Microelement capable of being tested and micro-transferred, manufacturing, testing and transferring method of microelement and display device

A manufacturing method and technology for micro-components, which are applied in the fields of semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problem of micro-components being unable to yield screening, and achieve improved light extraction efficiency and good current expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

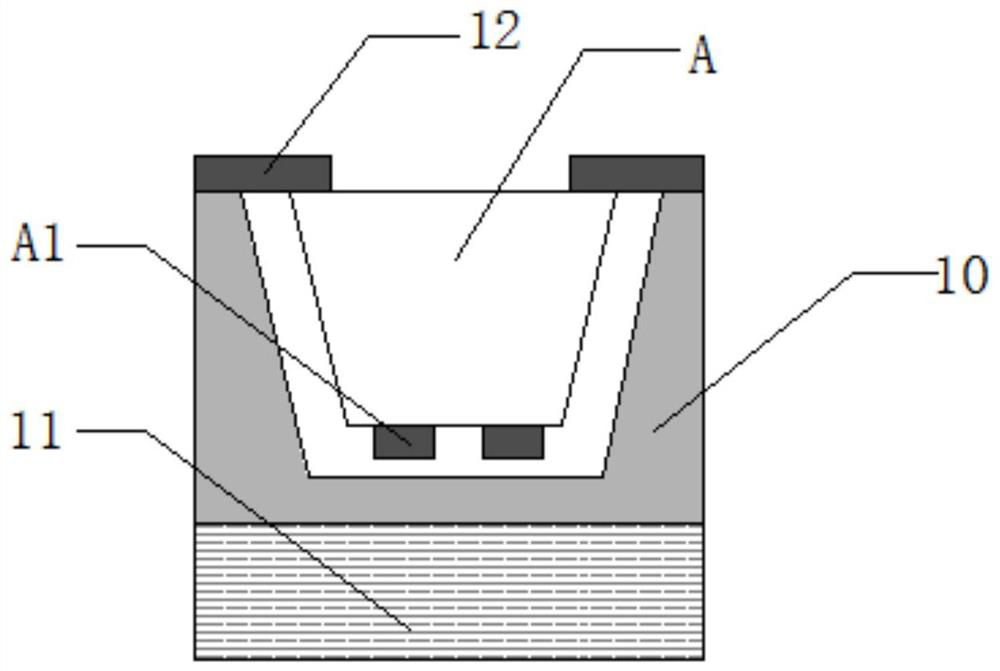

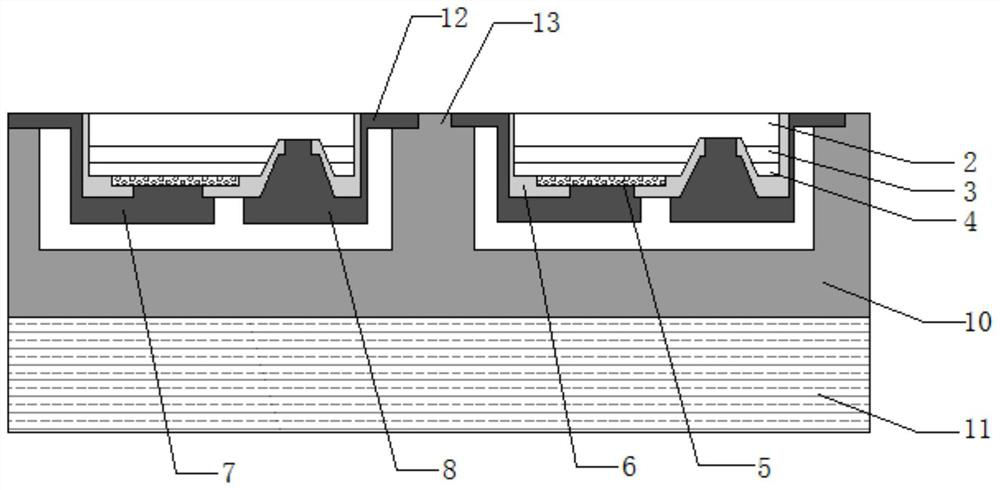

[0072] Such as figure 2 As shown, a micro-component that can be tested and micro-transferred, including:

[0073] supporting substrate 11;

[0074] A bonding layer 10, the bonding layer 10 is located on the surface of the supporting substrate 11;

[0075] Light-emitting structure, the light-emitting structure includes several LED chips A that hang upside down on the support substrate 11 and are separated from each other by the groove A2, the bonding layer 10 is arranged on the surface of the support substrate 11 and embedded in the groove A2 to form a support column, and the key The composite layer 10 has an air gap with each LED chip A; each LED chip A includes an epitaxial layer, a protective layer 6 covering the exposed area of the epitaxial layer, and a first electrode 7 and a second electrode located on the side of the epitaxial layer facing the supporting substrate 11. Electrode 8; the first electrode 7 and the second electrode 8 respectively extend to the surface o...

Embodiment 2

[0115] Such as figure 2 As shown, a micro-component that can be tested and micro-transferred, including:

[0116] supporting substrate 11;

[0117] A bonding layer 10, the bonding layer 10 is located on the surface of the supporting substrate 11;

[0118] Light-emitting structure, the light-emitting structure includes several LED chips A that hang upside down on the support substrate 11 and are separated from each other by the groove A2, the bonding layer 10 is arranged on the surface of the support substrate 11 and embedded in the groove A2 to form a support column, and the key The composite layer 10 has an air gap with each LED chip A; each LED chip A includes an epitaxial layer, a protective layer 6 covering the exposed area of the epitaxial layer, and a first electrode 7 and a second electrode located on the side of the epitaxial layer facing the supporting substrate 11. Electrode 8; the first electrode 7 and the second electrode 8 respectively extend to the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com