Device and method for preparing spherical titanium and titanium alloy powder

A technology for powder preparation and titanium alloy, applied in the direction of additive processing, etc., can solve the problems of high content of impurity elements in powder, high cost of powder preparation, and high price of original powder, and achieve low content of impurity elements, low stability requirements, and high component content. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

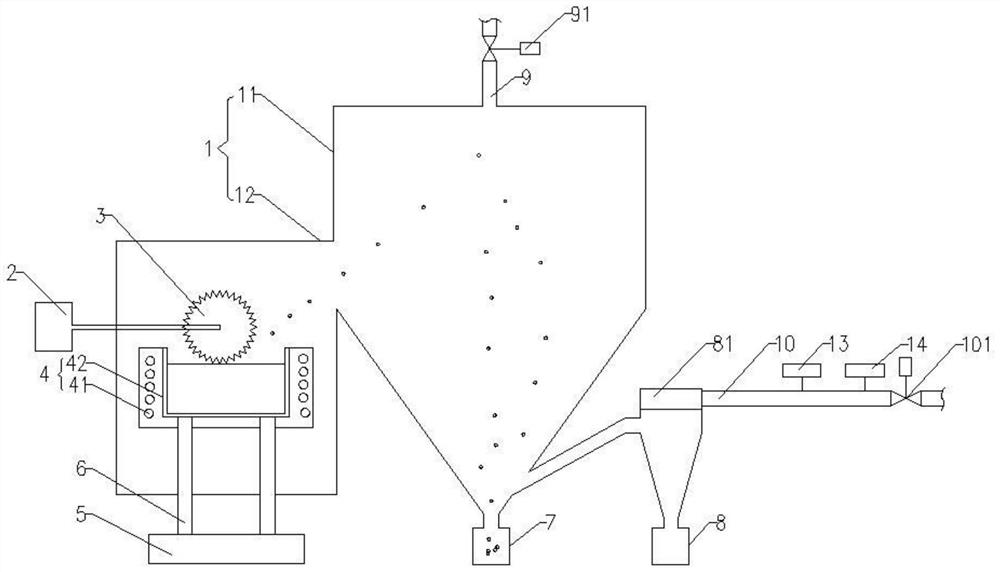

[0039] The preparation method of spherical titanium and titanium alloy powder comprises the following steps:

[0040] a. Melting of alloy ingots

[0041] Add the titanium ingot or titanium alloy ingot to the double-layer water-cooled copper crucible 42, keep the vacuum degree less than 0.1Pa, then fill it with argon, and make the titanium ingot or titanium alloy ingot melt on the double-layer water-cooled copper crucible 42 through the induction coil 41, Heating temperature is titanium ingot or titanium alloy ingot superheat degree 80 ~ 150 ℃;

[0042] b. Atomization of molten droplets

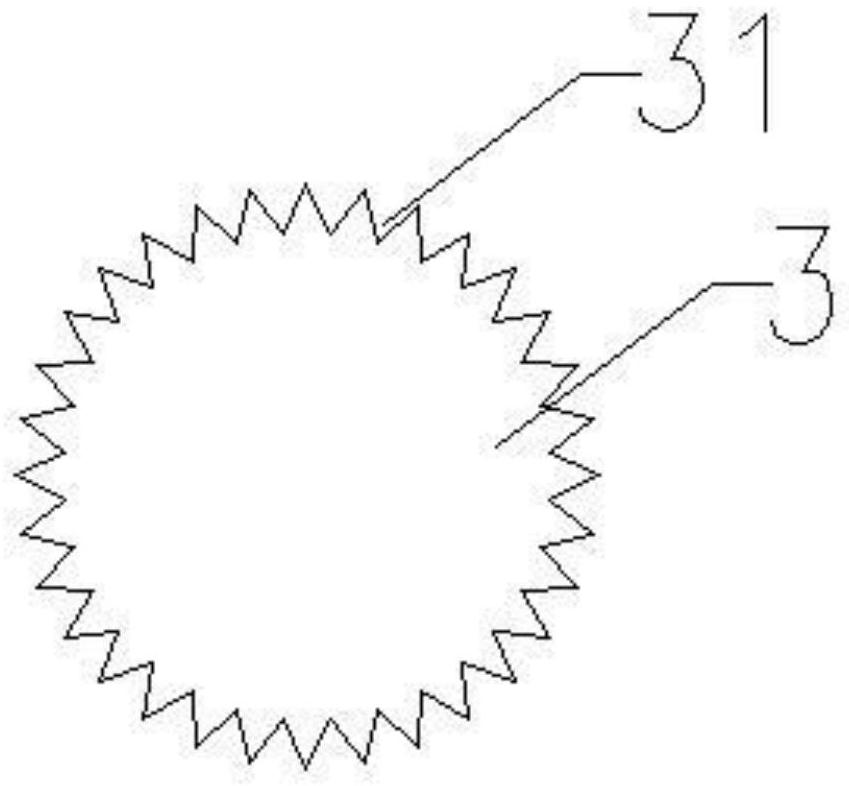

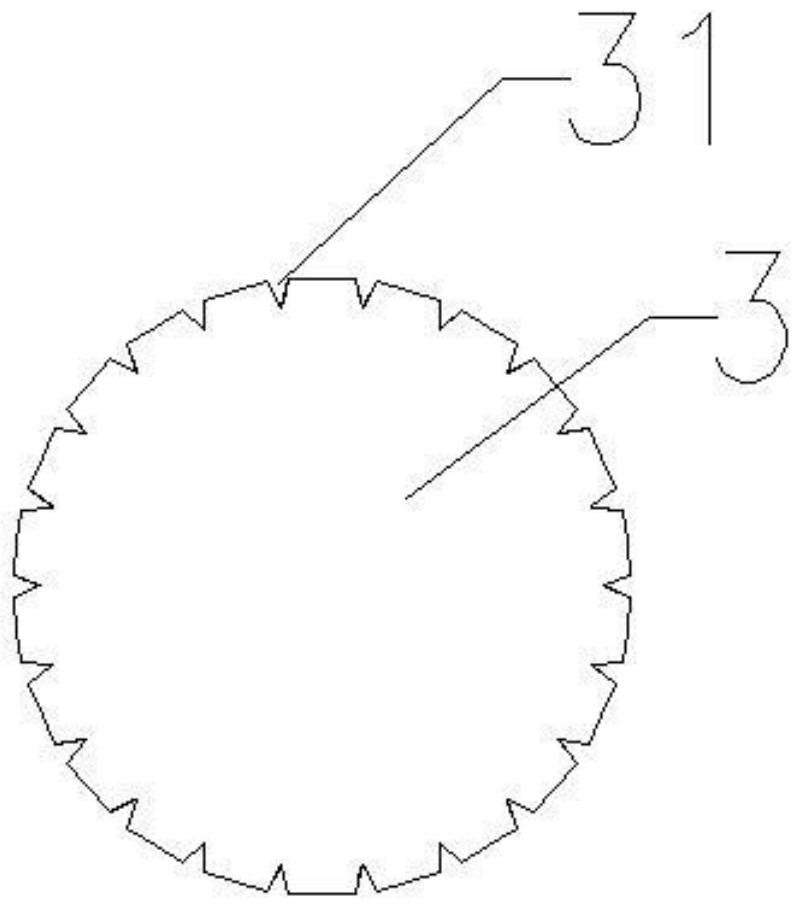

[0043] After the titanium ingot or titanium alloy ingot is completely melted and the liquid level is stable, the lower end of the rotating wheel 3 is placed under the liquid level of the double-layer water-cooled copper crucible 42, and the rotating wheel 3 rotates at a speed of 100,000 to 20,000 rpm, so that the molten droplet is under the action of centrifugal force, extending The parabola...

Embodiment 1

[0049] Adopt this device to prepare TC4 spherical titanium powder, and follow the following steps:

[0050] a. Melting of alloy ingots

[0051] Add the TC4 titanium ingot to the double-layer water-cooled copper crucible 42, vacuumize the device, the vacuum degree is 0.02Pa, then fill it with 99.999% argon, the pressure of the melting chamber 12 and the atomization chamber 11 is 115Kpa, turn on the power supply of the induction coil 41 The double-layer water-cooled copper crucible 42 is heated, and the heating temperature is 1760° C., until the ingot is completely melted.

[0052] b. Atomization of molten droplets

[0053] After the liquid level of the melt is stable, open the lifting device 5, and slowly raise the double-layer water-cooled copper crucible 42, and the rising speed of the liquid level is 50 μm / s; at the same time, turn on the motor 2, keep the rotating speed of the rotating wheel 3 at 20000 rpm, and the number of rotating wheels 3 20, the outer diameter of the...

Embodiment 2

[0060] Use this device to prepare TA0 spherical titanium powder, follow the following steps:

[0061] a. Smelting of titanium ingots

[0062] Put the TA0 titanium ingot into the double-layer water-cooled copper crucible 42, vacuumize the device, the vacuum degree is 0.08Pa, then fill it with 99.999% argon, the pressure of the melting chamber 12 and the atomization chamber 11 is 110Kpa, turn on the power supply of the induction coil 41 The double-layer water-cooled copper crucible 42 is heated at a temperature of 1800° C. until the ingot is completely melted.

[0063] b. Atomization of molten droplets

[0064] After the liquid level of the melt is stable, open the lifting device 5, slowly raise the double-layer water-cooled copper crucible 42, the liquid level rising speed is 20 μm / s, and turn on the motor 2 at the same time, the rotating speed of the rotating wheel 3 is 15000rpm, and the number of rotating wheels 3 is 10 The outer diameter of the rotating wheel 3 is 40cm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com