Patents

Literature

38results about How to "Improve reliability and longevity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

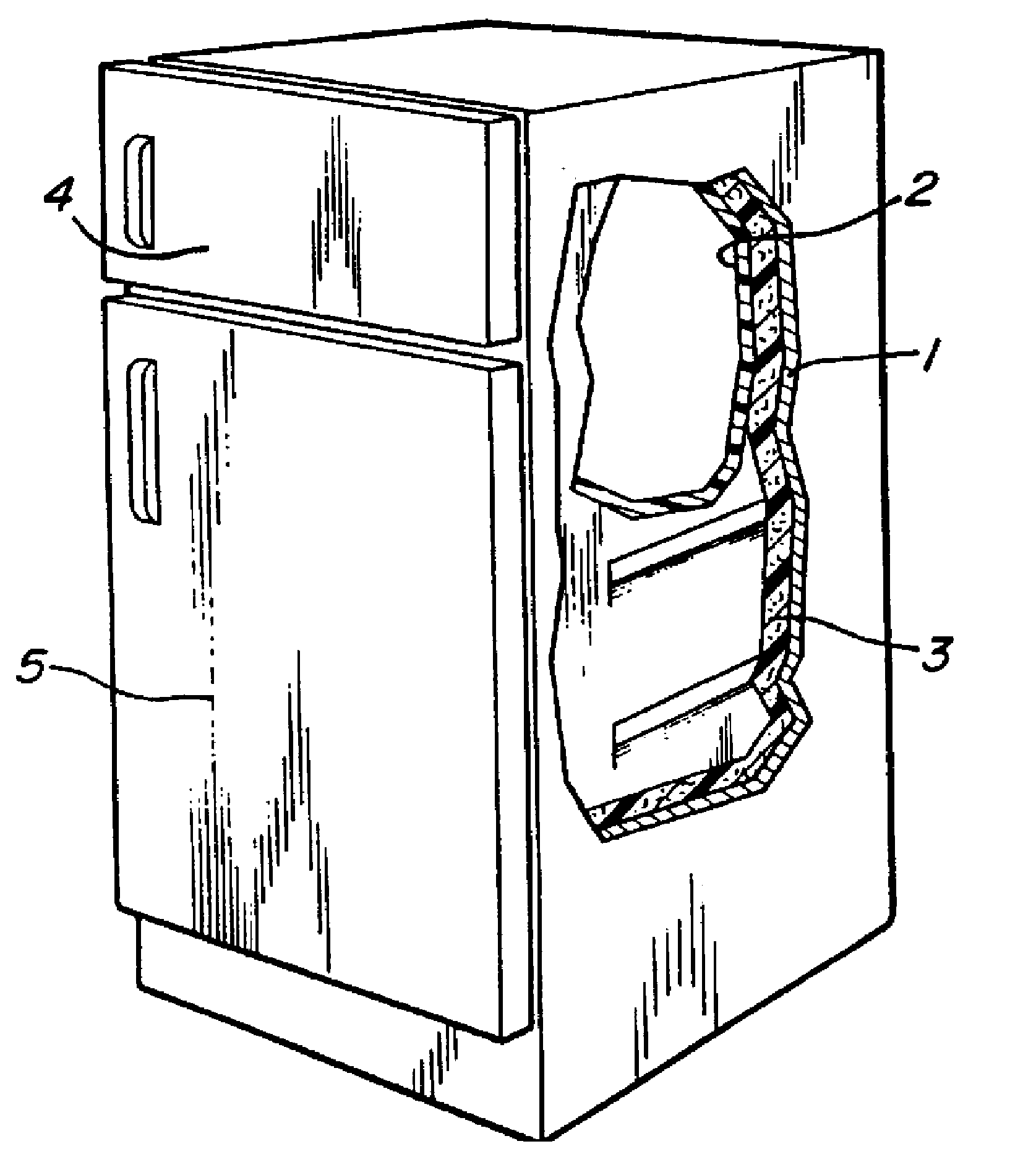

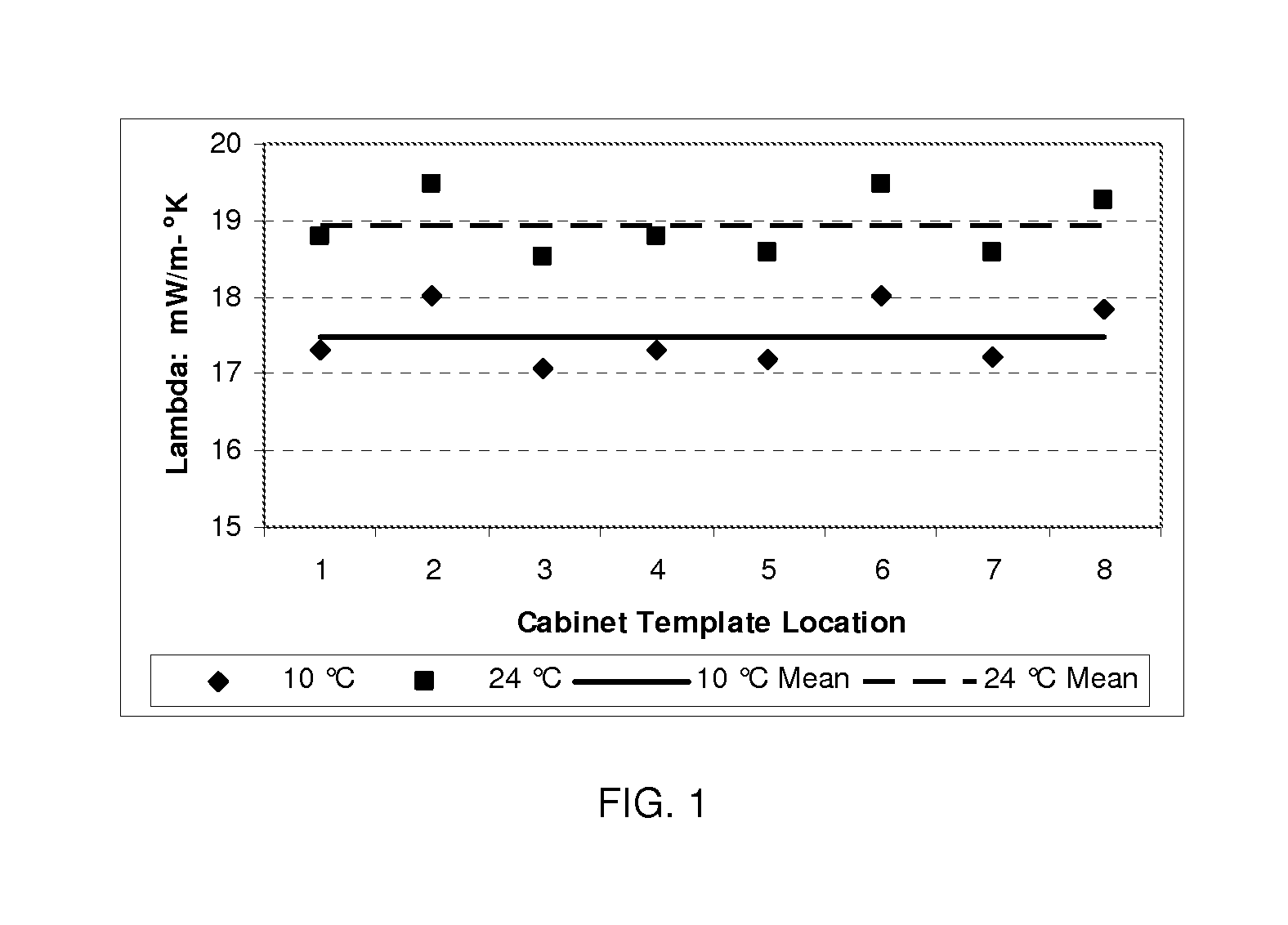

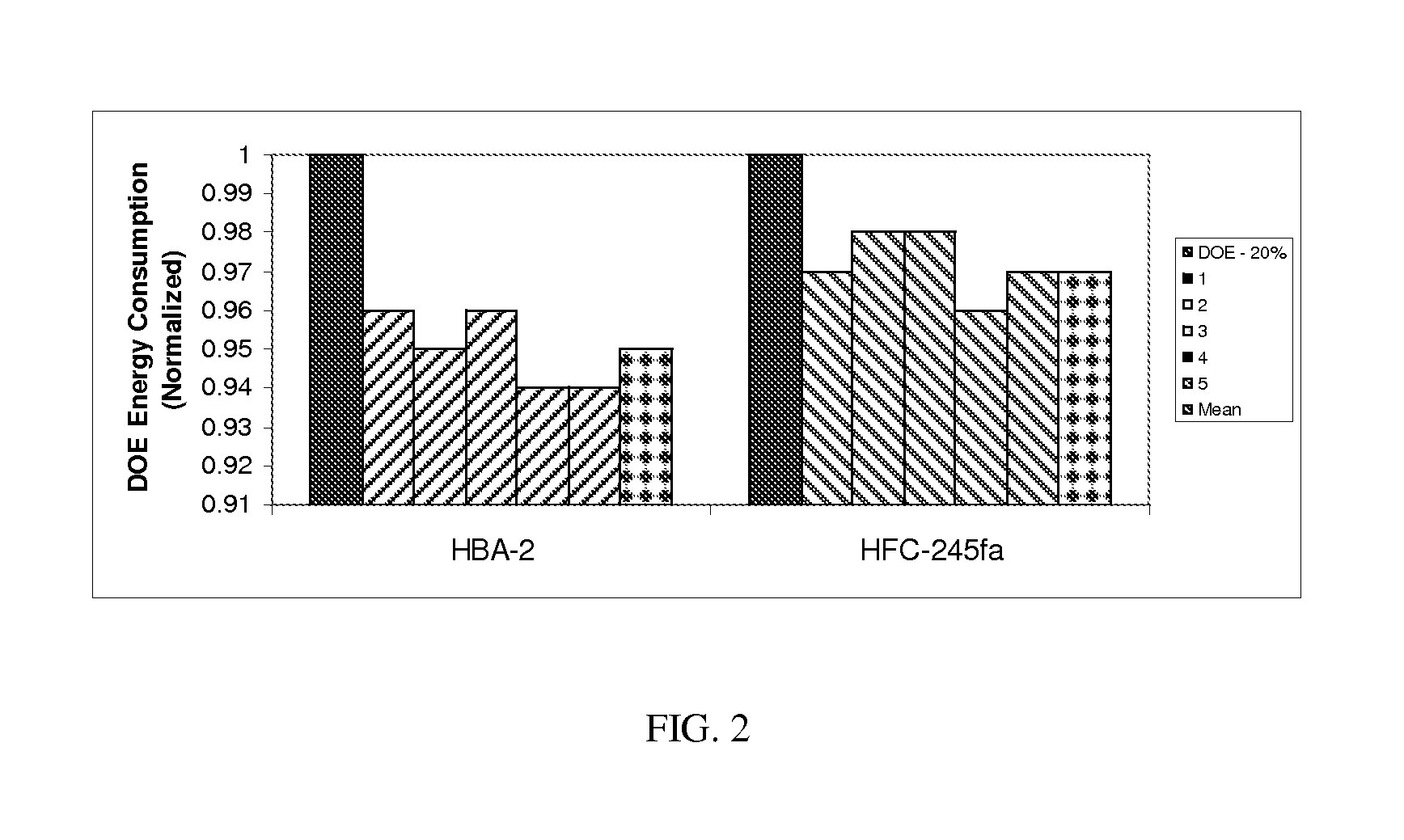

Devices for maintaining food products at low temperature

InactiveUS20140190978A1Low thermal conductivityLow costDomestic cooling apparatusLighting and heating apparatusMethacrylatePolyethylene terephthalate glycol

Disclosed is a thermal insulating device comprising: (a) a container or compartment for holding food and / or beverage in a cooled condition, said container comprising thermoformed liner having an average thickness of not greater than about 10 mm, said liner being formed at least in part from material selected from the group consisting of glass-clear polystyrene (GPPS), impact-modified polystyrene (HIPS), styrene-butadiene block copolymers, ASA, SAN, ABS, polyolefins, acrylates and methacrylates, polycarbonates (PCs), polyvinyl chloride (PVC), polyethylene terephthalate (PET) and mixtures, combinations, laminates and layers of these; and (b) thermal insulation adjacent said liner and comprising a polymeric material having closed cells therein wherein said cells are formed from and / or contain a blowing agent comprising at least about 50% by weight of transHFCO-1233zd.

Owner:HONEYWELL INT INC

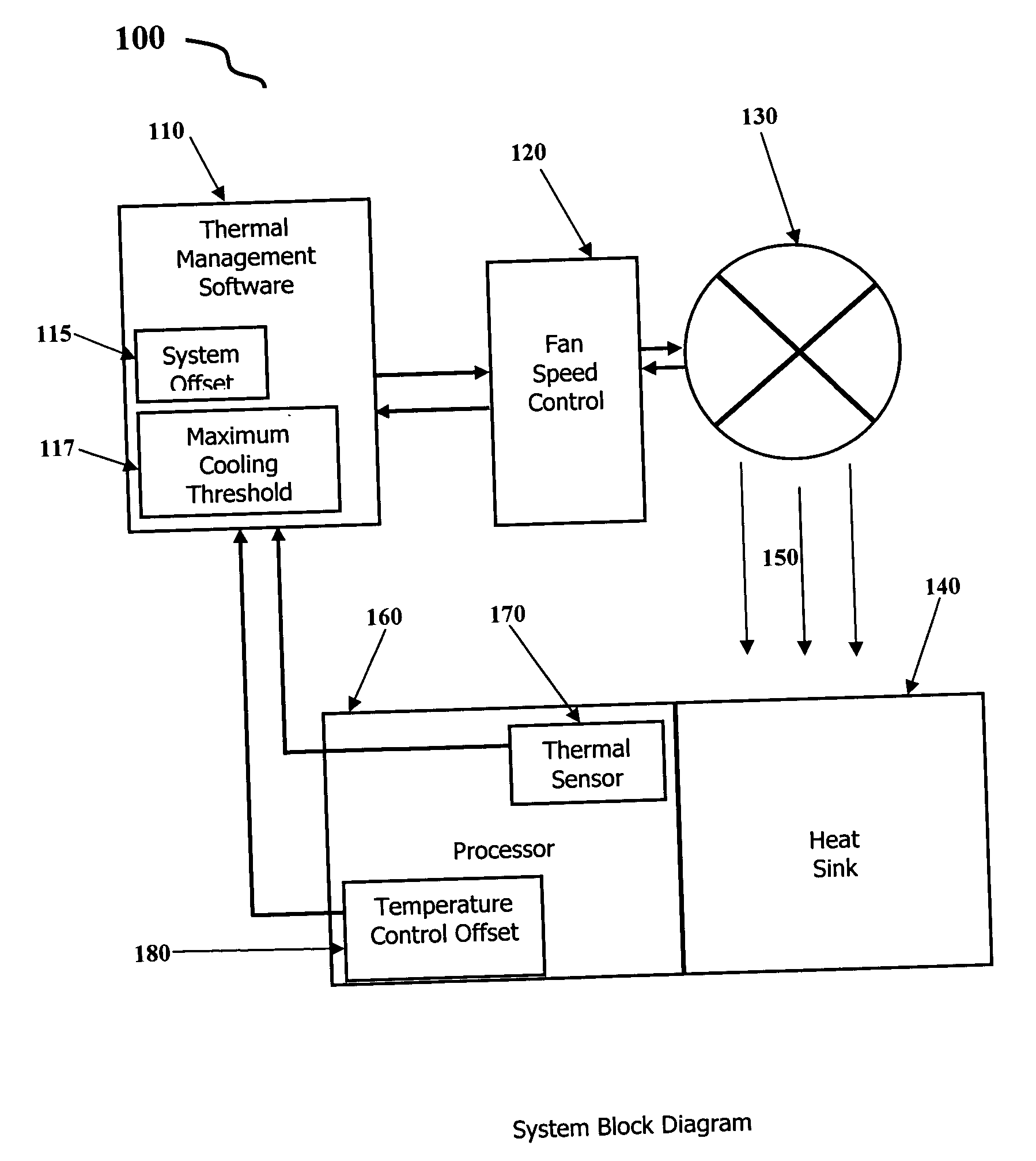

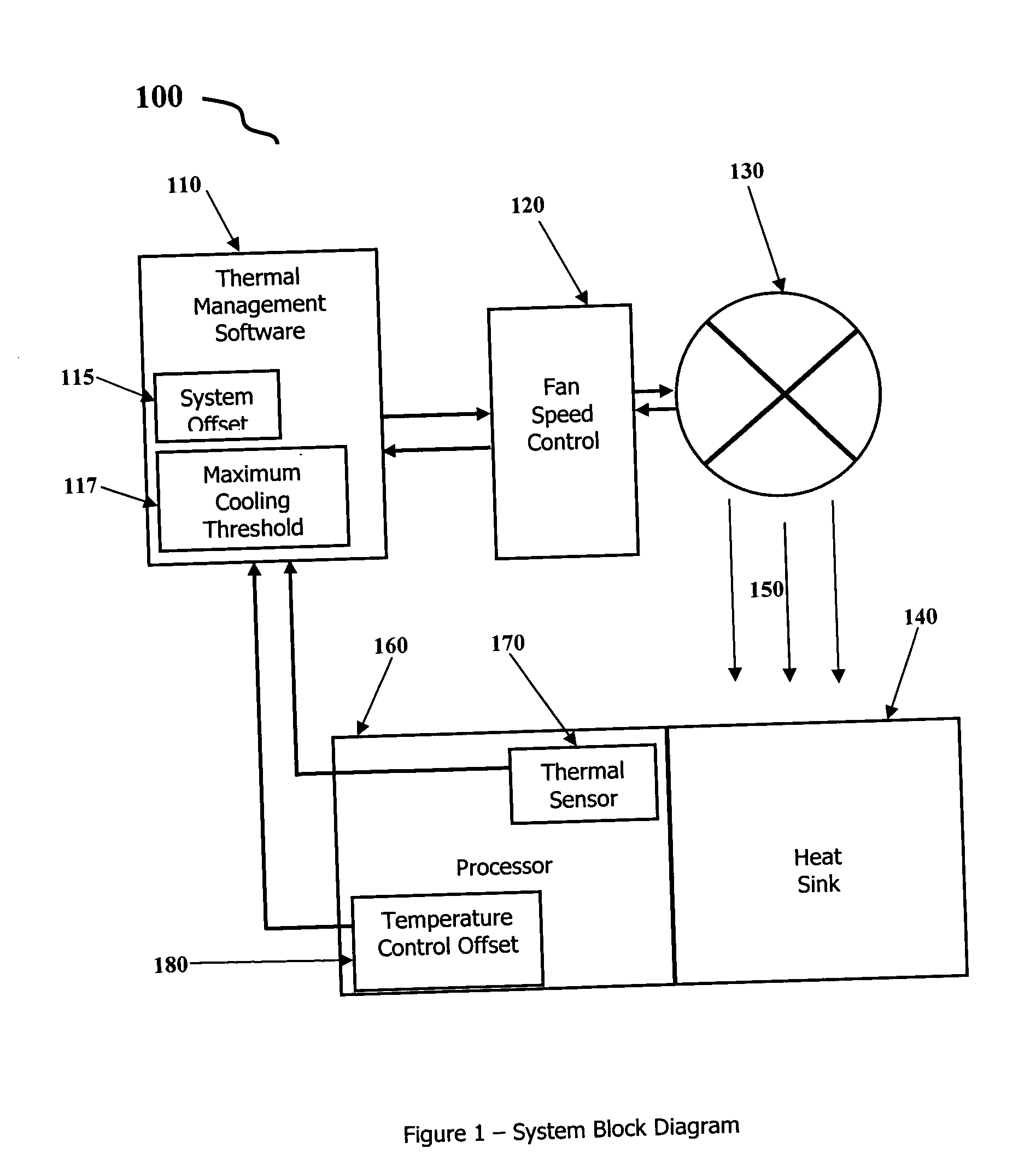

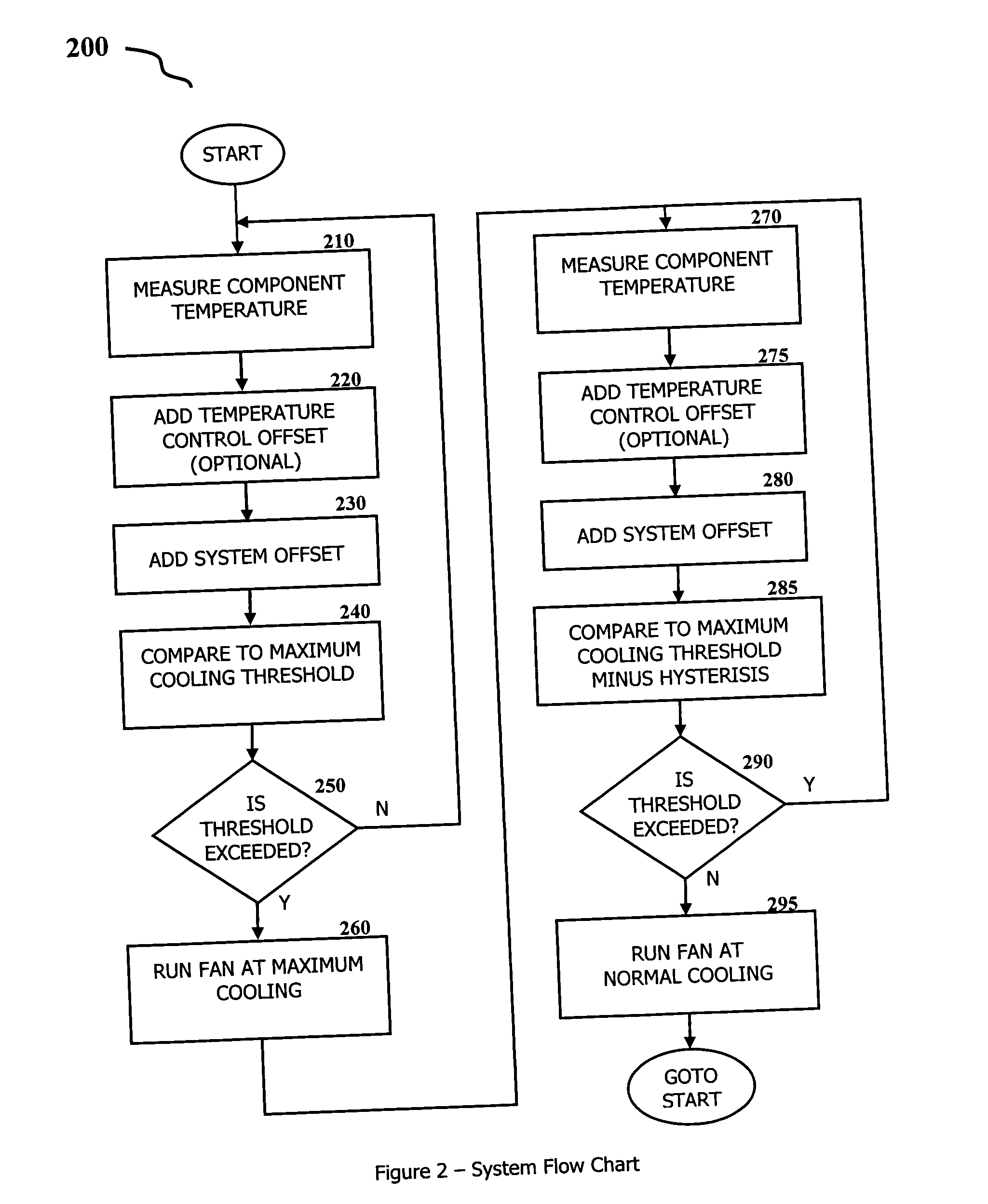

System and method for determining component temperature requiring maximum cooling

ActiveUS20060032250A1Improve reliability and longevityShorten the timeLighting and heating apparatusSemiconductor/solid-state device detailsMaximum levelSystem monitor

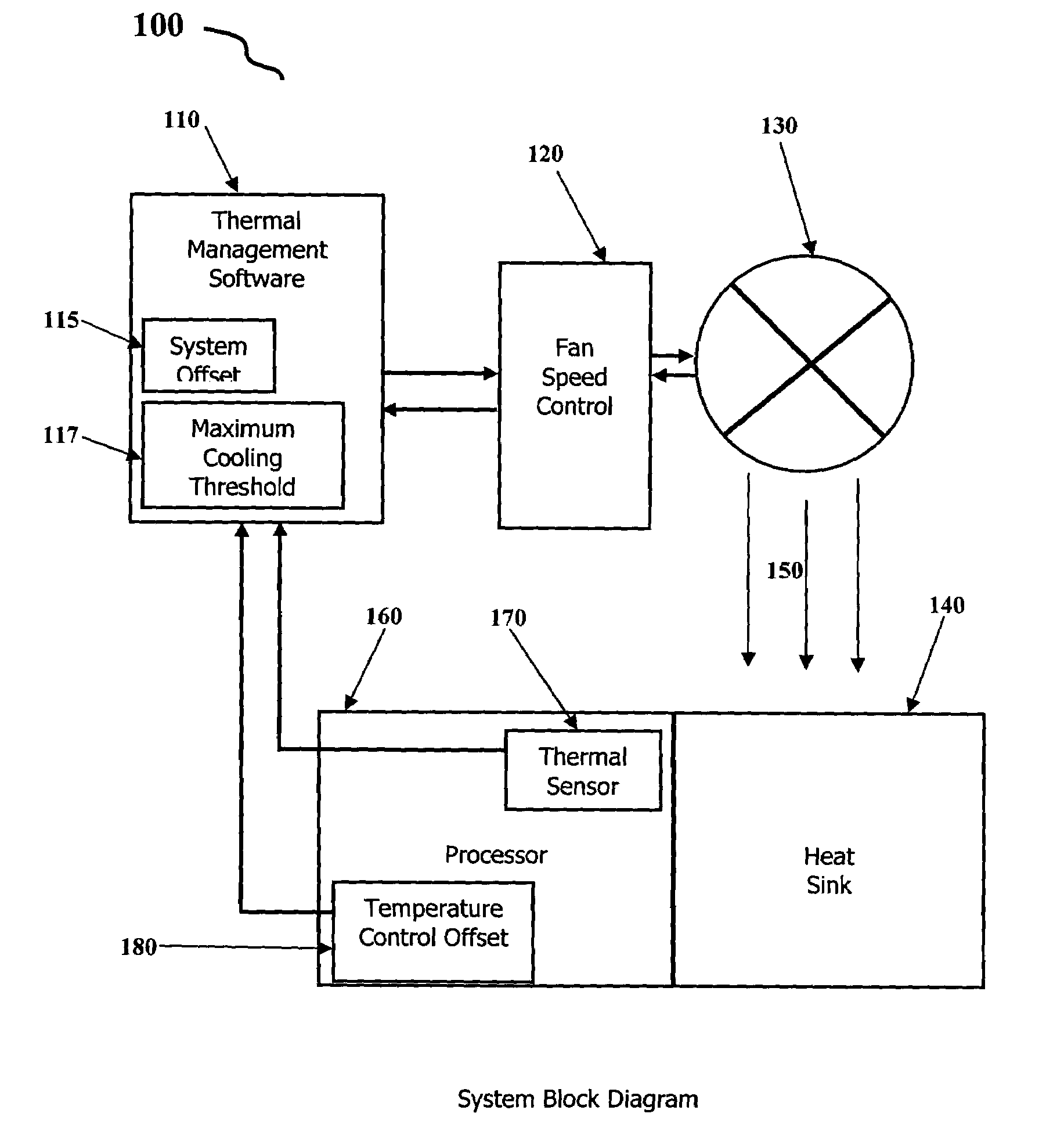

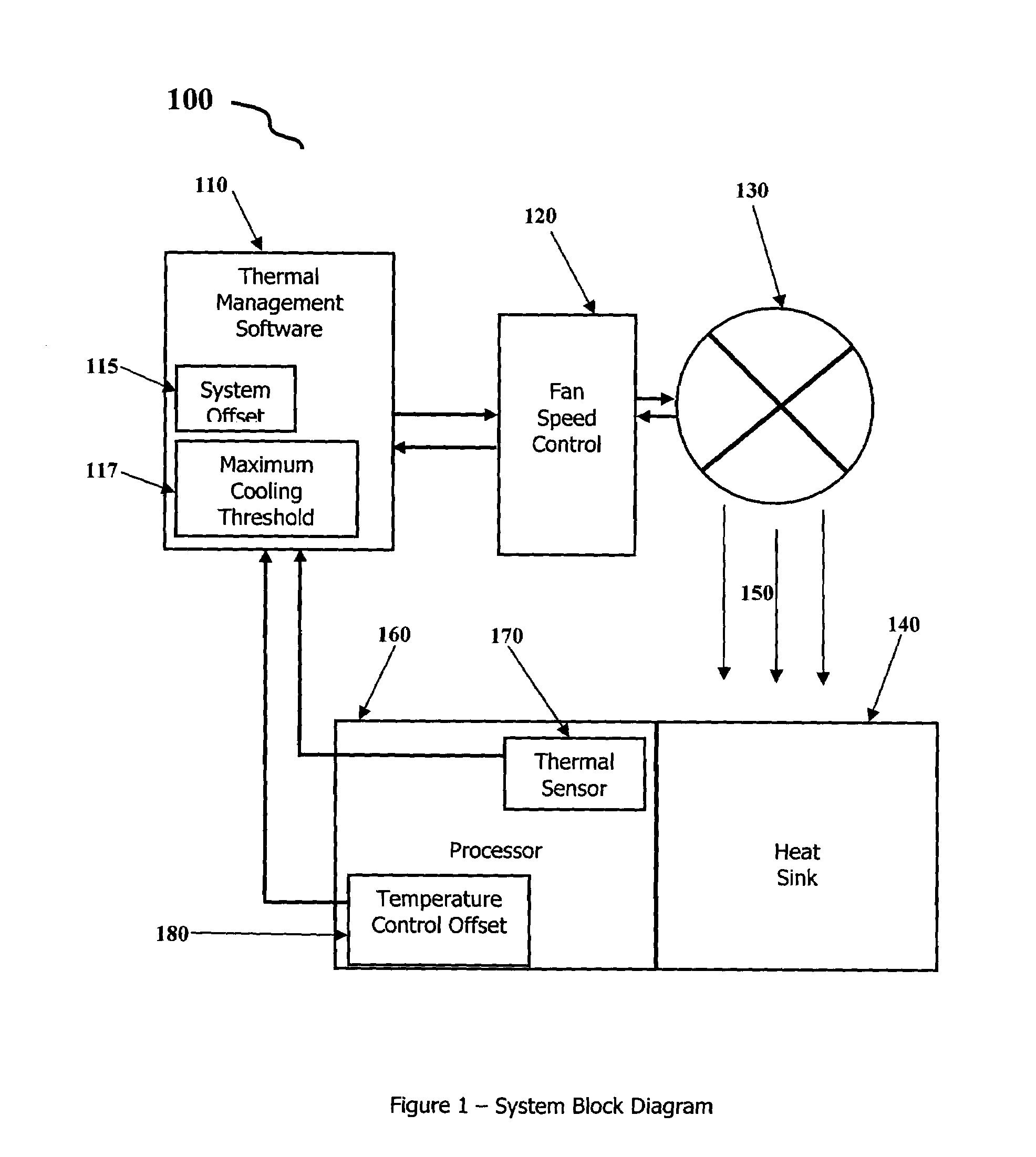

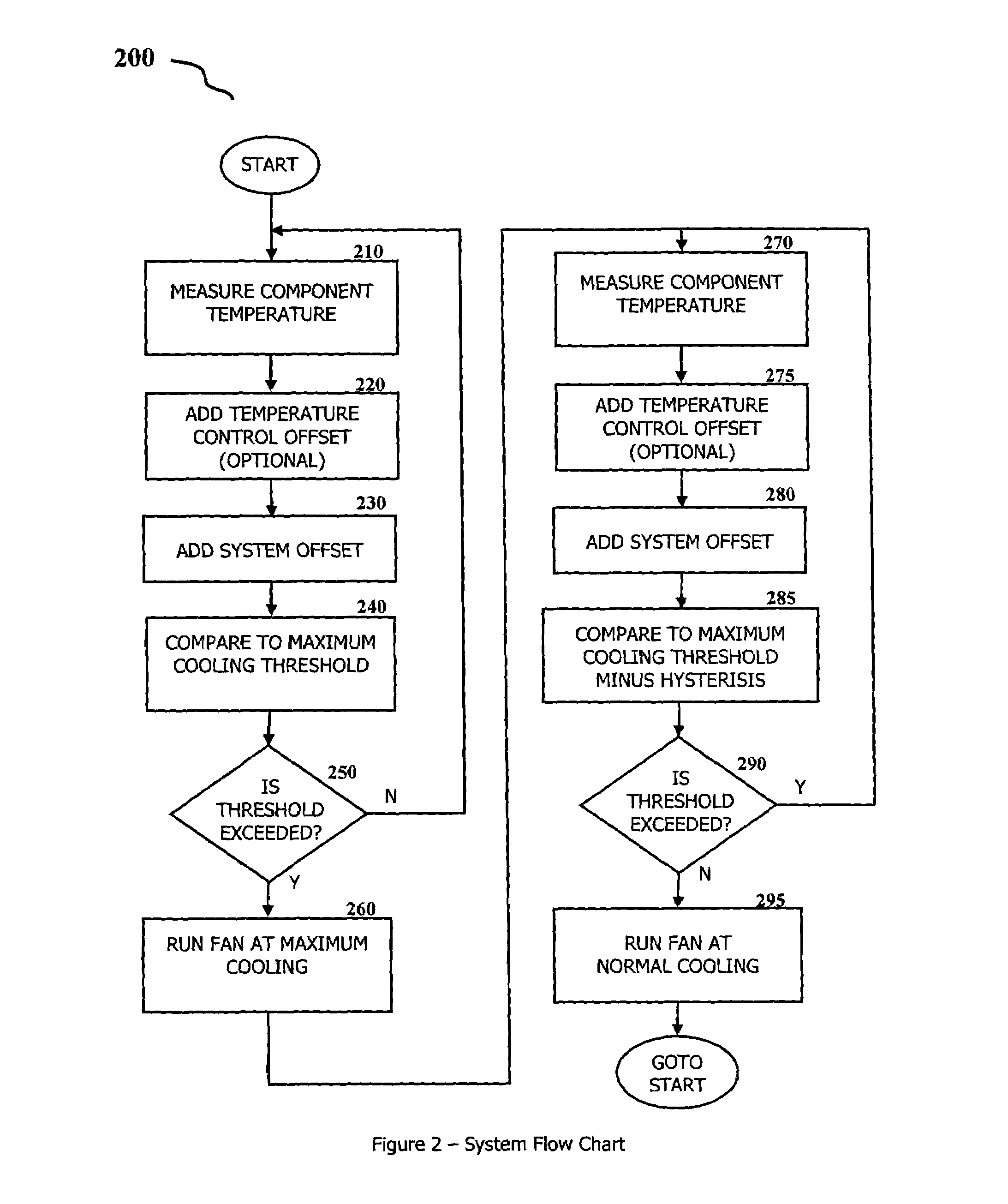

The present invention is directed to a system for determining a temperature of a component that requires a maximum level of cooling apparatus operation. The system monitors the component's temperature, then may add a compensation offset to account for variations in the manufacture of the component, and then adds a compensation offset to account for variation in the system in which the component is installed. The result is used to determine when the system's cooling apparatus needs to be operated at a maximum level of operation. The sum may be compared to a threshold to make this determination. This same mechanism may be used to determine various other cooling system trigger points, both when to increase cooling as well as decrease cooling.

Owner:GATEWAY

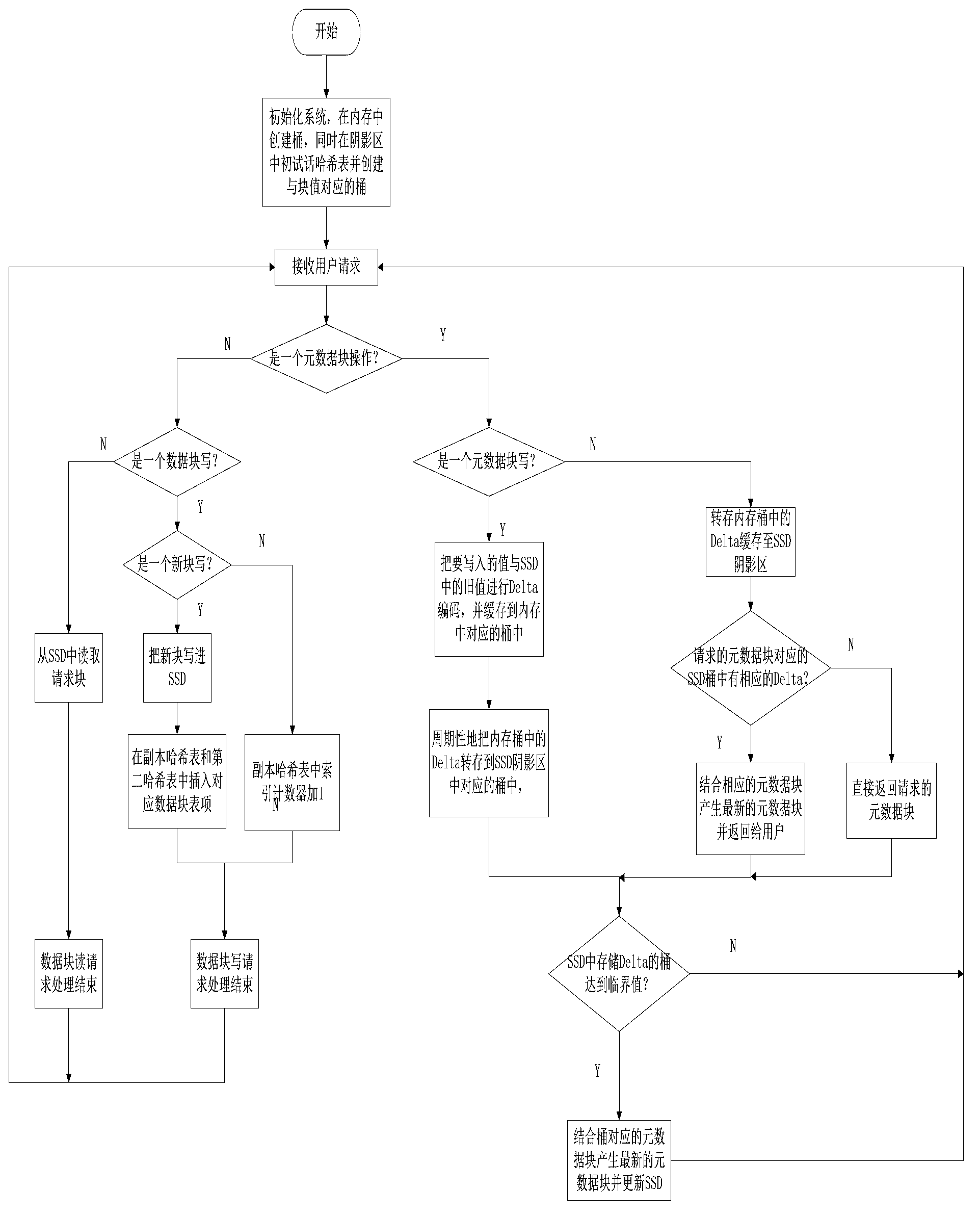

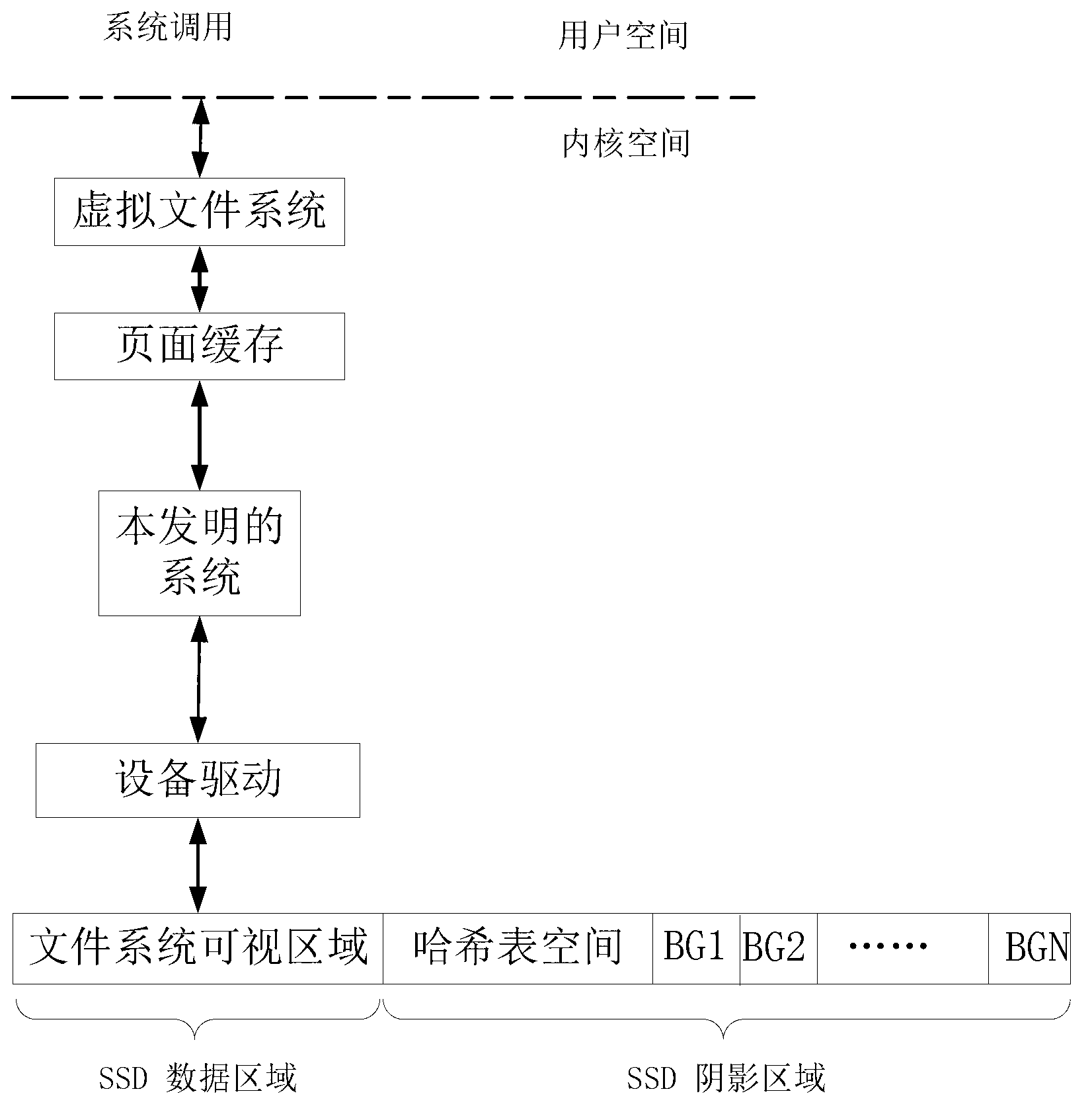

Method and system for increasing available capacity and service life of solid state disc

ActiveCN103309815AIncrease effective capacityImprove reliability and longevityMemory adressing/allocation/relocationSolid-stateFile system

The invention discloses a method and system for increasing available capacity and service life of an SSD (solid state disc). The method comprises the following steps: partial space is divided from an SSD and taken as a shadow area of the SSD, and a copy hash table and a second hash table are initialized in the shadow area; a plurality of buckets are divided from an internal storage, wherein the buckets and block groups are arranged in a one-to-one correspondence manner, and are identical in quantity; the space except the space occupied by both the copy hash table and the second hash table is divided into multiple different small areas which are in one-to-one correspondence with the block groups; the distribution of a file system on the SSD is analyzed; a query tree for recording addresses of meta data blocks and data blocks is generated according to the analysis result; the request of users is received; and whether the request is a meta data block request or a data block request can be judged according to the query tree. According to the invention, the repeated delete technology is applied to the data blocks, and the Delta coding technology is applied to the meta data blocks, so that the overall written times of the SSD experiences can be reduced, and finally the available capacity of the SSD is increased, and the service life of the SSD is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

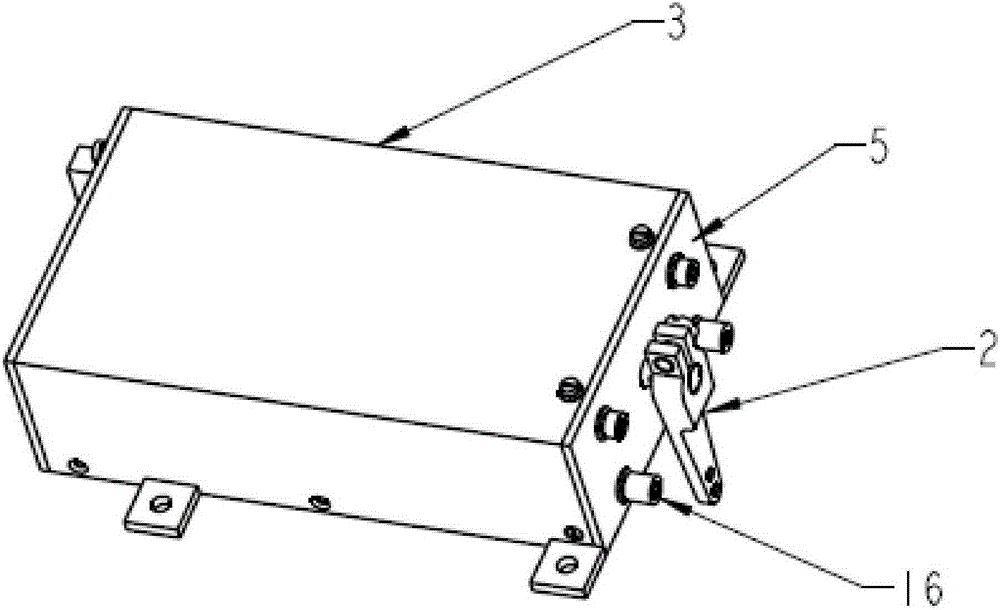

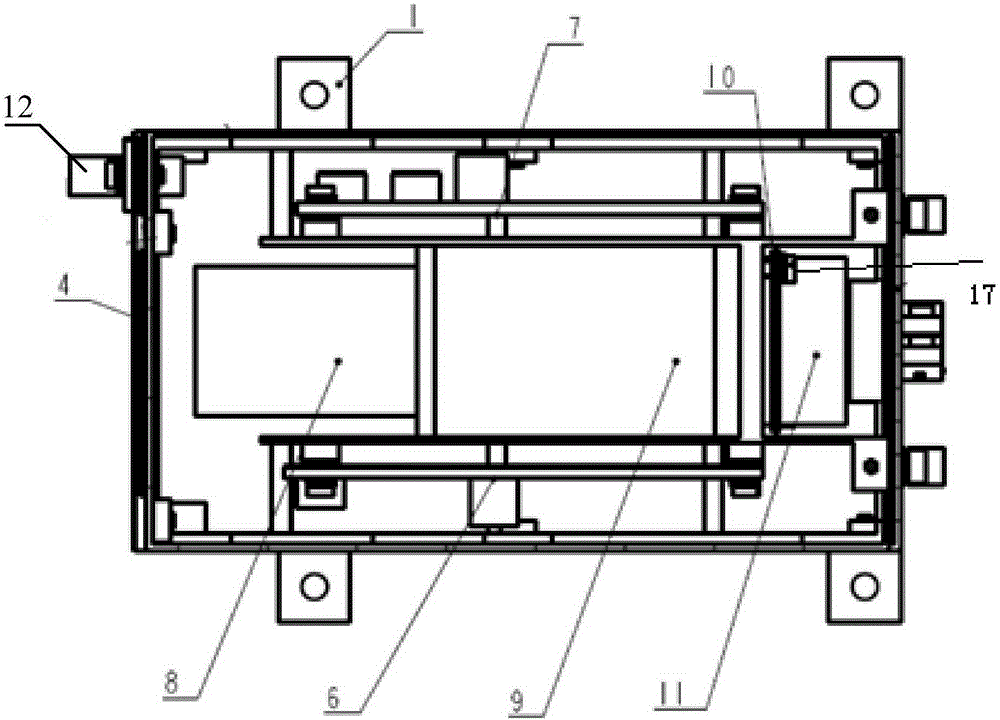

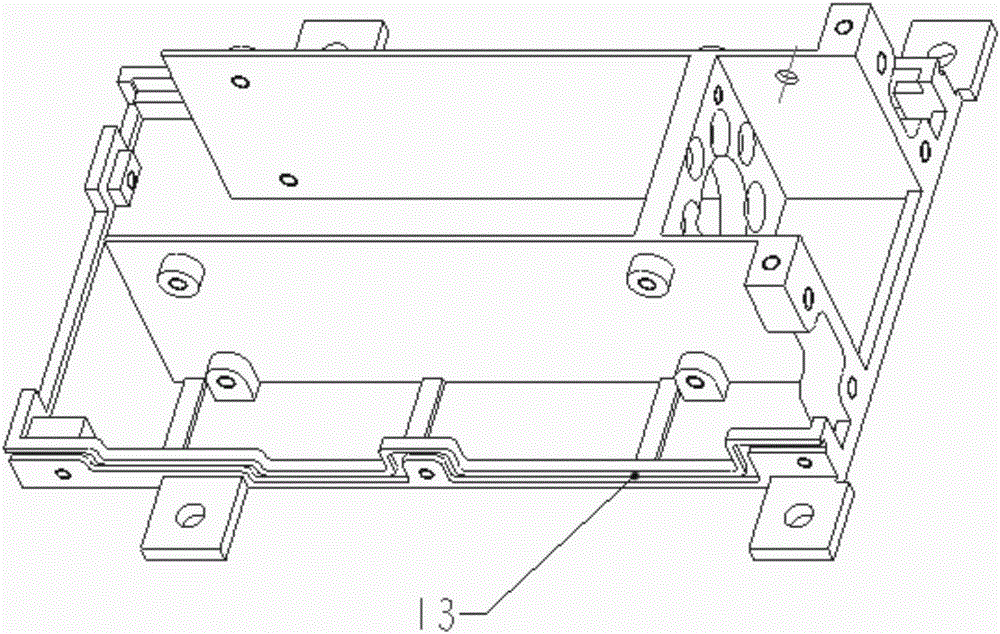

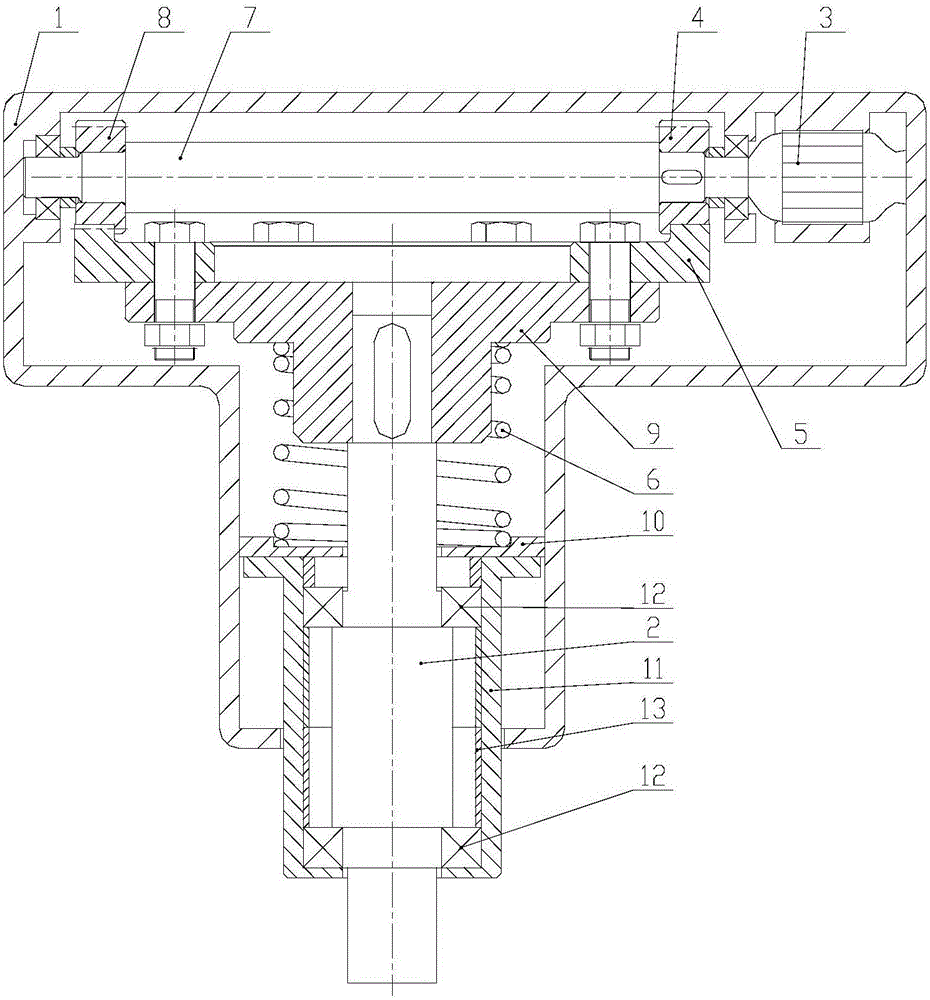

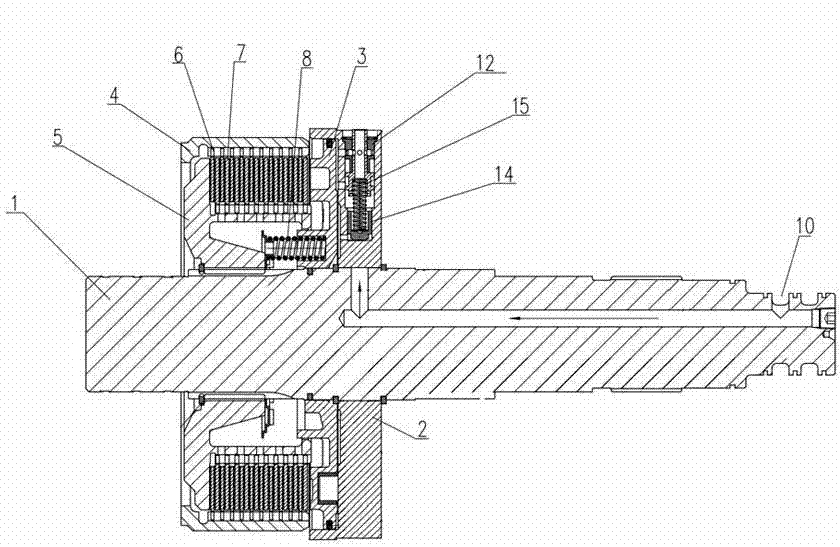

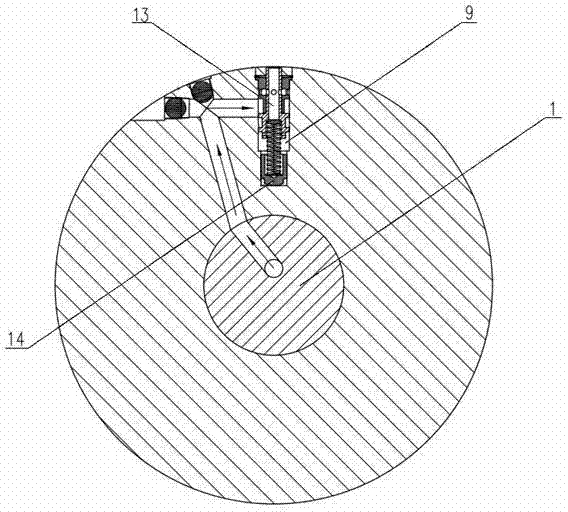

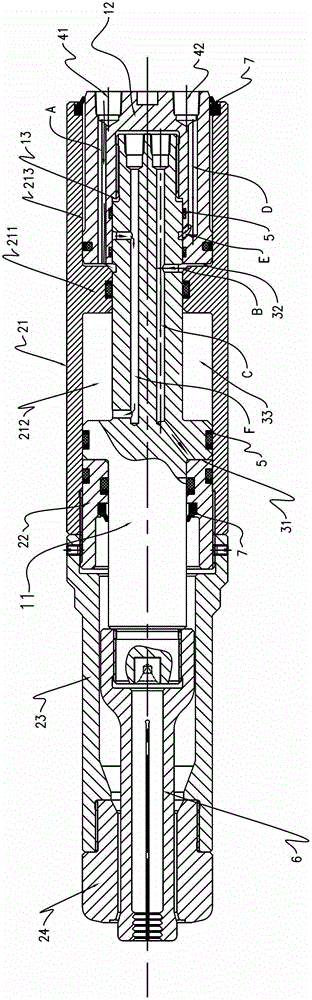

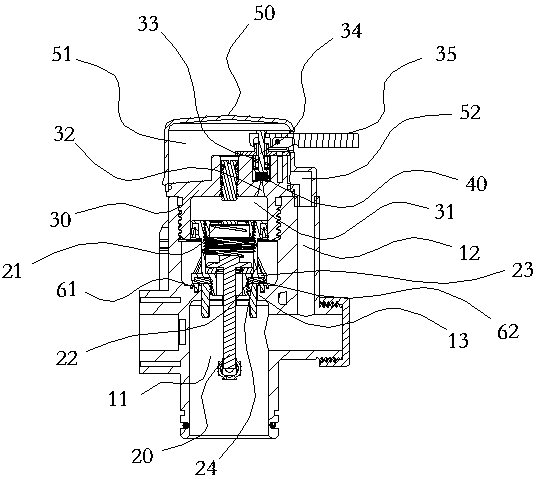

Integrated electric actuator for unmanned aerial vehicle

ActiveCN105173063ASatisfy continuous long working hoursImprove reliability and longevityWith power amplificationWorking lifeCurrent limiting

The invention discloses an integrated electric actuator for an unmanned aerial vehicle, which is specifically applied to the field of control surface control for unmanned aerial vehicles. According to the scheme, a brushless direct-current motor is used as a power source, and due to the scheme of serially connecting the brushless direct-current motor, a planetary reducer and a hollow angular displacement sensor, the actuator is compact in structure, and the spatial dimensions thereof are reduced, the working life thereof is prolonged, and the reliability thereof is improved; a shell of the actuator adopts a sealed structure design, and is high in dustproof and waterproof capacities, and adaptive to bad working environments; a control driver adopts the control strategy of a position and two-stage current limiting, a current-limiting ring is mainly used for limiting an excessive current occurring in a system under abnormal conditions, and protecting the safety of the electric actuator and the unmanned aerial vehicle; and with regard to a square-wave position angle instruction, real-time acquisition for the angle instruction is realized by means of interrupt capture, and the accuracy of acquisition for the angle instruction is improved by adopting the control strategy of angle amplitude-limiting filtering and instruction compensation, therefore, the accuracy of the flight attitude of the unmanned aerial vehicle can be greatly improved, and can achieve 0.1 degrees.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

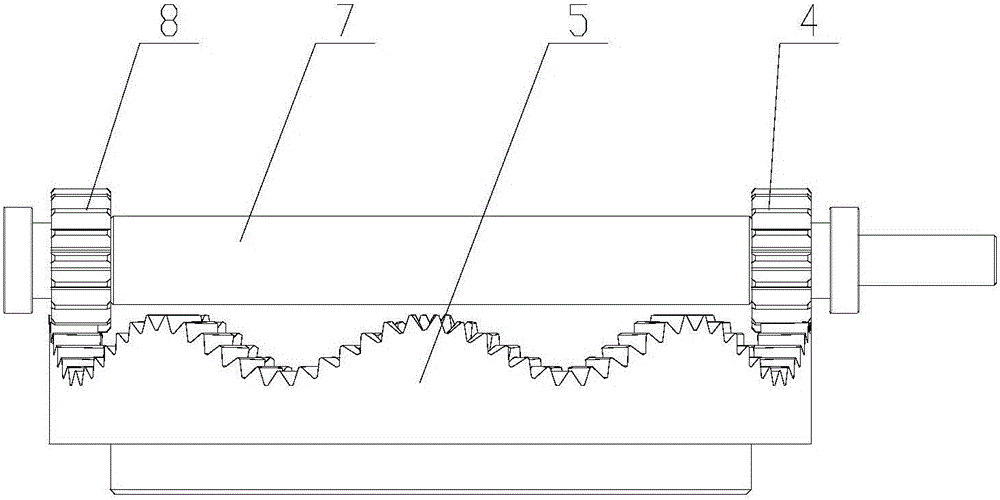

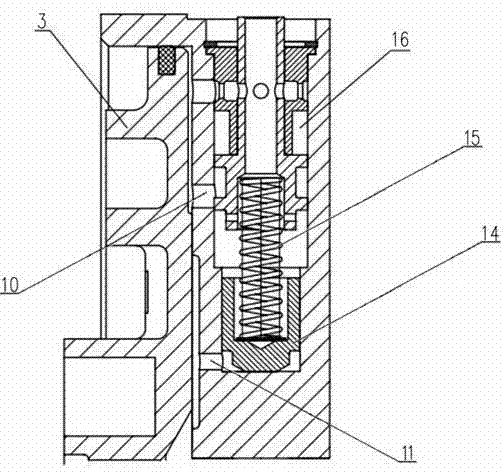

Novel composite impact drill

ActiveCN104985567AReduce vibrationImprove reliability and longevityPortable percussive toolsEngineeringReciprocating motion

The invention discloses a novel composite impact drill. The novel composite impact drill comprises a shell, a punch, a driving device, and an impact mechanism in transmission connection between the driving device and the punch, wherein the impact mechanism comprises a driving gear, an end curved surface gear and an elastic piece; the driving gear is mounted on the shell, and is driven by the driving device to rotate; the driving gear is engaged with the end curved surface gear; and the end curved surface gear is fixed on the punch; the elastic piece is supported between the shell and the end curved surface gear for providing axial elastic force to the end curved surface gear to keep the engagement between the end curved surface gear and the driving gear. The novel composite impact drill has the novel impact mechanism, and the driving gear can be driven by the motor; the driving gear and the end curved surface gear are engaged to generate a compound motion of rotation and axial movement so as to generate impact; the spring provides restoring force to generate a continuous reciprocating motion; and compared with the prior art, the novel composite impact drill simplifies the impact drill mechanism, and can achieve the purposes of reducing the vibration, prolonging the service life and improving the reliability.

Owner:CHONGQING UNIV

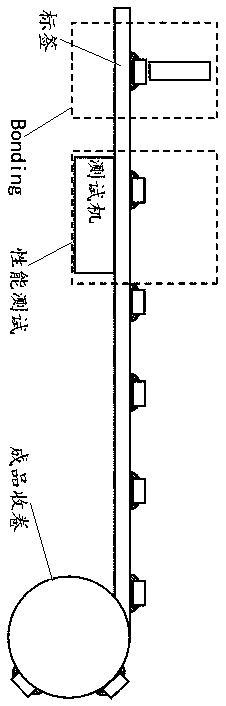

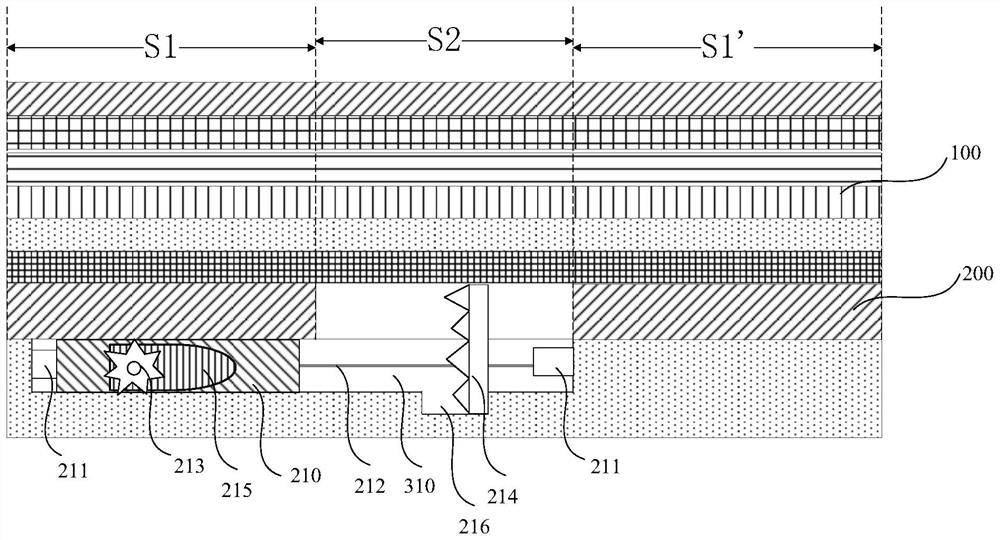

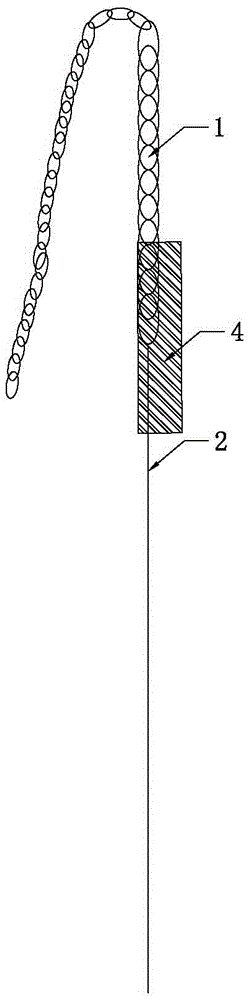

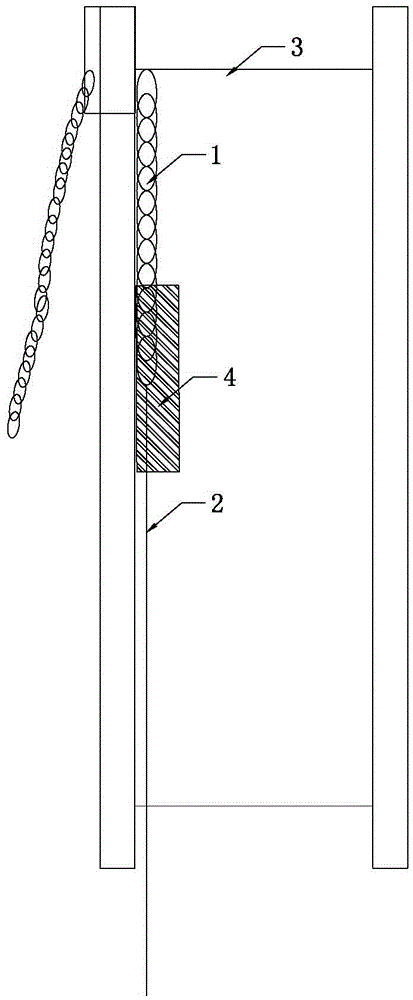

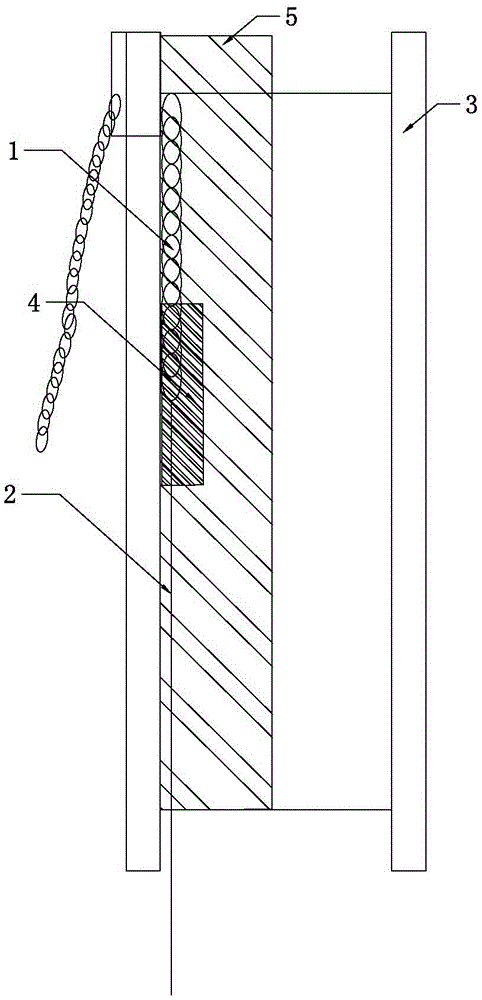

Online coating mechanism of RFID tag bonding machine and using method of online coating mechanism

InactiveCN109018499AImprove impact resistanceImprove reliability and longevityWrapping material feeding apparatusRecord carriers used with machinesEngineeringImpact resistance

The invention discloses an online coating mechanism of a RFID tag bonding machine and a using method of the online coating mechanism, and belongs to the technical field of RFID tags. According to theonline coating mechanism of the RFID tag bonding machine and the using method of the online coating mechanism, after chip bonding is completed, a protective film is additionally arranged on the surface of the chip to improve the impact resistance of the chip, so that the service life of existing products is prolonged, and the reliability of the products is improved. The coating mechanism is designed on an existing Bonding machine and is improved, so that the coating function is achieved without affecting the Bonding efficiency, and the mechanism with the coating function is obtained; and the position of the coating mechanism and the position of a performance testing or winding process device can be exchanged freely, so that the coating function is achieved in the Bonding process, and accordingly, the reliability of the chip is greatly improved while the cost is effectively controlled.

Owner:ARIZON RFID TECH YANGZHOU

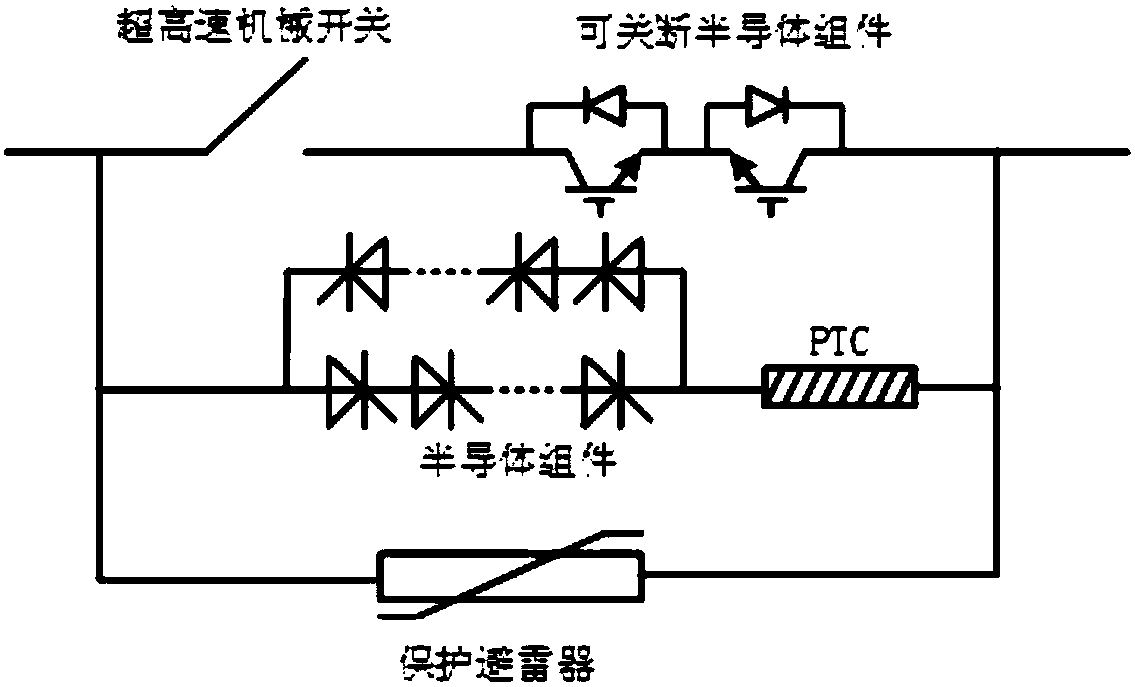

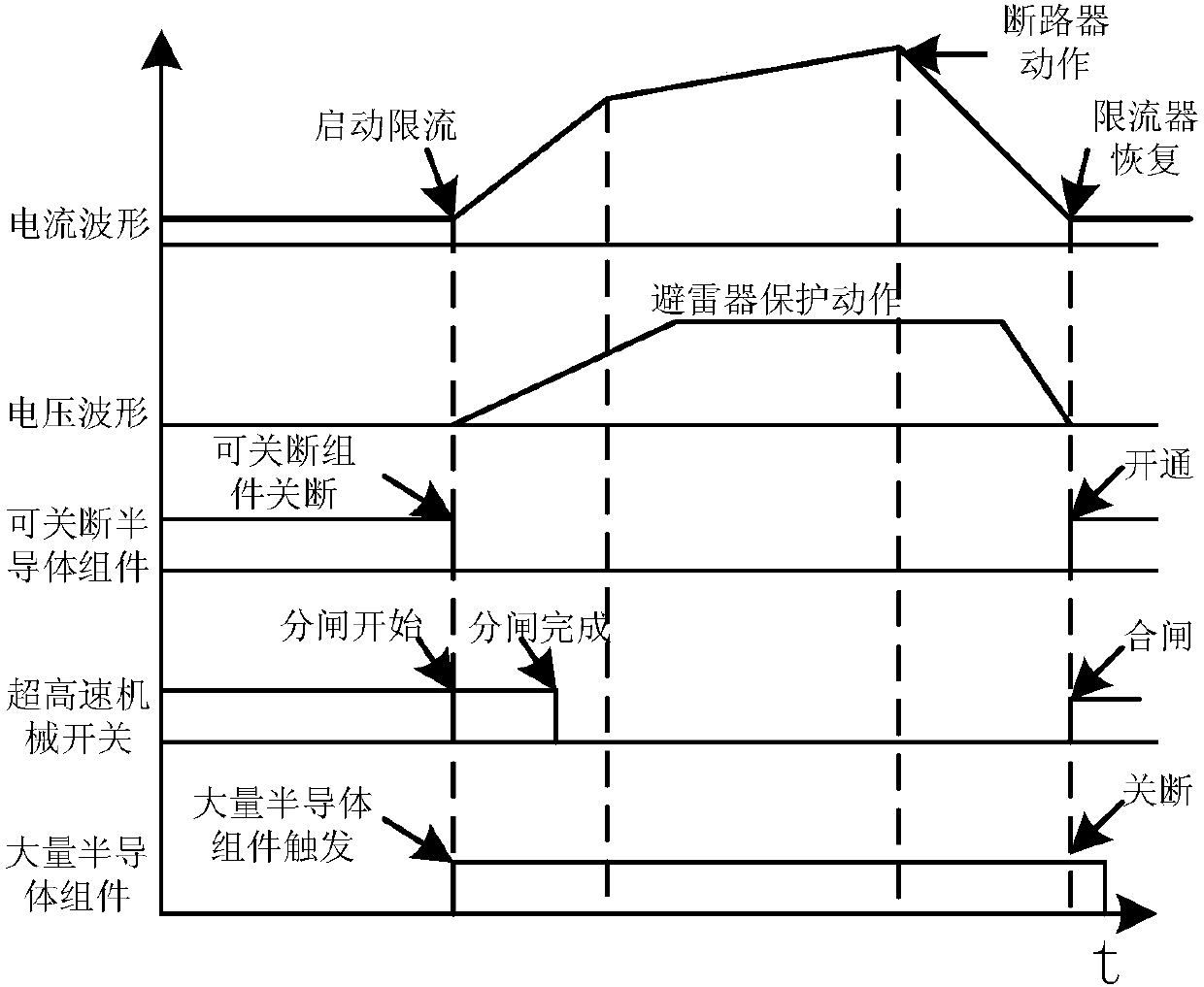

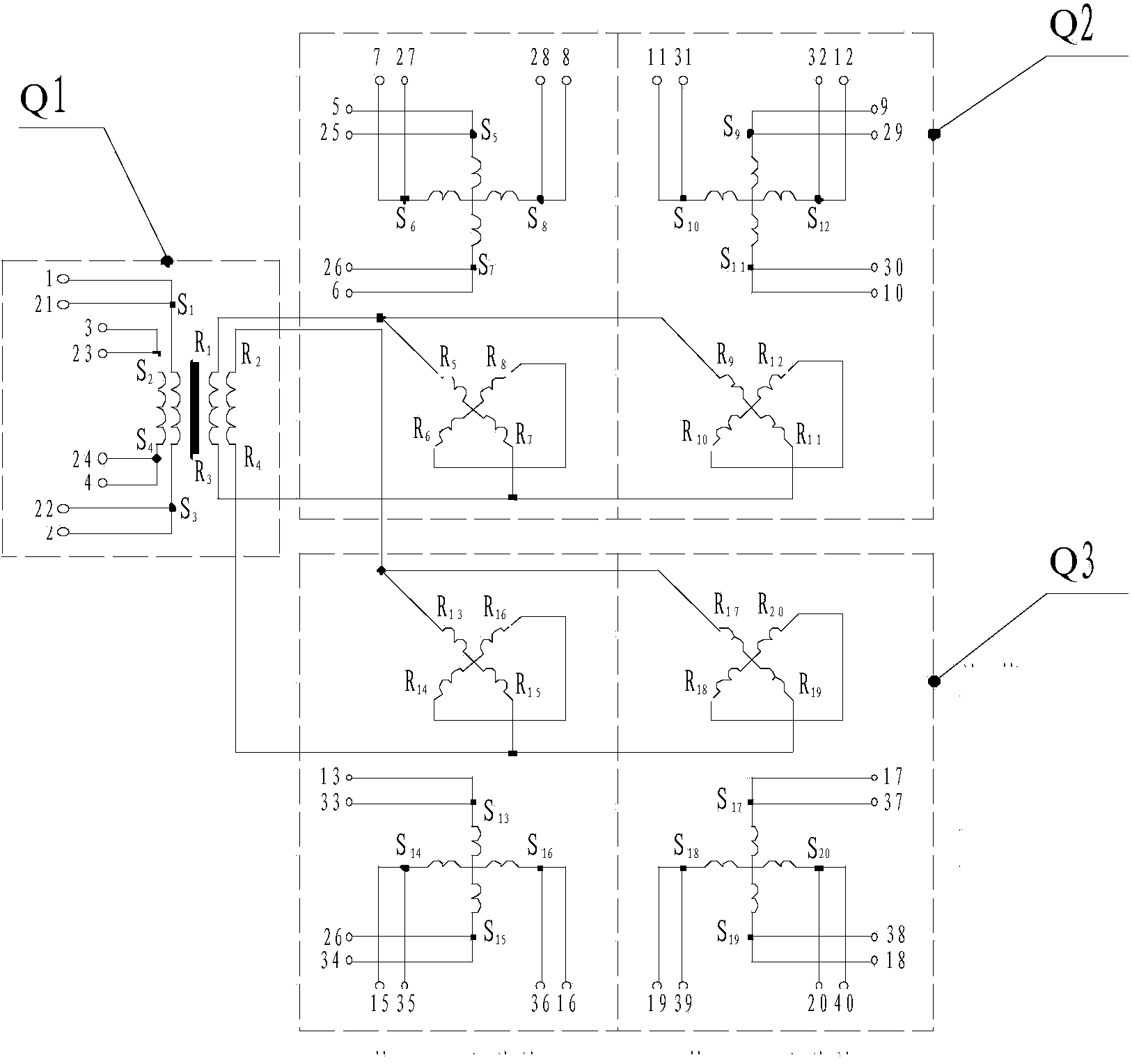

Positive temperature coefficient resistance material-based hybrid current limiter

PendingCN107769178ANo heat lossImprove reliability and longevityEmergency protective arrangements for limiting excess voltage/currentTemperature coefficientPositive temperature

The invention provides a positive temperature coefficient resistance material-based hybrid current limiter. The positive temperature coefficient resistance material-based hybrid current limiter comprises a steady-state current through branch, a current limitation path and a lightning arrester path which are connected in parallel, wherein the steady-state current through branch comprises an ultrahigh-speed mechanical switch and a semiconductor assembly capable of being switched off, which are connected in series, the steady-state current through branch is used for bypassing the current limitation path so as to transmit a load current when a power system normally runs, the current limitation path comprises a positive temperature coefficient (PTC) resistor and a semiconductor assembly which are connected in series, and the current limitation branch is used for suppressing a fault current when a fault occurs in the power system. Compared with the prior art, the PTC resistance material-based hybrid current limiter provided by the invention has the advantages that a limitation threshold of the fault current can be flexibly set, arc-free disconnection of the ultrahigh-speed mechanical switch also can be achieved, and the PTC resistance material-based hybrid current limiter is simple to operate and is reliable and practical.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

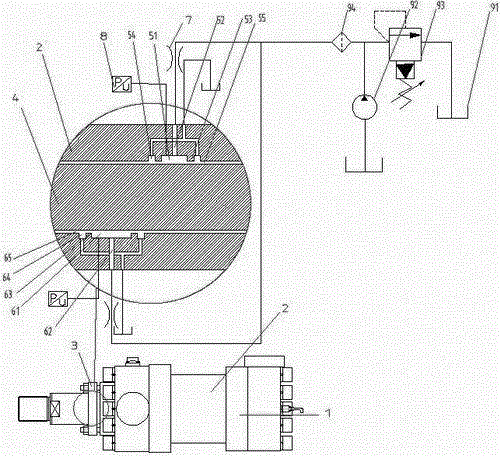

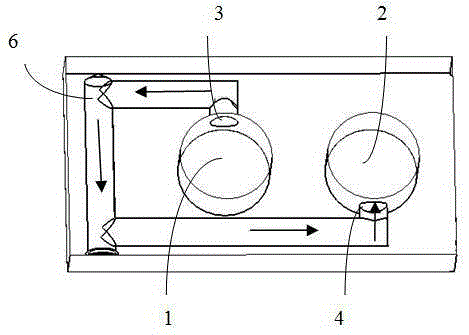

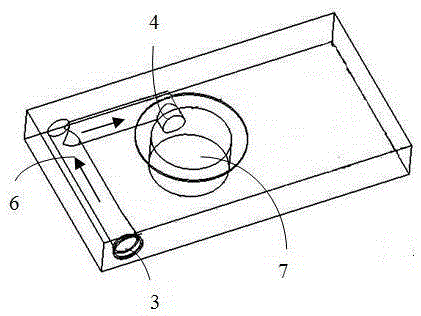

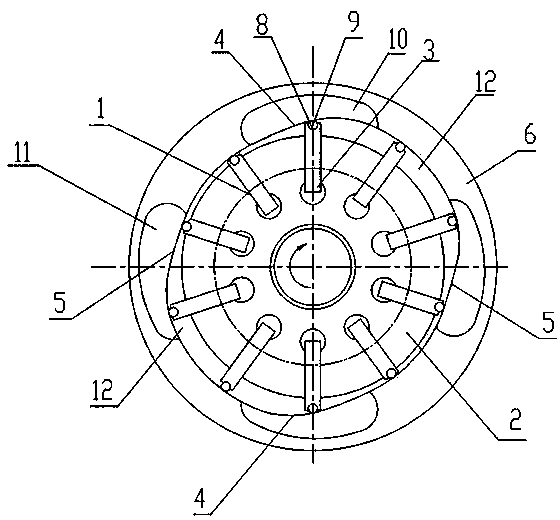

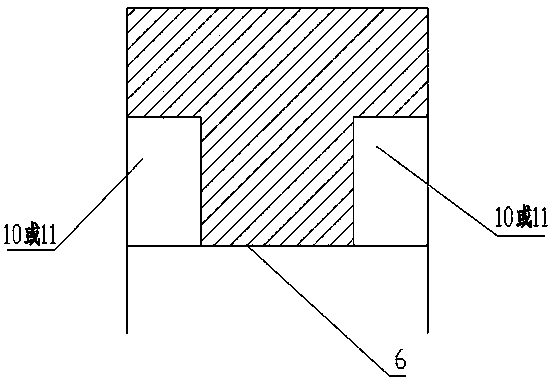

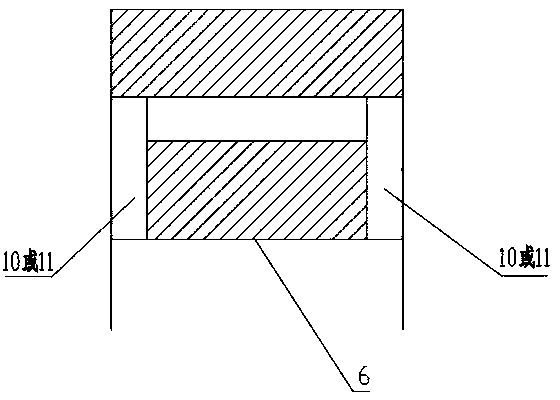

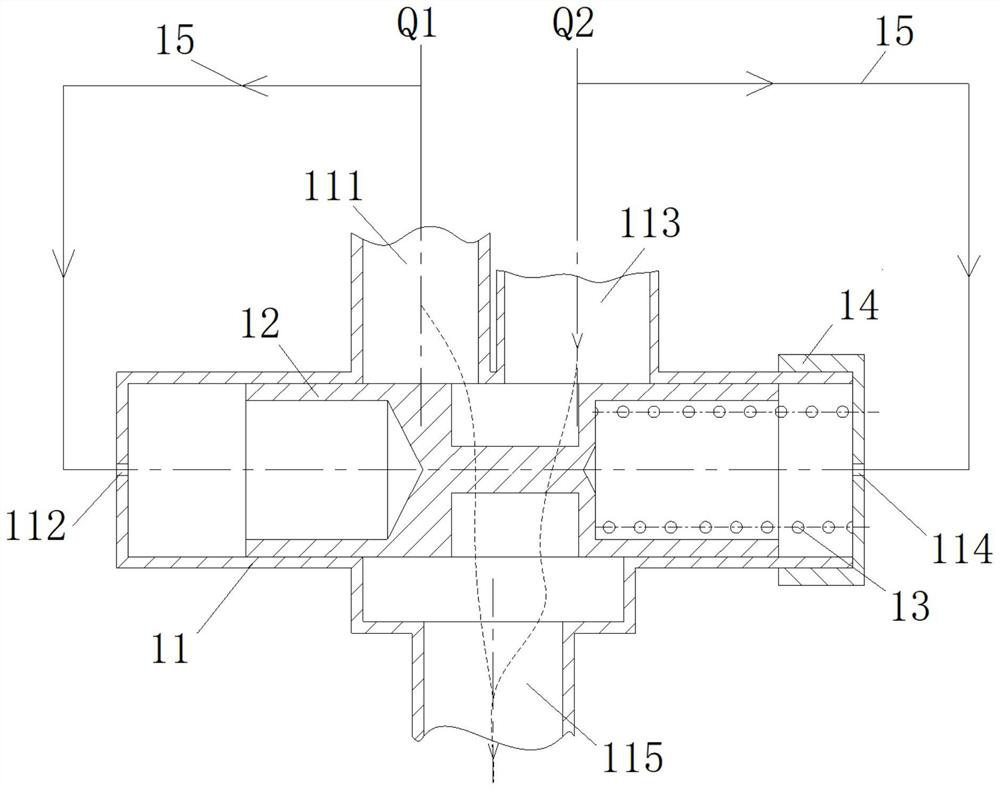

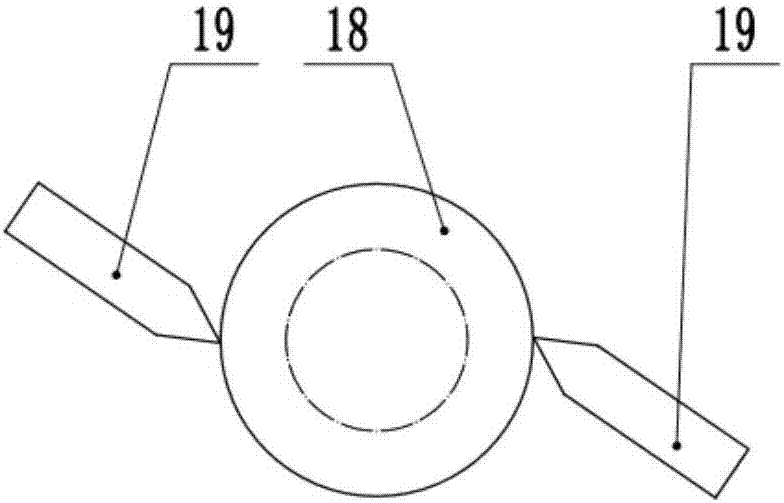

Wet type clutch with pressure stabilizing function

ActiveCN104279242AImprove reliability and longevityReduce vibrationFluid actuated clutchesPhysicsClutch

Owner:LUOYANG REASTAR TRANSMISSION

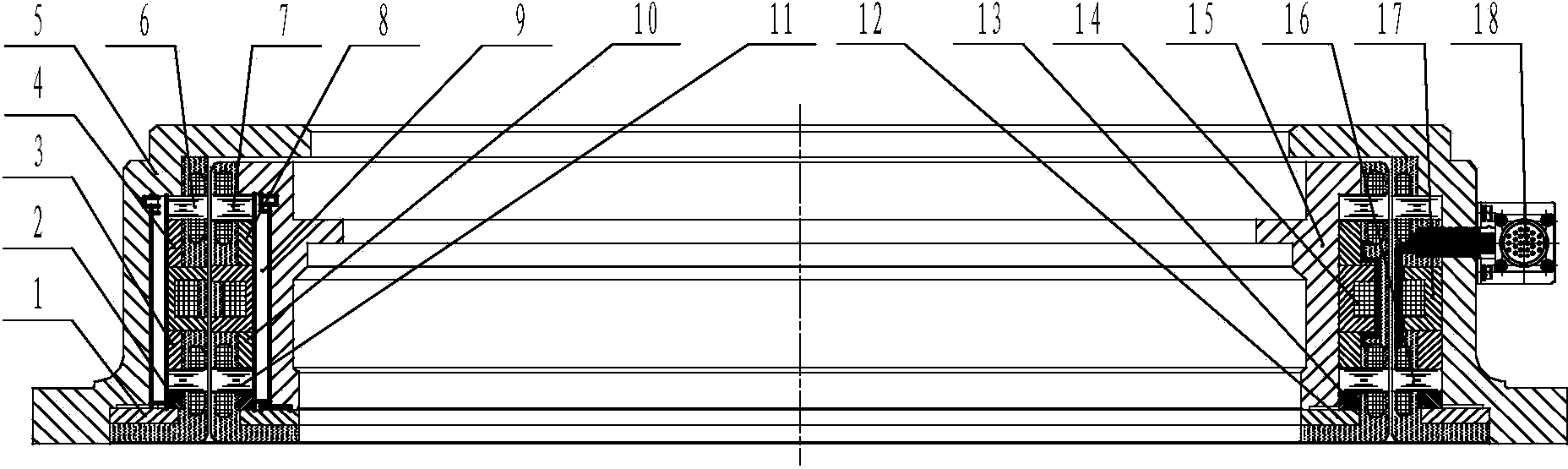

Multi-redundancy dual-channel non-contact rotary transformer

ActiveCN103871723AHigh precisionImprove reliability and longevityTransformersTransformers/inductances magnetic coresConductor CoilElectrical and Electronics engineering

A multi-redundancy dual-channel non-contact rotary transformer comprises a dual-redundancy ring transformer, a first dual-channel rotary transformer and a second dual-channel rotary transformer. A first ring transformer body and a second ring transformer body share the same iron core and have the same winding parameters completely; the multi-redundancy dual-channel non-contact rotary transformer is of a split magnetic path structure, a magnetic path of the first dual-channel rotary transformer is impendent from a magnetic path of the second dual-channel rotary transformer, and the single-pole dual-channel rotary transformer and the multiple-pole dual-channel rotary transformer are of a common magnetic path structure; two lead wires are led out of each of the input point, the output point and the earth point of the multi-redundancy dual-channel non-contact rotary transformer and connected with two electric connectors. According to the multi-redundancy dual-channel non-contact rotary transformer, the single-pole rotary transformer and the multiple-pole rotary transformer are combined, non-contact is achieved, multiple redundancies are achieved by adopting the dual-redundancy structural form, the dual-redundancy magnetic path form and the dual-redundancy circuit form, reliability of the multi-redundancy dual-channel non-contact rotary transformer is improved to a greater degree, the service life of the multi-redundancy dual-channel non-contact rotary transformer is prolonged to a greater degree, the failure rate of a system is reduced greatly, reliability of the system is improved greatly, angle measuring precision of the system is improved, and the service life of the system is prolonged.

Owner:XIAN MICROMOTOR RES INST

Determining maximum cooling for a component by retrieving an offset value

ActiveUS7484380B2Improve reliability and longevityShorten the timeLighting and heating apparatusSemiconductor/solid-state device detailsMaximum levelSystem monitor

The present invention is directed to a system for determining a temperature of a component that requires a maximum level of cooling apparatus operation. The system monitors the component's temperature, then may add a compensation offset to account for variations in the manufacture of the component, and then adds a compensation offset to account for variation in the system in which the component is installed. The result is used to determine when the system's cooling apparatus needs to be operated at a maximum level of operation. The sum may be compared to a threshold to make this determination. This same mechanism may be used to determine various other cooling system trigger points, both when to increase cooling as well as decrease cooling.

Owner:GATEWAY

Double-acting hydraulic riveter for short-tail rivet

InactiveCN102744354AReduce processing costsImprove reliability and longevitySafety coefficientEngineering

The invention relates to a double-acting hydraulic riveter for a short-tail rivet. The hydraulic riveter for the short-tail rivet is a riveting molding tool special for the short-tail rivet and comprises a front piston body, a rear piston body, a cylinder body, an anvil barrel, an anvil barrel seat, an inner barrel clamp and a front body, wherein the inner barrel clamp is connected with an outer thread at one end of the front piston body through an inner thread, and the other end of the front piston body is connected with an inner thread of the rear piston body through the outer thread and provided with a positioning boss to guarantee the axiality of the front piston body and the rear piston body; the cylinder body and the anvil barrel seat are connected with outer threads of the front body respectively, the front body, the front piston body and the cylinder body form a first oil chamber, and the front piston body, the rear piston body and the cylinder body form a second oil chamber; and aluminum alloy dustproof rings are arranged at positions of the front body and the rear piston body. The weight of the double-acting short-tail riveter is reduced by 1 / 4 of that of a traditional gun-type riveter, the processing is simple, the number of parts is small, the safety coefficient is high, the rejection rate of a critical component of an oil cylinder is low, the service life of products is effectively prolonged, and by means of a straight barrel type structure, the double-acting hydraulic riveter can be used on occasions which are limited in space.

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

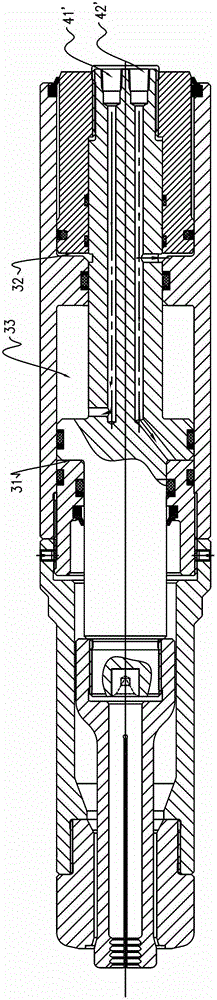

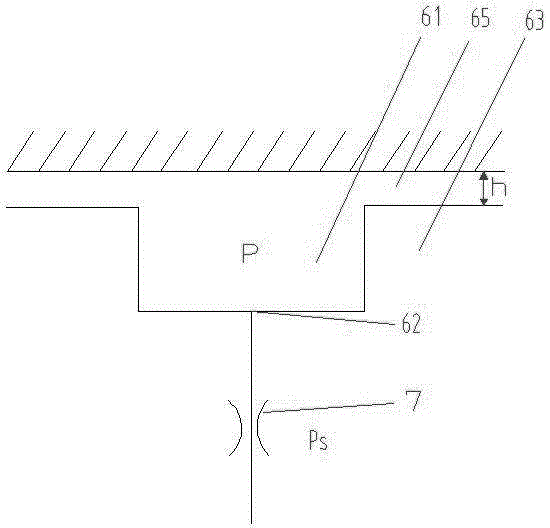

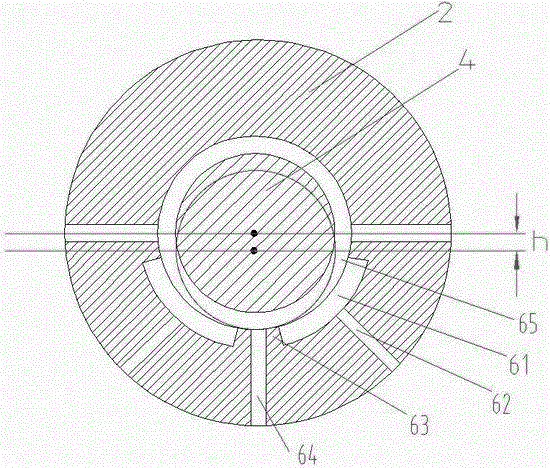

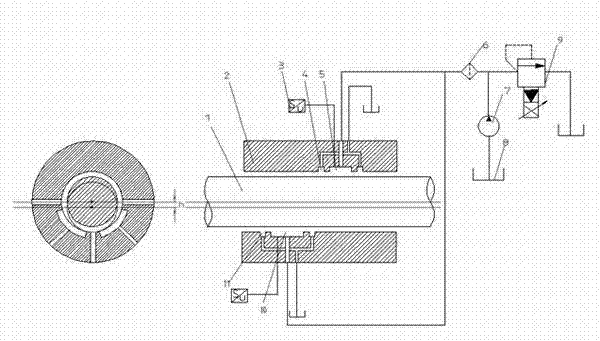

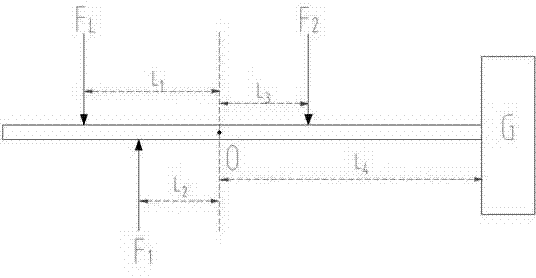

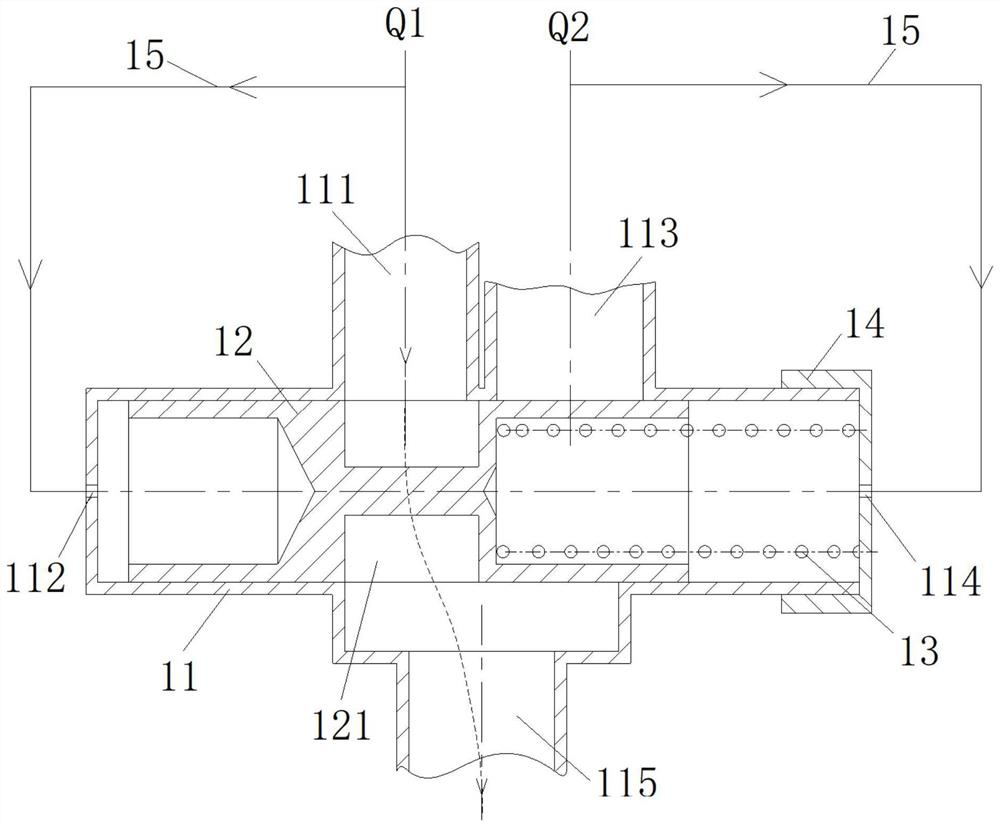

Designing method of constant-pressure oil supply type load-deflection resistance horizontal type servo oil cylinder

ActiveCN104454765AIncrease the bearing capacity and anti-eccentric load capacityImprove reliability and longevityFluid-pressure actuatorsLubricationCylinder block

The invention provides a designing method of a constant-pressure oil supply type load-deflection resistance horizontal type servo oil cylinder. The horizontal type servo oil cylinder comprises a cylinder body, a cylinder cover and a piston rod, wherein a guide sleeve of the cylinder cover is provided with oil pads not symmetrical up and down in the axis direction, the oil pad on the lower side of the piston rod is a supporting oil pad, the oil pad on the upper side of the piston rod is a bearing reaction oil pad, a hydraulic loop in front of a center oil inlet of each oil pad is connected with a damper, an independent oil supply system supplies pressure oil to the oil pads at the same time, and the pressure of the pressure oil provided by the oil supply system keeps unchangeable. According to the servo oil cylinder designed according to the method, in the whole working process, the piston rod and a piston keep a certain gap all the time, the guide sleeve and the cylinder body also keep a certain gap all the time, oil film lubrication is formed, friction between the piston rod and the guide sleeve as well as between the piston and the cylinder body is reduced, the bearing capacity and the load-deflection resistance capacity of the system are improved, the reliability of the horizontal type servo oil cylinder is greatly improved, and the service life of the horizontal type servo oil cylinder is prolonged greatly.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

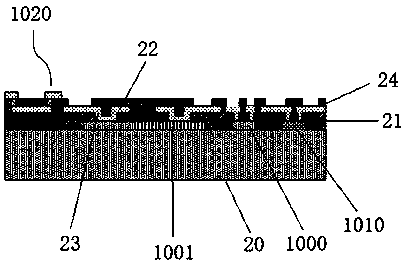

Test chip and integration method

PendingCN111007387AIncrease flexibilityImprove reliability and longevityElectronic circuit testingPhysicsElectromigration

The invention provides a test chip which comprises test units, the test units are distributed in the chip in a single or array mode, each test unit comprises a plurality of basic units distributed inan array mode, and the basic units are connected in series, in parallel or both in series and in parallel. Each basic unit comprises a thermal test module, a stress test module and an electromigrationtest module; wherein the thermal test module comprises a heating element and a temperature measuring element; the stress test module comprises a stress test element; the electromigration test modulecomprises an electromigration test element; and the heating element, the temperature measuring element, the stress testing element and the electromigration testing element are externally connected with a driving power supply and a signal reading circuit respectively. The invention also provides an integration method of the test chip.

Owner:苏州容启传感器科技有限公司

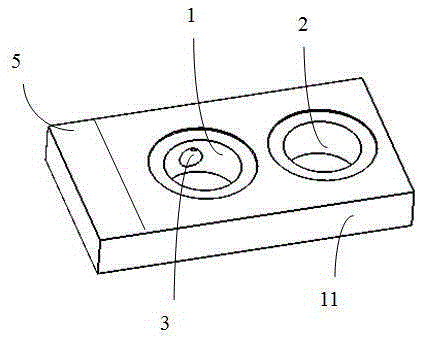

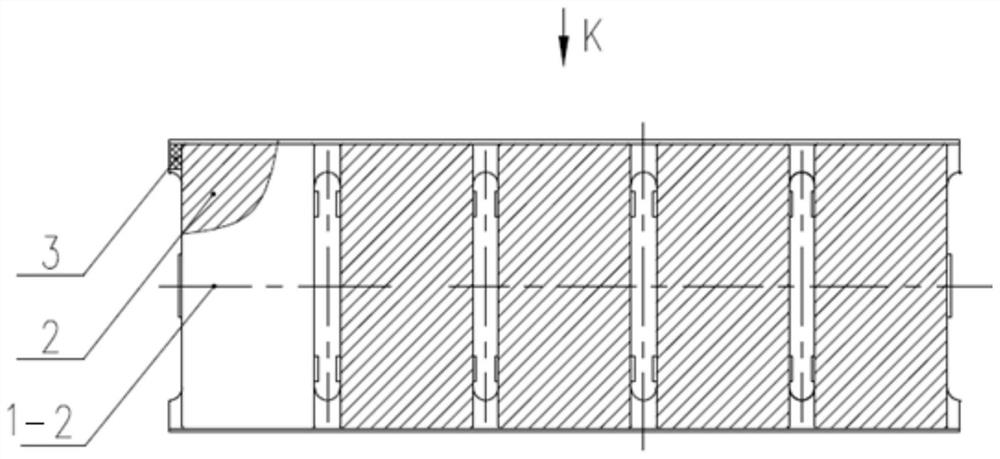

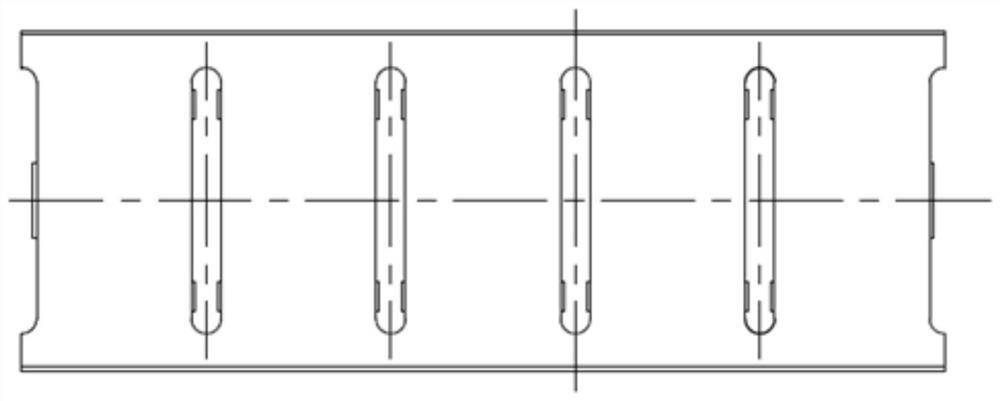

Large-channel semiconductor laser liquid refrigeration sheet and laser thereof

PendingCN106887787ANot easy to blockImprove reliability and longevityLaser detailsSemiconductor lasersPhysicsErbium lasers

The invention provides a large-channel semiconductor laser liquid refrigeration sheet and a semiconductor laser stack array employing the liquid refrigeration sheet. The large-channel semiconductor laser liquid refrigeration sheet comprises a refrigeration sheet main body provided with a liquid-inlet hole and a liquid-outlet hole, and a tubular liquid refrigeration channel used for communicating the liquid-inlet hole and the liquid-outlet hole is arranged in the refrigeration sheet main body. According to the large-channel semiconductor laser liquid refrigeration sheet, the liquid refrigeration channel is not easily blocked, the reliability of the device is improved, the lifetime of the device is prolonged, and the heat radiation effect of the large-channel refrigeration sheet is equivalent to that of a micro-channel refrigeration sheet in the same flow condition; and compared with the conventional macro-channel liquid refrigeration sheet, according to the large-channel liquid refrigeration sheet, the refrigeration area is increased, the thermal conduction path is shortened, and the heat radiation efficiency is improved.

Owner:FOCUSLIGHT TECH

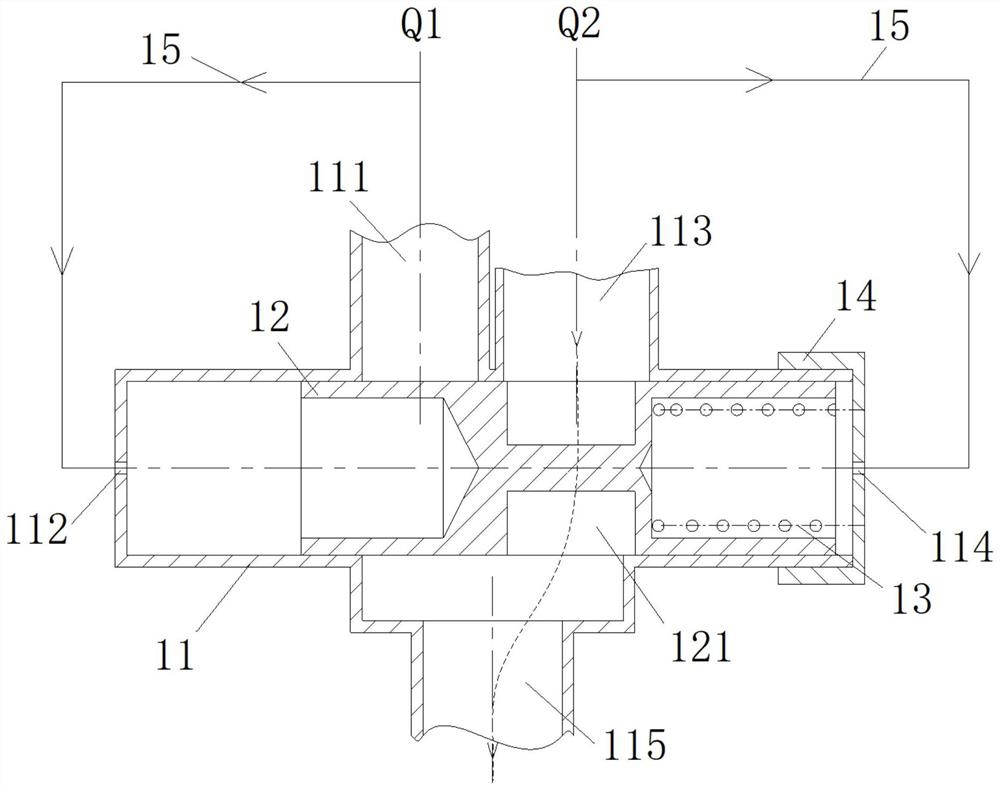

Pressure-variable oil-supply-type load-deflection-resistant horizontal servo oil cylinder design method

ActiveCN104500498AIncrease the bearing capacity and anti-eccentric load capacityImprove reliability and longevityFluid-pressure actuator componentsOil supplyCylinder block

The invention discloses a pressure-variable oil-supply-type load-deflection-resistant horizontal servo oil cylinder design method. A horizontal servo oil cylinder comprises a cylinder body and a piston rod, wherein a cylinder guide sleeve is provided with oil pads (5,10) which are in up-down asymmetry along the axis direction; the oil pad at the lower side of the piston rod (1) is a support oil pad; the oil pad at the upper side of the piston rod (1) is a counterforce-support oil pad (5); an independent oil supply system is used for supplying pressure oil to the oil pad at the same time, and the pressure of the pressure oil supplied by the oil supply system is controlled by a proportional overflow valve. By virtue of applying the support oil pad and the counterforce-support oil pad and utilizing the independent oil supply system to supply pressure oil to the oil pads, the bearing capacity and load-deflection-resistant capacity of the system are enhanced, the reliability of the horizontal servo oil cylinder is greatly enhanced and the service life of the horizontal servo oil cylinder is greatly prolonged.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

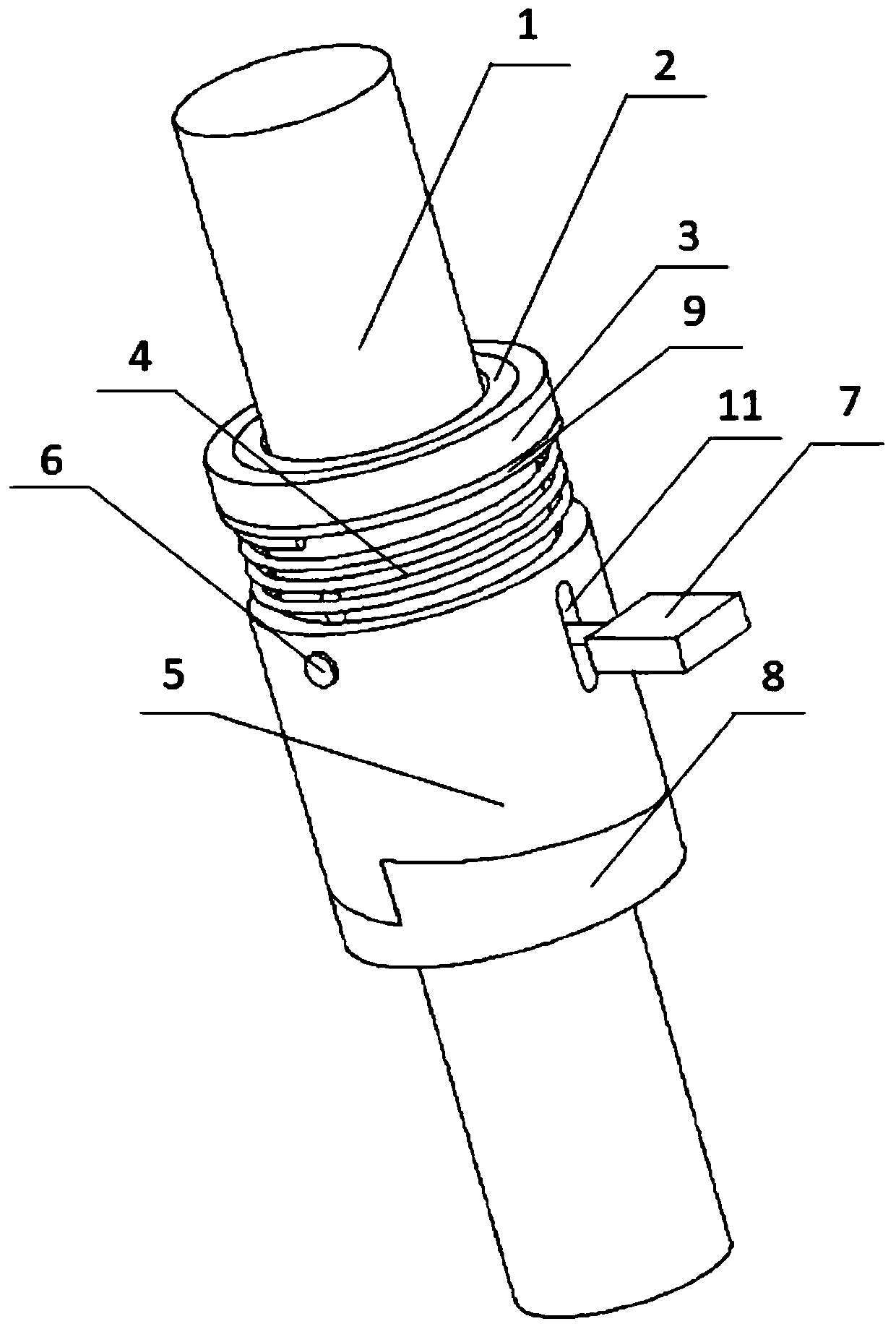

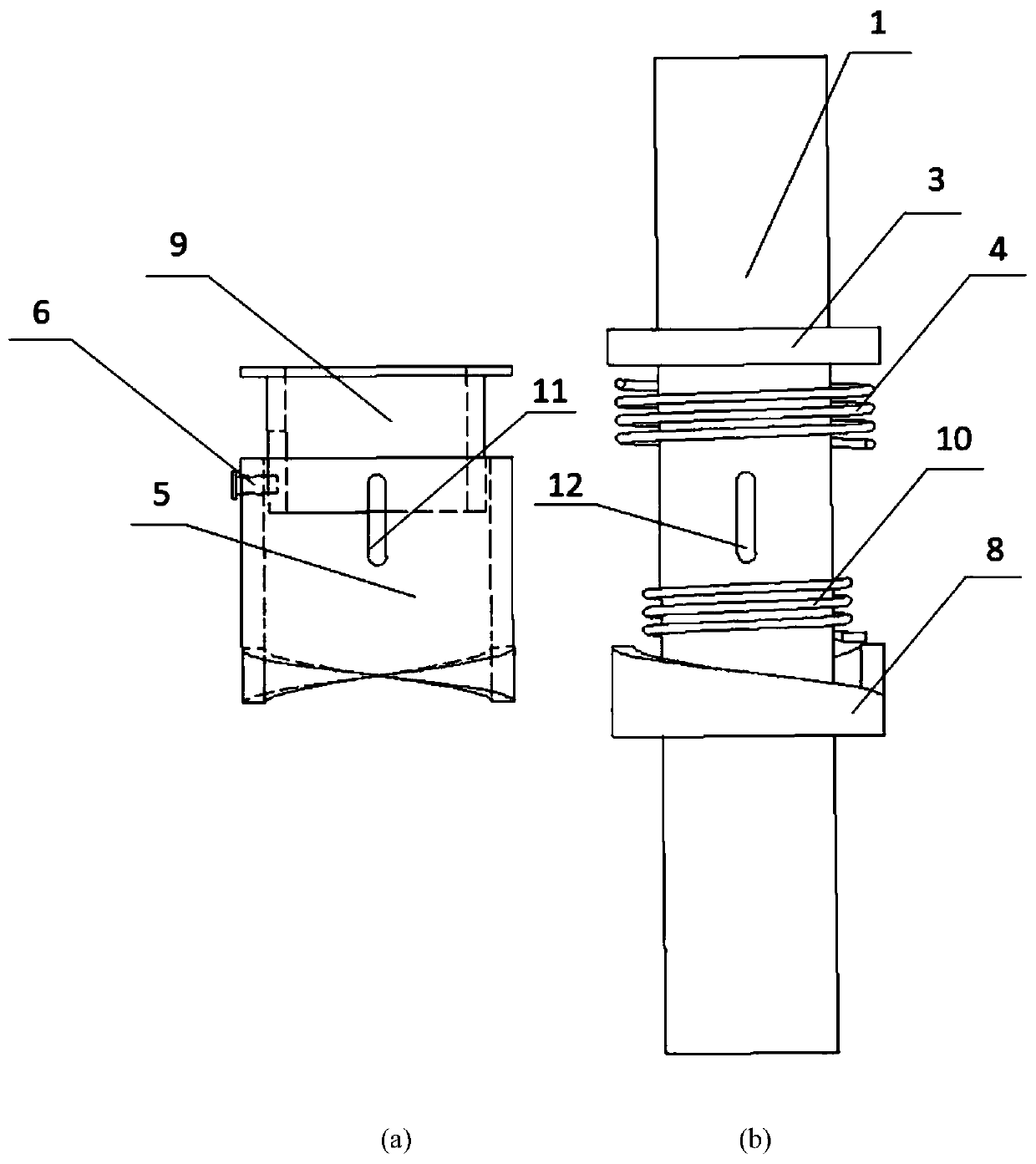

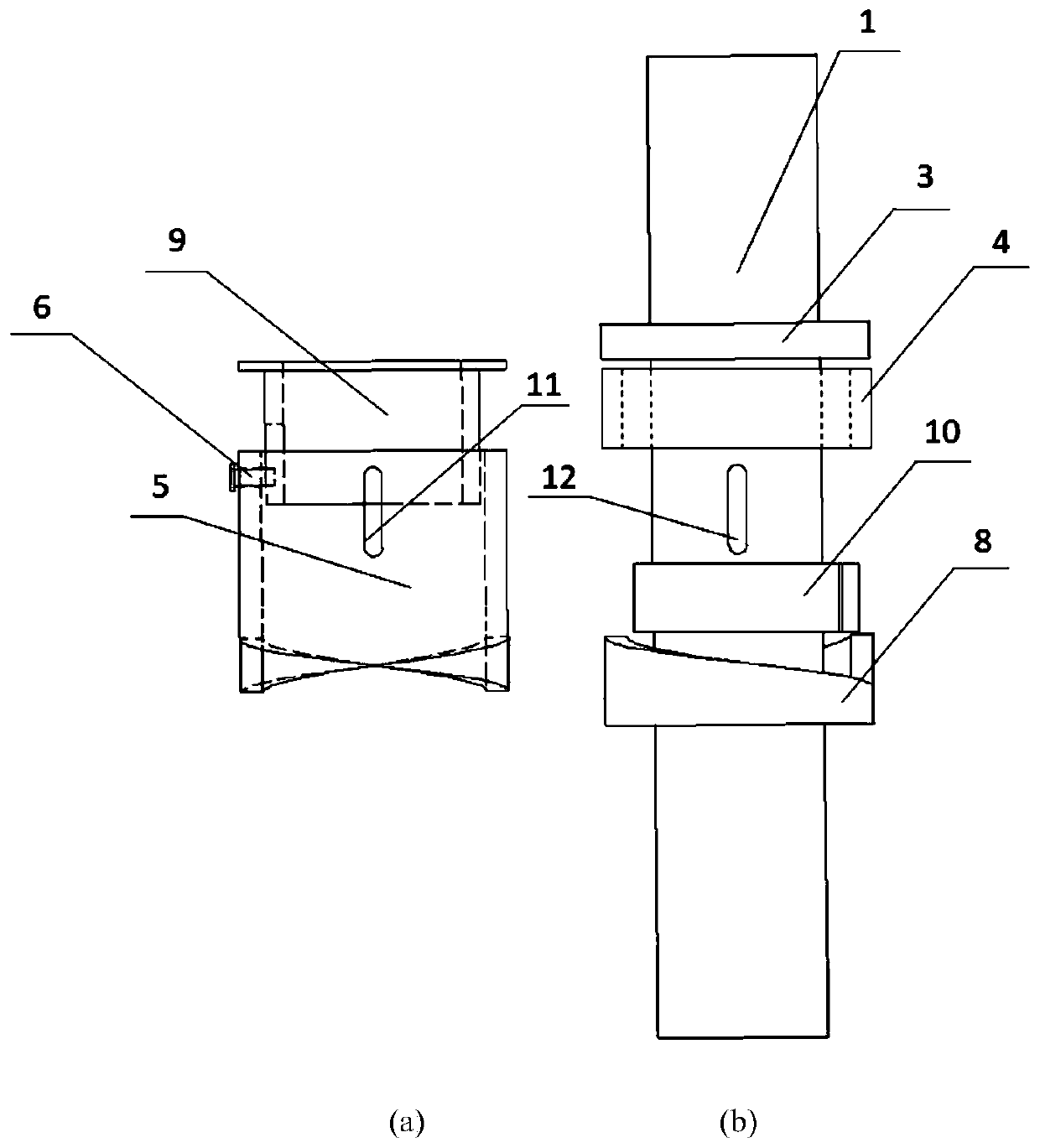

Soft main rotor locking device of rotor aircraft

The invention provides a soft main rotor locking device of a rotor aircraft. The soft main rotor locking device comprises a constraining assembly, a frictional speed-reducing assembly, an elastic compressing component and a braking component. Through arrangement of the frictional speed-reducing assembly, the rotating speed of a rotor is quickly reduced and conversion of the flight process is completed relatively fast; the impact load is relatively small in the locking process, and in the braking process of the braking component and an upper locking sleeve, the elastic component is arranged between the upper locking sleeve and a main rotor rotating shaft and a frictional force increases along with increase in the circumferential phase difference between the upper locking sleeve and a lowerfixing base, so that the time from rotation starting to rotation stop of the rotor is prolonged and impact energy is absorbed by elastic and frictional components; in the braking process of the braking component and the main rotor rotating shaft, the main rotor is already in the reverse rotating process after forward rotation stops, so that a rotating spring has relatively low elasticity, the rotating speed of the rotor is very low, and at the moment, the impact load is very small; therefore, in the whole locking process, almost no impact load exists, so that the reliability of the soft main rotor locking device is improved, the service life of the soft main rotor locking device is prolonged, and thus the soft main rotor locking device can be applied to medium and large rotor aircrafts.

Owner:南京灵龙旋翼无人机系统研究院有限公司

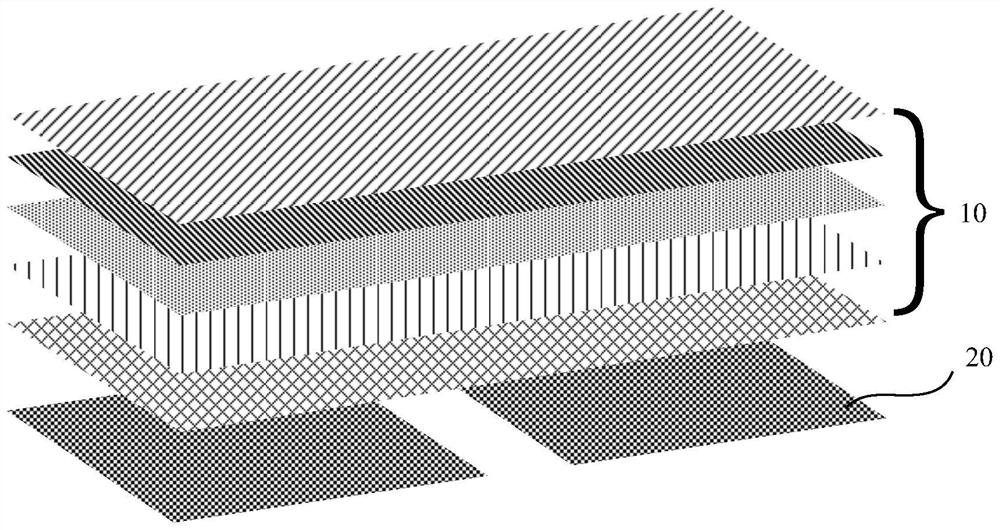

Foldable flexible display

ActiveCN112927608AReduce creasesImprove reliability and longevityIdentification meansMechanical engineeringFlexible display

The invention provides a foldable flexible display, which has a folded state and an unfolded state. The foldable flexible display comprises a flexible display screen, a fixed supporting piece and a movable supporting piece. The flexible display screen comprises a non-bent area and a bent display area, the non-bent area comprises a first display area and a second display area, and the bent display area is arranged between the first display area and the second display area. The fixed supporting piece comprises a first supporting piece and a second supporting piece which are arranged in the first display area and the second display area respectively and deviate from the display surface. The movable supporting piece can move between the non-bent area and the bent display area. When the foldable flexible display is in a folded state, the movable supporting piece is in the non-bent area. When the foldable flexible display is in an unfolded state, the movable support member is in the bent area. The flexible display is provided with the movable supporting piece which supports the bent display area so as to reduce creases of the area, the reliability of the display is improved, the service life of the display is prolonged, and the use experience of a user is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

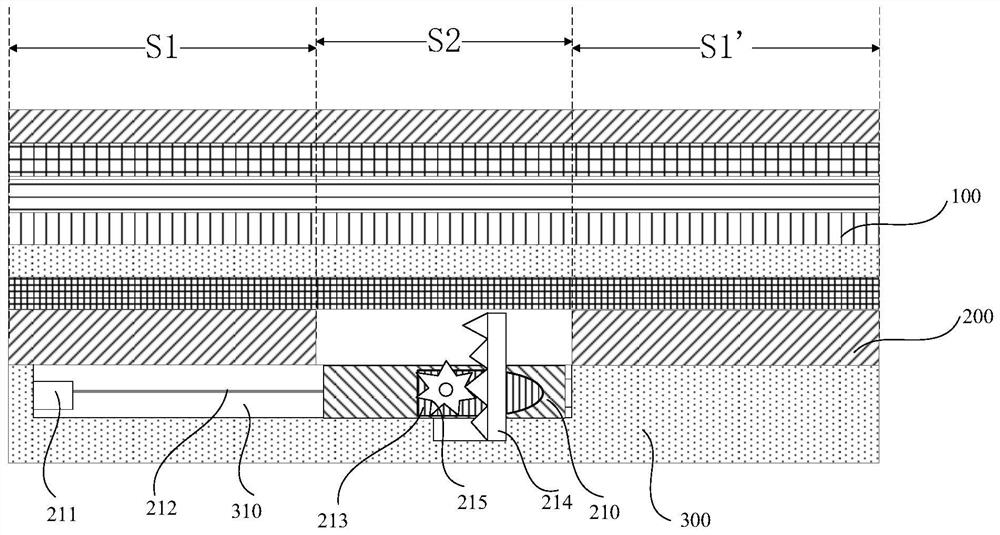

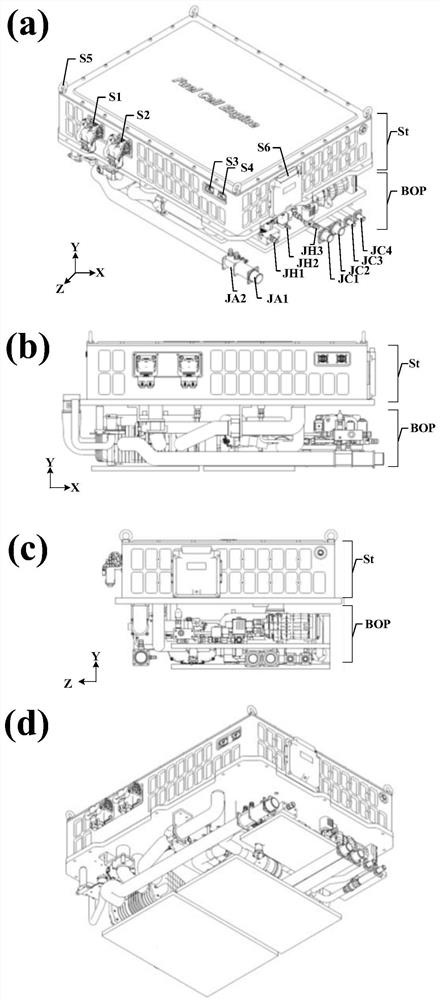

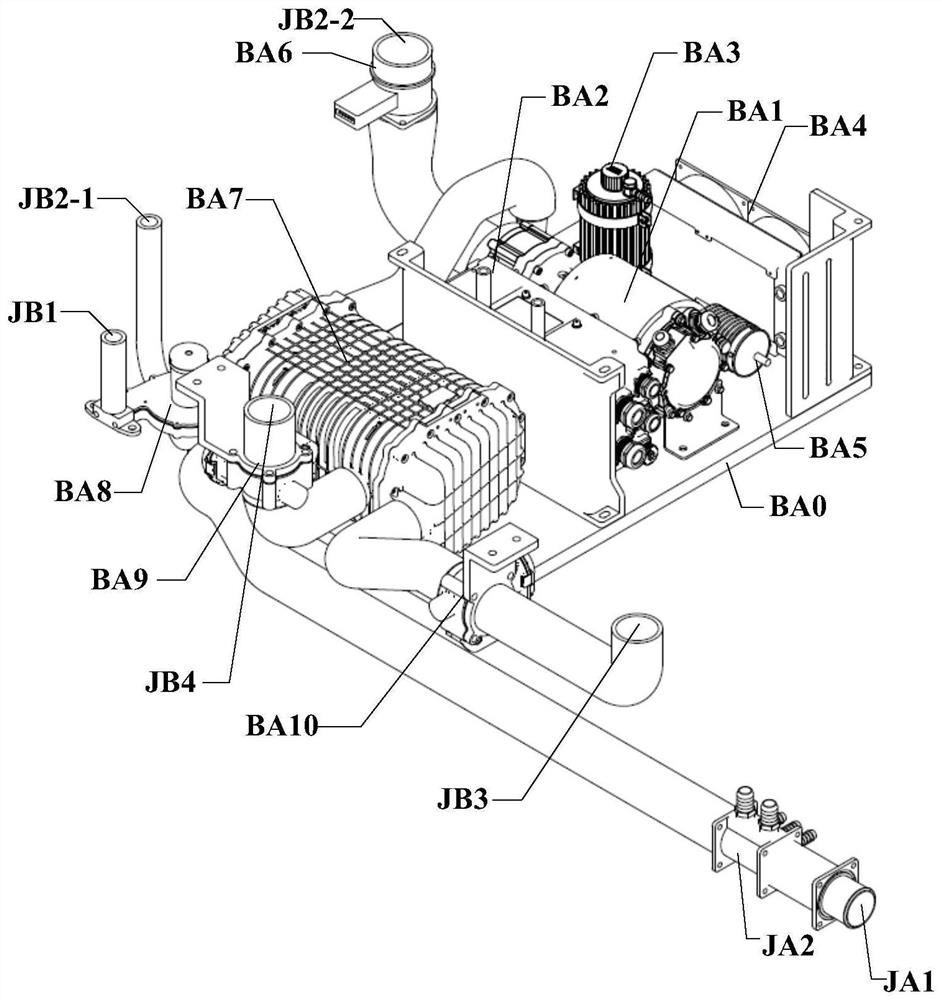

Proton exchange membrane fuel cell engine integrated device for vehicle

ActiveCN112635807AImprove reliability and longevityIncrease volumetric power densityPropulsion by batteries/cellsMotive system fuel cellsAutomotive engineeringEngineering

The invention provides a proton exchange membrane fuel cell engine integrated device for a vehicle, and belongs to the technical field of fuel cell engines. The device comprises an electric pile module, an electric control module, and an air module, a hydrogen module and a cooling module which are positioned at the lower part of the electric pile module, the electric pile module comprises an electric pile module base plate of an integrated component, the air module comprises an air module bottom plate of the integrated component, the hydrogen module comprises a hydrogen module bottom plate of the integrated component, and the cooling module comprises a cooling module bottom plate of the integrated component. The air module bottom plate, the hydrogen module bottom plate and the cooling module bottom plate are fixed below the electric pile module bottom plate through structural parts, so that integration is realized; and the electric pile module is connected with all parts in the air module, the hydrogen module and the cooling module through pipeline interfaces. Energy optimization control and stable operation of the engine are achieved through modular design, the reliability of the engine is improved, the service life of the engine is prolonged, the integration level is high, and the device is suitable for buses.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

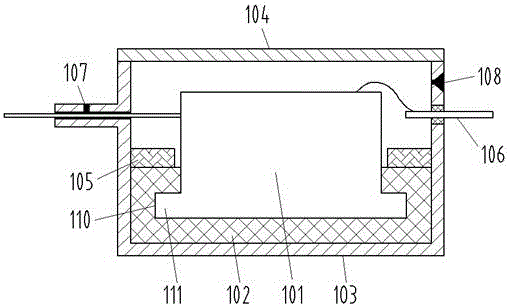

Optical device packaging apparatus and packaging method

ActiveCN106252340AImprove anti-interference abilityImprove reliability and longevitySolid-state devicesSemiconductor devicesNitrogen atmosphereBiomedical engineering

The invention relates to the technical field of optical communication and especially relates to the technology of an optical device packaging apparatus and packaging method. The optical device packaging apparatus comprises a packaging shell (103) used for packaging an optical device (101) and a packaging cover (104) which is arranged at the upper portion of the packaging shell (103) and can form a cavity body with the packaging shell (103), wherein the bottom surface inside the packaging shell (103) is provided with a shock pad (102); and the shock pad (102) is provided with an optical device (101) through a buckling mode and is in close contact with the optical device. The apparatus and method have the following advantages: 1, the packaging apparatus is provided with the shock pad so that external vibration and stress interference can be buffered or absorbed and the anti-interference capability and the work stability of the optical device are improved; and 2, the apparatus employs a nitrogen atmosphere for packaging, and when the optical device works in the nitrogen atmosphere, the life of the optical device can be prolonged and the reliability of the optical device can be improved.

Owner:GUANGXUN SCI & TECH WUHAN

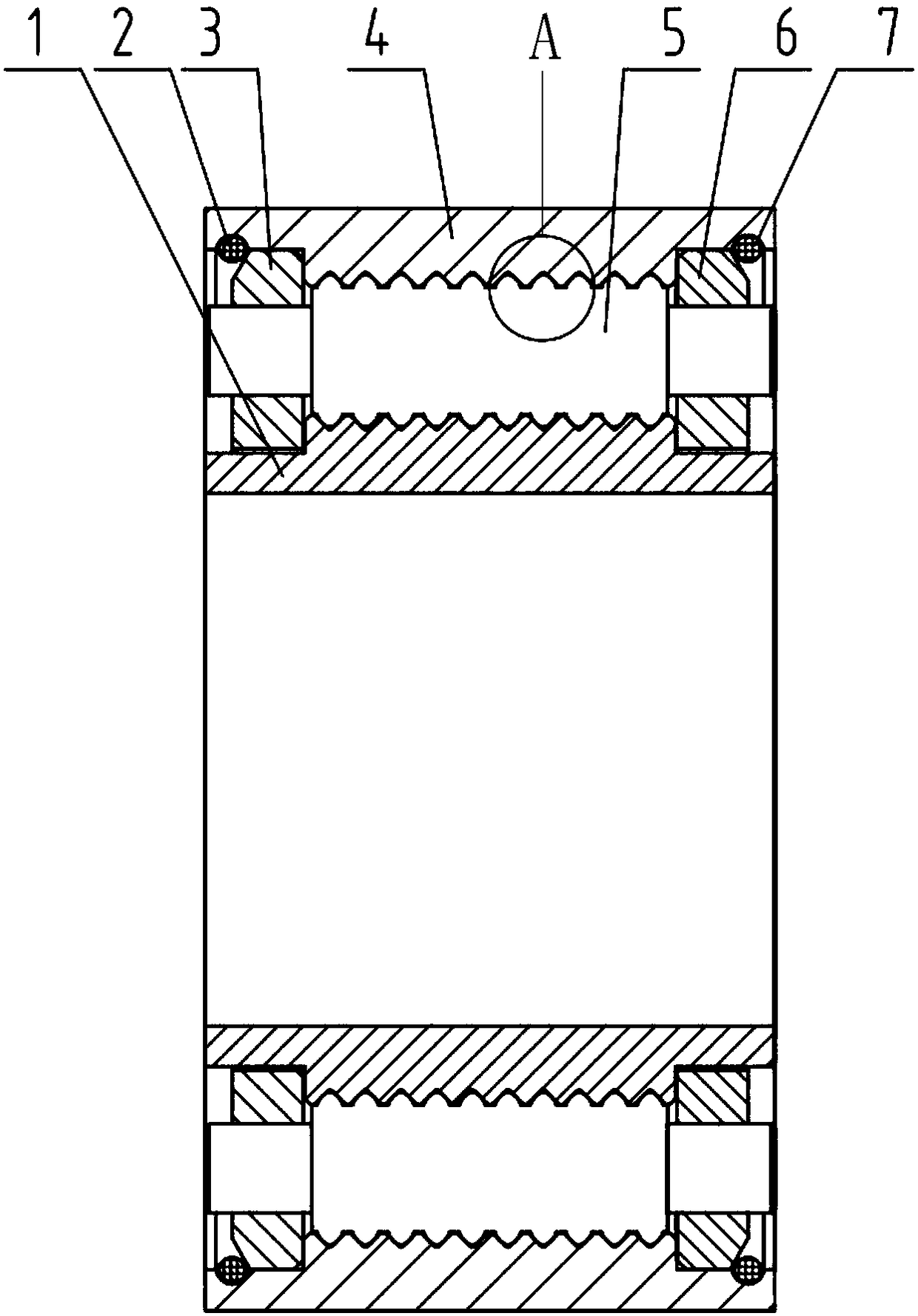

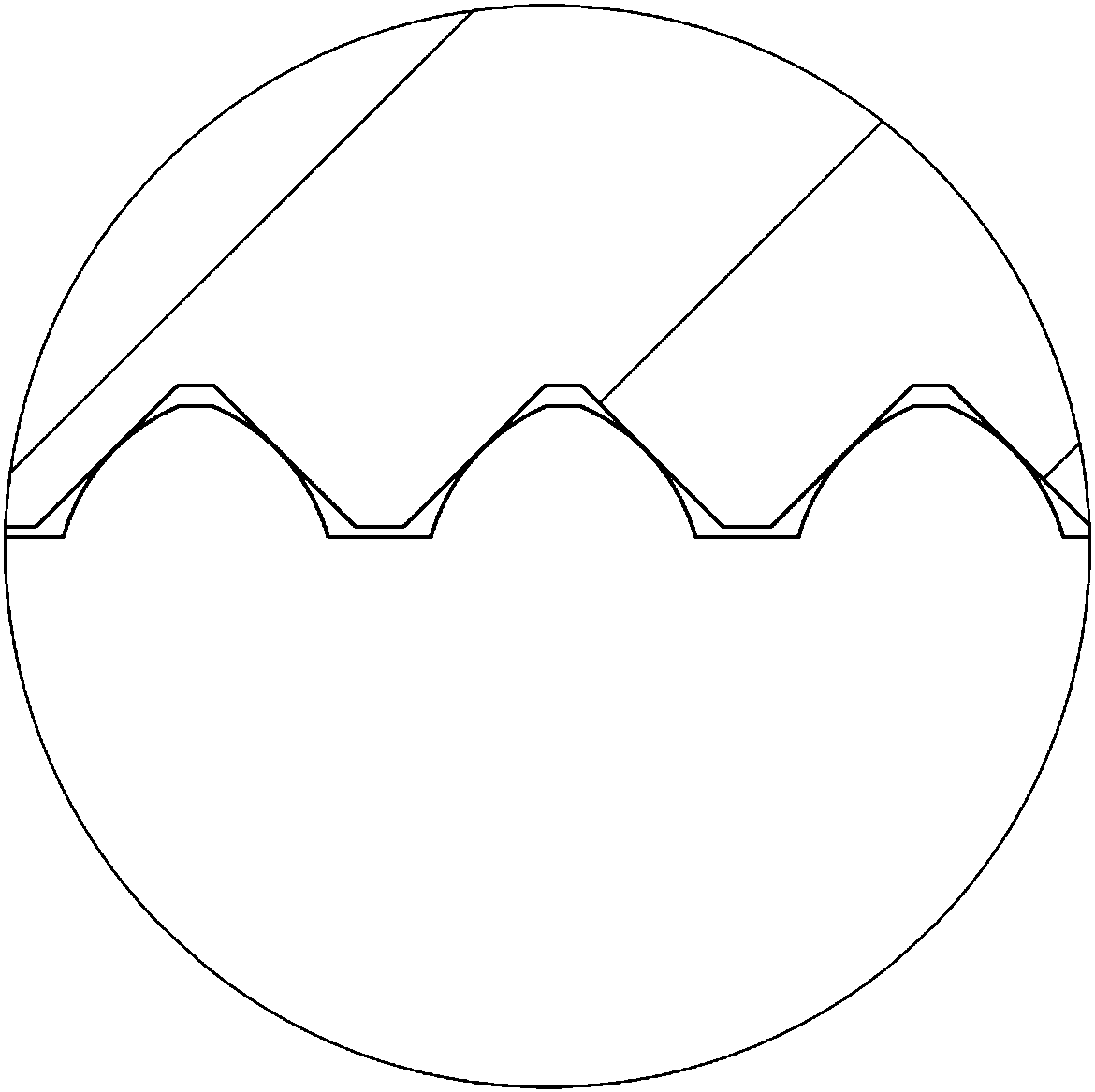

Threaded roller planetary bearing

PendingCN108302118AImprove reliability and longevityReduce volumeRoller bearingsGearingLoad carryingCarrying capacity

The invention provides a threaded roller planetary bearing. The threaded roller planetary bearing comprises a bearing inner ring, a bearing outer ring, a plurality of rollers and two planet carriers,wherein the screw pitch of the threads on the rollers is the same as that of the threads on the outer wall of the bearing inner ring and the inner wall of the bearing outer ring so as to realize engagement; the bearing inner ring is embedded into the bearing outer ring, the two planet carriers are respectively located on both ends of an annular space formed by embedding of the bearing inner ring and the bearing outer ring, and optical axis steps on both ends of the rollers are inserted into optical holes of the planet carriers, so that the plurality of rollers which are parallel to each otherrotate in the annular space. Compared with a conventional bearing of the same size, the load of the threaded roller planetary bearing is more than three times that of the conventional bearing, the maximum rotating speed is more than two times that of the conventional bearing, the service life is greatly prolonged, and the reliability is greatly increased. Therefore, the threaded roller planetary bearing has the advantages of small size, light weight, long service life, high rotating speed, high axial load carrying capacity and high radial load carrying capacity.

Owner:扬州众孚传动科技有限公司 +1

Low-abrasion hydraulic machine

ActiveCN104179679AImprove product performanceImprove reliability and longevityRotary piston pumpsRotary piston liquid enginesStatorCircular surface

The invention discloses a low-abrasion hydraulic machine. The low-abrasion hydraulic machine comprises a rotor having multiple radial grooves, a plurality of blades, a stator, and side plates arranged at the two ends of the stator and the rotor, wherein rolling ways are formed in the end surfaces, towards the inner surface of the stator, of the outer ends of the blades; rolling bodies are movably arranged in the rolling ways; fluid lubricating films are arranged between the rolling bodies and the rolling ways; the surfaces of the rolling bodies are projected on the front end surfaces of the blades; when the blades slide to extend out, the surfaces of the rolling bodies and the inner surface of the stator are contacted in a rolling friction manner; flow inlet windows are formed in corresponding positions of an ascending section of the inner surface of the stator or the end surfaces of the side plates; flow outlet windows are formed in corresponding positions of a descending section of the inner surface of the stator or the end surfaces of the side plates; the outer circular surface of the rotor, the inner surface of the stator, adjacent blades and rolling bodies and the side plates form fluid working cavities; the fluid working cavities in the ascending section are communicated with the flow inlet windows; and the fluid working cavities in the descending section are communicated with the flow outlet windows. The low-abrasion hydraulic machine adopts the low-abrasion rolling friction, so that the product performance is improved, the product reliability is improved, and the service life is prolonged.

Owner:胡阳

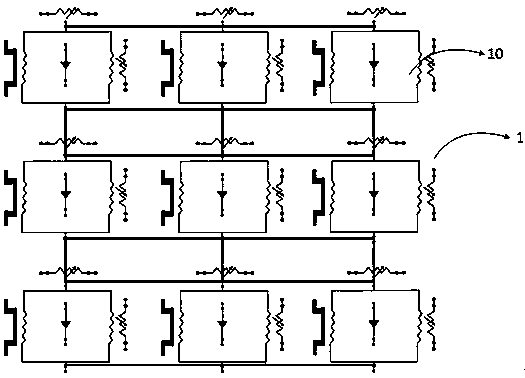

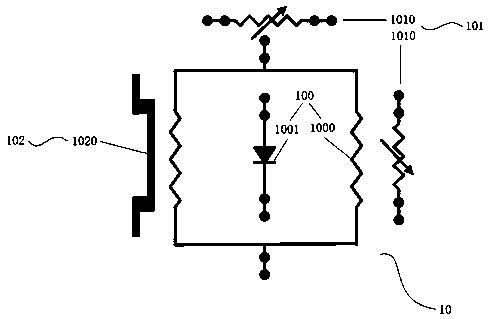

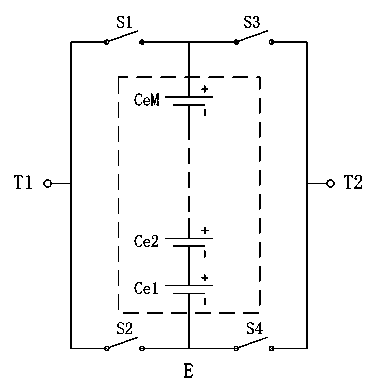

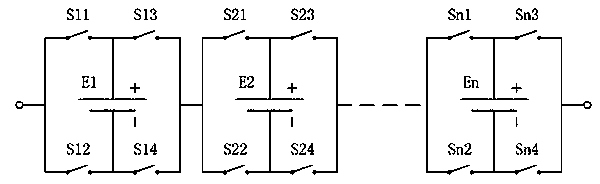

Controllable battery module

InactiveCN102332619BImprove reliability and longevityOvercome limitationsSecondary cells servicing/maintenanceBattery systemControl engineering

The invention discloses a controllable battery module. The controllable battery module comprises four controllable switches and a battery string which consists of energy storage battery monomers, wherein the four controllable switches are divided into two groups, and the two groups of controllable switches are connected in series respectively, and then are connected with the battery string in parallel; and the connecting points of the two groups of controllable switches which are connected in series are two leading-out line endpoints of the controllable battery module. By using the controllable battery module, different battery modules in a battery system can be controlled to be in different working states, the equilibrium operation and fault tolerance of the battery modules and mixed operation of the battery modules with different capacities are realized, and the service life and the reliability of the battery system are improved.

Owner:SHANGHAI JIAO TONG UNIV

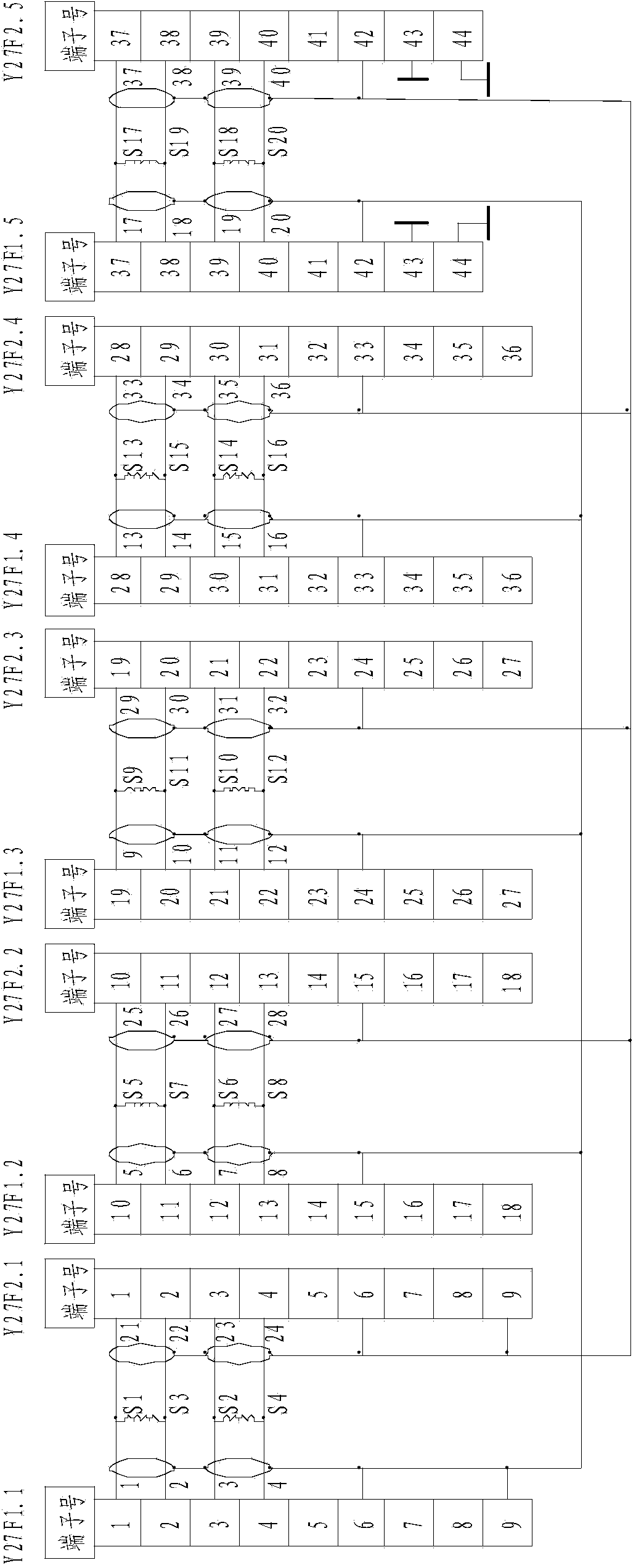

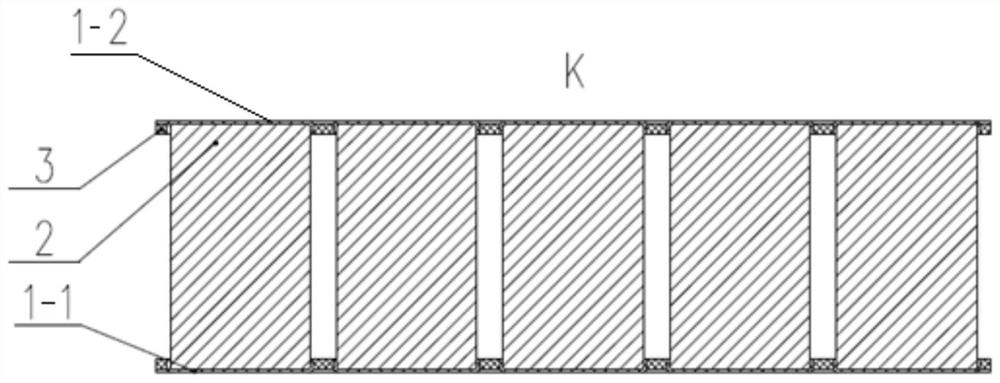

Winding technology of transformer and transformer manufactured with winding technology

ActiveCN106024373AImprove reliability and longevityImprove production efficiencyCoils manufactureManufacturing efficiencyWinding machine

The invention discloses a winding technology of a transformer and the transformer manufactured with the winding technology, and relates to the technical field of transformers. The winding technology of the transformer includes the steps that stranded parts of stranded wires are wrapped with first insulation tape; the stranded wires penetrate through the inner side of a wire feeding groove from the outer side of the wire feeding groove; the stranded wires are pressed on the inner side of the side wall of a rubber core; the stranded wires located on the inner side of the wire feeding groove are fixed on the rubber core through second insulation tape. The hidden danger problem of incompact parts of the stranded wires and the hidden danger problem of inter-turn short circuits are solved, the previous problem that as the tape is not fixed and also moves when a winding machine rotates, winding wires are broken is solved, the reliability of the transformer is improved, and the service life of the transformer is prolonged; meanwhile, the manufacturing efficiency of the transformer is higher, and the reject ratio is lower.

Owner:DONGGUAN DAZHONG ELECTRONICS

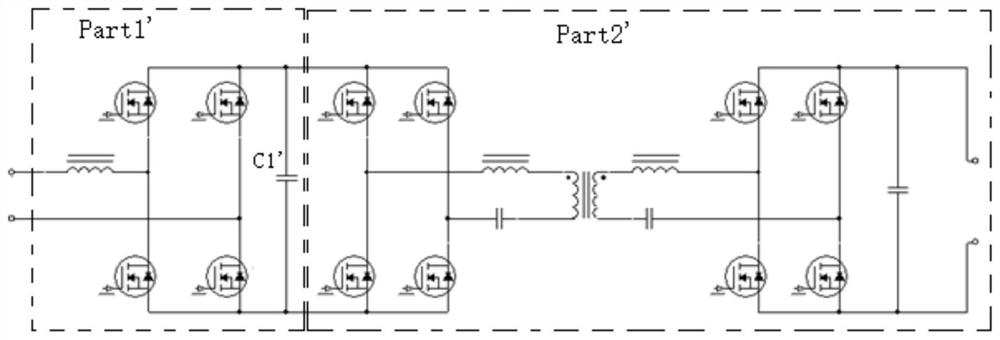

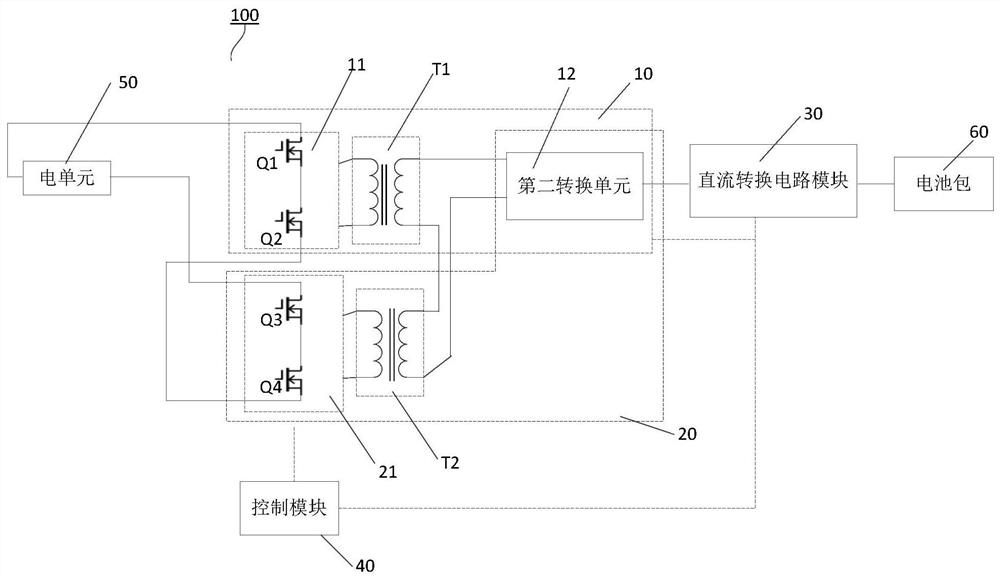

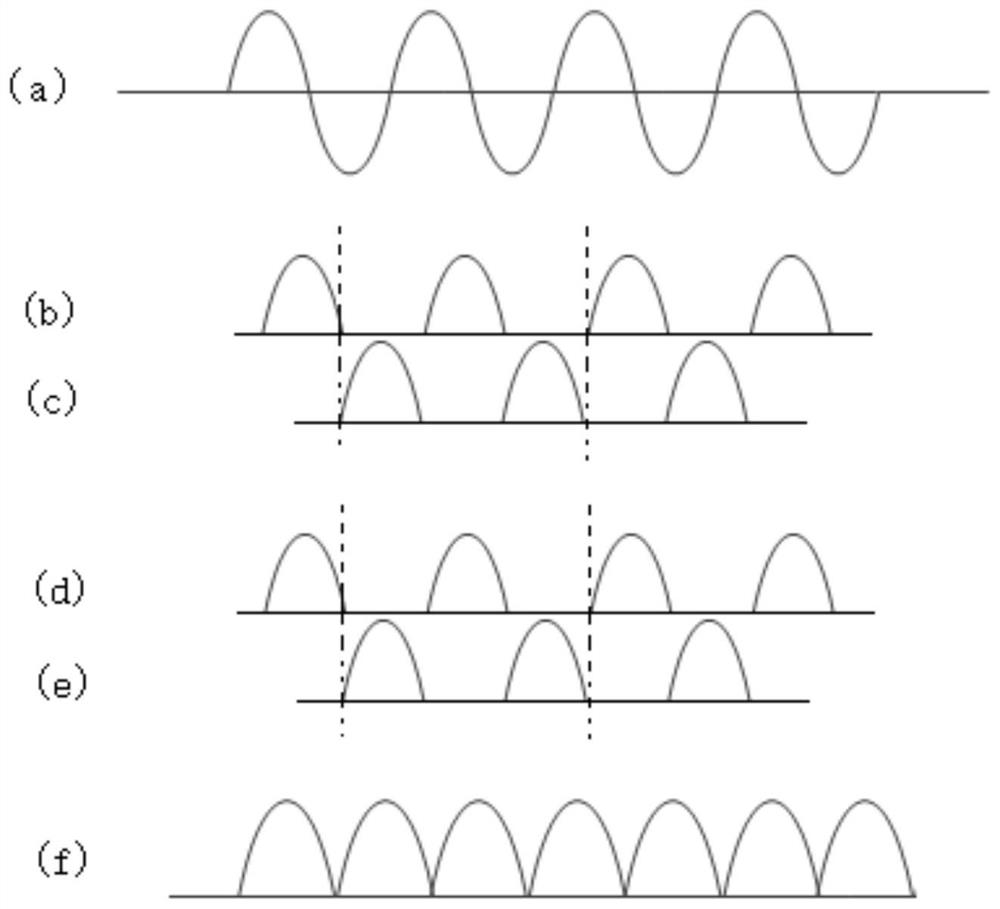

Vehicle-mounted charging system and vehicle with same

ActiveCN112572191AReduce size and costImprove reliability and longevityCharging stationsElectric vehicle charging technologyIn vehicleAutomotive engineering

The invention discloses a vehicle-mounted charging system and a vehicle with the same, the vehicle-mounted charging system comprises a first resonance circuit module, a second resonance circuit module, a direct current conversion circuit module and a control module, and the first resonance circuit module converts an electric signal of a first half cycle of power supply; the second resonance circuit module converts the electric signal of the second half period of power supply; the first resonance circuit module and the second resonance circuit module reuse a second conversion unit, and the direct current conversion circuit module performs DC-DC conversion on the input electric signal; the control module controls the gating of the first resonance circuit module in a first half period of power supply, controls the first resonance circuit module according to a time sequence signal of the first half period of power supply, controls the gating of the second resonance circuit module in a second half period of power supply, and controls the second resonance circuit module according to a time sequence signal of the second half period of power supply. According to the system and the vehicle,the electrolytic-capacitor-free design is adopted, the cost can be reduced, and the stability is improved.

Owner:BYD CO LTD

Permanent magnet fixing structure, fixing method, permanent magnet motor and vehicle

PendingCN114498967AImprove reliability and longevityImprove product qualityMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineryMagneto

The invention belongs to the field of permanent magnet motors, and provides a permanent magnet fixing structure, a fixing method, a permanent magnet motor and a vehicle. The permanent magnet fixing structure comprises a first cover plate and a second cover plate, and the first cover plate and the second cover plate are used for being fixed to the two ends of a plurality of permanent magnets respectively so as to achieve self-locking of the permanent magnets in the axial direction. And the permanent magnets are sequentially arranged according to the polarity direction of the permanent magnets. The first cover plate and the second cover plate are used for absorbing external force in the manufacturing and application process, the permanent magnet and the surface are effectively protected, the reliability of the permanent magnet motor is improved, the service life of the permanent magnet motor is prolonged, and the product quality is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Mechanical valve capable of switching air source in self-adaptive mode

PendingCN114215647AImprove reliability and longevityImprove performanceEngine controllersMachines/enginesPhysicsMechanical valve

The invention provides a self-adaptive air source switching mechanical valve which comprises a shell, the shell is provided with a containing cavity, a high-pressure air inlet and a low-pressure air inlet which are communicated with the containing cavity and are adjacent to each other are formed in the shell, and an air outlet which is communicated with the containing cavity is formed in the side, opposite to the high-pressure air inlet and the low-pressure air inlet, of the shell. A high-pressure control port is formed in the side, close to the high-pressure air inlet, of the containing cavity, and first pressure gas is connected into the high-pressure air inlet and the high-pressure control port through pipelines. The valve element is installed in the containing cavity and can slide, and the middle of the valve element is provided with a circulation part through which gas can flow; the cover plate is arranged on one side of the non-high-pressure control port of the shell, the cover plate is provided with a low-pressure control port, and the low-pressure gas inlet and the low-pressure control port are connected into second pressure gas through pipelines; and the spring is arranged between the valve core and the cover plate. According to the valve, the bearing cavity can be sealed, and the bearing can be cooled.

Owner:AECC SHENYANG ENGINE RES INST

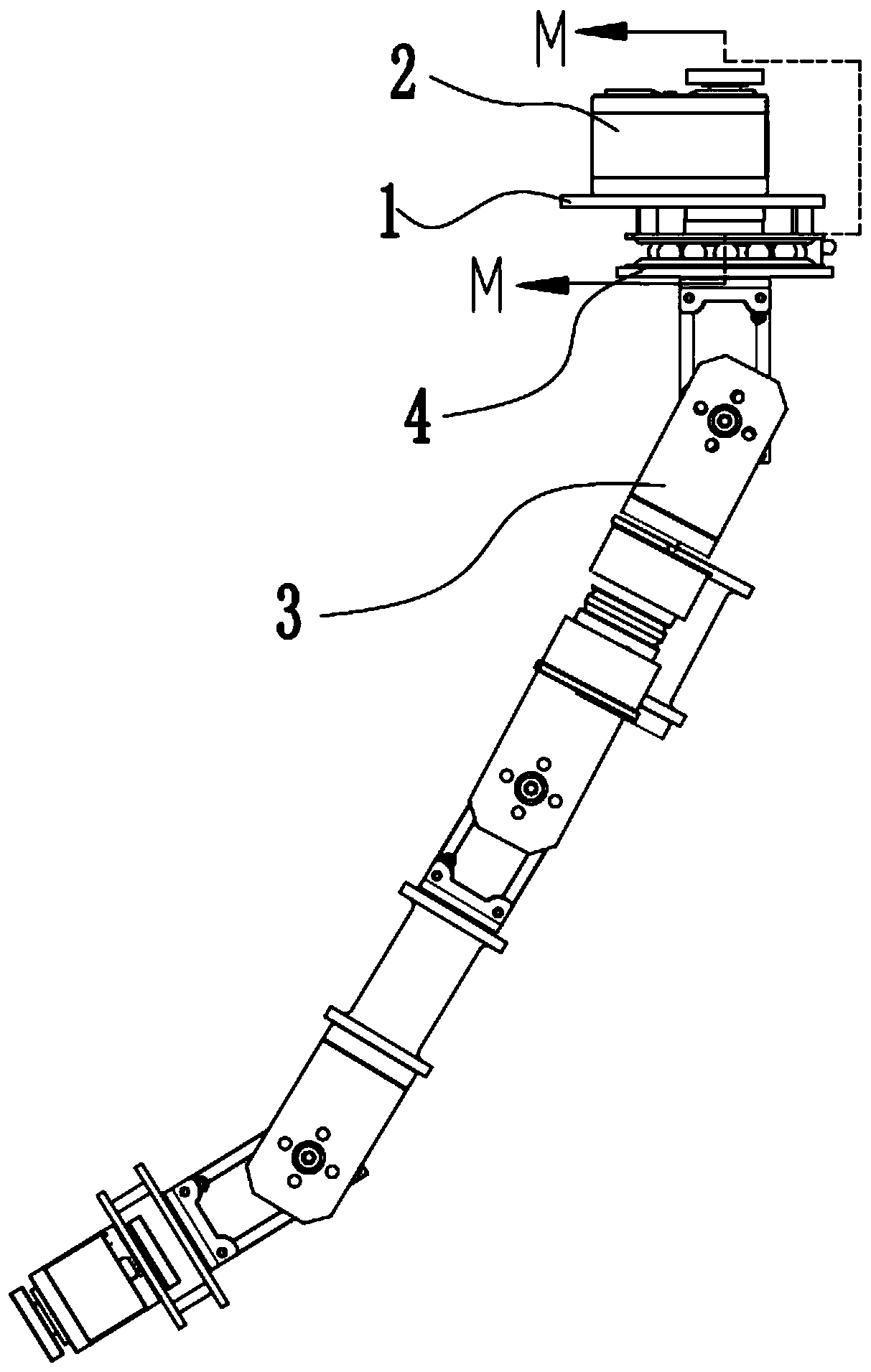

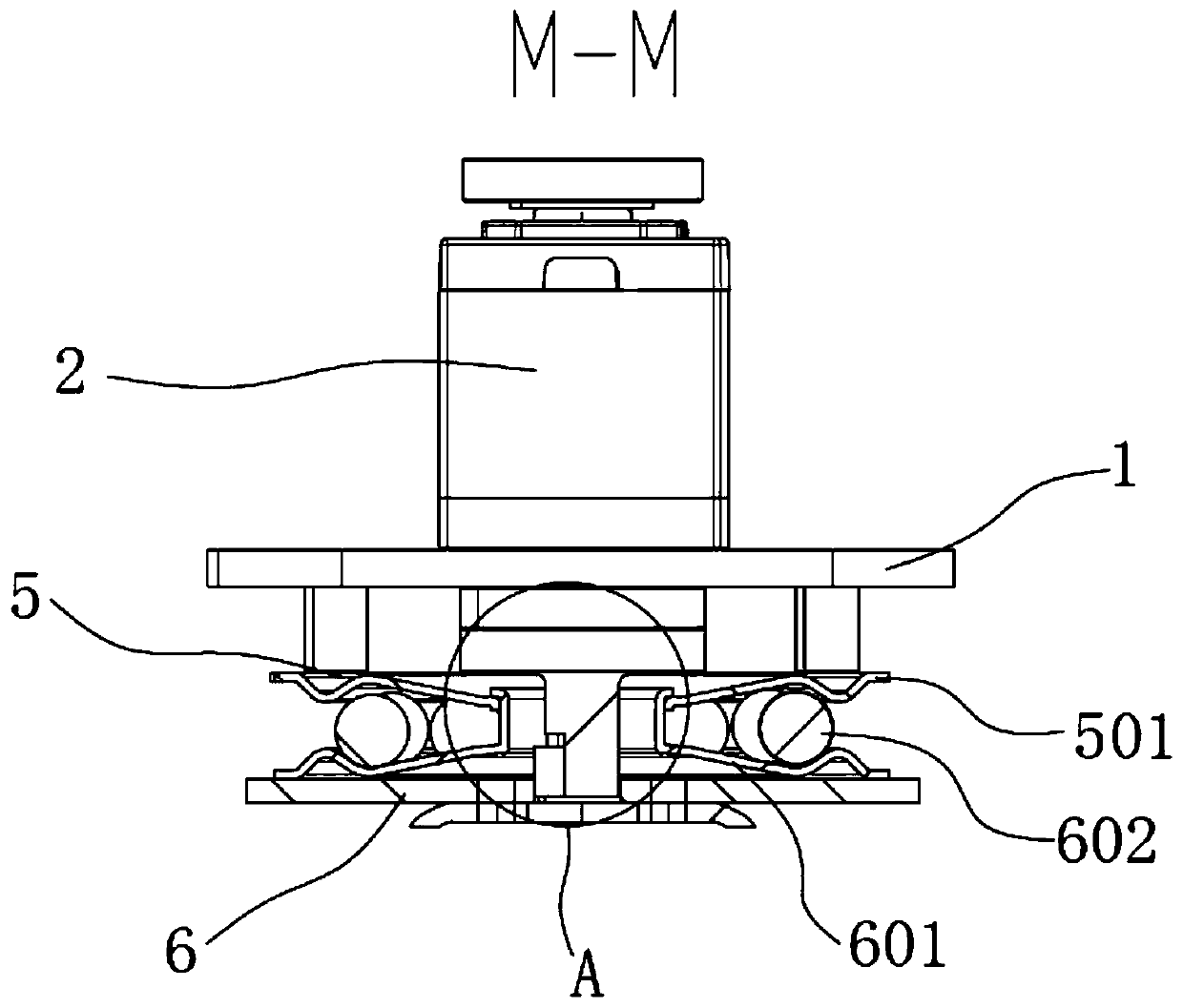

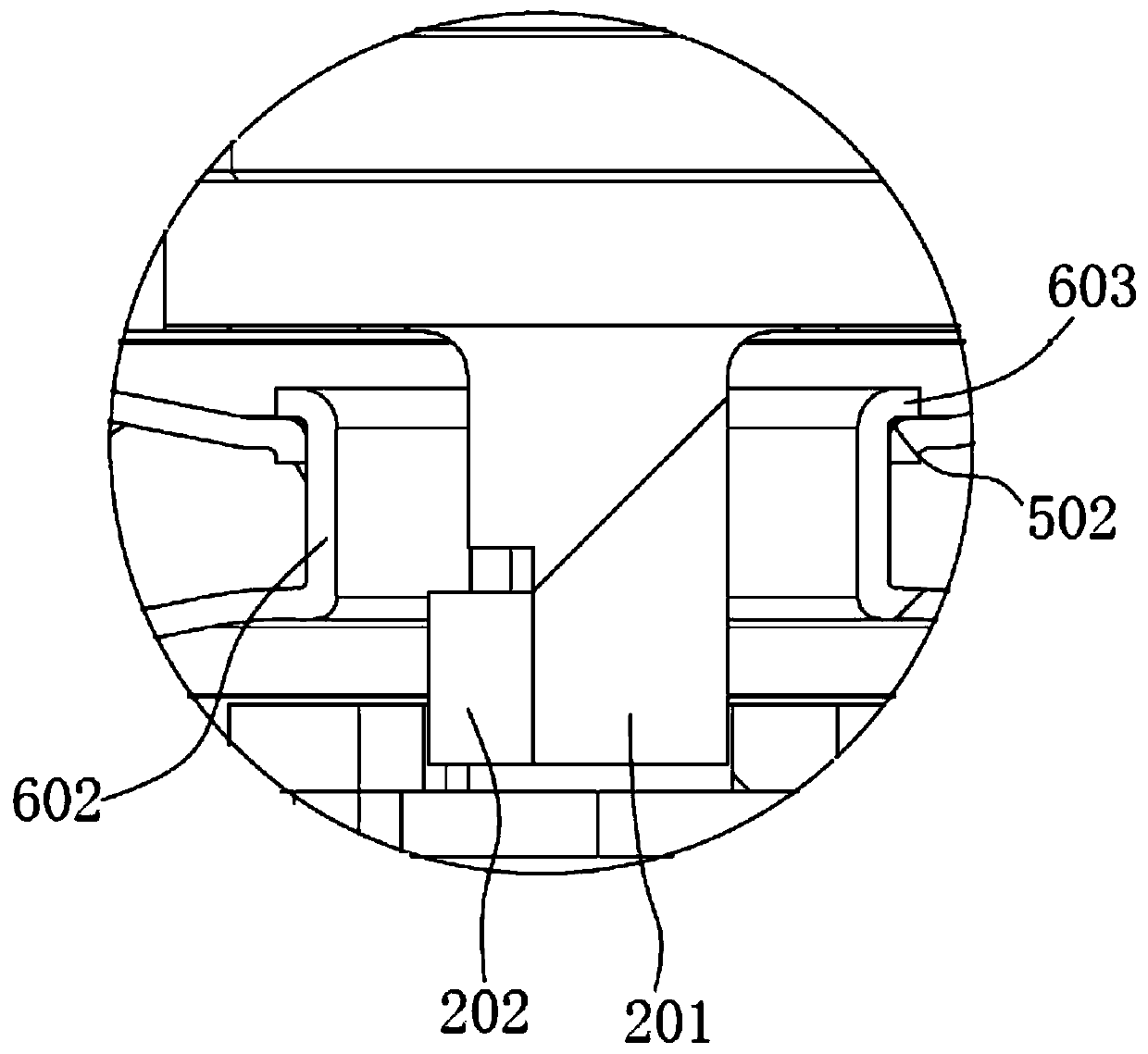

Multi-degree-of-freedom mechanical arm capable of being equipped on small and medium-sized mobile platforms

PendingCN111168663AImprove reliability and longevityReduce jitterProgramme-controlled manipulatorJointsMechanical engineeringControl engineering

Owner:SUN YAT SEN UNIV

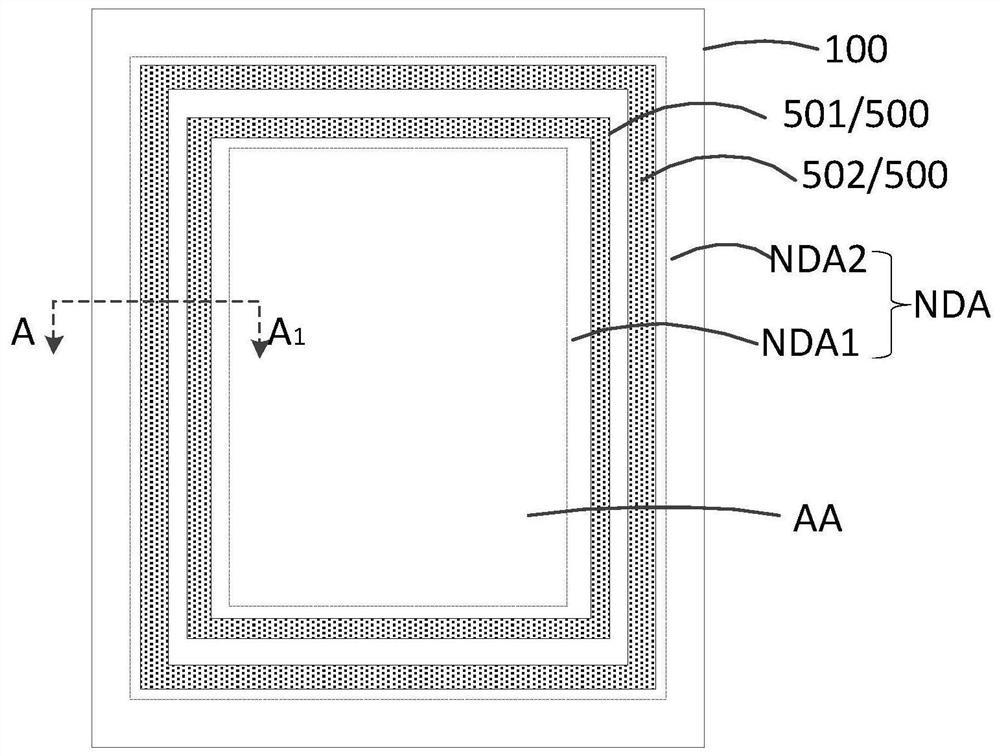

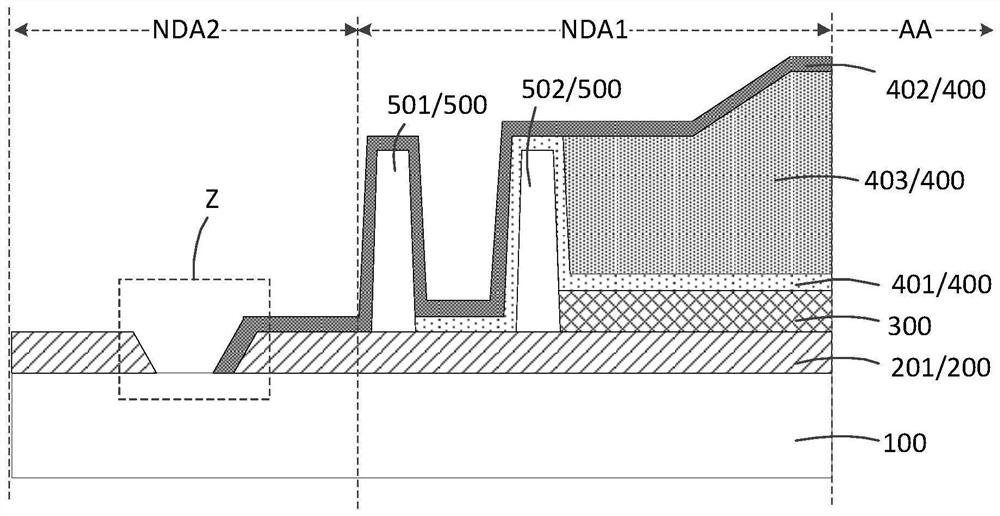

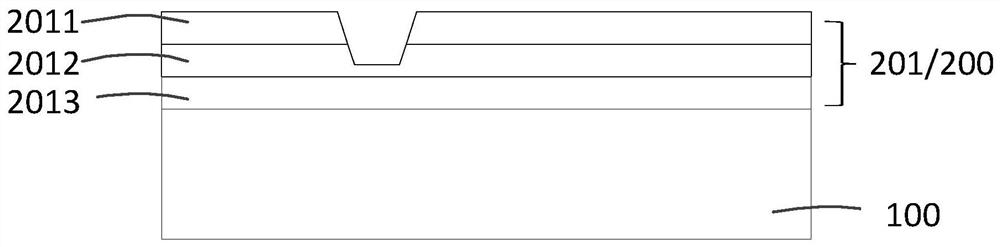

Display panel, its manufacturing method and display device

ActiveCN109728196BPrevent crack propagationImprove reliability and longevitySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsBlock layer

The invention describes a display panel, its manufacturing method and display device. The display panel includes: a base substrate with a display area and a non-display area, the non-display area includes a first non-display area and a second non-display area; at least one barrier is included along the direction away from the display area, and the barrier is located in the first non-display area. In the display area, the first non-display area surrounds the display area, and the second non-display area surrounds the first non-display area; the display function layer is located on the base substrate, and the display function layer includes at least one inorganic insulating layer; the inorganic layer insulating layer is in the The second non-display area forms a groove; the barrier layer is located on the side of the display function layer away from the base substrate, and the barrier layer includes at least a first inorganic barrier layer; the first inorganic barrier layer at least partially covers the groove. The invention can prevent the crack diffusion and water and oxygen intrusion, and improves the reliability and service life of the display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

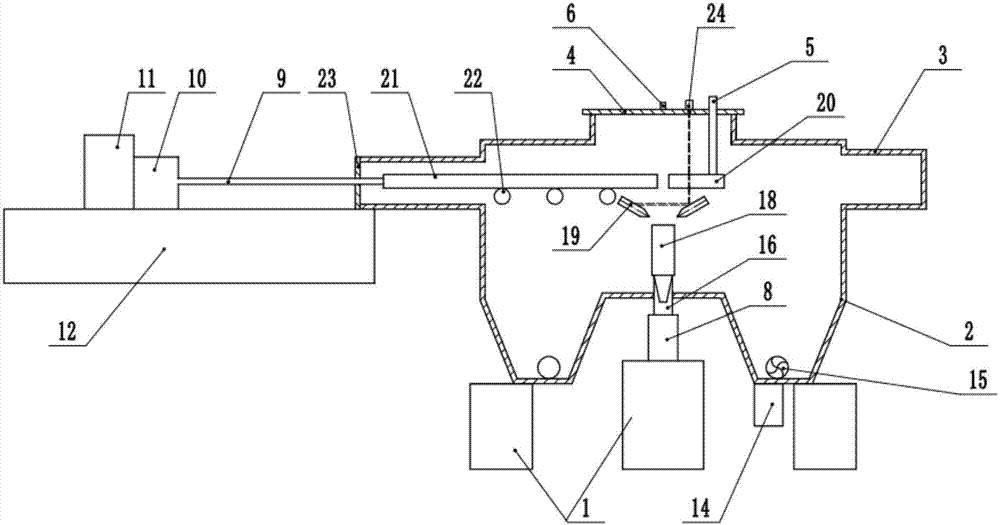

Combined type equipment for manufacturing spherical powder through rotating electrode

ActiveCN107377986AImprove reliability and longevityImprove fine powder rateTransportation and packagingMetal-working apparatusIonElectrically conductive

The invention discloses combined type equipment for manufacturing spherical powder through a rotating electrode. The right end of a furnace body located on a base is provided with a vacuum connection pipe, and the vacuum connection pipe is connected with a vacuum system. A bed stand arranged at the left end of the furnace body is horizontally provided with a first electric main shaft and a current collecting device, wherein the first electric main shaft and the current collecting device are linked coaxially. A transmission shaft is coaxially linked to the current collecting device. The transmission shaft extends into the left portion of the furnace body in a sealed manner, and current guiding is conducted through the current collecting device. A rodlike blank is supported on the left portion inside the furnace body, and the tail end of the rodlike blank is linked with the front end of the transmission shaft. A transferred arc plasma gun is horizontally arranged on the right portion inside the furnace body. A second electric main shaft is vertically mounted on a vertical lifting mechanism at the upper end of the base and extends into the lower portion of the furnace body in a sealed manner, and the upper end of the second electric main shaft is coaxially linked with the rotating electrode. The rotating electrode is located under the front end of the rodlike blank. Two non-transferred-arc plasma guns are symmetrically arranged at the two sides of the rotating electrode in an inclined manner. By means of the combined type equipment, the rotating electrode is separated from electric conduction, and fusion is separated from tossing-out; and the fine powder rate is increased, and production efficiency is improved.

Owner:BAOJI FANMEI MATERIAL TECH

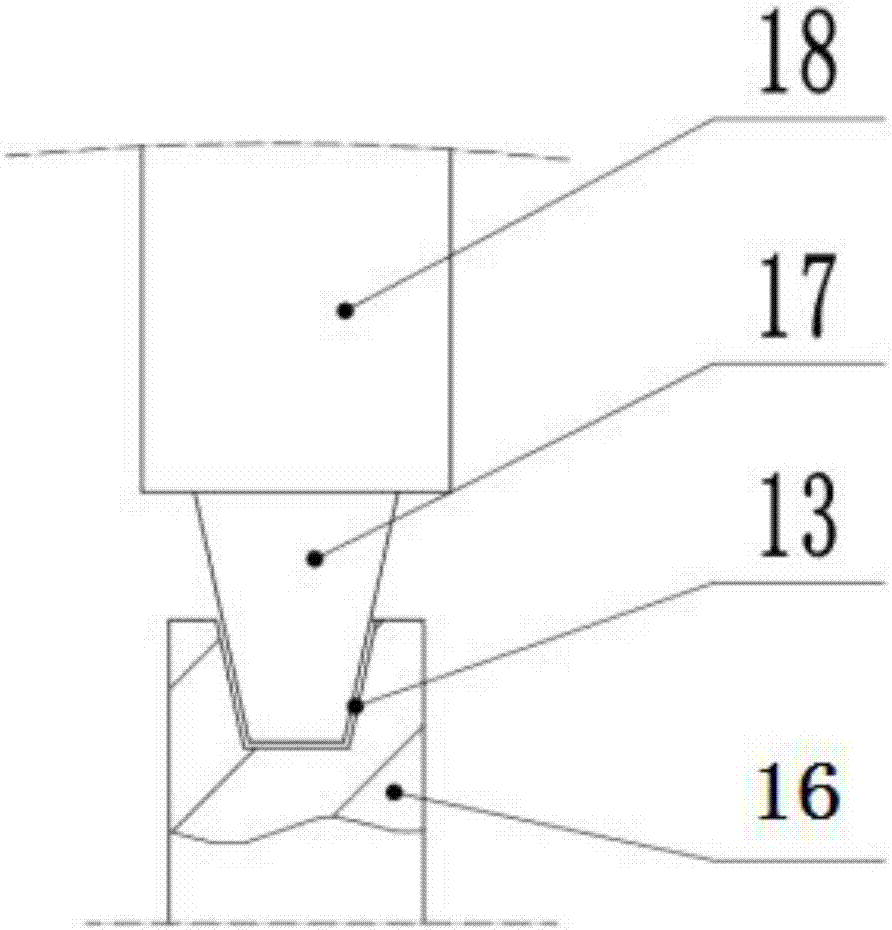

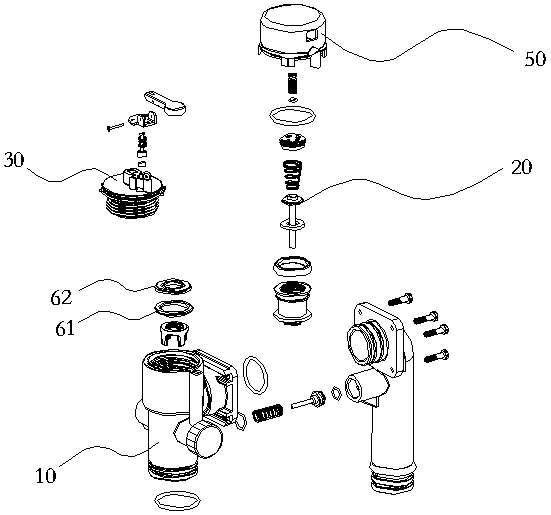

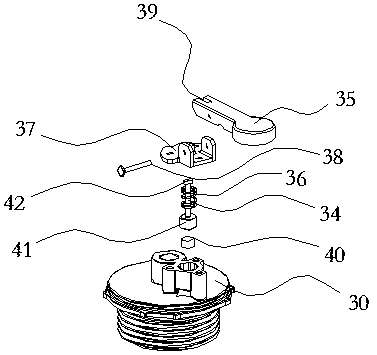

Drain valve for water closet

InactiveCN108301474AReduce pressing forceImprove reliability and longevityFlushing devicesEngineeringToilet

The invention discloses a drain valve for a water closet. The drain valve comprises a valve body which is provided with a water intake cavity, wherein a valve element component is arranged in the water intake cavity; an end cover is connected to the valve body at the upper side of the valve element component; a compartment for preparing pressure is defined between the end cover and the valve element component; a going-through port, which communicates with the compartment, is arranged in the vale element component; a pressure relief hole is kept in the end cover; and a sealing pad, which is used for opening and closing the pressure relief hole, is arranged on the end cover. With the application of the drain valve, pressing force of consumers can be greatly reduced, so that the consumers canfeel comfortable in using the water closet.

Owner:XIAMEN RUNNER IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com