Process for preparing Nb and/or Ta powder

A production method and technology of tantalum powder, which is applied in the field of production of niobium and/or tantalum powder, can solve problems such as inability to obtain niobium powder, loss of precious metal tantalum, pollution of niobium powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

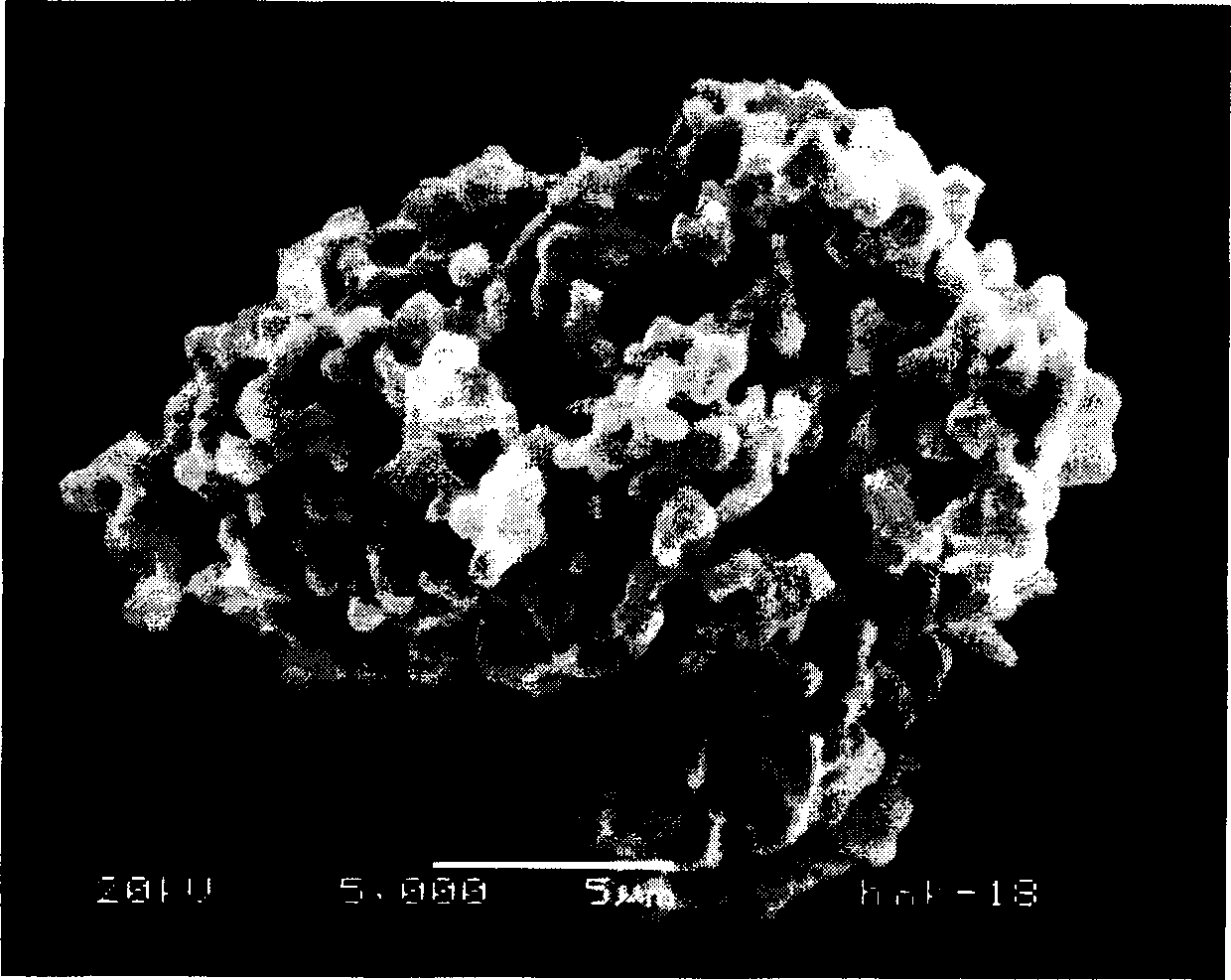

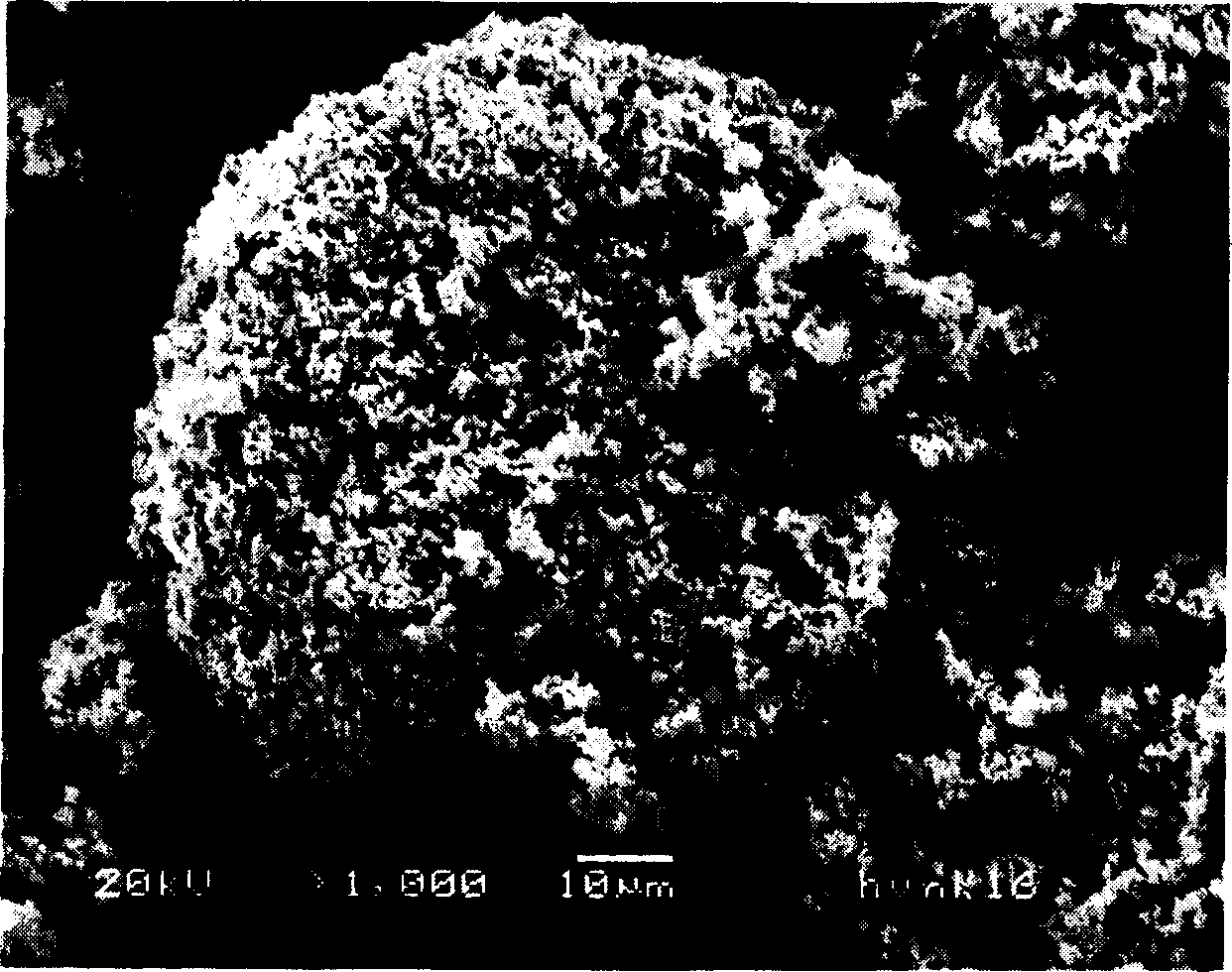

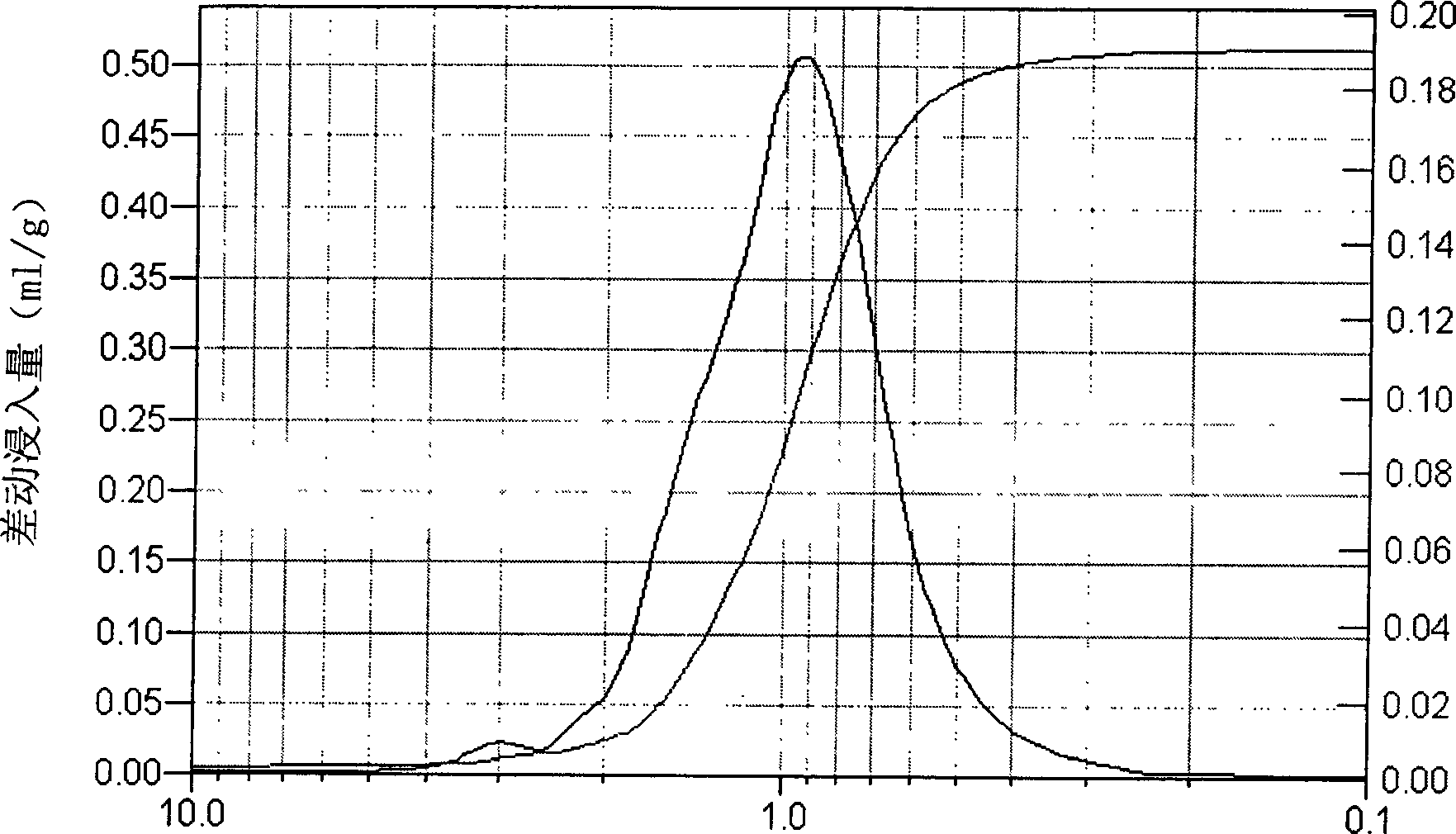

[0046] 15 kg of potassium fluorooxyniobate (containing 1.02 kg of Nb 2 o 5 ) niobium raw material, with 25 kg of NaCl, 15 kg of KCl, 12 kg of CaCl 2 Put it into a closed reaction vessel with a stirring blade and a heat-resistant alloy lining inside with an inert gas inlet and outlet, heat it to 700°C under an argon atmosphere, inject 6,500 grams of liquid metal sodium, and make it undergo a reduction reaction, and then Heat up to 800°C for 1 hour. After cooling to room temperature, the reaction materials are stripped out, washed with water and pickled, and then dried to obtain 4107 grams of niobium powder. The BET specific surface area of the original powder is 6.56m 2 / g, the oxygen content of the original powder of niobium powder is 9800ppm. attached figure 1 It is the scanning electron micrograph of the microstructure of this niobium powder. It can be seen that the niobium powder particles are porous aggregates with large specific surface area composed of many primary ...

Embodiment 2

[0059] The niobium raw material of 29 kg of potassium oxyfluoroniobate containing 1.03 kg of niobium oxide was mixed with 25 kg of NaCl and 2 kg of CaCl 2 , 40 kilograms of KCl are injected 11750 grams of liquid metal sodium at 800 ℃ according to the same method of embodiment 1, and other production processes are all identical with embodiment 1. Obtain 8350 grams of niobium powder, the BET specific surface area of the former powder is 6.41m 2 / g, the oxygen content of the original powder of niobium powder is 11000ppm. The reduction recovery of niobium powder is shown in Table 1.

[0060] The raw niobium powder obtained above was subjected to doping, deoxidation and thermal agglomeration treatment in the same manner as in Example 1 to obtain agglomerated niobium powder.

[0061] The main chemical impurity content of niobium powder is shown in Table 2, and the physical properties are shown in Table 3. The porosity of agglomerated niobium powder is 88.99%.

[0062] Using th...

Embodiment 3

[0064] Mix the tantalum raw material containing 2.10 kg of tantalum oxide and 30 kg of potassium fluorotantalate with 65 kg of NaCl, 20 kg of KCl, and 8.0 kg of MgCl 2 Put it into a closed reaction vessel lined with a heat-resistant alloy with a stirring blade and an inert gas inlet and outlet. Heating to 800°C under an argon atmosphere, injecting 10,500 grams of liquid metal sodium to cause a reduction reaction, then raising the temperature, keeping it at 850°C for 1 hour, cooling to room temperature, stripping off the reaction material, washing with water, pickling, and then drying Dry, obtain tantalum powder 14094 grams, the BET specific surface area of former powder is 3.86m 2 / g, its oxygen content is 7800ppm. The reduction recovery rate of tantalum powder is shown in Table 1.

[0065] The raw tantalum powder obtained above is doped, deoxidized and thermally agglomerated according to existing methods to obtain agglomerated tantalum powder.

[0066] The main chemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com