Patents

Literature

38results about How to "Improved damage tolerance performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-damage tolerance type ultrahigh strength aluminum alloy and preparation method thereof

The invention relates to a high-damage tolerance type ultrahigh strength aluminum alloy and a preparation method thereof. The high-damage tolerance type ultrahigh strength aluminum alloy comprises the following components in percentage by weight: 8.5-10.0 percent of Zn, 1.0-2.5 percent of Mg, 1.0-2.0 percent of Cu, 0.06-0.20 percent of Zr, 0.02-0.05 percent of Ti, not more than 0.08 percent of Fe, not more than 0.06 percent of Si and the balance of Al and unavoidable impurities, wherein the Fe content is larger than Si content. The method comprises the following steps: firstly, smelting and casting; then carrying out homogenization on an alloy casting blank by stages, carrying out hot rolling on the homogenized casting blank and carrying out solid dissolution on a hot rolled plate; prestretching the plate in four hours after quenching; and finally immediately carrying out double-stage ageing processing on the prestretched plate. The obtained alloy has higher strength and damage tolerance and is suitable for being applied in an airplane part exposed in the atmospheric environment for a long time.

Owner:CHINA ALUMINUM INT ENG CORP

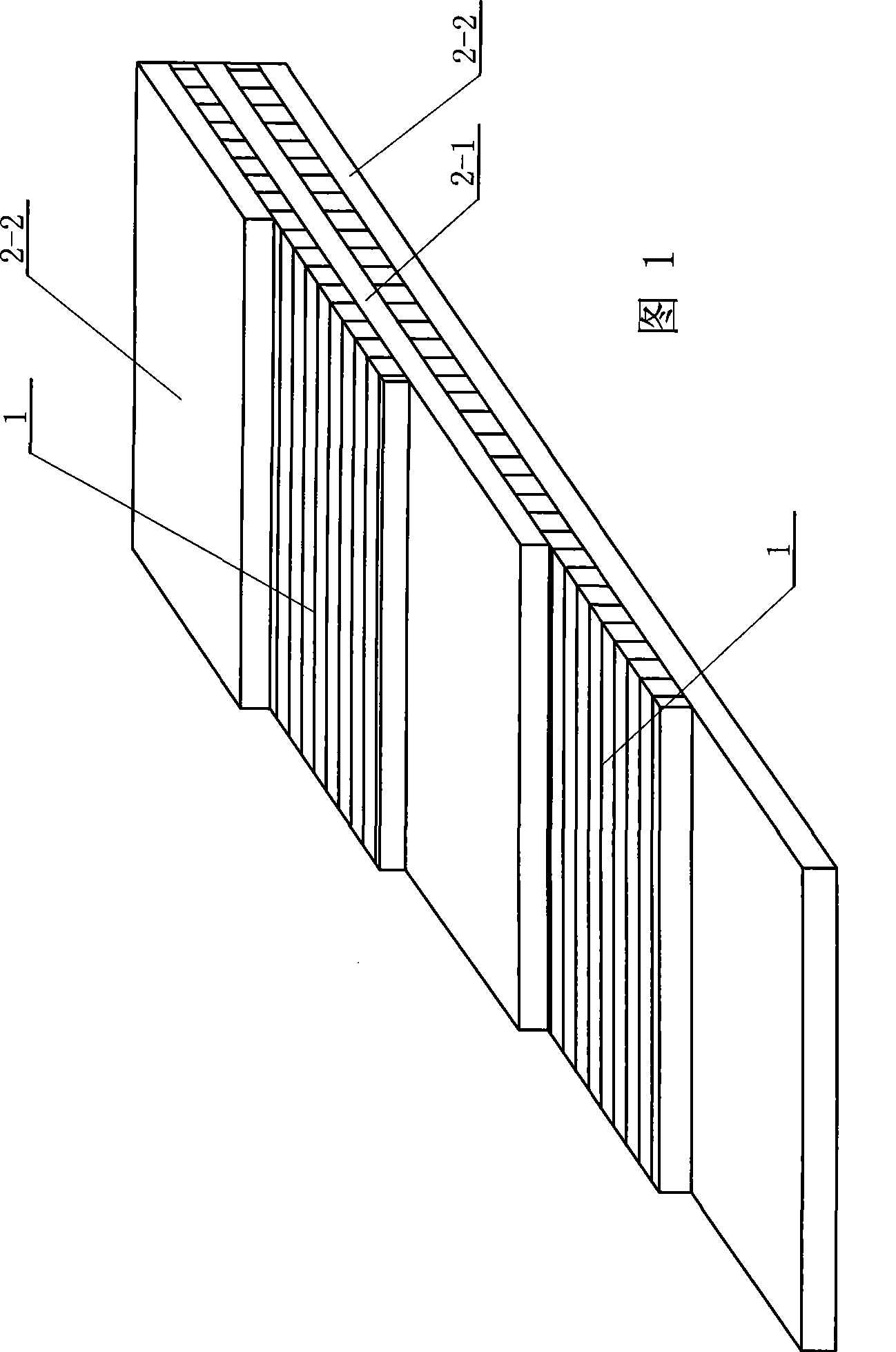

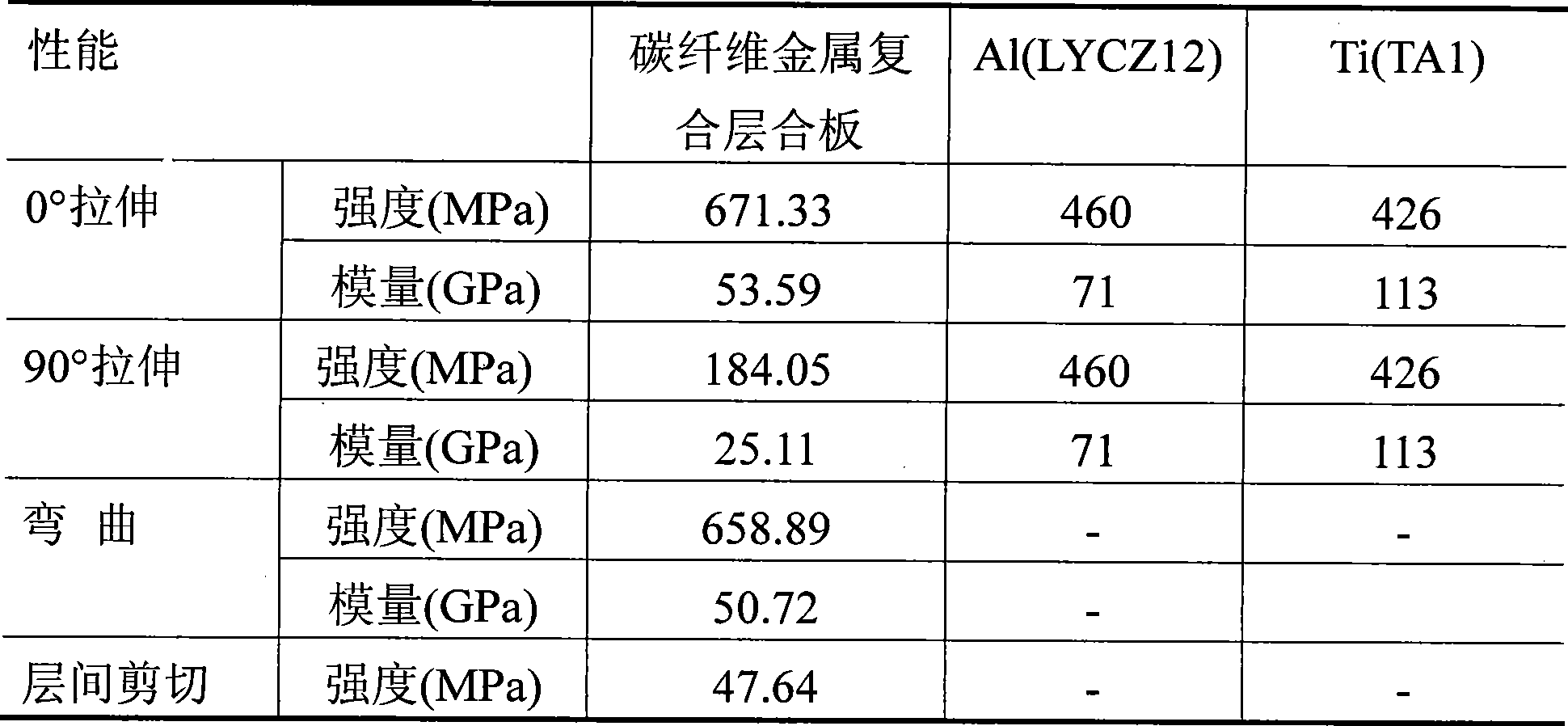

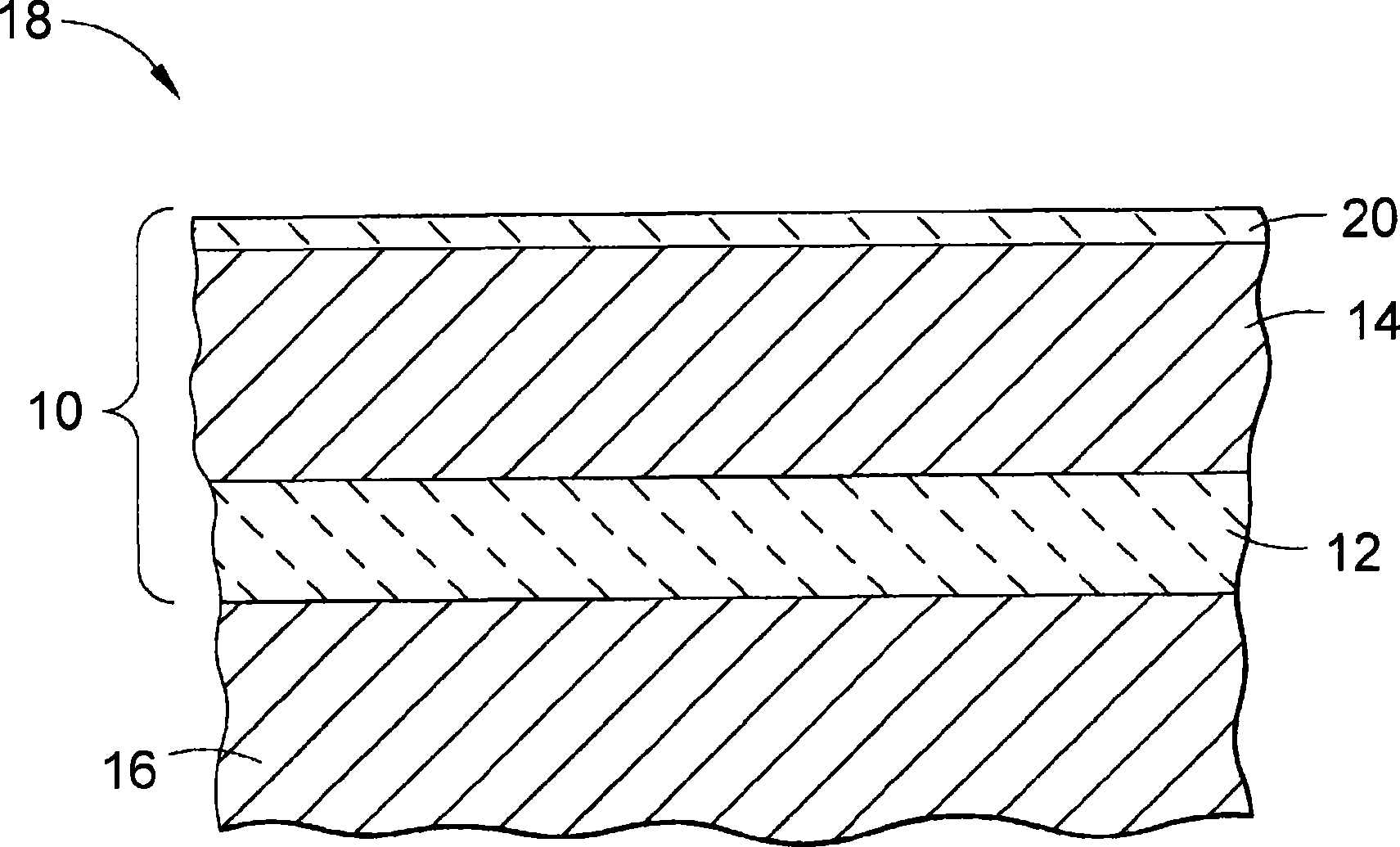

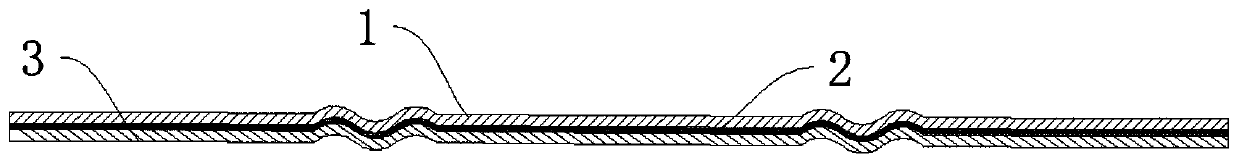

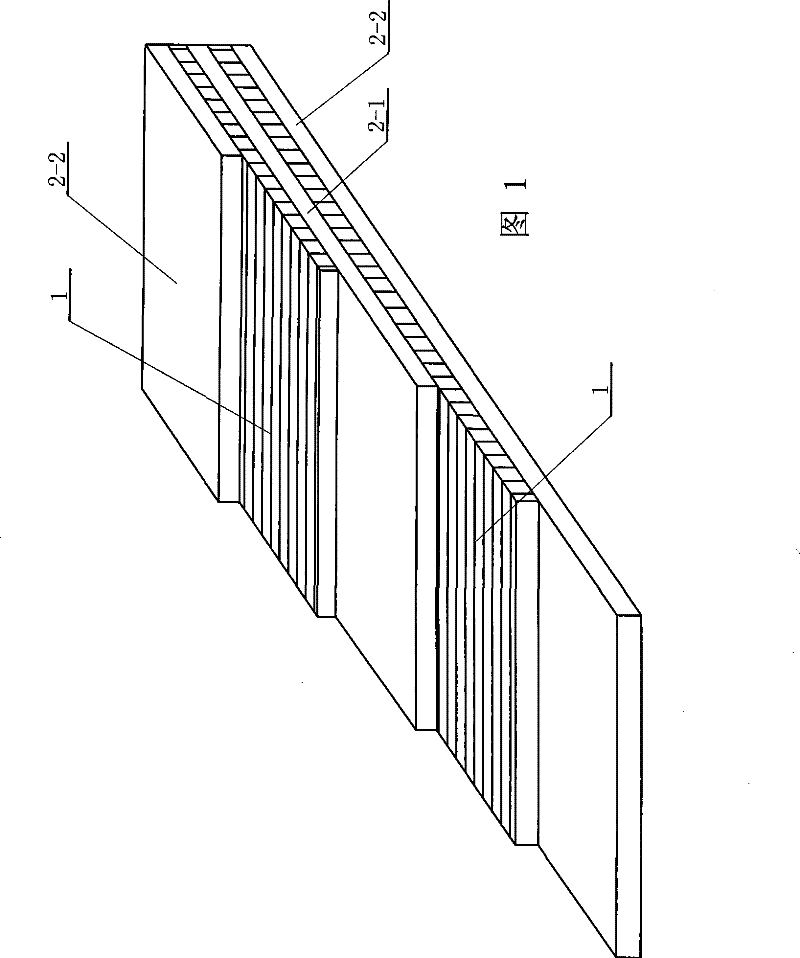

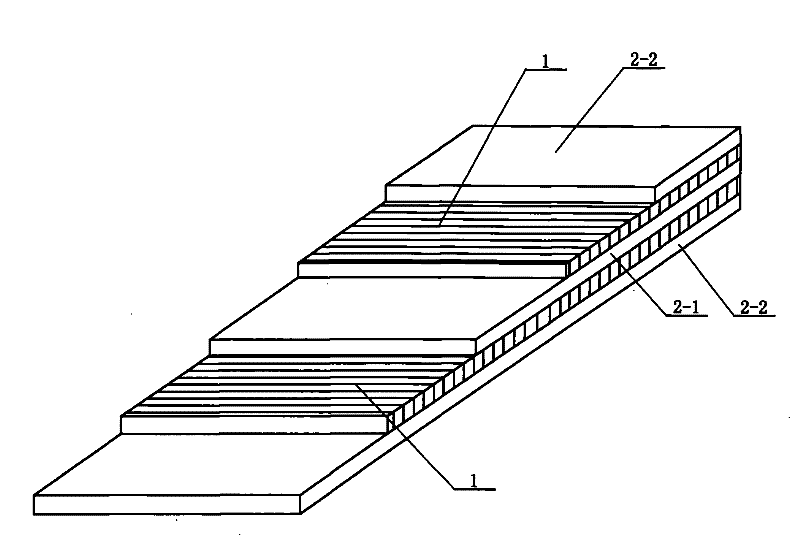

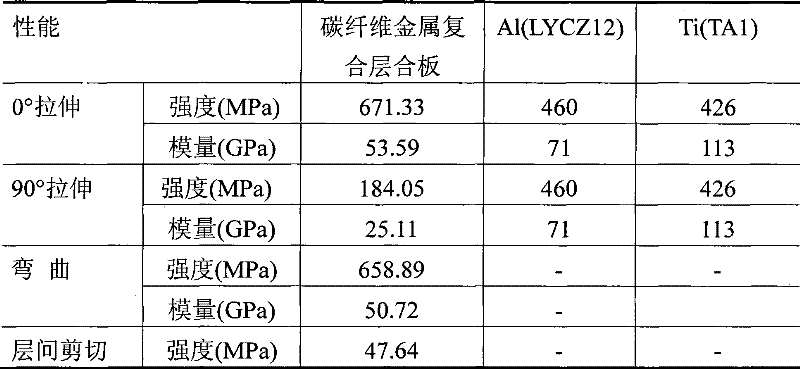

Manufacture method of carbon fiber metal composite laminated plate

InactiveCN101417524AFlame retardantImpact resistantLamination ancillary operationsLaminationFiberEpoxy

A manufacturing method of a carbon fiber metal composite laminated plate relates to a manufacturing method of a fiber metal composite laminated plate. The method aims at solving the problems that no manufacturing methods for manufacturing aircraft structural material with high specific stiffness, high specific strength, tenacity and workability exist in China. The method comprises the following steps of: carrying out surface treatment to three pieces of metal plates; winding a carbon fiber composite material layer which is soaked in liquid cement on one of the metal plates, wherein, the liquid cement is prepared by epoxy resin, a metaphenylene diamine curing agent and an anhydrous alcohol solvent according to the mass ratio of 1:0.1 to 0.18:0.15 to 0.2; fixedly arranging another two metal plates on the upper surface and the lower surface of the carbon fiber composite material layer so as to be integrally put into a mould, and then treated with mould assembling, drying, solidification by adopting the method of gradient temperature increasing, and demoulding. The manufacturing method of the invention is simple and is easy for operation. The carbon fiber metal composite laminated plate manufactured by the method of the invention has the advantages of high specific stiffness, high specific strength, also high tenacity and workability of metal material, good fatigue property, and good damage tolerance capability.

Owner:HARBIN INST OF TECH

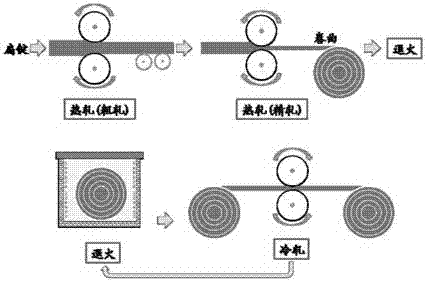

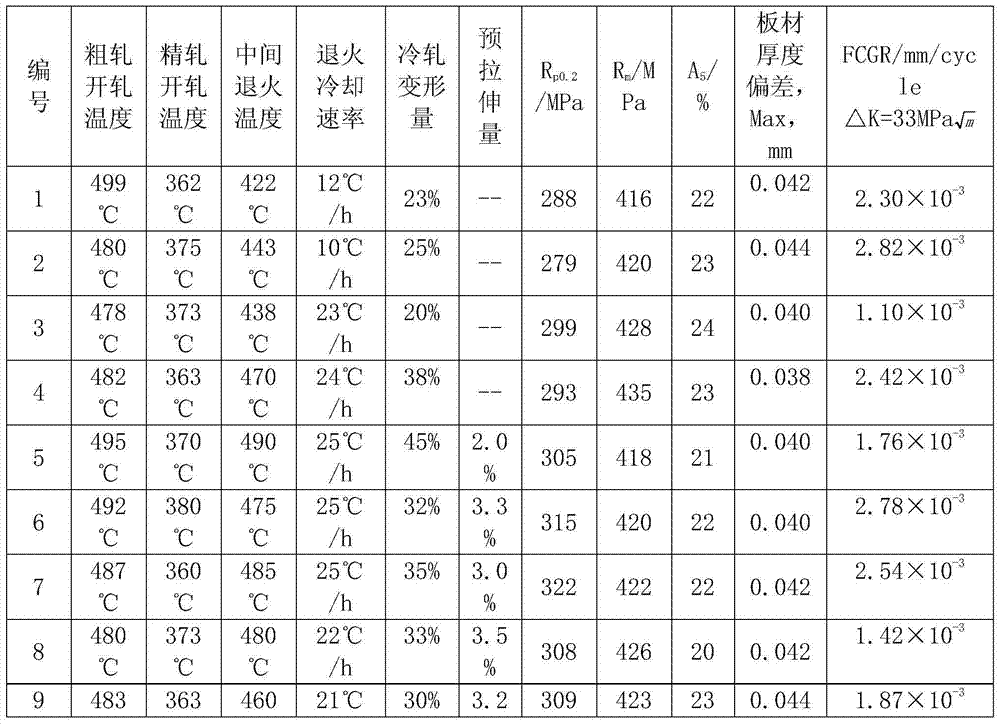

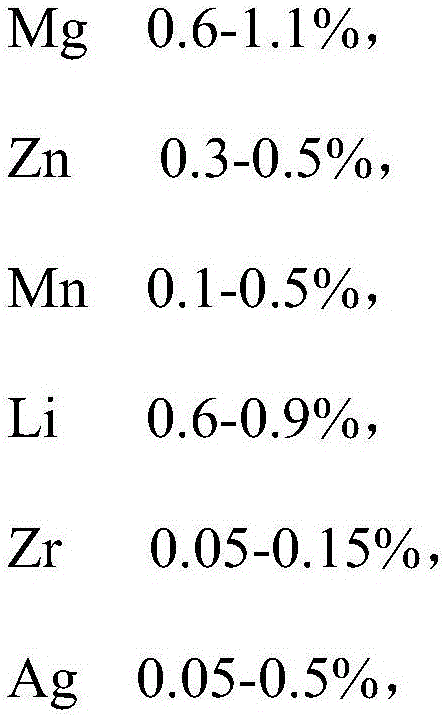

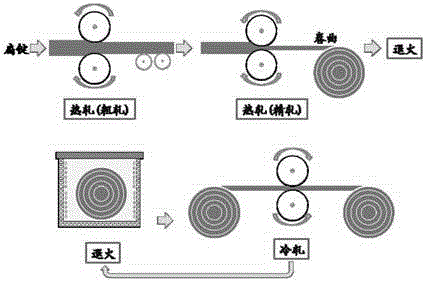

Preparation method of Al-Cu-Li-X series aluminum lithium alloy sheet

The invention discloses a preparation method of an Al-Cu-Li-X series aluminum lithium alloy sheet. The sheet prepared by the method is 0.8mm-8.0mm in thickness. The method comprises the following steps: cogging and hot-rolling homogenized slab ingots to a specified thickness and coiling; carrying out annealing treatment, uncoiling and carrying out band-type cold-rolling; carrying out intermediate annealing according to deformation during cold-rolling, thus obtaining the sheets with uniform thicknesses. The sheets can be in different states after being subjected to solution treatment, prestretching and aging treatment, so as to meet different usage requirements. Compared with the prior art, the aluminum lithium alloy sheet with high surface quality, uniform sheet size and smooth sheet shape is prepared by the method through band-type cold-rolling. The sheets can be in different states by different heat-treating processes, so as to meet usage requirements under different application conditions.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

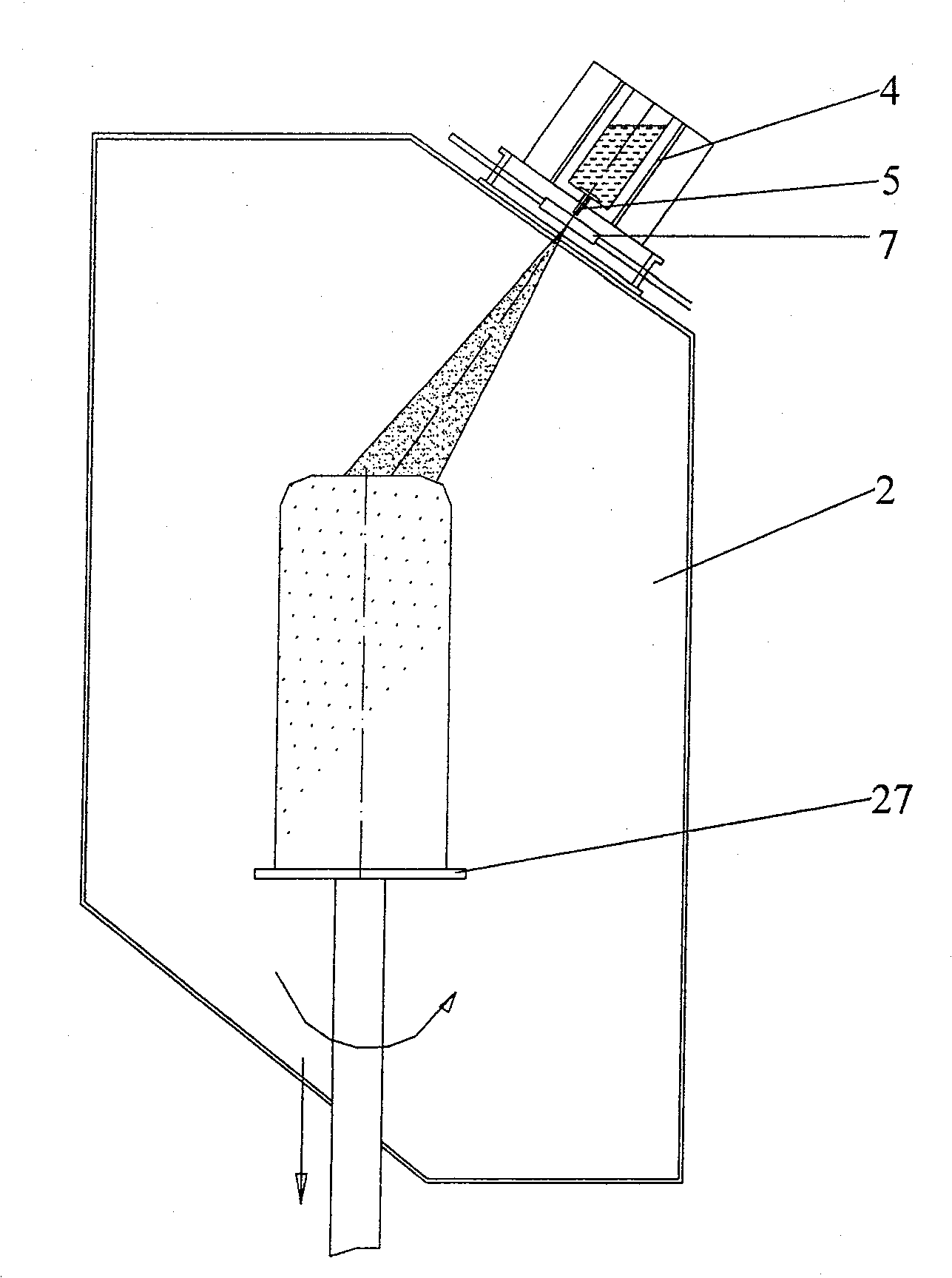

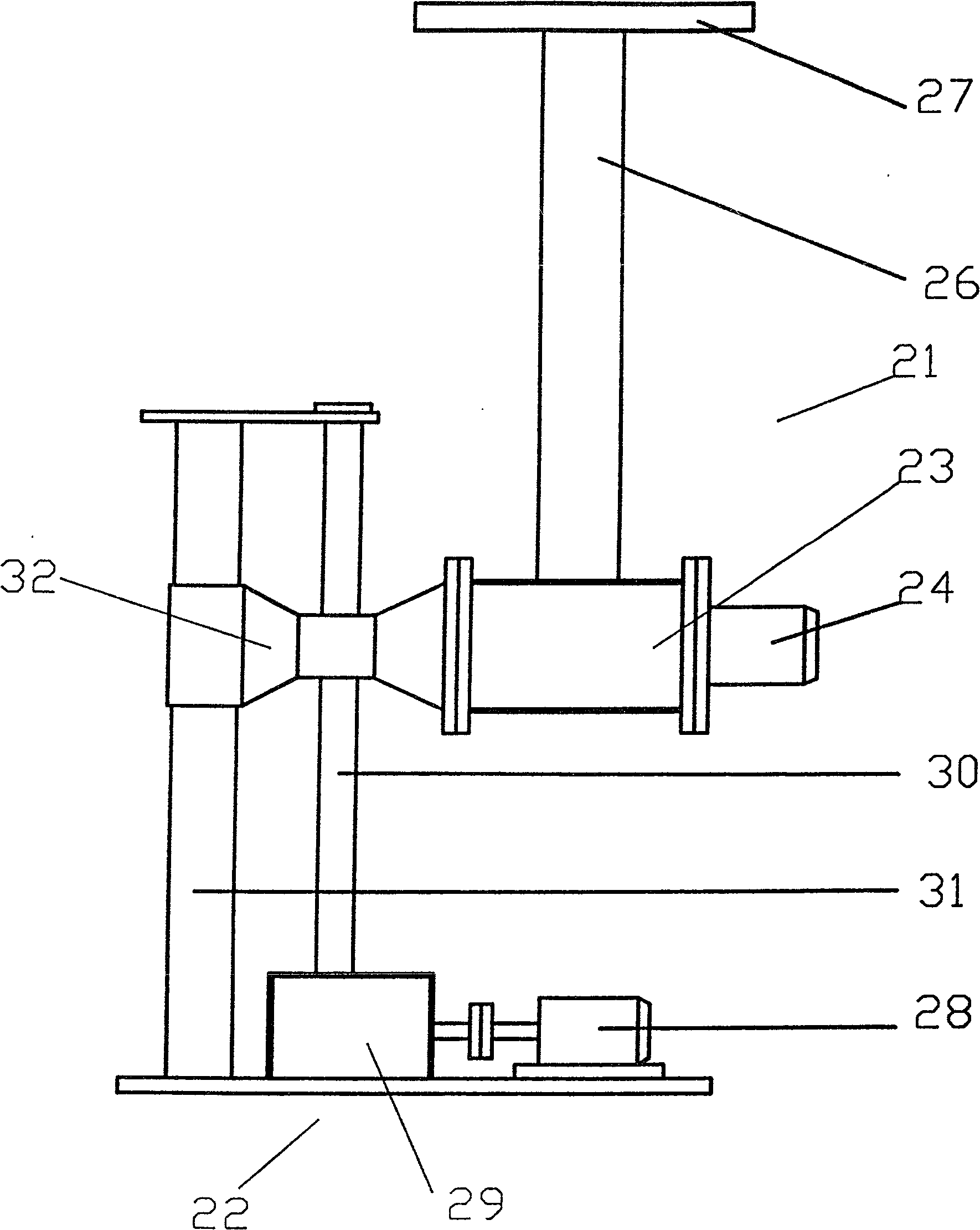

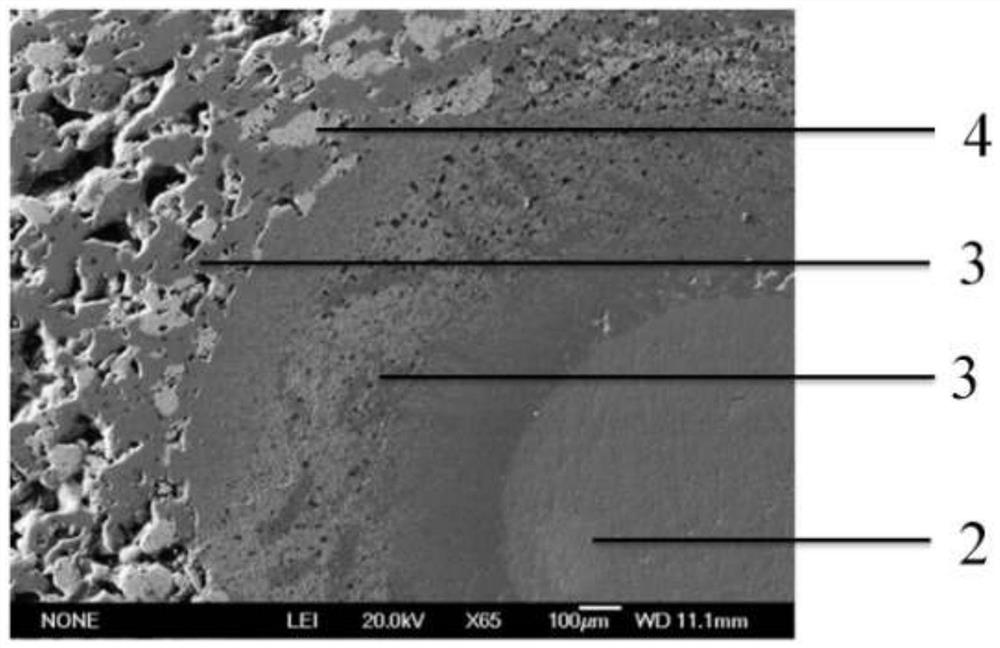

Erosion and corrosion-resistant coating system and process therefor

InactiveCN101481800AImprove antifouling performanceExtend your lifeMolten spray coatingEngine fuctionsThermal sprayingCoating system

The present invention relates to a erosion and corrosion-resistance coating system and process thereof. A coating system and process capable of providing erosion and corrosion-resistance to a component, particularly a steel compressor blade of an industrial gas turbine. The coating system includes a metallic sacrificial undercoat on a surface of the component substrate, and a ceramic topcoat deposited by thermal spray on the undercoat. The undercoat contains a metal or metal alloy that is more active in the galvanic series than iron, and electrically contacts the surface of the substrate. The ceramic topcoat consists essentially of a ceramic material chosen from the group consisting of mixtures of alumina and titania, mixtures of chromia and silica, mixtures of chromia and titania, mixtures of chromia, silica, and titania, and mixtures of zirconia, titania, and yttria.

Owner:GENERAL ELECTRIC CO

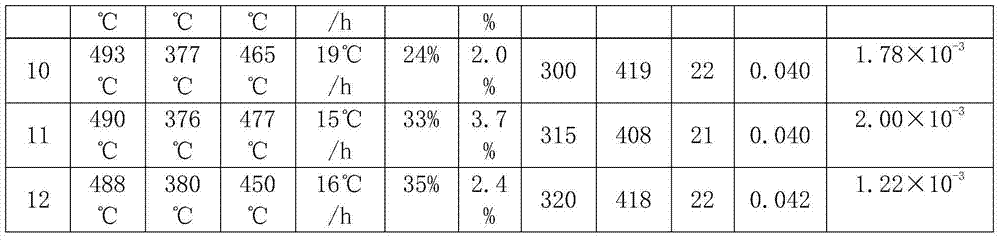

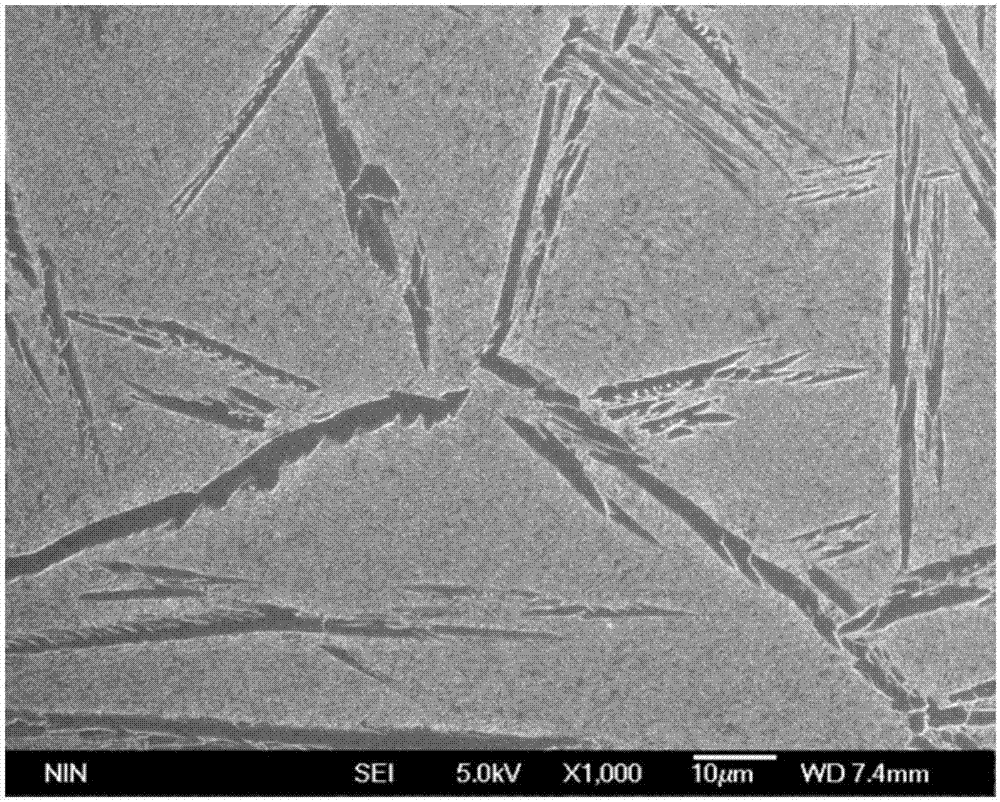

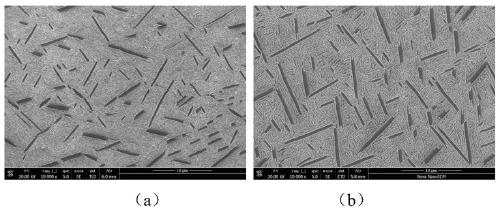

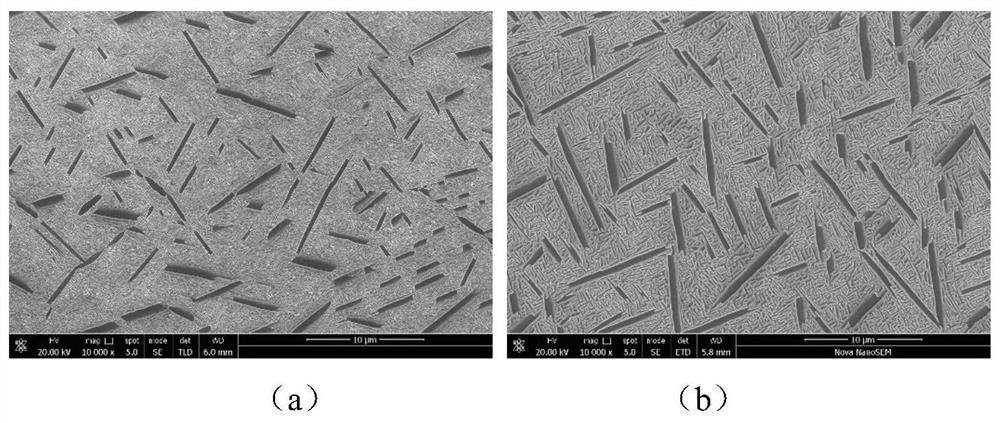

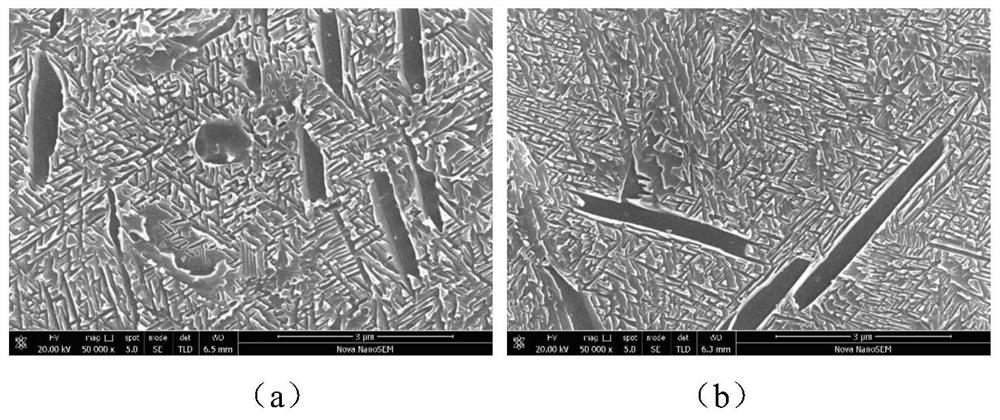

Thermal processing process for improving damage tolerance performance of titanium alloy forge piece

The invention provides a thermal processing process for improving the damage tolerance performance of a titanium alloy forge piece. The thermal processing process comprises the following steps: (1) carrying out solution treatment on a titanium alloy forge piece forged below a phase transformation point temperature; (2) after the solution treatment, cooling the titanium alloy forge piece to a temperature which is 60-80 DEG C lower than the phase transformation point, and carrying out air cooling until the titanium alloy forge piece reaches a room temperature; and (3) carrying out ageing treatment on the air-cooled titanium alloy forge piece, and carrying out air cooling until the titanium alloy forge piece reaches a room temperature. By utilizing the titanium alloy forge piece, with an initial microscopic structure containing an equiaxed structure, a basket-weave structure or a duplex structure, forged below the phase transformation point temperature, as a thermal processing object, the thermally processed titanium alloy forge piece has a relatively high strength and good plasticity and tenacity and simultaneously has relatively low fatigue crack extending rate, so that the limitation that the strength, plasticity and damage tolerance performance of titanium alloy which is subjected to traditional solution treatment-ageing treatment or solution furnace cooling treatment are difficult to be well matched is broken through.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

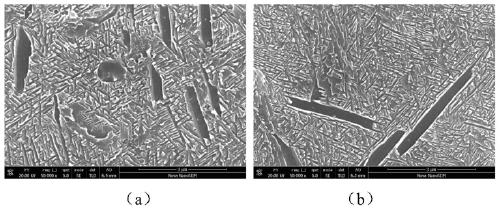

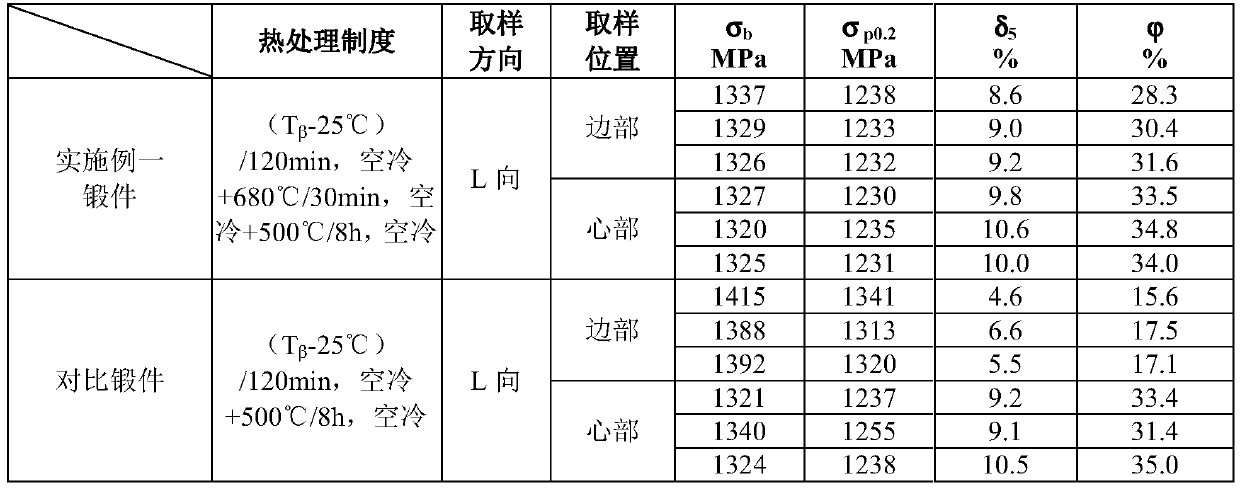

Heat treatment process of titanium alloy

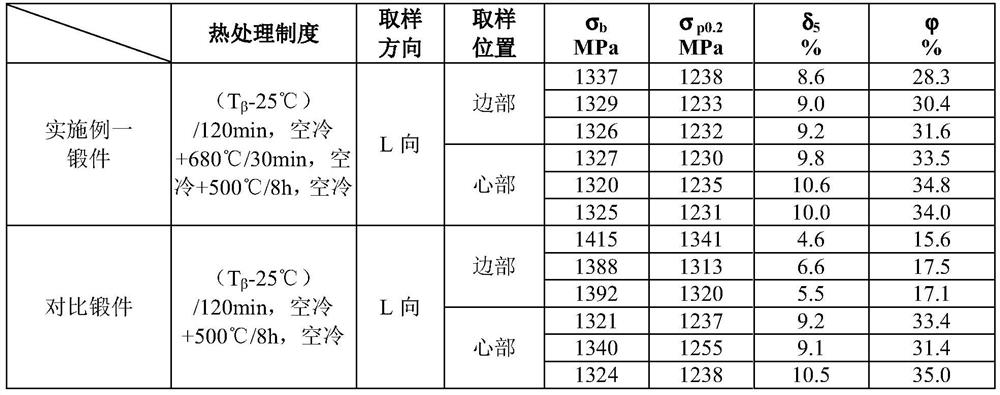

The invention discloses a heat treatment process of a titanium alloy, and belongs to the technical field of material science. The heat treatment process is mainly as follows: the heating temperature T of the first heating treatment is greater than or equal to (Tbeta-50) DEG C and less than or equal to (Tbeta+60) DEG C, the holding time t is equal to eta 1*delta max, the delta max is the maximum section thickness of a titanium alloy forged piece, the eta 1 is a heating coefficient, the value of the heating coefficient is 0.6-1.5min / mm, after the heat preservation on the forged piece is completed, the forged piece is discharged from a furnace and is subjected to air cooling, wind cooling, oil cooling or water cooling to a room temperature; the heating temperature T of the second heating treatment is greater than or equal to 650 DEG C and less than 780 DEG C, the holding time t is equal to (eta 2*delta max) / 2, the delta max is the maximum section thickness of the titanium alloy forged piece, the eta 2 is a heating coefficient, the value of the heating coefficient is 0.3-1.2min / mm, after the heat preservation on the forged piece is completed, the forged piece is discharged from the furnace and is subjected to air cooling to a room temperature; and the heating temperature T of the third heating treatment is greater than or equal to 480 DEG C and less than 650 DEG C, the holding time t is greater than or equal to 240min and less than or equal to 600min, and after the heat preservation on the forged piece is completed, the forged piece is discharged from the furnace and is subjected to air cooling to a room temperature. The heat treatment process solves the problems that after near-beta, metastable beta-type and fully-stable beta-type titanium alloys are subjected to solution treatment and ageing, the side and heart of the forged piece have large difference in structure properties, and is particularly suitable for preparing the high-strength titanium alloy forged piece with uniform structure properties and a large section / variable cross section.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

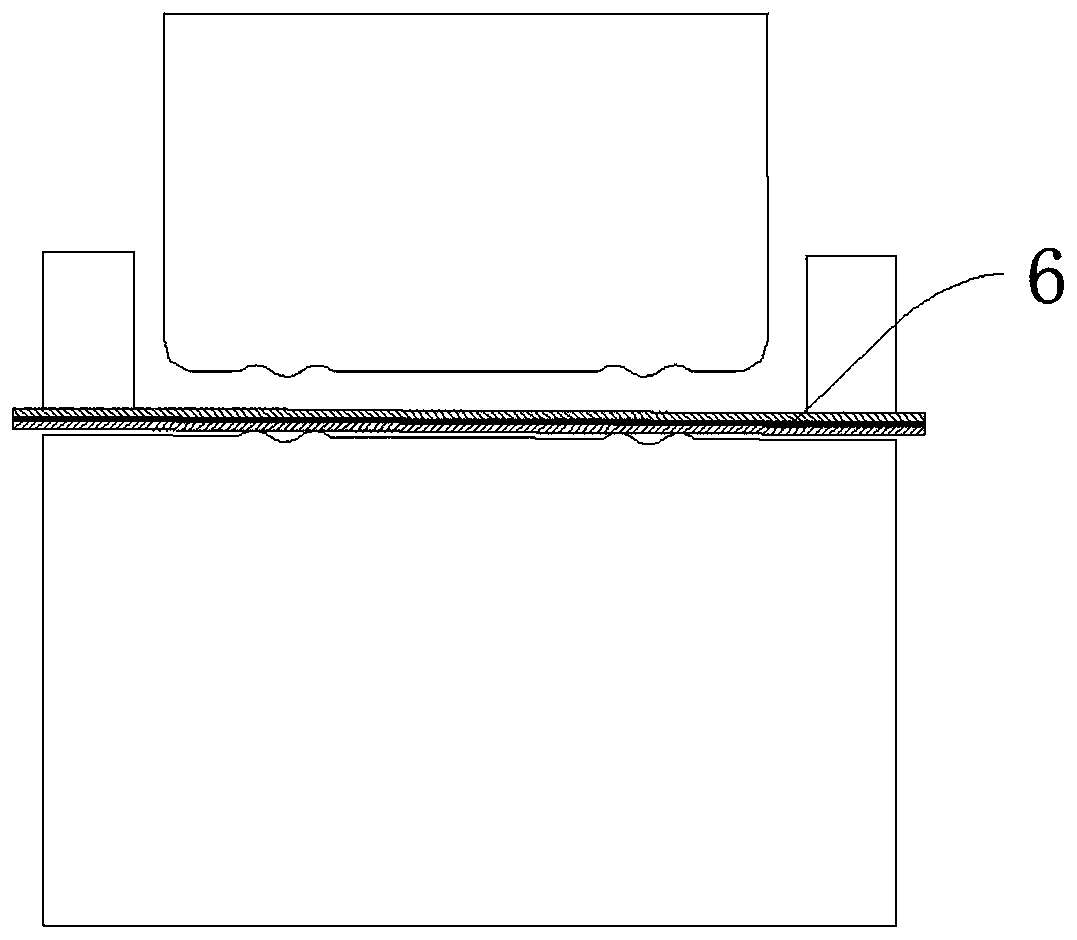

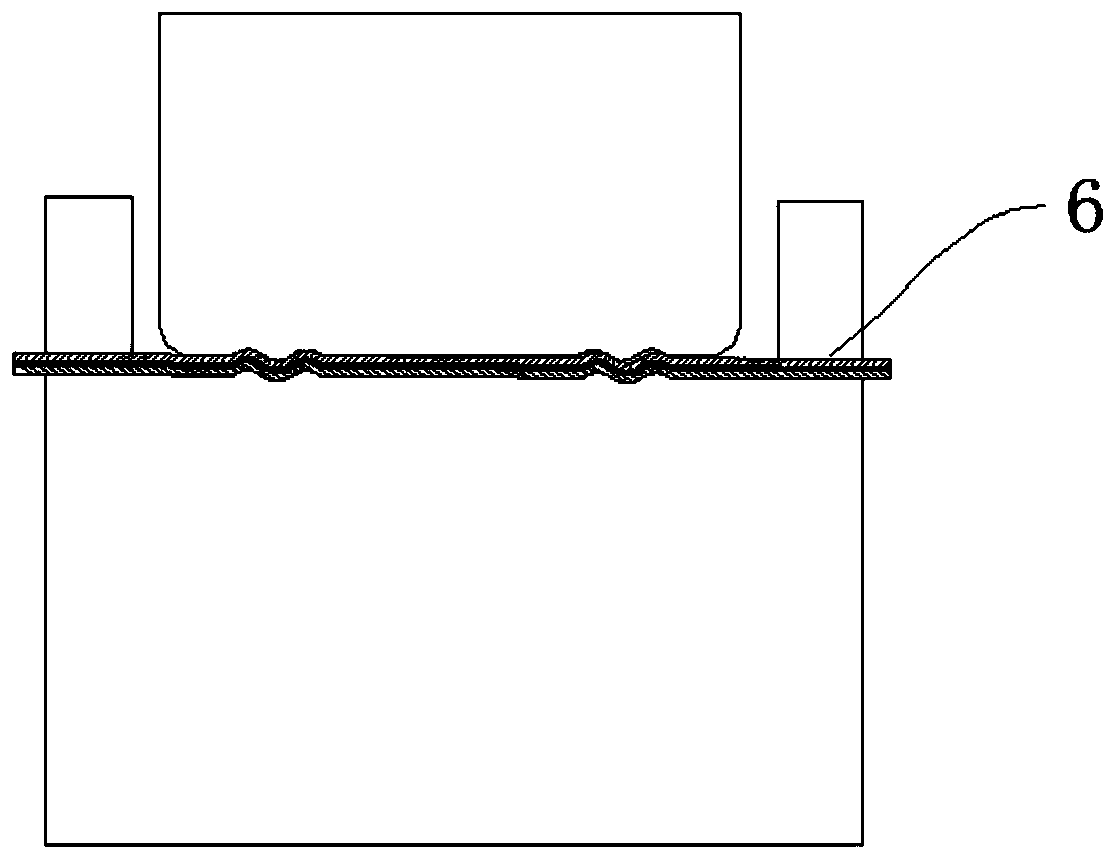

Method of forming fiber-aluminum alloy composite part

ActiveCN110143034AExtrude in timeOut in time, fromLamination ancillary operationsLaminationEpoxyFiber

The invention provides a method of forming a fiber-aluminum alloy composite part. The method comprises the following steps: 1, cutting an aluminum alloy plate and a fiber cloth according to a shape ofthe part; 2, subjecting the aluminum alloy plate to solid solution treatment, and immediately subjecting the aluminum alloy plate from the solid solution treatment to pre-pressing treatment, allowingfor uniform distribution of gridded grooves on a surface, glued to the fiber cloth, of the aluminum alloy plate, and then subjecting the pre-pressed aluminum alloy plate to quenching treatment; 3, subjecting the quenched aluminum alloy plate to degreasing treatment, and subjecting the fiber cloth to pre-impregnation treatment in an epoxy resin glue solution; 4, forming a sandwich plate in the order of aluminum alloy plate, fiber prepreg and aluminum alloy plate, and pre-pressing the sandwich plate; and 5, putting the obtained sandwich plate into a stamping die, closing the die and holding thetemperature, and then carrying out solidification to obtain the fiber-aluminum alloy composite part. The method overcomes the shortcoming of low elongation rate during the formation of a fiber material and improves the strength of the composite material part.

Owner:WUHAN UNIV OF TECH

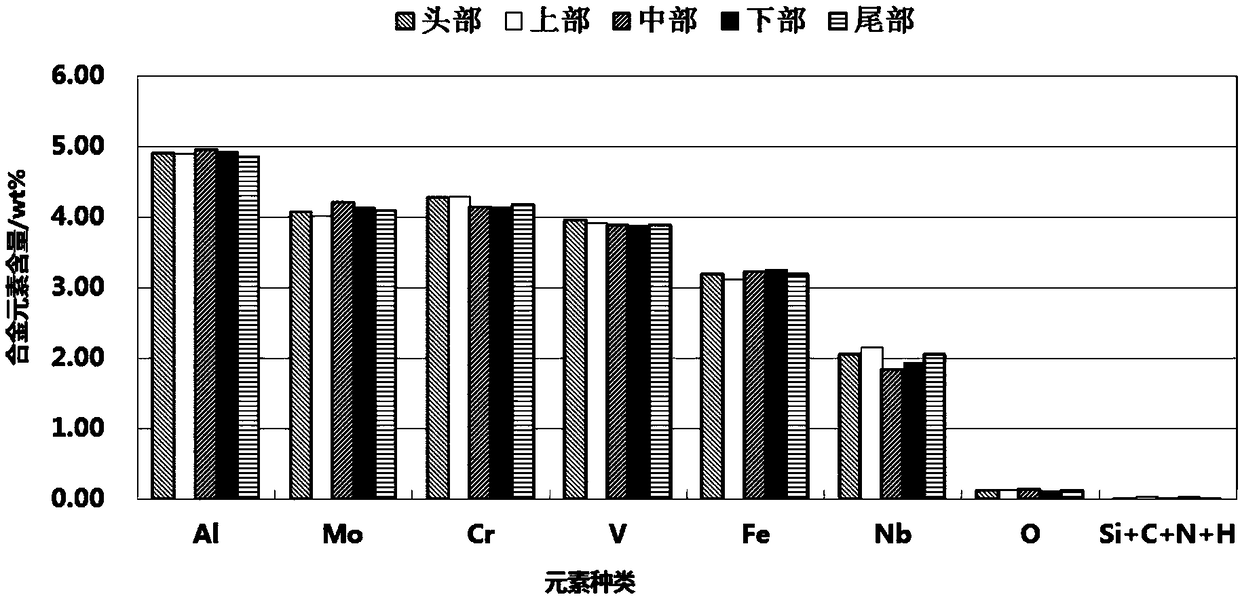

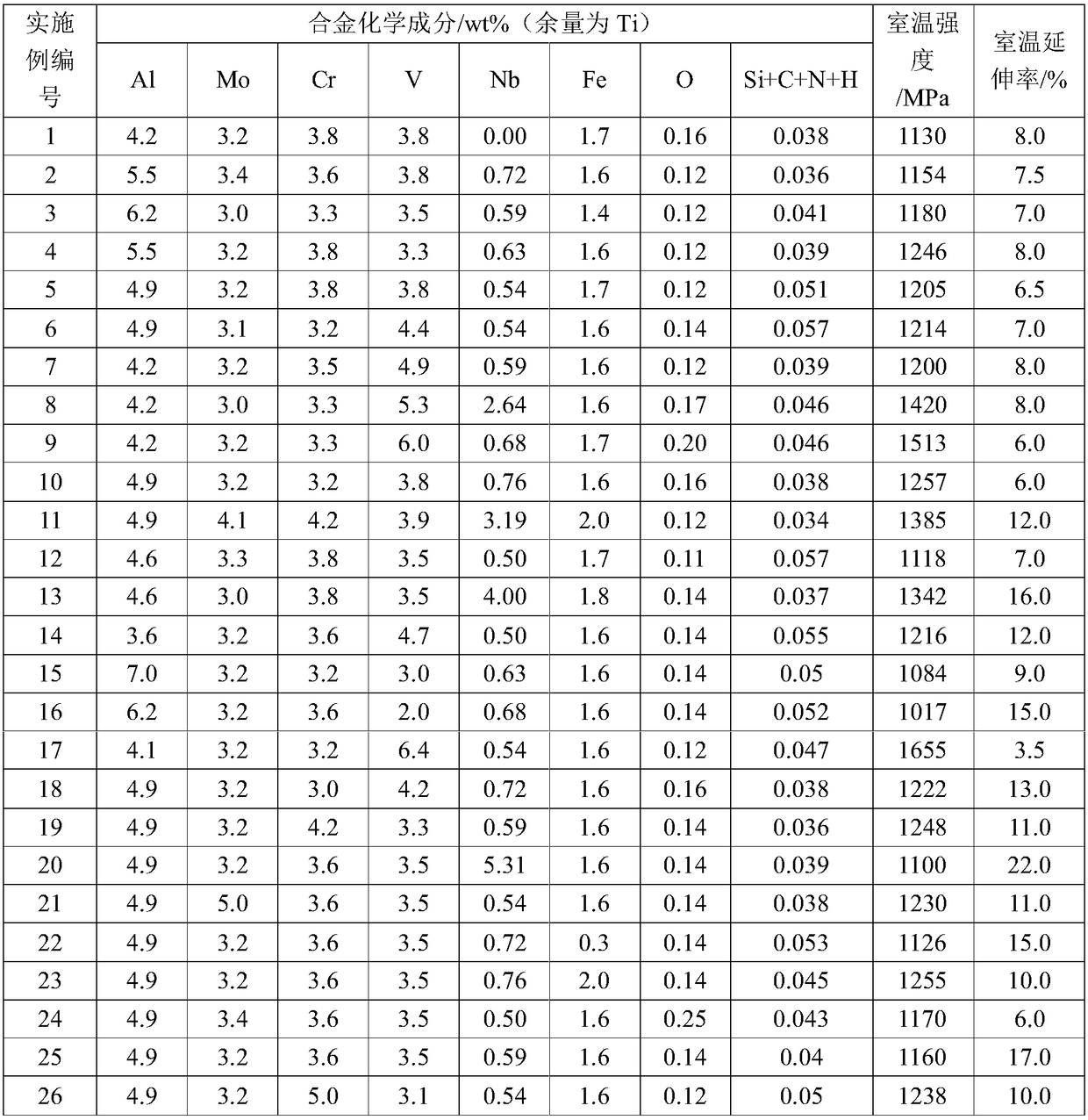

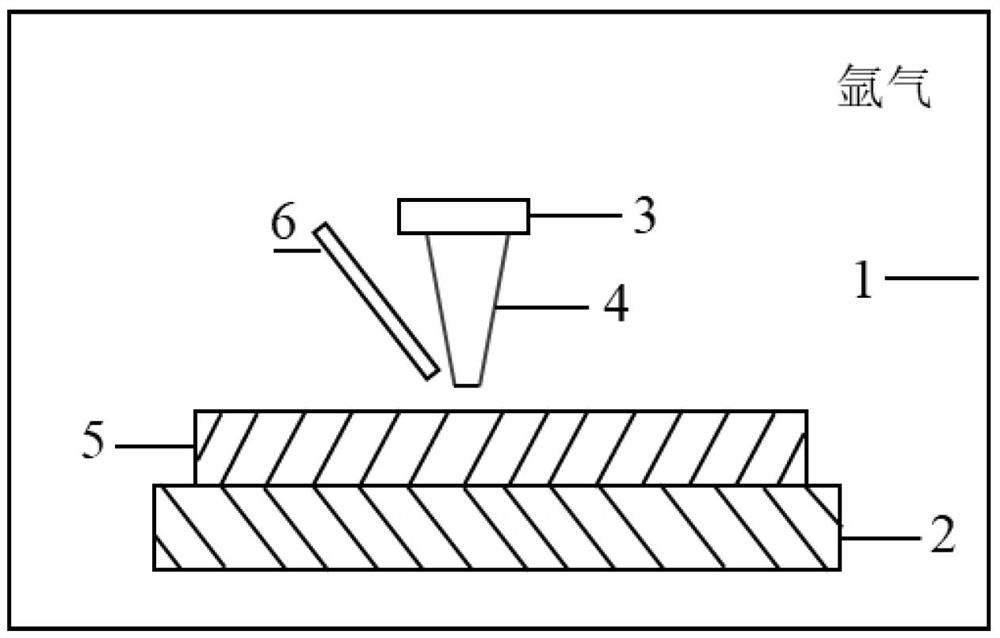

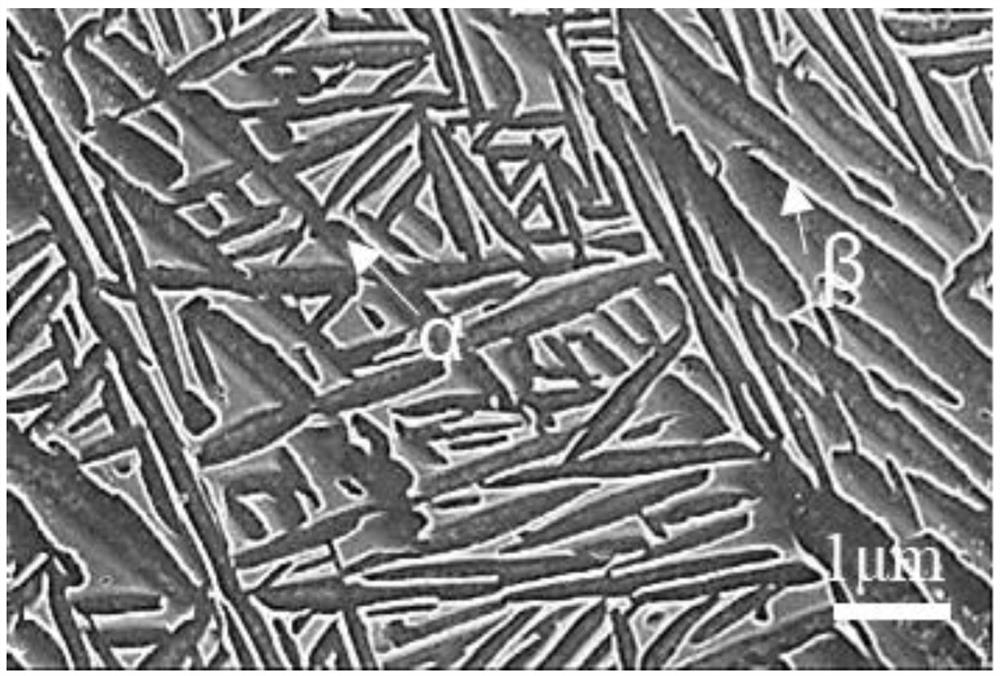

Reinforced and toughened metastable beta titanium alloy and preparation method thereof

InactiveCN108342616ALow content of impurity elementsReduce the content of elementsChemical compositionHigh density

The invention discloses a reinforced and toughened metastable beta titanium alloy. The reinforced and toughened metastable beta titanium alloy comprises the following elements in percentage by weight:3.6-6.0% of Al, 3.0-5.0% of Mo, 3.0-5.0% of V, 2.0-5.9% of Cr, 1.0-4.0% of Nb, 0.4-2.0% of Fe, 0.05-0.3% of O, and the balance of Ti and inevitable impurities; the total quantity of impurity elementsis not higher than 0.15%; and the weight percentage sum of all the components is 100%. The invention further discloses a preparation method of the titanium alloy. Through changing of the adding formof Nb element, formation of the high-density inclusion defect of Nb-enriched non-melted blocks is prevented. Step variable-power smelting process parameters are adopted, so that the ingot chemical component uniformity is improved, and the component uniformity and the performance stability of the WSTi544432 metastable beta titanium alloy are guaranteed.

Owner:西部超导材料科技股份有限公司

High-strength and high-toughness titanium alloy with good additive manufacturing forming performance and used at high temperature of 600 DEG C

ActiveCN113046595AGood additive manufacturing formabilityHigh temperature strengthAdditive manufacturing apparatusHeat stabilityTitanium alloy

The invention discloses a high-strength and high-toughness titanium alloy with good additive manufacturing forming performance and used at the high temperature of 600 DEG C, and belongs to the technical field of metal additive manufacturing. The titanium alloy comprises the following components in percentage by mass: 6.2-7.5% of Al, 1.2-4.5% of V, 1.2-4.5% of Mo, 0.5-2.0% of Nb, 3.2-9.6% of Zr, less than or equal to 0.02% of Mn, less than or equal to 0.02% of C, less than or equal to 0.01% of Ni, less than or equal to 0.20% of Si, less than or equal to 0.20% of Sn, less than or equal to 0.04% of Cr, less than or equal to 0.02% of O, less than or equal to 0.01% of P, less than or equal to 0.01% of S, less than or equal to 0.006% of N and the balance of Ti, and the mass percentage ratio of Al to (V + Mo + Nb + Zr) is 5:(4.2-13). Through alloy component design, alpha phase refining, strength improving, beta phase content optimizing, plasticity improving and melt thermal stability enhancing are achieved, the toughness of the alloy at the high temperature of 600 DEG C is improved to the maximum degree, and the alloy can be used for additive manufacturing forming.

Owner:DALIAN UNIV OF TECH

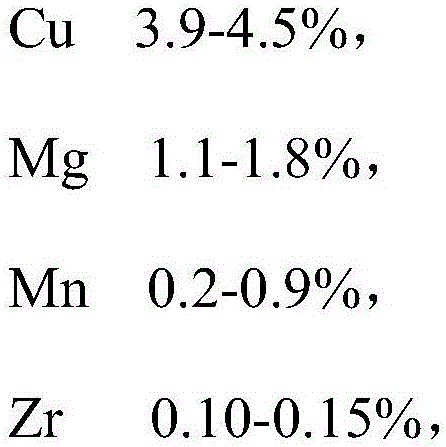

Method for improving damage tolerance performance of Al-Cu-Mg alloy

InactiveCN105734469AImproved resistance to fatigue damage toleranceImproved damage tolerance performanceFatigue damageCrazing

A method for improving the damage tolerance performance of an Al-Cu-Mg alloy is to carry out a solid solution + water quenching treatment on an Al-Cu-Mg alloy plate, and then perform a cold rolling pre-deformation treatment with a deformation amount of 6-15%, and then Perform aging treatment. The process of the invention is simple and reasonable, through cold rolling with small deformation amount after solid solution quenching, a certain compressive stress layer is generated on the surface of the plate, and the formation and expansion of cracks under the action of fatigue stress are effectively inhibited. With the natural aging treatment, the surface layer has a large density of dislocations due to the pre-deformation of cold rolling, which makes the alloy precipitate large-sized Cu-Mg atomic clusters during the natural aging process, and increases the Cu / Mg mass ratio of the clusters, so that The surface layer of the plate produces a large order strengthening effect and modulus strengthening effect; artificial aging treatment can cause the plate to precipitate a fine and dispersed second phase, and at the same time, the higher density dislocations on the surface can form a finer and dispersed second phase on the surface of the plate. Two phases, thereby hindering the formation and propagation of fatigue cracks in the surface area, and improving the fatigue resistance damage tolerance performance of the plate. This surface-hard-core-tough structure can effectively improve the damage tolerance performance of the plate, and is suitable for industrial applications.

Owner:CENT SOUTH UNIV

Heat treatment method for obtaining high-toughness and high-damage-tolerance dual-phase titanium alloy

ActiveCN113249667AImprove toughnessImproved damage tolerance performanceDamage toleranceTitanium alloy

The invention discloses a heat treatment method for obtaining a high-toughness and high-damage-tolerance double-phase titanium alloy. The heat treatment method comprises the following steps of high-temperature annealing treatment, specifically, keeping the temperature for 0.1-2 hours at T1 temperature, reasonably controlling the cooling speed, preferably, controlling the temperature range from T1 to T-200 DEG C to be 2-50 DEG C / s, controlling the value range of T1 between Tbeta10 DEG C and T, controlling the value range of T between Tbeta10 DEG C and T, controlling the value range of T between Tbeta10 DEG C and T, wherein T is the beta transformation temperature of the double-phase titanium alloy. According to the method, the toughness and the damage tolerance performance of the double-phase titanium alloy are improved by controlling the heat treatment temperature and the cooling speed. The method can be used for the two-phase titanium alloy with two structures under the room temperature conditions of TC11, TA15, TC4, TC17, TC18 and the like, is not limited by the original manufacturing process of the titanium alloy, and is suitable for forge pieces, castings, welding pieces and additive manufacturing pieces of the two-phase titanium alloy.

Owner:北京煜鼎增材制造研究院股份有限公司

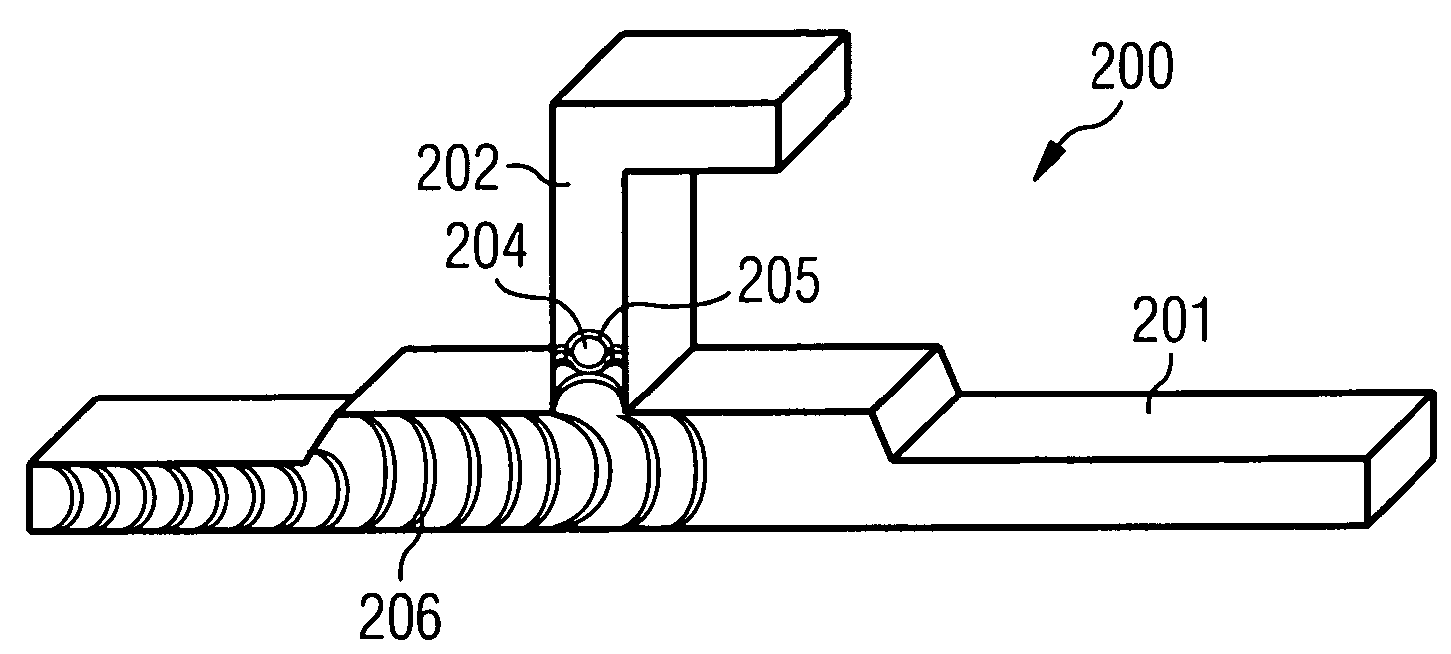

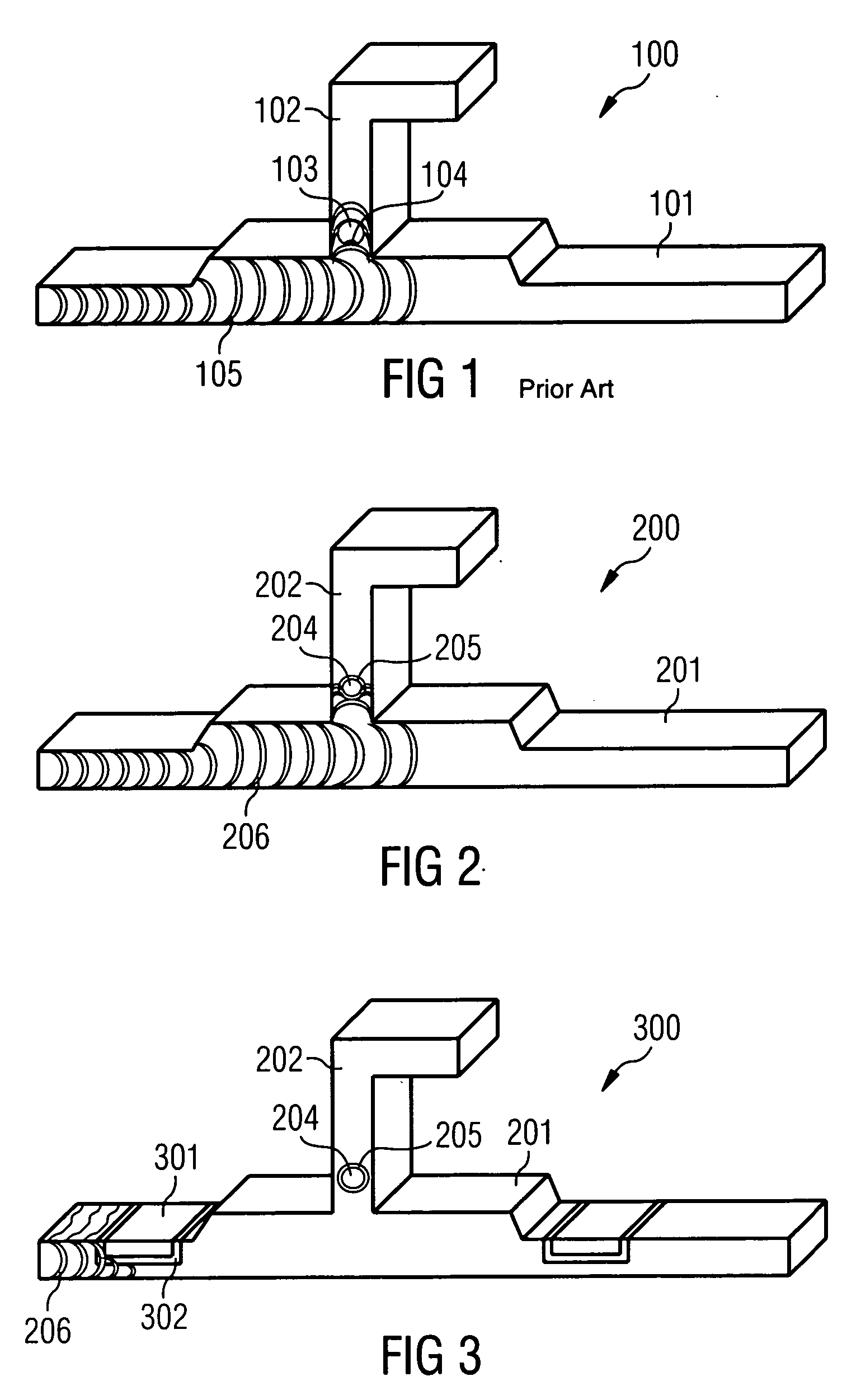

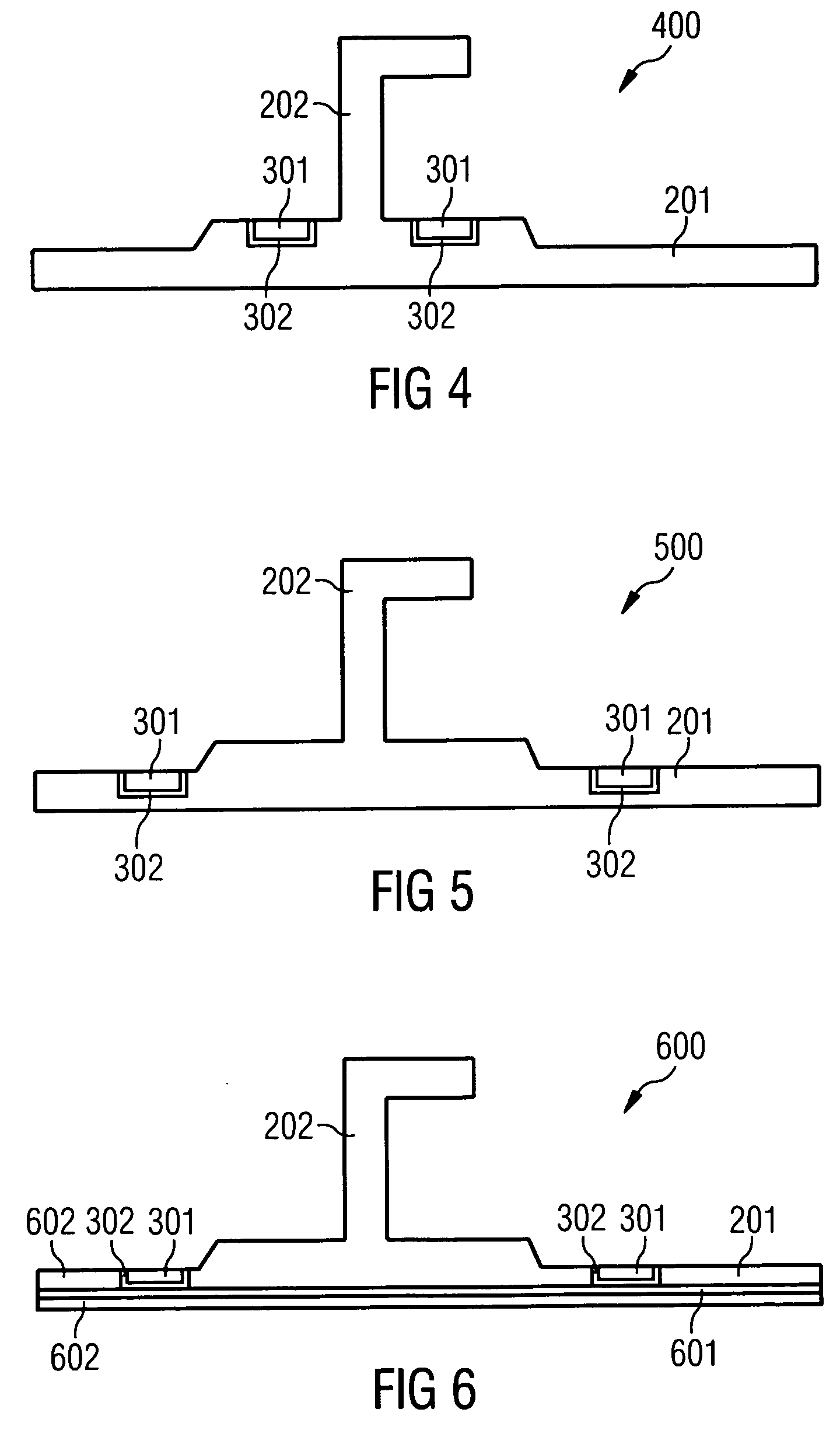

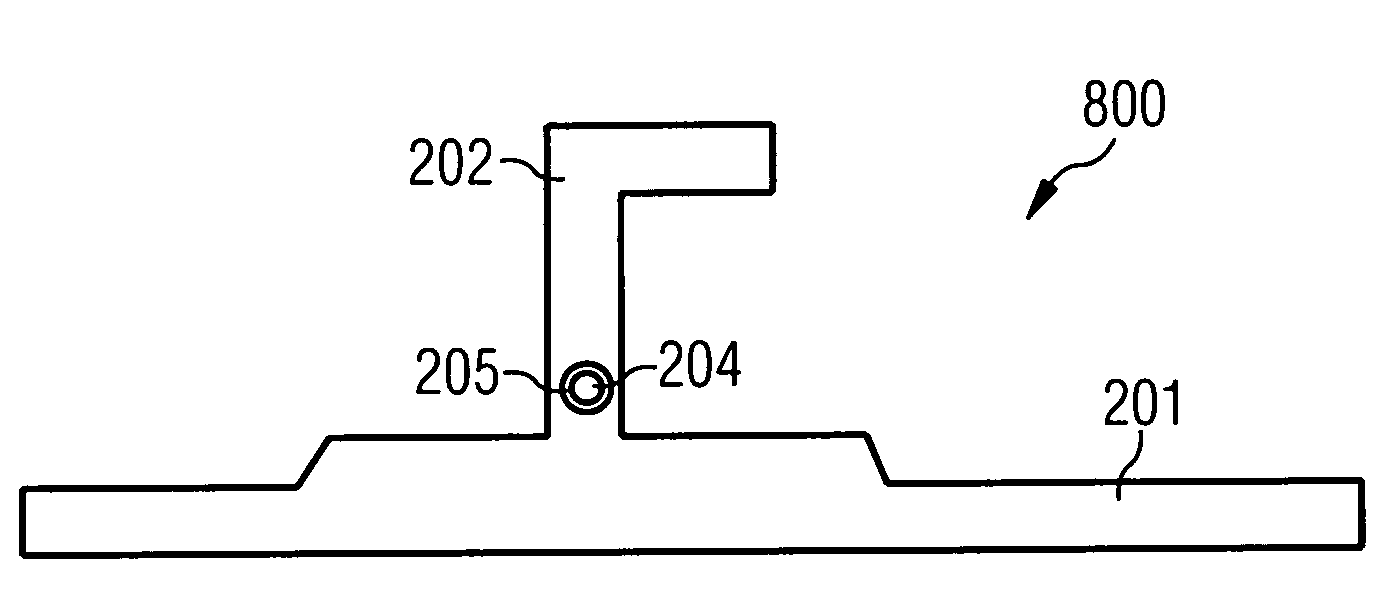

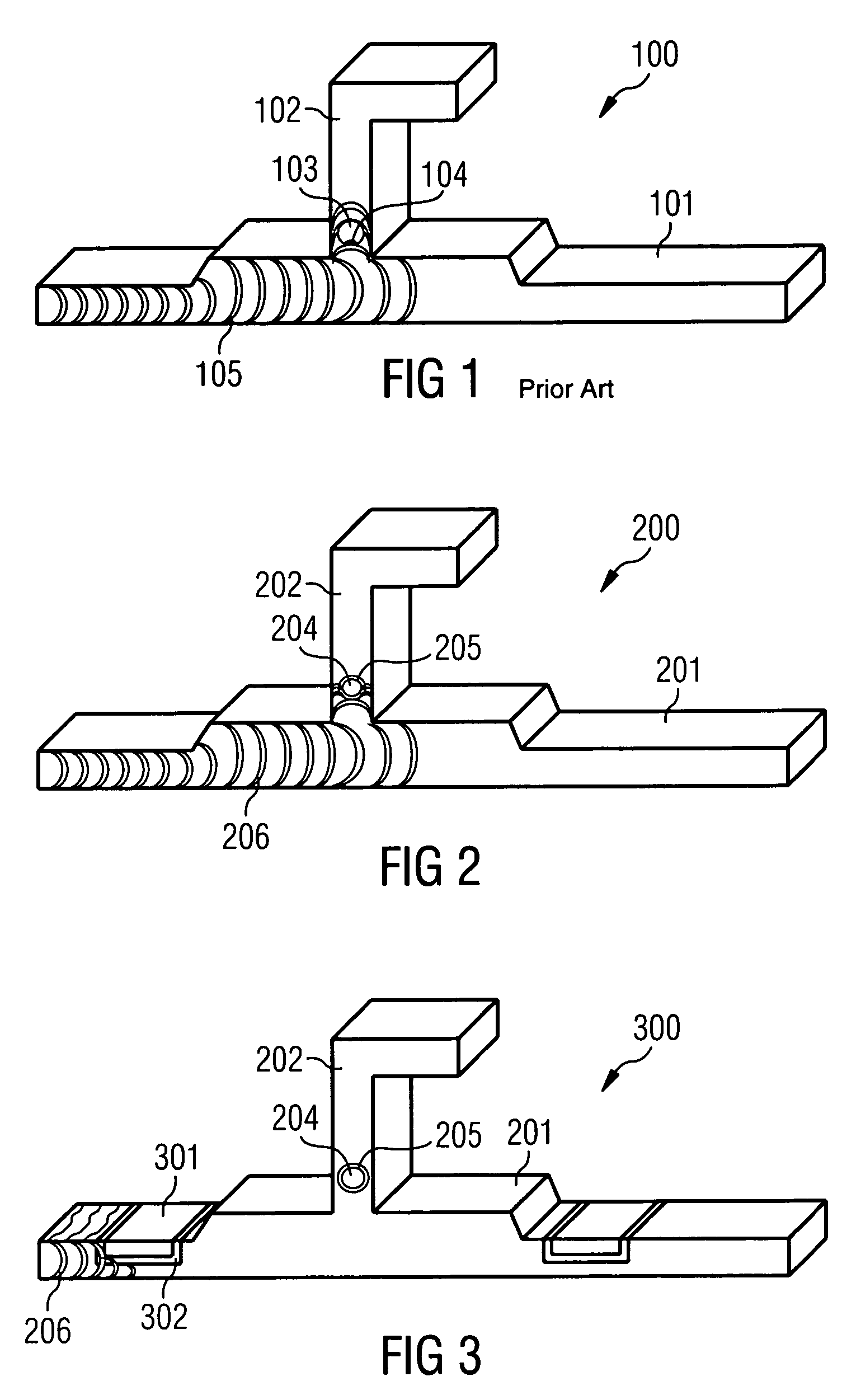

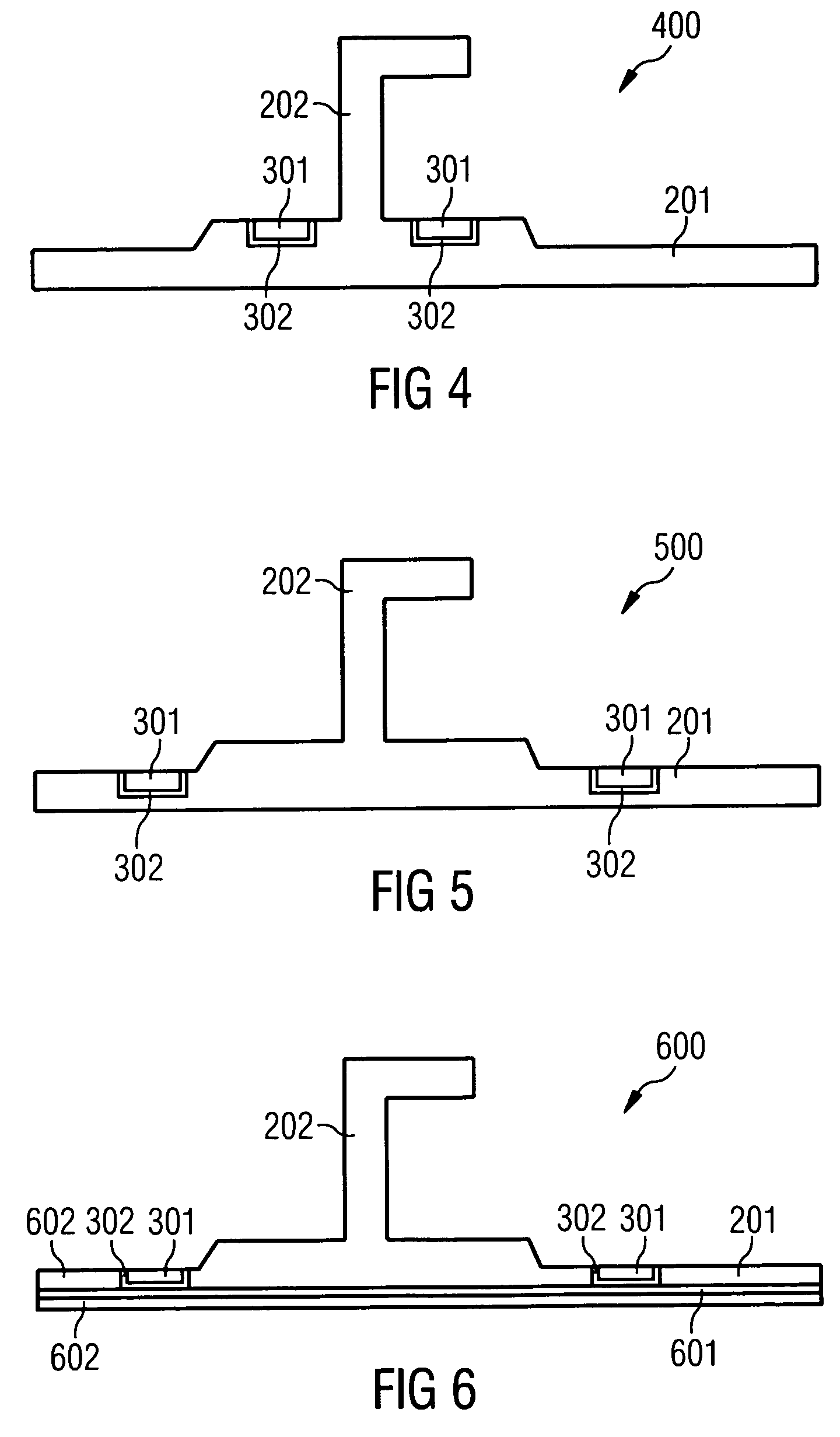

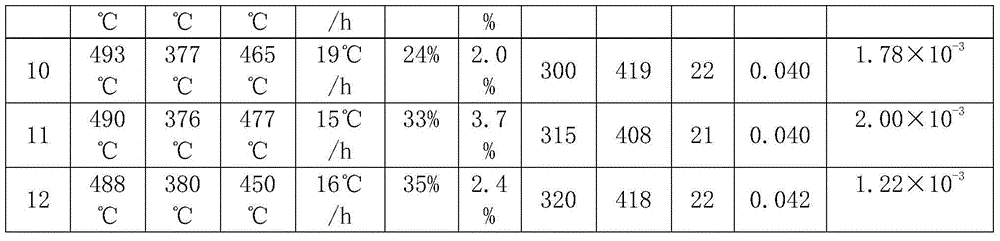

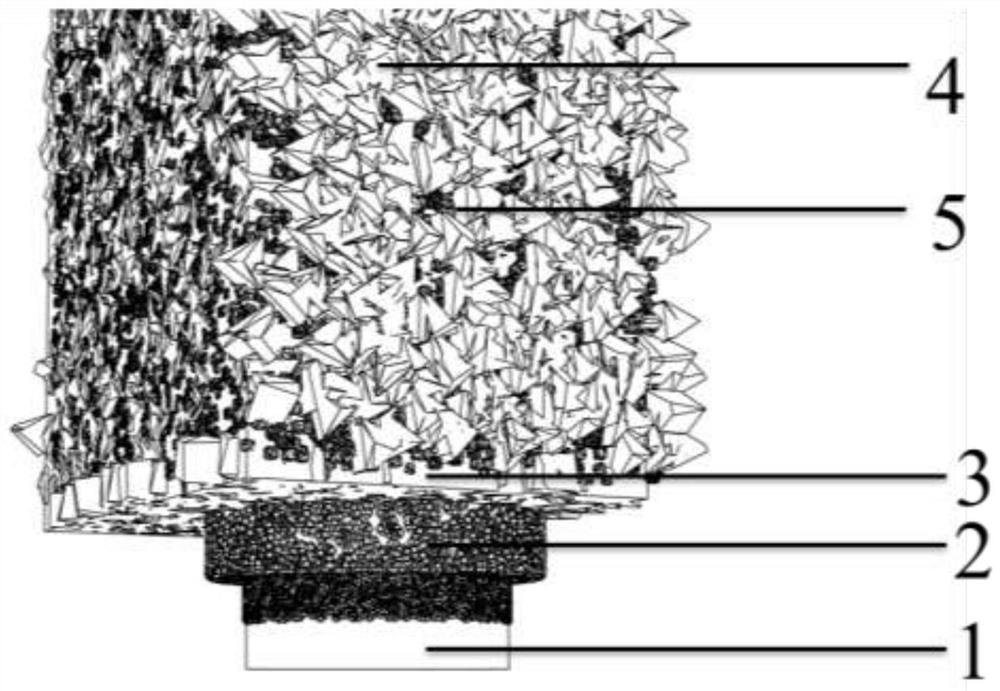

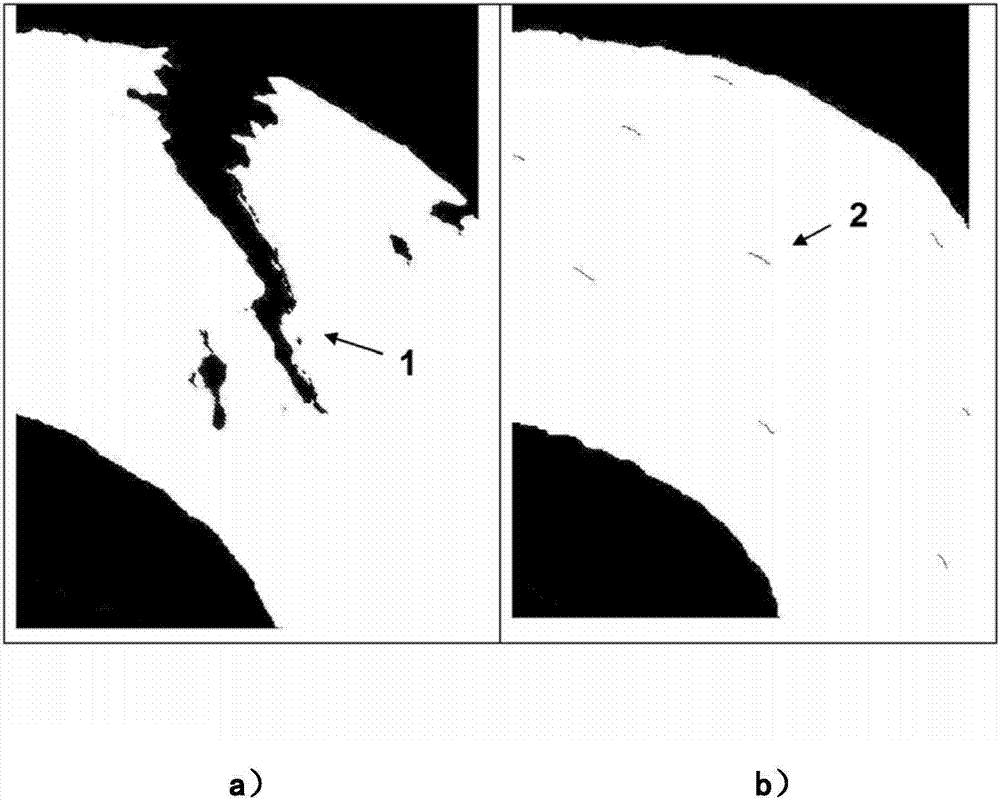

Structural element, method for manufacturing a structural element and use of a structural element for an aircraft hull

InactiveUS20060156662A1Suppressing crack growthImprove mechanical propertiesFuselage framesAircraft stabilisationInter layerMechanical engineering

A structural element includes the following elements: a carrier element, a reinforcing element, and a sheathing element. At least a portion of the reinforcing element is enveloped by the sheathing element and the reinforcing element is embedded in the carrier element. Materials of the elements are selected to inhibit crack initiation or propagation in the elements and / or from one element to another. An intermediate layer of a different material may be added between elements to further inhibit crack initiation and propagation and to inhibit corrosion, such as galvanic corrosion.

Owner:AIRBUS OPERATIONS GMBH

Structural element, method for manufacturing a structural element and use of a structural element for an aircraft hull

InactiveUS7850118B2Prevent crack propagationImproved damage tolerance performanceFuselage framesAircraft stabilisationEngineeringMechanical engineering

A structural element includes the following elements: a carrier element, a reinforcing element, and a sheathing element. At least a portion of the reinforcing element is enveloped by the sheathing element and the reinforcing element is embedded in the carrier element. Materials of the elements are selected to inhibit crack initiation or propagation in the elements and / or from one element to another. An intermediate layer of a different material may be added between elements to further inhibit crack initiation and propagation and to inhibit corrosion, such as galvanic corrosion.

Owner:AIRBUS OPERATIONS GMBH

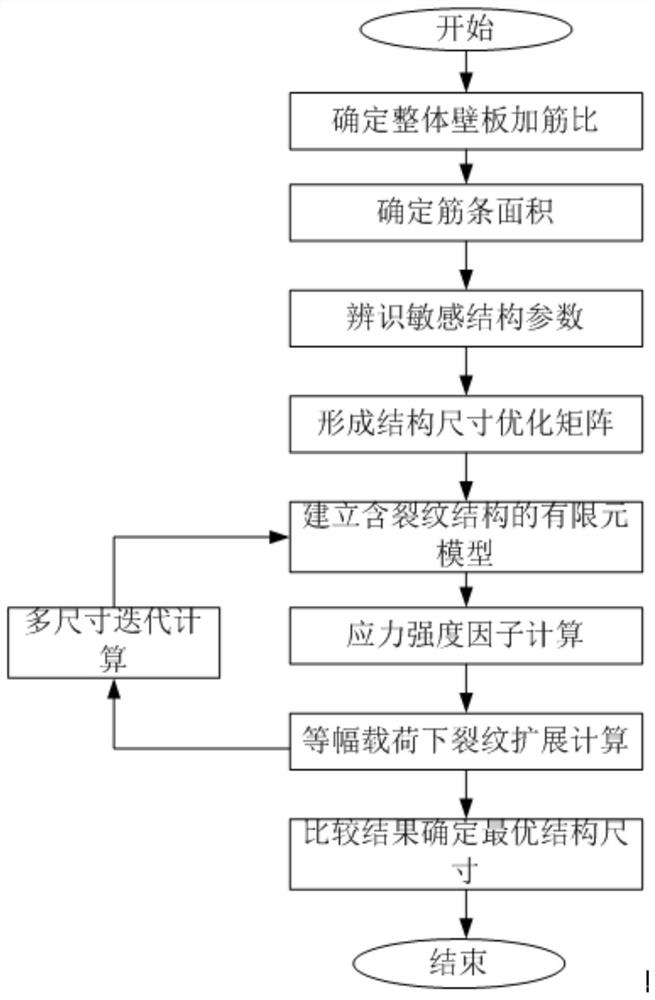

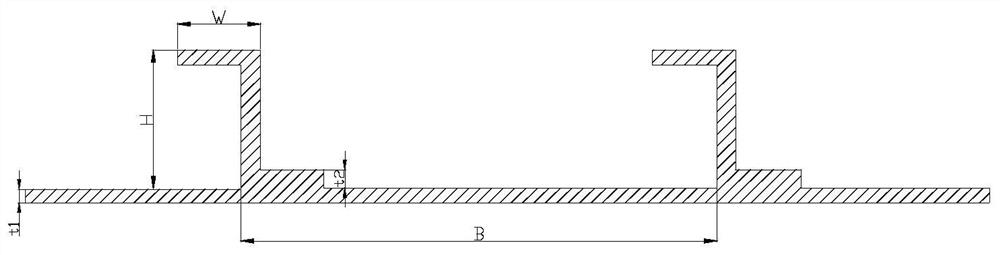

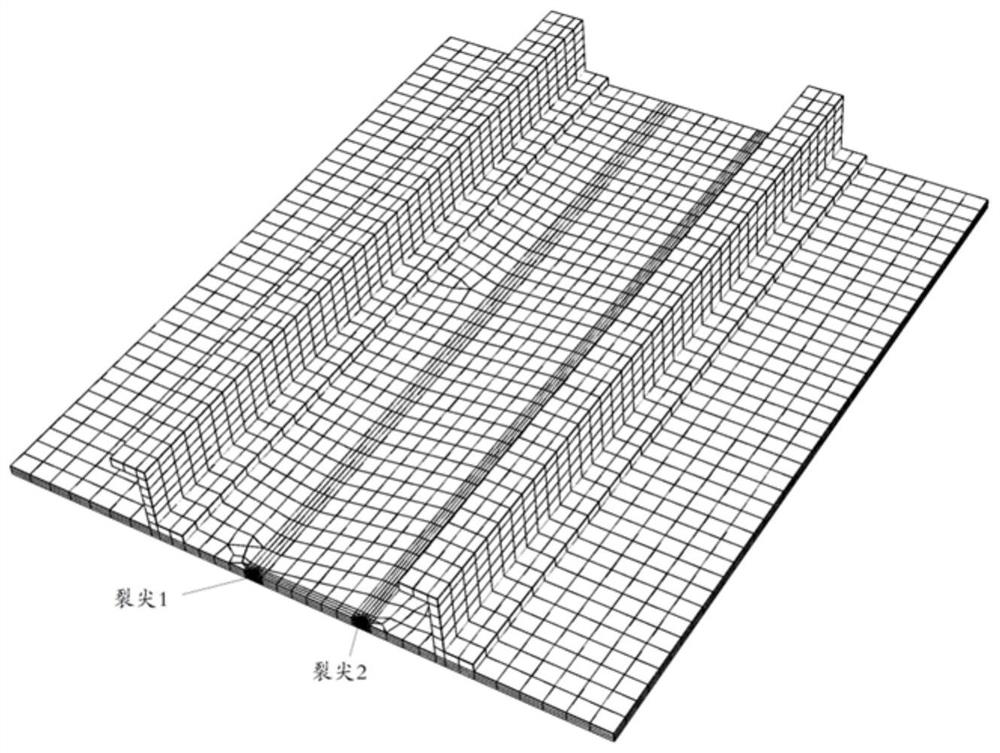

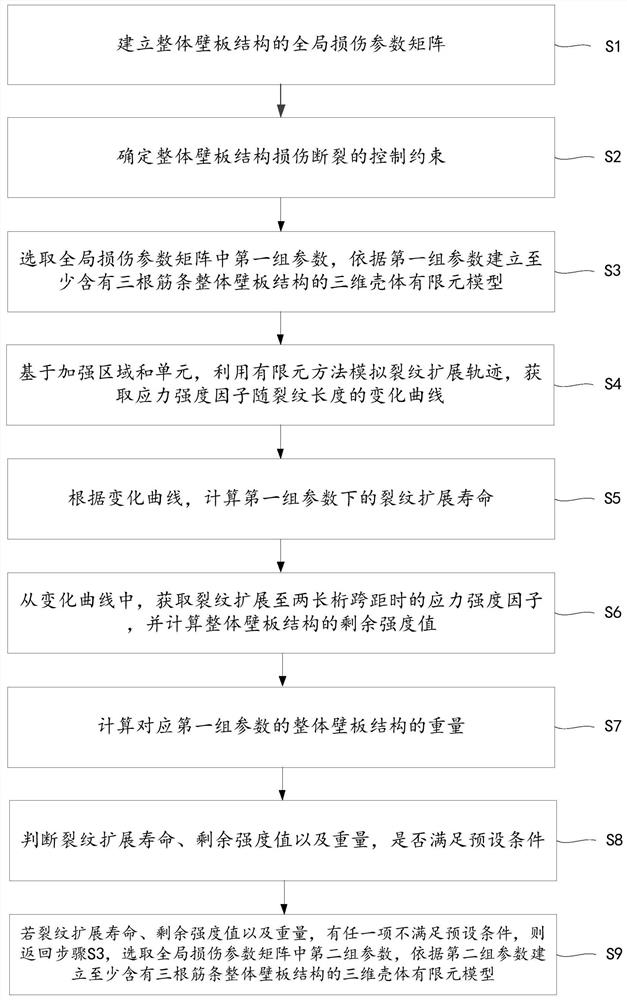

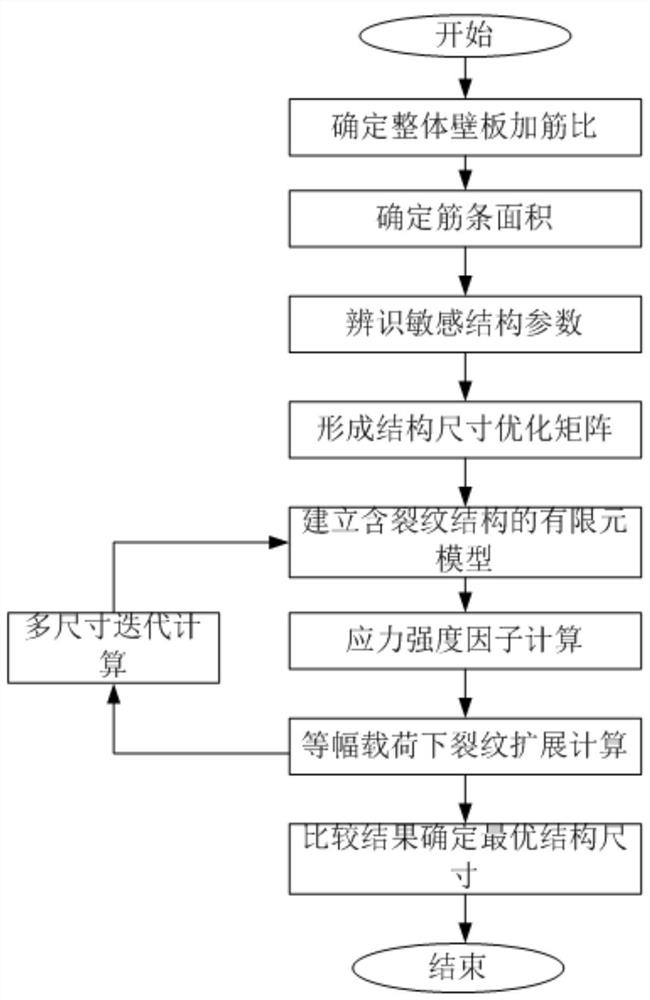

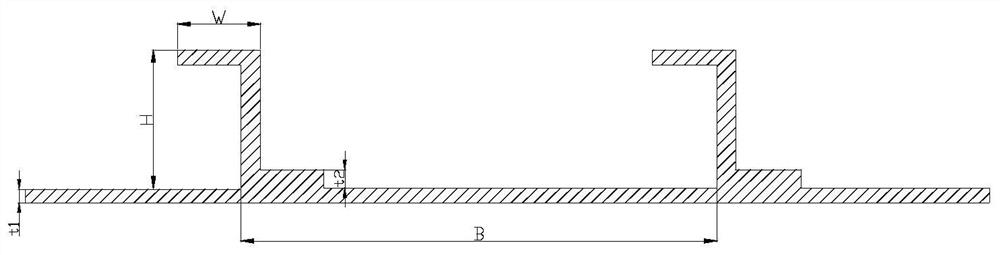

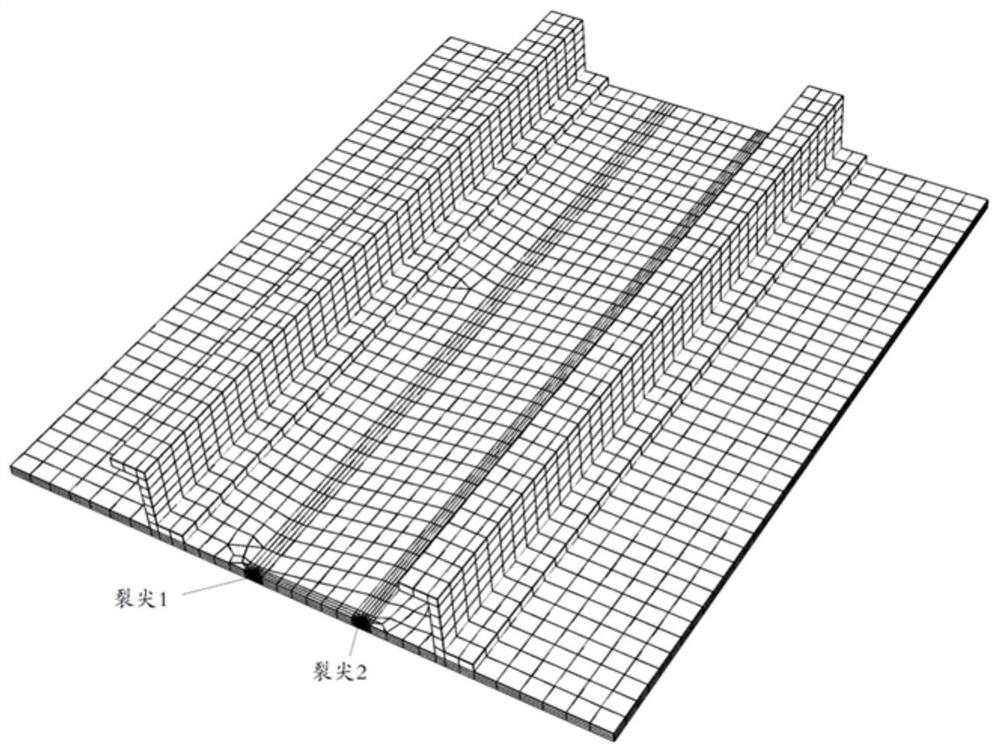

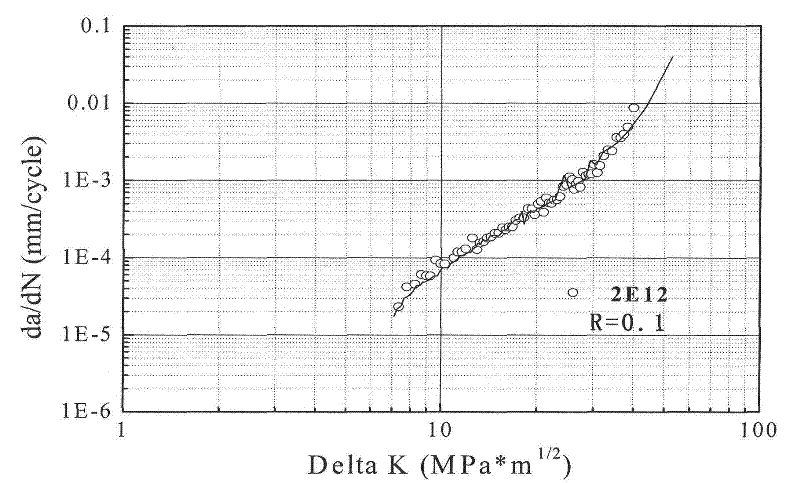

Rib integral wall plate damage tolerance optimization method

InactiveCN112733262AImproved damage tolerance performanceEasy to useGeometric CADDesign optimisation/simulationElement modelAlgorithm

The invention belongs to the field of aircraft structure damage tolerance design, and discloses a rib integral panel damage tolerance optimization method, which comprises the steps of integral panel reinforcement ratio determination, rib sensitive parameter recognition, structure size optimization matrix establishment, crack-containing integral panel finite element model establishment, stress intensity factor k calculation and crack propagation life calculation. And determining optimal structure parameters through comparison of crack propagation lives under different sizes.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

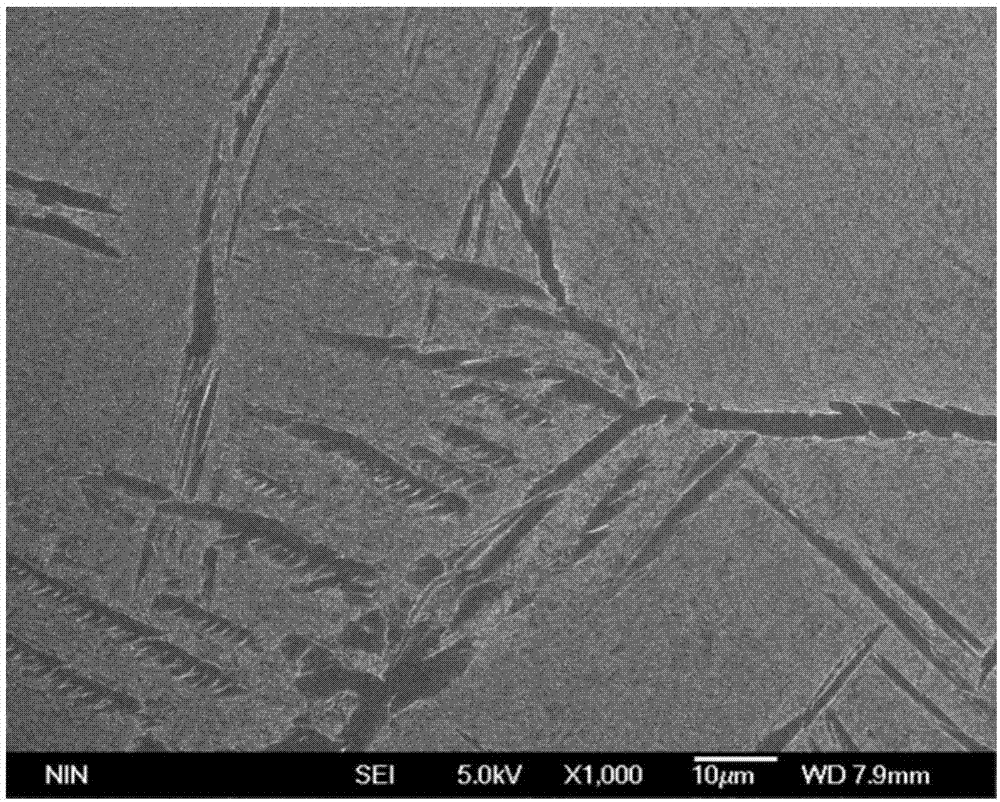

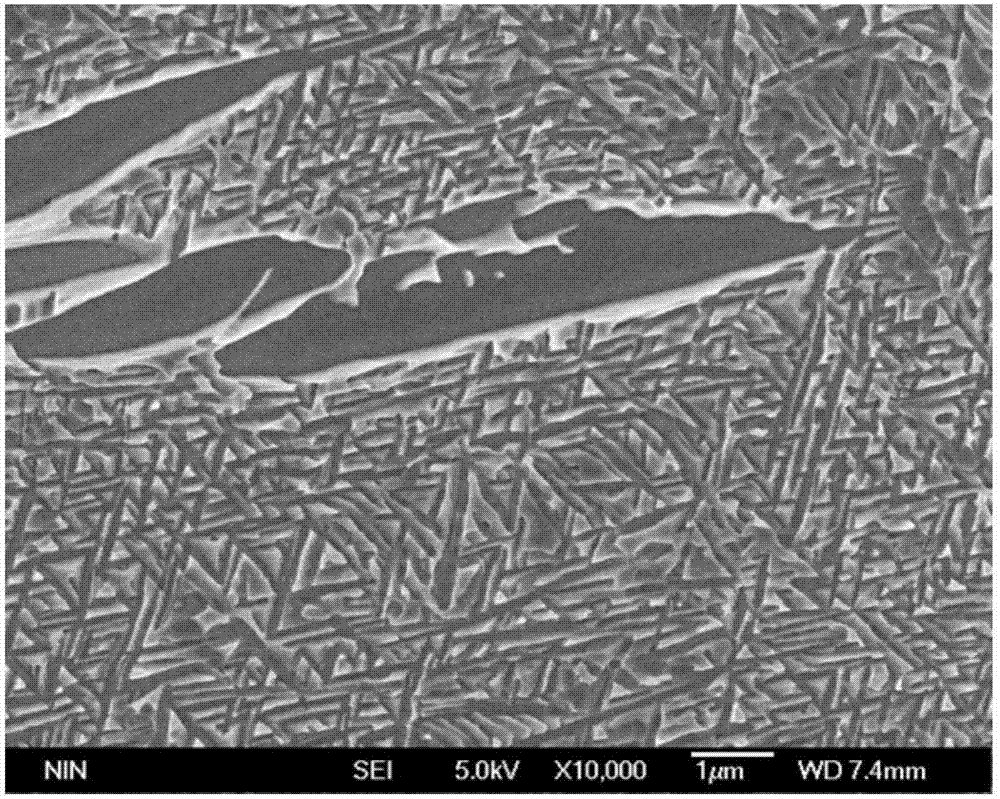

Heat treatment process for allowing TC21 alloy to obtain basket-weave microstructure after superplastic deformation in two-phase region

The invention provides a heat treatment process for allowing a TC21 alloy to obtain a basket-weave microstructure after superplastic deformation in a two-phase region. The heat treatment process includes the steps: firstly carrying out superplastic tensile of a TC21 tensile specimen at the temperature of 900 DEG C and a set strain rate until tensile failure; after tensile failure of the tensile specimen, immediately carrying out water cooling; cutting out a uniform-deformation part of the tensile-failure specimen to be used as a heat treatment specimen; carrying out first heat treatment on the heat treatment specimen, heating a heat treatment furnace up to 10-20 DEG C above a beta-phase transition temperature, putting the heat treatment specimen into the heat treatment furnace, carrying out heat preservation for 1 hour, and followed by carrying out first air cooling; then, carrying out second heat treatment on the heat treatment specimen, heating the heat treatment furnace up to 20-30 DEG C below the beta-phase transition temperature, putting the heat treatment specimen into the heat treatment furnace, carrying out heat preservation for 1 hour, and followed by carrying out second air cooling; and then, carrying out third heat treatment on the heat treatment specimen, heating the heat treatment furnace up to 360-370 DEG C below the beta-phase transition temperature, putting the heat treatment specimen into the heat treatment furnace, carrying out heat preservation for 4 hours, followed by carrying out third air cooling, and thus obtaining the basket-weave microstructure.

Owner:NANCHANG HANGKONG UNIVERSITY

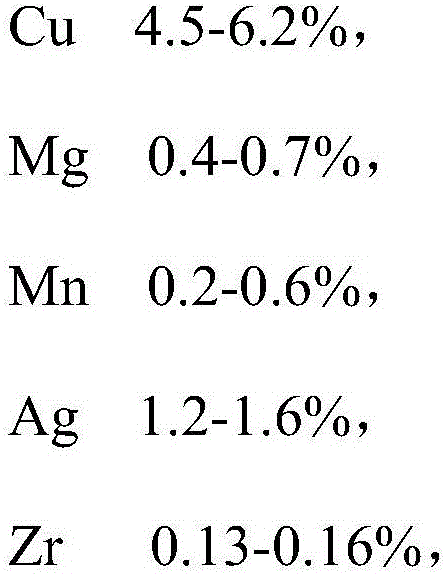

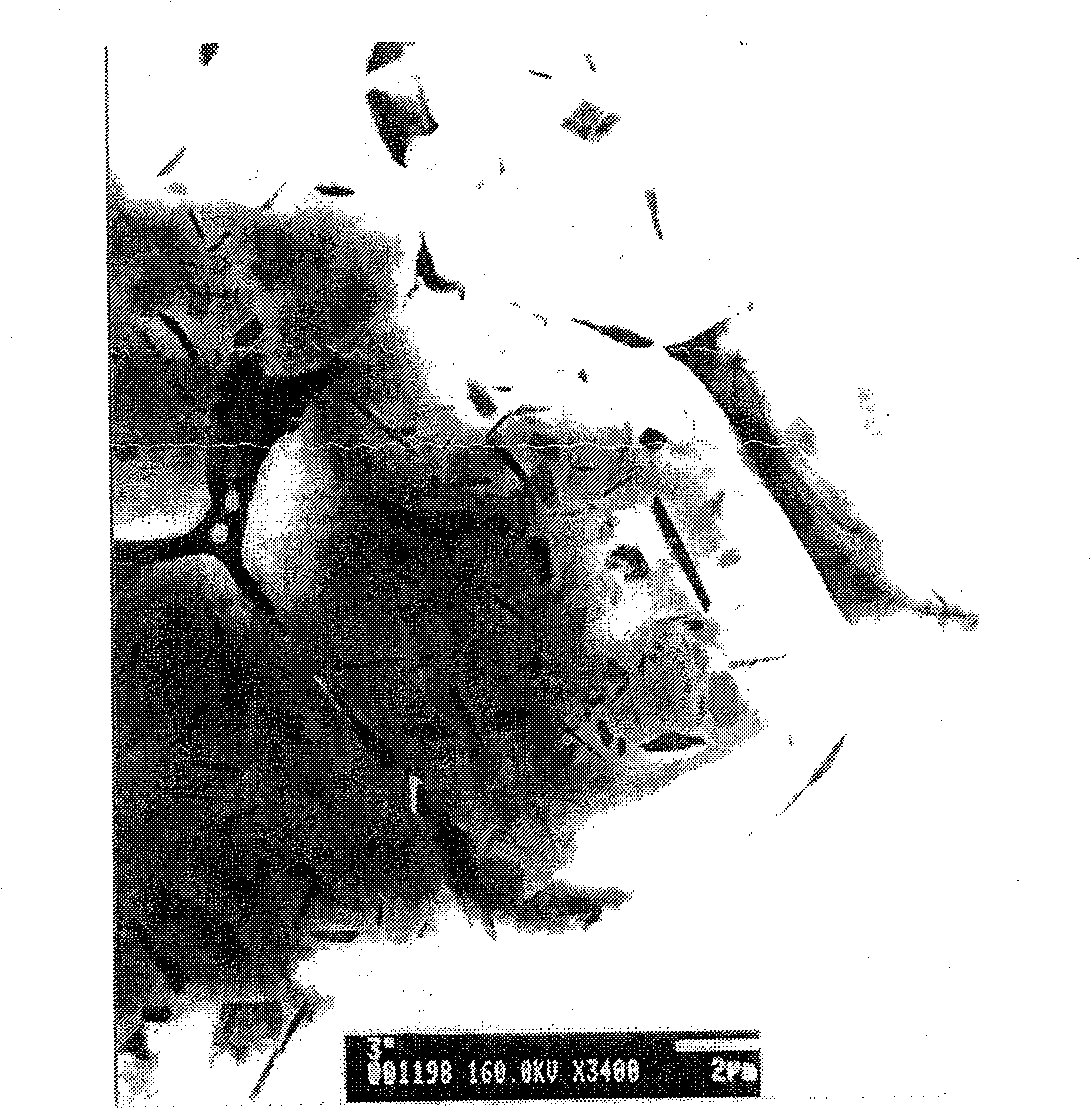

High Zn content, superstrength and supertoughness, high destroy limit type aluminium alloy material and preparation method

ActiveCN100415918CHigh plasticity and damage tolerance propertiesImprove plasticityMicrostructureAluminium alloy

This invention discloses a high strength, high toughness and high damage-tolerance aluminum alloy with high zinc-content, which is composed of Zn 9-10 wt.%, Mg 2.0-2.5 wt.%, Cu 1.2-1.7 wt.%, Zr 0.2-0.5 wt.%, Fe less than 0.05 wt.%, Si less than 0.05 wt.% and Al as balance. The aluminum alloy is manufactured by: mixing the raw materials, smelting, casting into alloy ingots, melting the ingots at 780-800 deg.C, carrying out fast-solidification injection molding with inert gas as an atomization gas under 0.5-1.0 MPa. The aluminum alloy has such advantages as uniform component distribution, uniform microstructure and no segregation. After reasonable thermal treatment, the aluminum alloy has an ultimate tensile strength high than 750 MPa and an elongation rate of 8-11%. The fracture toughness and fatigue strength of the aluminum alloy are better than those of 7050T74 material. The aluminum alloy can be used as key structures in aerospace and aviation industry, nuclear industry and military industry.

Owner:GRIMAT ENG INST CO LTD

A kind of preparation method of al-cu-li-x series aluminum-lithium alloy sheet

The invention discloses a preparation method of an Al-Cu-Li-X series aluminum lithium alloy sheet. The sheet prepared by the method is 0.8mm-8.0mm in thickness. The method comprises the following steps: cogging and hot-rolling homogenized slab ingots to a specified thickness and coiling; carrying out annealing treatment, uncoiling and carrying out band-type cold-rolling; carrying out intermediate annealing according to deformation during cold-rolling, thus obtaining the sheets with uniform thicknesses. The sheets can be in different states after being subjected to solution treatment, prestretching and aging treatment, so as to meet different usage requirements. Compared with the prior art, the aluminum lithium alloy sheet with high surface quality, uniform sheet size and smooth sheet shape is prepared by the method through band-type cold-rolling. The sheets can be in different states by different heat-treating processes, so as to meet usage requirements under different application conditions.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Polyolefin dispersion and epoxy dispersion blends for improved damage tolerance

ActiveUS20210301073A1Suitable viscosityReduce formationTransportation and packagingChemical/physical processesPolymer sciencePolyolefin

The present invention provides aqueous compositions for making damage tolerant coatings comprising a blend of (i) from 2 to 30 wt. %, based on the total weight of solids in the composition, of an acid or anhydride functionalized polyolefin dispersion having an average particle size of from 0.2 to 5 microns, and (ii) a film forming dispersion of one or more epoxy resins chosen from epoxy resins having an epoxy equivalent weight (EEW) of from 150 to 4,000 having an average particle size of from 0.2 to 1.0 microns, wherein the polyolefin dispersion is stabilized with from 2 to 8 wt. %, based on the total weight of solids in the composition, one or more anionic surfactants, such as a sulfate containing surfactant, and, further wherein, the compositions have a pH of from 3 to 8.

Owner:DOW GLOBAL TECH LLC

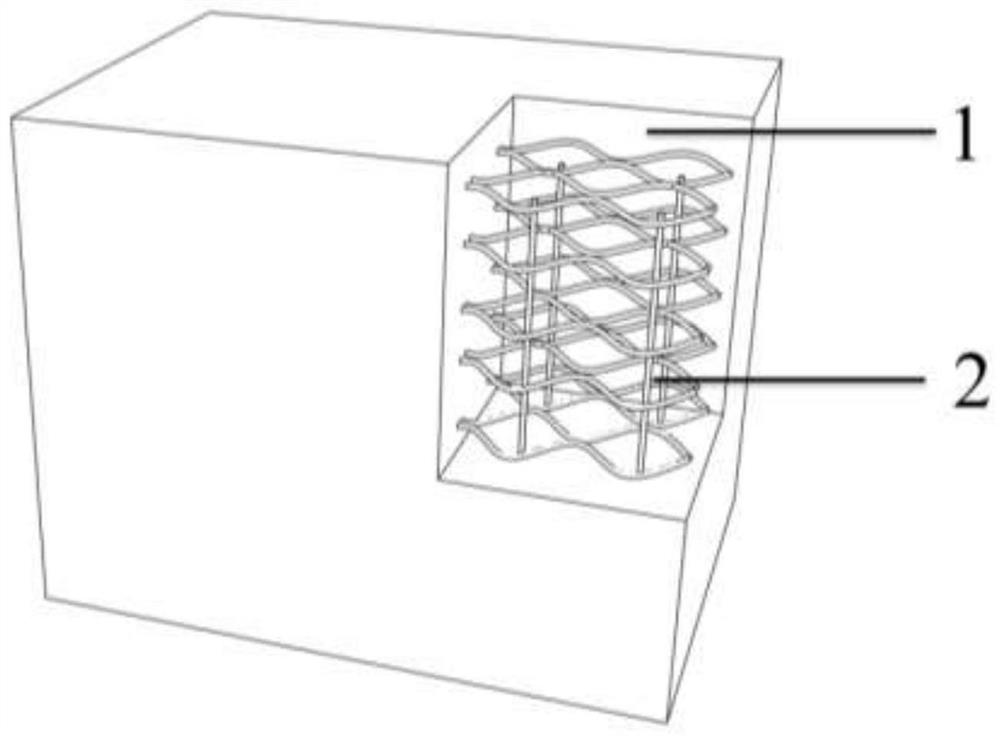

A three-dimensional fiber skeleton toughened cermet and its preparation method

The invention discloses a three-dimensional fiber-skeleton toughened cermet, which comprises the following components according to the volume percentage: 2%-9% of skeletonized metal fibers, 60%-80% of micron carbon and nitride grains, submicron 8% to 24% of high-grade carbide grains and 6% to 10% of Fe binder phase, the sum of the volume percentages of the above components is 100%, the metal fibers are Ta fibers or Nb fibers, micron-sized carbon, nitride crystals Particles are micron WC, WN, Cr 2 C 3 , CrN, TiC, TiN, SiC, SiN grains or one or more, and the submicron carbide grains are submicron NbC grains or TaC grains. The invention also discloses a method for preparing a three-dimensional fiber-skeleton toughened cermet. The three-dimensional fiber-skeleton toughened cermet prepared by the method not only has the characteristics of high strength, wear resistance and high hardness of traditional carbide ceramic materials, but also has good Toughness and damage tolerance properties, with broad application prospects.

Owner:XIAN UNIV OF TECH

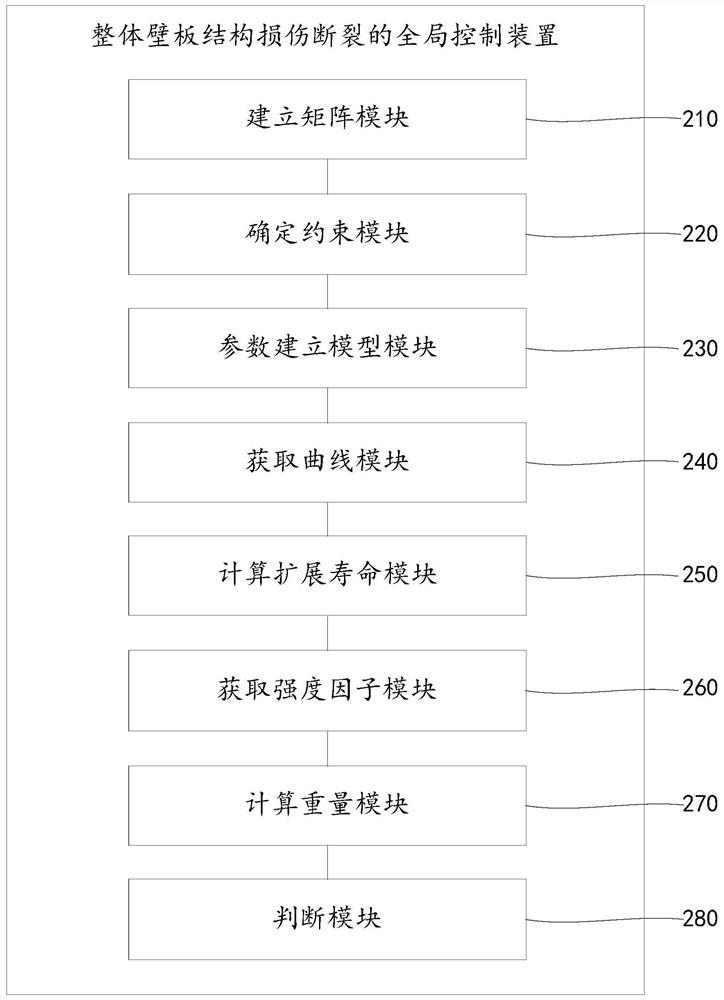

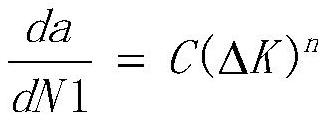

Global control method and device for damage and fracture of integral wallboard structure

ActiveCN113343529AImproved damage tolerance performanceEasy to useSustainable transportationDesign optimisation/simulationFlight vehicleResidual strength

The invention discloses a global control method and device for damage fracture of an integral panel structure, and relates to the field of aircraft structure damage tolerance design, and the method comprises the steps: building a global damage parameter matrix of the integral panel structure; determining a control constraint; selecting a first group of parameters, and establishing a three-dimensional shell finite element model containing at least three rib integral wallboard structures according to the first group of parameters; simulating a crack propagation track by using a finite element method based on the reinforced area and unit, and obtaining a change curve of the stress intensity factor along with the crack length; according to the change curve, calculating the crack propagation life, the residual strength value and the weight under the first group of parameters; judging whether the crack propagation life, the residual strength value and the weight meet preset conditions or not; and if any one does not meet the preset condition, returning to the step of selecting a second group of parameters. According to the method and device, the crack propagation speed is delayed to the maximum extent, the damage tolerance performance of the whole wallboard is improved, and rapid iteration of optimization design is guaranteed.

Owner:TSINGHUA UNIV +2

Polyolefin dispersion and epoxy dispersion blends for improved damage tolerance

ActiveUS11447600B2Improved damage tolerance performanceImprove impact resistanceMixing methodsTransportation and packagingPolymer sciencePolyolefin

The present invention provides aqueous compositions for making damage tolerant coatings comprising a blend of (i) from 2 to 30 wt. %, based on the total weight of solids in the composition, of an acid or anhydride functionalized polyolefin dispersion having an average particle size of from 0.2 to 5 microns, and (ii) a film forming dispersion of one or more epoxy resins chosen from epoxy resins having an epoxy equivalent weight (EEW) of from 150 to 4,000 having an average particle size of from 0.2 to 1.0 microns, wherein the polyolefin dispersion is stabilized with from 2 to 8 wt. %, based on the total weight of solids in the composition, one or more anionic surfactants, such as a sulfate containing surfactant, and, further wherein, the compositions have a pH of from 3 to 8.

Owner:DOW GLOBAL TECH LLC

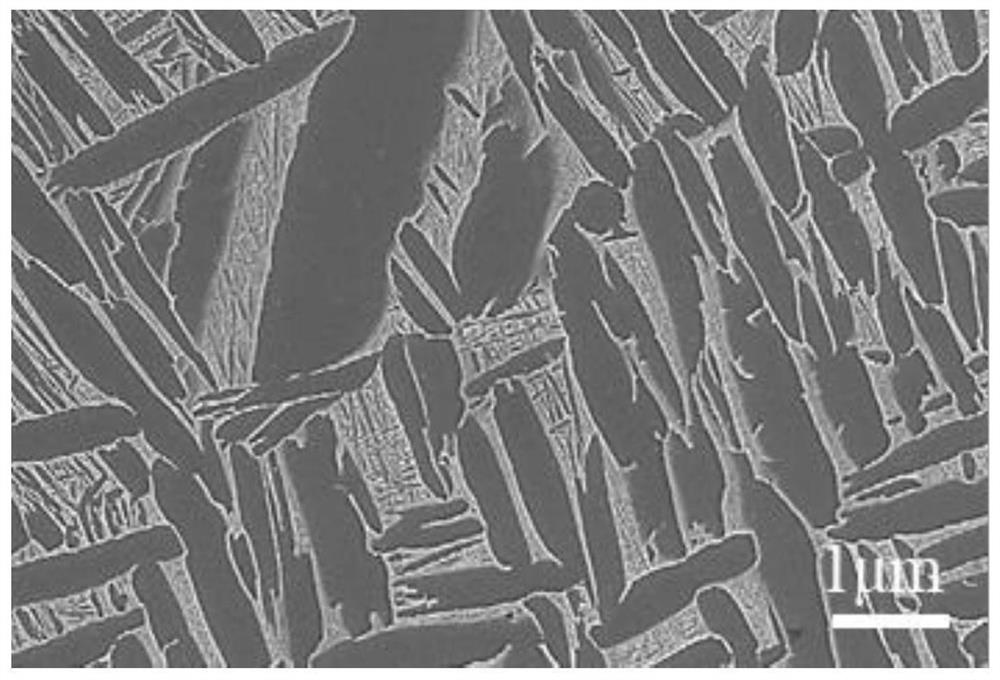

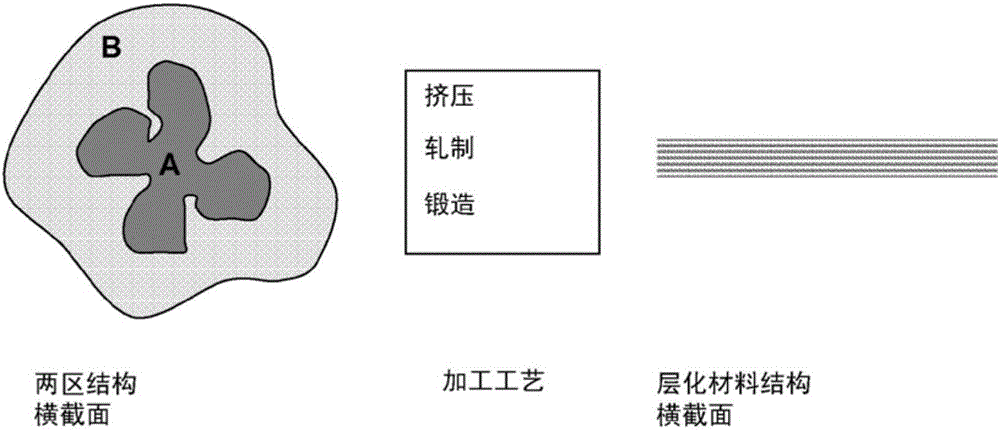

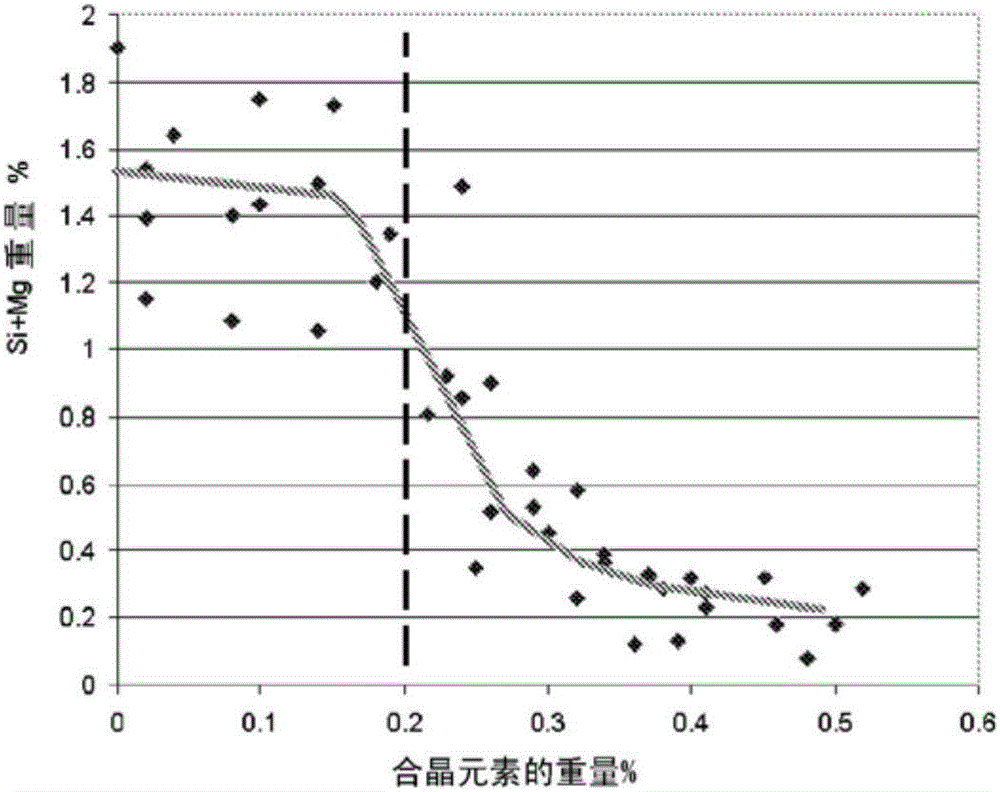

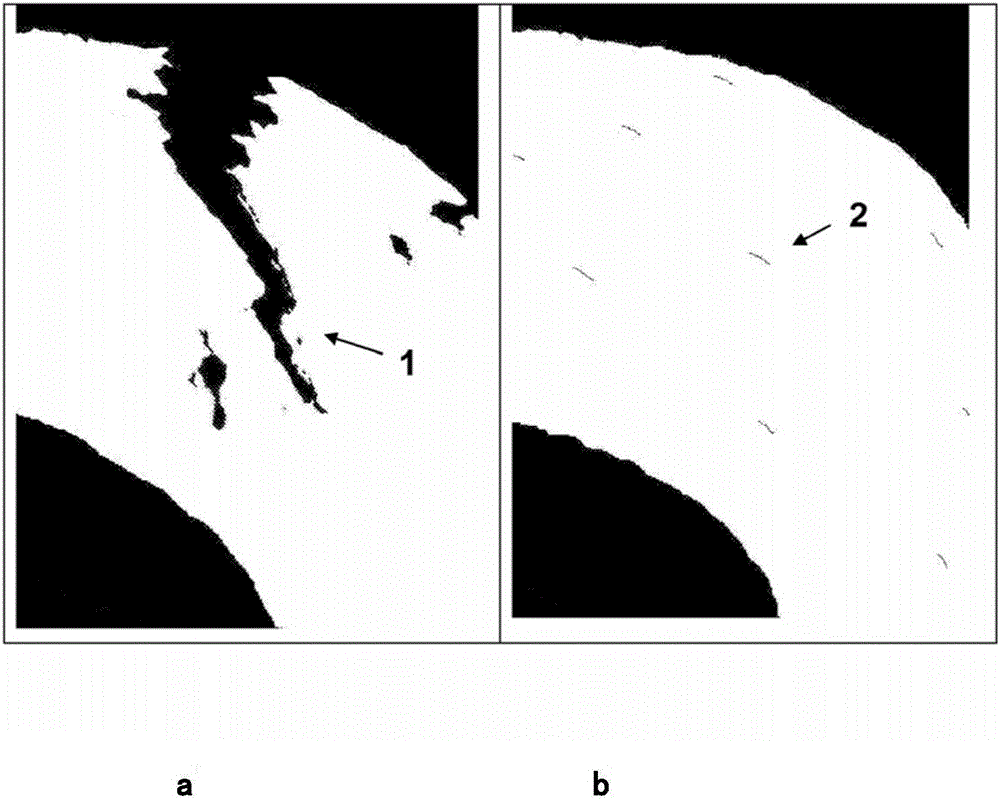

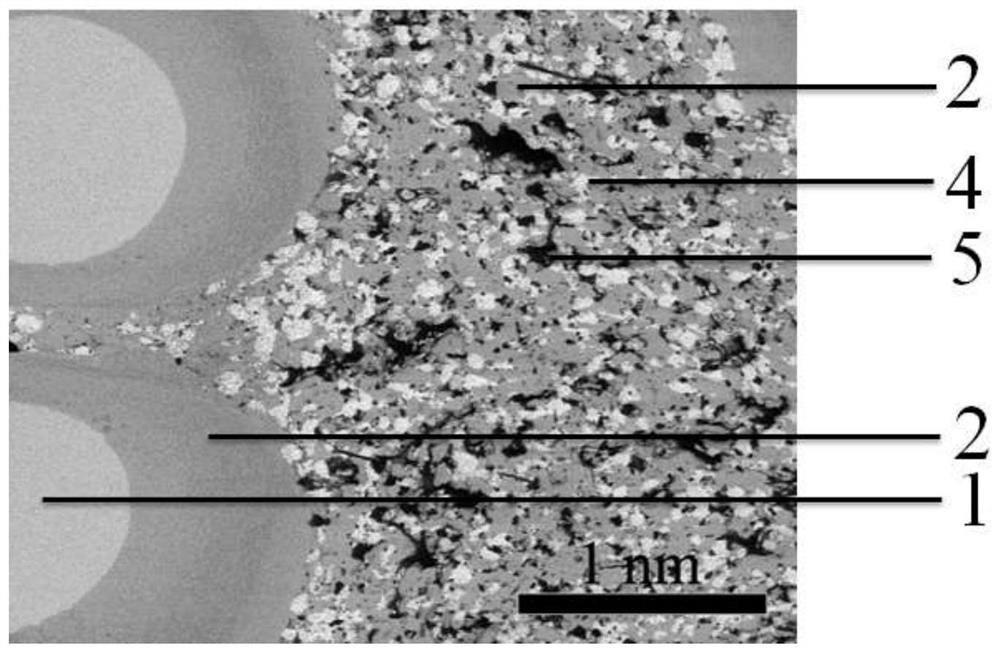

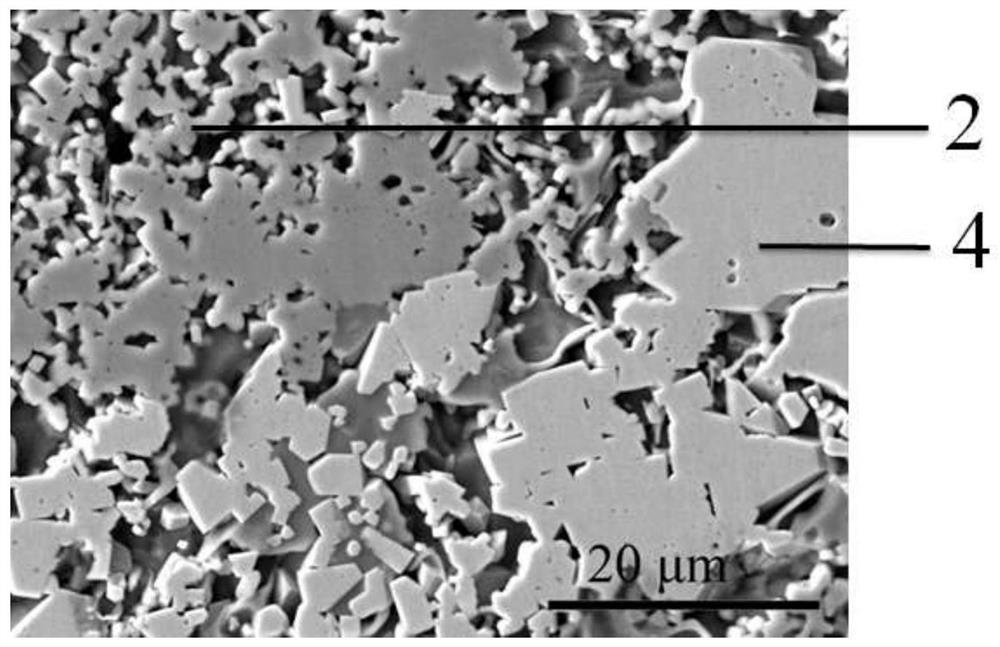

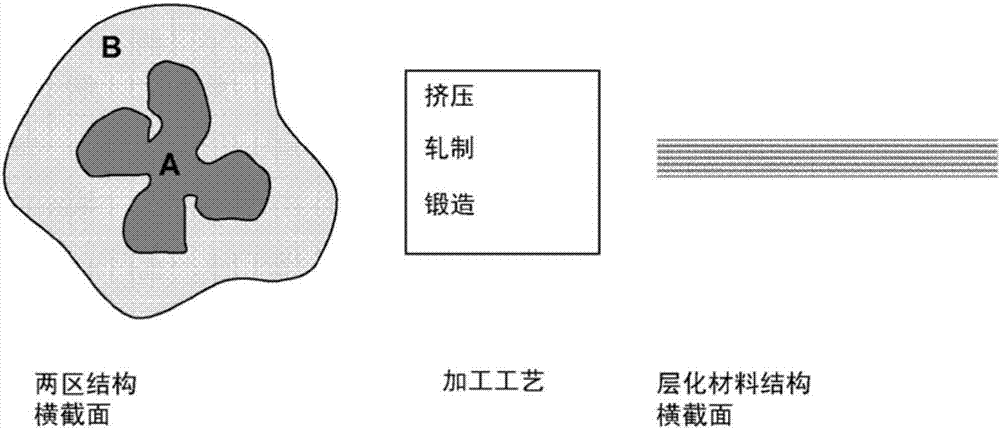

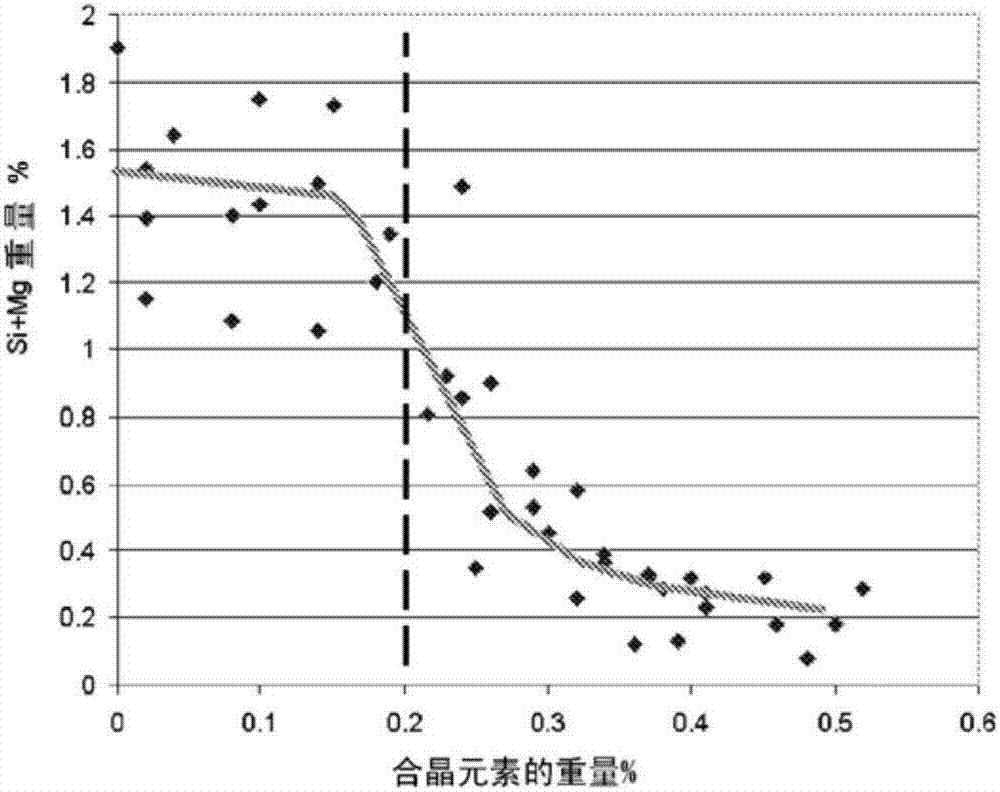

Damage-tolerant aluminum materials with layered microstructures

ActiveCN103025901BImproved damage tolerance performanceRetain high strengthMetal layered productsDamage toleranceHigh intensity

The invention discloses a wrought aluminum material which improves the damage tolerance while retaining the high strength of the material. Furthermore, the present invention discloses a precipitation hardenable aluminum alloy cast aluminum material comprising grains having two distinct regions, a first central region rich in elements capable of peritectic reactions with aluminum and a surrounding first region The second region is rich in elements capable of eutectic reaction with aluminum.

Owner:SAP AG

A multi-scale self-lubricating tungsten carbide matrix composite material and its preparation method

Owner:XIAN UNIV OF TECH

A kind of heat treatment process of titanium alloy

ActiveCN110273118BImproved damage tolerance performanceImprove fatigueSolution treatmentRoom temperature

The invention discloses a heat treatment process of a titanium alloy, and belongs to the technical field of material science. The heat treatment process is mainly as follows: the heating temperature T of the first heating treatment is greater than or equal to (Tbeta-50) DEG C and less than or equal to (Tbeta+60) DEG C, the holding time t is equal to eta 1*delta max, the delta max is the maximum section thickness of a titanium alloy forged piece, the eta 1 is a heating coefficient, the value of the heating coefficient is 0.6-1.5min / mm, after the heat preservation on the forged piece is completed, the forged piece is discharged from a furnace and is subjected to air cooling, wind cooling, oil cooling or water cooling to a room temperature; the heating temperature T of the second heating treatment is greater than or equal to 650 DEG C and less than 780 DEG C, the holding time t is equal to (eta 2*delta max) / 2, the delta max is the maximum section thickness of the titanium alloy forged piece, the eta 2 is a heating coefficient, the value of the heating coefficient is 0.3-1.2min / mm, after the heat preservation on the forged piece is completed, the forged piece is discharged from the furnace and is subjected to air cooling to a room temperature; and the heating temperature T of the third heating treatment is greater than or equal to 480 DEG C and less than 650 DEG C, the holding time t is greater than or equal to 240min and less than or equal to 600min, and after the heat preservation on the forged piece is completed, the forged piece is discharged from the furnace and is subjected to air cooling to a room temperature. The heat treatment process solves the problems that after near-beta, metastable beta-type and fully-stable beta-type titanium alloys are subjected to solution treatment and ageing, the side and heart of the forged piece have large difference in structure properties, and is particularly suitable for preparing the high-strength titanium alloy forged piece with uniform structure properties and a large section / variable cross section.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

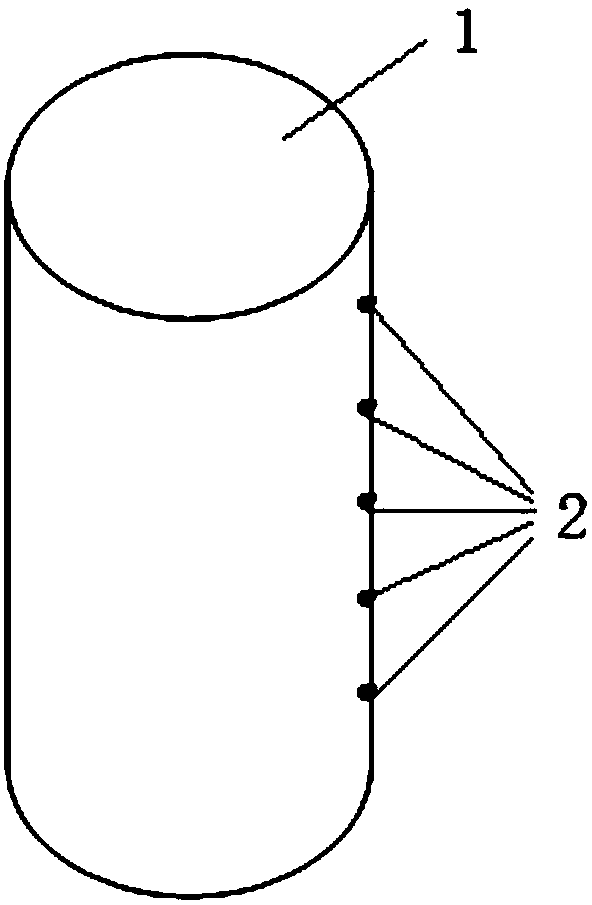

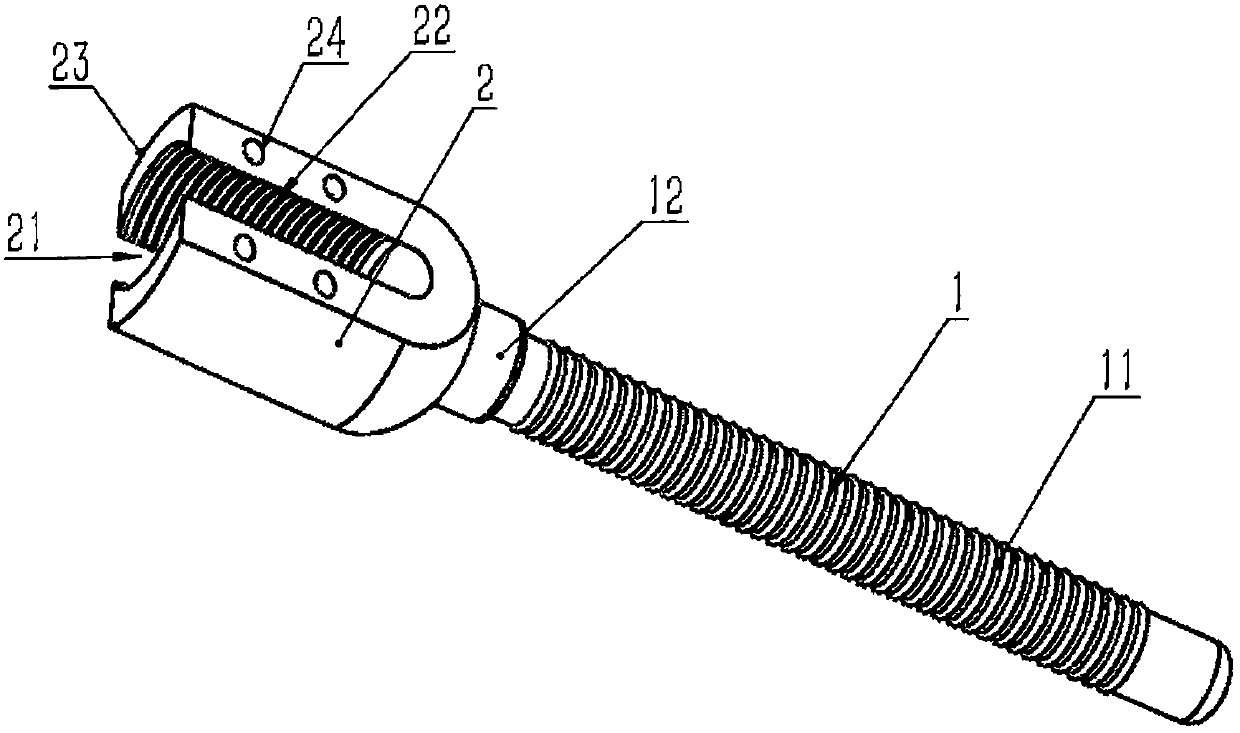

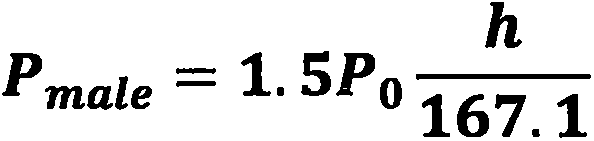

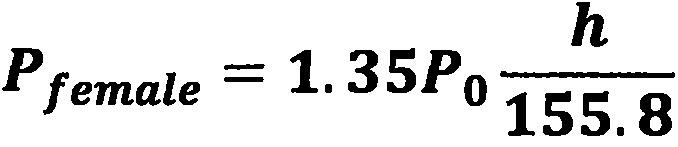

Medical titanium alloy fixing screw with inner thread head

PendingCN109091218ALightweight and high strengthGood biocompatibilityFastenersManufacturing technologyInjury tolerance

The invention relates to the technical field of machining and making of medical titanium alloy, in particular to a medical titanium alloy fixing screw with an inner thread head. The medical titanium alloy fixing screw with the inner thread head comprises a screw rod (1) and a screw head (2) which is positioned at one end of the screw rod (1), wherein a longitudinal opening (21) which extends alongthe screw rod (1) is formed in a free end of the screw head (2); and inner threads (23) are arranged on the inner wall of the longitudinal opening (21). The medical titanium alloy fixing screw with the inner thread head is characterized in that the screw head (2) is a hexagonal screw head, the longitudinal opening (21) is a round hole, a transition section (12) is arranged at a position where thescrew rod (1) is combined to the screw head (2), and the radius of the transition section (12) is between the radius of the screw rod (1) and the radius of the screw head (2). The technical problem that in the prior art, stress barrier and biological compatibility are poor is solved. The injury tolerance can further be improved. Compared with a traditional design, the medical titanium alloy fixing screw with the inner thread head is higher than crack generation resistance and higher in mounting speed, and pain of a patient is relieved.

Owner:BAOJI CHUANGXIN METAL MATERIALS

Damage tolerance optimization method for rib integral panel

PendingCN113190923AImproved damage tolerance performanceEasy to useGeometric CADDesign optimisation/simulationElement modelAlgorithm

The invention belongs to the field of aircraft structure damage tolerance design, and discloses a rib integral panel damage tolerance optimization method, which comprises the steps of integral panel reinforcement ratio determination, rib sensitive parameter identification, structure size optimization matrix establishment, crack-containing integral panel finite element model establishment, stress intensity factor k calculation and crack propagation life calculation, and determining optimal structural parameters by comparing the crack propagation lives under different sizes.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

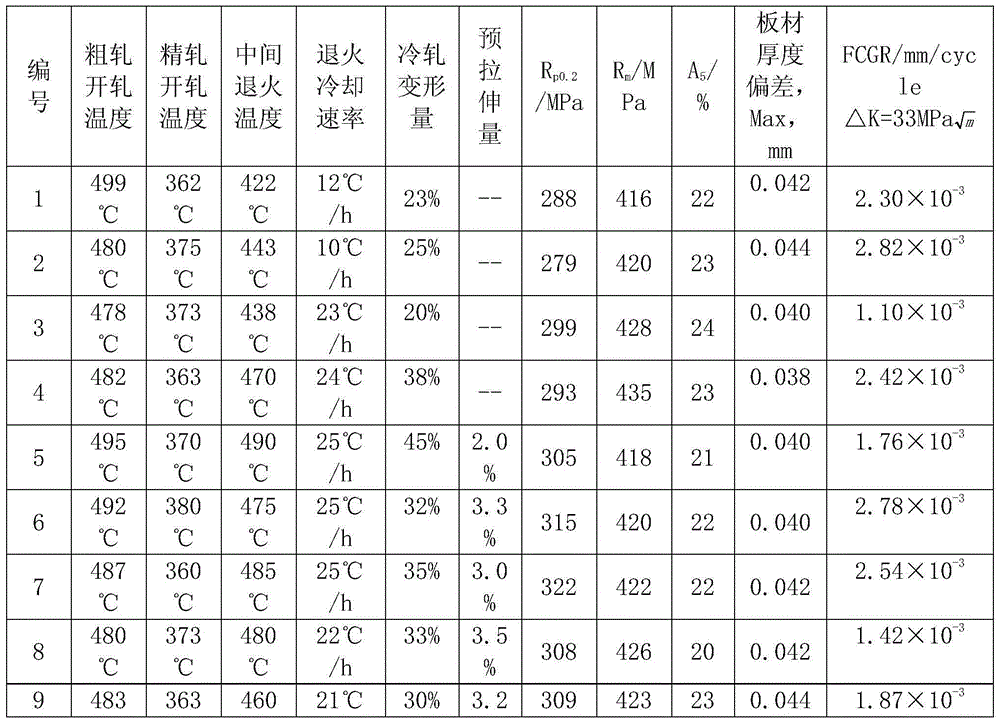

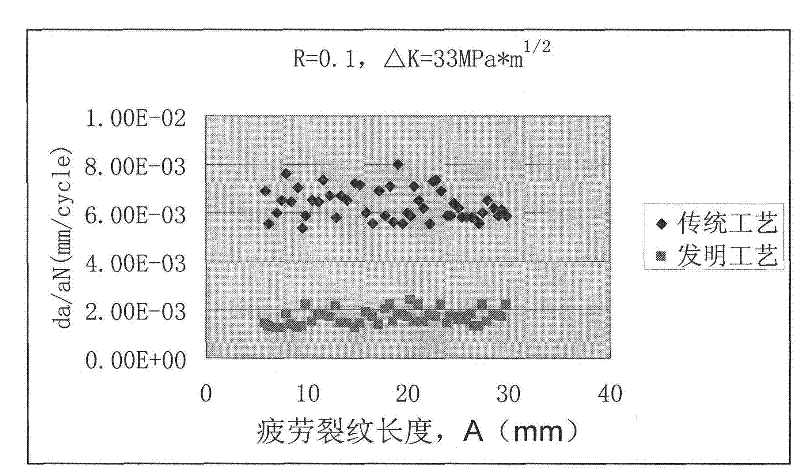

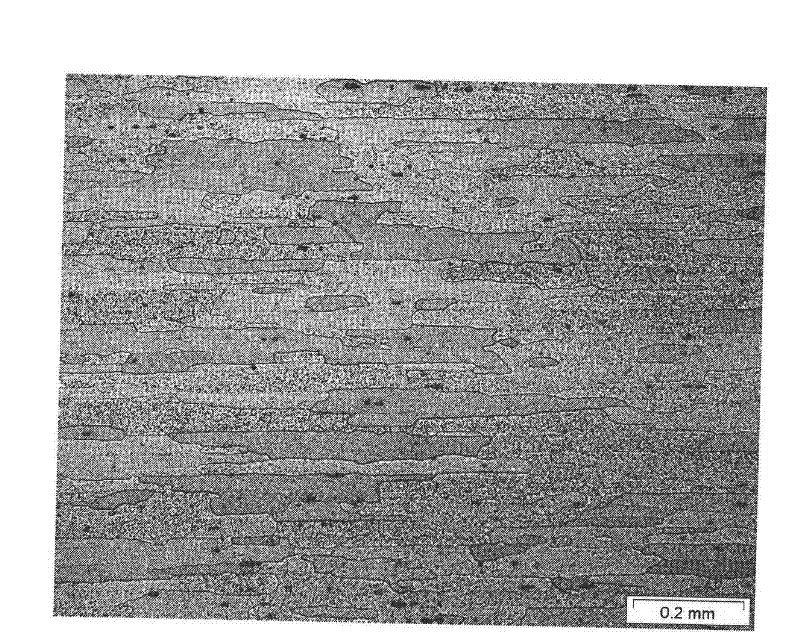

Method for improving damage-tolerance property of 2,000-type aluminium alloy plate material

ActiveCN101967615BEase of production implementationReduce fatigue crack rateMetallurgyDamage tolerance

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Manufacture method of carbon fiber metal composite laminated plate

InactiveCN101417524BFlame retardantImpact resistantLamination ancillary operationsLaminationFiberFirming agent

A manufacturing method of a carbon fiber metal composite laminated plate relates to a manufacturing method of a fiber metal composite laminated plate. The method aims at solving the problems that no manufacturing methods for manufacturing aircraft structural material with high specific stiffness, high specific strength, tenacity and workability exist in China. The method comprises the following steps of: carrying out surface treatment to three pieces of metal plates; winding a carbon fiber composite material layer which is soaked in liquid cement on one of the metal plates, wherein, the liquid cement is prepared by epoxy resin, a metaphenylene diamine curing agent and an anhydrous alcohol solvent according to the mass ratio of 1:0.1 to 0.18:0.15 to 0.2; fixedly arranging another two metal plates on the upper surface and the lower surface of the carbon fiber composite material layer so as to be integrally put into a mould, and then treated with mould assembling, drying, solidificationby adopting the method of gradient temperature increasing, and demoulding. The manufacturing method of the invention is simple and is easy for operation. The carbon fiber metal composite laminated plate manufactured by the method of the invention has the advantages of high specific stiffness, high specific strength, also high tenacity and workability of metal material, good fatigue property, and good damage tolerance capability.

Owner:HARBIN INST OF TECH

Damage-tolerant aluminum material with layered microstructure

InactiveCN107022700AImproved damage tolerance performanceRetain high strengthMetal layered productsAlloyMaterials science

The invention discloses a forged aluminum material capable of improving the damage tolerance while retaining the high material strength, and further discloses a precipitation hardenable aluminum-alloy cast aluminum material which comprises two obvious areas of crystal grains, wherein the first area is positioned at the center and rich in at least one element capable of reacting with aluminum in a peritectic manner; and the second area is positioned around the first area and rich in at least one element capable of reacting with aluminum in an eutectic manner.

Owner:SAP AG

A Heat Treatment Process for Improving Damage Tolerance Performance of Titanium Alloy Forgings

The invention provides a thermal processing process for improving the damage tolerance performance of a titanium alloy forge piece. The thermal processing process comprises the following steps: (1) carrying out solution treatment on a titanium alloy forge piece forged below a phase transformation point temperature; (2) after the solution treatment, cooling the titanium alloy forge piece to a temperature which is 60-80 DEG C lower than the phase transformation point, and carrying out air cooling until the titanium alloy forge piece reaches a room temperature; and (3) carrying out ageing treatment on the air-cooled titanium alloy forge piece, and carrying out air cooling until the titanium alloy forge piece reaches a room temperature. By utilizing the titanium alloy forge piece, with an initial microscopic structure containing an equiaxed structure, a basket-weave structure or a duplex structure, forged below the phase transformation point temperature, as a thermal processing object, the thermally processed titanium alloy forge piece has a relatively high strength and good plasticity and tenacity and simultaneously has relatively low fatigue crack extending rate, so that the limitation that the strength, plasticity and damage tolerance performance of titanium alloy which is subjected to traditional solution treatment-ageing treatment or solution furnace cooling treatment are difficult to be well matched is broken through.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com