Pressure-variable oil-supply-type load-deflection-resistant horizontal servo oil cylinder design method

A design method and technology for servo cylinders, applied in the field of servo hydraulics, can solve the problems of eccentric friction between the piston and the cylinder, affecting the output characteristics and reliability of the servo cylinder, so as to prolong the reliability and life, increase the bearing capacity and anti-bias. The effect of load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically described below in conjunction with the accompanying drawings.

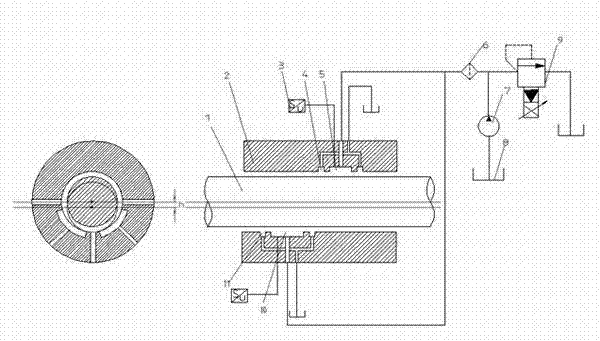

[0019] Such as figure 1 As shown, the horizontal servo cylinder of the present invention includes a cylinder body 2 and a piston rod 1, and one or more pairs of up and down asymmetrical oil pads are arranged on the cylinder guide sleeve along the axial direction, wherein the oil pads on the lower side of the piston rod 1 are supported Oil pad 10, support The oil pad 10 is composed of an oil cavity, a central oil inlet hole, an oil sealing edge and a support oil return groove 11. The oil pad on the upper side of the piston rod 1 is a counter force oil pad 5, and the counter force oil pad 5 is composed of an oil cavity, a central oil inlet hole, an oil sealing edge, and a counter force oil return groove 4. And the independent oil supply system feeds pressure oil to each oil pad at the same time. The oil supply system includes an oil tank 8, a hydraulic pump 7, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com