Semiconductor LED structure with high extracting efficiency and its preparing method

A technology for light-emitting diodes and extraction efficiency, which is applied in semiconductor devices, electrical components, circuits, etc., and can solve problems such as low extraction efficiency, low external quantum efficiency, and low LED light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

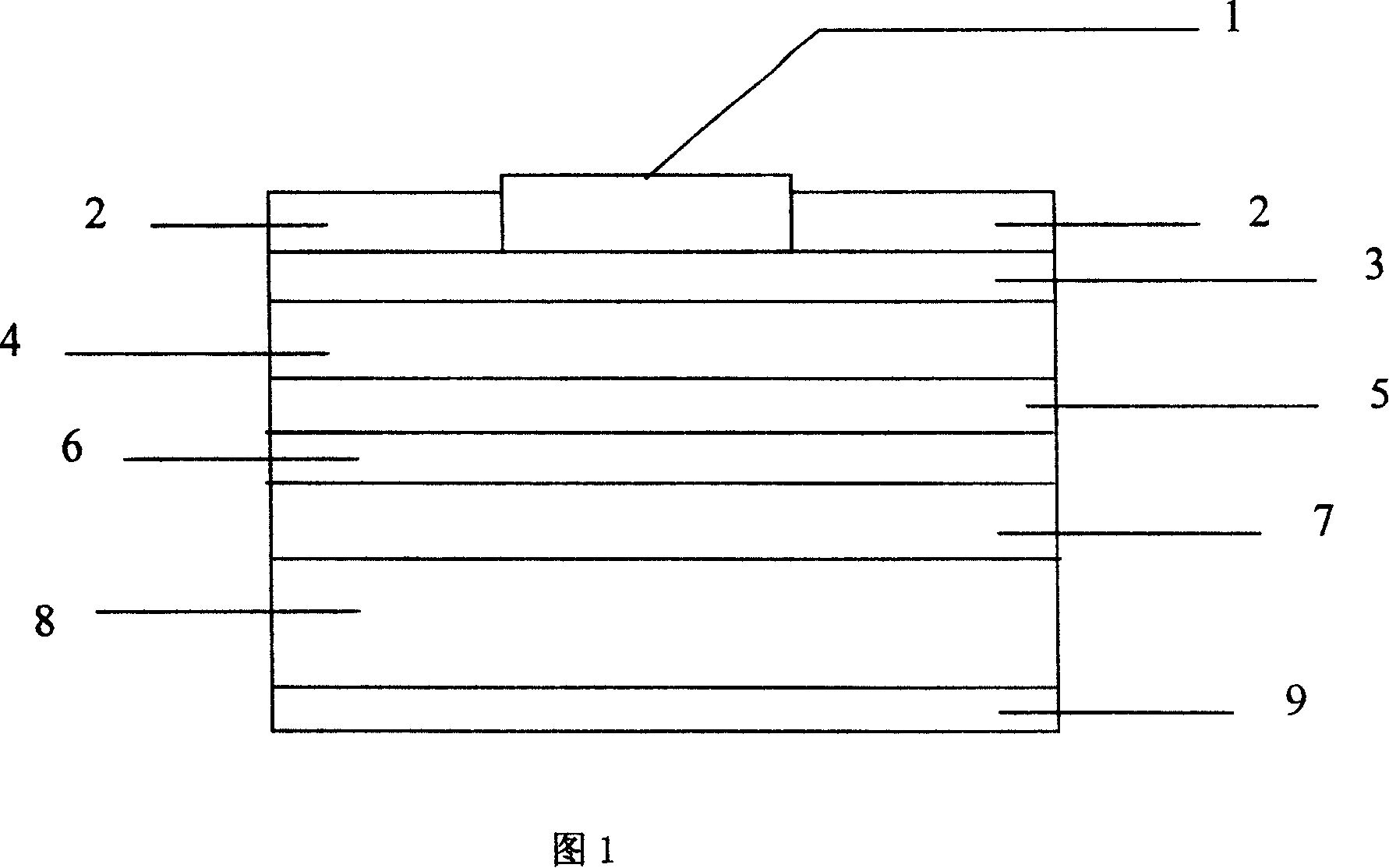

[0031] 1) Preparing a red LED epitaxial wafer, that is, growing an N-type semiconductor 7, a multi-quantum well active region 6, a P-type semiconductor 5, and a GaP layer 4 sequentially on a substrate 8, and the uppermost semiconductor material of the LED epitaxial wafer is GaP layer 4;

[0032] 2) Put the sample cleaned with acetone, absolute ethanol and deionized water into the ITO electron beam evaporation station, grow an ITO transparent conductive film 3 with an optical thickness of 1 / 2 wavelength on the GaP layer 4, and the growth temperature is 190 ℃, the oxygen flow rate is 3sccm, and the evaporation rate is 0.2nm / s; (In the actual preparation process, according to the conditions of your own equipment, you can flexibly adjust the growth process parameters such as growth temperature and oxygen flow rate to prepare the required ITO transparent conductive film3);

[0033] 3) Use PECVD equipment to grow Si on the ITO transparent conductive film 3 x N y Dielectric film 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com