Patents

Literature

75results about How to "Prevent crack propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

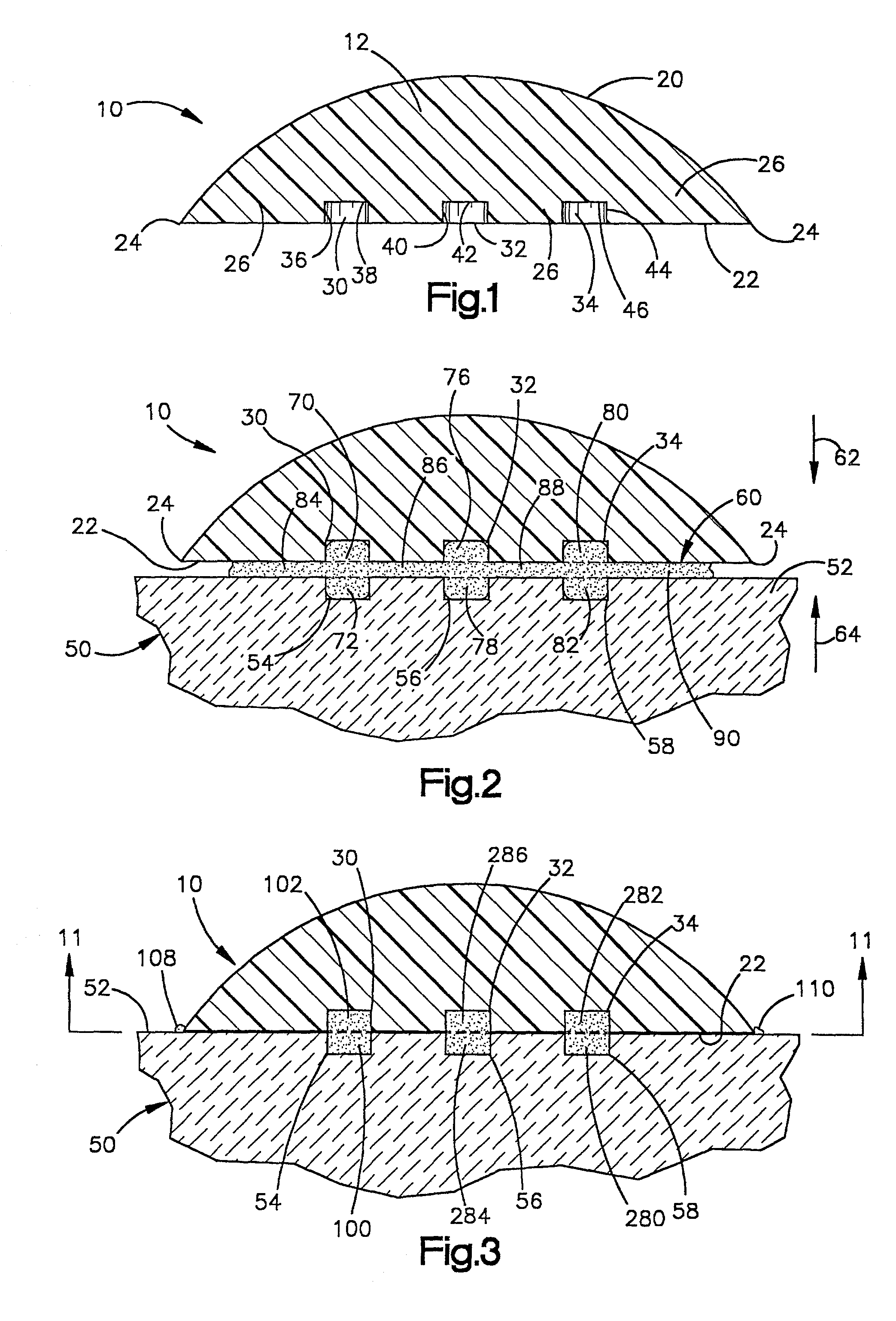

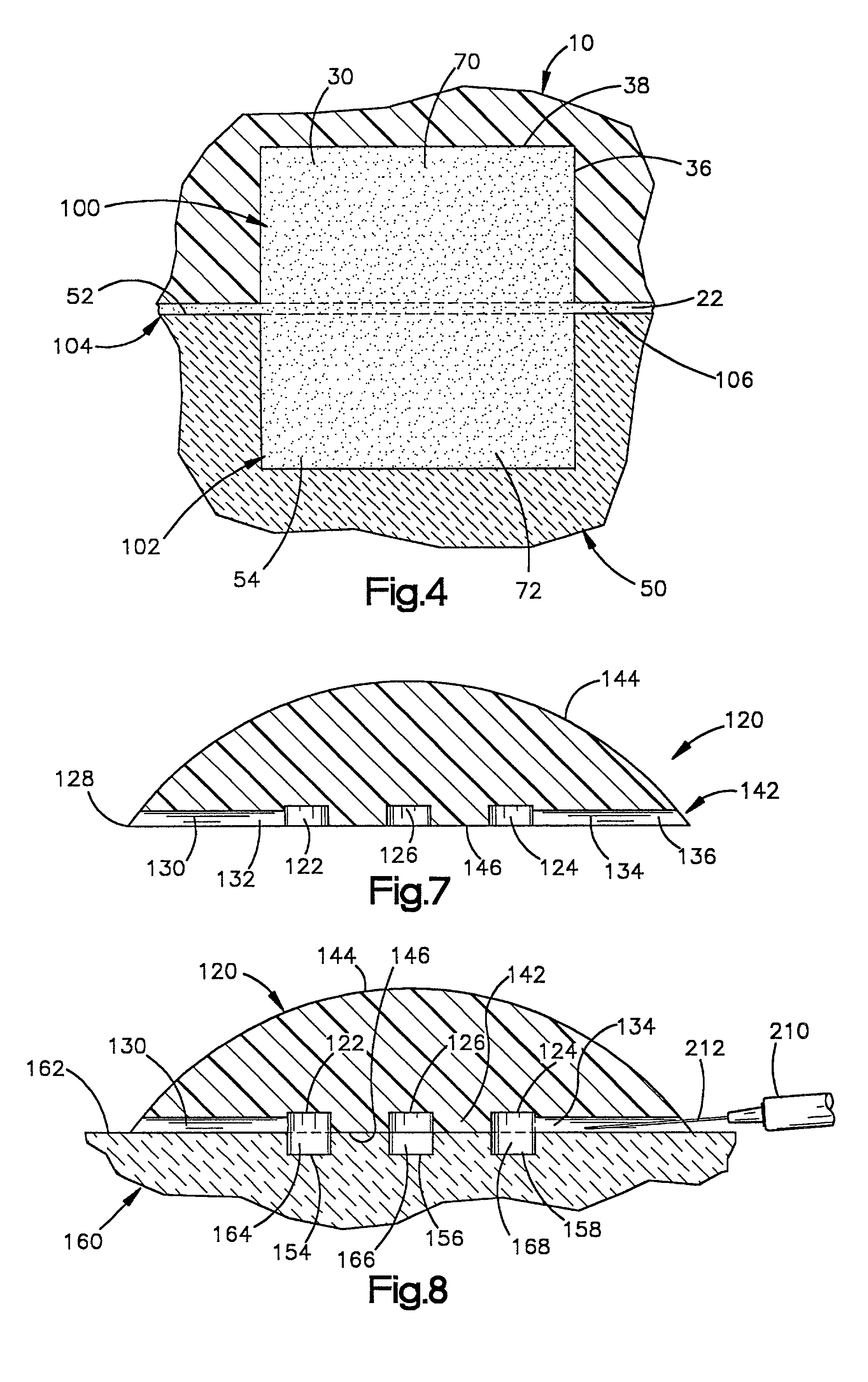

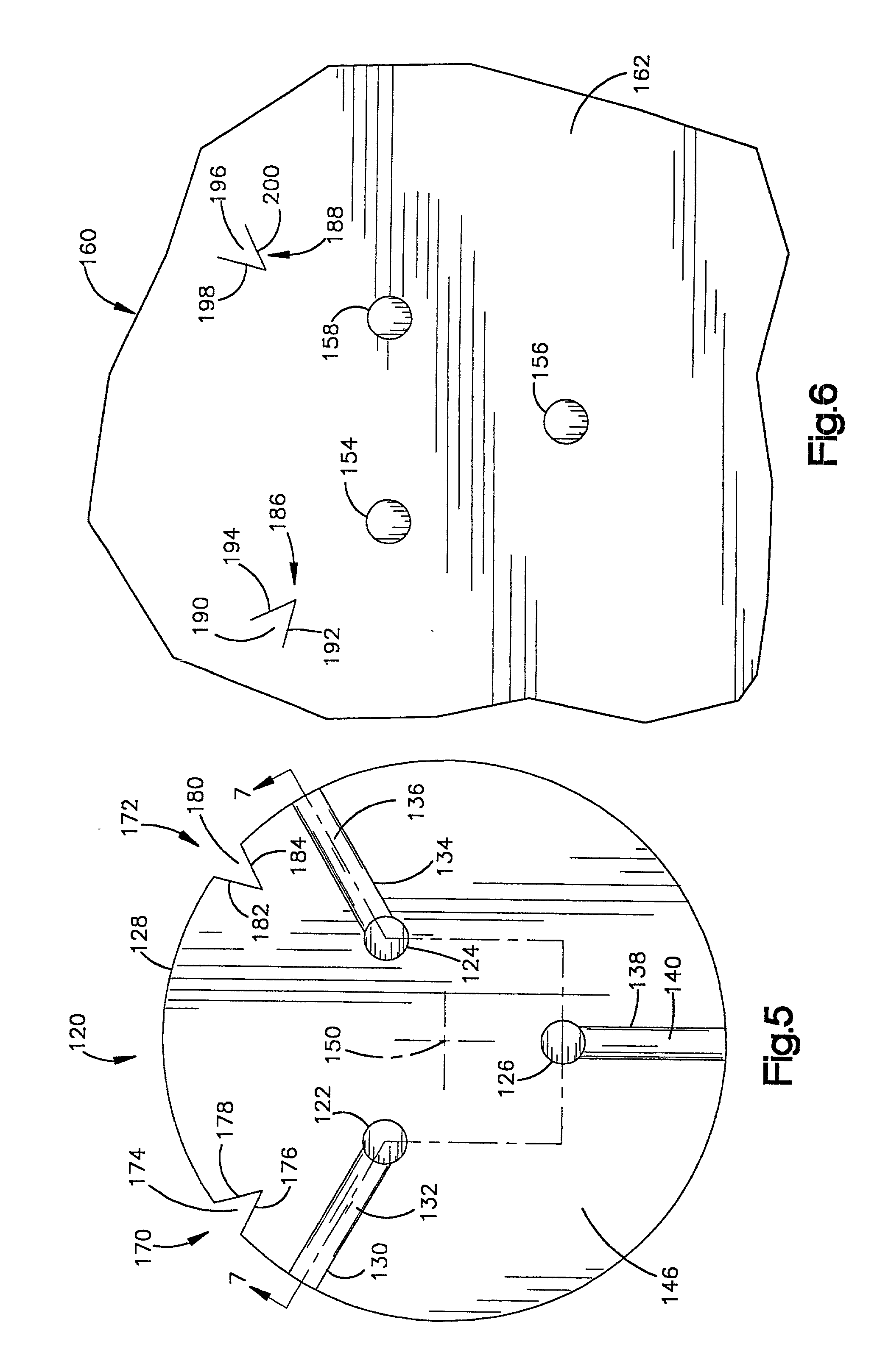

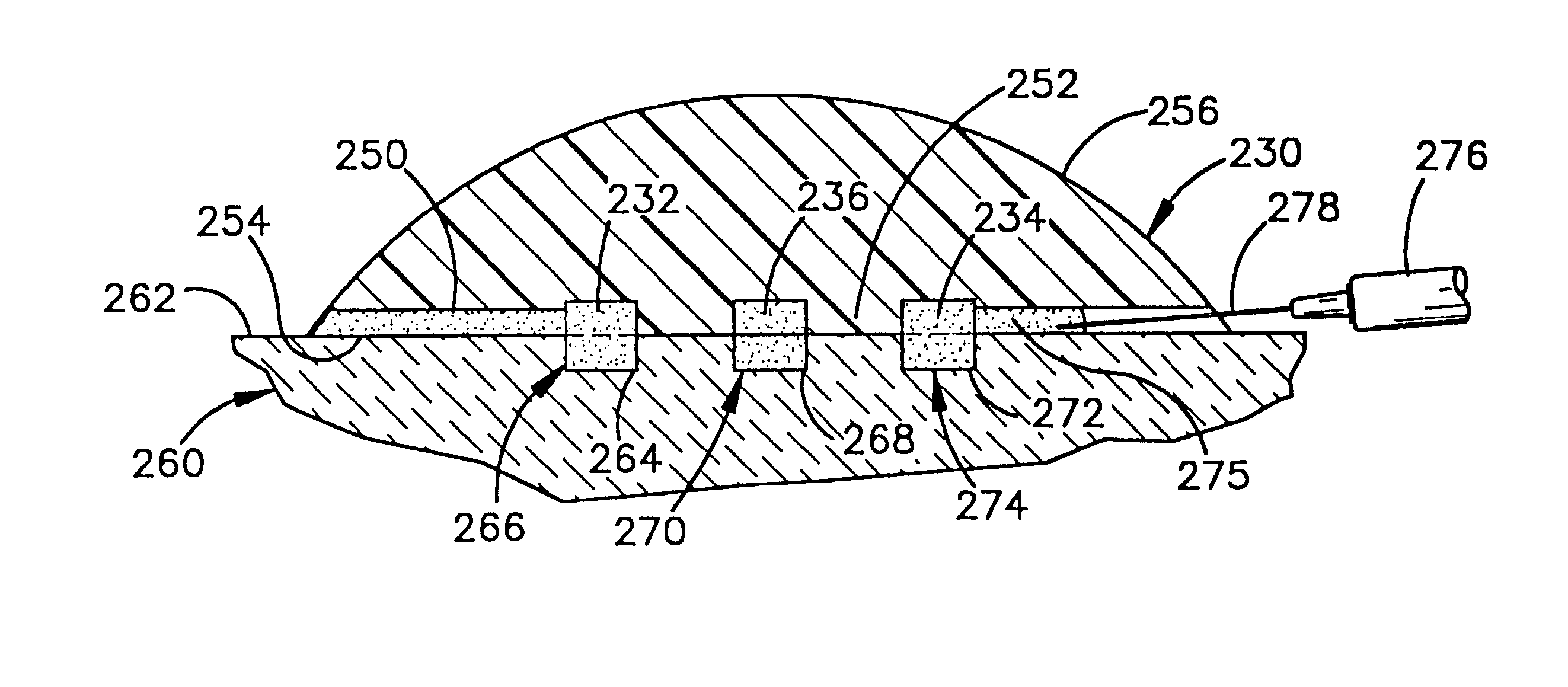

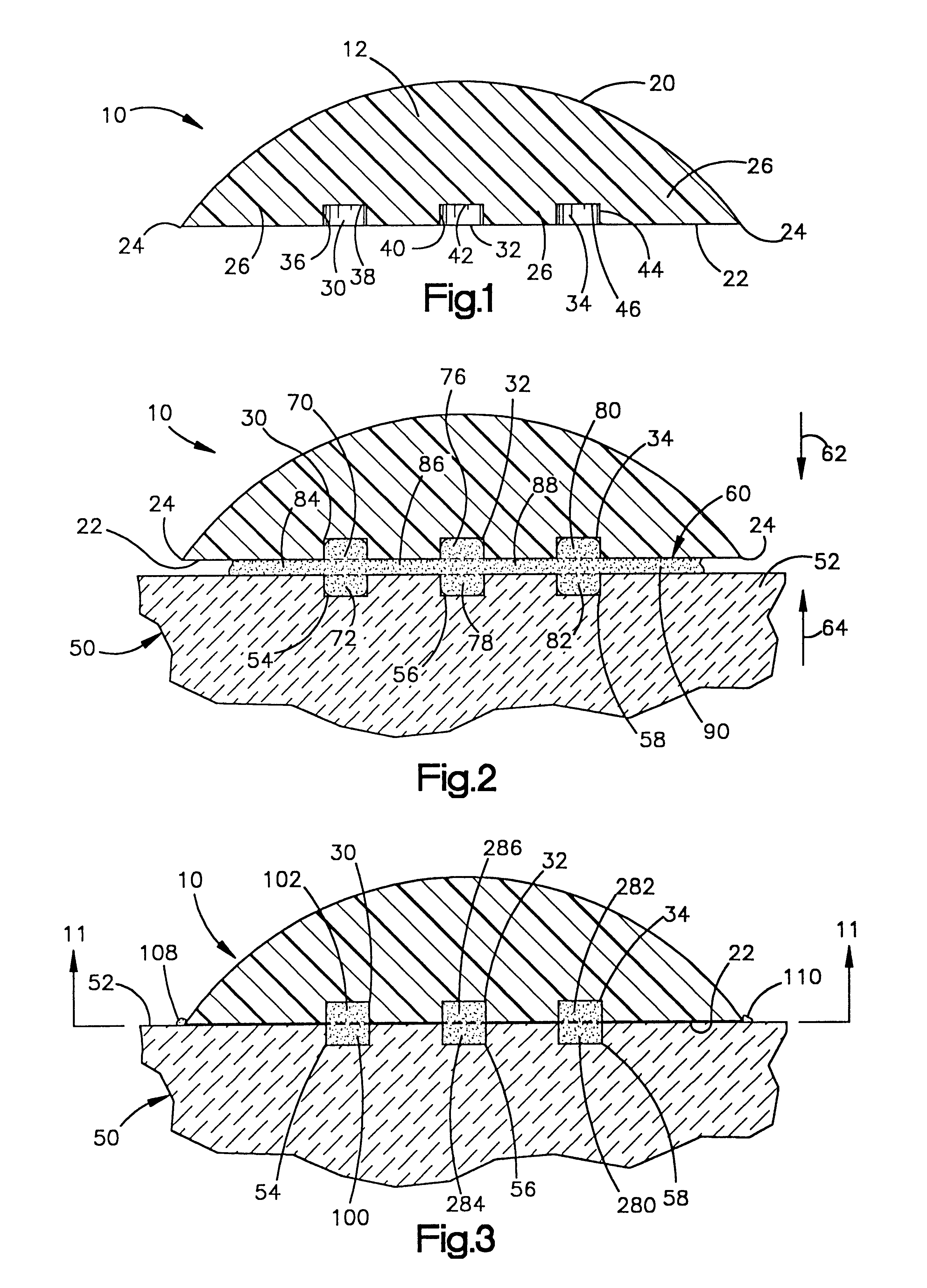

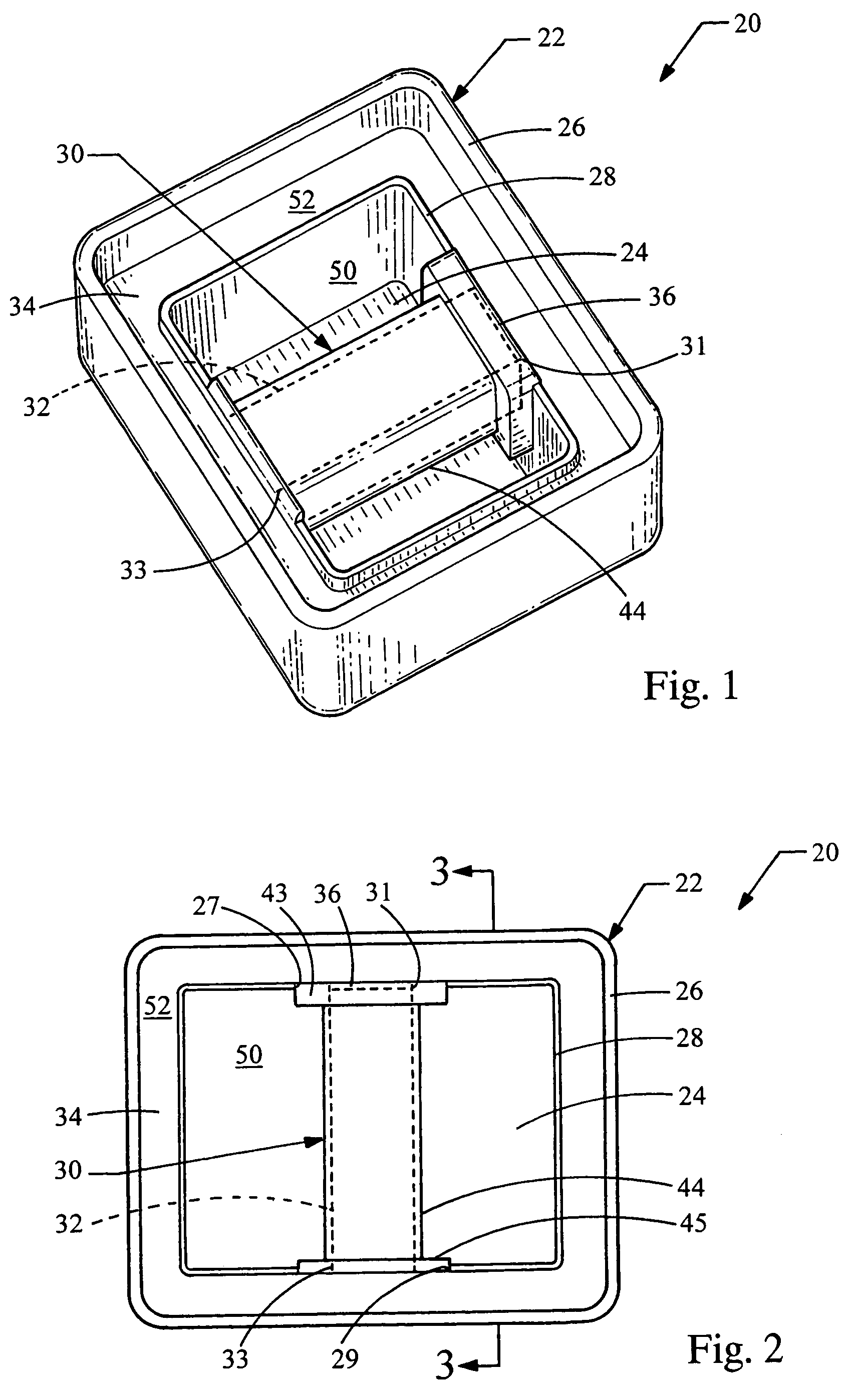

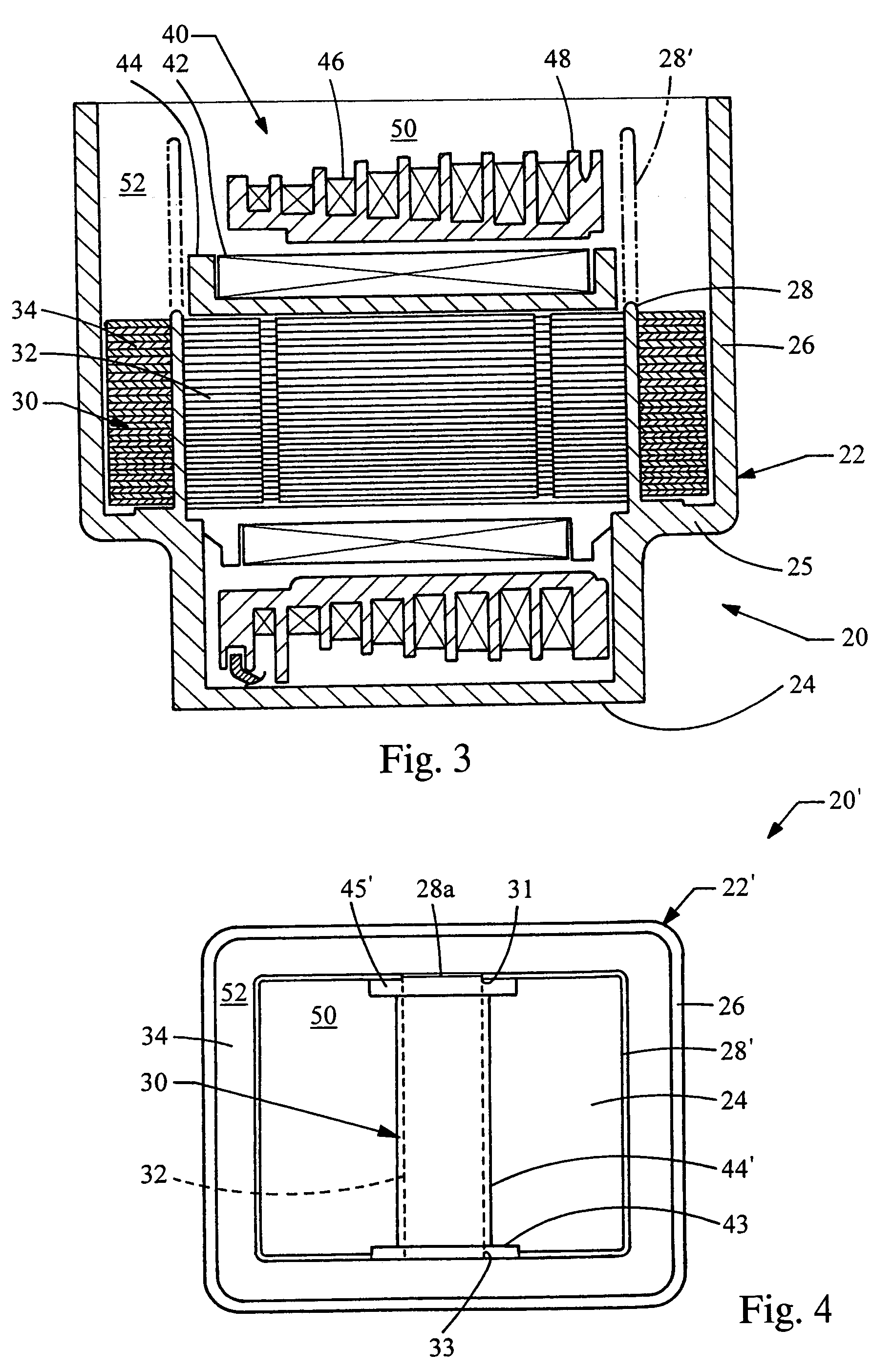

Bone implant and method of securing

InactiveUS20010023371A1Prevent crack propagationBone implantJoint implantsBone implantMaterials science

The present invention is an implant for securing to a bone to form a plurality of cement cells. The implant has a bone engagement portion for engagement with the bone. The implant has surfaces defining a first plurality of cement compartments in the bone engagement portion for alignment with a second plurality of cement compartments in the bone to form a plurality of cement cells extending between the implant and the bone when the implant is secured to the bone. The cement cells receive cement therein to form plugs of cement extending between the implant and the bone to secure the implant to the bone.

Owner:BONUTTI SKELETAL INNOVATIONS

Bone implant and method of securing

The present invention is an implant for securing to a bone to form a plurality of cement cells. The implant has a bone engagement portion for engagement with the bone. The implant has surfaces defining a first plurality of cement compartments in the bone engagement portion for alignment with a second plurality of cement compartments in the bone to form a plurality of cement cells extending between the implant and the bone when the implant is secured to the bone. The cement cells receive cement therein to form plugs of cement extending between the implant and the bone to secure the implant to the bone.

Owner:BONUTTI 2003 TRUST A THE +1

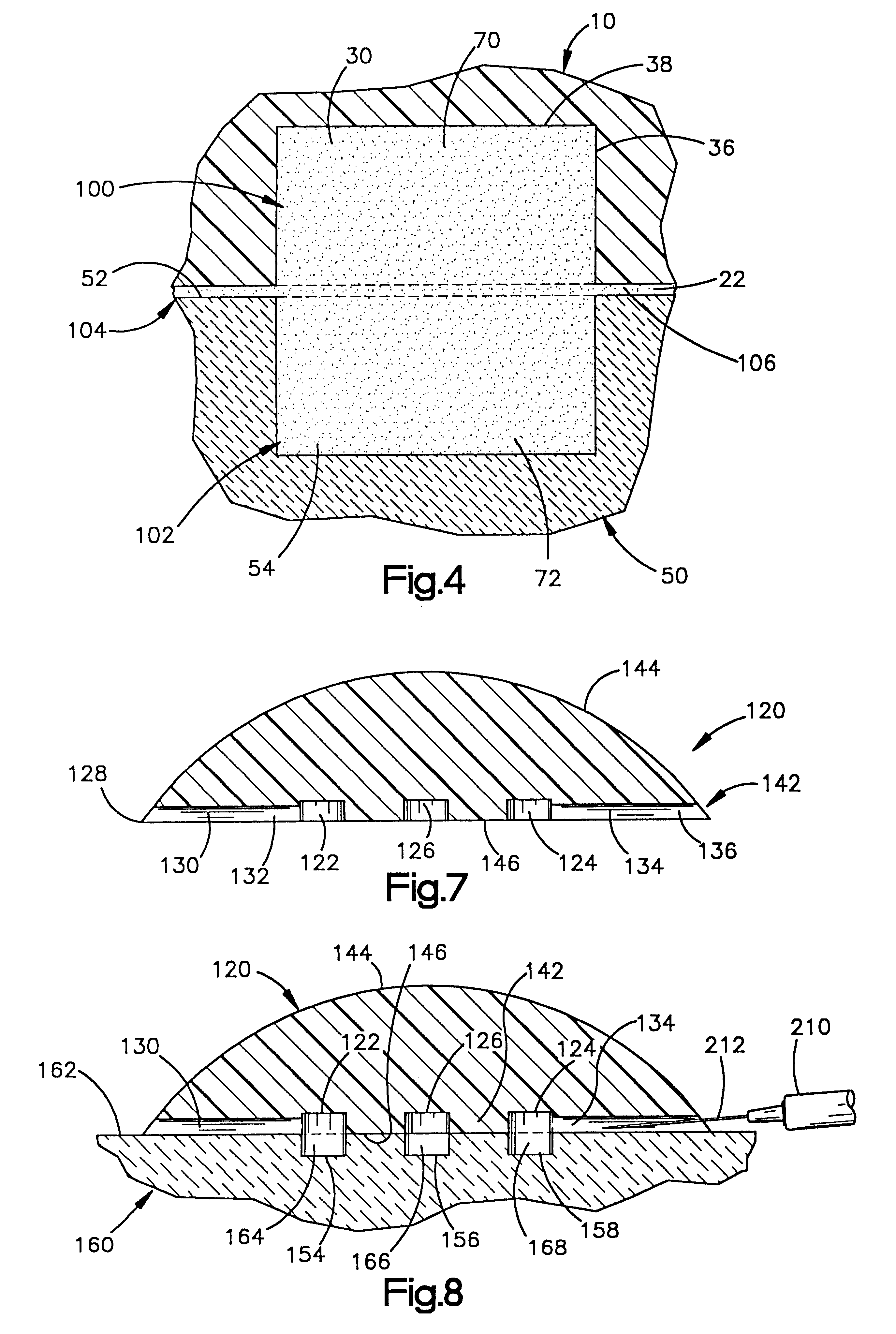

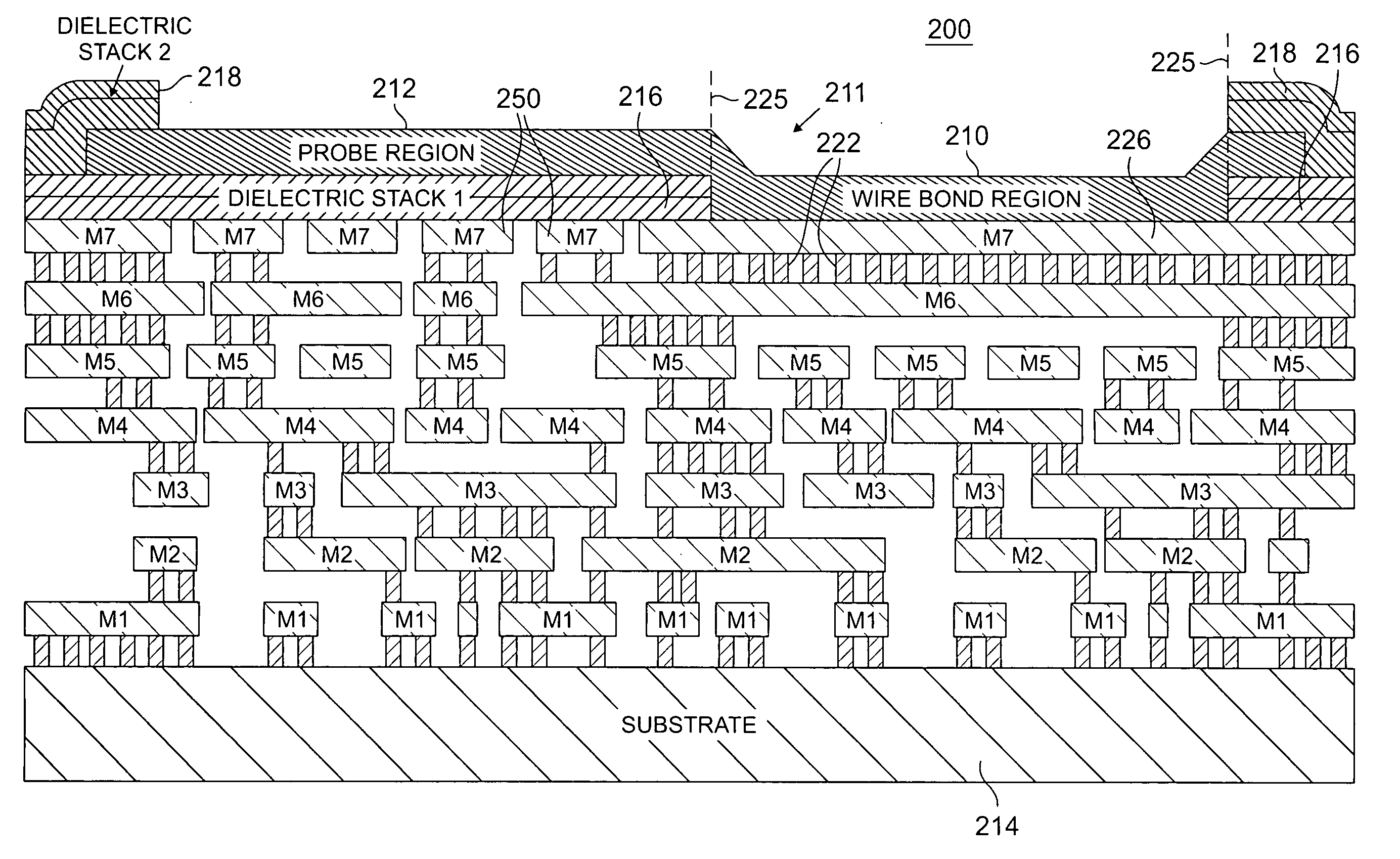

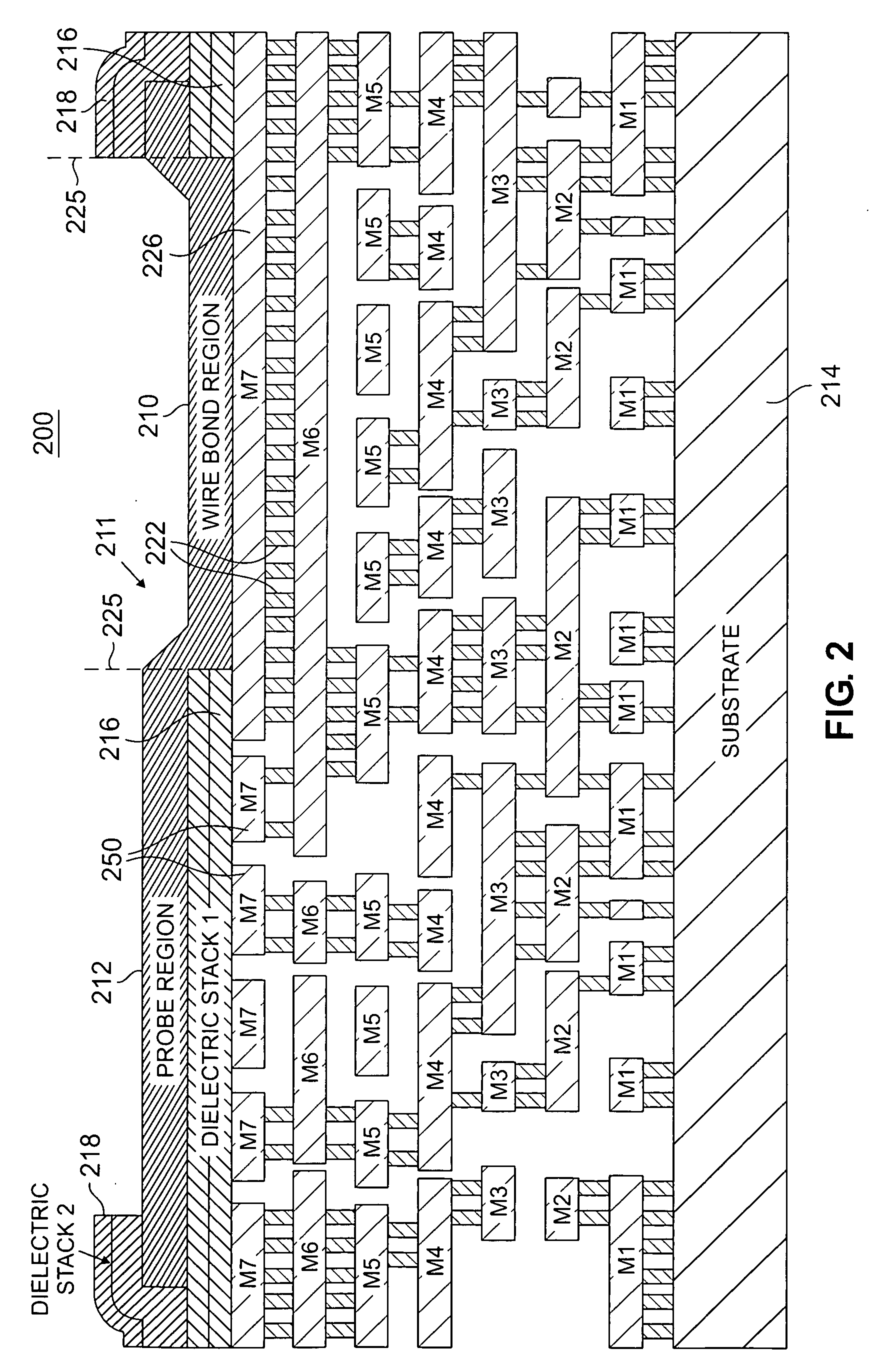

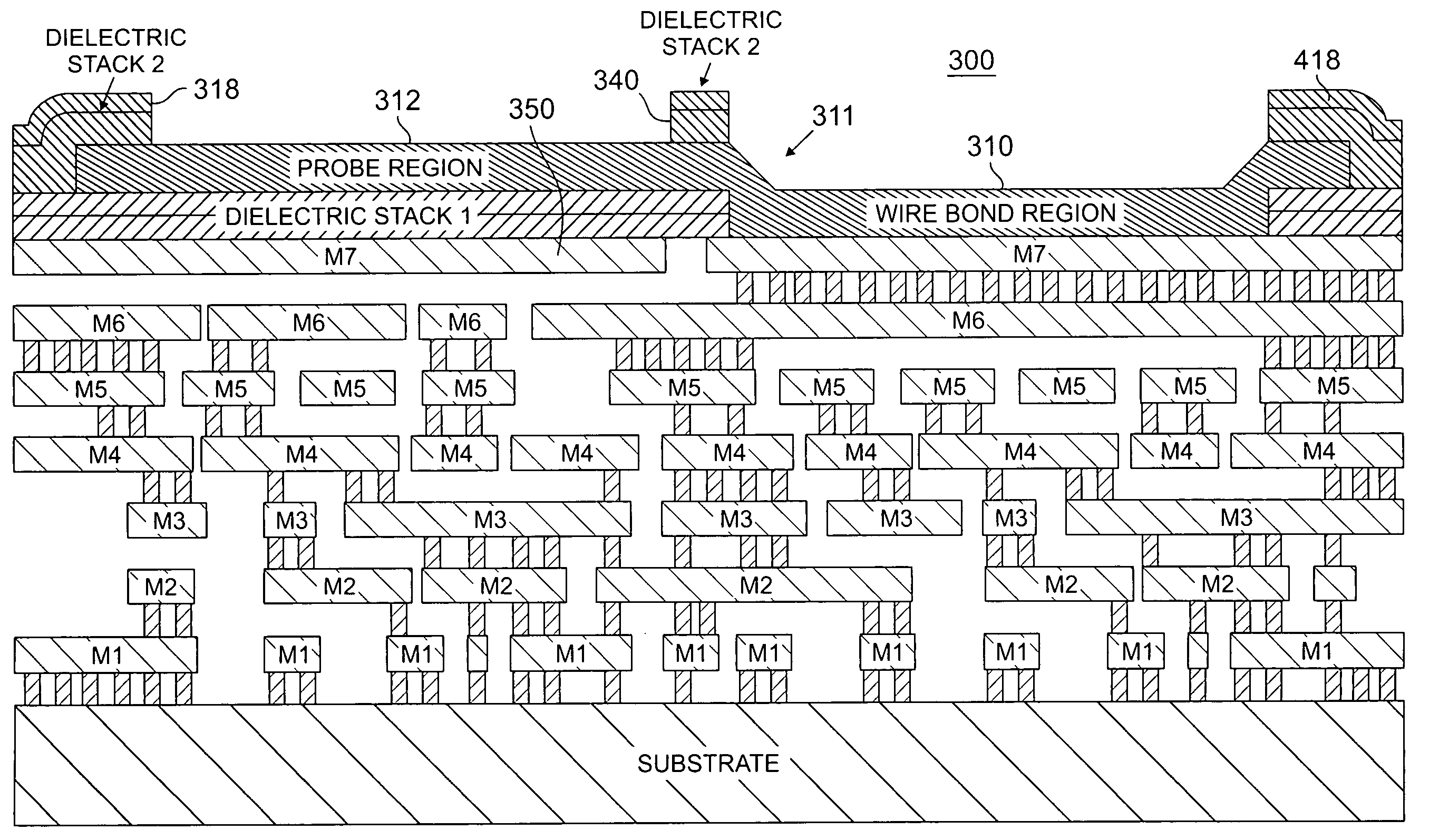

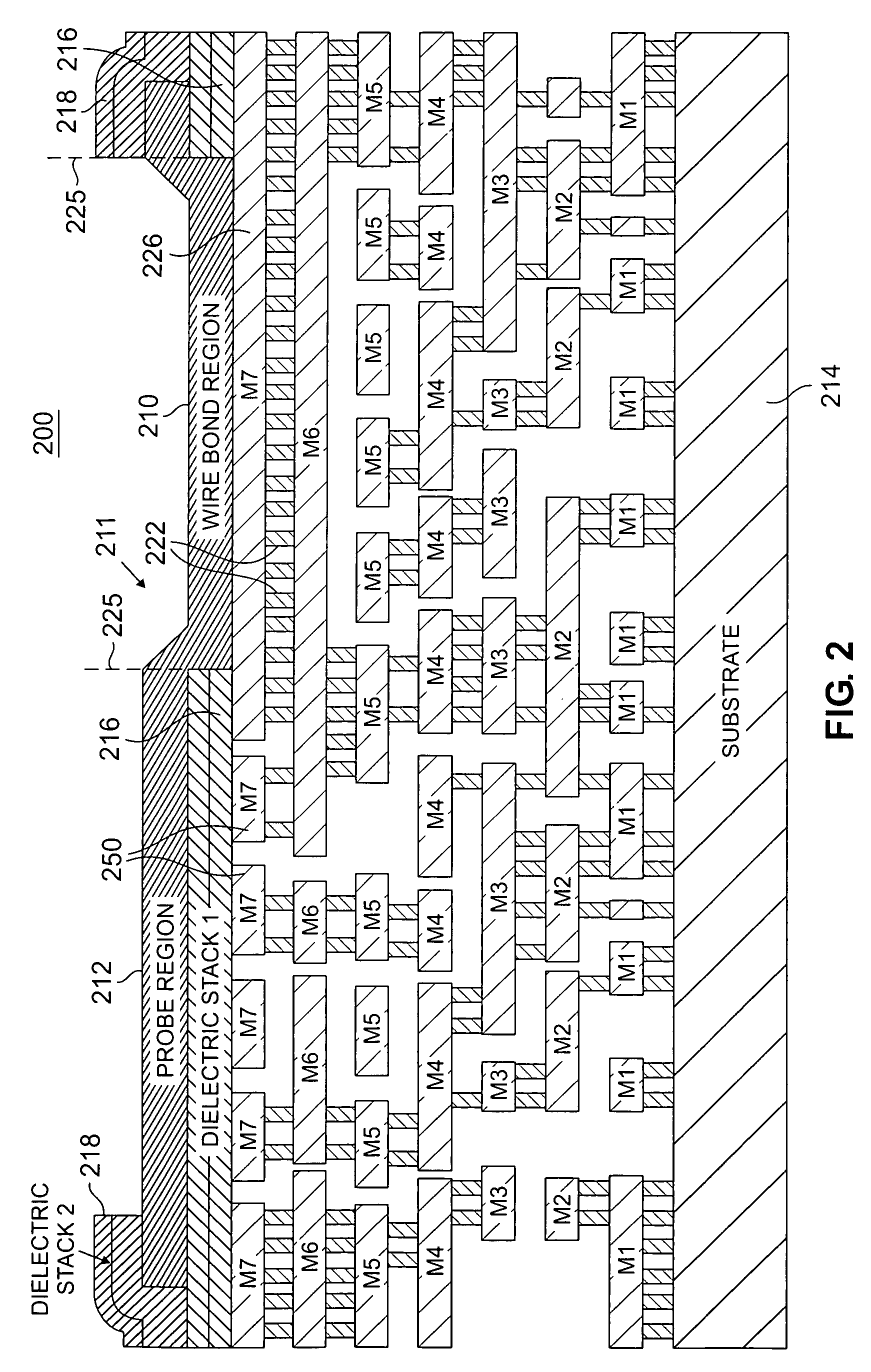

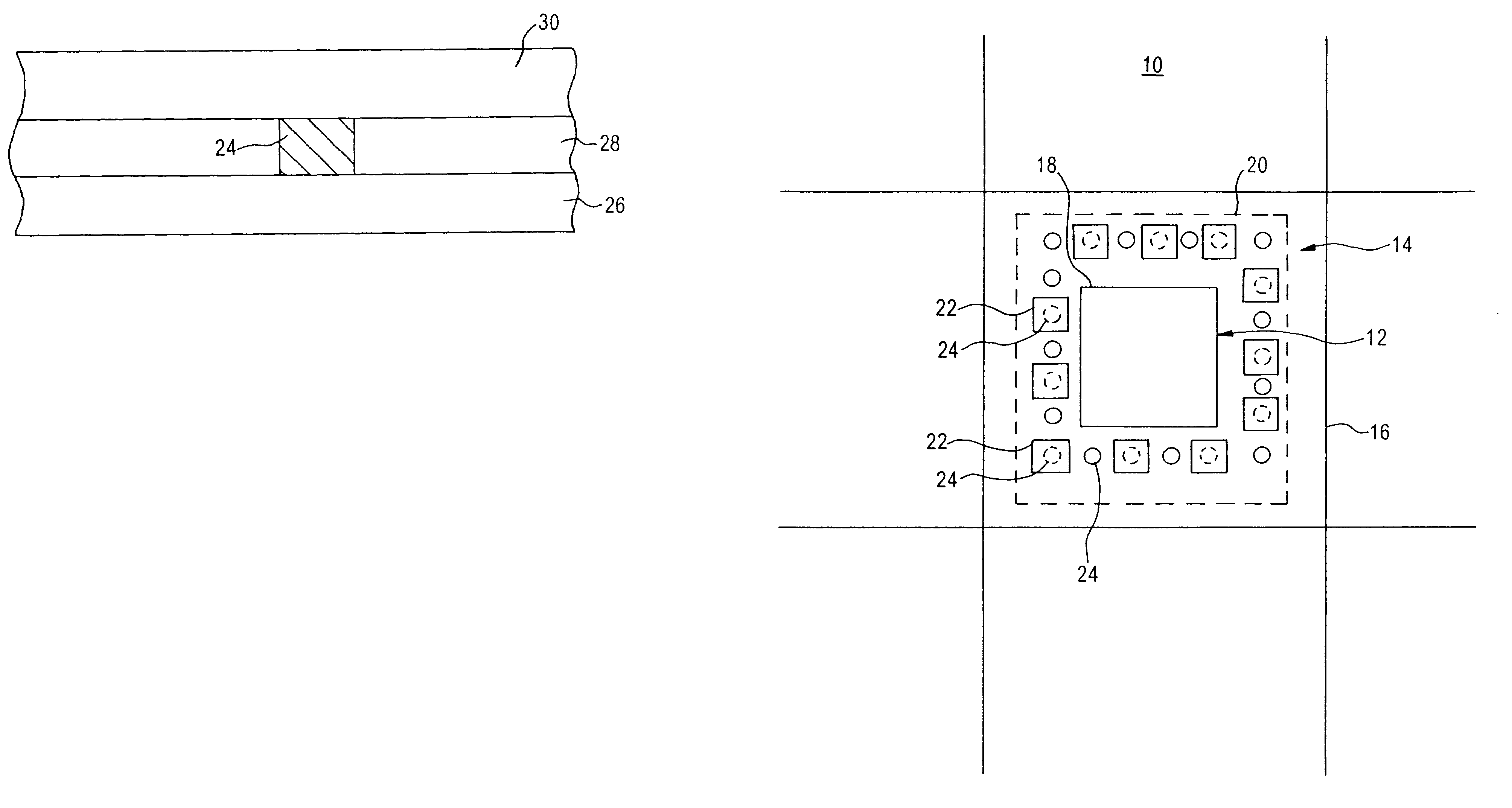

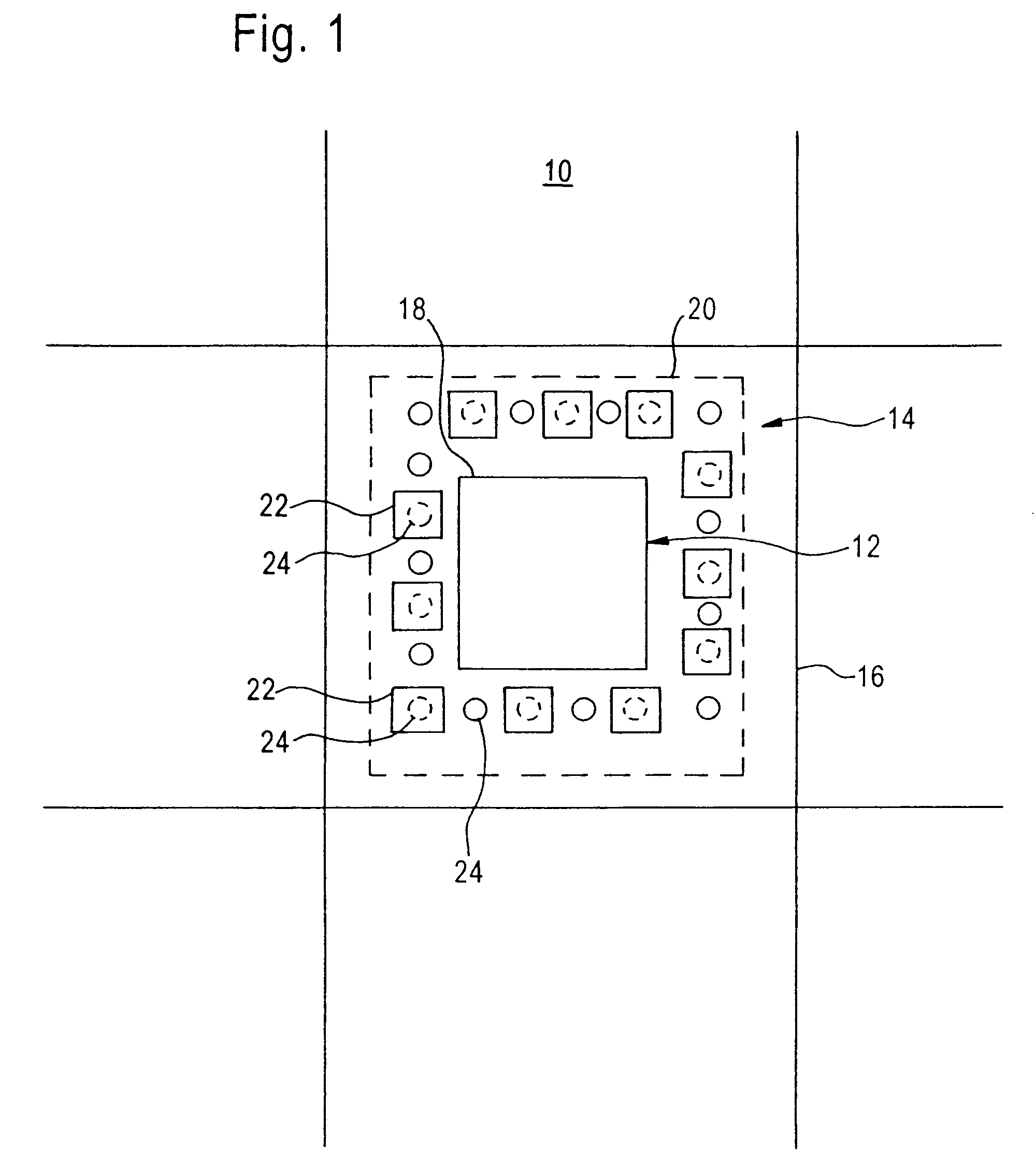

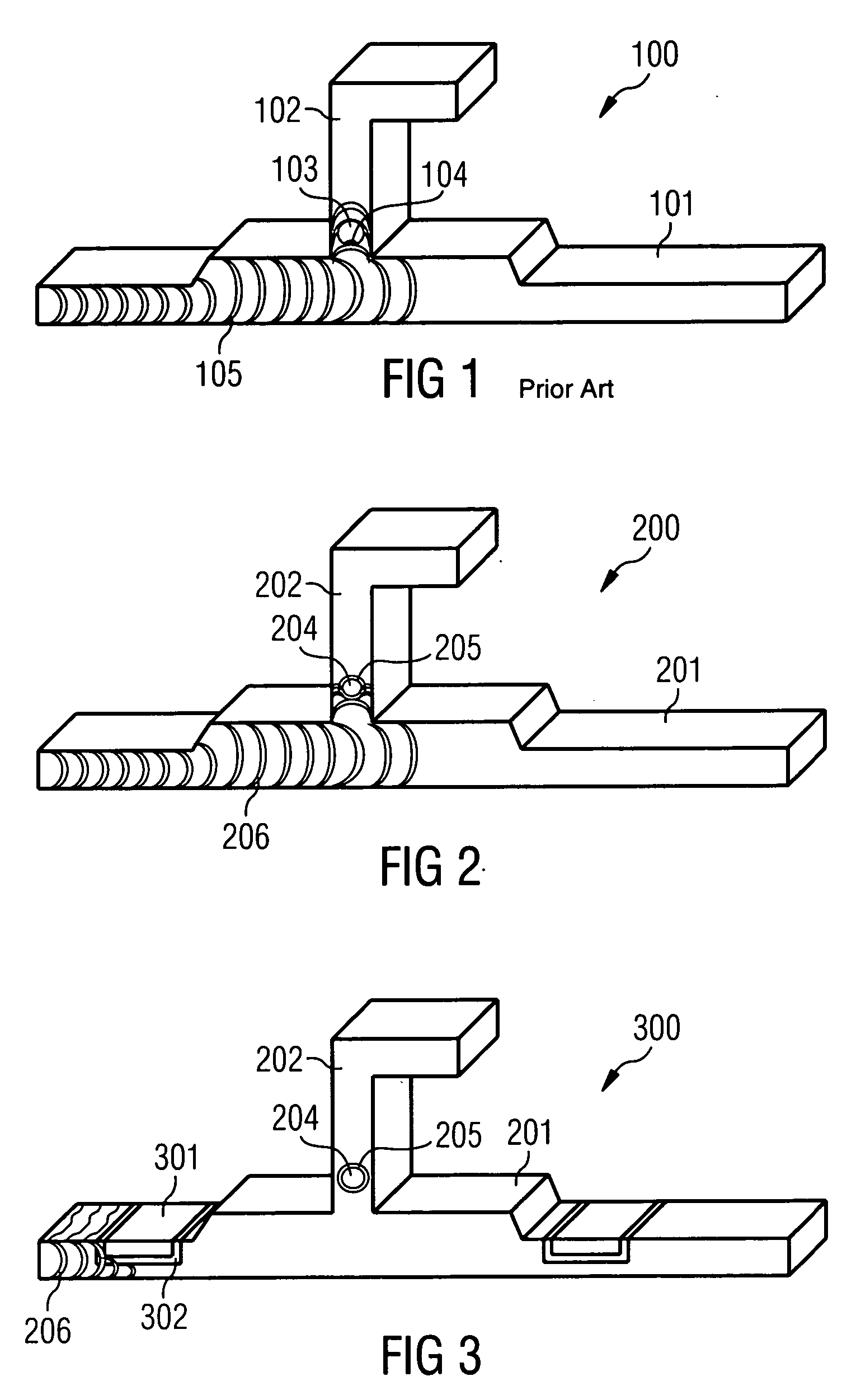

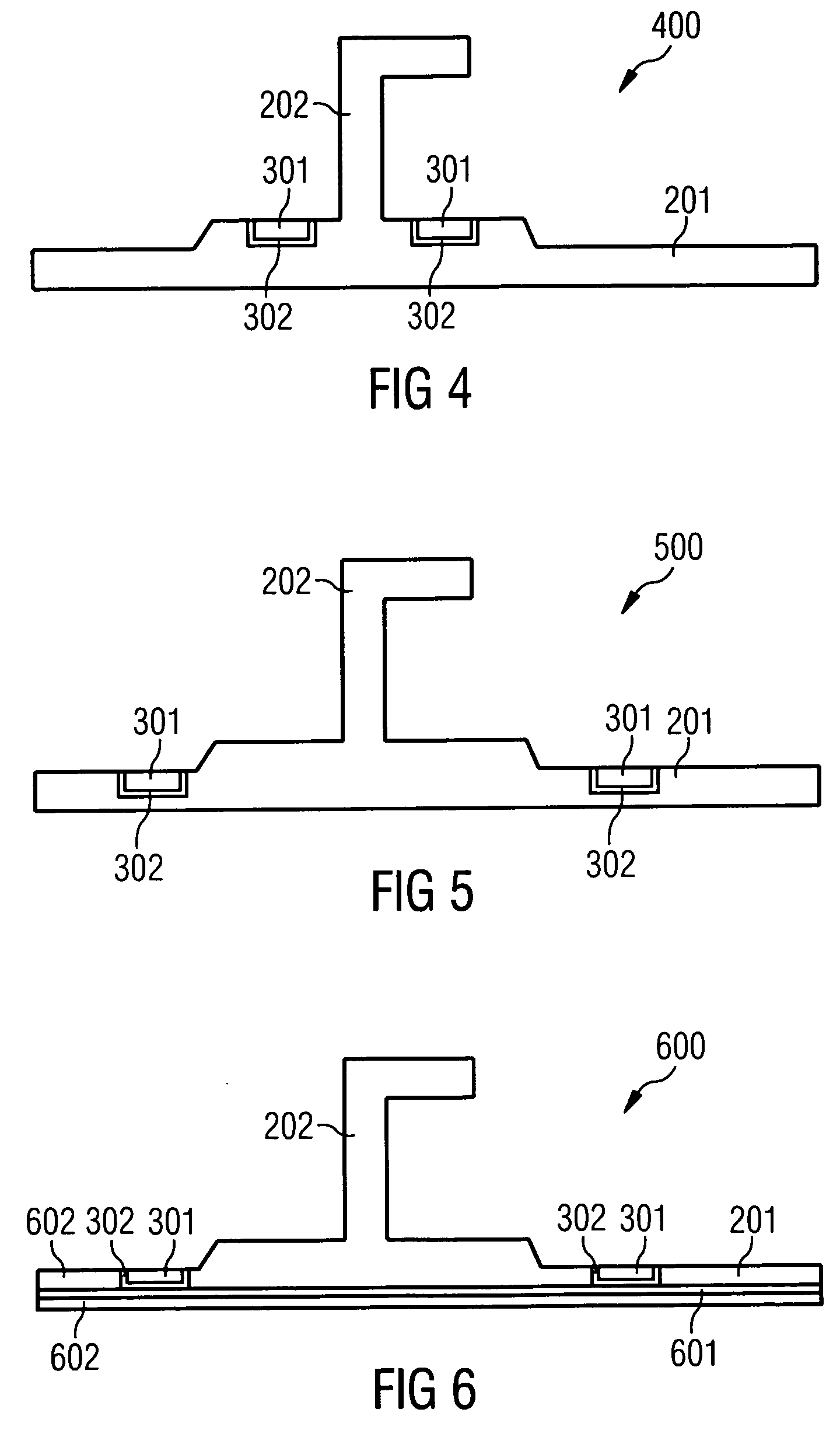

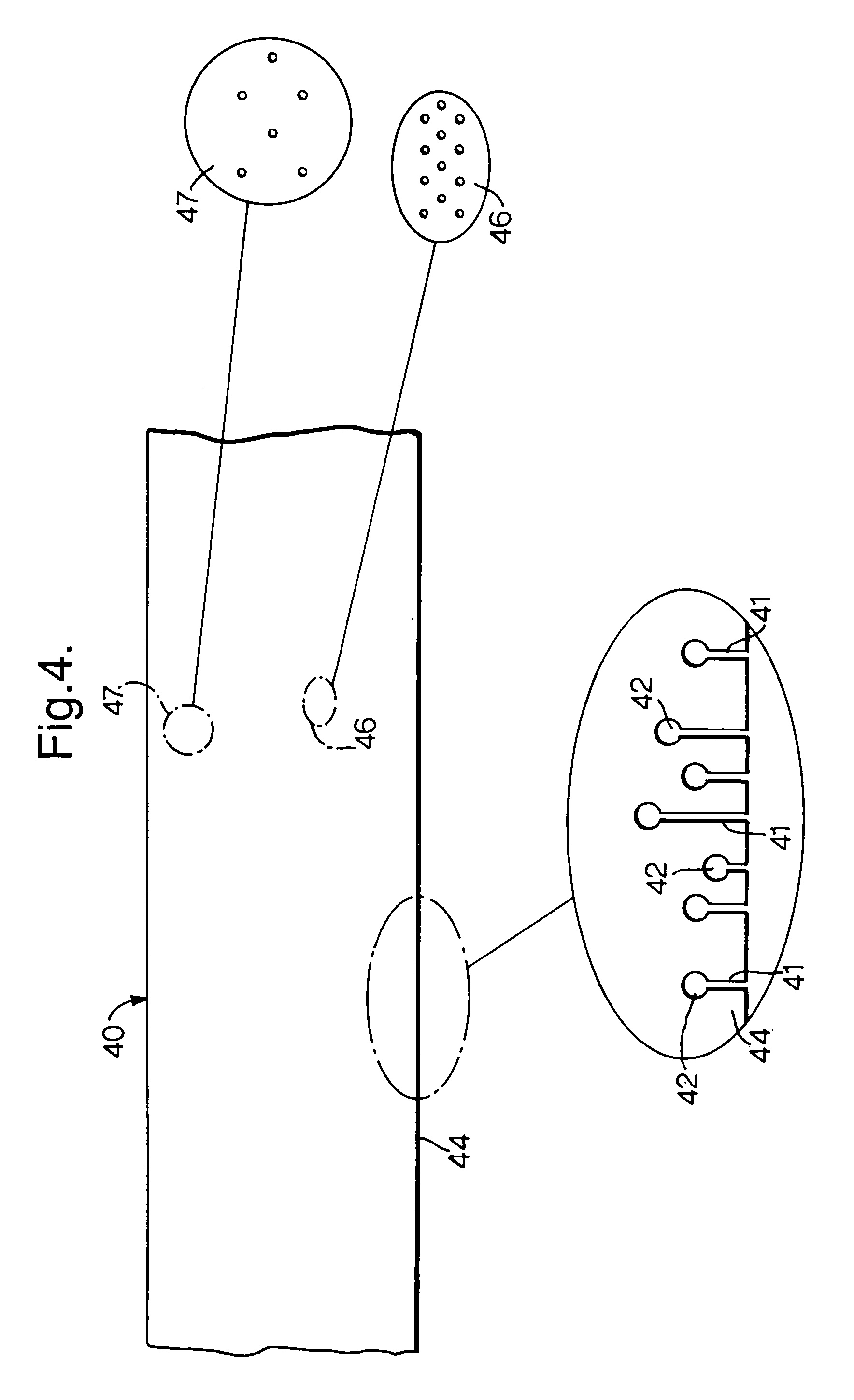

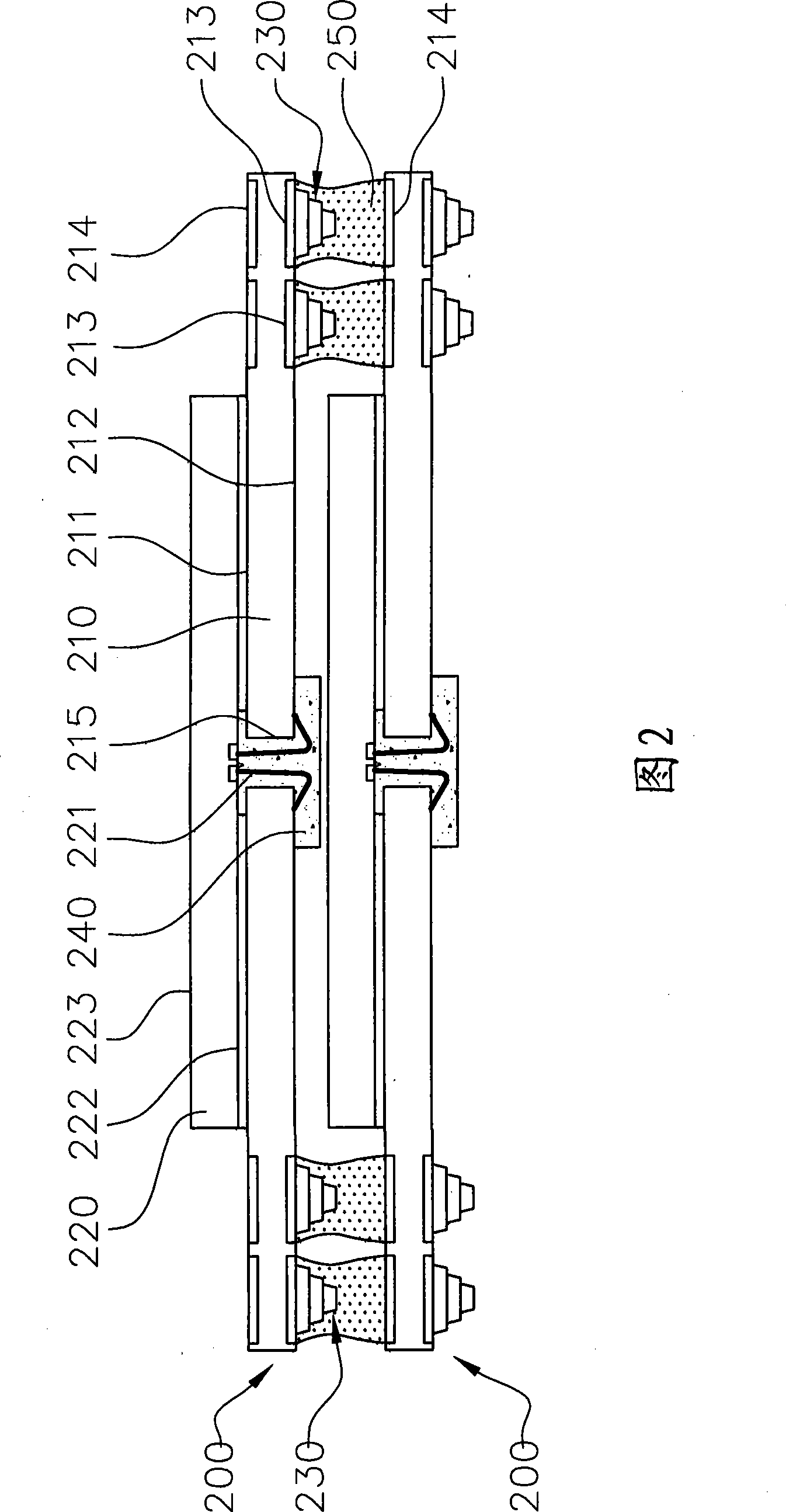

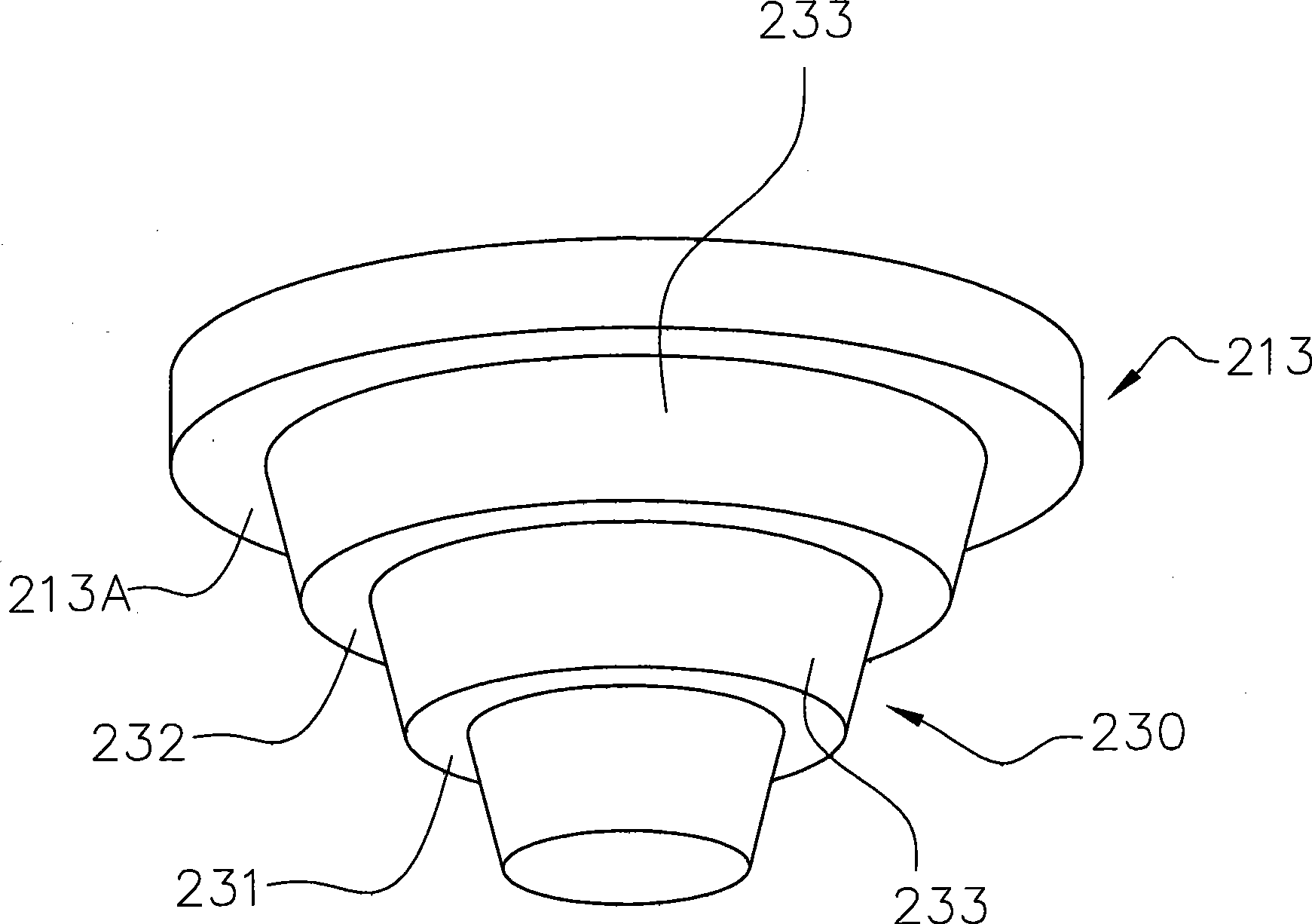

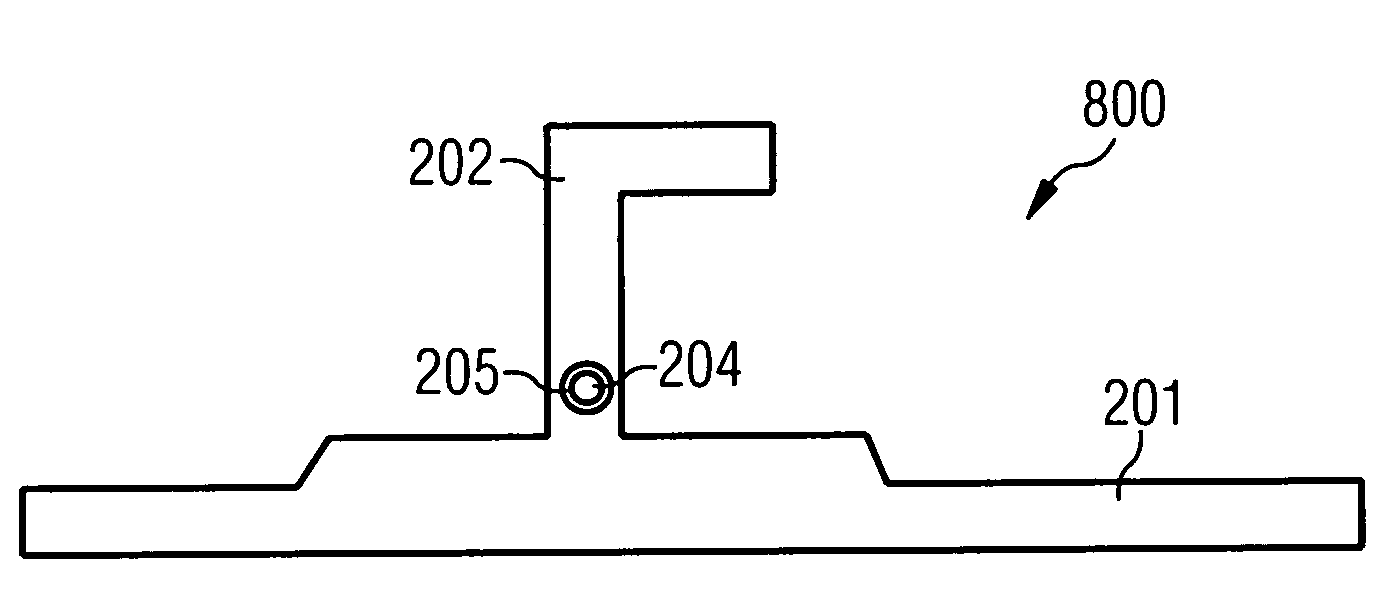

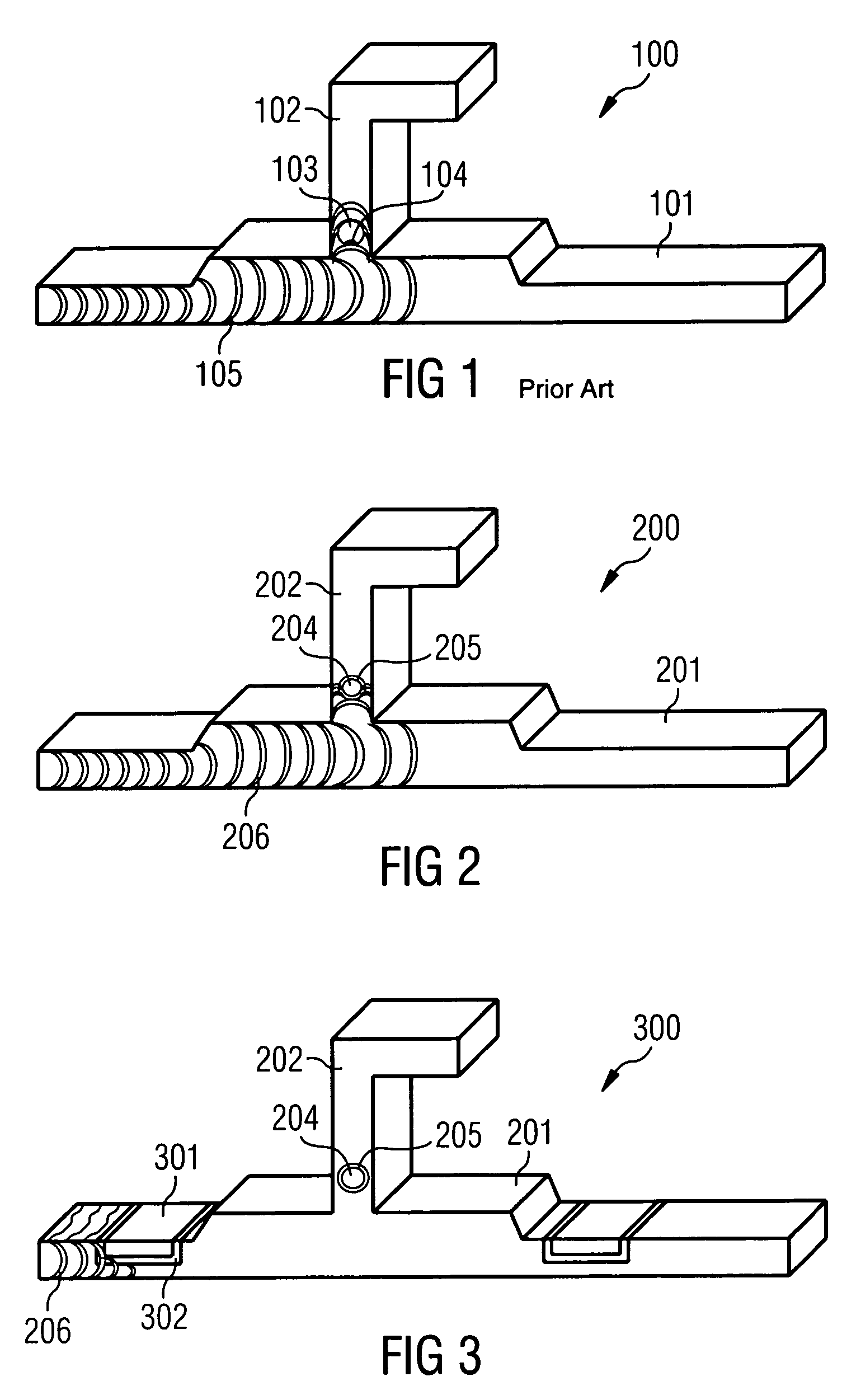

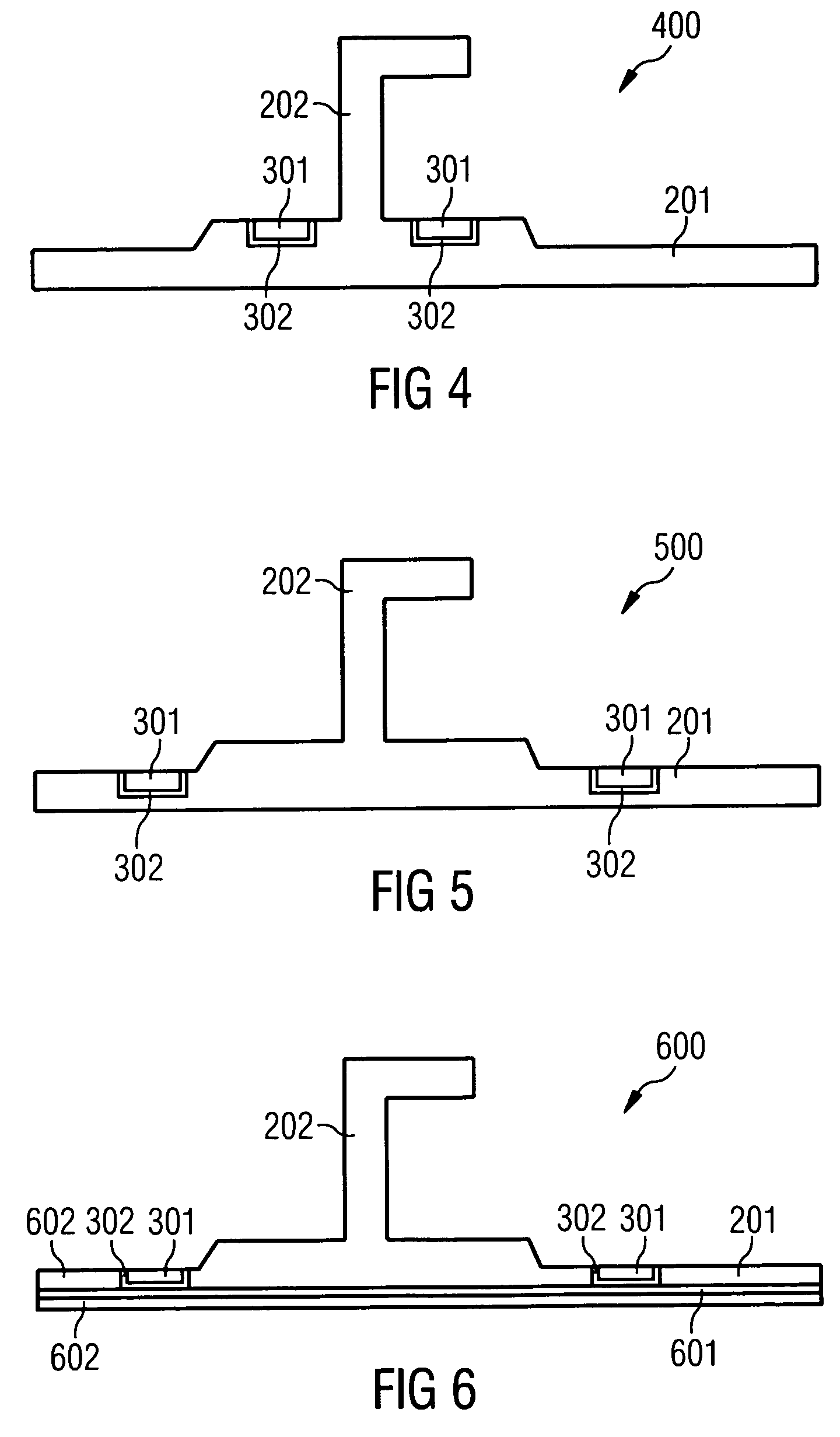

Reinforced bond pad for a semiconductor device

ActiveUS20060065969A1Good adhesionAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectBiomedical engineering

Disclosed herein are novel support structures for pad reinforcement in conjunction with new bond pad designs for semiconductor devices. The new bond pad designs avoid the problems associated with probe testing by providing a probe region that is separate from a wire bond region. Separating the probe region 212 from the wire bond region 210 and forming the bond pad 211 over active circuitry has several advantages. By separating the probe region 212 from the wire bond region 210, the wire bond region 210 is not damaged by probe testing, allowing for more reliable wire bonds. Also, forming the bond pad 211 over active circuitry, including metal interconnect layers, allows the integrated circuit to be smaller.

Owner:BELL SEMICON LLC

Reinforced bond pad for a semiconductor device

ActiveUS7115985B2Good adhesionAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectLead bonding

Owner:BELL SEMICON LLC

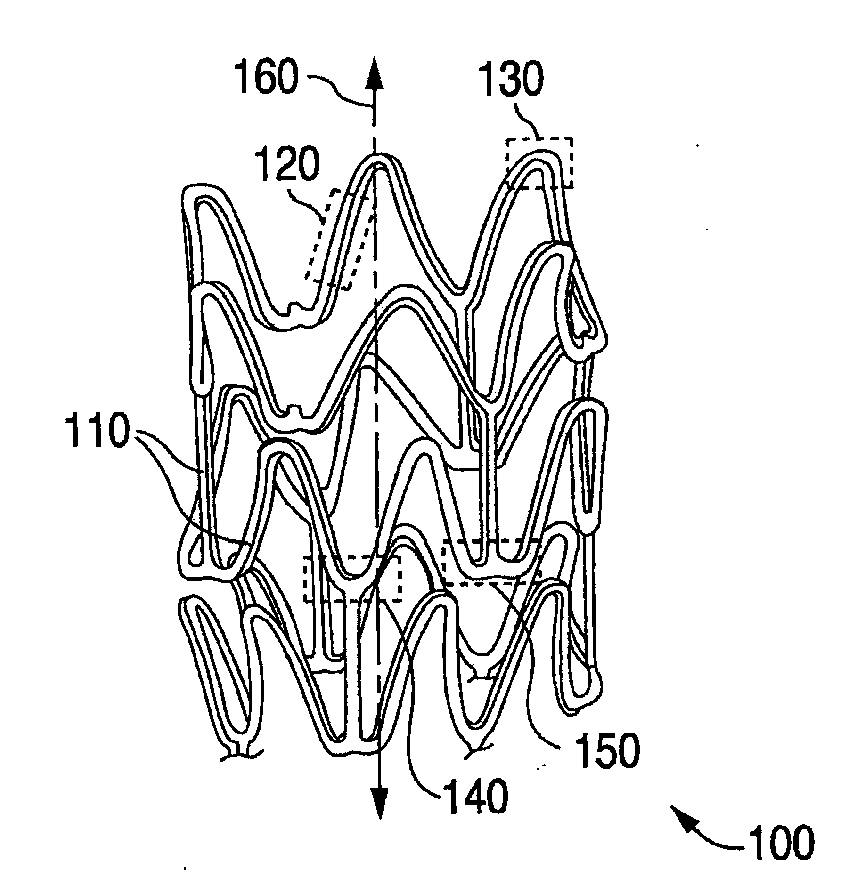

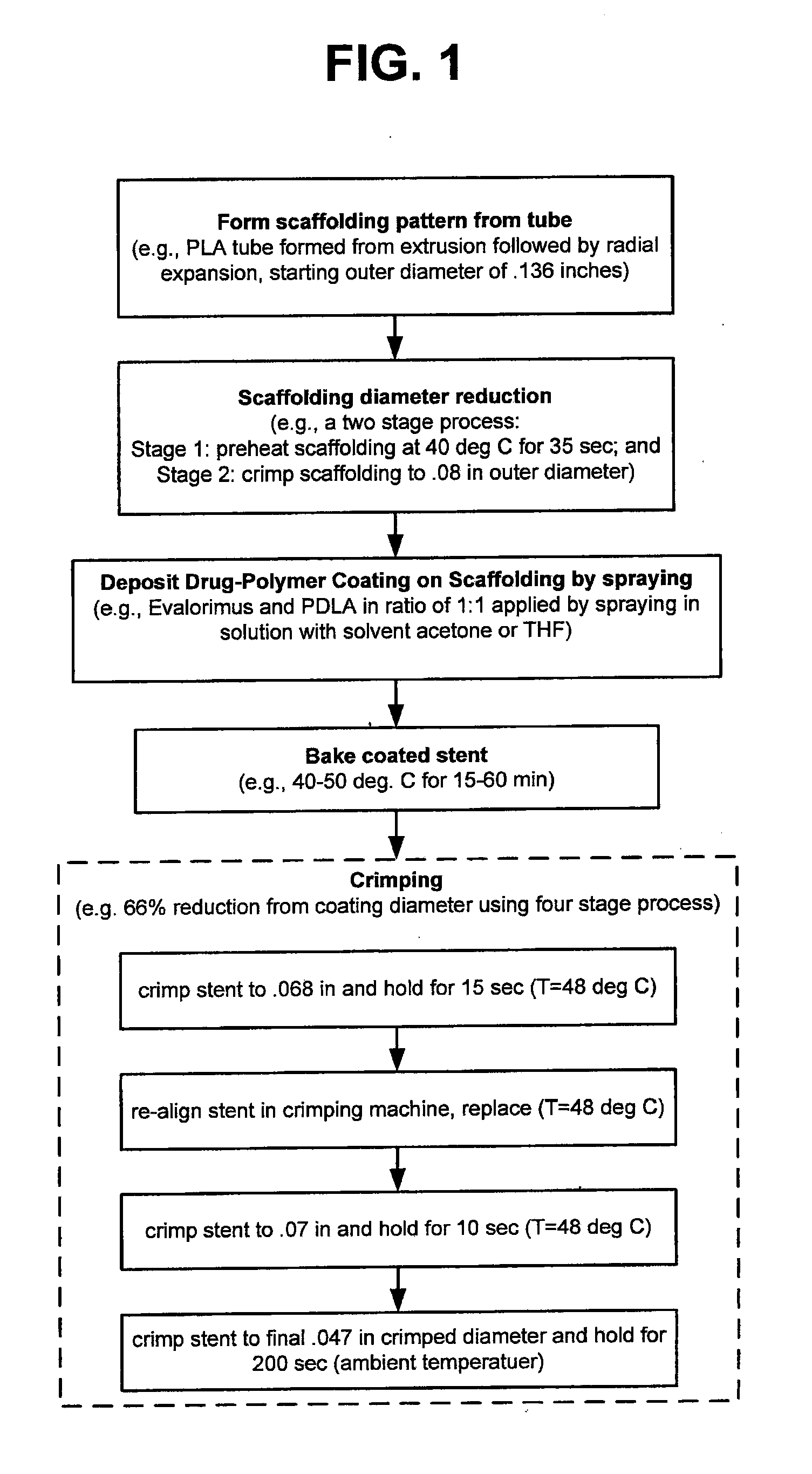

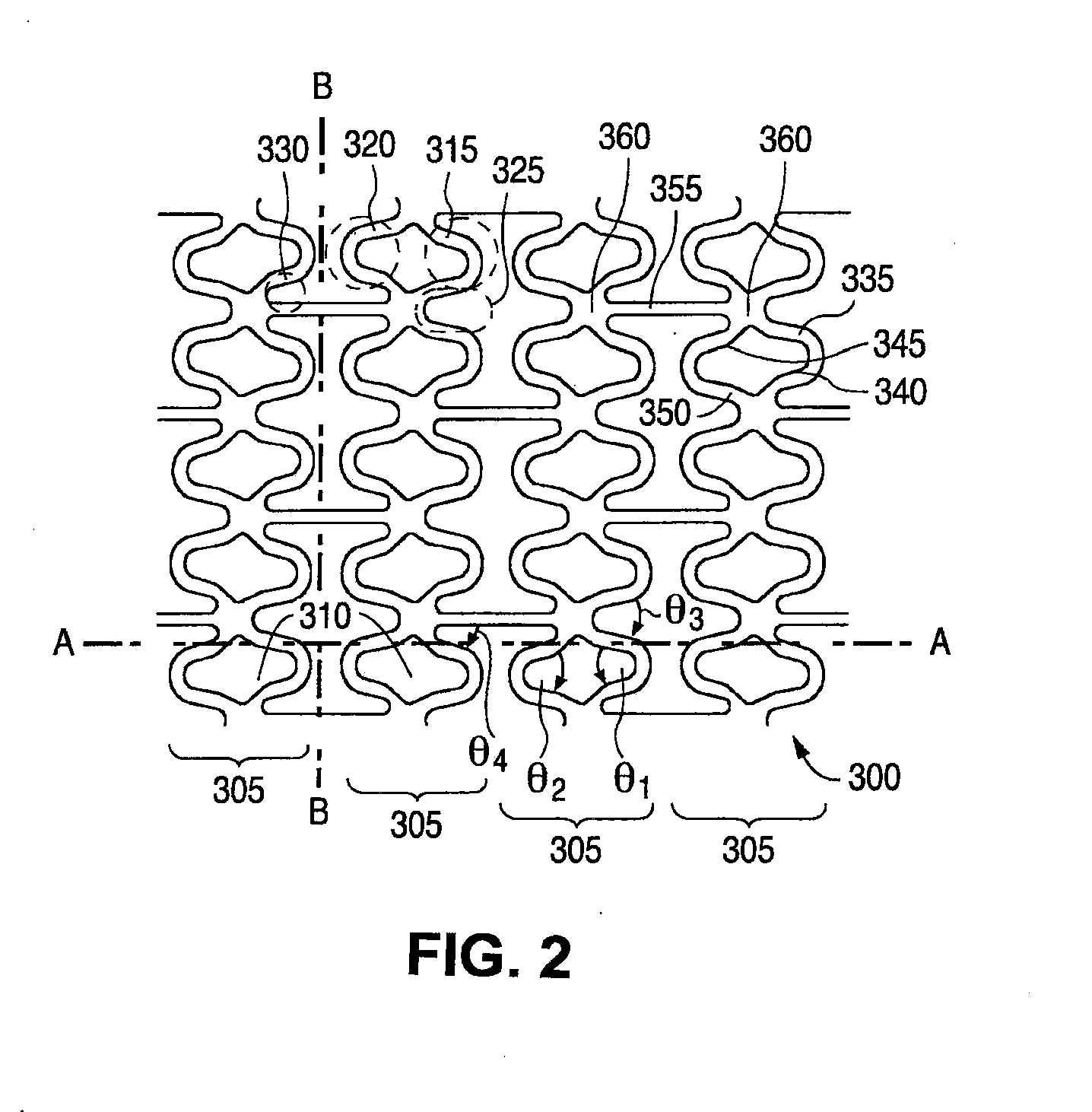

Methods To Increase Fracture Resistance Of A Drug-Eluting Medical Device

InactiveUS20100323091A1Improve fracture resistanceRelieve stress/strainStentsPharmaceutical containersPolymer coatingsMedical device

Owner:ABBOTT CARDIOVASCULAR

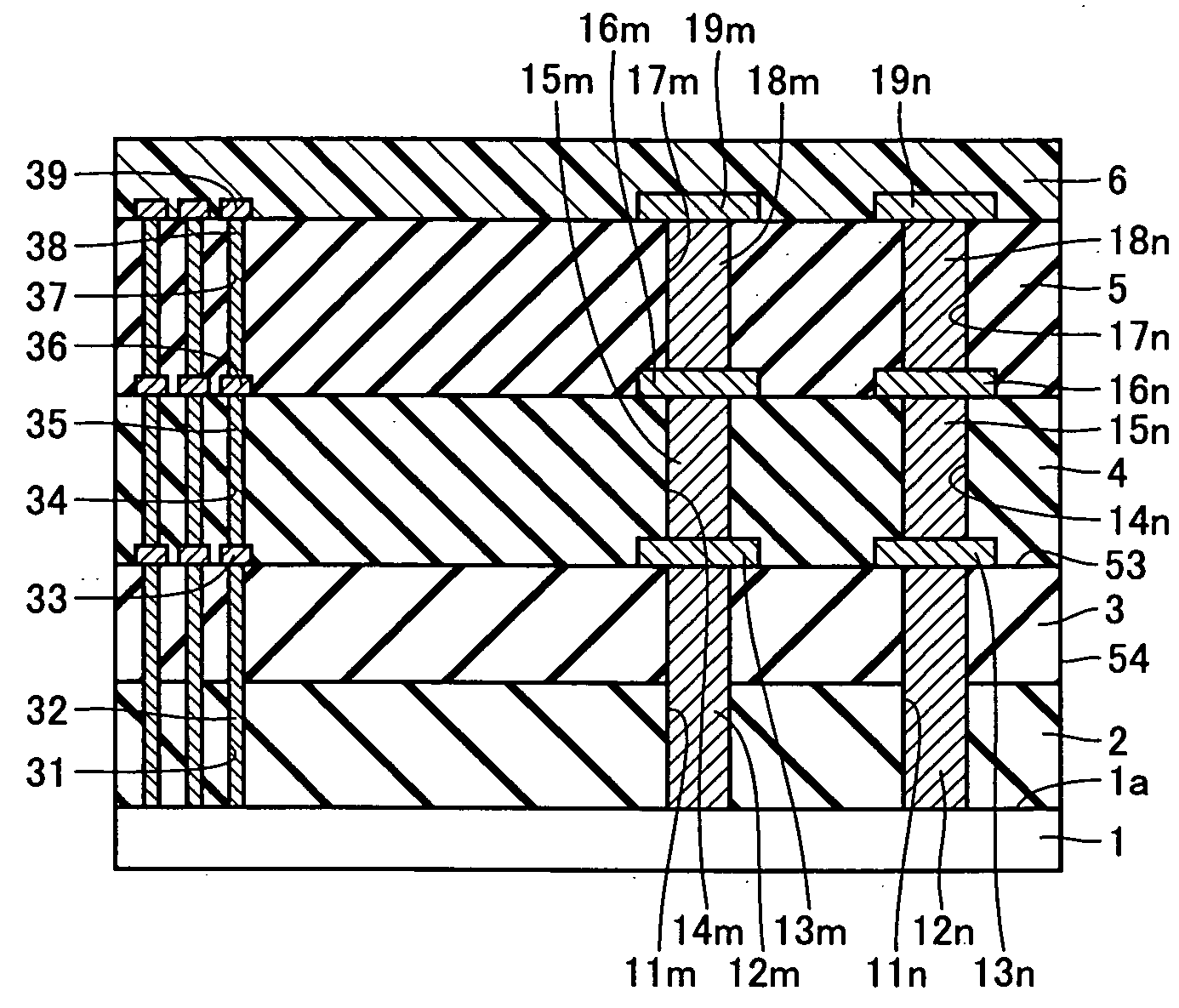

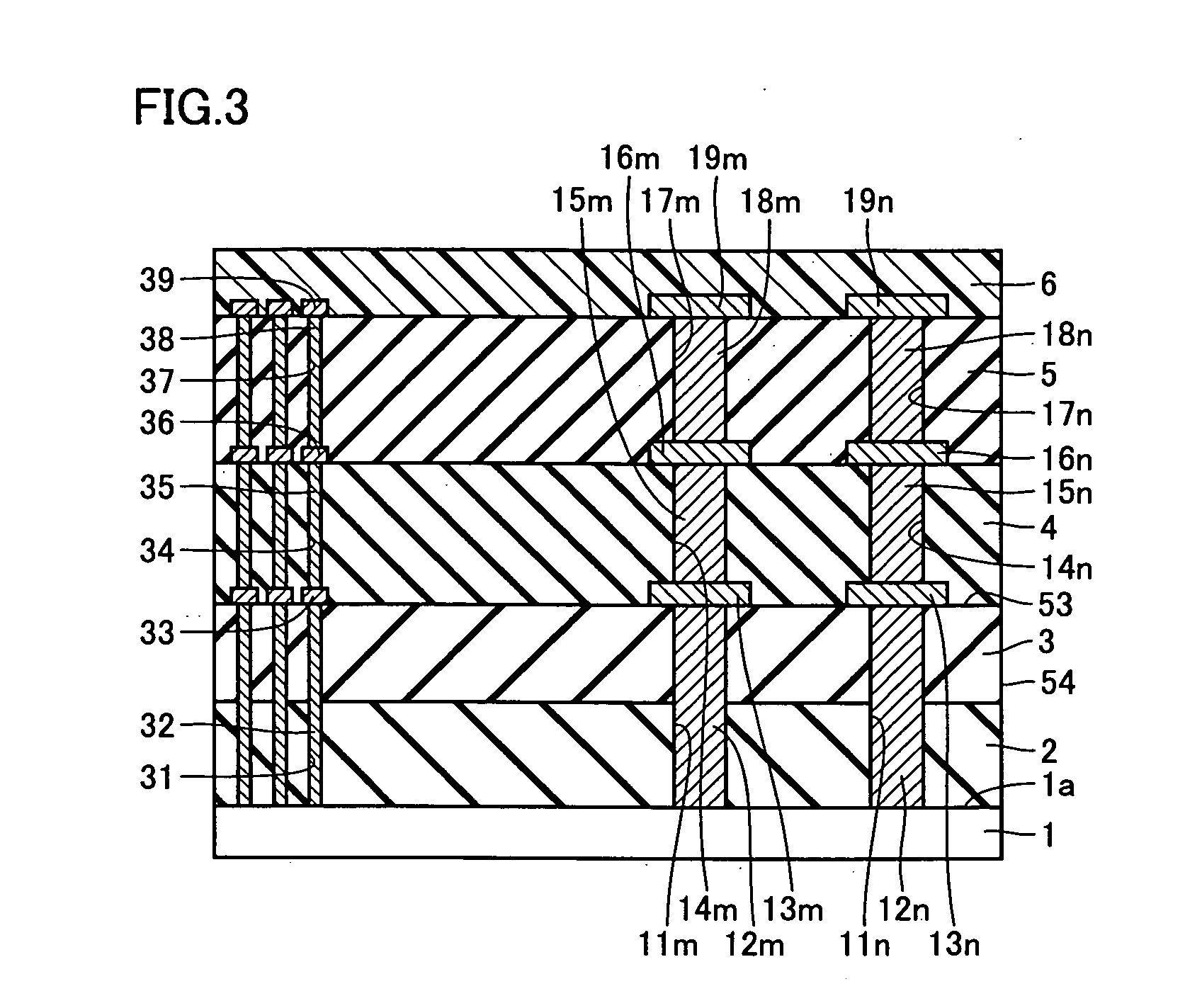

Semiconductor device

InactiveUS20050087878A1Improve reliabilityPrevent crack propagationSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device includes a silicon substrate having a main surface, a memory cell formed on the main surface, and an interlayer insulating film formed on the main surface to cover the memory cell. The interlayer insulating film has a top surface and a peripheral edge. In the interlayer insulating film, grooves are formed to be placed between the memory cell and the peripheral edge, to extend in parallel with the main surface and to extend in a predetermined direction at a spacing with each other, and a groove is formed to diverge from the grooves and to extend in a direction different from the extending direction of the grooves. The semiconductor device further includes metal film filling the grooves. Thus, crack propagation from the peripheral edge to the inside of the interlayer insulating film can surely be prevented to provide a semiconductor device with high reliability.

Owner:RENESAS TECH CORP

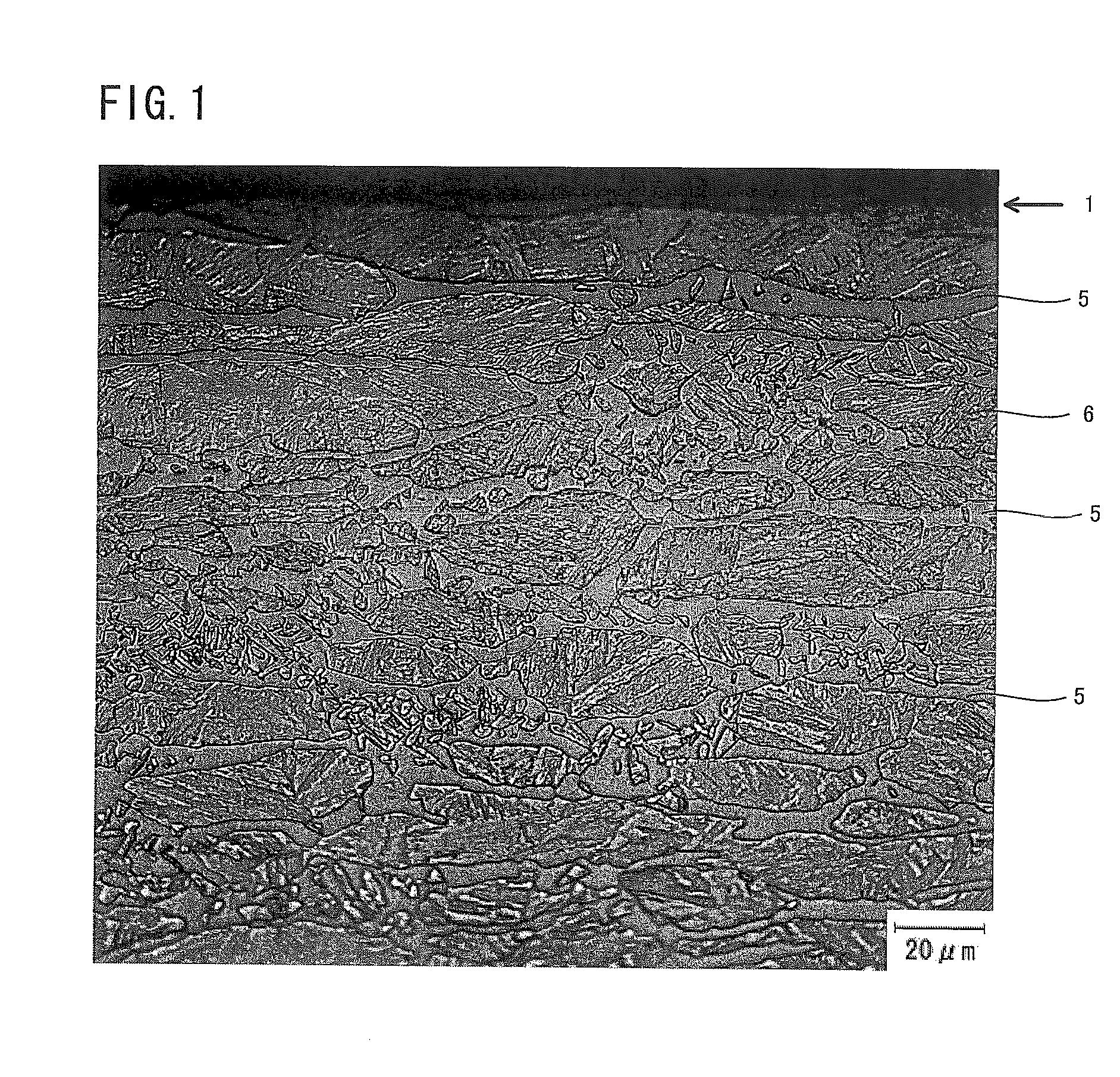

Stainless steel for oil well, stainless steel pipe for oil well, and method of manufacturing stainless steel for oil well

ActiveUS20120031530A1High strengthImprove corrosion resistanceFurnace typesHeat treatment process controlMicro structureChemical composition

The chemical composition of a stainless steel in accordance with the present invention consists of C: not more than 0.05%, Si: not more than 0.5%, Mn: 0.01 to 0.5%, P: not more than 0.04%, S: not more than 0.01%, Cr: more than 16.0 and not more than 18.0%, Ni: more than 4.0 and not more than 5.6%, Mo: 1.6 to 4.0%, Cu: 1.5 to 3.0%, Al: 0.001 to 0.10%, and N: not more than 0.050%, the balance being Fe and impurities, and satisfies Formulas (1) and (2). Also, the micro-structure thereof contains a martensitic phase and a ferritic phase having a volume ratio of 10 to 40%, and the ferritic phase distribution ratio is higher than 85%.Cr+Cu+Ni+Mo≧25.5 (1)−8≦30(C+N)+0.5Mn+Ni+Cu / 2+8.2−1.1(Cr+Mo)≦−4 (2)

Owner:NIPPON STEEL CORP

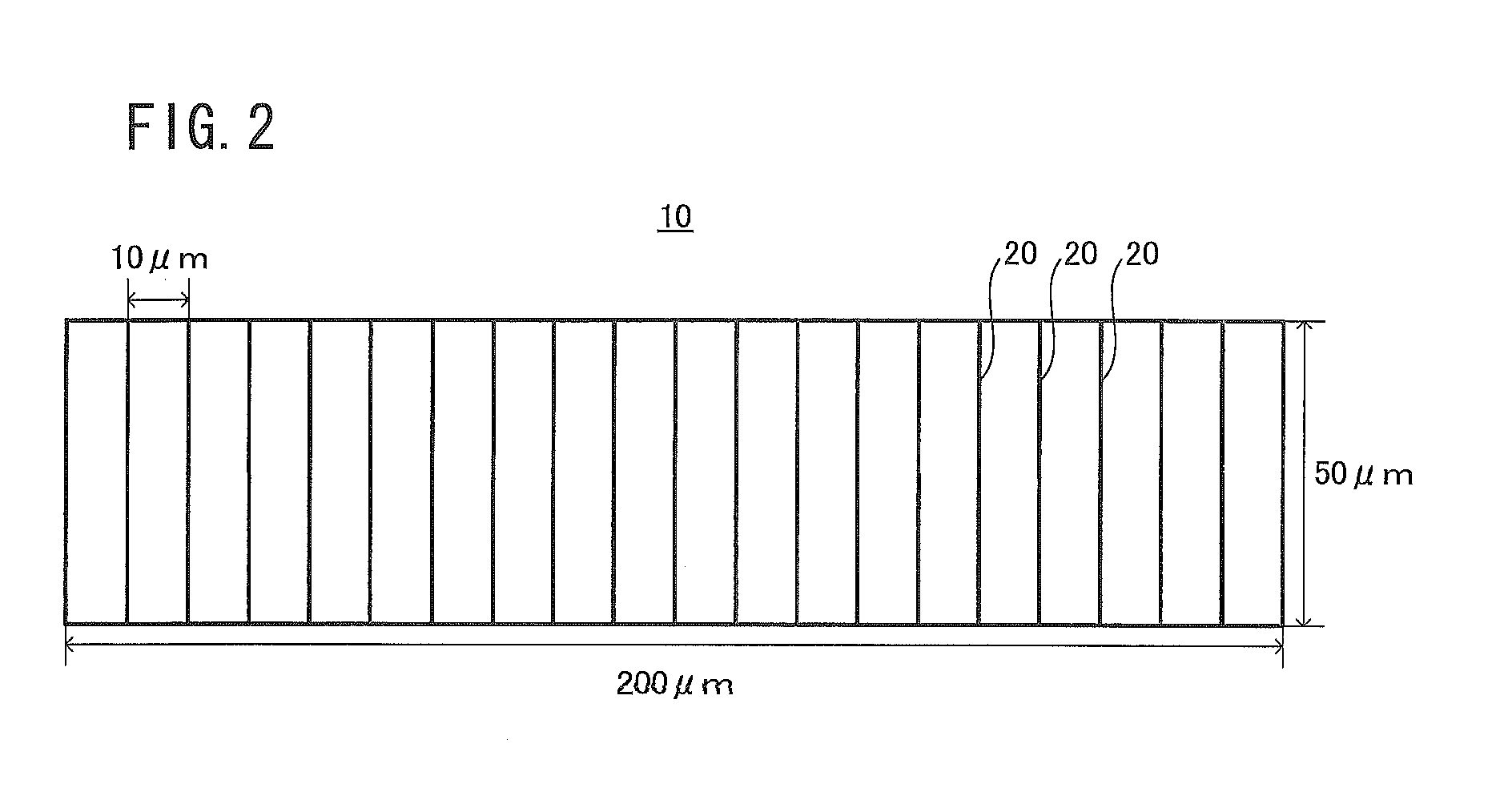

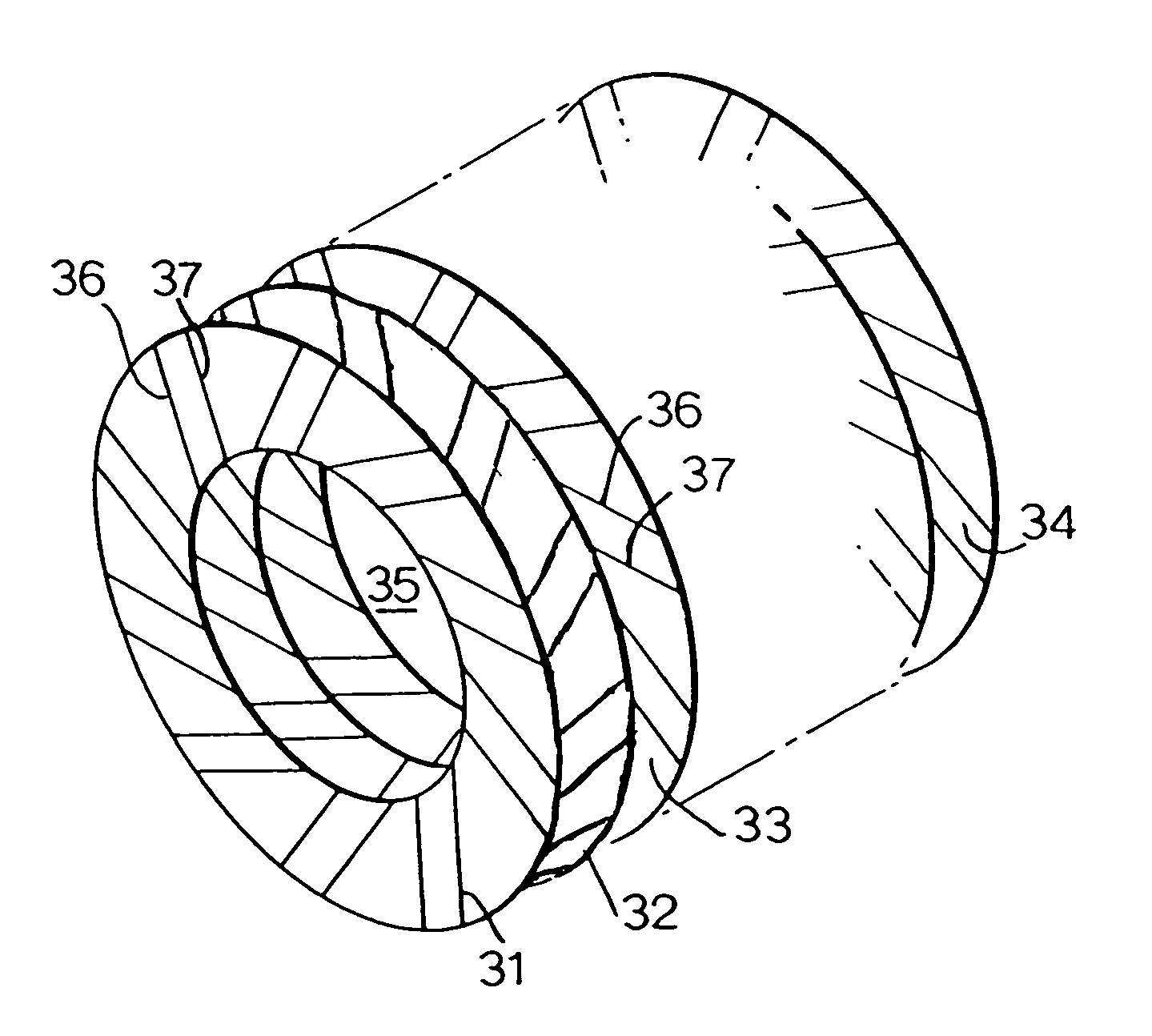

Property modulated materials and methods of making the same

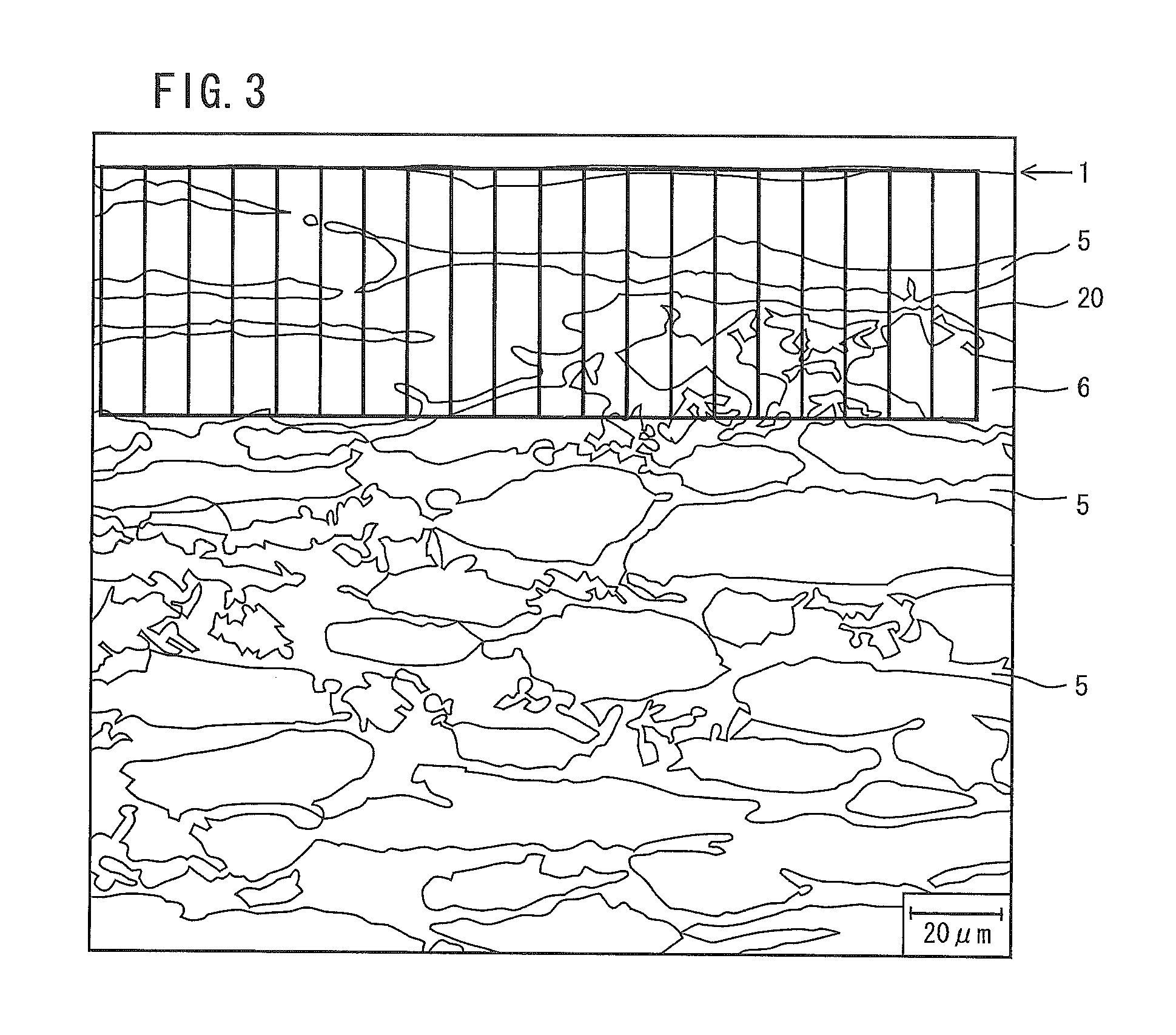

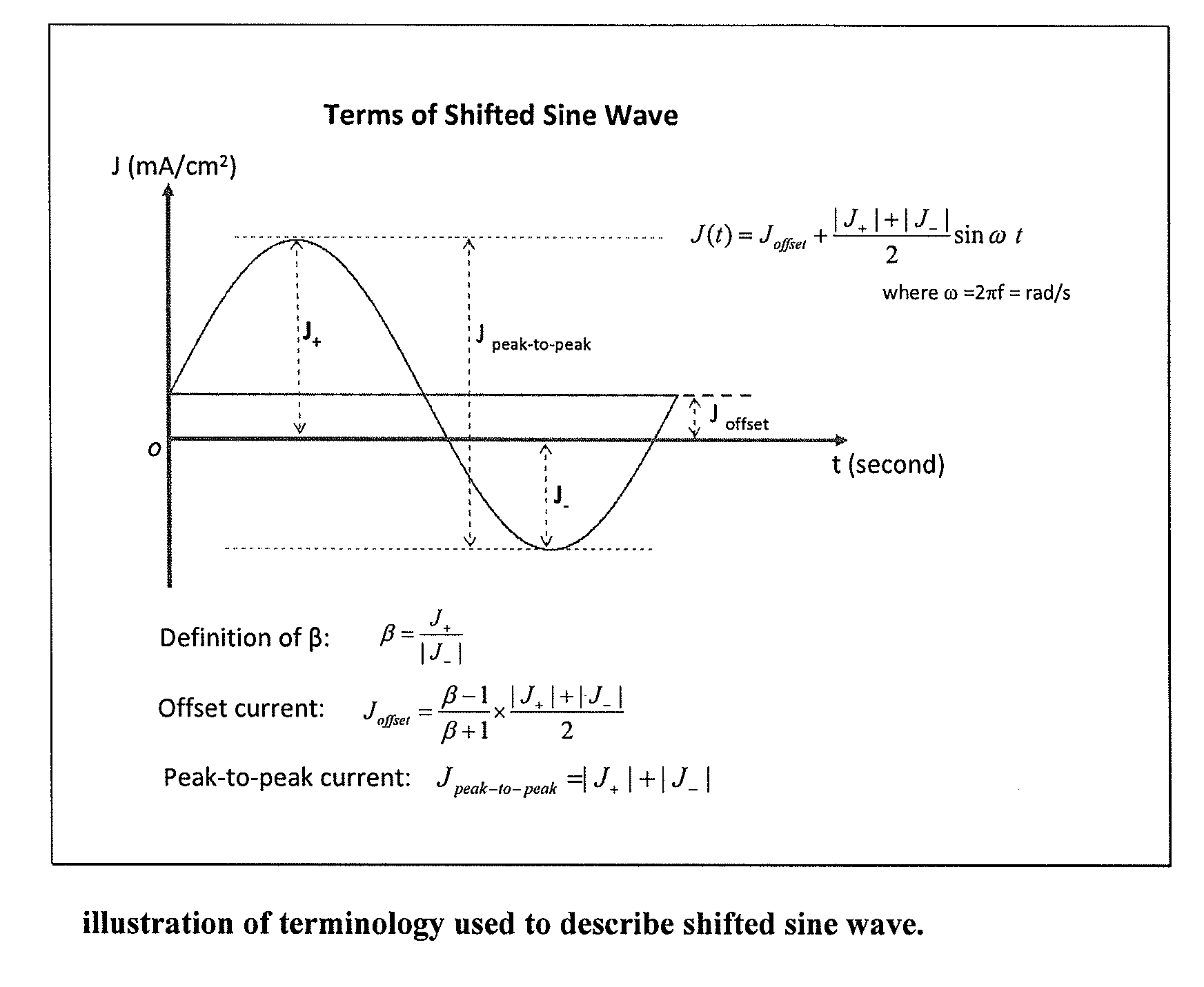

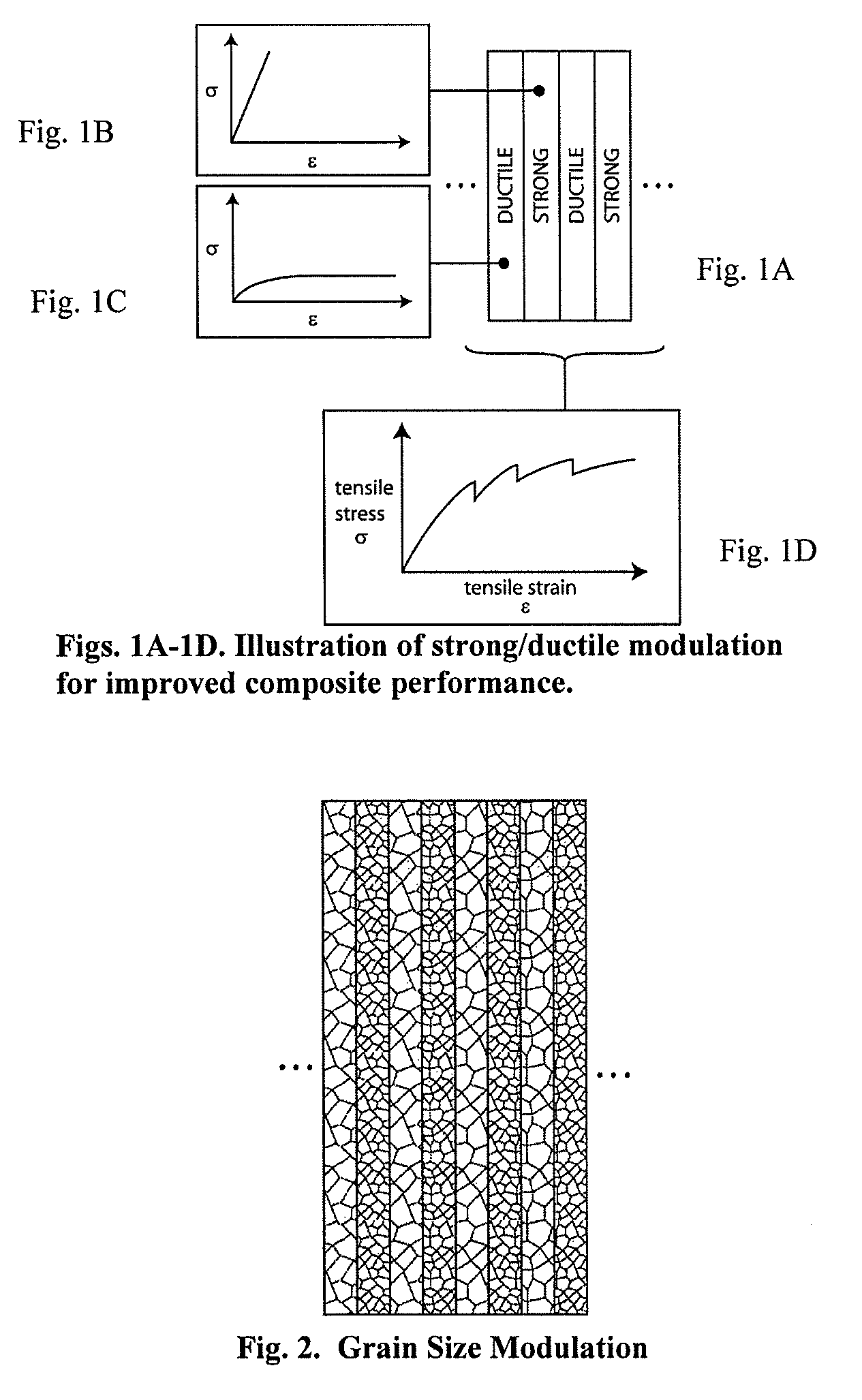

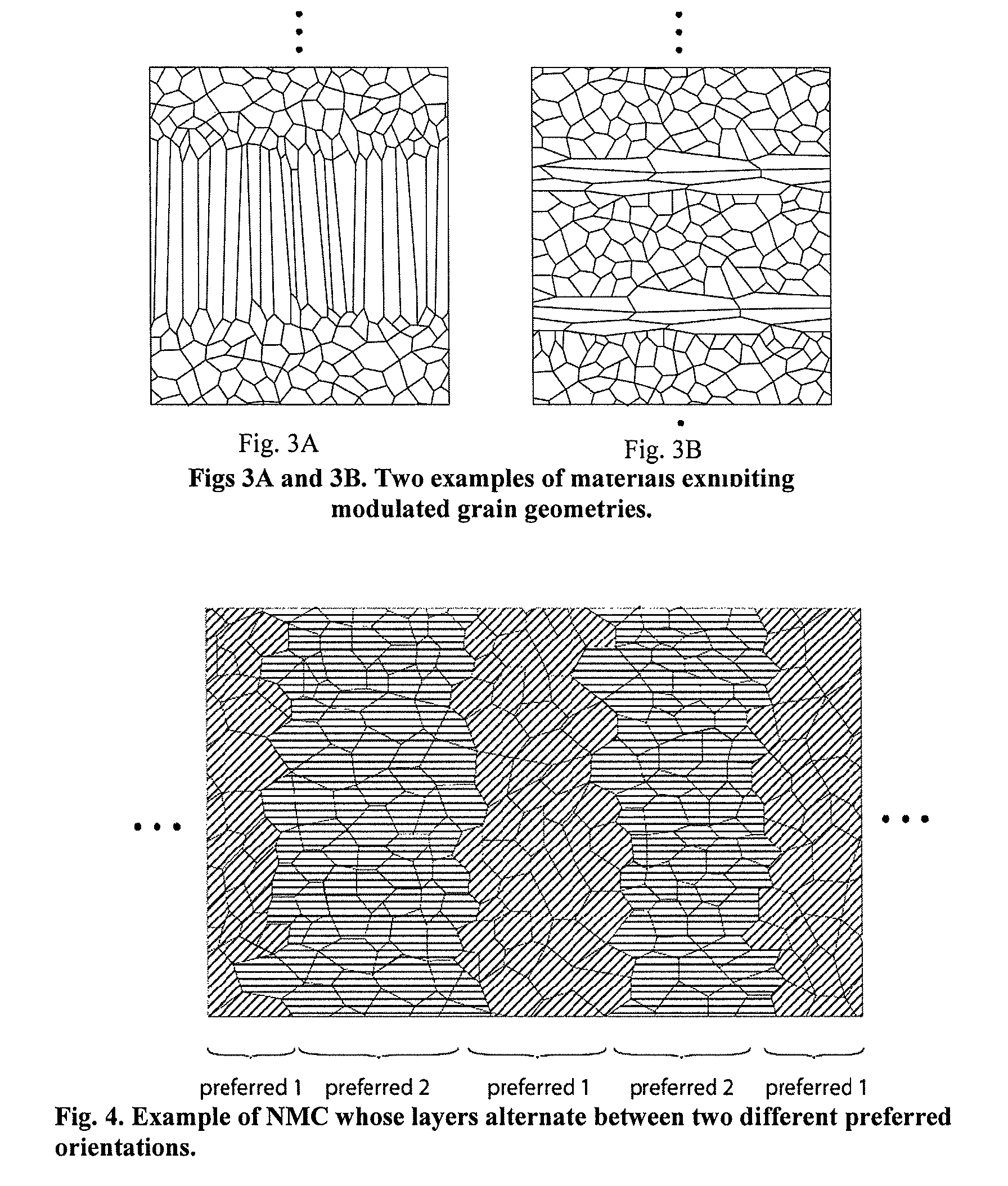

ActiveUS9234294B2Prevent crack propagationPromote growthCellsElectroforming processesCrystal orientationVolumetric Mass Density

Owner:MODUMETAL LLC

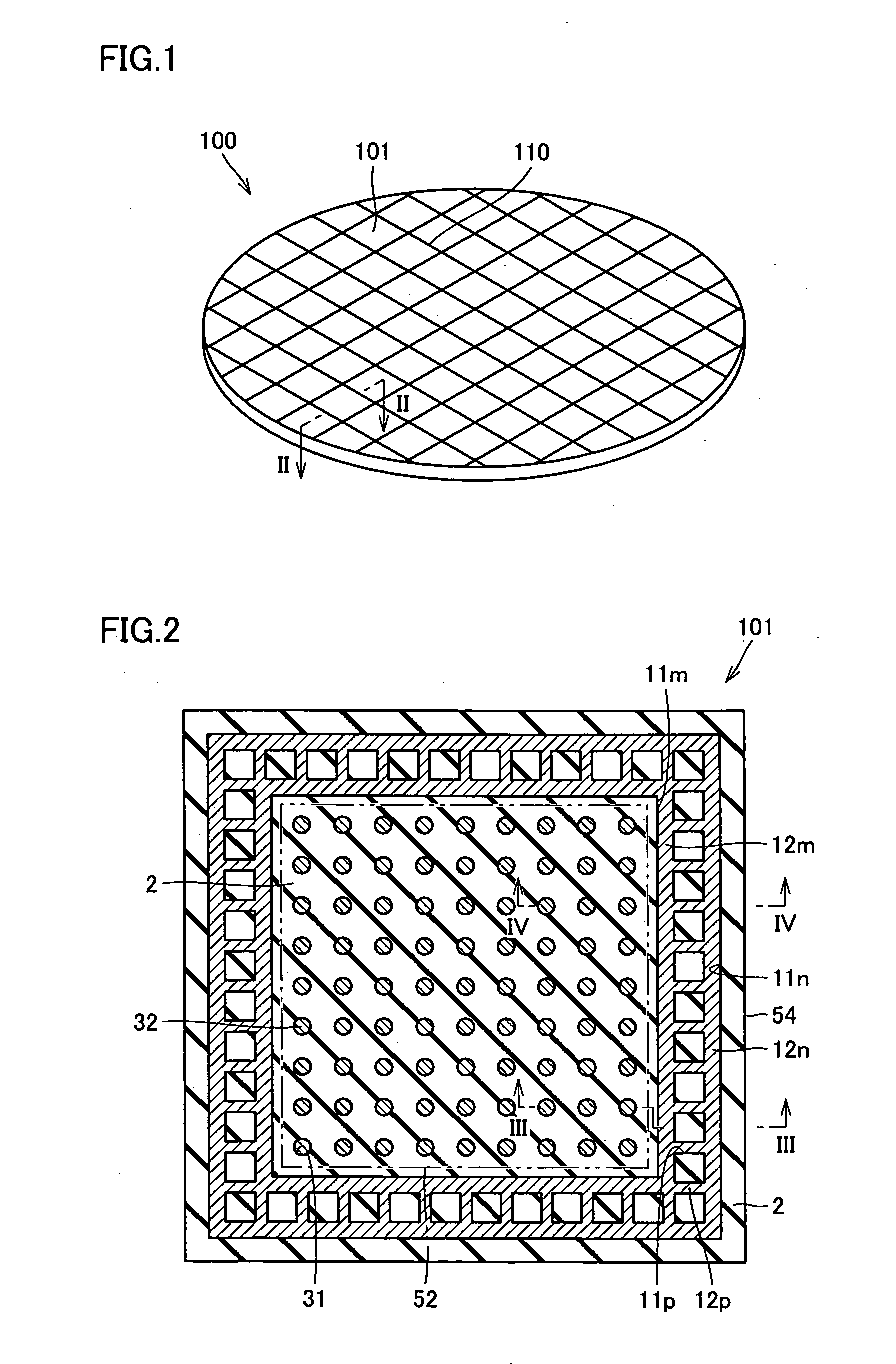

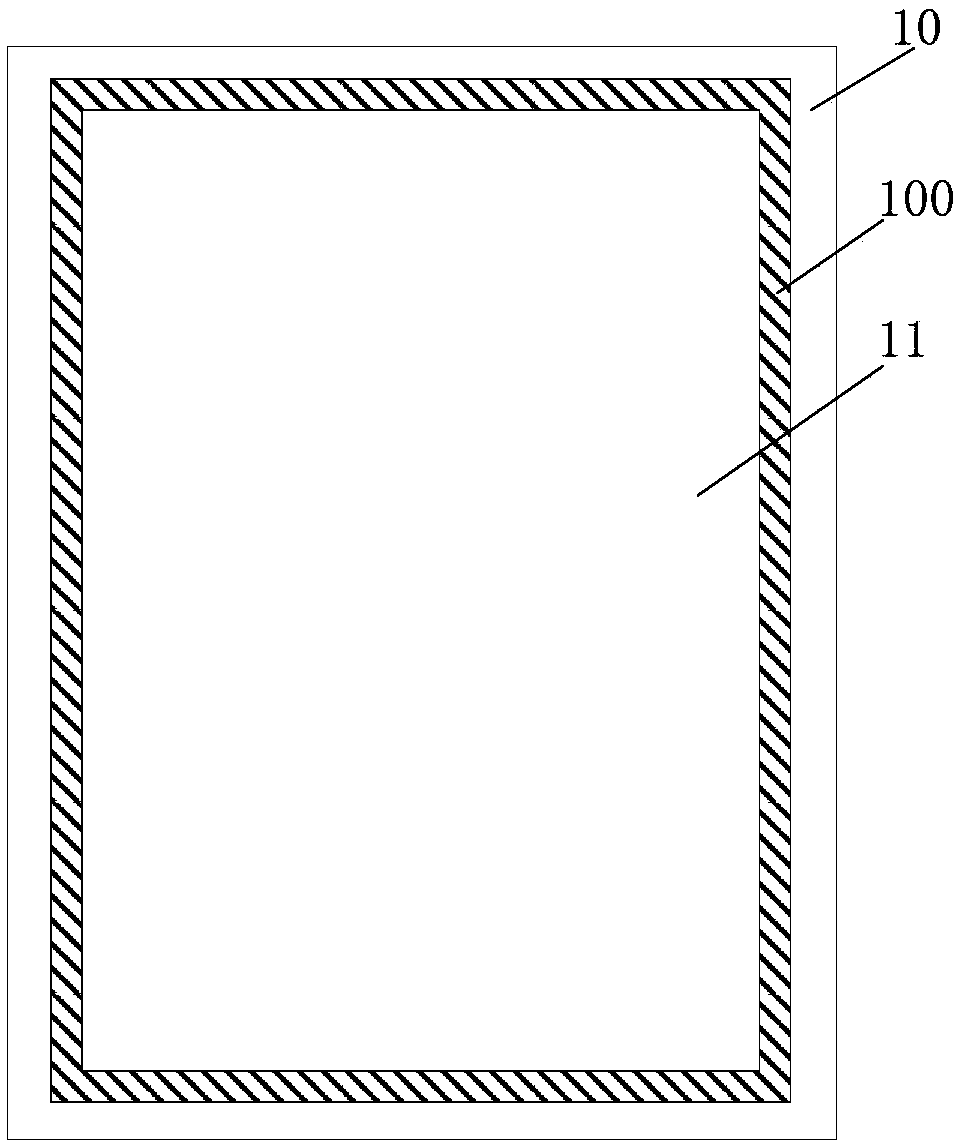

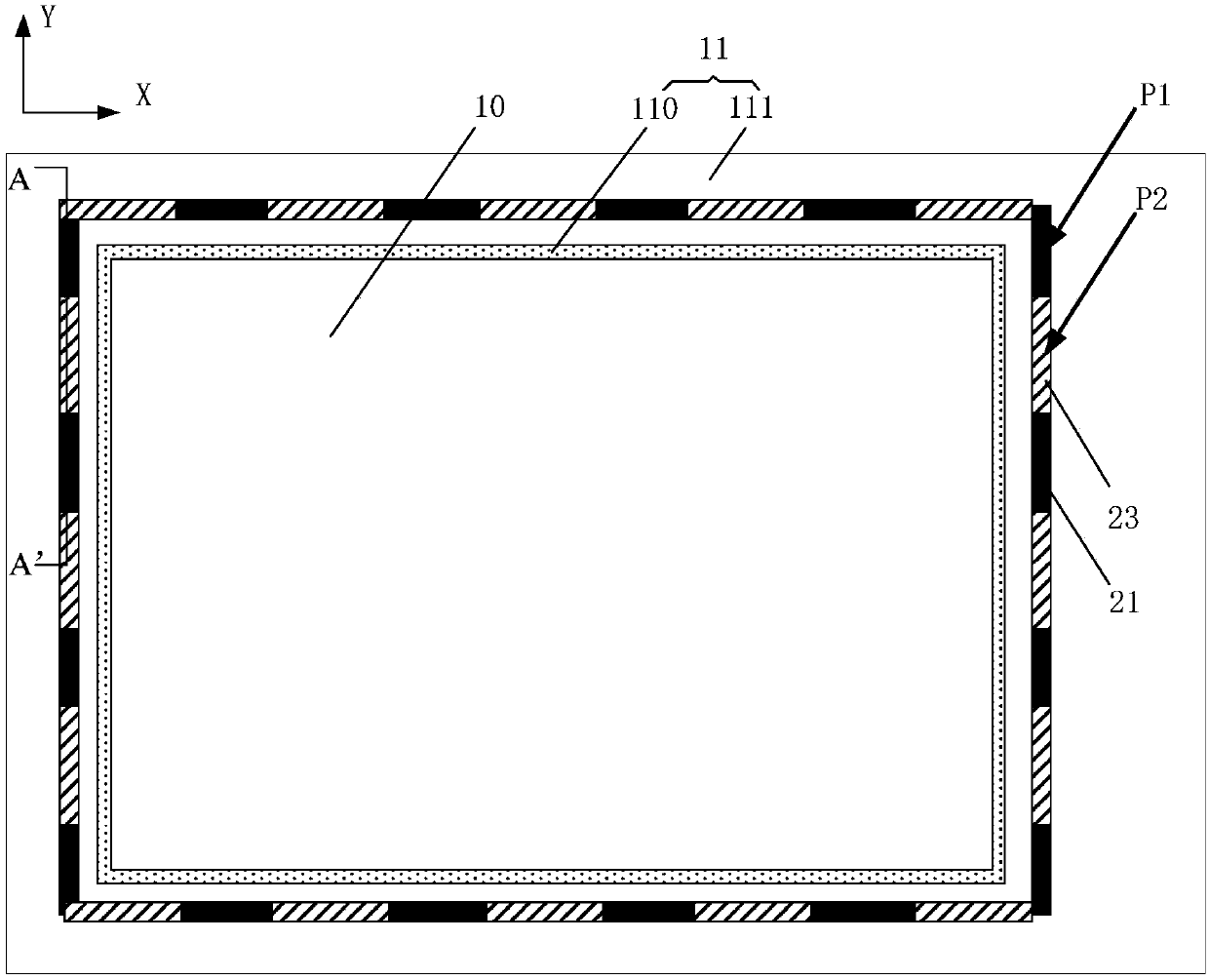

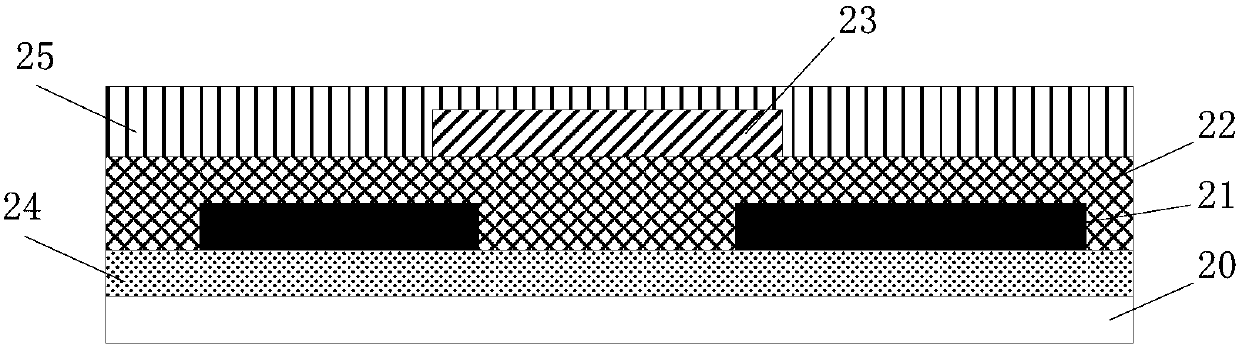

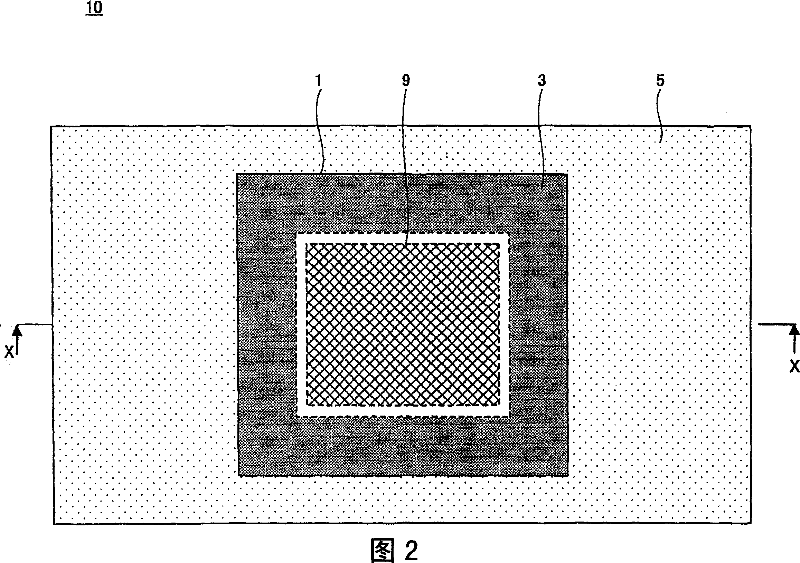

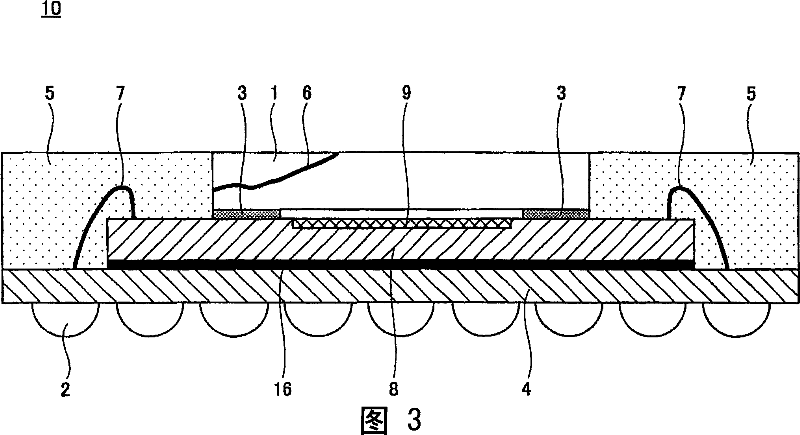

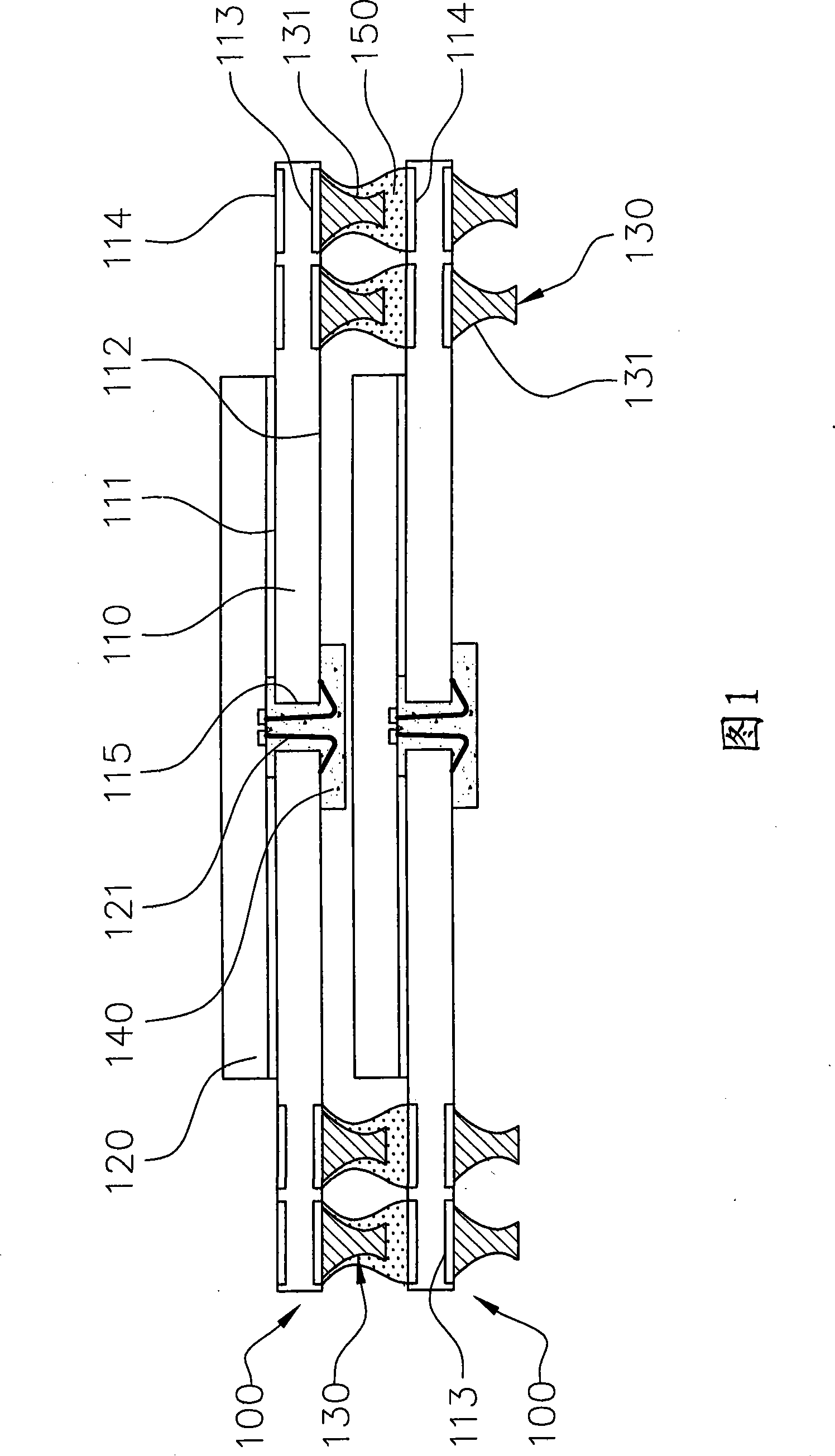

Array substrate, display panel and display device

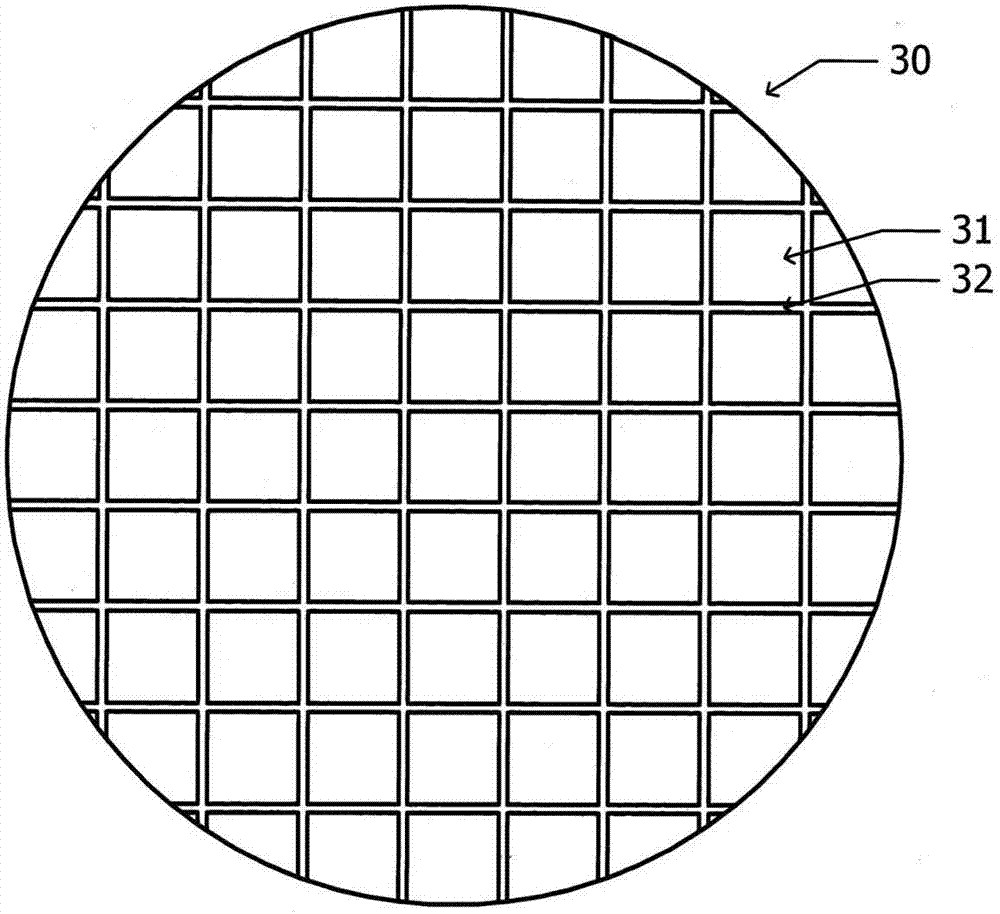

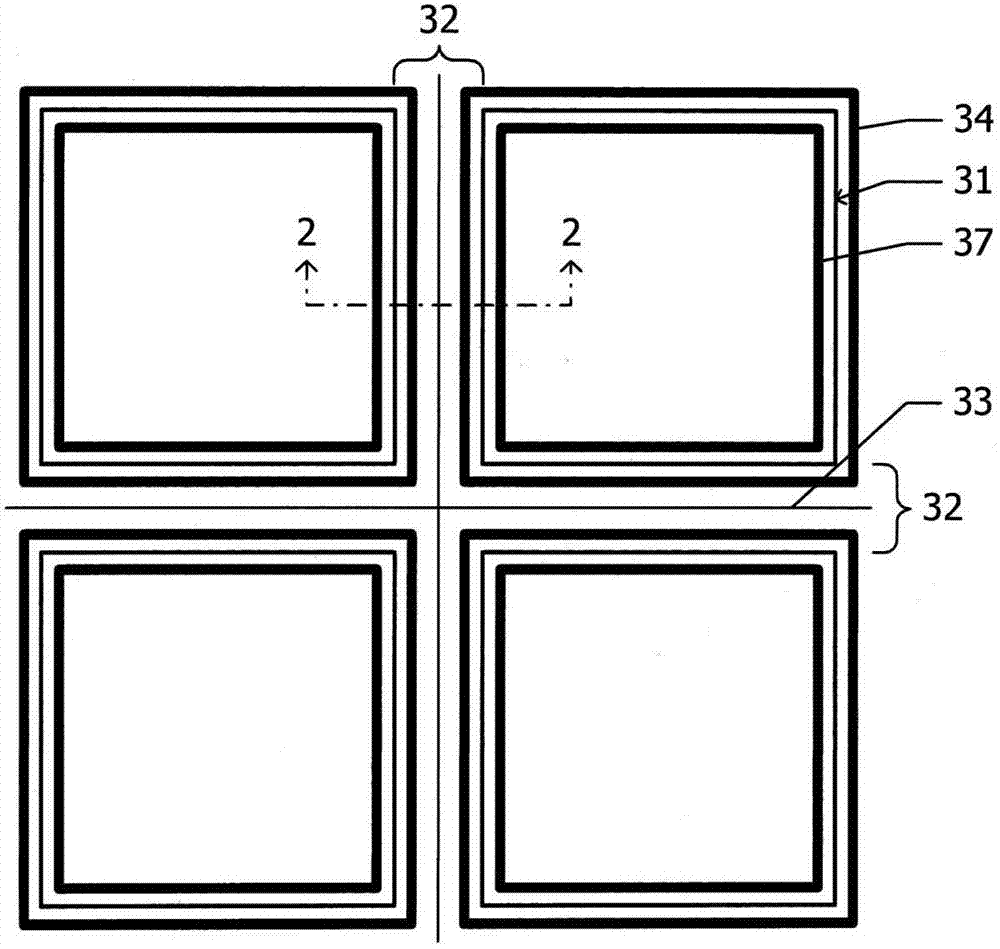

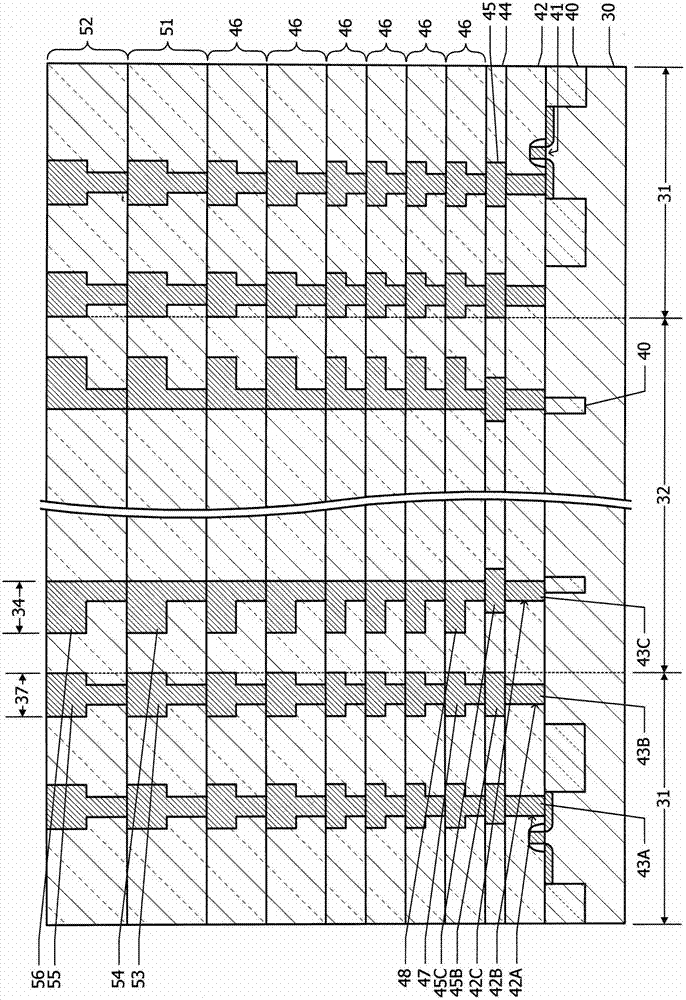

ActiveCN107863357APrevent crack propagationIncrease productivitySolid-state devicesSemiconductor devicesDisplay deviceFlexible display

The invention discloses an array substrate, a display panel and a display device. The array substrate includes a display area and a non-display area around the display area. The non-display area includes a peripheral circuit area and an edge area. The peripheral circuit area surrounds the display area, and the edge area surrounds the peripheral circuit area. The array substrate includes a substrate, at least one first protective figure arranged on the substrate at intervals, a first inorganic layer arranged on the substrate and the at least one first protective figure, and at least one secondprotective figure arranged on the first inorganic layer at intervals. The at least one first protective figure and the at least one second protective figure are located in the edge area. The orthographic projections of the geometric centers of the first protective figures in the plane of a flexible display plane do not overlap the orthographic projections of the geometric centers of the second protective figures in the plane of the flexible display plane. By using the array substrate, the problem of crack diffusion during display panel cutting can be prevented, and the production efficiency ofthe display panel can be enhanced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

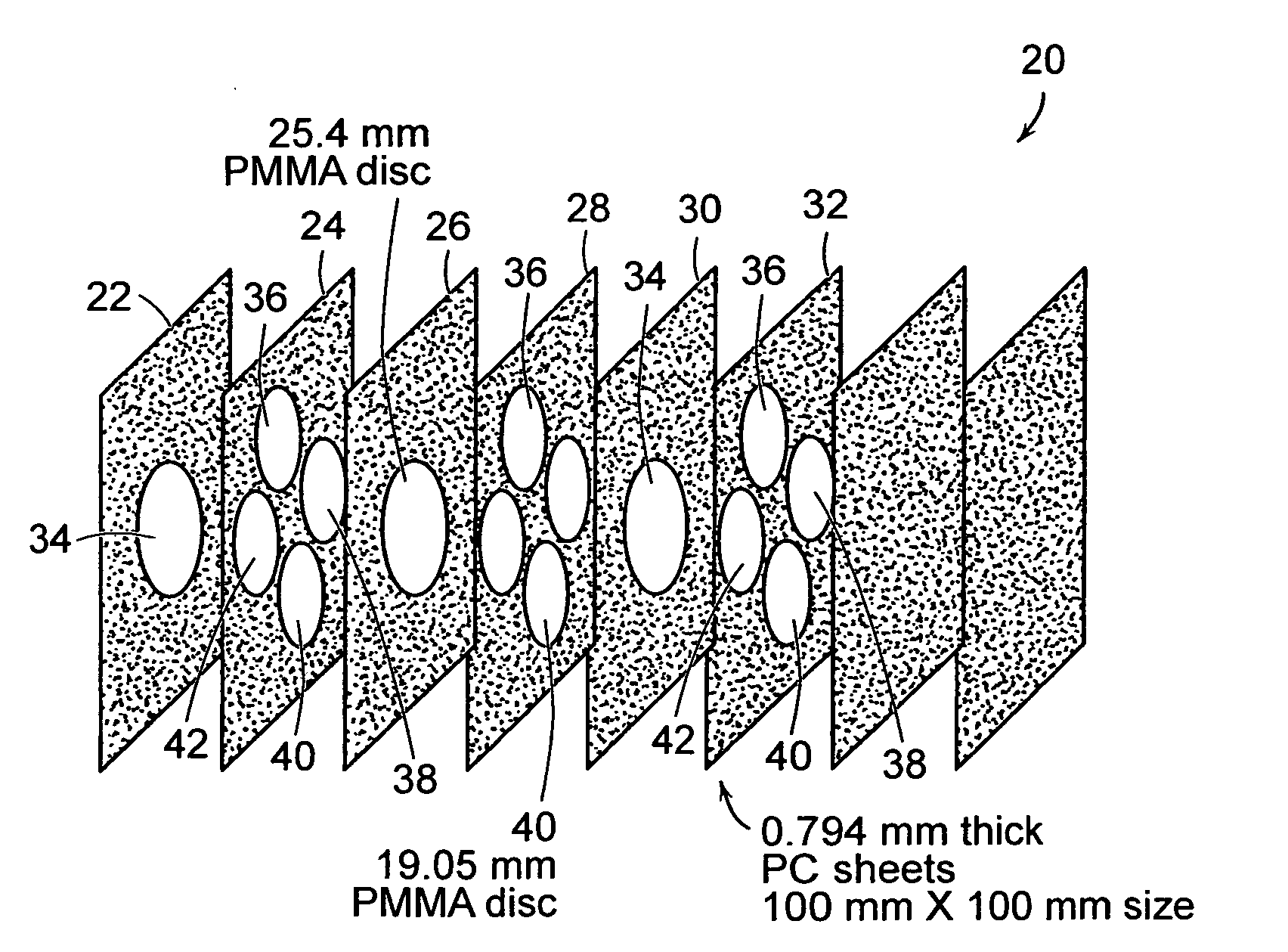

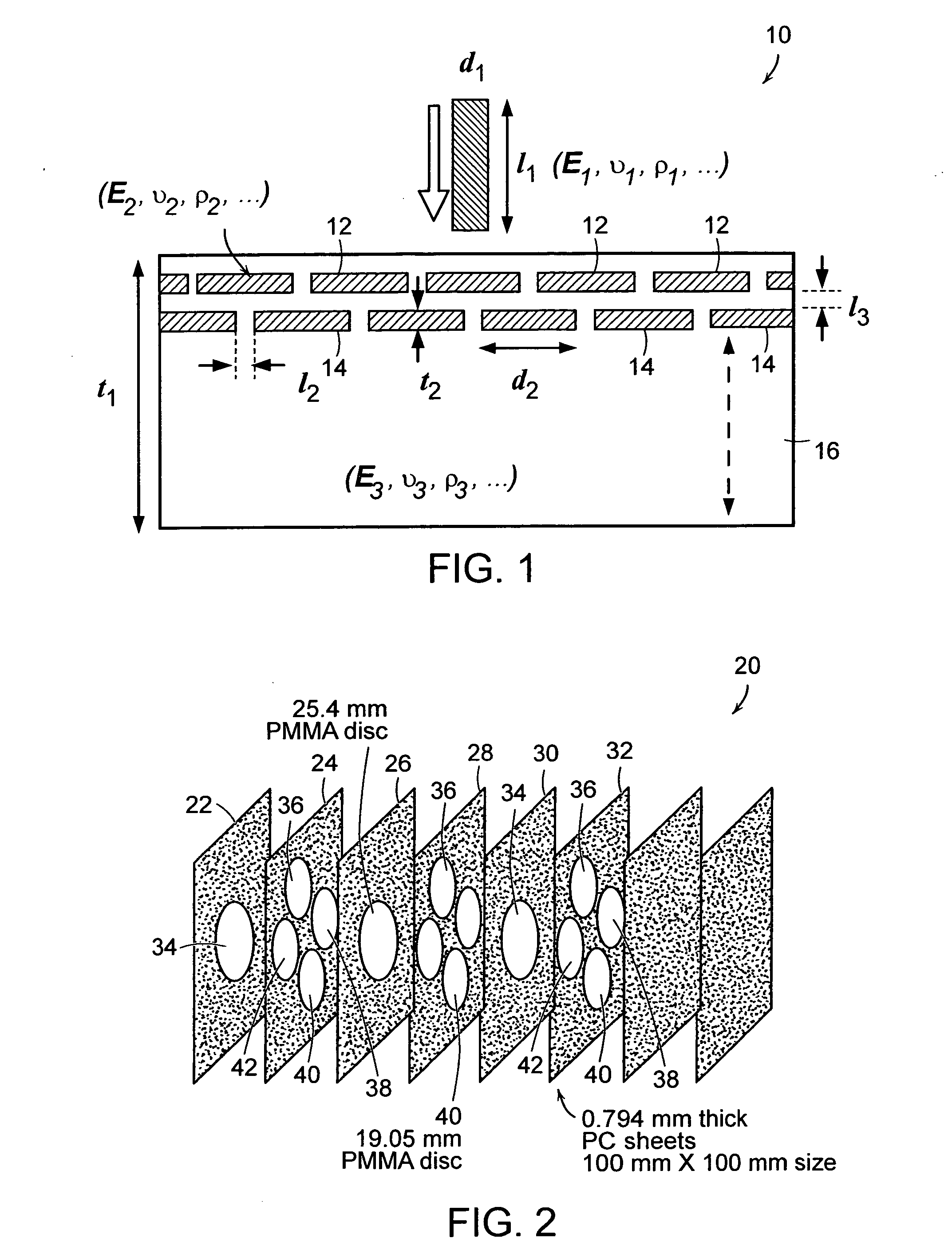

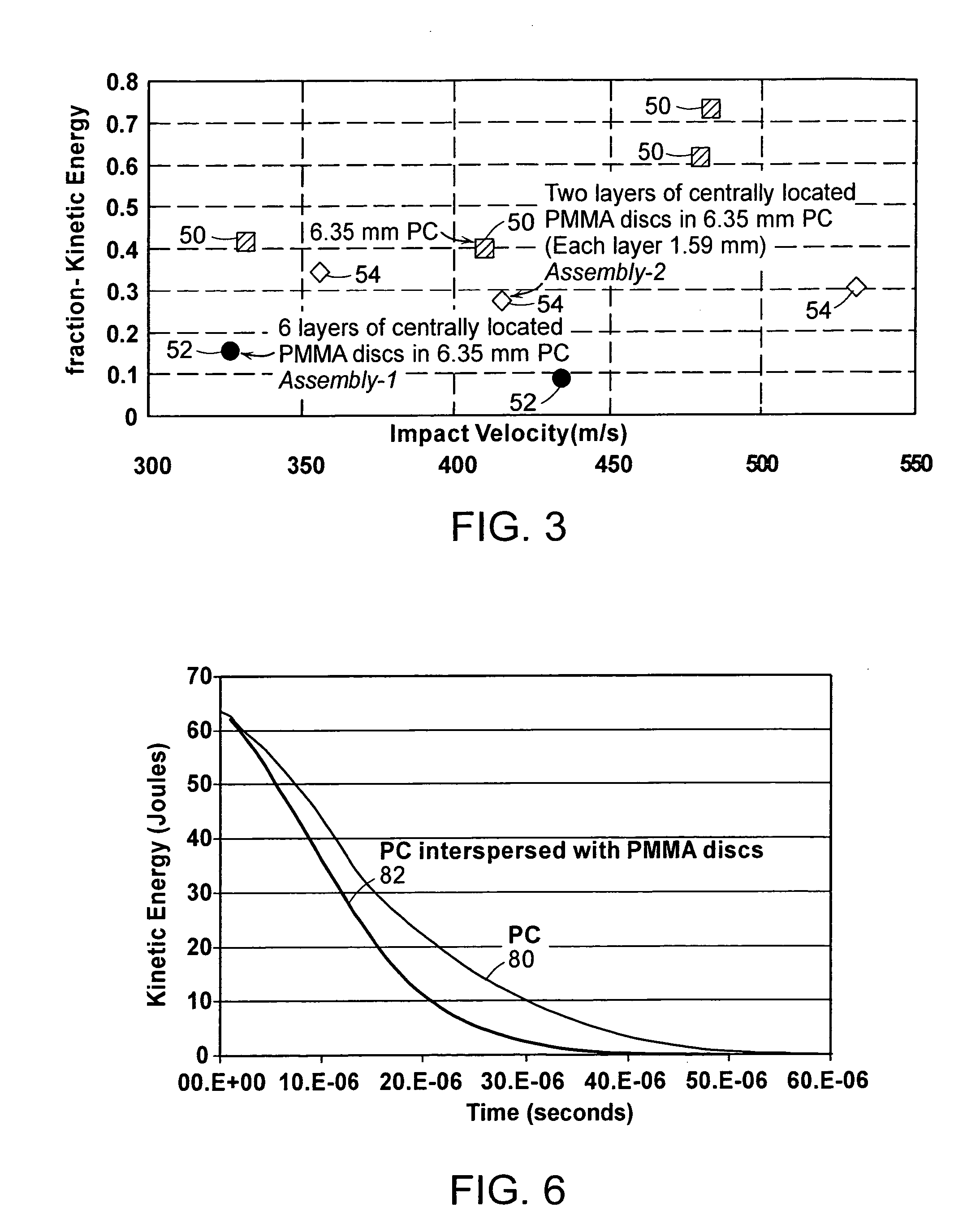

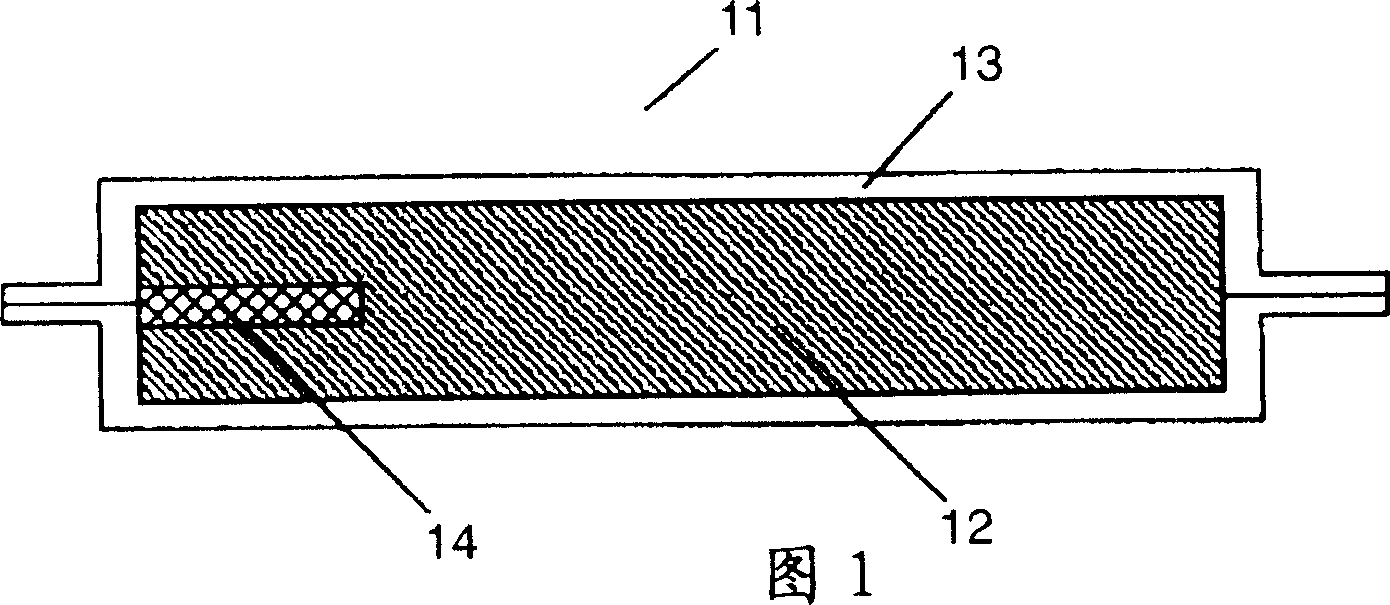

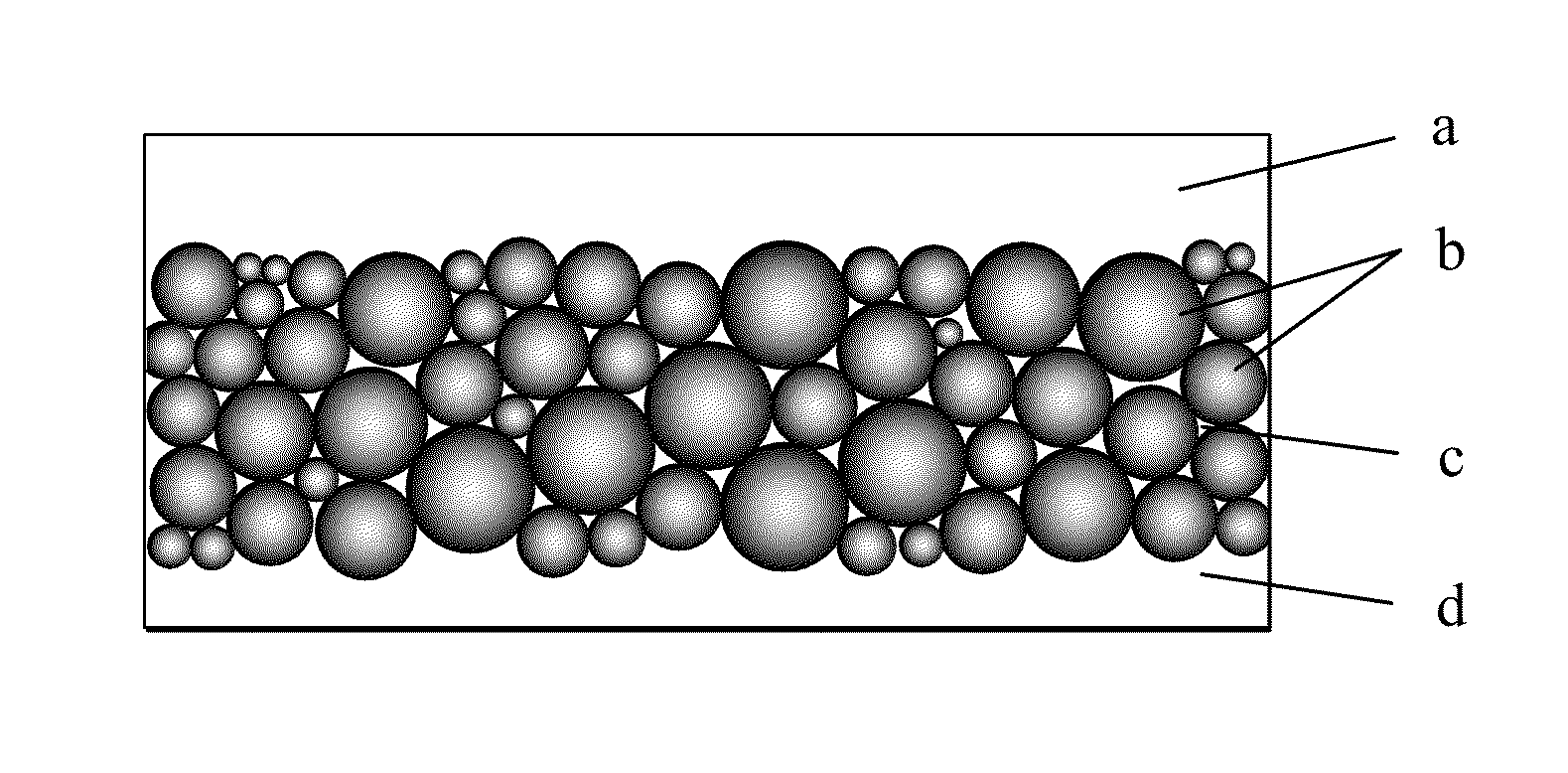

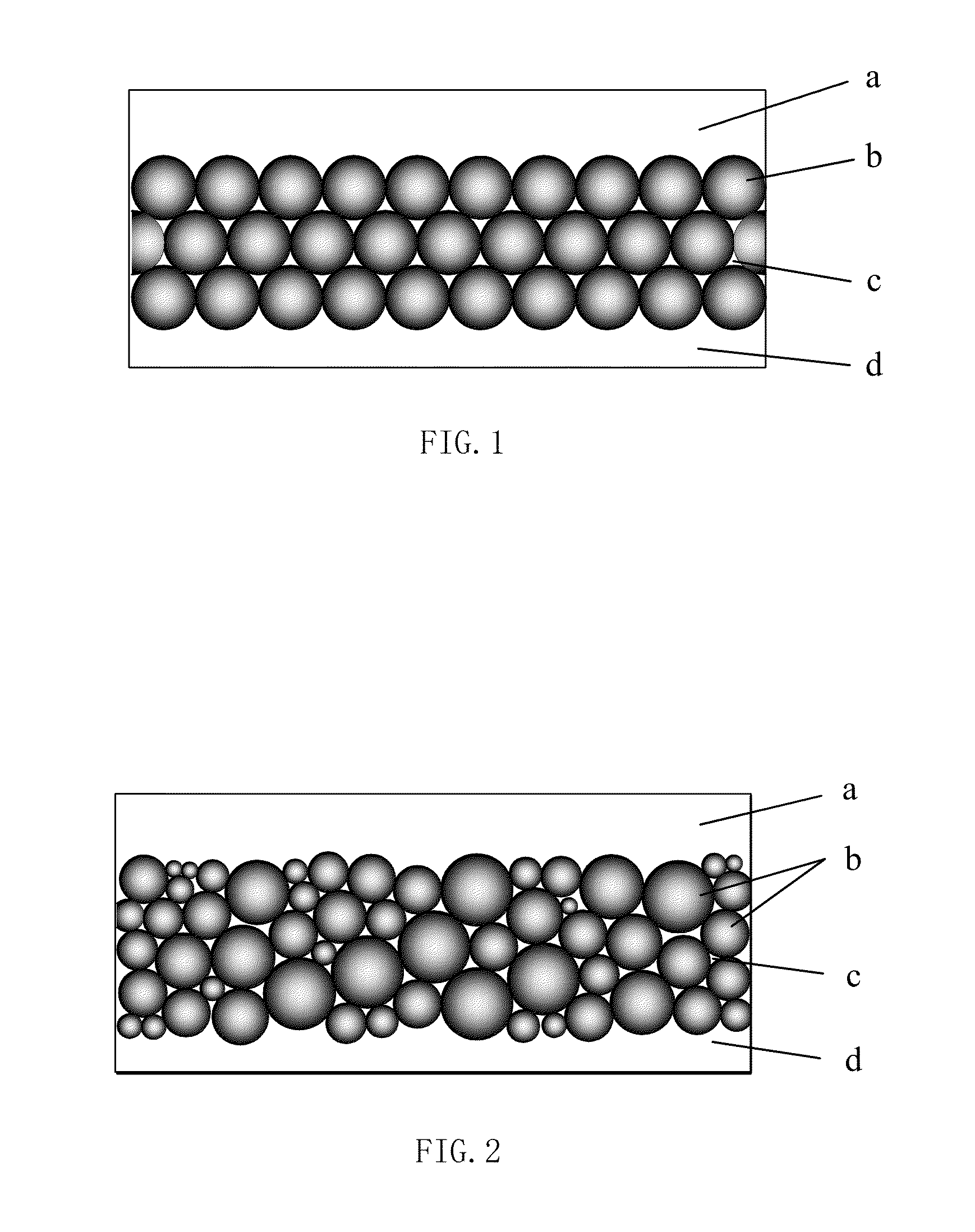

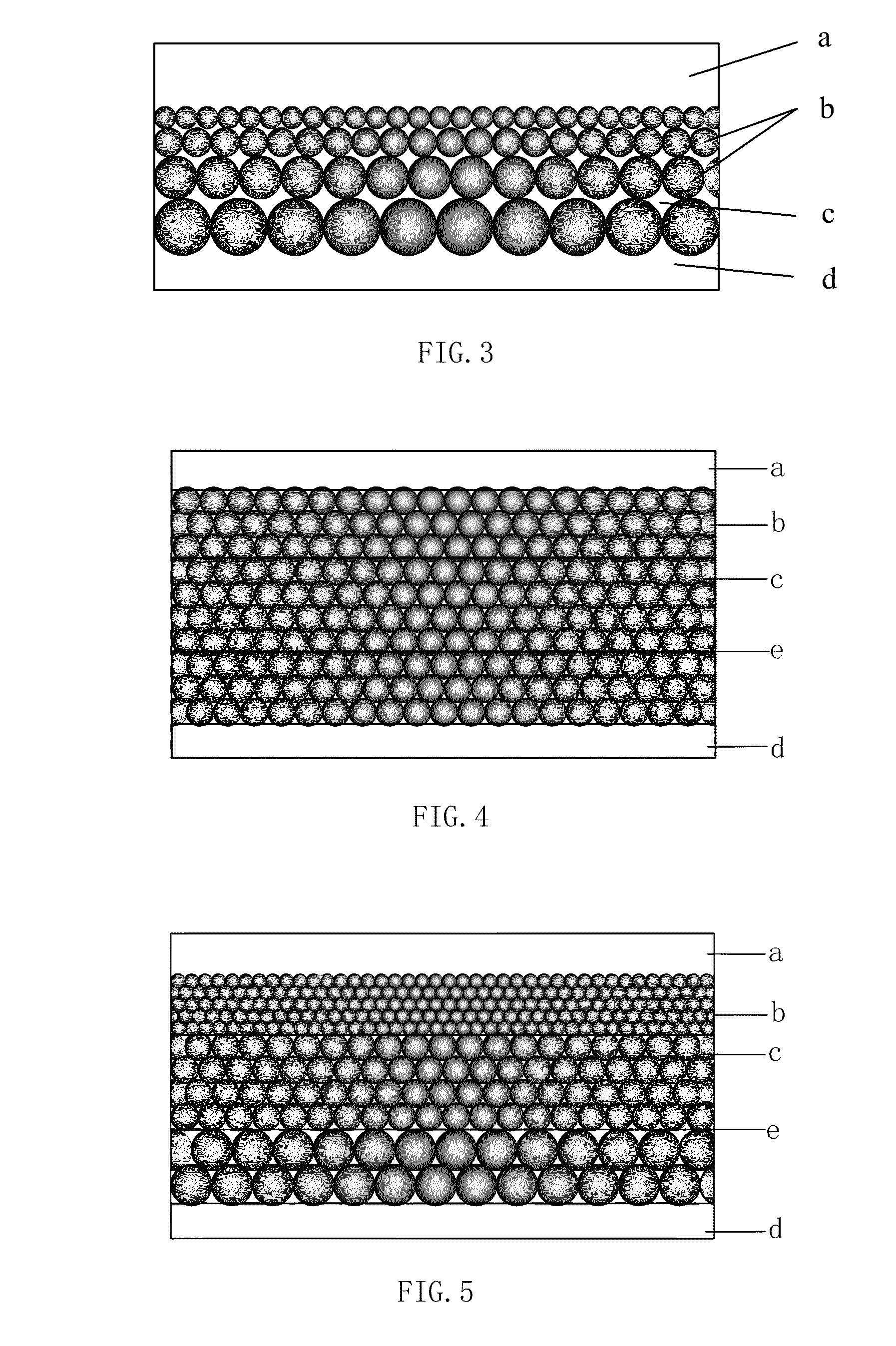

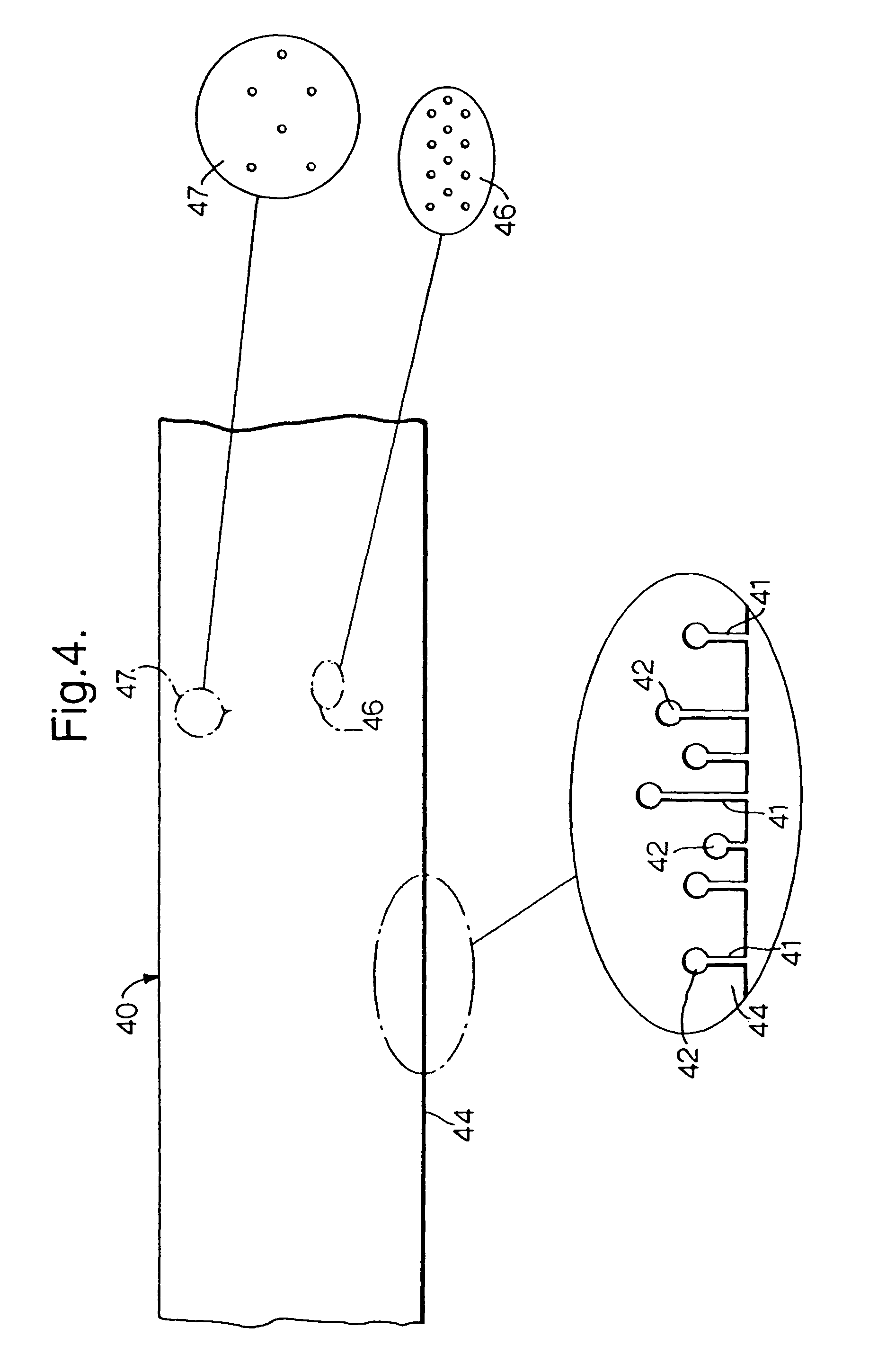

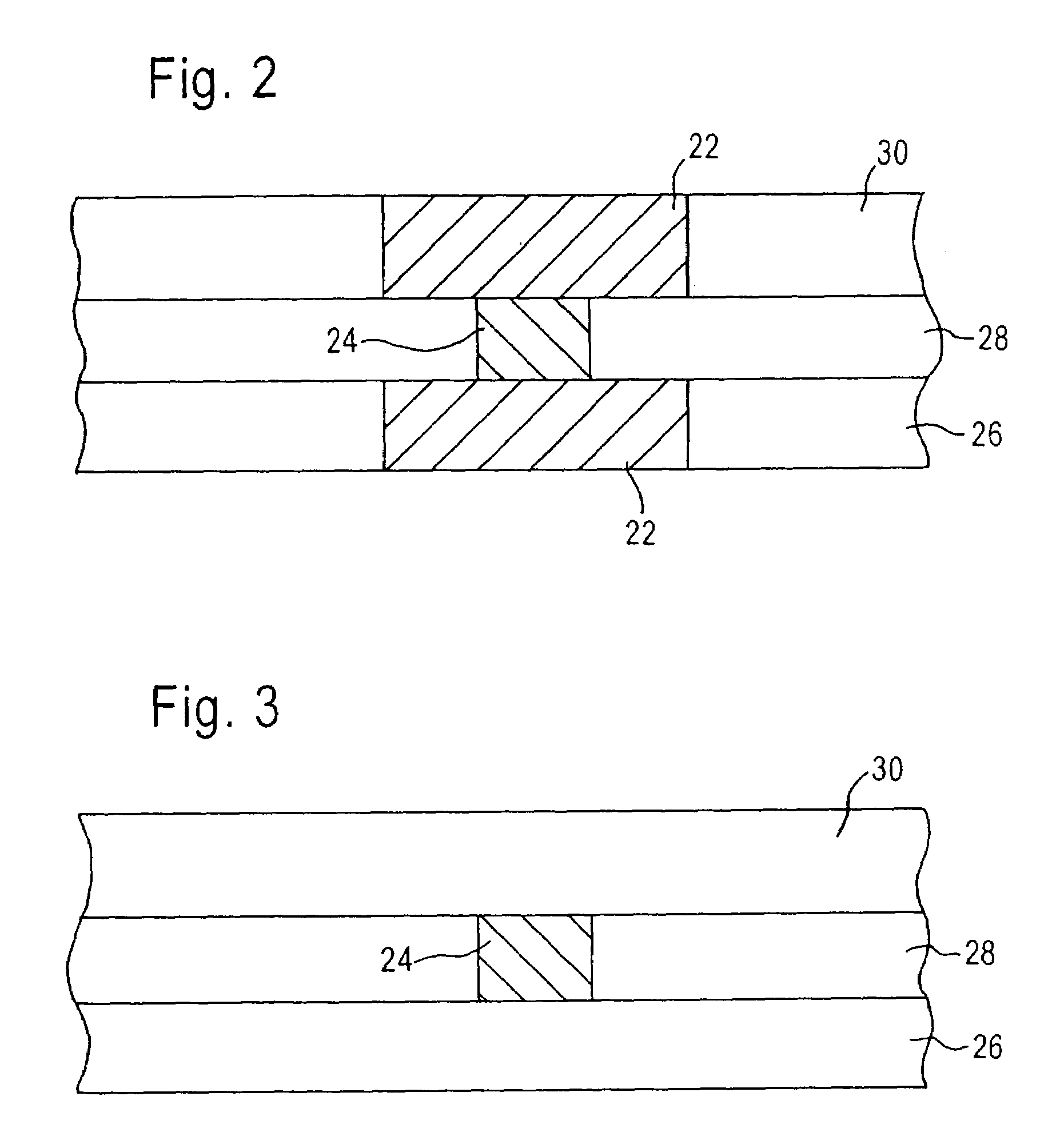

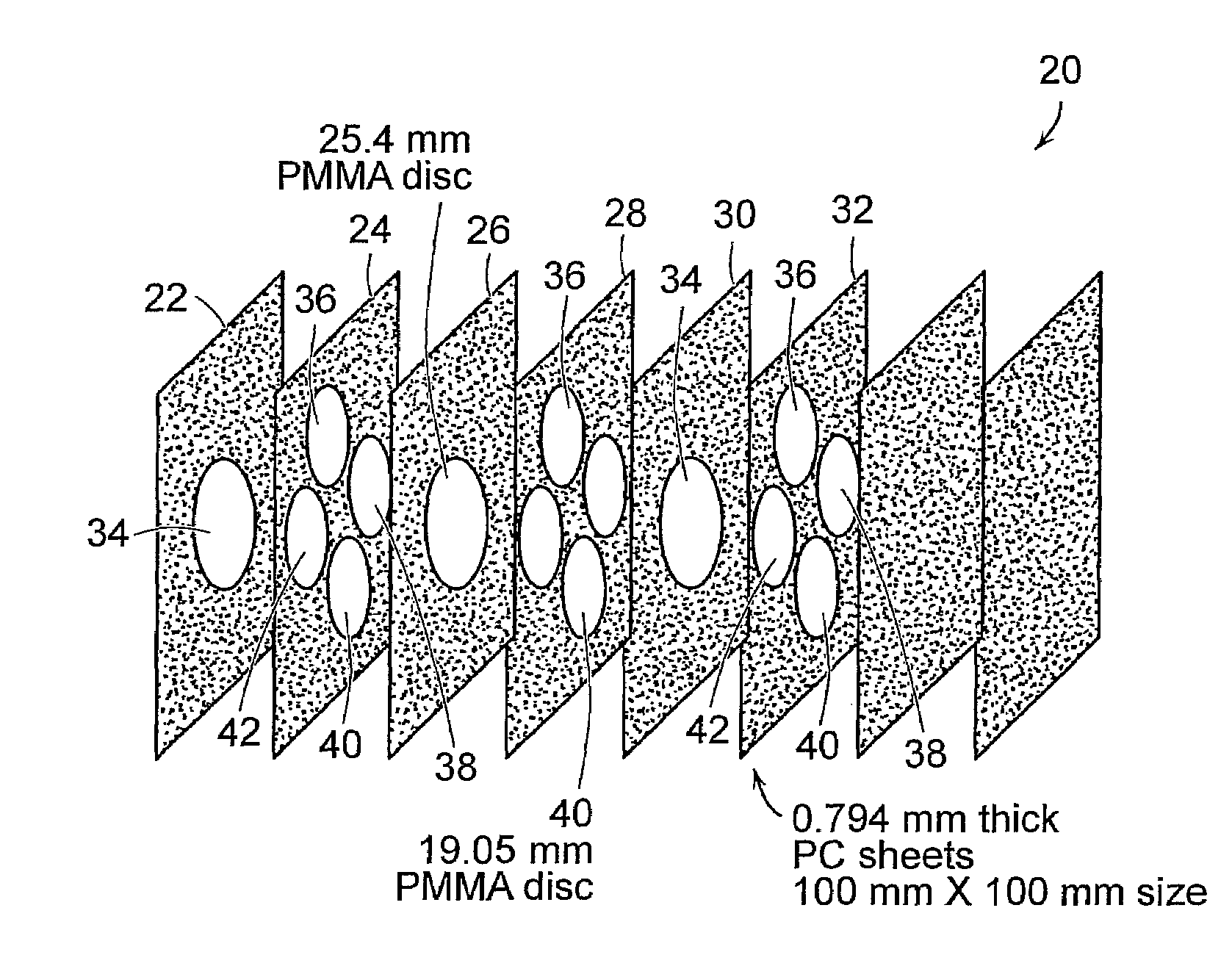

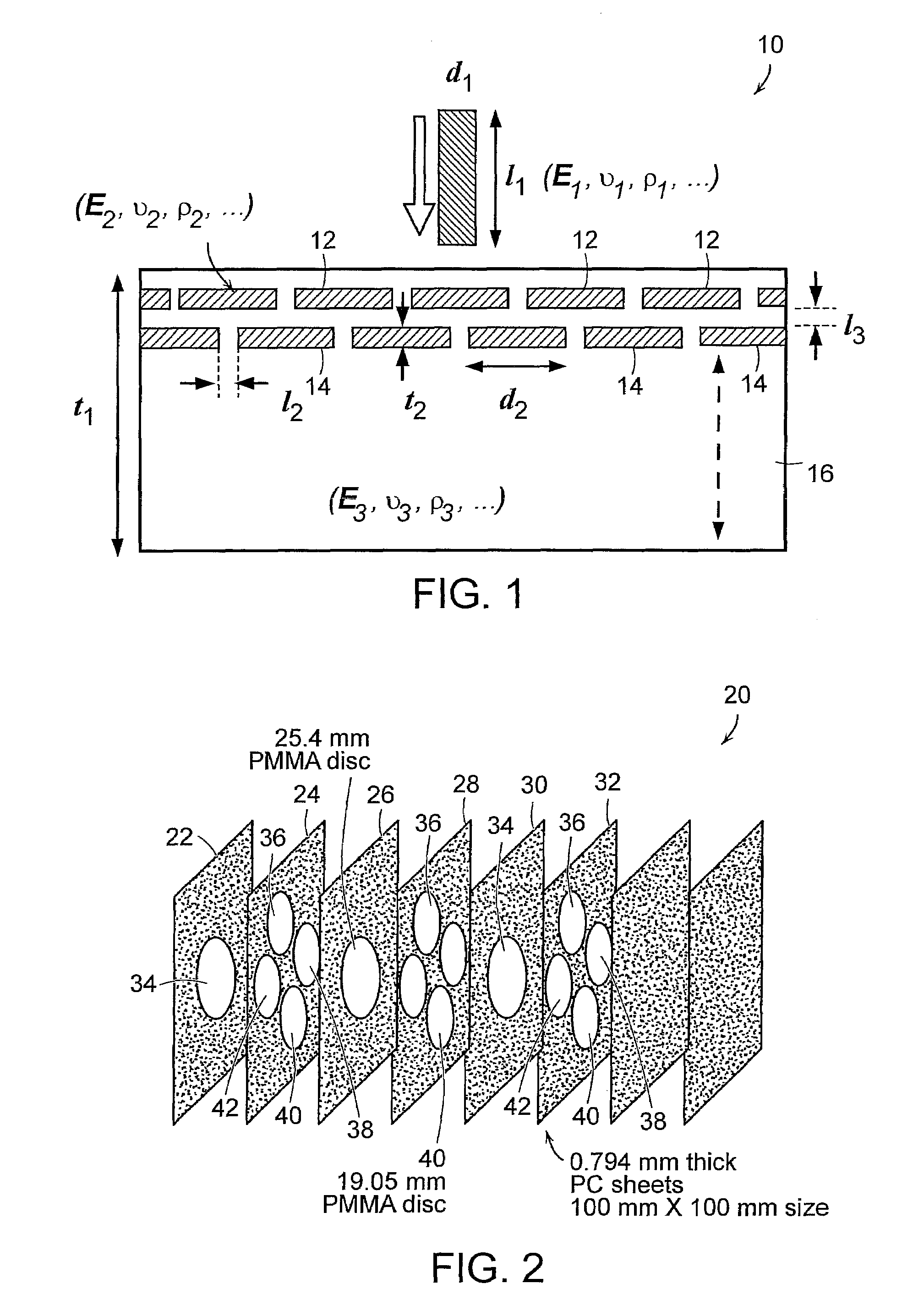

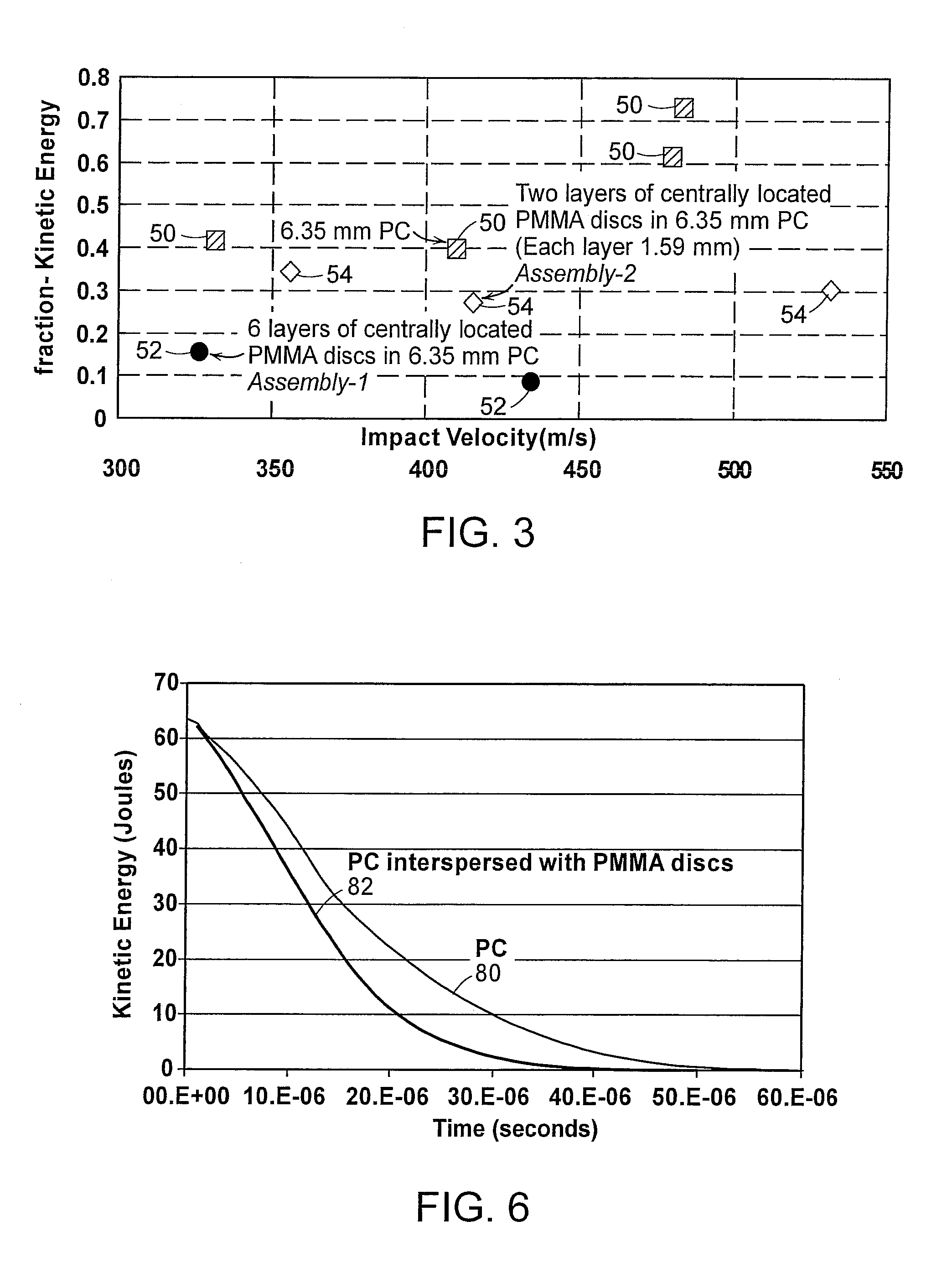

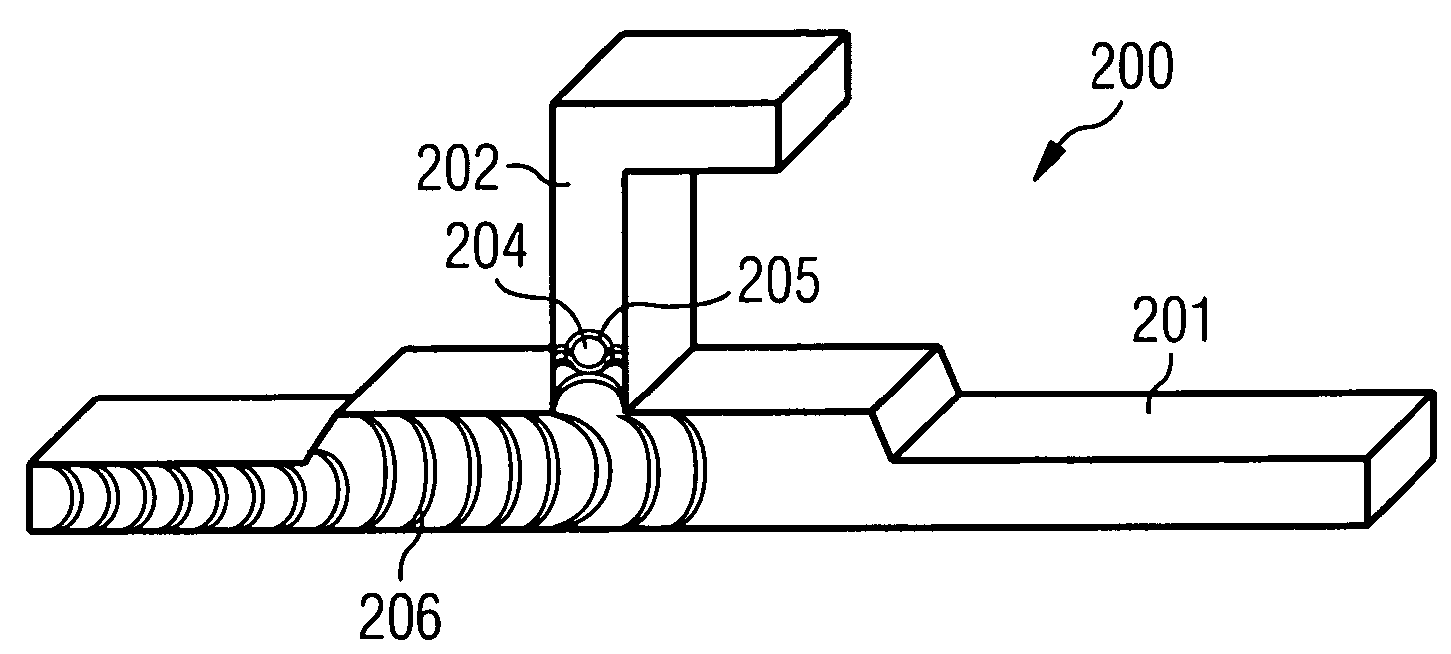

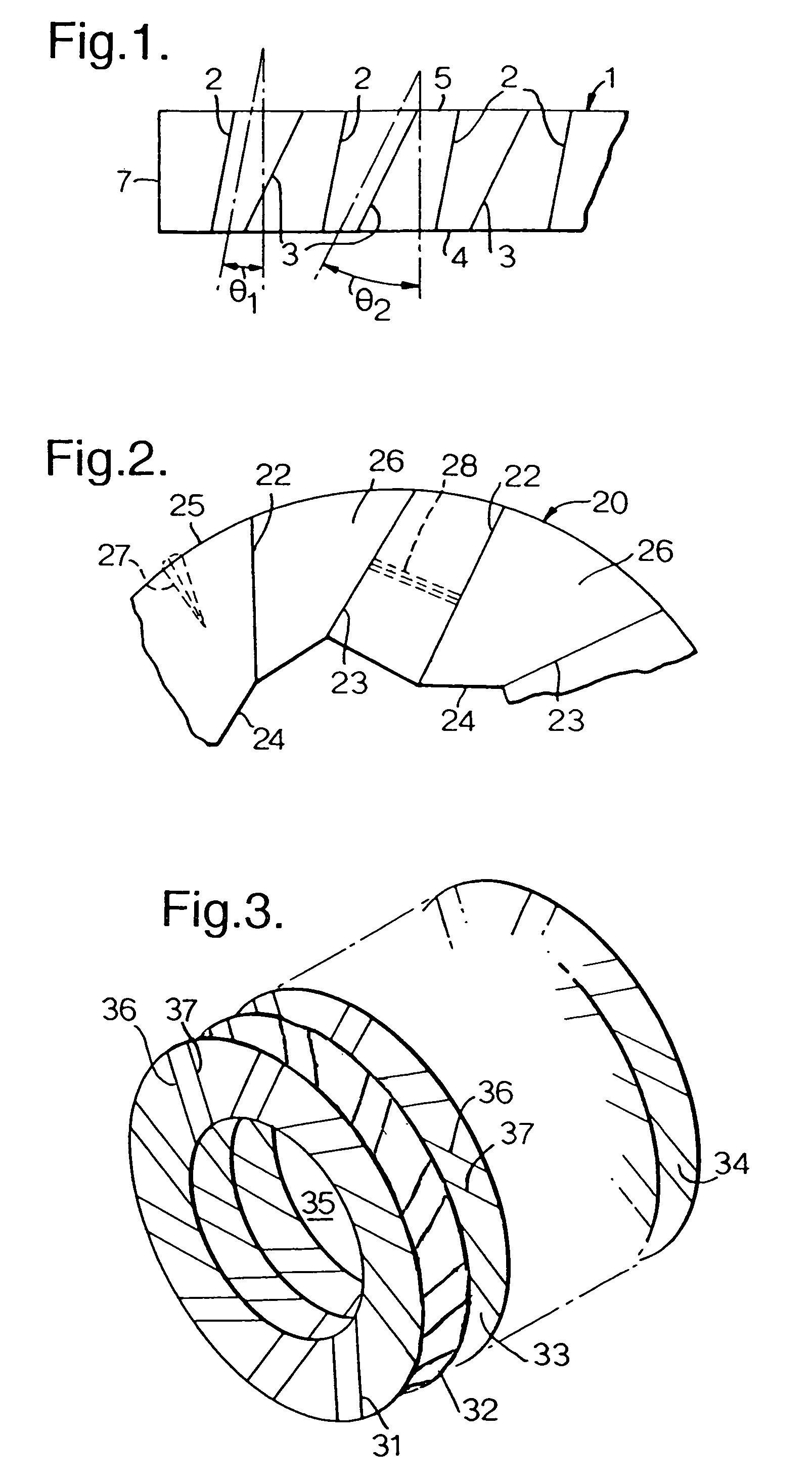

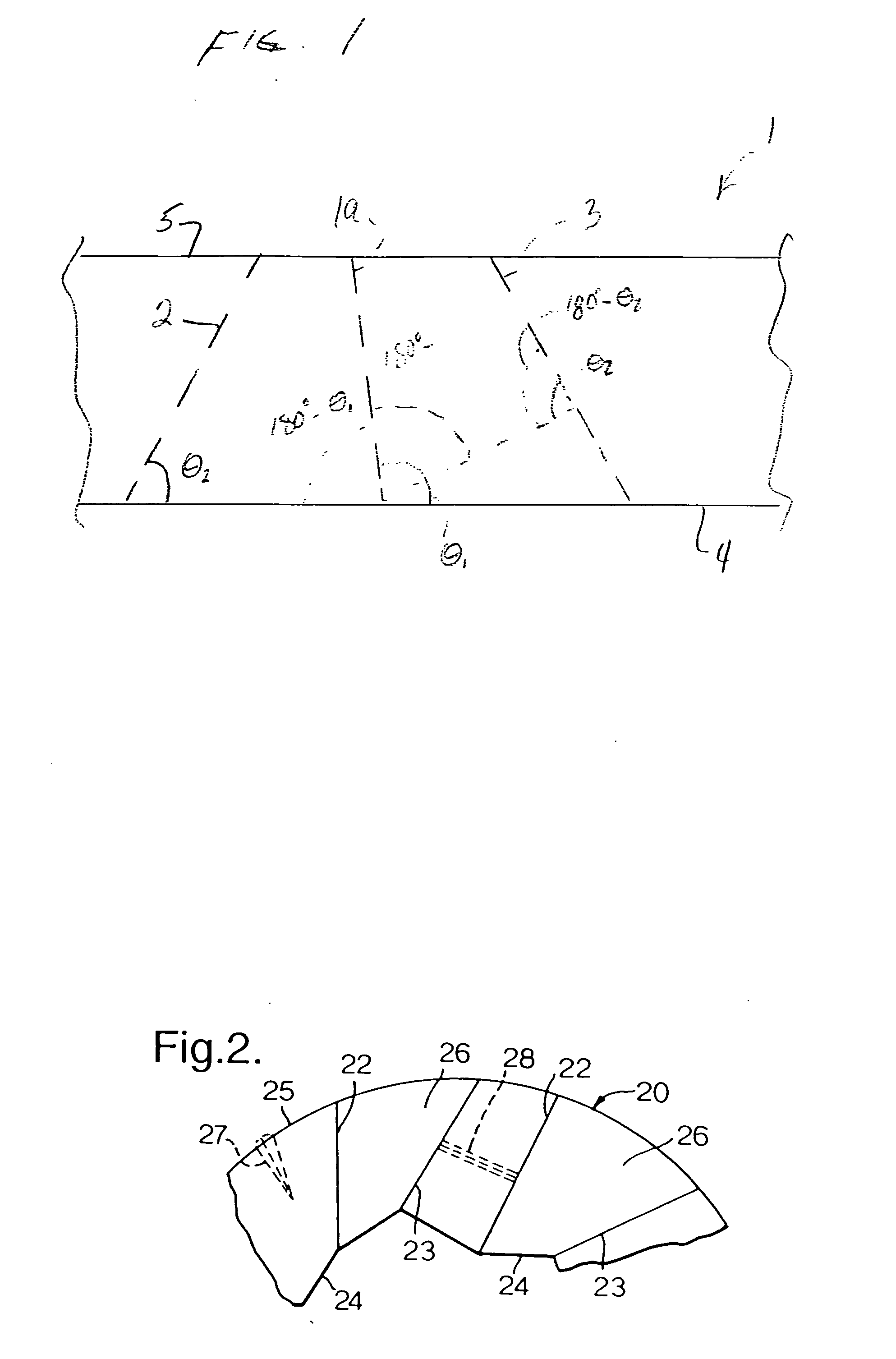

Hierarchical material assemblies and articles for use in projectile impact protection

InactiveUS20060249012A1Dissipate energyPrevent crack propagationPersonal protection gearArmour platesEngineeringProjectile

A hierarchical composite armor is disclosed for protection against projectile impact comprising a plurality of platelets and a matrix substrate. The plurality of platelets are distributed in at least a first layer and in a second layer parallel to the first layer wherein the distribution of the platelets in the second layer is at least slightly offset from and overlaps the distribution of platelets in the first layer. The platelets are less thick than the overall thickness of the composite armor, and the platelets include a first material. The matrix substrate encapsulates the platelets, and the matrix substrate is different than the first material. The platelets and matrix substrate form an interactive network that dissipates a projectile's impact energy over an area much greater than the size of the projectile by synergistically transmitting the impact energy from platelets close to an impact location to platelets away from the impact location. The failure is localized to the primary interaction zone between the projectile and the platelets and matrix substrate. The geometry and distribution of the platelets is tailored to optimize the kinetic energy absorption by the composite armor.

Owner:MASSACHUSETTS INST OF TECH

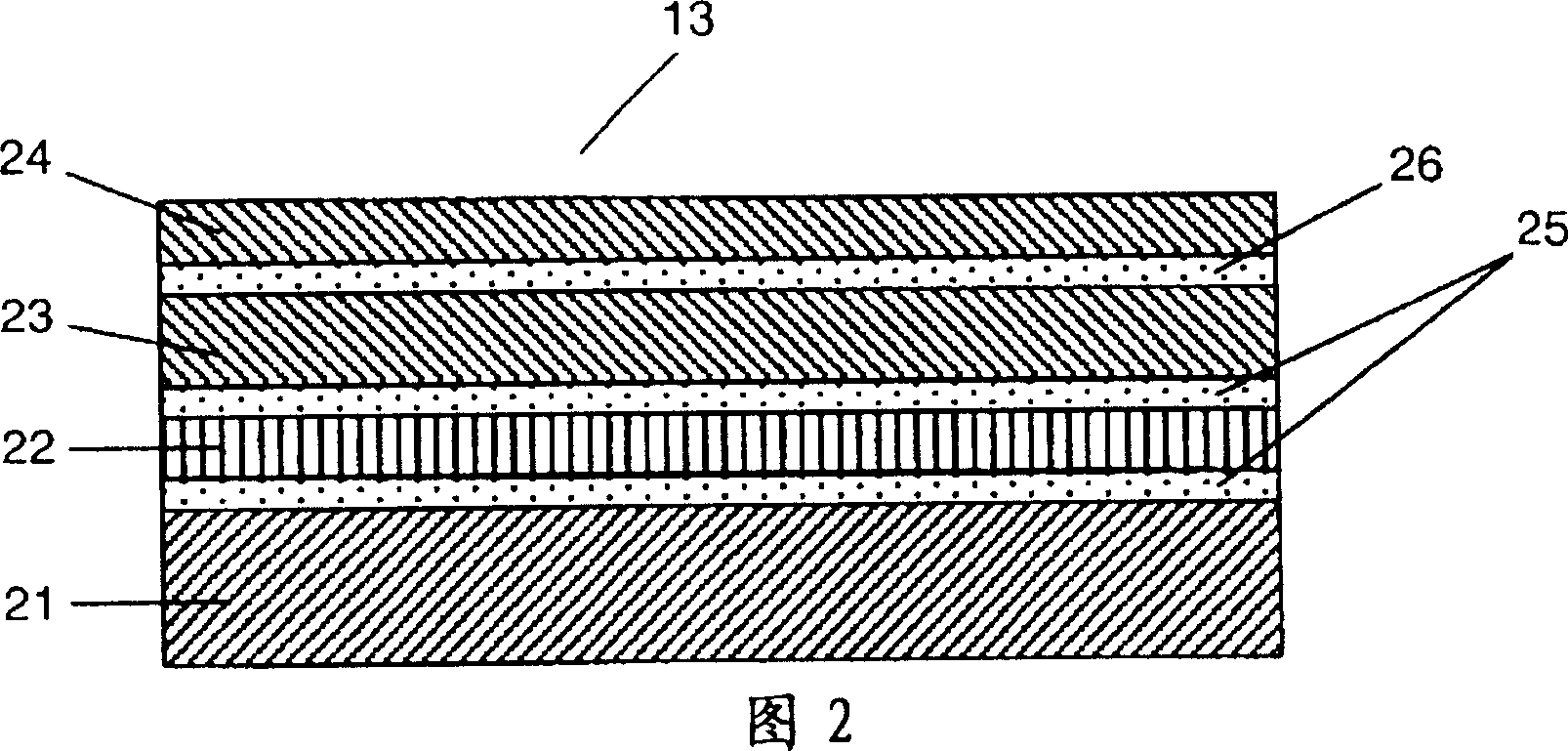

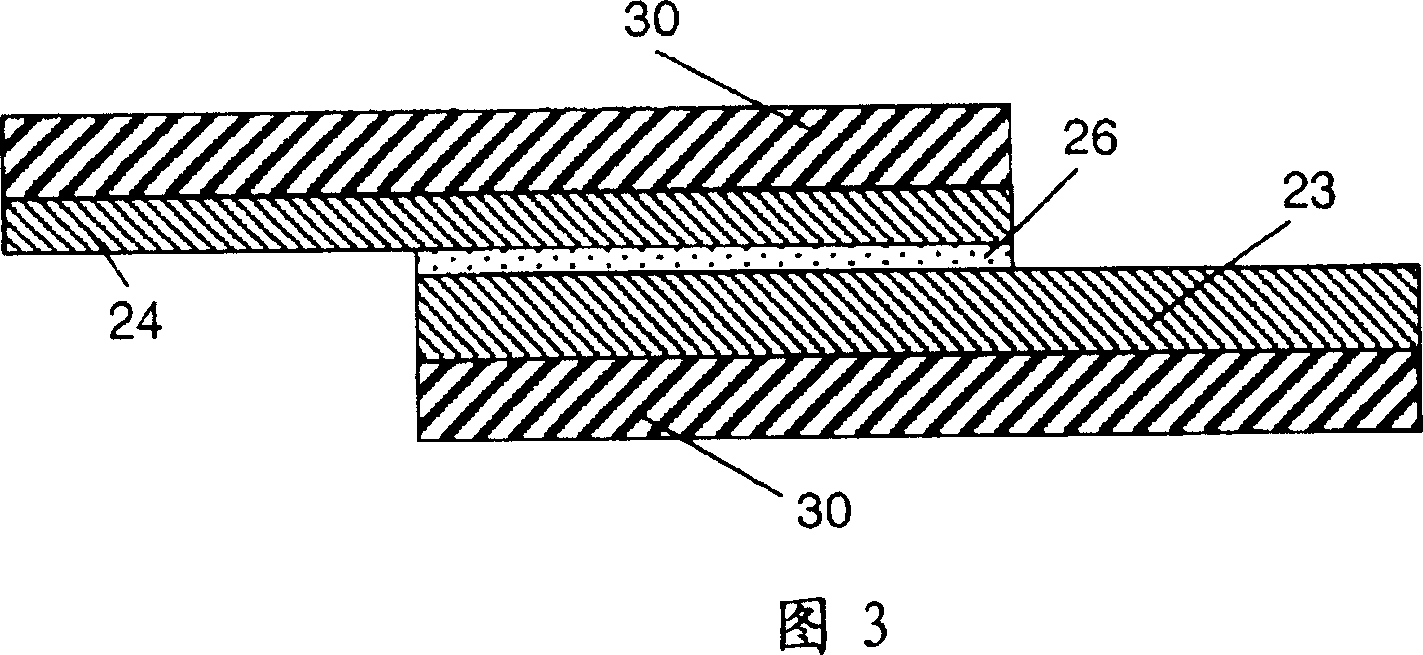

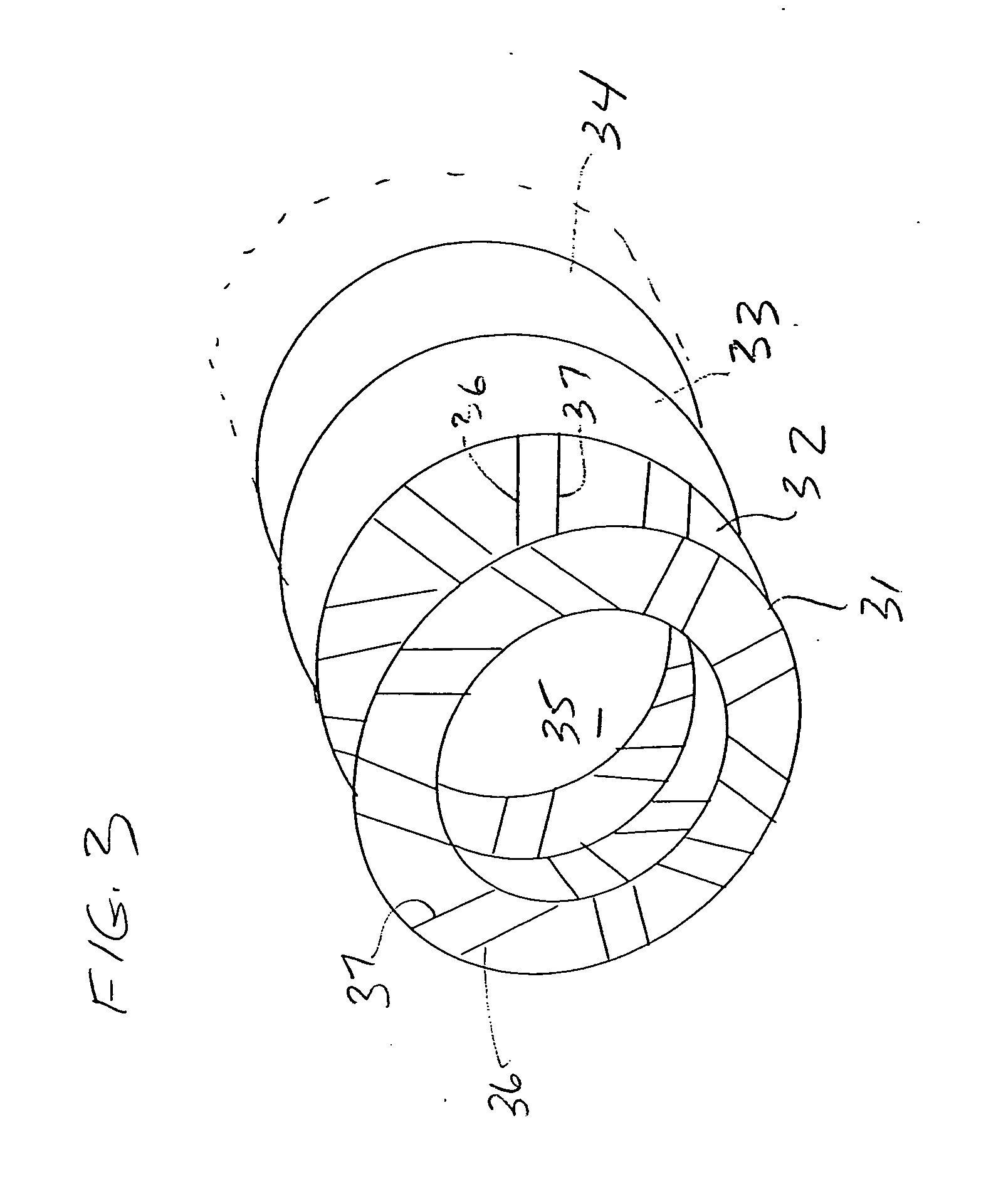

Vacuum heat insulation material and cold reserving apparatus with the same

ActiveCN1961175APrevent crack propagationPrevent penetrationThermal insulationPipe protection by thermal insulationForeign matterPlastic film

An outer coating material (13) of a vacuum heat insulation material is a layered body made by layering, with adhesive agent layers (25, 26) in between, a sealant layer (21), a metal layer (22), a first plastic film layer (23), and a second plastic film layer (24), in that order from the inner side. When the vacuum heat insulation material is pierced by a foreign object, one layer in the inside of the layered body shuts off propagation of breakage caused by the piercing to prevent production of a through pin hole. By use of the outer coating material with high gas barrier ability and excellent pin hole resistance against piercing by a fine foreign object, a high-quality vacuum heat insulation material capable of maintaining excellent heat insulation performance for a long period is obtained.

Owner:PANASONIC CORP

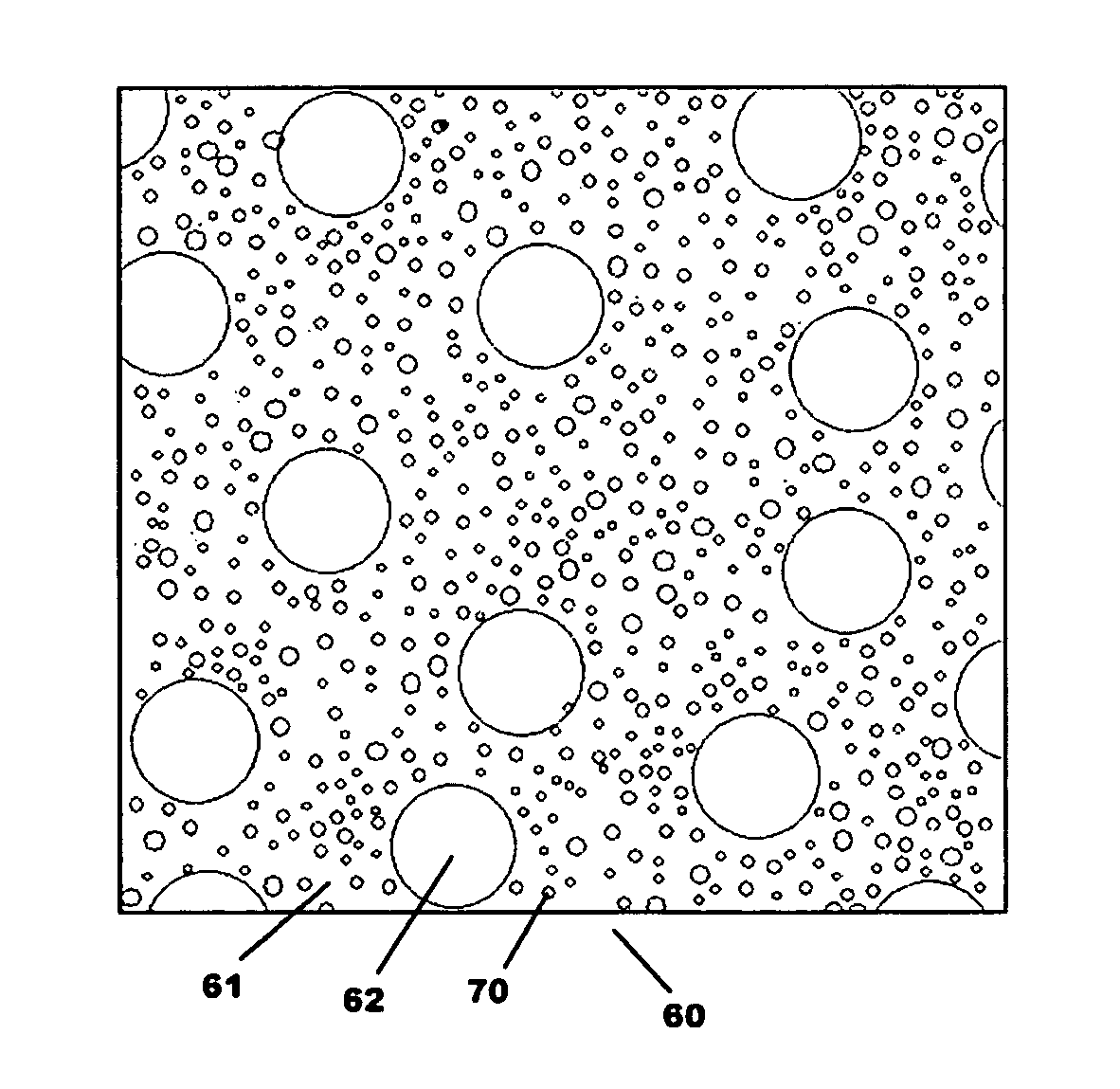

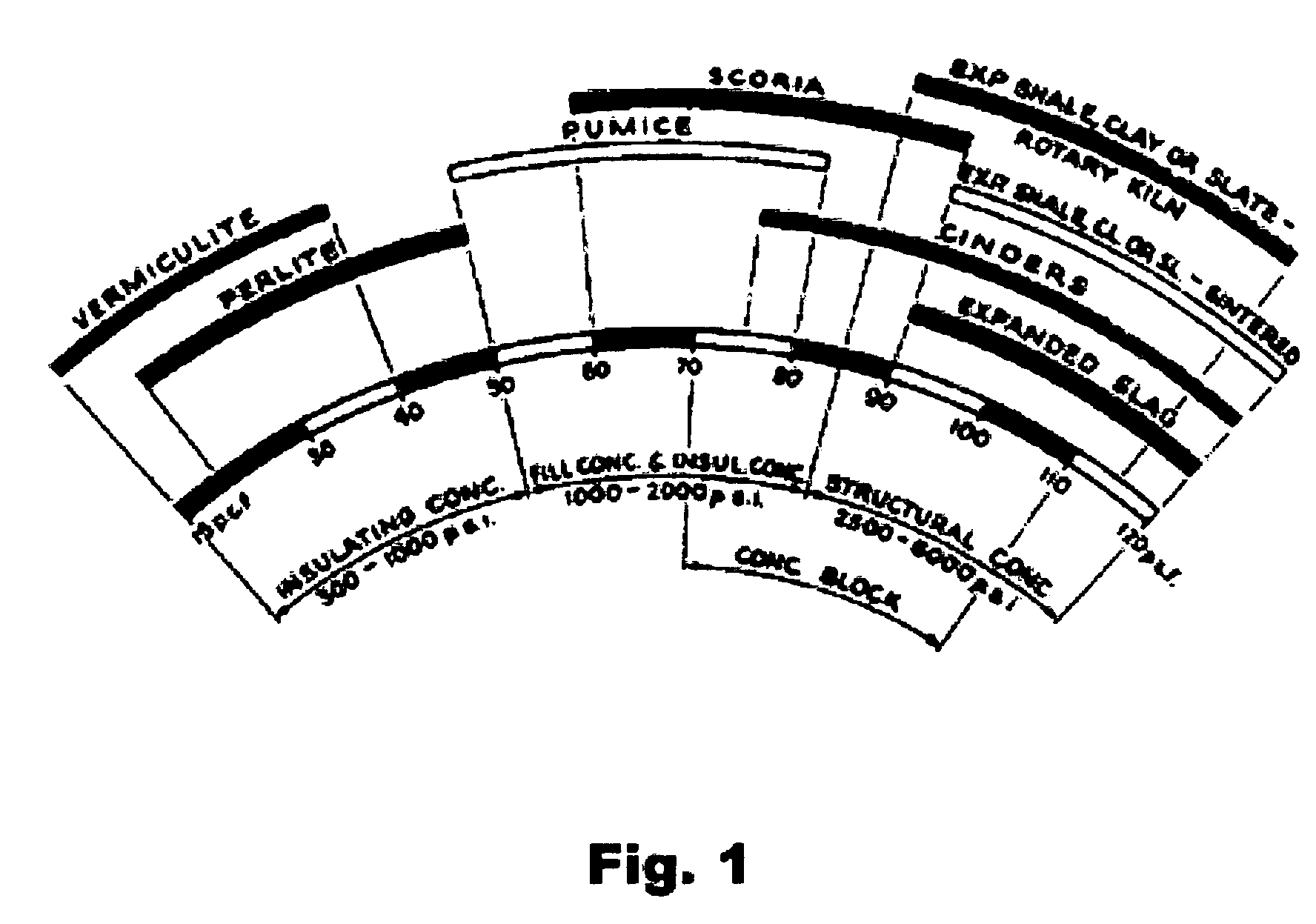

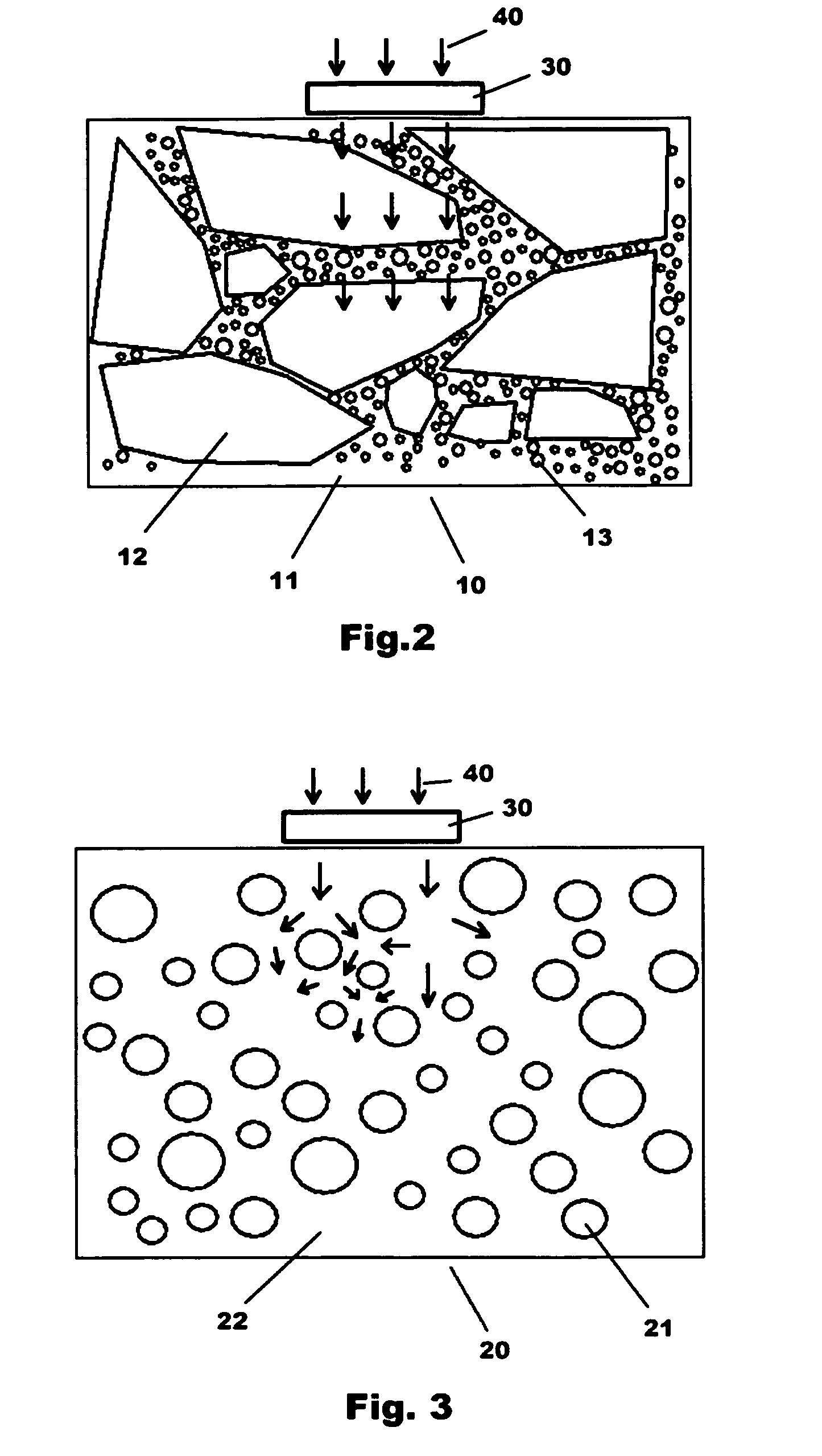

Lightweight structural concrete provided with various wood properties

A lightweight structural concrete with screw-ability and nail-ability similar to wood is composed of non-structural and ultra lightweight aggregate such as expanded perlite of a particular size distribution and amount, entrained air cells of another specific size distribution and amount, and dense cementitious composition of a cement binder, a fine grade structural filler no larger than masonry sand grade, a pozzolan, and optional micro-fibers for reinforcement. This structural concrete matrix is optimized to hold 13 gauge T-nails and bugle head wood screws with thread ranging from 8 to 11 threads per inch and diameter of 0.10″ to 0.137″. The resulting concrete will have consistent screw-ability and nail-ability similar that of wood.

Owner:BUI THUAN H

Metal Matrix Ceramic Composite and Manufacturing Method and Application Thereof

The invention relates to a metal matrix ceramic composite and manufacturing method and application thereof. The metal matrix ceramic composite, is completely formed by permeating at least part of a matrix metal into an array of ceramic granules by means of squeeze-casting, and the volume percentage of the ceramic granules may be adjusted within a range of 10%-80% of the metal matrix ceramic composite according to the usage requirements. The metal matrix ceramic composites can not only retain high performance of anti-penetration, but also have the strong toughness of the metal; in addition, this composite has features of low density, resistance against ordinary mechanical cutting and flame cutting, and inhibition of crack propagation and the like. Therefore, said composite has broad application prospects in the protection of such important security facilities as safes, automatic teller machines and vault gates.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Fe-Based Amorphous Alloy Strip

ActiveUS20090242082A1Increase flux densityExcellent soft magnetic propertiesInorganic material magnetismAlloyAlternating current

The present invention provides a Fe—B—Si system amorphous alloy thin strip excellent in high magnetic flux density, thermal stability, amorphous formability improved workability and low core loss. The present invention further provides a Fe—B—Si system amorphous alloy thin strip which has the reduced cost without using high purity iron resources such as an electrolytic iron as iron resources used in an amorphous alloy thin strip, and also has core loss less than 0.10 W / kg at W13 / 50 in soft magnetic property in alternating-current field. The Fe—B—Si system amorphous alloy thin strip according to the present invention contains an appropriate amounts of N, C, P to improve thermal stability, amorphous formability, workability (brittleness), and core loss without deteriolating magnetic flux density, and contains, in atomic %, B: 5-25%, Si: 1-30%, N: 0.001-0.2%, C: 0.003-10%, P: 0.001-0.2% and the balance being Fe and unavoidable impurities, and optionally contains Co or Ni substituted to less than 15% of the Fe amount, or Cr at less than 5% substituted to the Fe amount. Further, Mn: 0.15-0.5 mass %, S: 0.004-0.05 mass % can be included.

Owner:NIPPON STEEL CORP

Seals and a method of making seals

InactiveUS7744093B2Increase flexibilityPrevent crack propagationEngine sealsLeakage preventionMechanical engineeringMaterial Perforation

A seal and method of making seals utilizes folds in order to form creases in a length of material such that the creases reinforce individual seal elements or surfaces while perforations or slots in a seal edge allow air leakage from one side of the seal element or surface to the other. Thus, air pressurization can take place between spaced seal elements or surfaces and this allows air flotation or riding of a rotating component relative to a static housing component. The perforations are typically graduated from the seal edge in order to provide the best pressurization and air-riding effect for proximity or gap control between the sealing edge and the rotating component surface. The slots effectively provide flexibility to the sealing edge such that the seal component emulates a brush seal.

Owner:ROLLS ROYCE PLC

Crack resistant scribe line monitor structure and method for making the same

ActiveUS7091621B1Prevent and reduce propagationMore crack resistantSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsStress reliefMechanical engineering

A method and structure prevents crack propagation to the active die circuitry of a main die area during sawing around the outer periphery of the main die area. Stress relief elements, such as dummy vias, are provided in the scribe line area between the saw lane and the main die area. The dummy vias prevent cracks induced by the sawing process from propagating to the main die area.

Owner:ADVANCED MICRO DEVICES INC

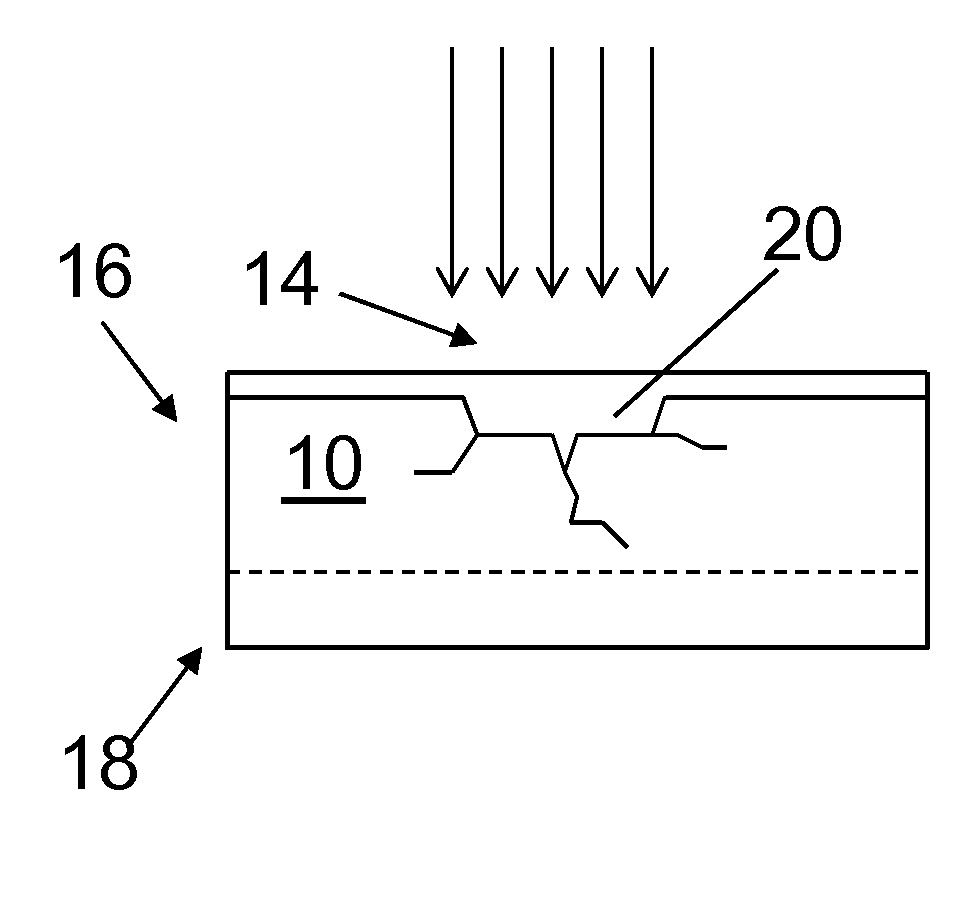

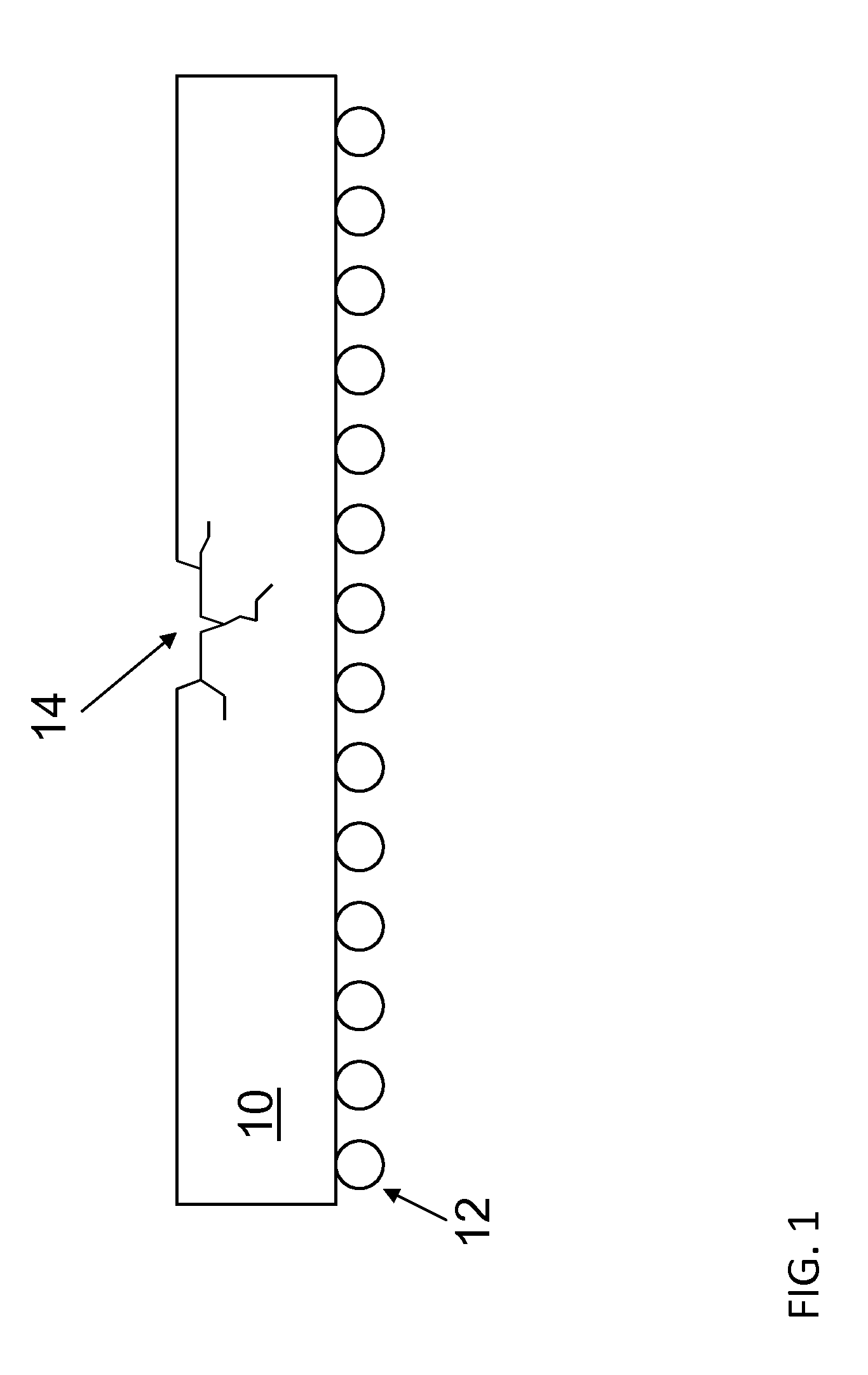

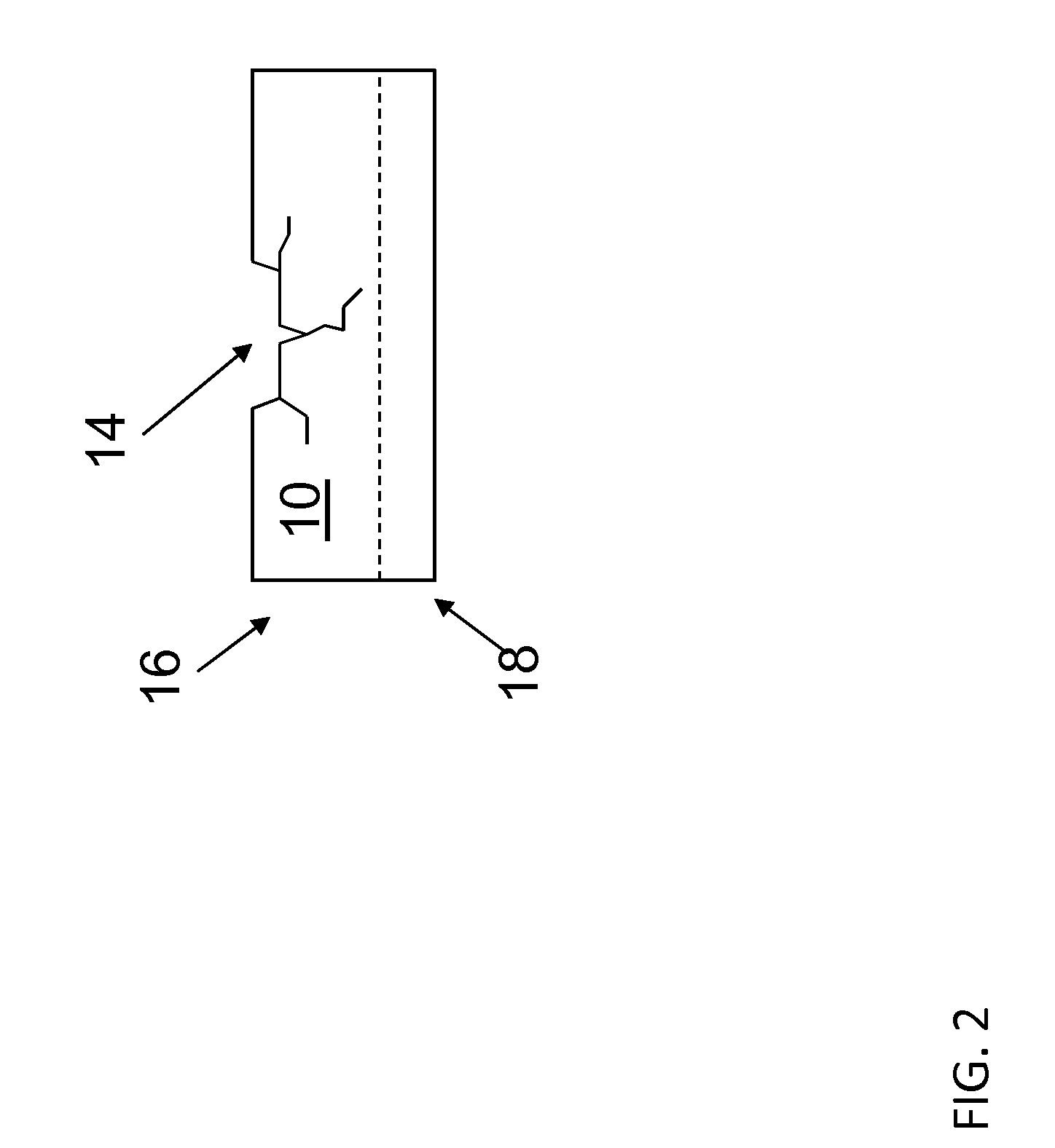

Inhibiting propagation of imperfections in semiconductor devices

InactiveUS20140042594A1Prevent crack propagationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCrazingSemiconductor

Aspects of the disclosure provide a method of inhibiting crack propagation in a silicon wafer. In one embodiment, a method of repairing an imperfection on a surface of a semiconductor device is disclosed. The method includes: screening for imperfections on a surface of a silicon wafer of a semiconductor device; and in response to at least one imperfection on the surface of the silicon wafer, depositing a material on the surface of the silicon wafer.

Owner:GLOBALFOUNDRIES INC

Semiconductor Device And Process For Producing Semiconductor Device

ActiveCN103208461AAvoid crackingPrevent crack propagationSemiconductor/solid-state device detailsSolid-state devicesSemiconductorMetal

A semiconductor device includes: a substrate in which a product region and scribe regions are defined; a 1st insulation film formed above the substrate; a metal film in the 1st insulation film, disposed within the scribe regions in such a manner as to surround the product region; a 2nd insulation film formed on the 1st insulation film and the metal film; a 1st groove disposed more inside than the metal film in such a manner as to surround the product region, and reaching from a top surface of the 2nd insulation film to a position deeper than a top surface of the metal film; and a 2nd groove disposed more outside than the metal film in such a manner as to surround the metal film, and reaching from the top surface of the 2nd insulation film to a position deeper than the top surface of the metal film.

Owner:FUJITSU LTD

Semiconductor device

InactiveCN101043042APrevent crack propagationImprove reliabilityTelevision system detailsSemiconductor/solid-state device detailsEdge surfaceEngineering

A semiconductor device includes a semiconductor element having an upper surface where an imaging area is formed; a transparent member separated from the semiconductor element by a designated distance and facing the semiconductor element; and a sealing member configured to seal an edge part of the semiconductor element and an edge surface of the transparent member; wherein a groove forming part is formed in the transparent member, the groove forming part being situated at an edge surface side of the transparent member outside of an external edge of the imaging area of the semiconductor element.

Owner:FUJITSU MICROELECTRONICS LTD

Hierarchical material assemblies and articles for use in projectile impact protection

InactiveUS7472637B2Dissipate energyPrevent crack propagationArmoured vehiclesPersonal protection gearPlateletEngineering

Owner:MASSACHUSETTS INST OF TECH

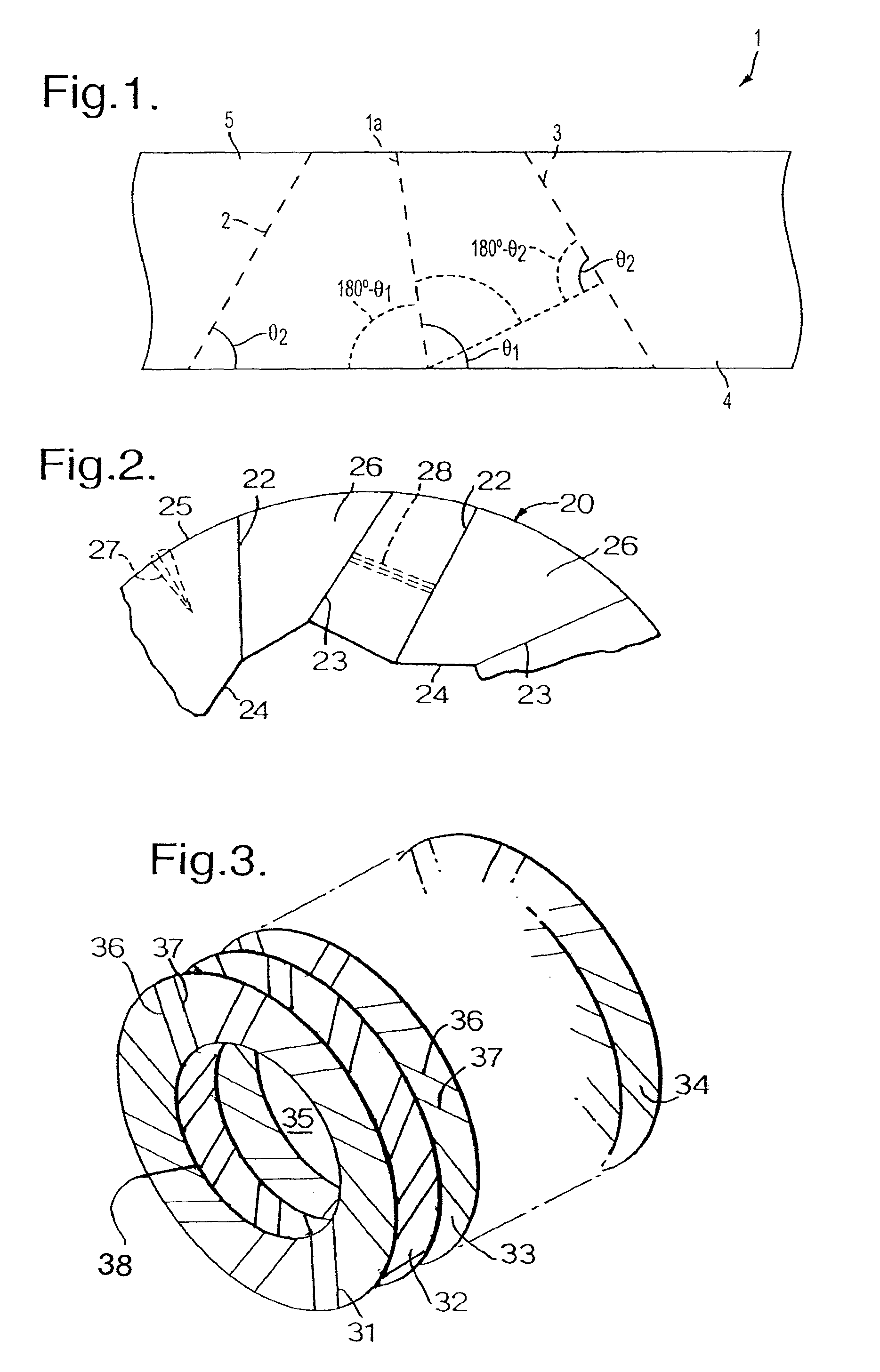

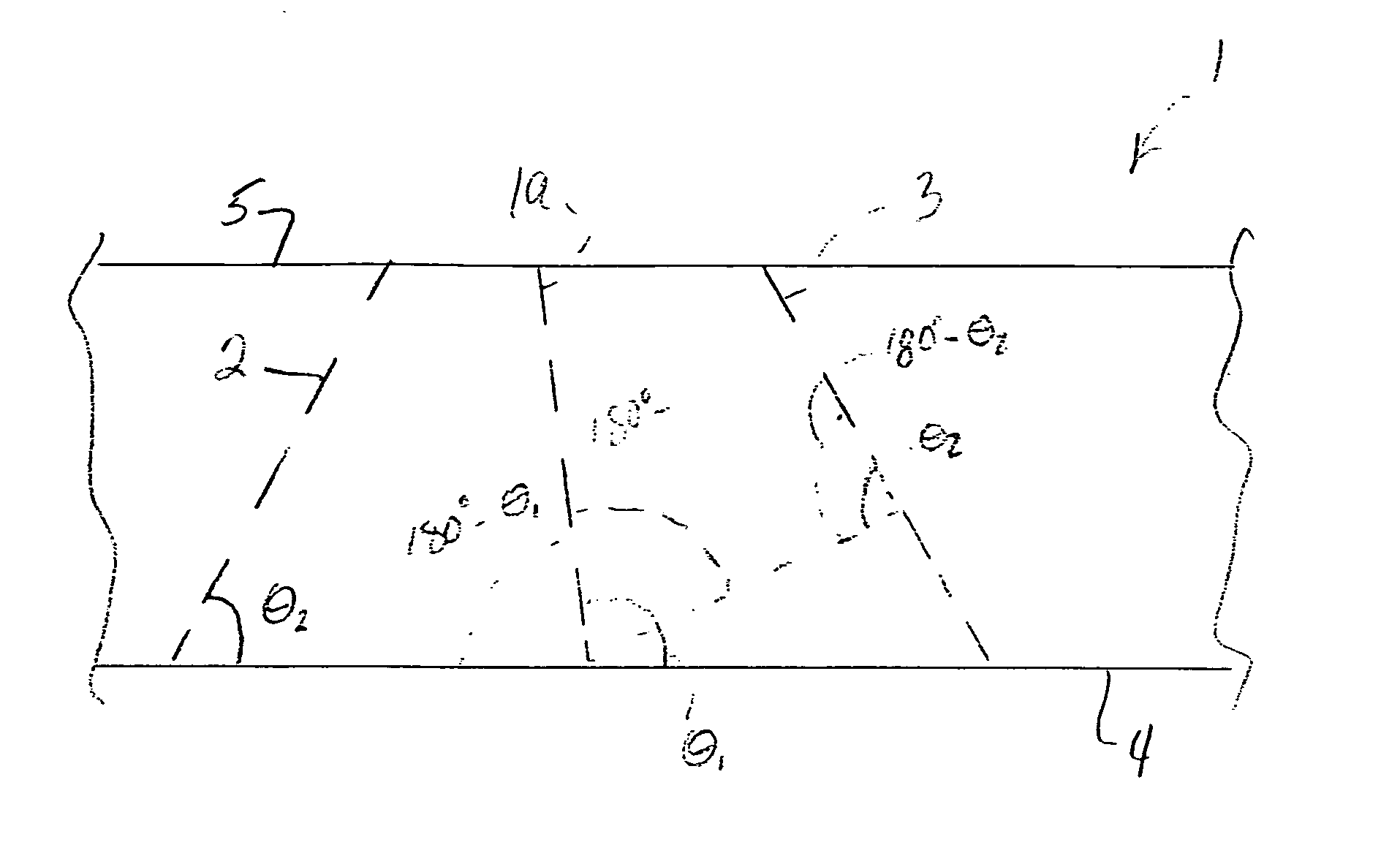

Structural element, method for manufacturing a structural element and use of a structural element for an aircraft hull

InactiveUS20060156662A1Suppressing crack growthImprove mechanical propertiesFuselage framesAircraft stabilisationInter layerMechanical engineering

A structural element includes the following elements: a carrier element, a reinforcing element, and a sheathing element. At least a portion of the reinforcing element is enveloped by the sheathing element and the reinforcing element is embedded in the carrier element. Materials of the elements are selected to inhibit crack initiation or propagation in the elements and / or from one element to another. An intermediate layer of a different material may be added between elements to further inhibit crack initiation and propagation and to inhibit corrosion, such as galvanic corrosion.

Owner:AIRBUS OPERATIONS GMBH

Seals and a method of making seals

InactiveUS7827685B2Increase flexibilityPrevent crack propagationEngine sealsPump componentsEngineeringMechanical engineering

A seal and method of making seals utilises folds in order to form creases in a length of material such that the creases reinforce individual seal elements or surfaces whilst perforations or slots in a seal edge allow air leakage from one side of the seal element or surface to the other. Thus, air pressurisation can take place between spaced seal elements or surfaces and this allows air flotation or riding of a rotating component relative to a static housing component. The perforations are typically graduated from the seal edge in order to provide the best pressurisation and air-riding effect for proximity or gap control between the sealing edge and the rotating component surface. The slots effectively provide flexibility to the sealing edge such that the seal component emulates a brush seal.

Owner:ROLLS ROYCE PLC

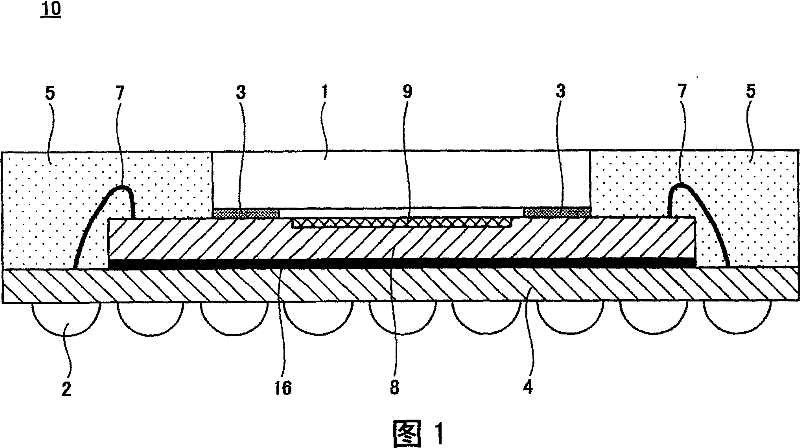

Semiconductor packaging construction with weld crack restraint ring

InactiveCN101369559APrevent cracks from spreadingAvoid the problem of electrical open circuitSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention is related to a semiconductor encapsulating structure, comprising: a wafer carrier that includes an upper surface and a lower surface, wherein the lower surface is provided with plural first conduction pads; a water which is arranged and electrically connected with the wafer carrier; and plural turriform projections that are correspondingly arranged on these first conduction pads, for welding outwards, each of the turriform projections includes at least a first crack suppression ring which is parallel to these first conduction pads and which is used for suppressing expansion of the welding crack. The invention can effectively prevent the expansion of crack at solder-welding interfaces and avoid the issue of electric breaking as the external terminals provided at the wafer carrier are the turriform projections and at least one crack suppression ring is contained in the invention. Furthermore, the invention also can increase welding fixation strength in order to achieve high production durability. The invention is particularly suitable for a stacked structure and extremely practicable owing to effective suppression of the crack expansion at micro-contact welding sites.

Owner:POWERTECH TECHNOLOGY

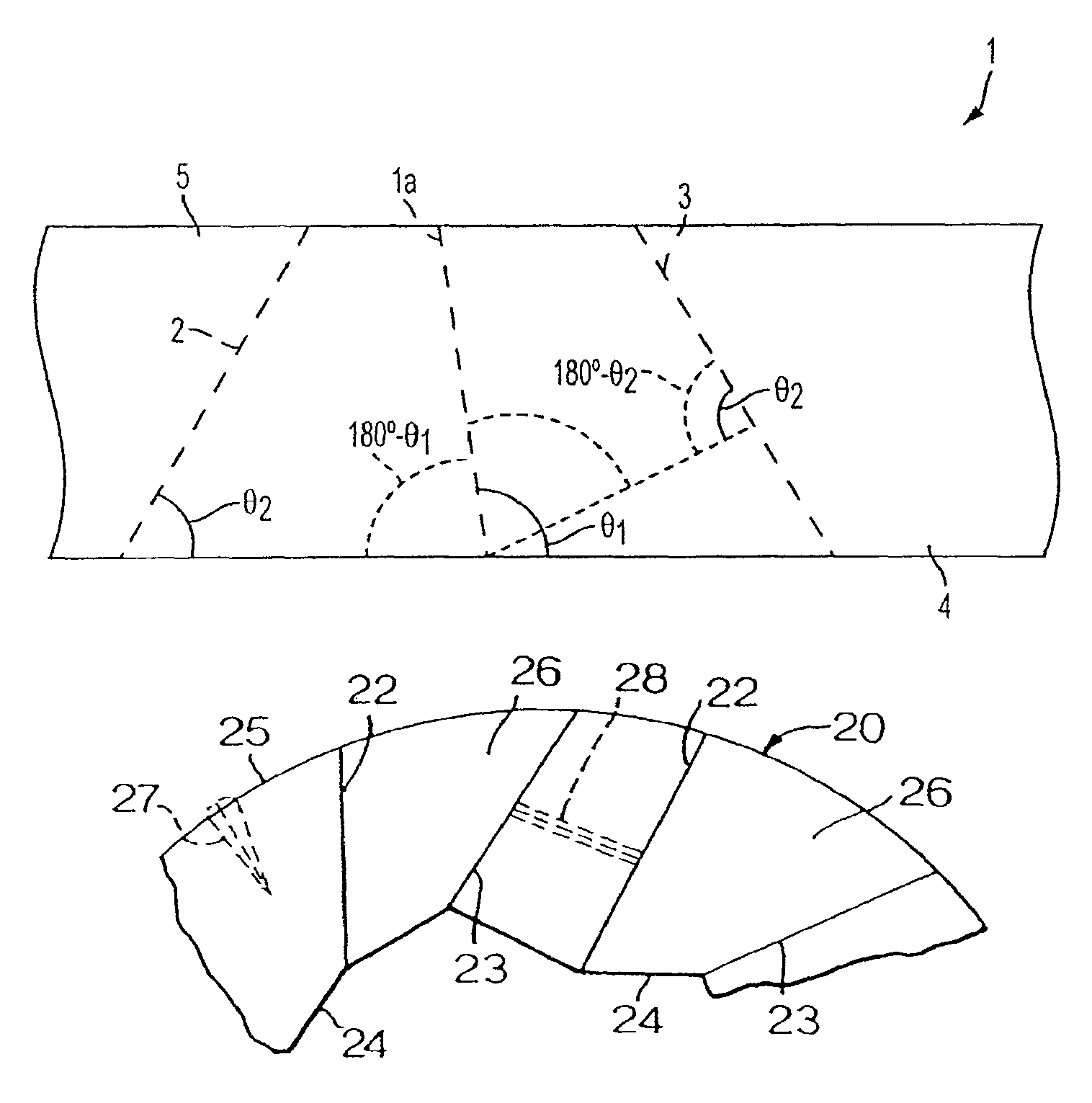

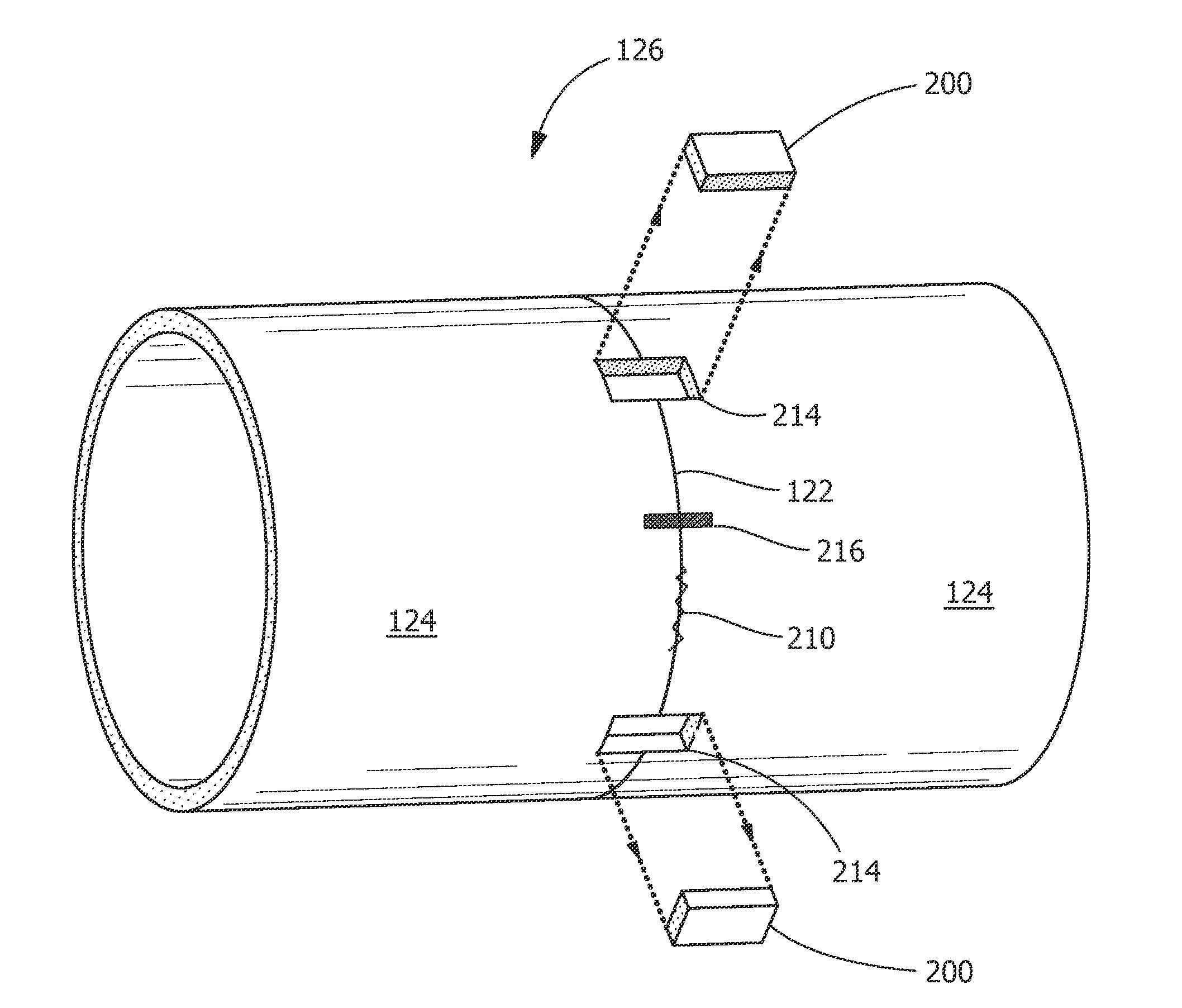

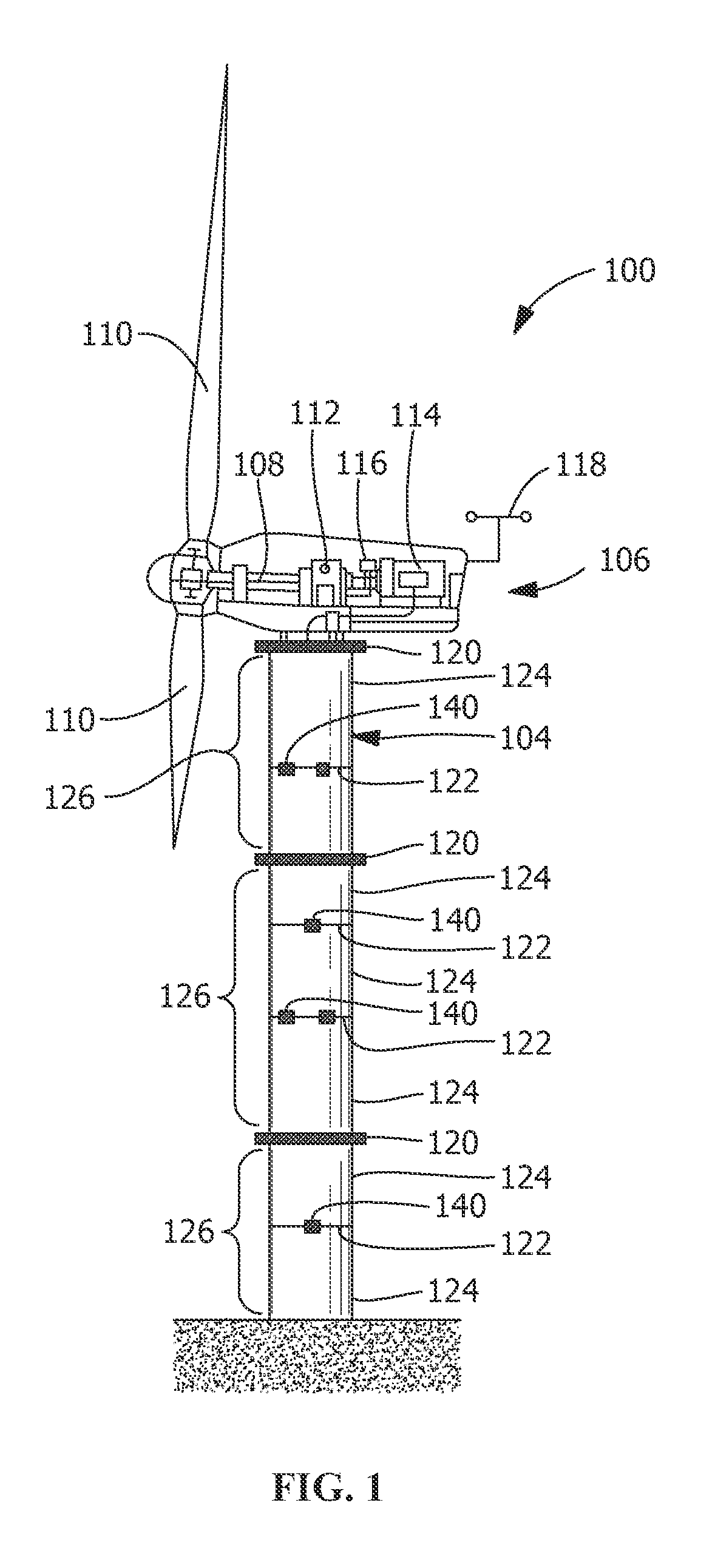

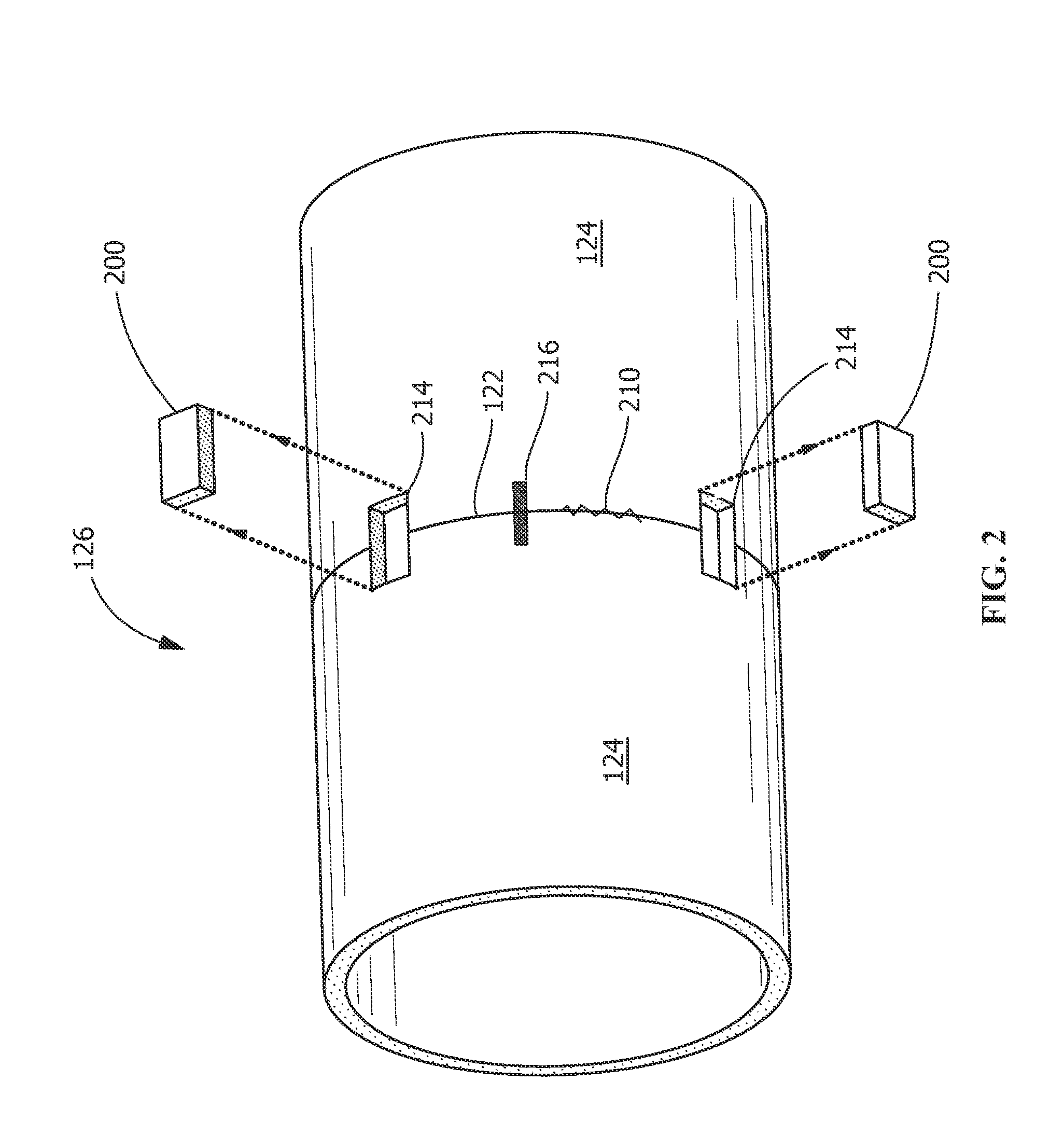

Crack-resistant member, a method of preventing crack propagation, and a method of assembling a tower

ActiveUS20140059964A1Prevent crack propagationBuilding repairsFoundation repairHeat-affected zoneEngineering

A crack-resistant member for preventing crack propagation, a method of preventing crack propagation, and method of assembly a tower are provided. The crack-resistant member includes at least one insert attached to at least one removed portion at a predetermined location along a girth weld and adjacent a heat affected zone of the tower. The at least one insert is positioned perpendicular to a weld direction and intersecting the girth weld. The at least one insert prevents crack propagation in the girth weld of the tower.

Owner:GENERAL ELECTRIC CO

Seals and a method of making seals

InactiveUS20070126187A1Increase flexibilityPrevent crack propagationEngine sealsLeakage preventionEngineeringMaterial Perforation

A seal and method of making seals utilises folds in order to form creases in a length of material such that the creases reinforce individual seal elements or surfaces whilst perforations or slots in a seal edge allow air leakage from one side of the seal element or surface to the other. Thus, air pressurisation can take place between spaced seal elements or surfaces and this allows air flotation or riding of a rotating component relative to a static housing component. The perforations are typically graduated from the seal edge in order to provide the best pressurisation and air-riding effect for proximity or gap control between the sealing edge and the rotating component surface. The slots effectively provide flexibility to the sealing edge such that the seal component emulates a brush seal.

Owner:ROLLS ROYCE PLC

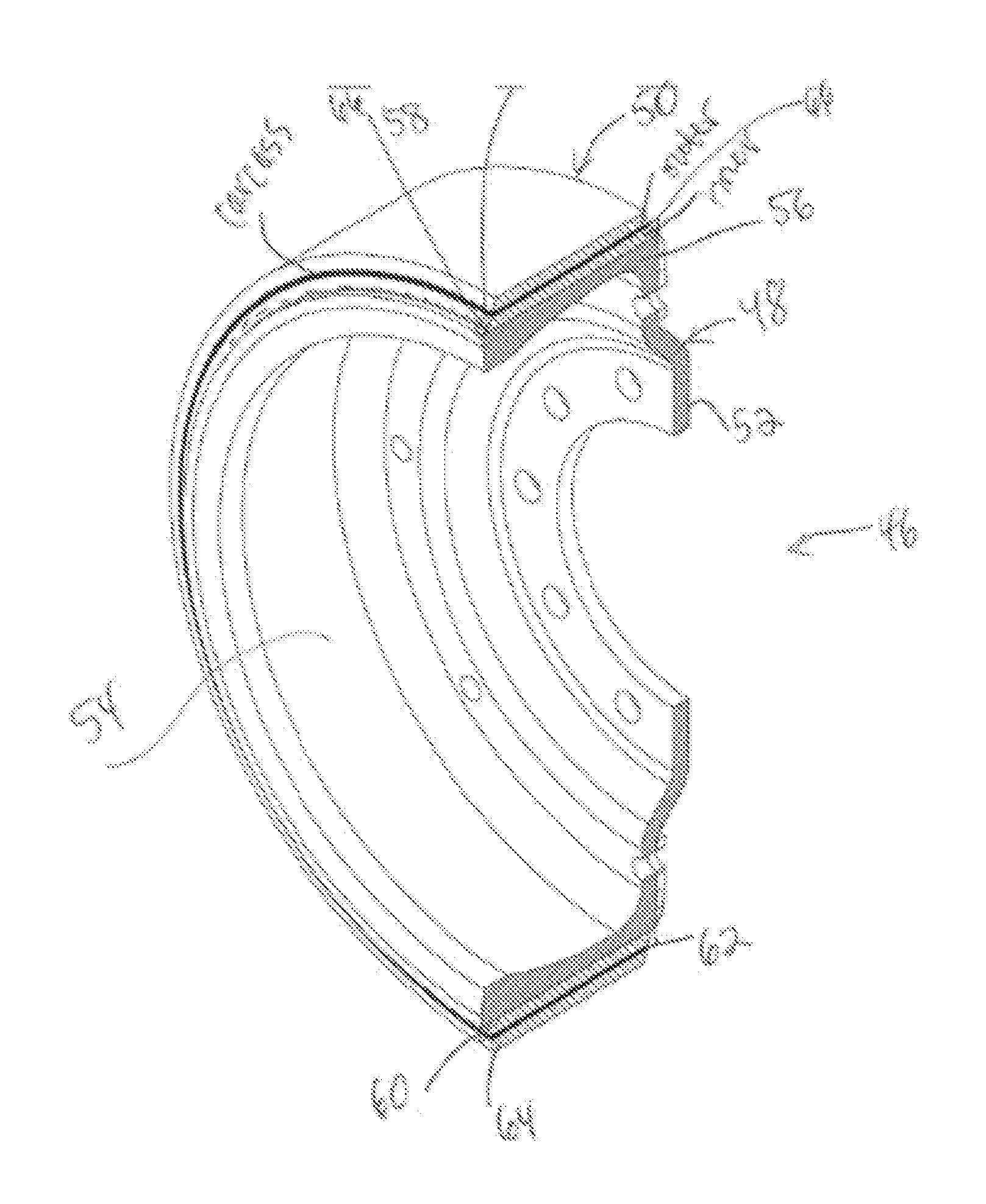

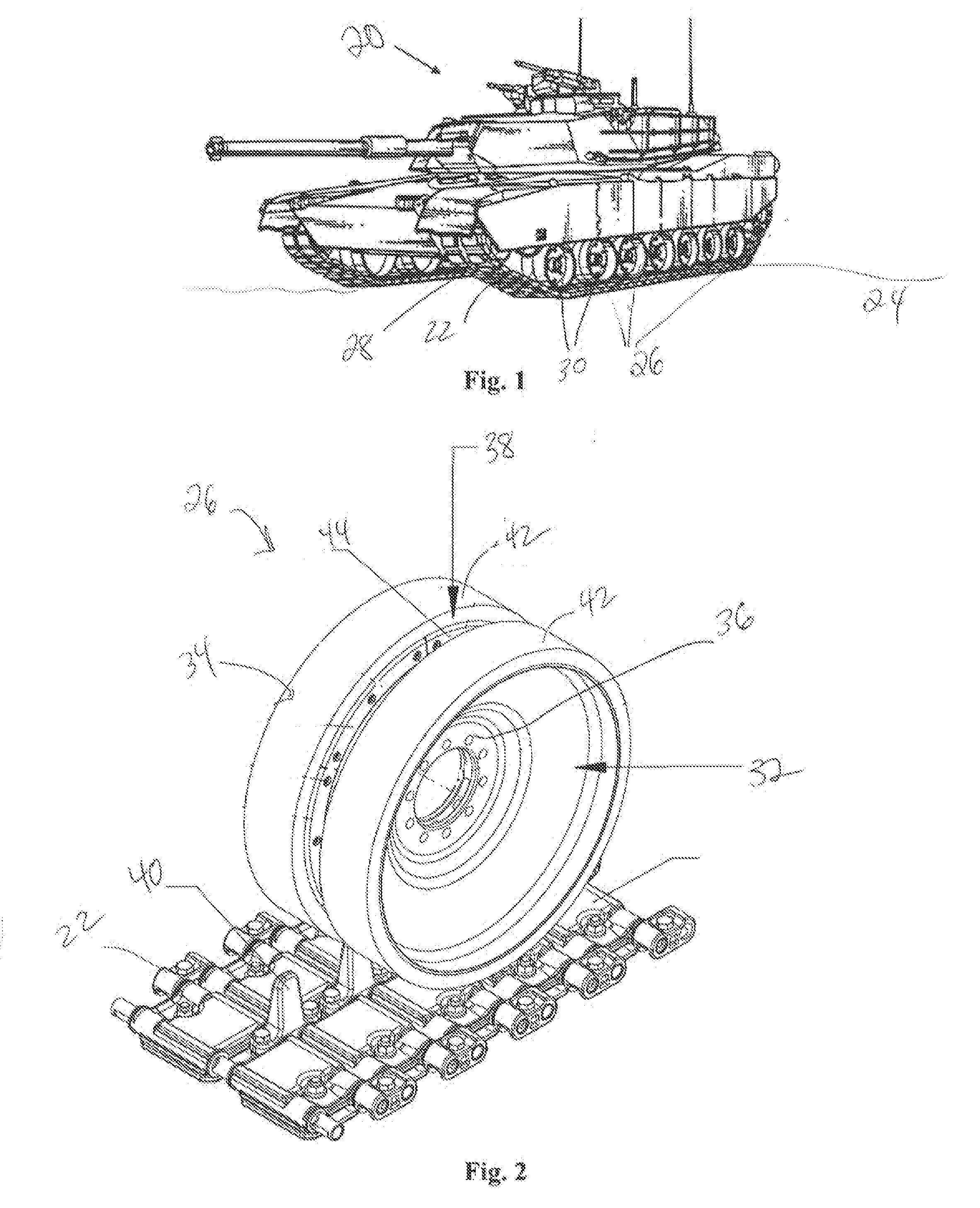

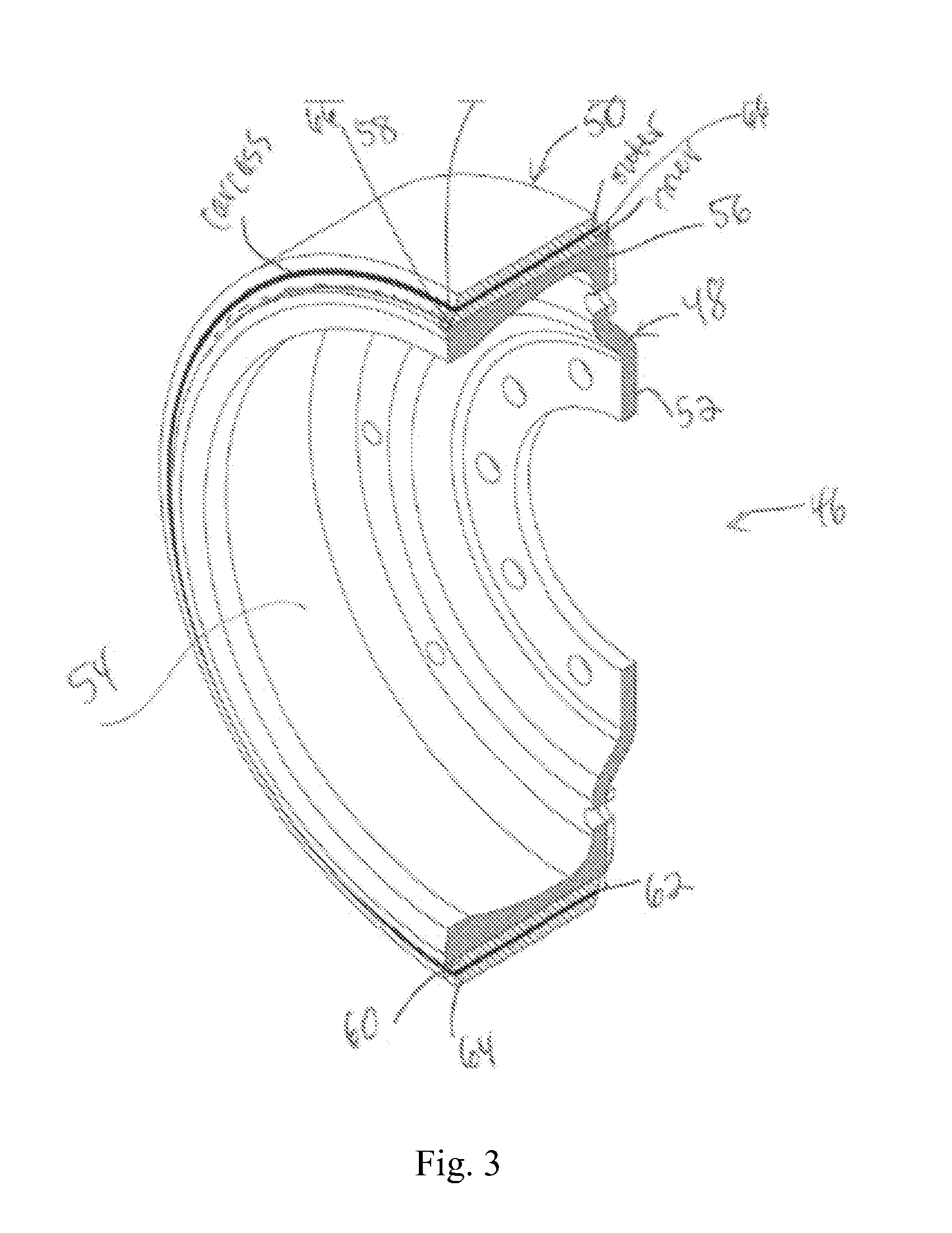

Elastomeric tire for a tracked vehicle

ActiveUS20120146394A1Extended service lifeReduce replacement frequencyNon-inflatable tyresEngine componentsControl theoryFlange

A road wheel for a tracked vehicle is provided with a circular mounting flange having a dished wall extending radially outwards and circumferentially therefrom, a peripheral rim having a first edge and a second edge with the rim connected to an outer edge of the dished wall at an intermediate region of the rim, and a first lip extending from the first edge. Another road wheel for a tracked vehicle is provided with a mounting flange, a peripheral rim, at least one inner dished wall, at least one outer dished wall offset from the inner dished wall along the flange, and at least two connector walls with each connector wall extending between the inner dished wall, outer dished wall, and the peripheral rim.

Owner:GSE TECH

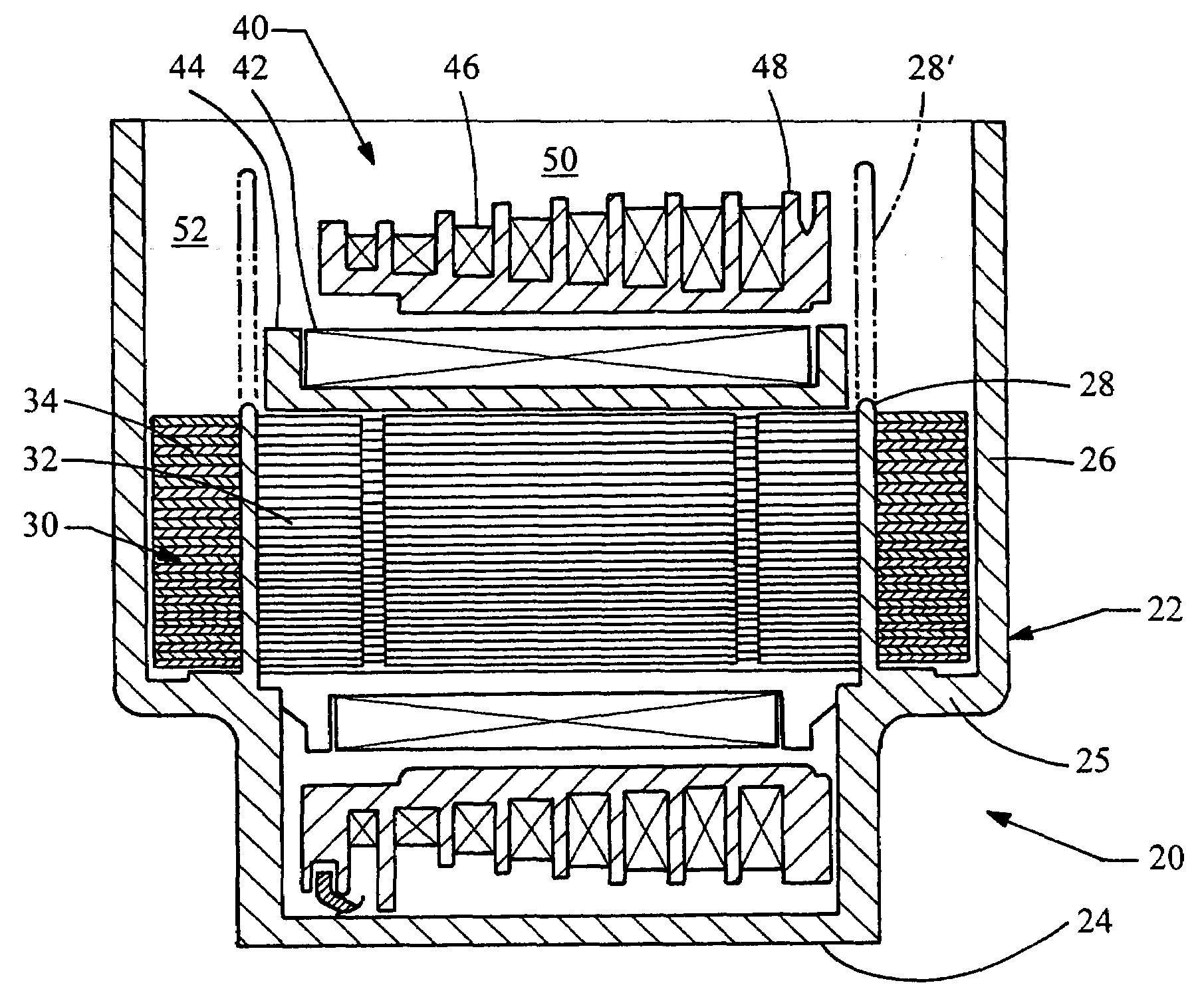

Ignition coil with separating wall

InactiveUS7209023B2MiniaturizationPrevent crack propagationTransformersTransformers/inductances casingsIgnition coilOuter core

Owner:FORD GLOBAL TECH LLC

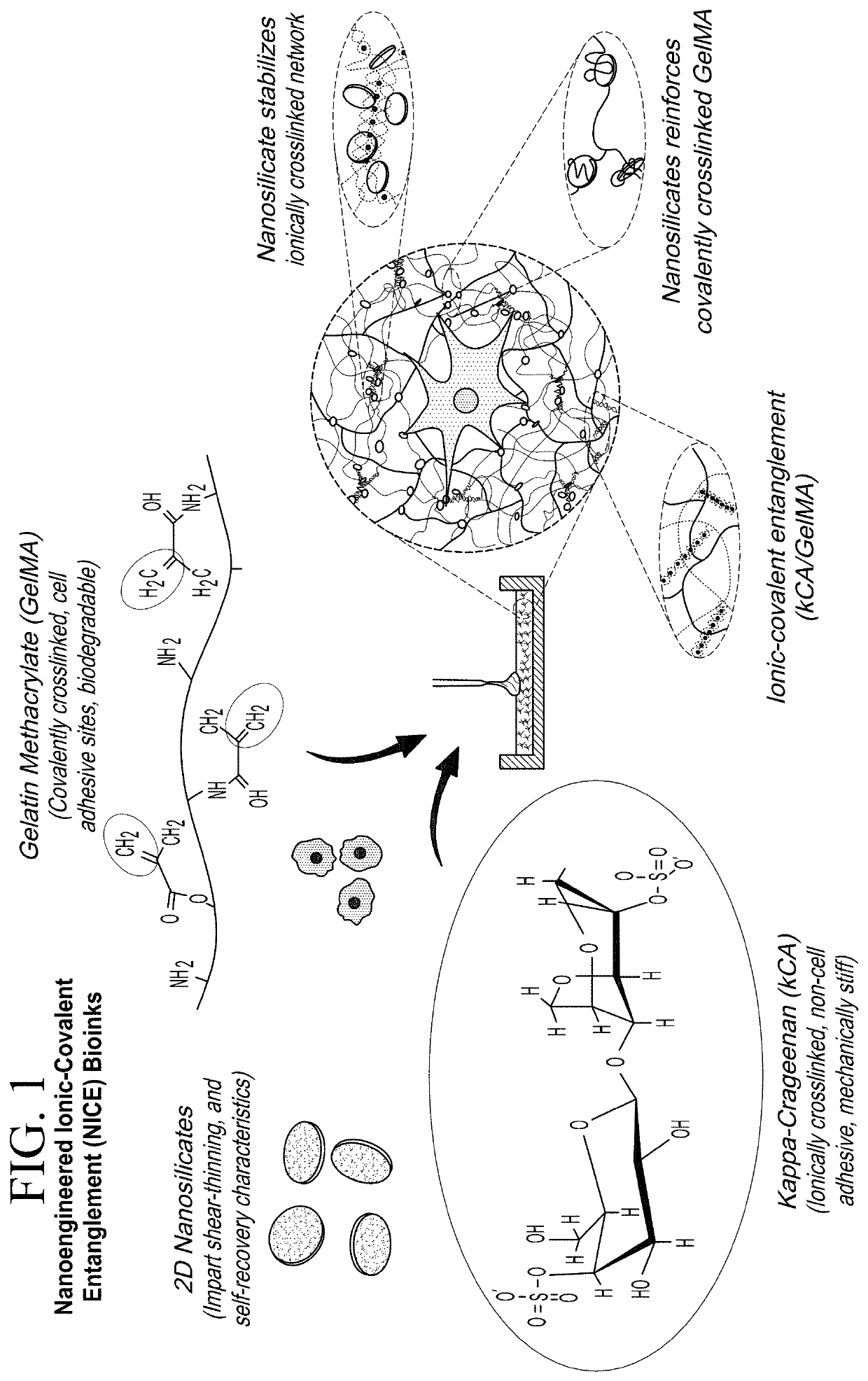

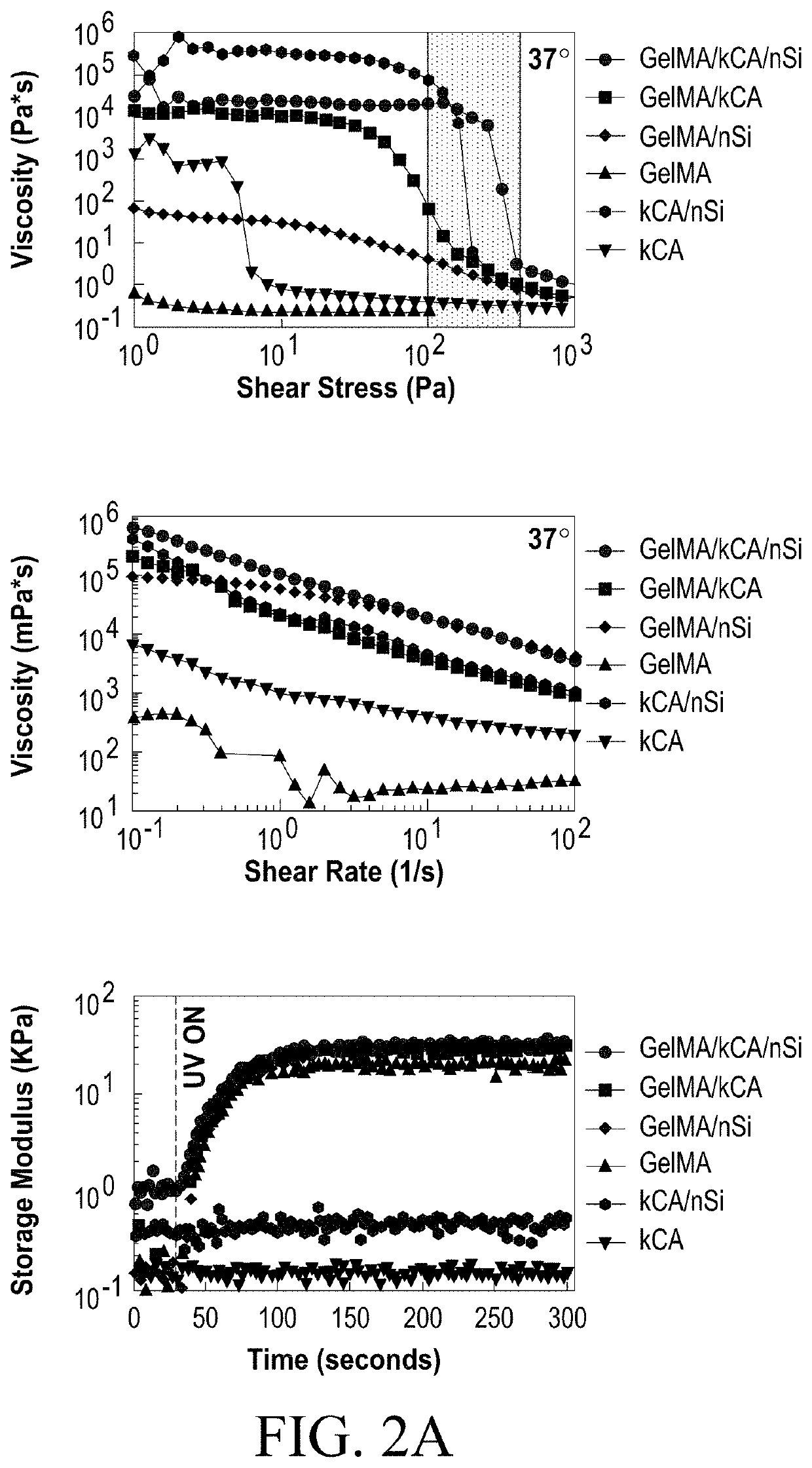

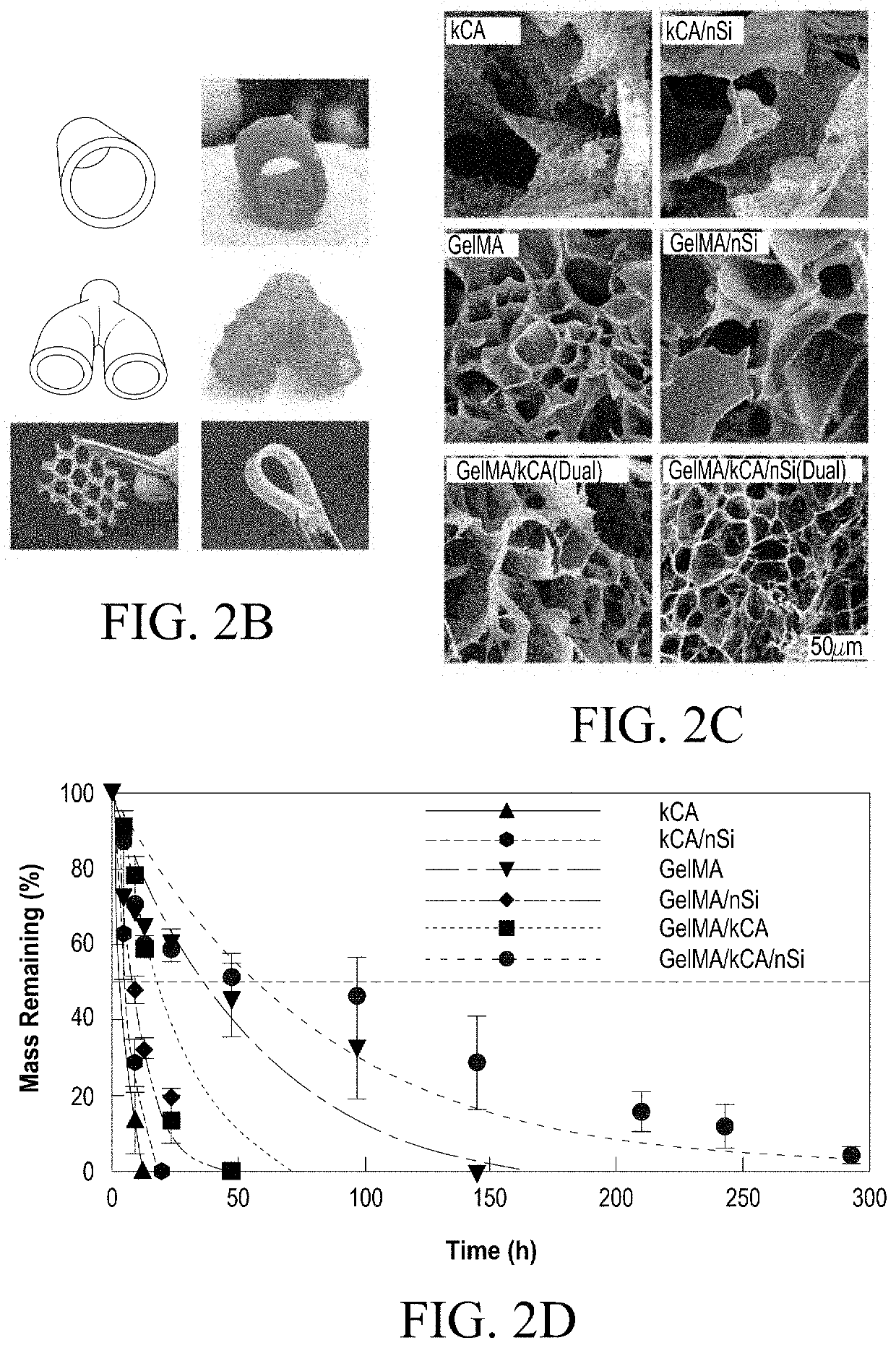

Nanocomposite Ionic-Covalent Entanglement Reinforcement Mechanism and Hydrogel

ActiveUS20200071550A1Superior adaptability and utilityConsume energyAdditive manufacturing apparatusPharmaceutical delivery mechanismNano siliconPolymer science

A biodegradable and biocompatible three dimensional construct comprising a combination of a nano silicate (e.g., laponite) and two different polymers, the two polymers each individually providing at least one covalently linked polymer chain and at least one ionically linked polymer chain, the polymeric chains forming a dual strengthening intertwined polymeric system. The constructs demonstrate improved mechanical and strength properties, while the bioinks provide a material having superior printability characteristics suitable for printing a three dimensional biodegradable construct having an aspect ratio of greater than 2.0. The bioink may also comprise cells or combinations of cells. Methods of using the constructs and bioinks for wound healing preparations and tissue regeneration are also provided.

Owner:TEXAS A&M UNIVERSITY

Structural element, method for manufacturing a structural element and use of a structural element for an aircraft hull

InactiveUS7850118B2Prevent crack propagationImproved damage tolerance performanceFuselage framesAircraft stabilisationEngineeringMechanical engineering

A structural element includes the following elements: a carrier element, a reinforcing element, and a sheathing element. At least a portion of the reinforcing element is enveloped by the sheathing element and the reinforcing element is embedded in the carrier element. Materials of the elements are selected to inhibit crack initiation or propagation in the elements and / or from one element to another. An intermediate layer of a different material may be added between elements to further inhibit crack initiation and propagation and to inhibit corrosion, such as galvanic corrosion.

Owner:AIRBUS OPERATIONS GMBH

Fe-based amorphous alloy strip

ActiveUS7744703B2Easy to crackIncrease flux densityInorganic material magnetismAlloyAlternating current

The present invention provides a Fe—B—Si system amorphous alloy thin strip excellent in high magnetic flux density, thermal stability, amorphous formability improved workability and low core loss. The present invention further provides a Fe—B—Si system amorphous alloy thin strip which has the reduced cost without using high purity iron resources such as an electrolytic iron as iron resources used in an amorphous alloy thin strip, and also has core loss less than 0.10 W / kg at W13 / 50 in soft magnetic property in alternating-current field. The Fe—B—Si system amorphous alloy thin strip according to the present invention contains an appropriate amounts of N, C, P to improve thermal stability, amorphous formability, workability (brittleness), and core loss without deteriolating magnetic flux density, and contains, in atomic %, B: 5-25%, Si: 1-30%, N: 0.001-0.2%, C: 0.003-10%, P: 0.001-0.2% and the balance being Fe and unavoidable impurities, and optionally contains Co or Ni substituted to less than 15% of the Fe amount, or Cr at less than 5% substituted to the Fe amount. Further, Mn: 0.15-0.5 mass %, S: 0.004-0.05 mass % can be included.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com