Three-way flange

A general flange and flange technology, which is applied in the field of pipeline connection design, can solve the problems that flanges cannot be installed and pipeline design is limited, and achieve the effect of avoiding fracture and flexible pipeline design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

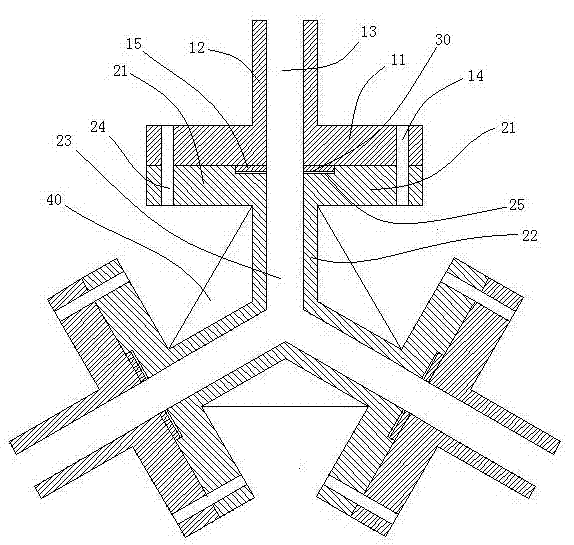

[0018] Such as figure 1 As shown, a three-way flange is composed of three butt flange groups. Each flange group consists of a first flange, a second flange and a gasket 30 . in:

[0019] The first flange includes a first flange 11 and a first pipe 12, and a first pipe through hole 13 is provided in the middle of the first flange 11 and the first pipe 12, and is located in the first pipe through hole. A plurality of first screw holes 14 are provided on the periphery;

[0020] The second flange includes a second flange 21 and a second pipe 22, and the middle of the second flange 21 and the second pipe 22 is provided with a second pipe through hole 23, which is located in the second pipe through hole. A plurality of second screw holes 24 are provided on the periphery;

[0021] The first pipeline through hole 13 communicates with the second pipeline through hole 23 correspondingly, and the first screw hole 14 corresponds to the second screw hole 24 one by one;

[0022] The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com