High-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder

A technology of pre-alloyed powder and tungsten-based alloy, which is applied in the forming field of high-specific gravity tungsten-based alloy, can solve the problems of limited size and complexity of forming samples, difficulty in adapting to industrial production, and complex process, and can meet the requirements of additive manufacturing process. , The effect of reducing the difficulty of forming and improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

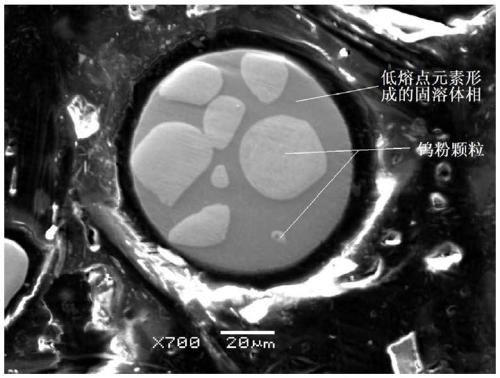

[0033] Step 1. Preparation of pre-alloyed powder: W-Ni-Fe tungsten-based alloy is formulated according to the mass ratio of W, Ni and Fe of 90:7:3, and then the green body is obtained by pressing, and the green body is vacuum sintered in turn, The W-Ni-Fe tungsten-based alloy bar is obtained by forging, and the W-Ni-Fe tungsten-based alloy bar is placed in the plasma rotating electrode powder making equipment, and the W-Ni-Fe preform is prepared by the plasma rotating electrode powder making method. Alloy powder; the W-Ni-Fe pre-alloyed powder is a spherical body in which the solid solution phase formed by Ni and Fe wraps tungsten powder particles, and the particle size of the W-Ni-Fe pre-alloyed powder is less than 100 μm. The particle size of the tungsten powder particles in the alloy powder is 20 μm to 90 μm, and the thickness of the solid solution phase formed by Ni and Fe is 10 μm to 20 μm, such as figure 1 shown;

...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] Step 1. Preparation of pre-alloyed powder: W-Ni-Mn tungsten-based alloy is formulated according to the mass ratio of W, Ni, and Mn of 95:3:2, and then the green body is obtained by pressing, and the green body is vacuum sintered, The W-Ni-Mn tungsten-based alloy bar is obtained by forging, and the W-Ni-Mn tungsten-based alloy bar is placed in the plasma rotating electrode powder making equipment, and the W-Ni-Mn preformed powder is prepared by the plasma rotating electrode powder making method. Alloy powder; the W-Ni-Mn pre-alloyed powder is a spherical body in which a solid solution phase of Ni and Mn wraps tungsten powder particles, and the particle size of the W-Ni-Mn pre-alloyed powder is less than 100 μm. The particle size of the tungsten powder particles of the alloy powder is 20 μm to 90 μm, and the thickness of the solid solution phase formed by Ni and Mn is 10 μm to 20 μm;

[0043] Step 2: Acquisition of s...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] Step 1. Preparation of pre-alloyed powder: W-Ni-Co tungsten-based alloy is formulated according to the mass ratio of W, Ni and Co of 93:4:3, and then pressed to obtain a green body, which is then vacuum sintered, The tungsten-based alloy bar is obtained by forging, and the tungsten-based alloy bar is placed in the plasma rotating electrode powder making equipment, and the W-Ni-Co pre-alloyed powder is prepared by using the plasma rotating electrode powder making method; the W-Ni-Co The pre-alloyed powder is a spherical body in which the solid solution phase formed by Ni and Co wraps tungsten powder particles. The particle size of the W-Ni-Co pre-alloyed powder is less than 100 μm, and the particle size of the tungsten powder particles of the W-Ni-Co pre-alloyed powder is 20 μm to 90 μm, the thickness of the solid solution phase formed by Ni and Co is 10 μm to 20 μm;

[0052] Step 2: Acquisition of slice data and sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com