Double-acting hydraulic riveter for short-tail rivet

A double-acting, riveting gun technology, applied in the field of riveting guns, double-acting short-tail rivet hydraulic riveting guns, can solve problems such as complex repair and maintenance, non-reusable, hidden dangers, etc., to reduce processing costs and improve products Yield, reliability and life improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

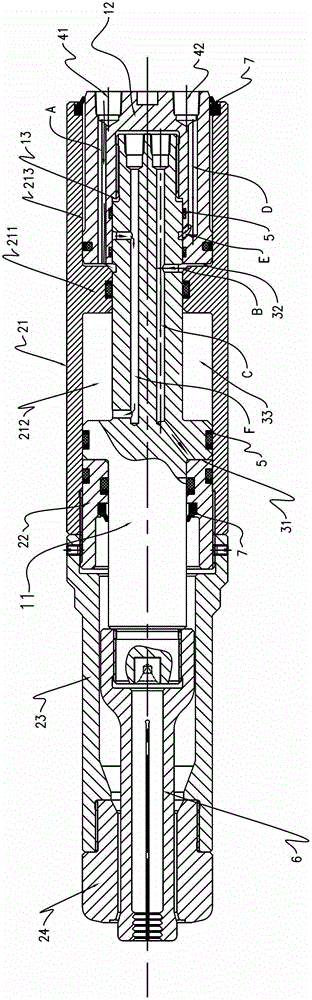

[0032] The cylinder part is composed of a cylindrical cylinder body 21, a front body 22, an anvil cylinder seat 23 and an anvil cylinder 24, all of which are cylindrical bodies. Coaxial fixed connection, wherein the anvil cylinder 24 is threaded on the top of the anvil cylinder base 23, and the butt connection between the cylinder body 21 and the anvil cylinder base 23 is realized through the built-in precursor 22. The cylinder body 21 is a forging and is machined. An annular protrusion 211 is arranged inside the cylinder body 21. On the front and rear sides of the protrusion 211 are a front cavity 212 and a rear cavity 213. The front and rear cavities are built in An oil chamber can be formed behind the piston, and the cylinder body has a simple structure. The precursor 22 is an annular body, which is provided with the inner side of the connection between the cylinder and the anvil, and the outer side of the precursor 22 is provided with threads to realize the connection betw...

Embodiment 2

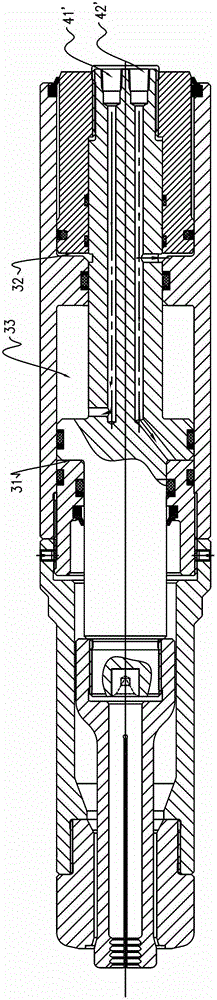

[0039] Such as figure 2 As shown, the main structure of the structure in this embodiment is basically the same as in Embodiment 1, the difference is that the front piston body 11 is inserted in the rear piston body 12, and the front piston body passes through the rear piston body and extends to the rear piston body outside. The external interface 41' of the first oil passage is set at the rear tail of the front piston body 11, and the first oil passage directly penetrates the first oil chamber and the second oil chamber, which is a modification of the first oil passage in the first embodiment .

[0040] Similarly, the external port 42' of the second oil passage is arranged at the rear tail of the front piston body, and the second oil passage directly penetrates into the third oil chamber. The layout of this oil circuit is relatively simple and has high application value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com