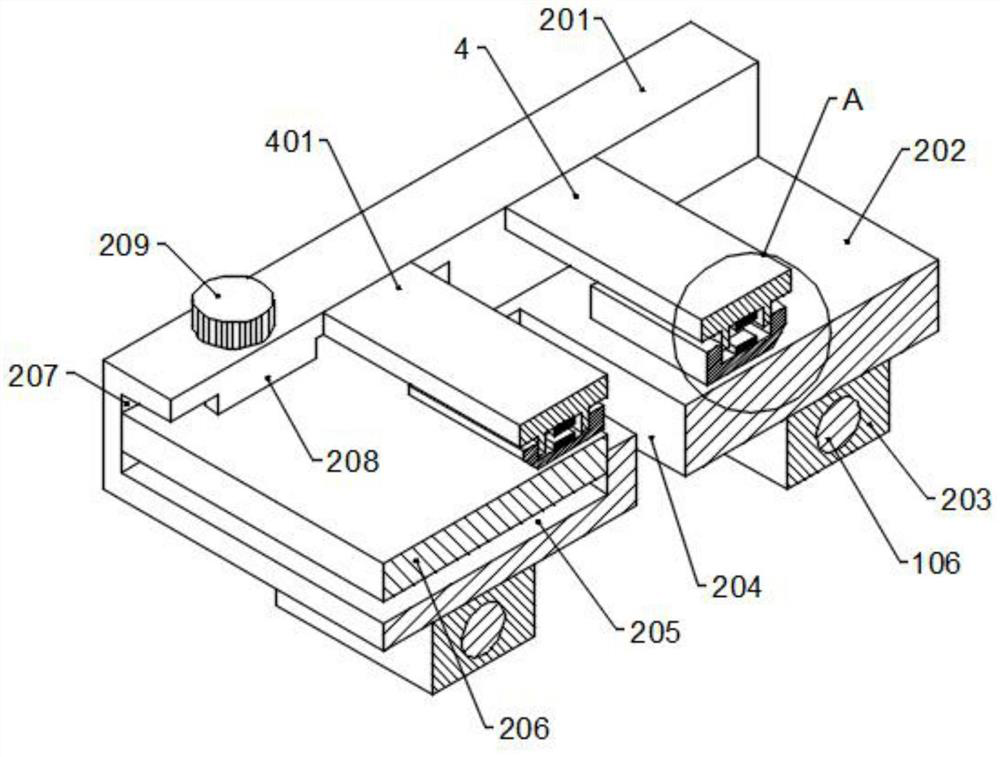

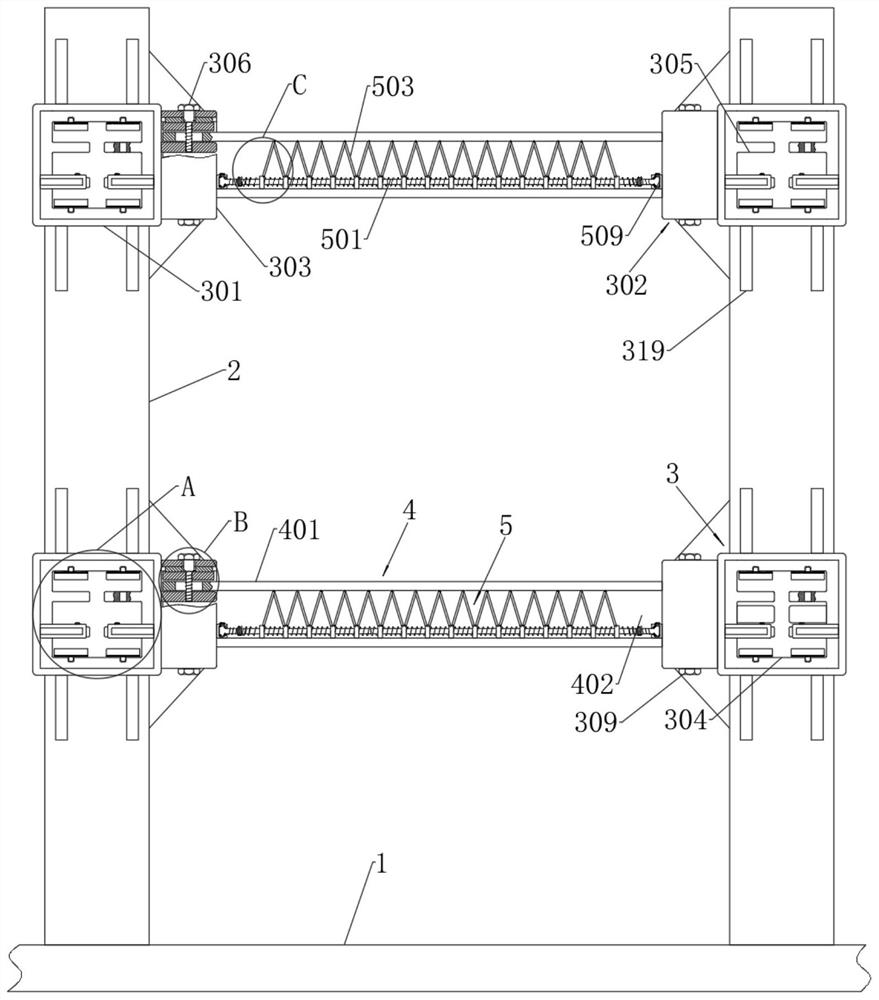

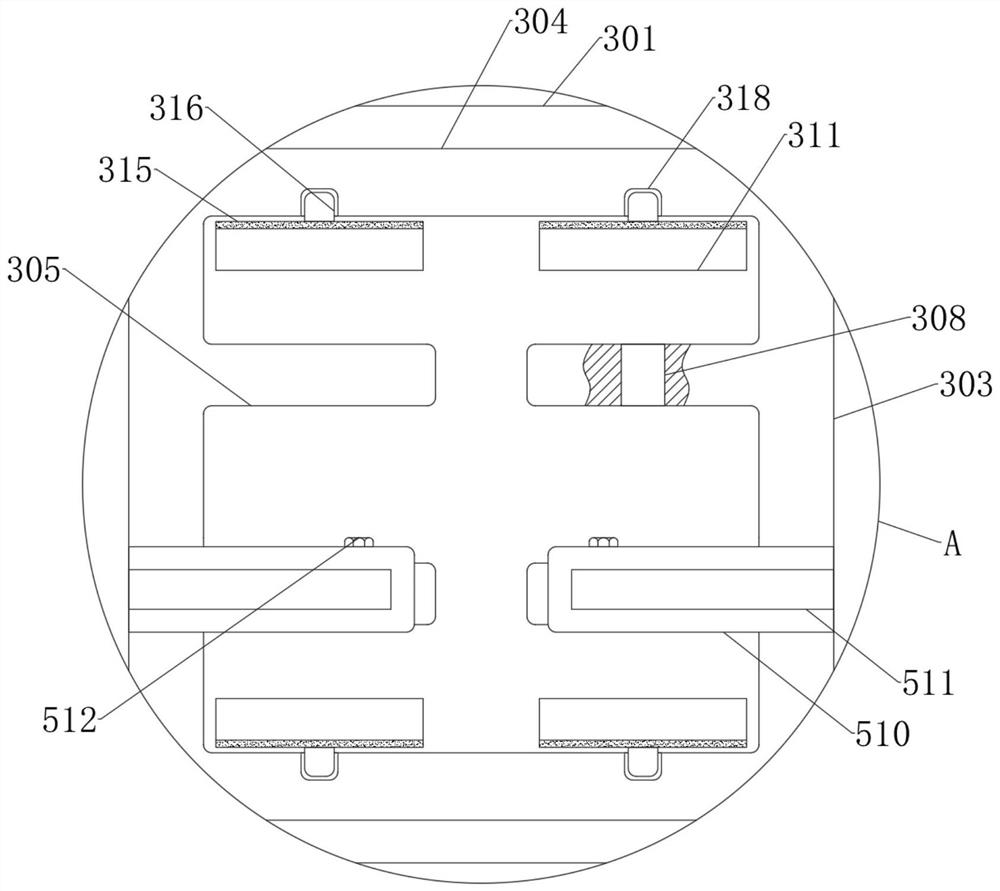

Plate composite forming machining equipment based on electromagnetic riveting and friction stir welding

ActiveCN114043248AImprove processing efficiencyImprove stabilityOther manufacturing equipments/toolsPositioning apparatusEngineeringMachining

The invention discloses plate composite forming processing equipment based on electromagnetic riveting and friction stir welding in the technical field of riveting equipment, which comprises a worktable, a mounting seat and a top plate, a movable screw and two positioning seats are arranged on the worktable, an electromagnetic riveting mechanism is arranged on the mounting seat, and a friction stir mechanism is correspondingly arranged on the top plate. A feeding assembly is arranged on one side of the friction stir mechanism. By cooperation of the stirring friction mechanism and the electromagnetic riveting mechanism, stable deformation locking structures are formed on the two sides of the bottom while a rivet and two plates are subjected to stirring friction solid-phase welding, and the plate riveting stability is improved; the protruding structures at the bottoms of the plates form an outer wrapping structure in a certain shape, and the problems of breakage and the like caused by the fact that the bottoms of rivets penetrate through the plates are solved; and riveting machining, feeding and discharging of the plate can be conducted at the same time through the two positioning bases, and the machining efficiency is improved.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

Three-way flange

A three-way flange comprises first flanges, second flanges and gaskets which are arranged between the first flanges and the second flanges, wherein each first flange comprises a first flange plate and a first pipeline; each second flange comprises a second flange plate and a second pipeline; each gasket is arranged in a gasket groove in the middle part of the second flange plate, and the middle part of the first flange plate is provided with a convex edge which is matched with the gasket groove; and the second pipelines of three second flanges are welded together to form a tee joint. Targeting at a complicated pipeline design, the flange is designed into a three-way type, so that the three-way flange is applicable to a pipeline with multiple branches, the pipeline design is more flexible, and the problem that the three-way flange is broken when bearing high pressure can be effectively avoided through the design of a reinforcing rib.

Owner:广州铭泰船舶科技有限公司

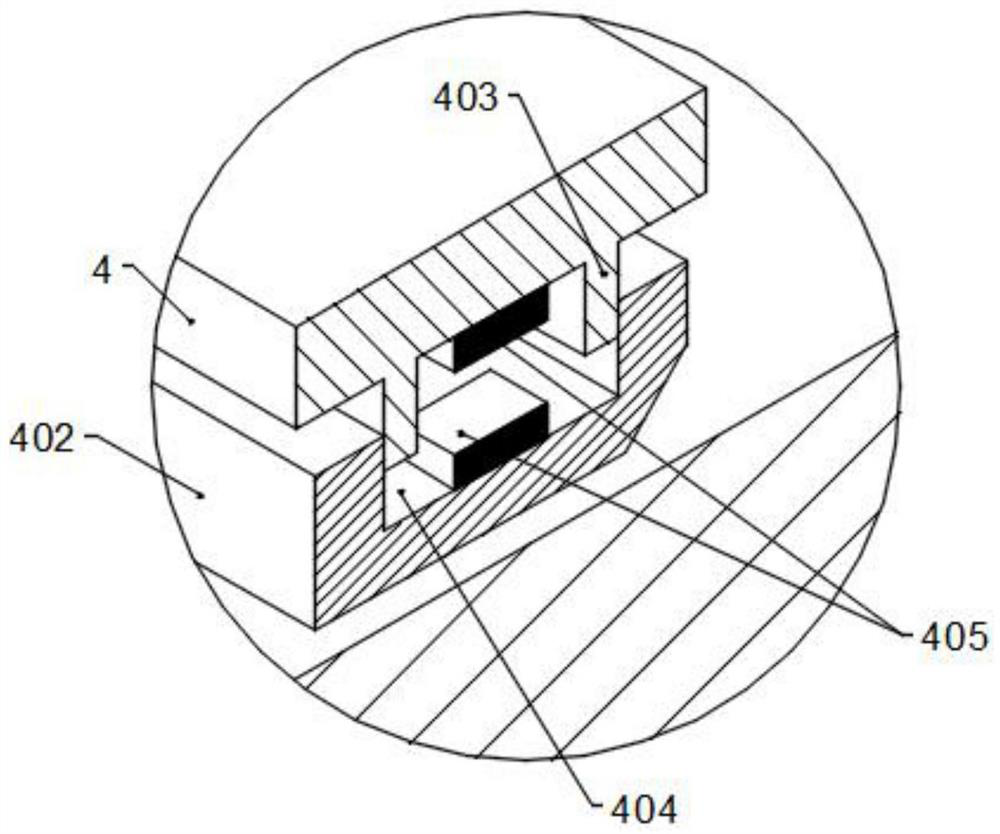

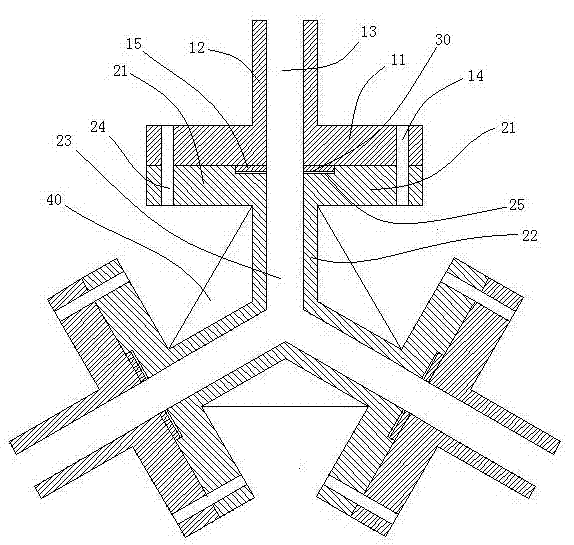

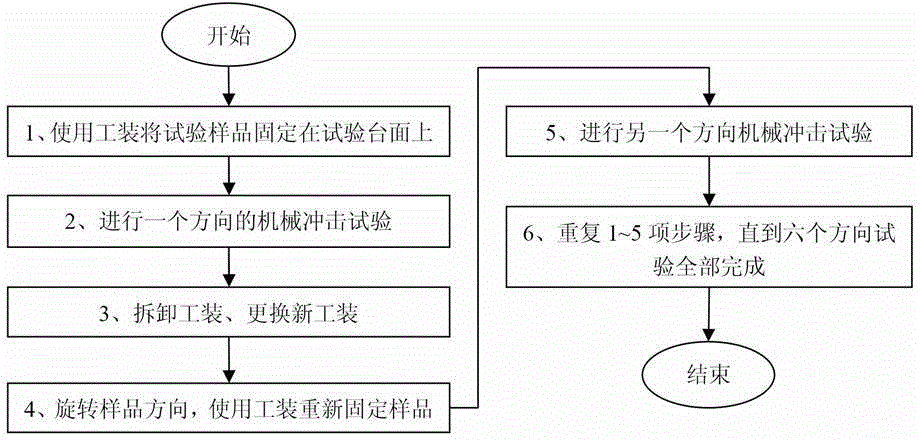

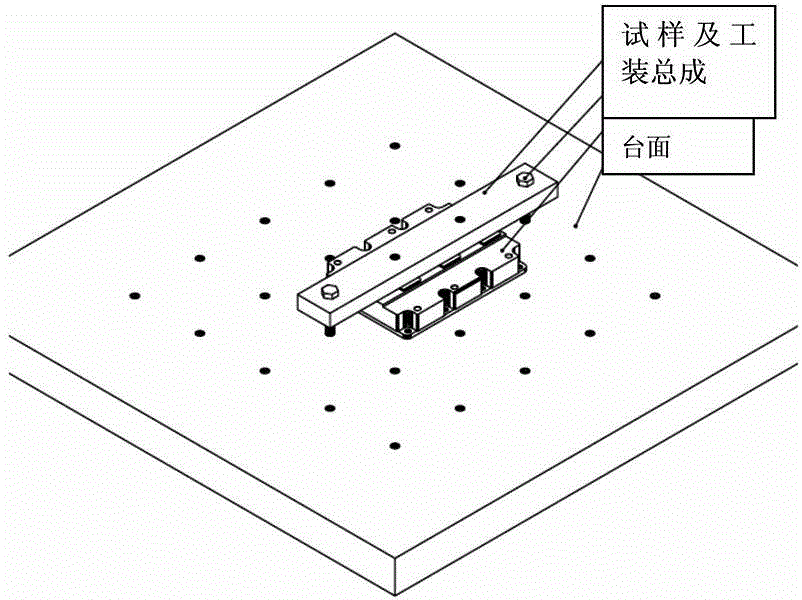

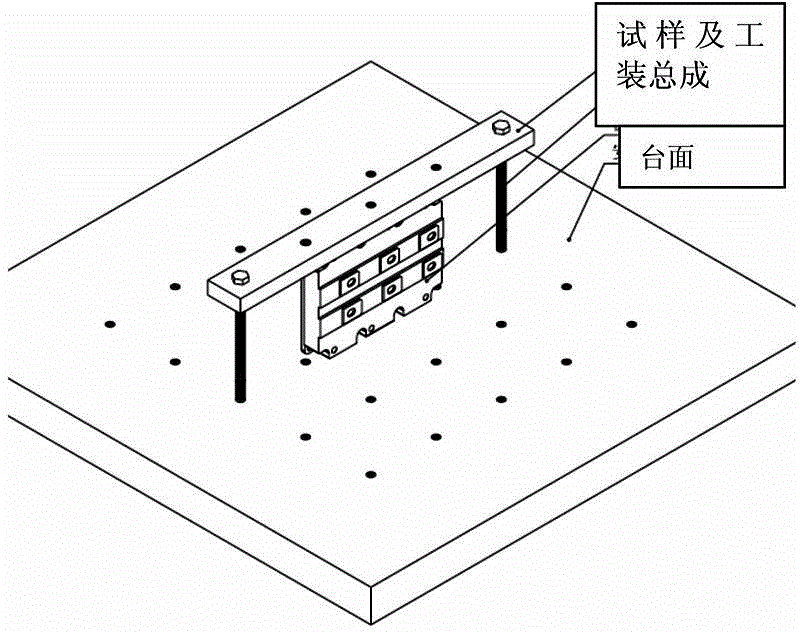

Fixture for mechanical shock test on power semiconductor module, and test method

InactiveCN104949814AAvoid shell breakageSimplified Mechanical Shock Test ProceduresShock testingEngineeringTest sample

The invention discloses a fixture for a mechanical shock test on a power semiconductor module, and a test method. The fixture comprises a square bottom plate and four side plates, wherein the four side plates are vertical to the bottom plate and located on one side of the bottom plate respectively; sample installation holes for fixing test samples are formed in the bottom plate; the four side plates are paired in parallel to form a group respectively, wherein first fixed installation holes for X-axis directional installation on the installation table surface of a test bed are formed in the side plates of one group, and second fixed installation holes for Y-axis directional installation on the installation table surface of the test bed are formed in the side plates of the other group; third fixed installation holes for Z-axis directional installation on the installation table surface of the test bed are formed in the bottom plate. The method is a test method based on the fixture. The fixture and the test method disclosed by the invention have the advantages of being simple in structure principle, simpler and more convenient to operate, more accurate and reliable in test data, capable of effectively preventing the test samples from damages, and the like.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Optical adhesive and flexible device

PendingCN110922899AIncreasing the thicknessLarge thickness large thicknessSynthetic resin layered productsSolid-state devicesAdhesiveChemistry

The embodiment of the invention provides an optical adhesive and a flexible device, relates to the technical field of display, and can solve the problem of large bending stress of the flexible devicein the bending process. The optical adhesive comprises at least one layer of thermocuring adhesive film and at least one layer of photocuring adhesive film, and the thermocuring adhesive films and thephotocuring adhesive films are alternately arranged in a laminated manner.

Owner:BOE TECH GRP CO LTD

Preparation method of surface stain cleaner for rattan-woven crafts

ActiveCN106398909AAvoid problems such as moldy interface breakageNo harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsZinc stearateStain

The invention discloses a preparation method of a surface stain cleaner for rattan-woven handicrafts. The preparation method mainly comprises the following steps: firstly preparing radix puerariae powder; then preparing a mixture of magnesium sulfate, nano-silicon dioxide, zinc stearate and octadecanol, mixing with 50% of radix puerariae powder; distilling, and collecting distillate; preparing a mixture of auxiliary liquid and the distillate in a stirring tank, adding the residual 50% of powder to obtain the cleaner. The preparation method provided by the invention has advantages that the cleaner prepared by the method can be sprayed on crafts to clean dust on the crafts; meanwhile, the cleaner prepared by the invention is not sticky, cannot be adsorbed on the crafts, and can flow rapidly, so as to have no damage to materials of the crafts and avoid craft molding, interface fracture and other problems caused by touching water.

Owner:FUNAN COUNTY TIANYI CRAFTS

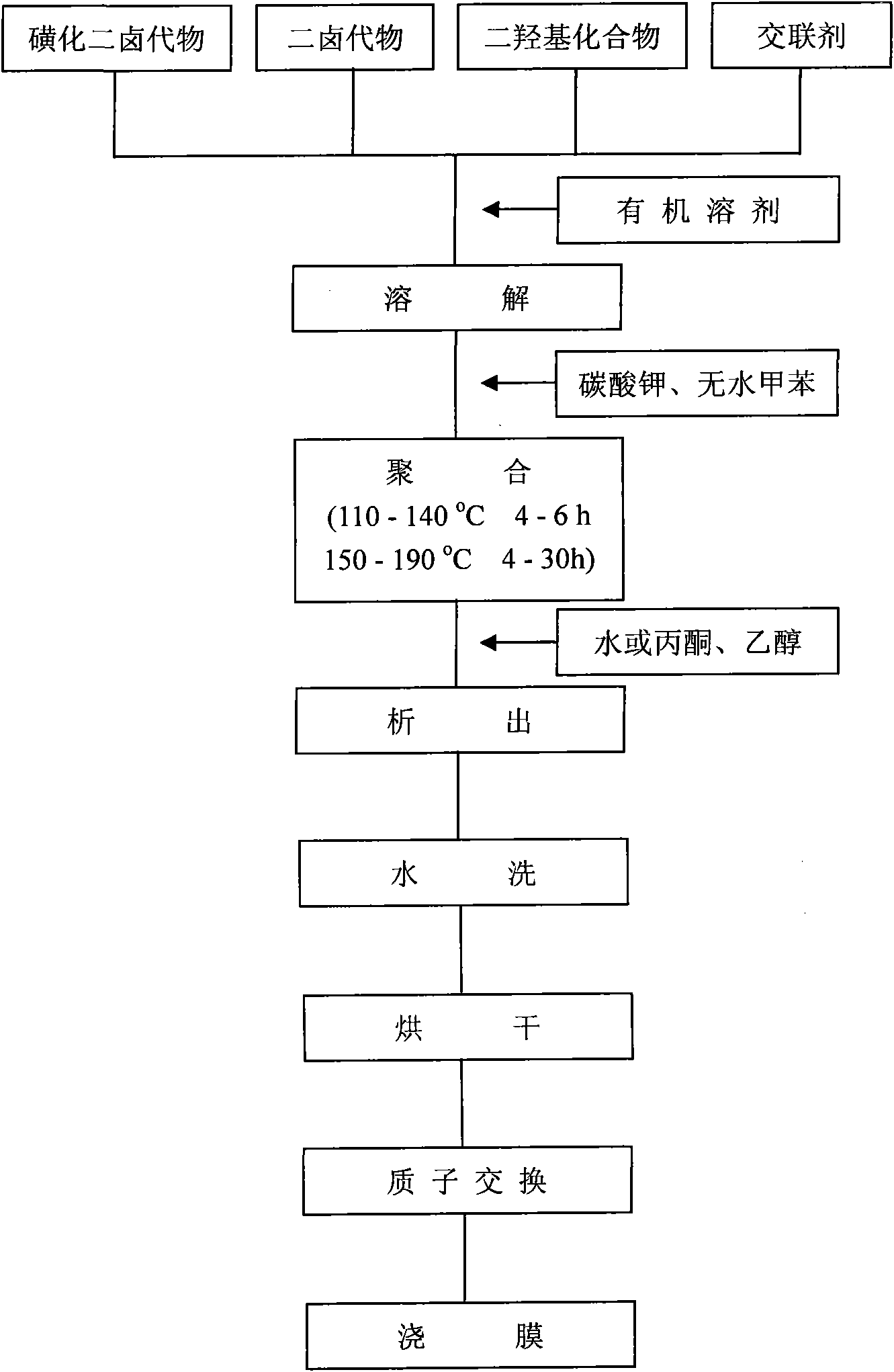

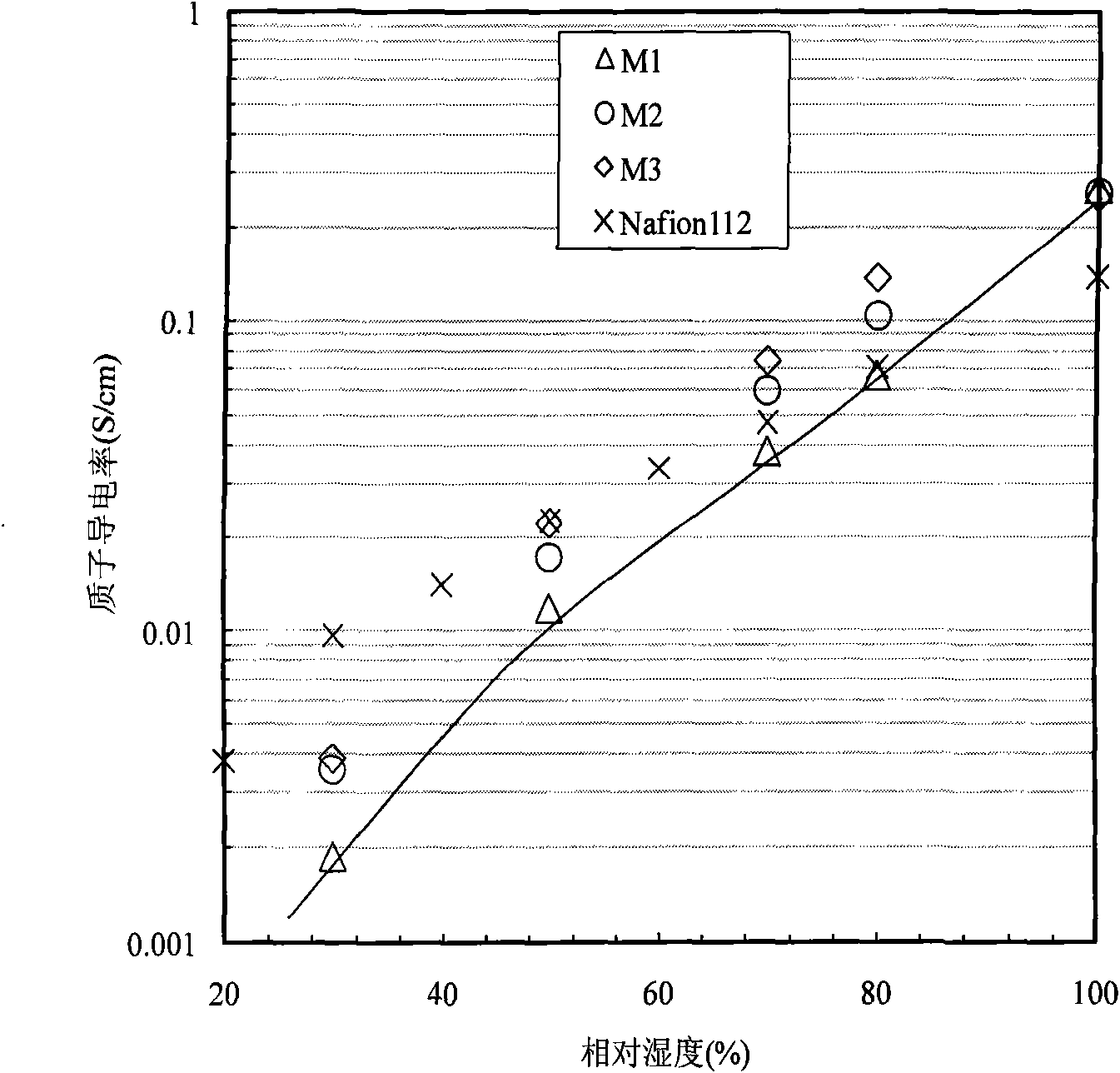

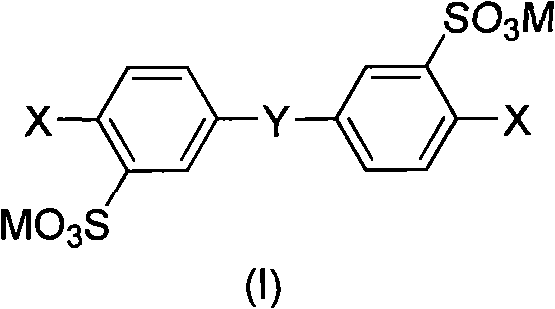

Preparation method of direct crosslinking proton exchange membrane

InactiveCN101643548AAvoid problems such as breakageImprove water stabilitySemi-permeable membranesOrganic diaphragmsNitrogen gasPotassium carbonate

The invention discloses a preparation method of a direct crosslinking proton exchange membrane. The preparation method comprises the following steps: adding a sulfonated dihalogen compound, a non-sulfonated dihalogen compound, a dihydroxy compound and a crosslinking agent to a four-mouth flask with a stirring device, an oil-water separator, a reflux condensing tube, a constant-pressure drop funnel, a nitrogen inlet and a nitrogen outlet; adding an aprotic polar organic solvent until being fully dissolved; adding potassium carbonate and then adding anhydrous toluene; increasing temperature andreacting for 4-6 hours; removing water generated in the reaction; increasing the temperature to 150-190 DEG C and reacting for 4-30 hours; decreasing the temperature; diluting by the aprotic polar organic solvent; pouring into water, acetone or ethanol to separate out fibroid products; filtering, washing and drying to obtain a direct crosslinking sulfonated polymer product; dissolving the obtainedproduct into the aprotic polar organic solvent; casting and drying; and obtaining a proton polymer membrane after acid exchange. The method has simple process, and the prepared product has good stability and high conductivity.

Owner:NANJING UNIV OF SCI & TECH

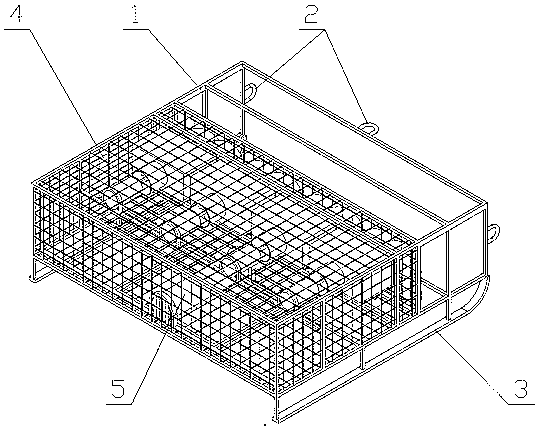

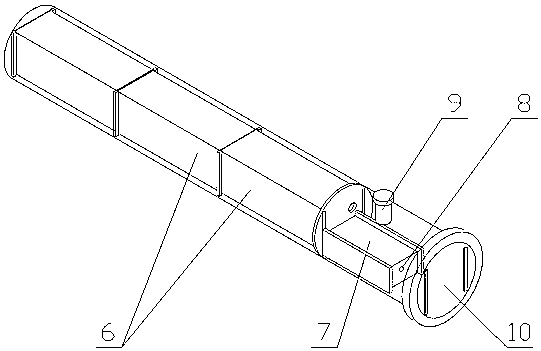

Pumping ecological catching net device

PendingCN109463360ASimple structureIngenious designPisciculture and aquariaEngineeringControl switch

The invention discloses a pumping ecological catching net device. The pumping ecological catching net device is characterized by comprising a frame body (1), a plurality of pulling rings (2) are arranged at the front end of the frame body (1), and a pair of sleigh plates (3) are symmetrically distributed at the bottom of the frame body (1); the back portion of the frame body (1) is closed by a netto form a net box (4), a plurality of pumping mechanisms are arranged in the net box (4) and uniformly distributed on the net box (4) transversely, and a sealing bucket (5) is further arranged in thescreen box (4); a storage battery (6) and a PLC control module (7) are arranged in the sealing bucket (5), a Bluetooth control switch (8) is further arranged on the PLC control module (7), a cable sealing port (9) is formed in the side wall of the sealing bucket (5), and a transparent sealing cover body (10) is further arranged at one end of the sealing bucket (5).

Owner:DALIAN OCEAN UNIV +1

Modified aerogel for filling internal hollow cavity of hollow glass

InactiveCN107381582ASettle settlementPrevent powderingSilicon compoundsGel preparationThermal insulation

The invention discloses modified aerogel for filling an internal hollow cavity of hollow glass and relates to the technical field of hollow glass processing. The modified aerogel is prepared by the steps as follows: (1) gel preparation, (2) gel aging, (3) modification and (4) drying. According to the modified aerogel, conventional aerogel is modified with a self-made modifier, so that the modified aerogel is prepared, the outstanding thermal-insulation property can be developed after the hollow glass is filled with the modified aerogel, tests show that the U value is as low as 0.01 W / m<2>.K and the Sc value is as low as 0.06 when filling thickness of the modified aerogel is 30 mm; besides, with the adoption of the modified aerogel, the problem of settlement of the conventional aerogel after long-time use can be effectively solved, and the problems of powdering, damage and the like caused by production, transportation, frame attaching, hoisting, mounting and the like are solved.

Owner:安徽艺云玻璃有限公司

A prefabricated steel structure frame for green and environmentally friendly buildings

ActiveCN113123464BImprove support capacityImprove bearing strengthBuilding constructionsSteel columnsUltimate tensile strength

Owner:赛末点智能建筑(上海)有限公司

Loudspeaker with FPC (flexible printed circuit) and bonding pad integrally formed and assembly method of loudspeaker

PendingCN114666715AAvoid fatigueAvoid problems such as breakageDiaphragm constructionEngineeringLoudspeaker

The invention relates to a loudspeaker with an FPC and a bonding pad integrally formed and an assembling method thereof. The loudspeaker comprises a lower shell, a vibrating diaphragm, a magnetic circuit system, a voice coil and the FPC. The vibrating diaphragm and the lower shell form a corresponding sound cavity, and the FPC is arranged in the sound cavity; the FPC and the bonding pad are integrally formed, the FPC is electrically connected with the bonding pad, the lower shell is provided with a bonding pad placement position, and the bonding pad is led out from the interior of the sound cavity and is fixedly arranged at the bonding pad placement position; and the voice coil is electrically connected to the FPC through a voice coil lead led out of the voice coil. According to the loudspeaker, the structure of a traditional loudspeaker is changed, the FPC is arranged between the vibrating diaphragm and the lower shell, the voice coil and the voice coil lead are vibrated along with the vibrating diaphragm and the FPC, and the problems of fatigue, breakage and the like of the voice coil lead are solved.

Owner:厦门东声电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com