Reinforced and toughened metastable beta titanium alloy and preparation method thereof

A technology for strengthening and toughening, beta titanium alloys, applied in the field of titanium alloys, can solve problems such as the inability to produce aging strengthening effects, and achieve the effects of improving damage tolerance, improving chemical composition uniformity, and reducing melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

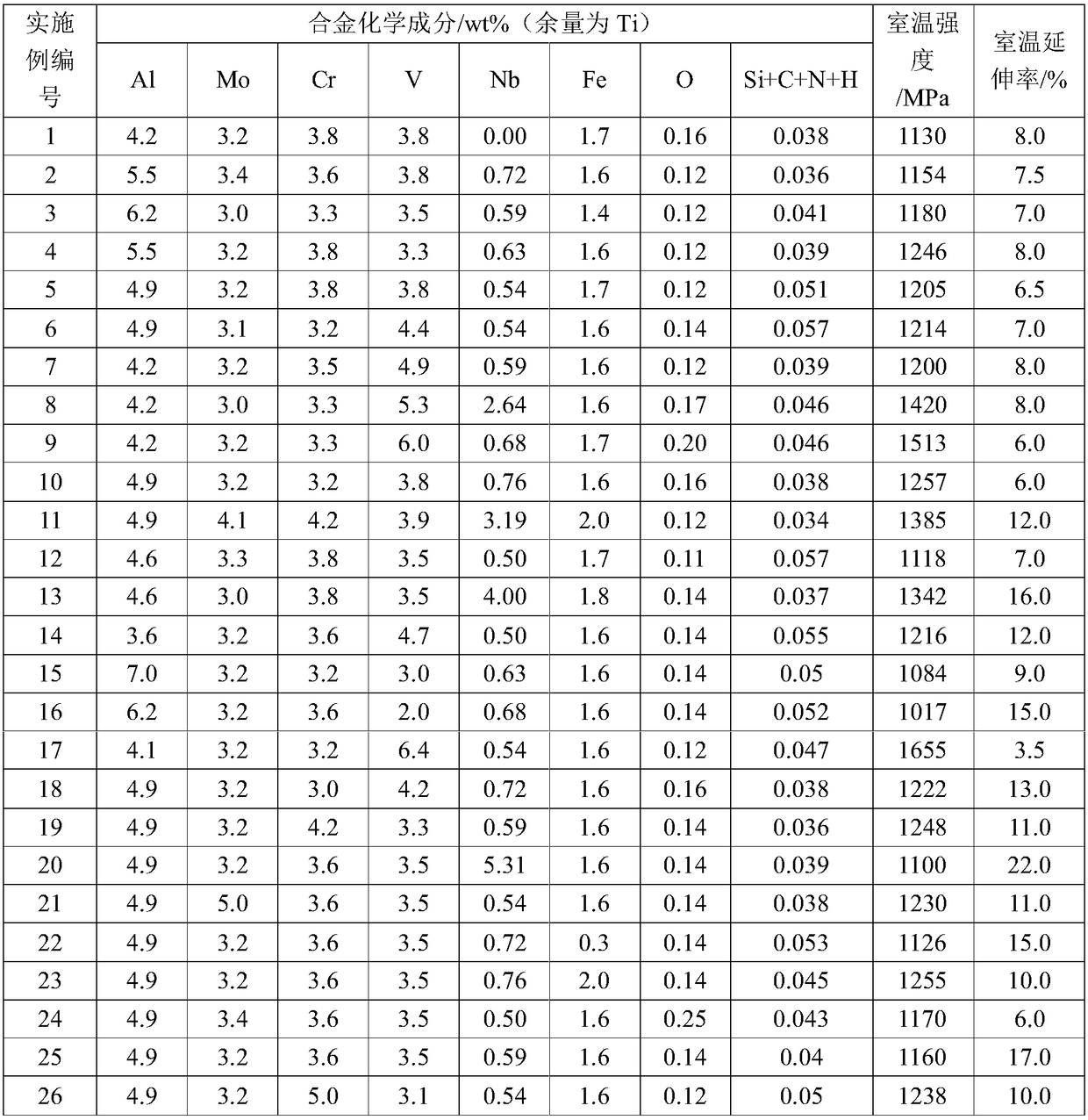

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned reinforced and toughened metastable β-titanium alloy is specifically implemented according to the following steps:

[0027] Step 1, preparation of consumable electrodes:

[0028] According to the requirements of the alloy composition, weigh the powdered aluminum vanadium niobium alloy, granular aluminum molybdenum alloy, aluminum chromium and aluminum iron alloy, aluminum beans, and small particle sponge titanium not exceeding 0.8mm, and mix each raw material and press it into a diagonal The length is 240mm electrode block. The electrode blocks are clamped in series, and the electrode blocks are welded into consumable electrodes by plasma arc;

[0029] Step 2, vacuum consumable smelting:

[0030] The consumable electrode obtained in step 1 was vacuum smelted three times in a vacuum consumable electric arc furnace to obtain WSTi544432 titanium alloy ingot.

[0031] The primary melting parameters are: melting voltage 32-36V...

Embodiment 1

[0049] Step 1, preparation of consumable electrodes:

[0050] According to the requirements of the alloy composition, weigh the powdered aluminum vanadium niobium alloy, granular aluminum molybdenum alloy, aluminum chromium and aluminum iron alloy, aluminum beans, and small particle sponge titanium not exceeding 0.8mm, and mix the raw materials and press them into a diagonal The length is 240mm electrode block. The electrode blocks are clamped in series, and the electrode blocks are welded into consumable electrodes by plasma arc;

[0051] Step 2, vacuum consumable smelting:

[0052] The consumable electrode obtained in step 1 was vacuum smelted three times in a vacuum consumable electric arc furnace to obtain WSTi544432 titanium alloy ingot.

[0053] The primary melting parameters are: melting voltage 32-34V, melting current 20-22kA.

[0054] Secondary smelting parameters are: smelting voltage 34-36V, smelting current 23-25kA.

[0055] The three melting parameters are as ...

Embodiment 2

[0057] Step 1, preparation of consumable electrodes:

[0058] According to the requirements of the alloy composition, weigh the powdered aluminum vanadium niobium alloy, granular aluminum molybdenum alloy, aluminum chromium and aluminum iron alloy, aluminum beans, and small particle sponge titanium not exceeding 0.8mm, and mix the raw materials and press them into a diagonal The length is 240mm electrode block. The electrode blocks are clamped in series, and the electrode blocks are welded into consumable electrodes by plasma arc;

[0059] Step 2, vacuum consumable smelting:

[0060] The consumable electrode obtained in step 1 was vacuum smelted three times in a vacuum consumable electric arc furnace to obtain WSTi544432 titanium alloy ingot.

[0061] The primary melting parameters are: melting voltage 34-36V, melting current 22-24kA.

[0062] Secondary smelting parameters are: smelting voltage 36-38V, smelting current 25-27kA.

[0063] The three melting parameters are: af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com