Patents

Literature

111 results about "Stable element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stable element. a nonradioactive element, one not subject to spontaneous nuclear degeneration. Some kinds of stable elements are calcium, iron, lead, potassium, and sodium.

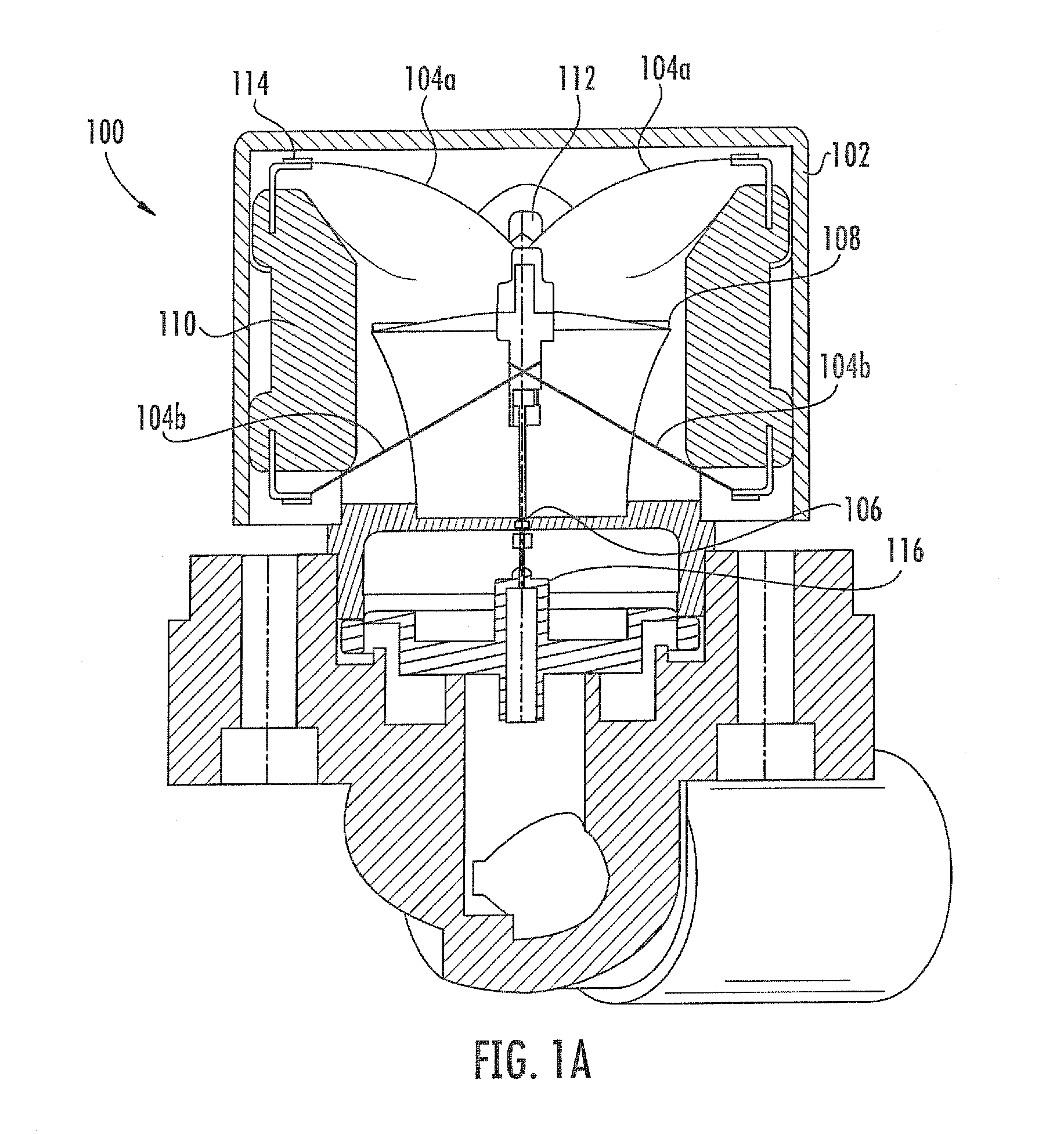

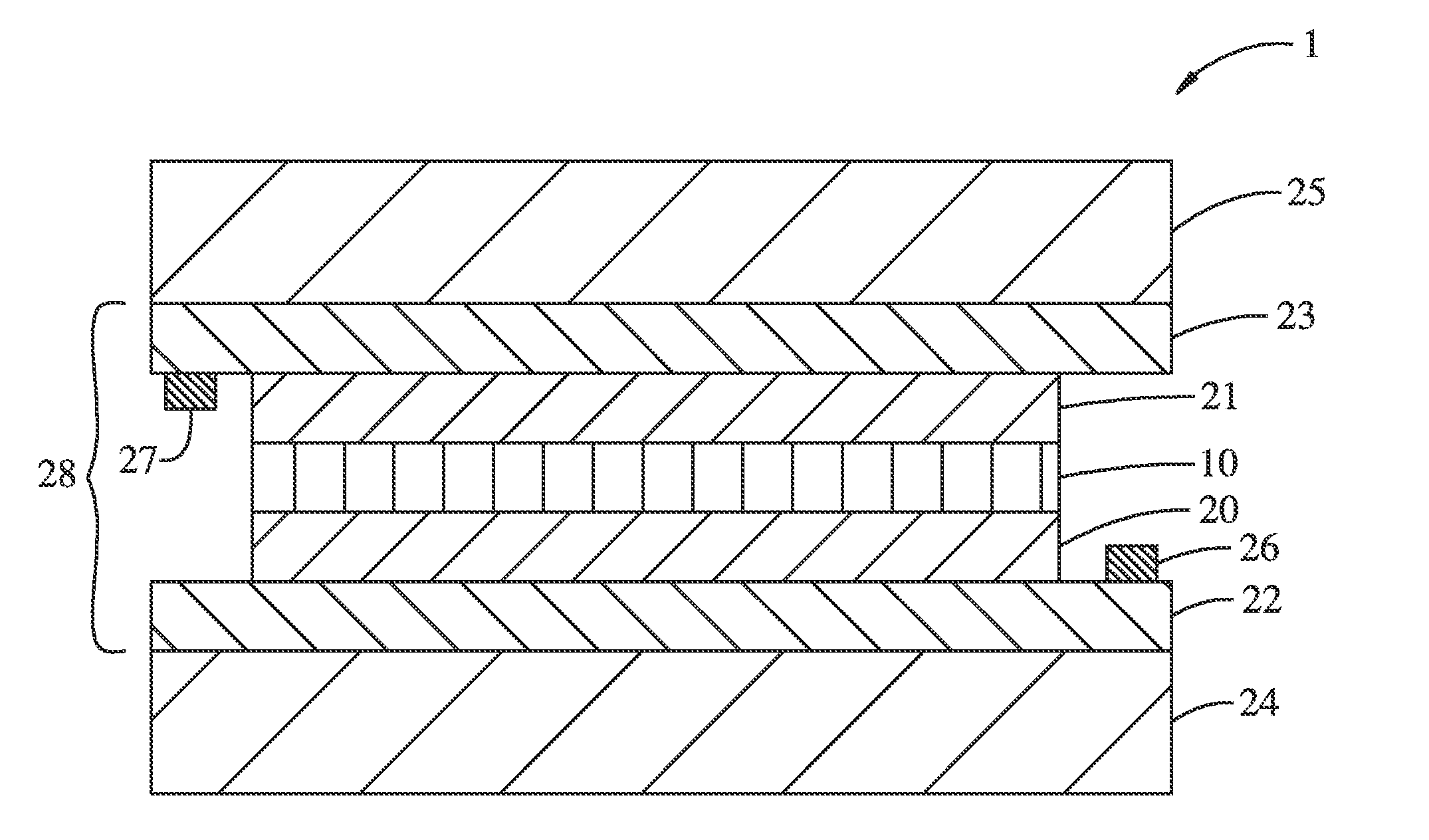

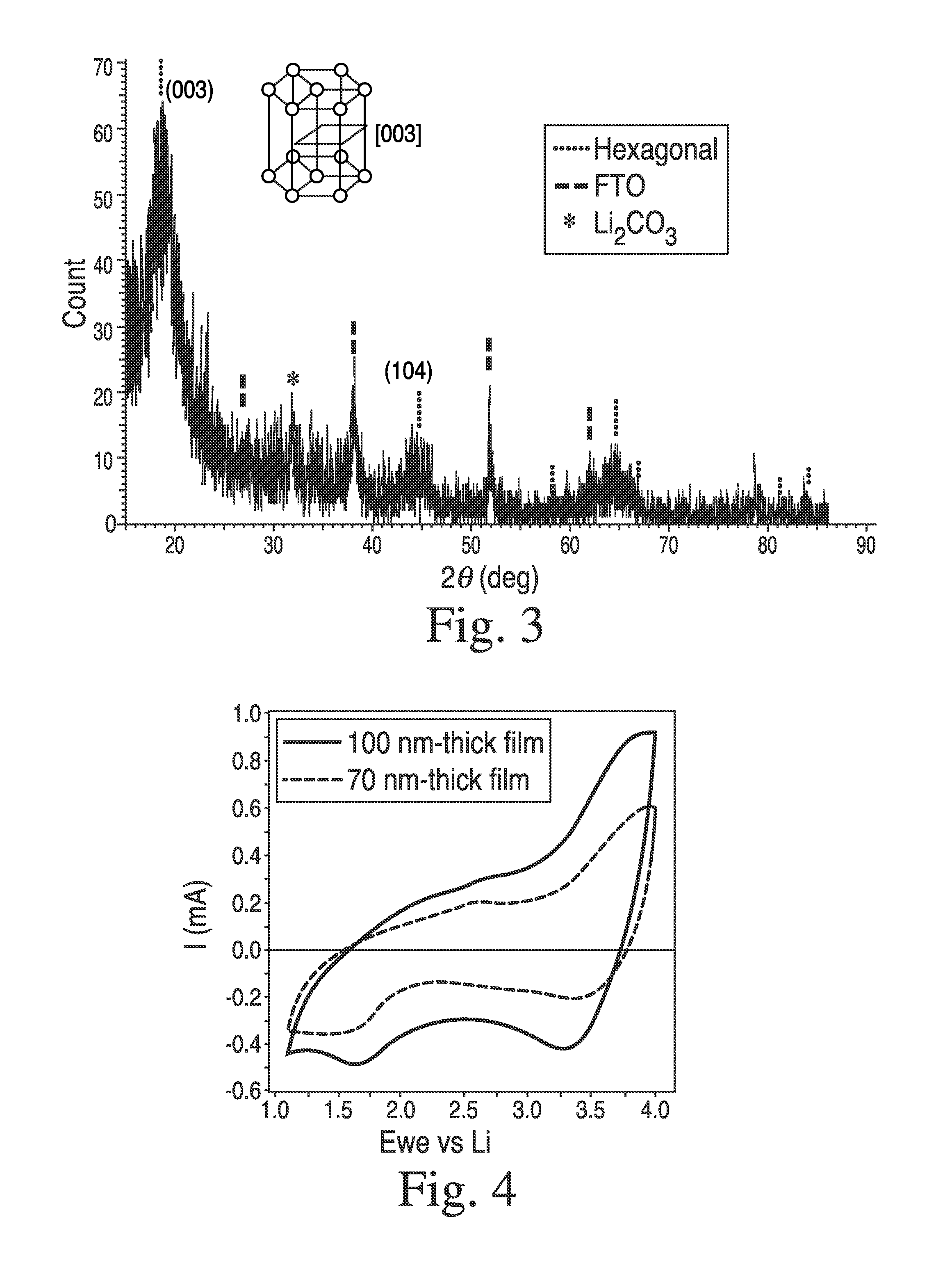

Process for preparing a multi-layer electrochromic structure

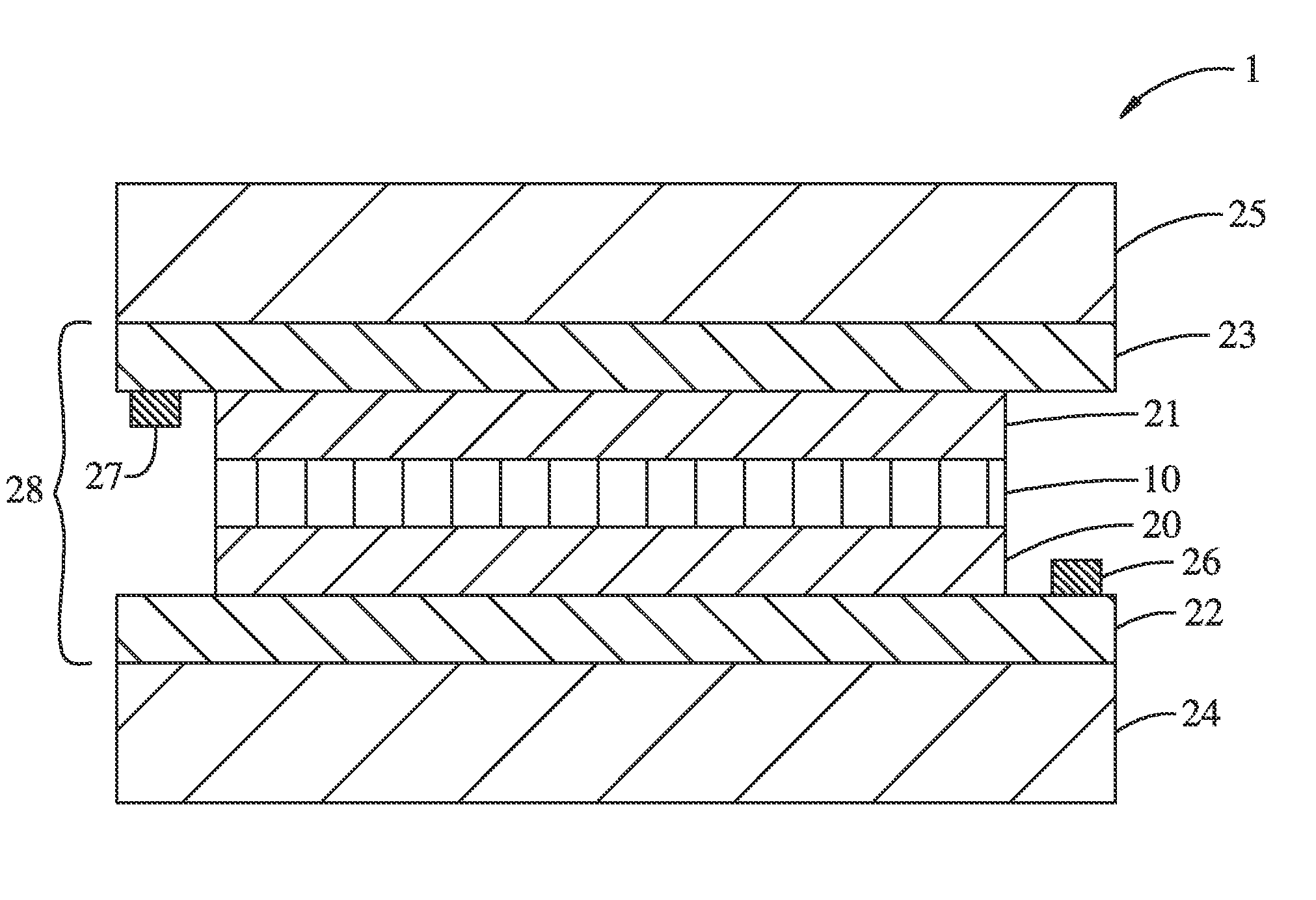

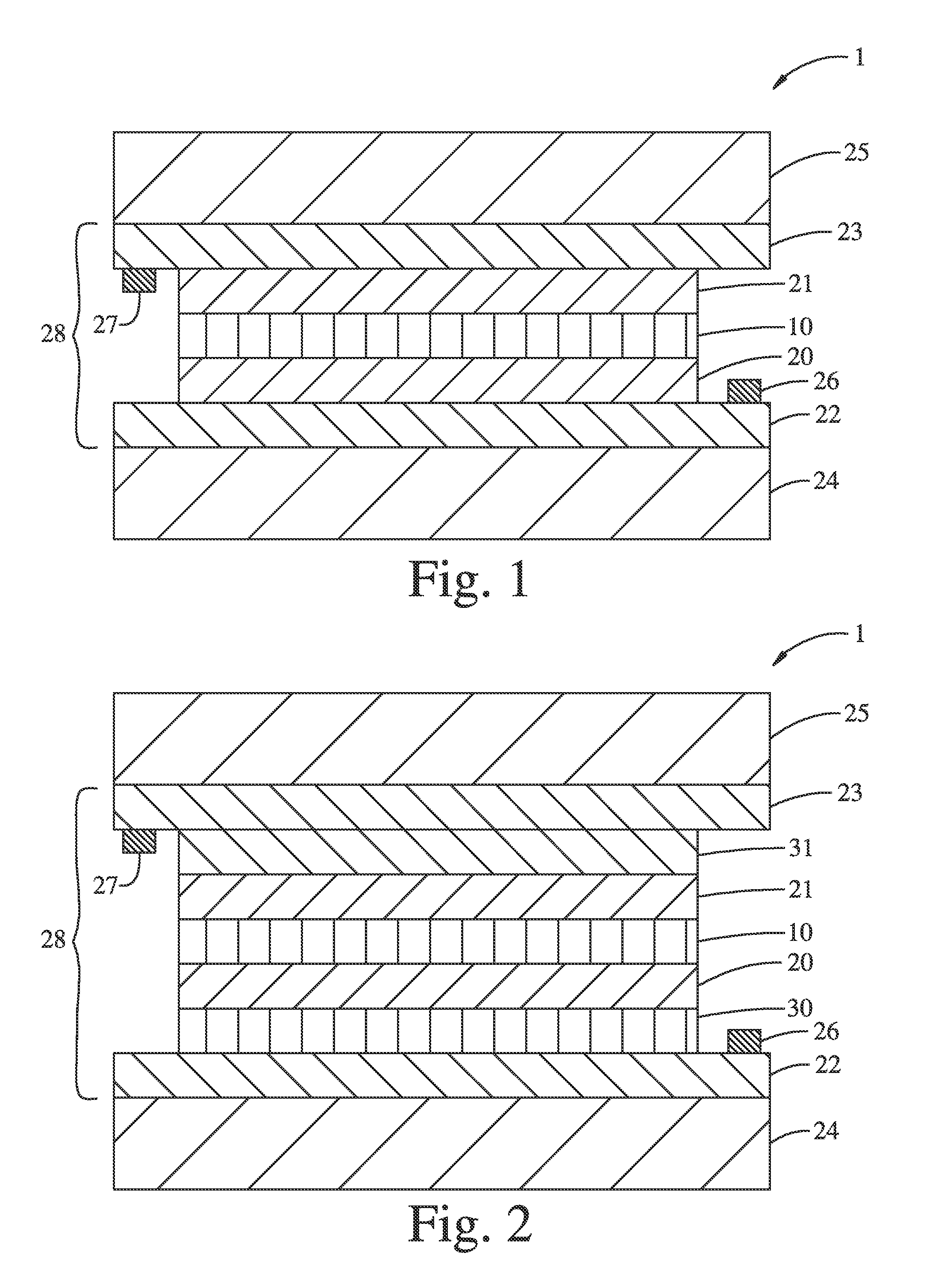

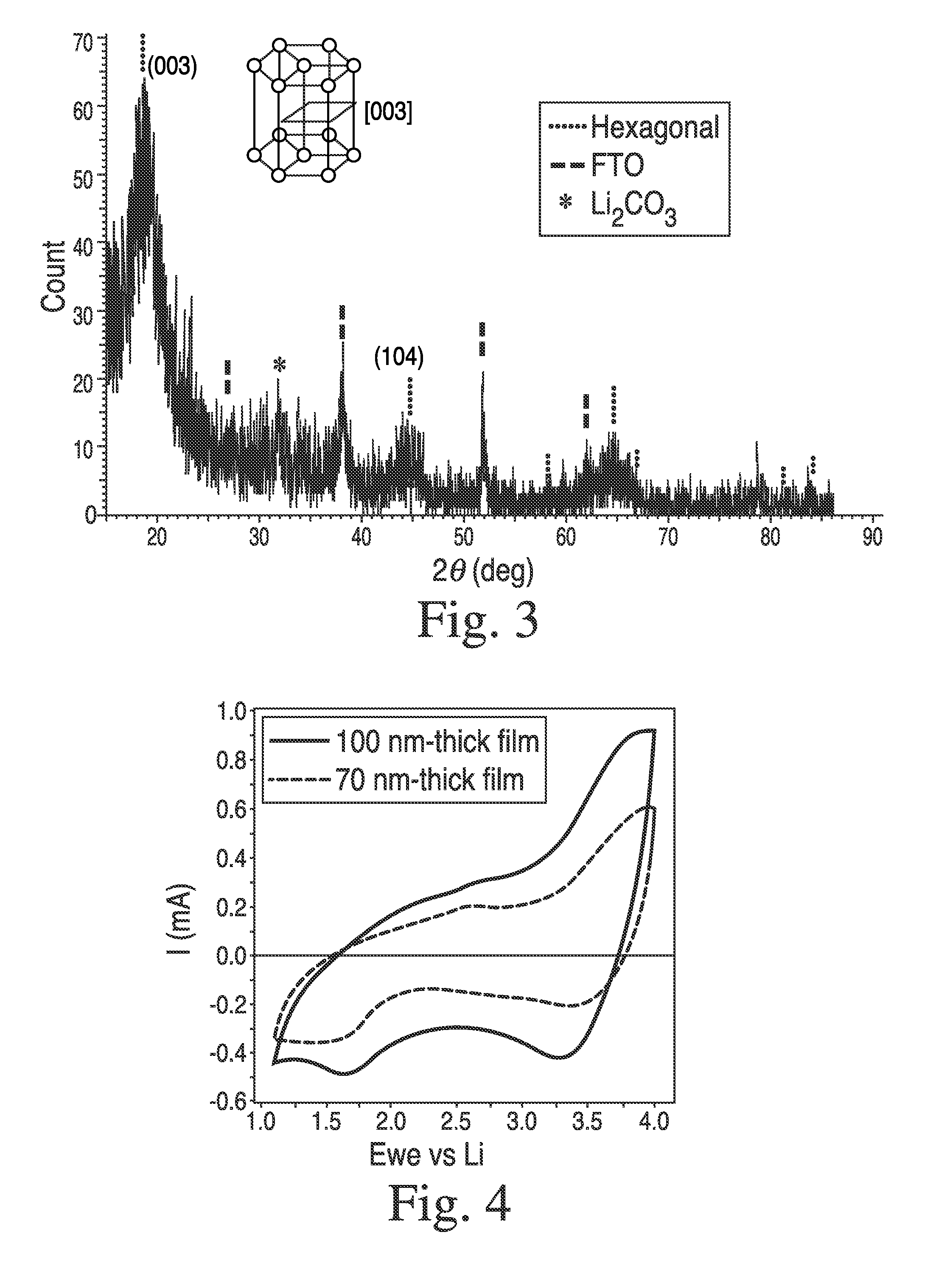

Process for preparing a multi-layer electrochromic structure comprising depositing a film of a liquid mixture onto a substrate and treating the deposited film to form an anodic electrochromic layer comprising a lithium nickel oxide composition, the anodic electrochromic layer comprising lithium, nickel and the bleached state stabilizing element(s) wherein in the film (i) the ratio of lithium to the combined amount of nickel and the bleached state stabilizing element(s) is at least 0.4:1, (ii) the ratio of the combined amount of the bleached state stabilizing element(s) to the combined amount of nickel and the bleached state stabilizing elements in the lithium nickel oxide composition is at least about 0.025:1, and (iii) the bleached state stabilizing element(s) is / are selected from the group consisting of Y, Ti, Zr, Hf, V, Nb, Ta, Mo, W, B, Al, Ga, In, Si, Ge, Sn, P, Sb and combinations thereof.

Owner:KINESTRAL TECH

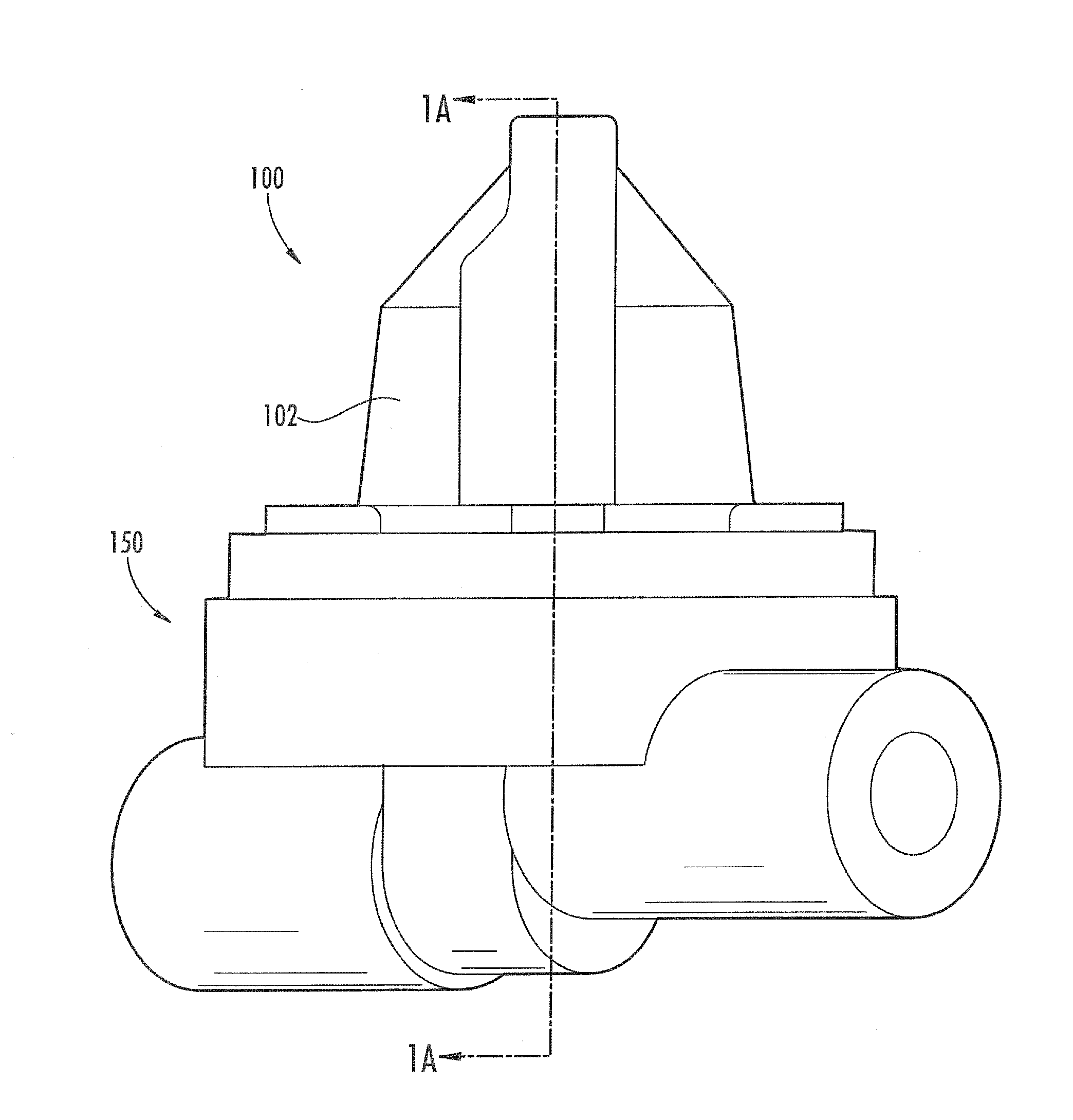

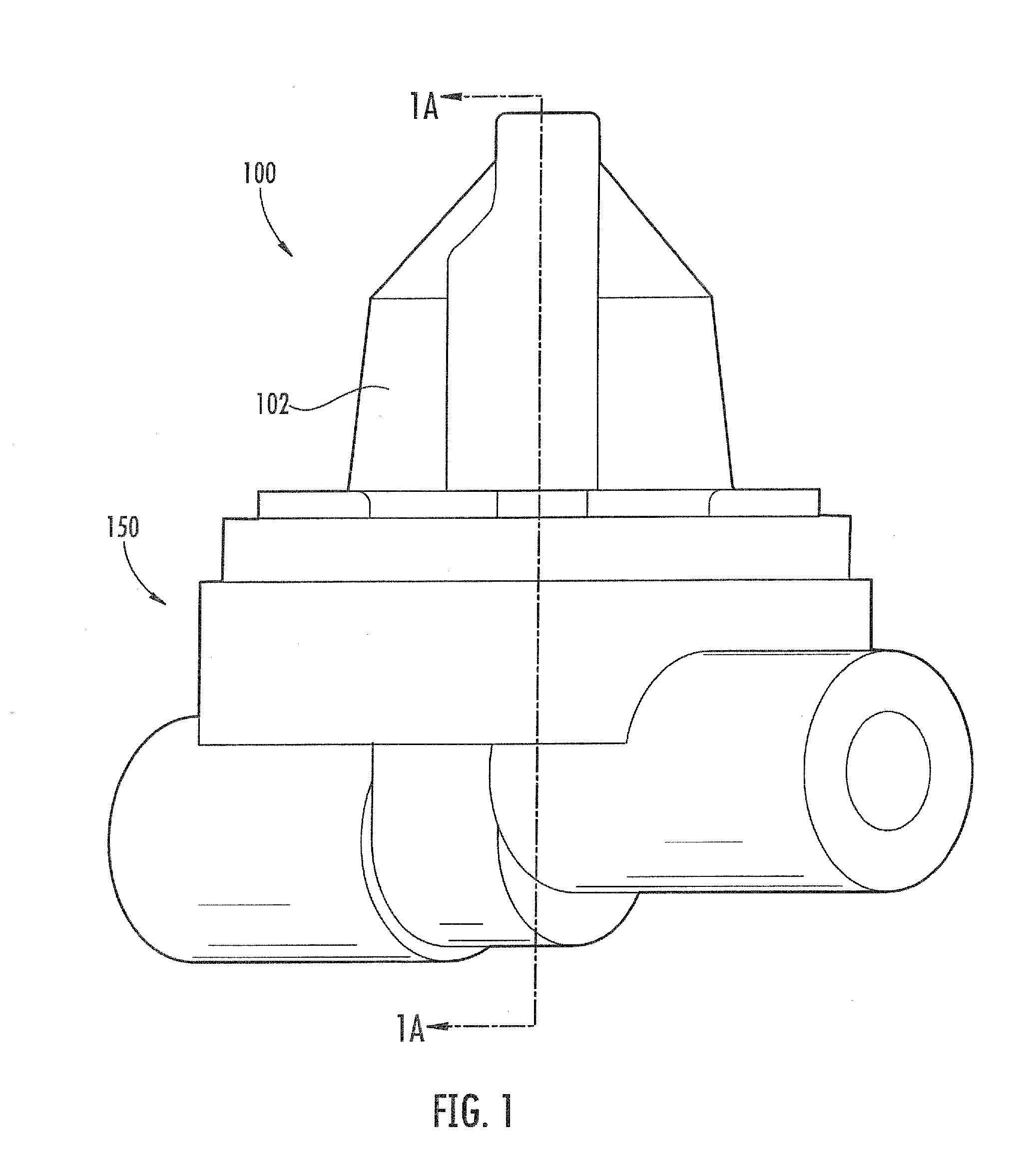

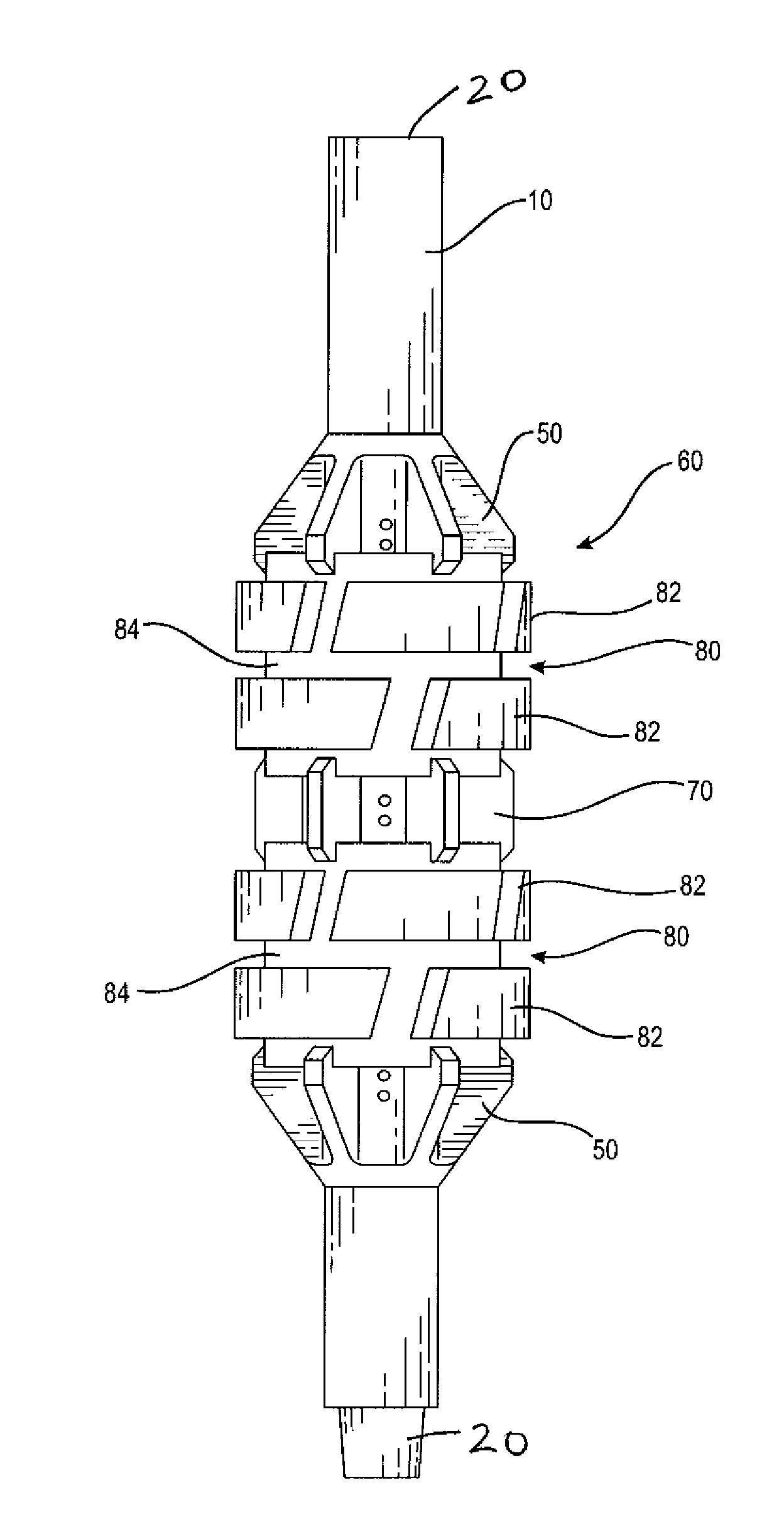

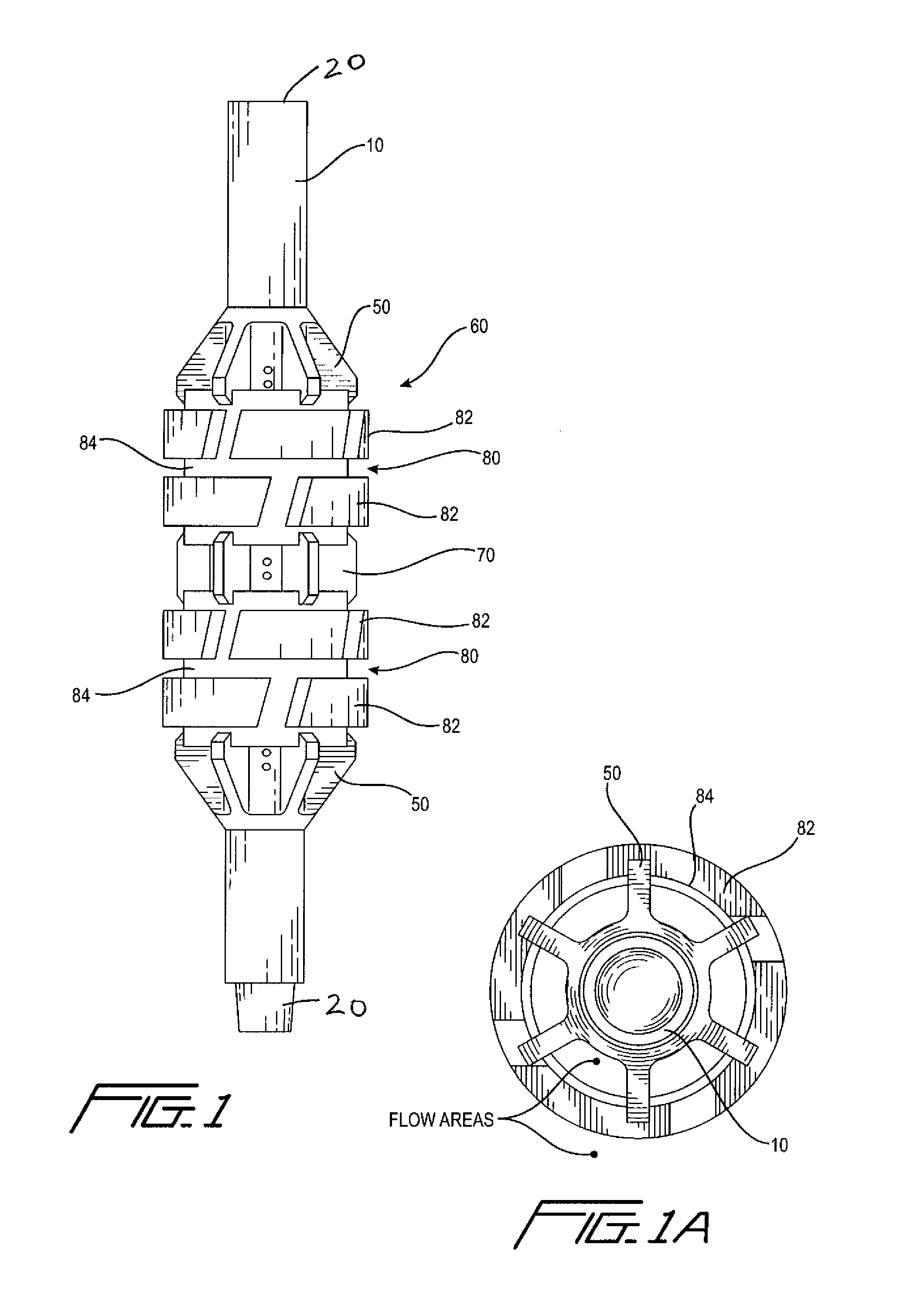

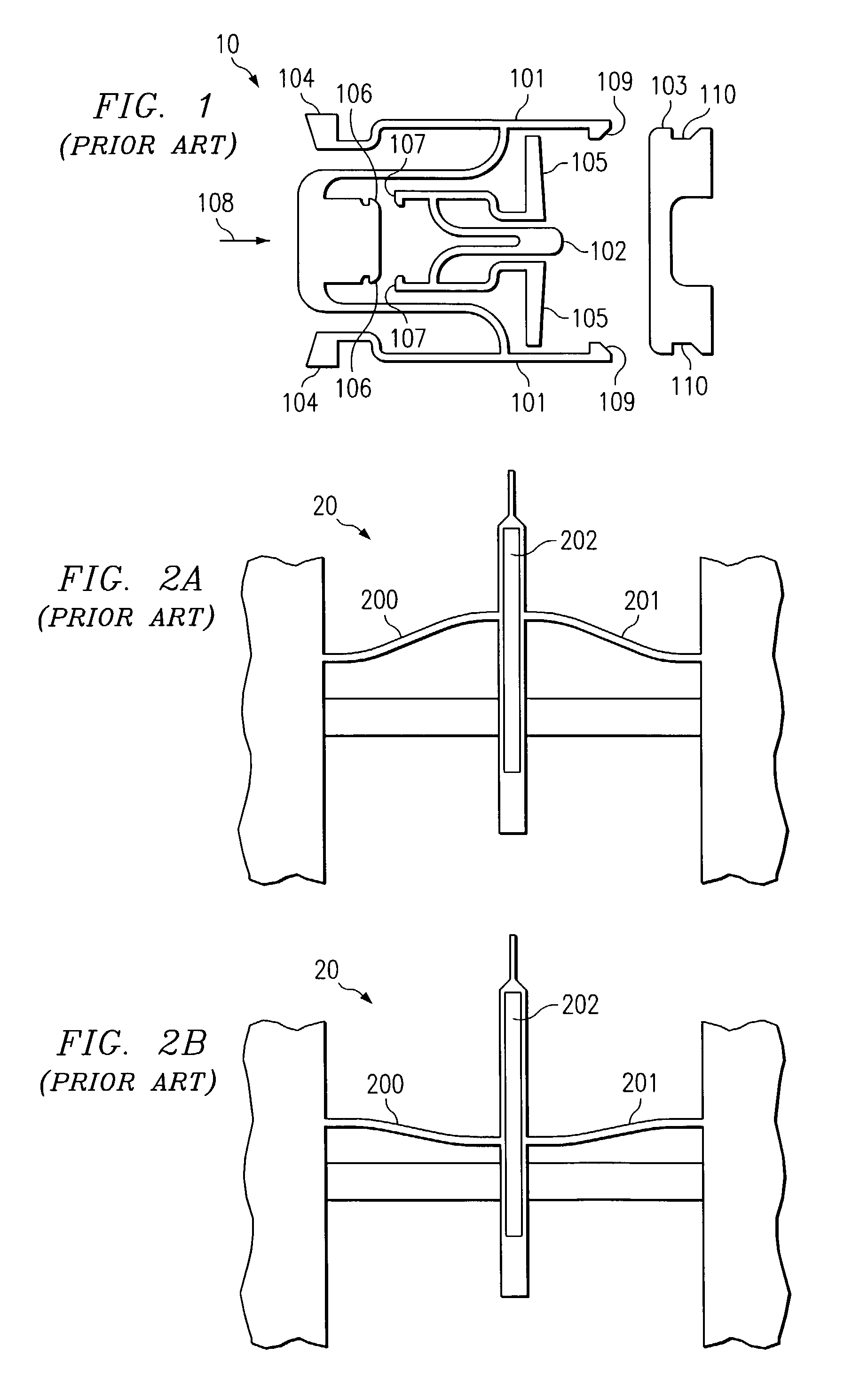

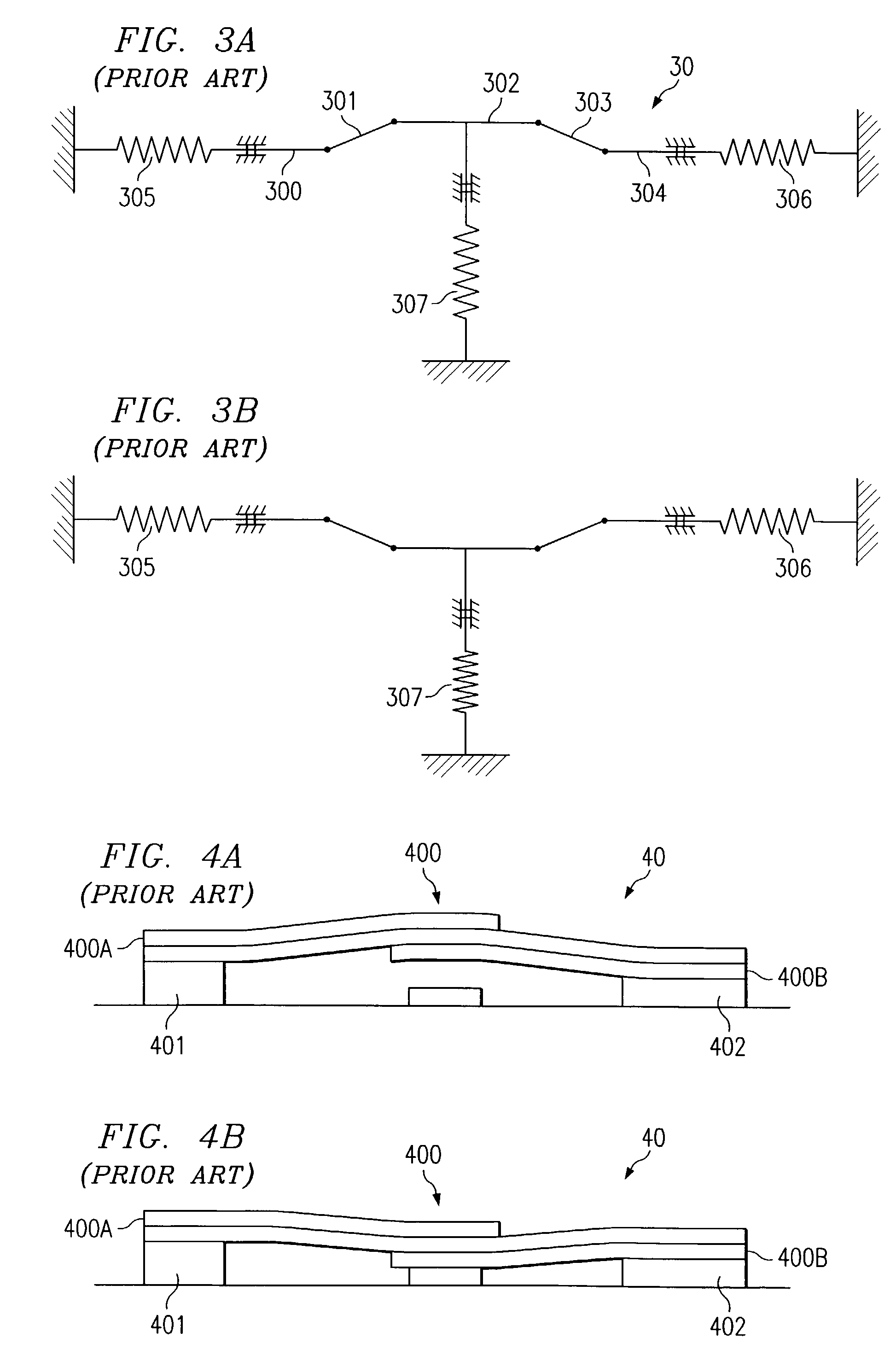

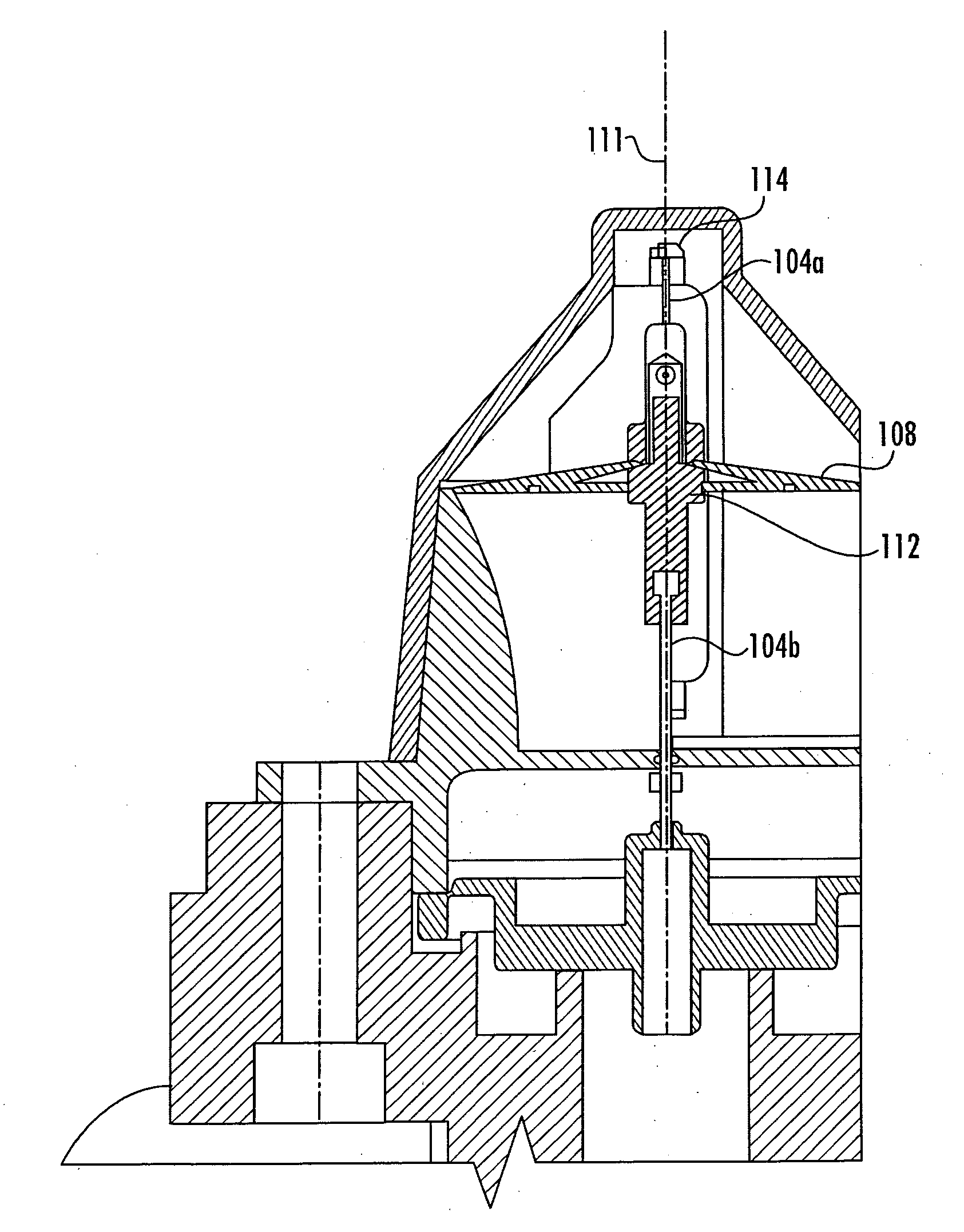

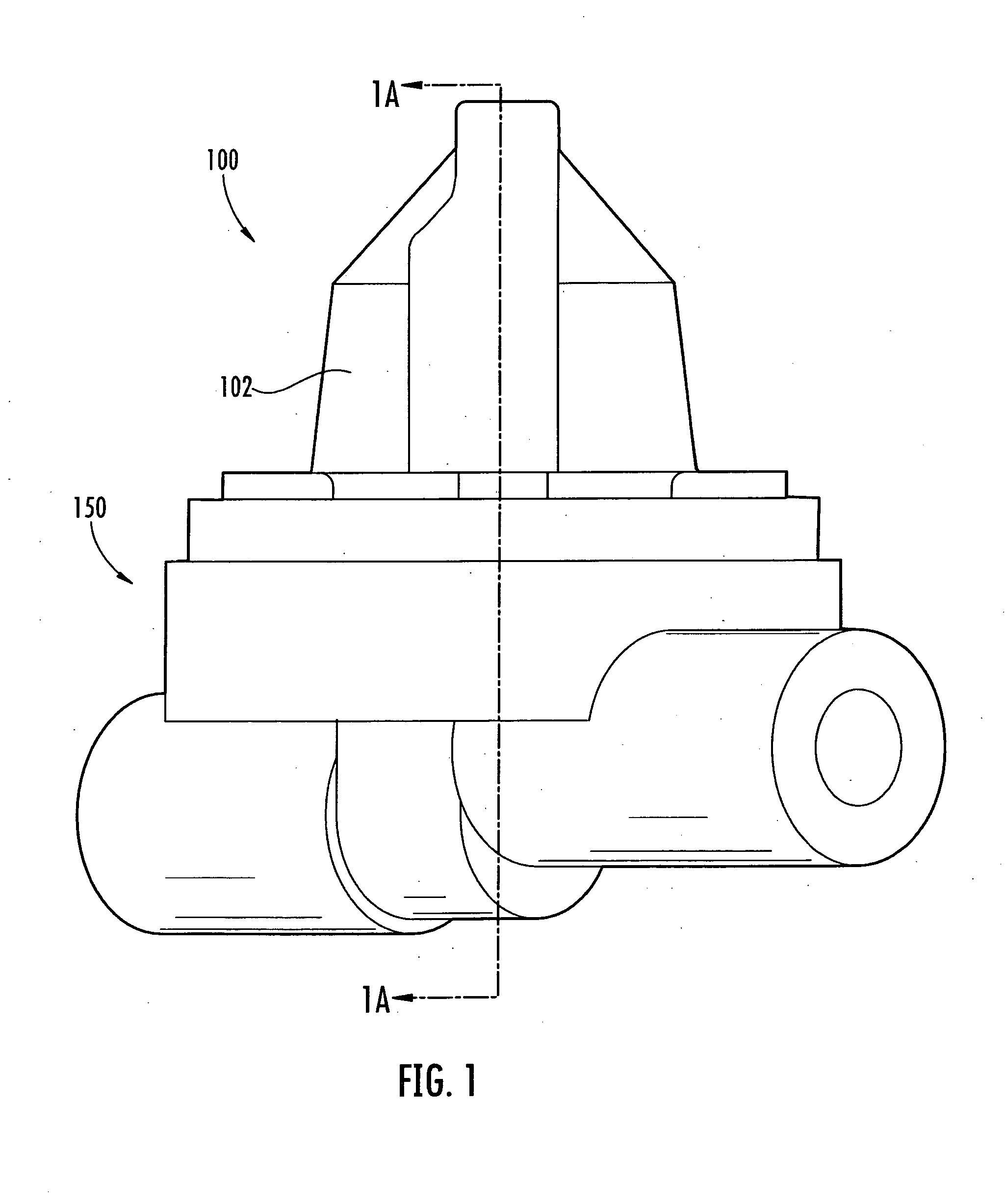

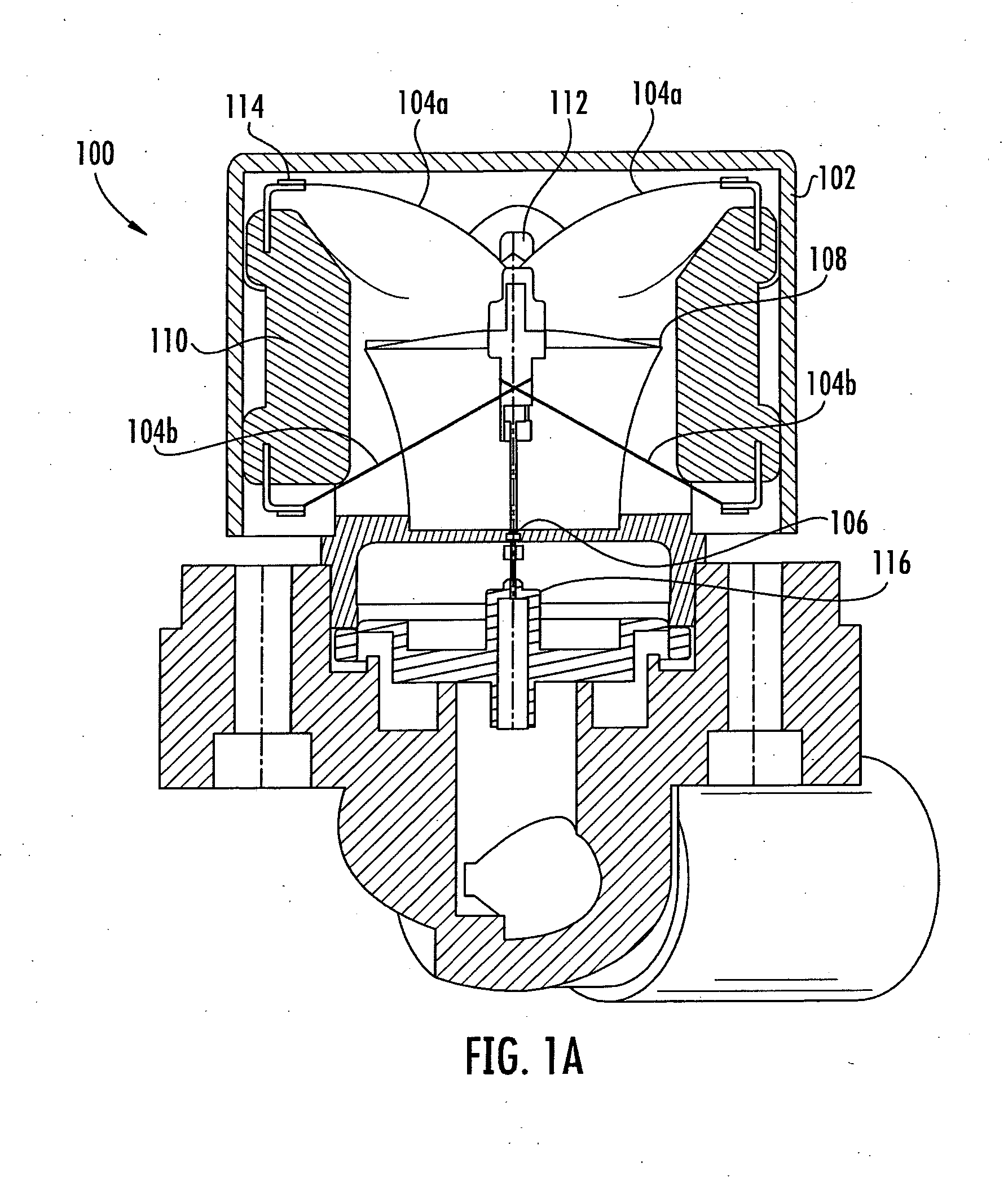

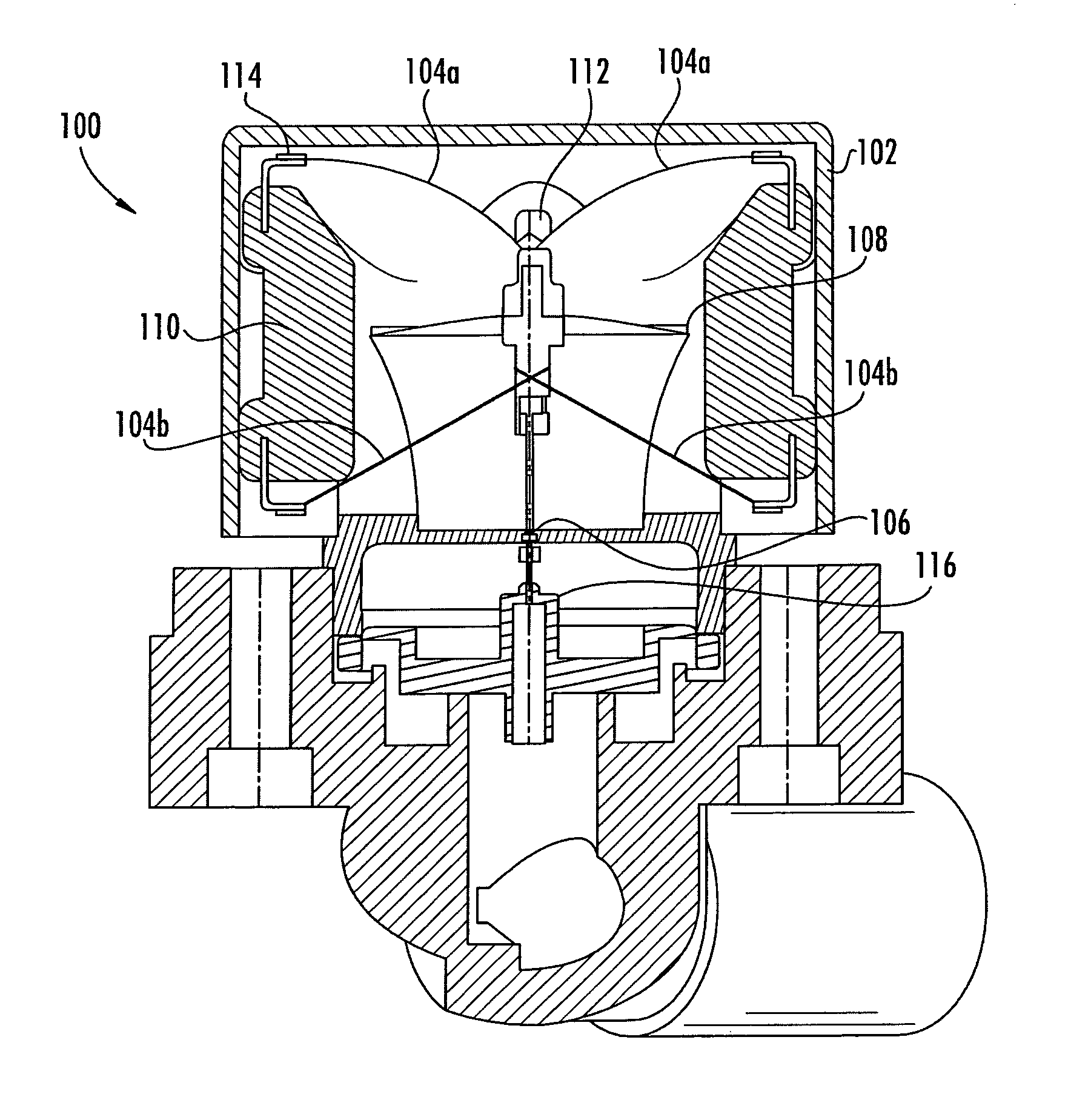

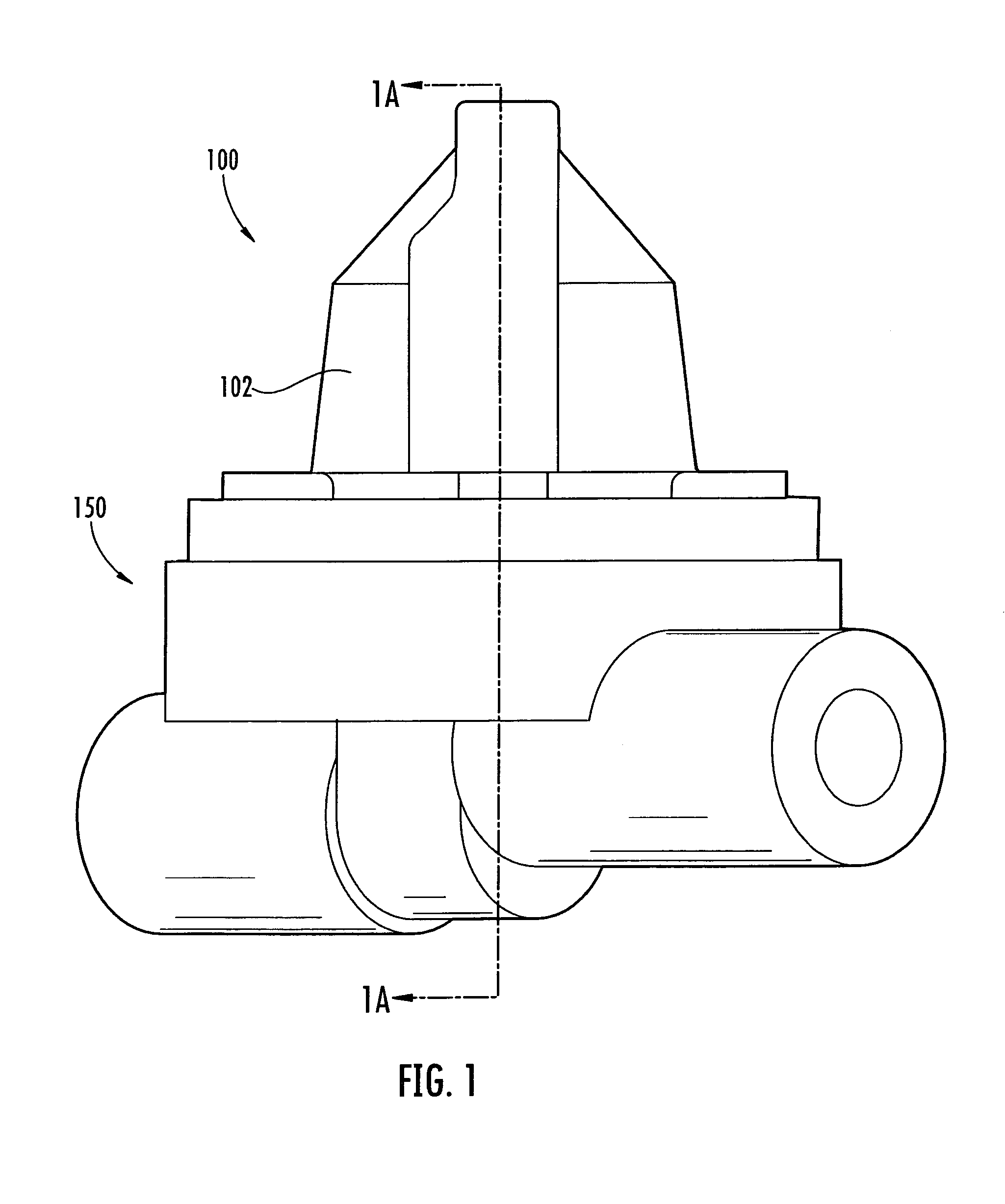

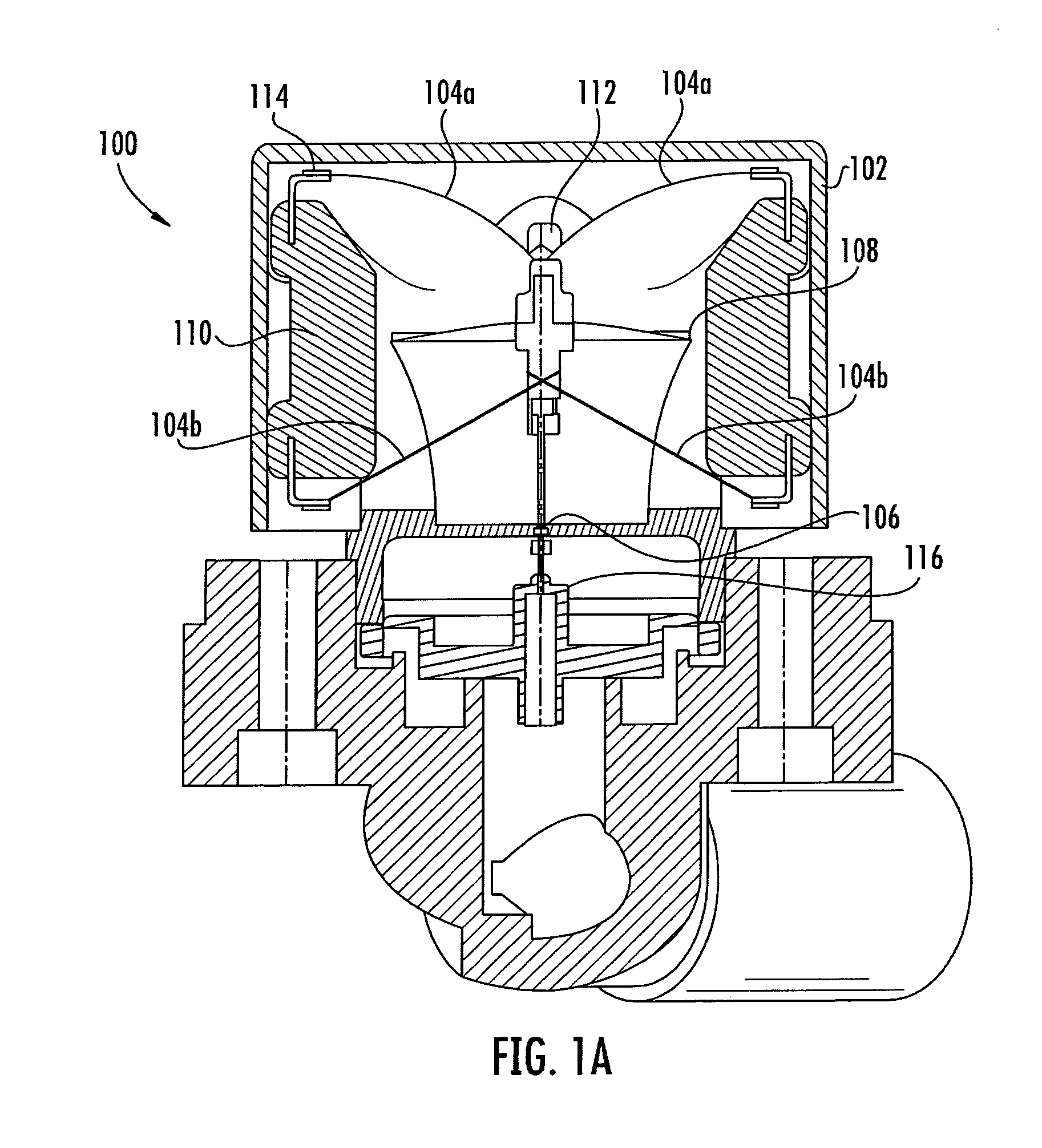

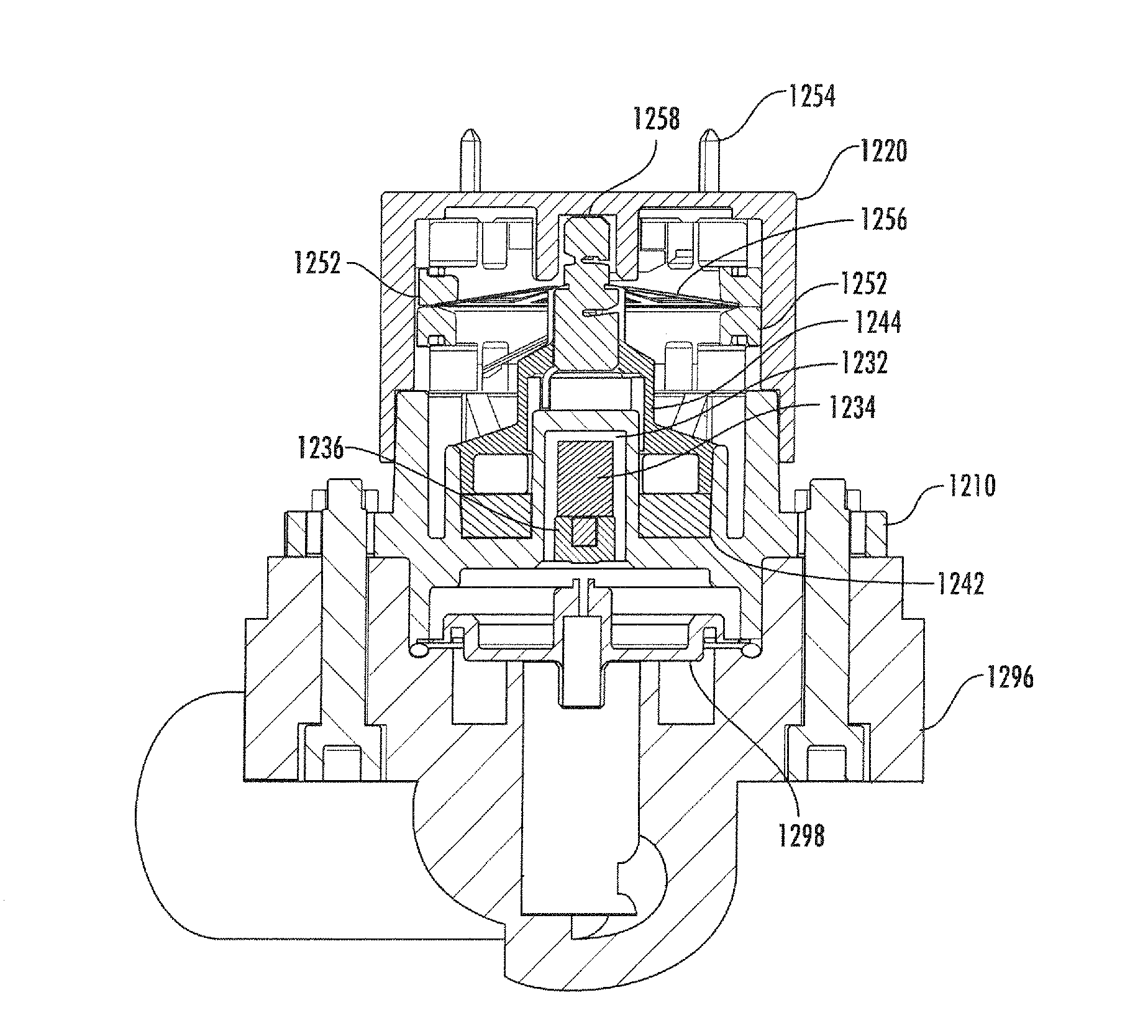

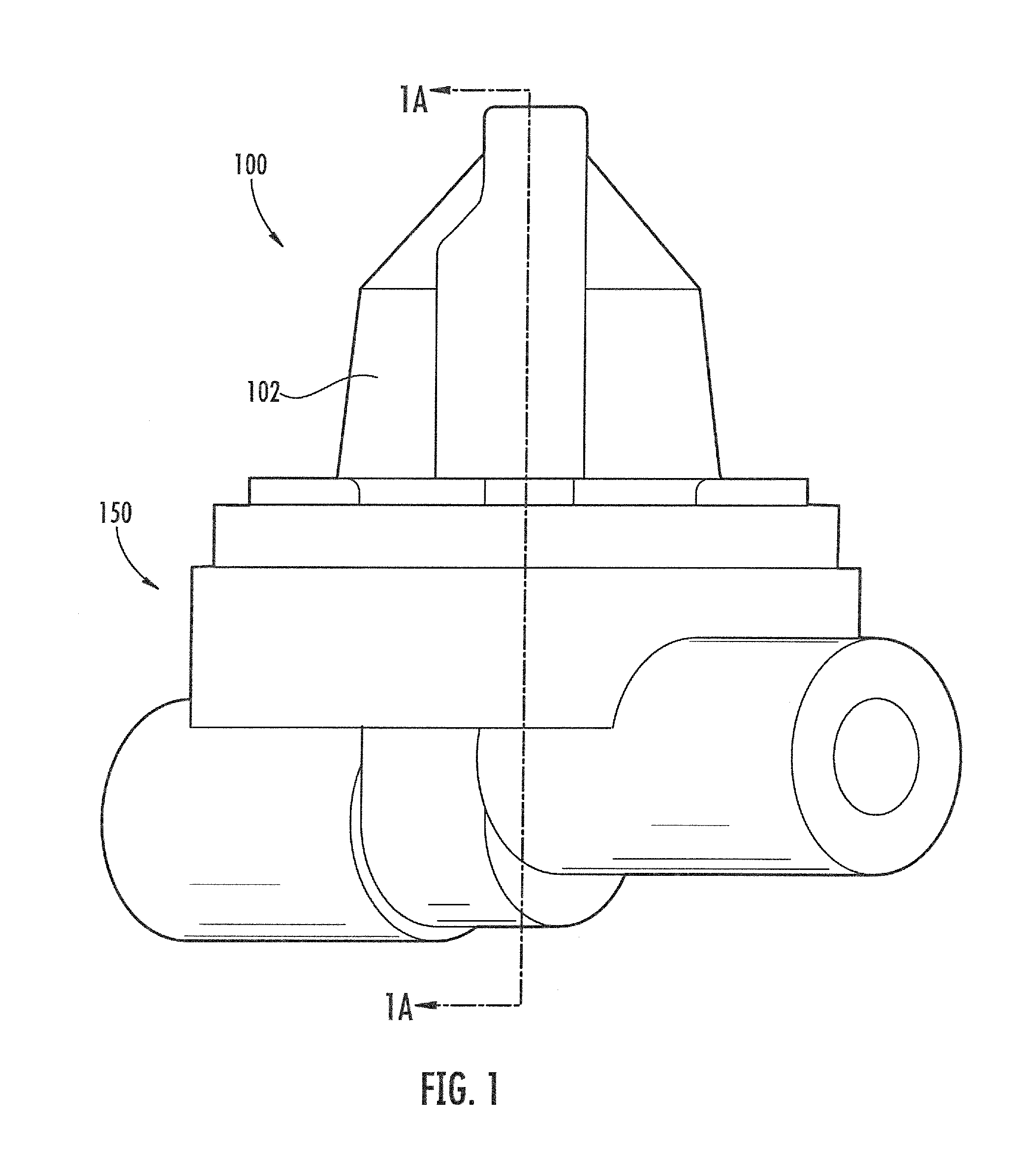

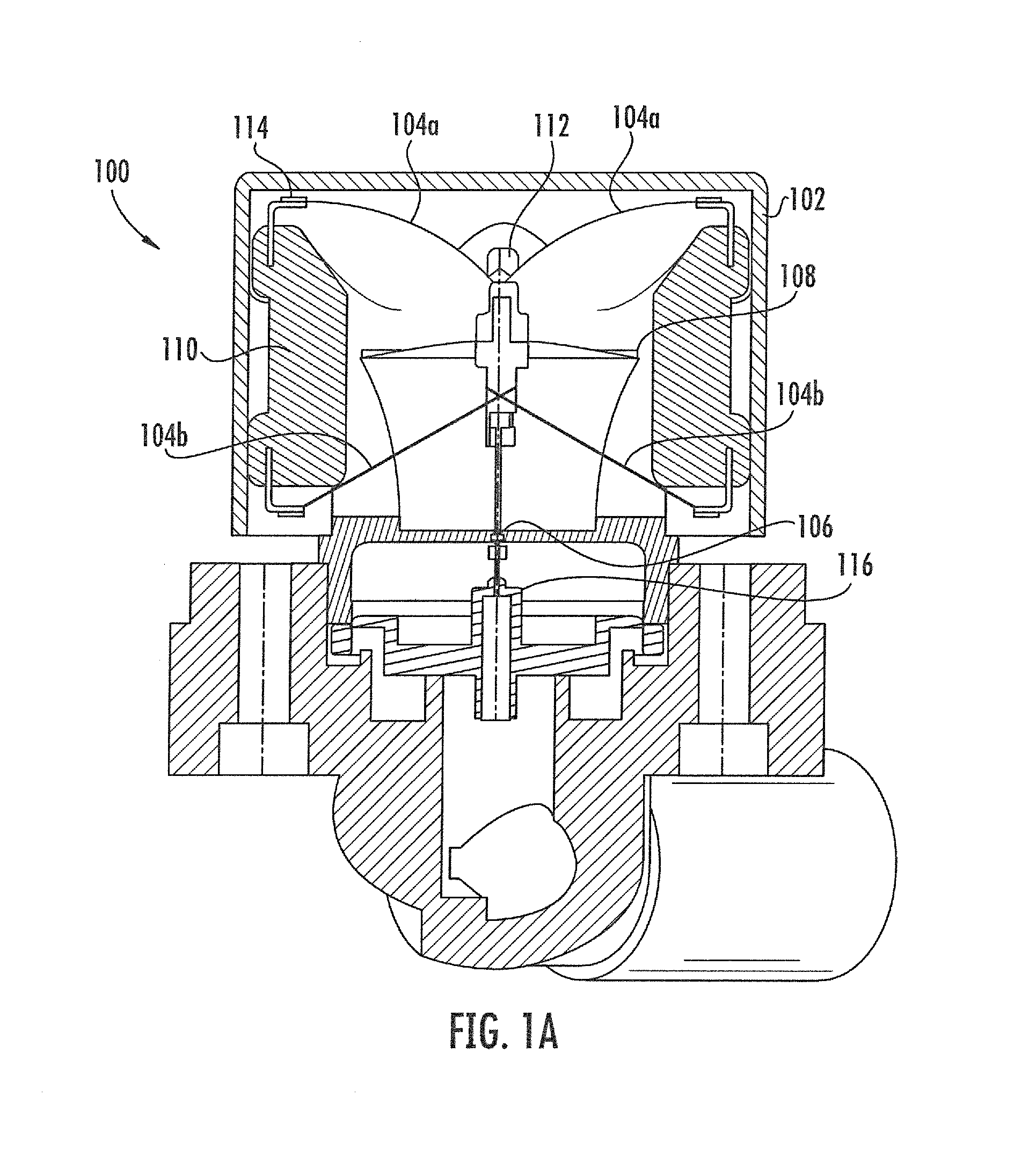

Memory alloy-actuated apparatus and methods for making and using the same

InactiveUS20120151913A1Reduce operating costsLess ecologically damaging wasteOperating means/releasing devices for valvesMechanical power devicesValve actuatorShape-memory alloy

Actuator apparatus having a multi-stable element actuated by memory alloy actuating elements. In one embodiment, the multi-stable actuator comprises a bistable (two-state) diaphragm element adapted to alternate between two stable configurations via forces exerted on the diaphragm by more than one memory alloy filaments in response to thermal activation. The bistable diaphragm element is coupled to a magnetic actuator element resident on a dry portion of a valve fitting, while a plunger actuated by the magnetic actuator element is resident on a wet portion of a valve fitting. Methods for making and using the bistable actuator apparatus are also disclosed.

Owner:AUTOSPLICE SYST

Process for preparing a multi-layer electrochromic structure

Process for preparing a multi-layer electrochromic structure comprising depositing a film of a liquid mixture onto a substrate and treating the deposited film to form an anodic electrochromic layer comprising a lithium nickel oxide composition, the anodic electrochromic layer comprising lithium, nickel and the bleached state stabilizing element(s) wherein in the film (i) the ratio of lithium to the combined amount of nickel and the bleached state stabilizing element(s) is at least 0.4:1, (ii) the ratio of the combined amount of the bleached state stabilizing element(s) to the combined amount of nickel and the bleached state stabilizing elements in the lithium nickel oxide composition is at least about 0.025:1, and (iii) the bleached state stabilizing element(s) is / are selected from the group consisting of Y, Ti, Zr, Hf, V, Nb, Ta, Mo, W, B, Al, Ga, In, Si, Ge, Sn, P, Sb and combinations thereof.

Owner:KINESTRAL TECH

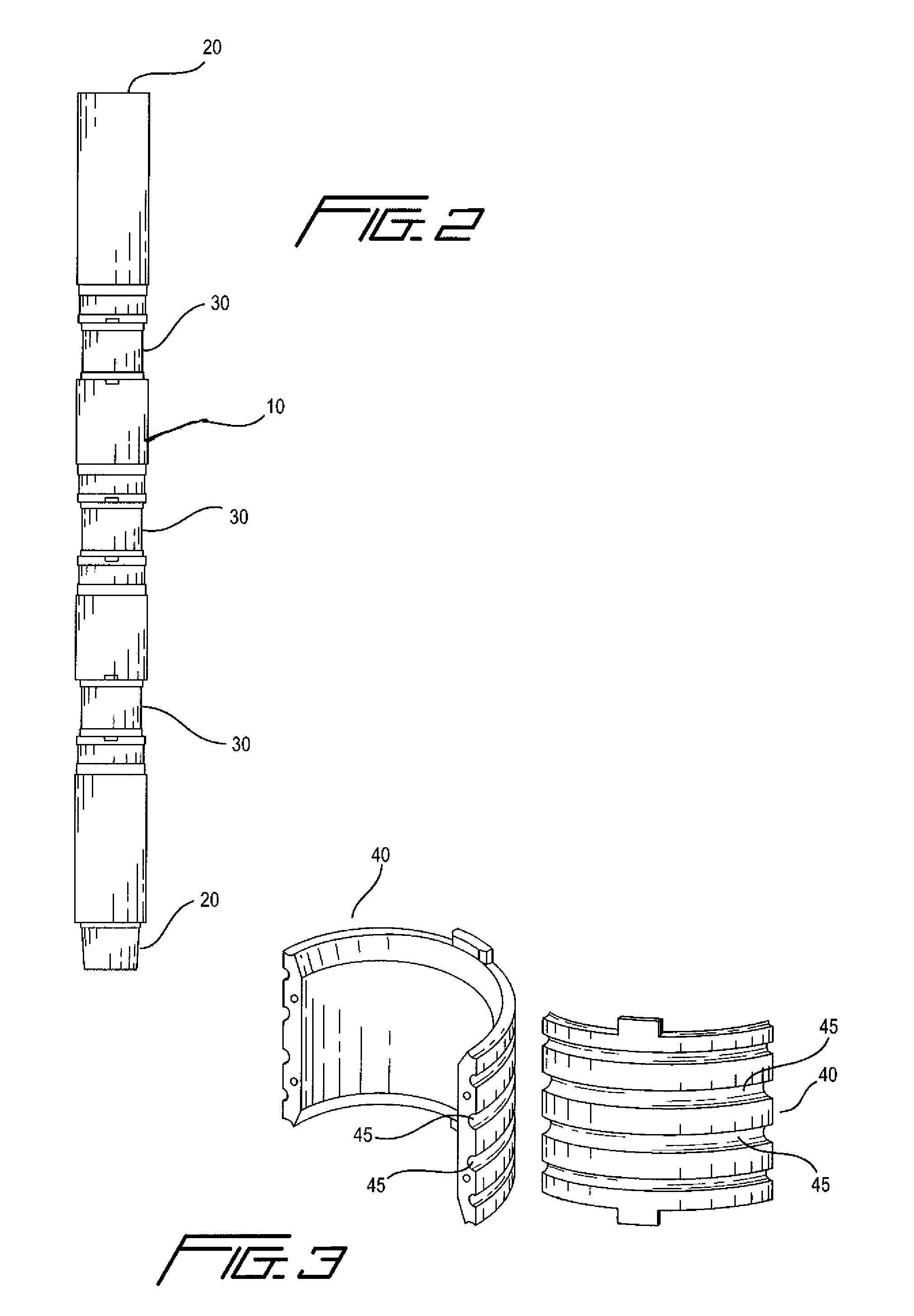

Multi-Purpose Well Servicing Apparatus

Apparatus for cleaning the inner wall of wellbore tubulars, and for capturing downhole debris in the wellbore An elongated, tubular central mandrel has threaded connections on either end for makeup into a tubular string The mandrel has recesses on its outer circumference into which split rings are mounted Various service elements are then attachable to the central mandrel, by sliding them over the mandrel and holding them in place with stabilizer elements which connect to the split rings Different embodiments of the service elements include a brush assembly, a junk basket, and a magnet The stabilizer elements may be mounted onto the split rings so as to either be rotationally locked with respect to the mandrel, or so as to be capable of rotating with respect to the mandrel, since the service elements are held in place on the central mandrel by the stabilizer elements.

Owner:HALLIBURTON ENERGY SERVICES INC

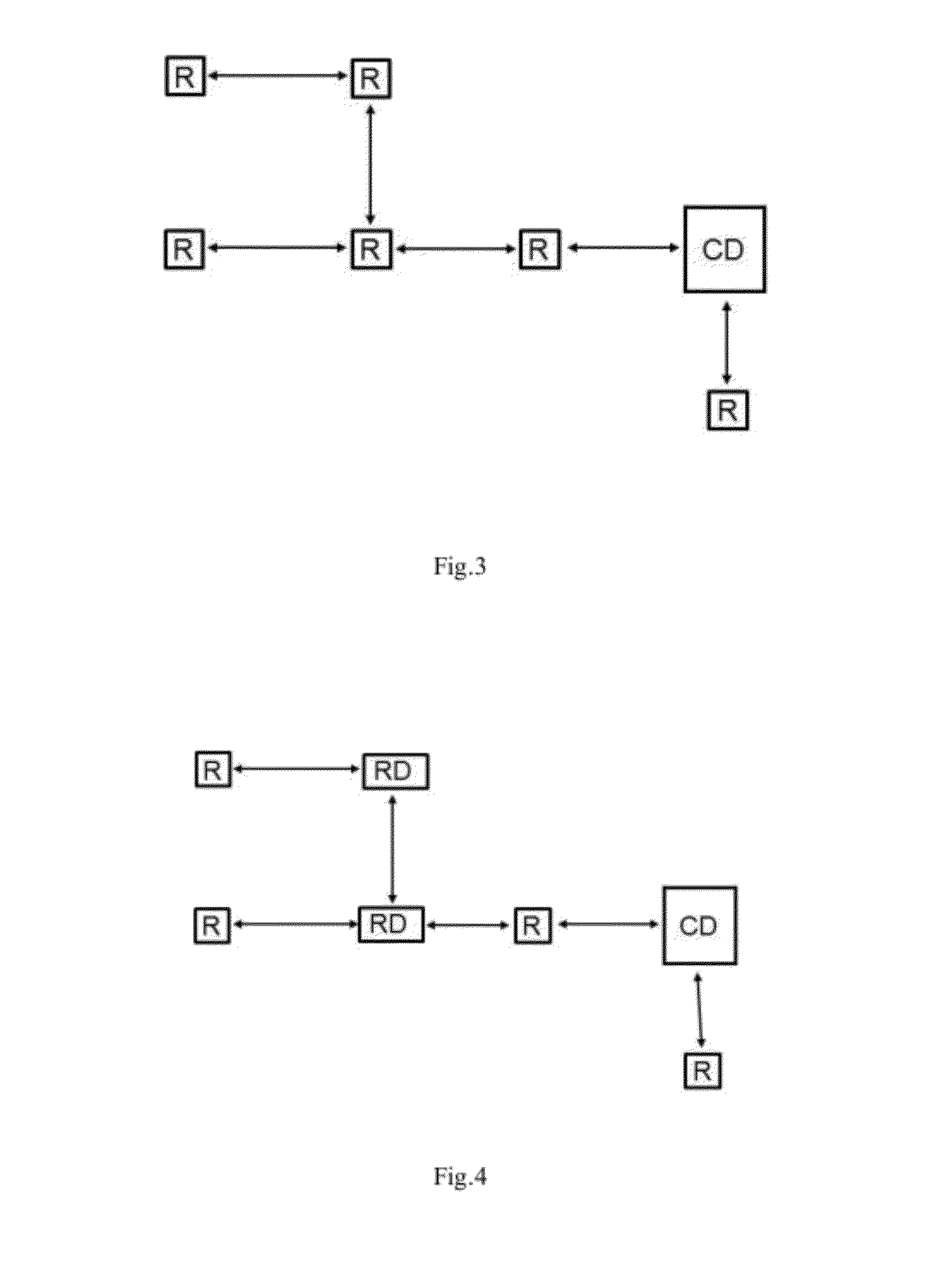

Storing mechanical potential in a MEMS device using a mechanically multi-stable mechanism

A system and method for storing potential energy in a microcomponent is disclosed comprising a multi-stable element having two or more equilibrium states and a stopper to restrict the multi-stable element from entering at least one of the two or more equilibrium states. The pre-charged microcomponent may then preferably be transported to another location and use the stored potential energy to perform some action.

Owner:ZYVEX LABS LLC

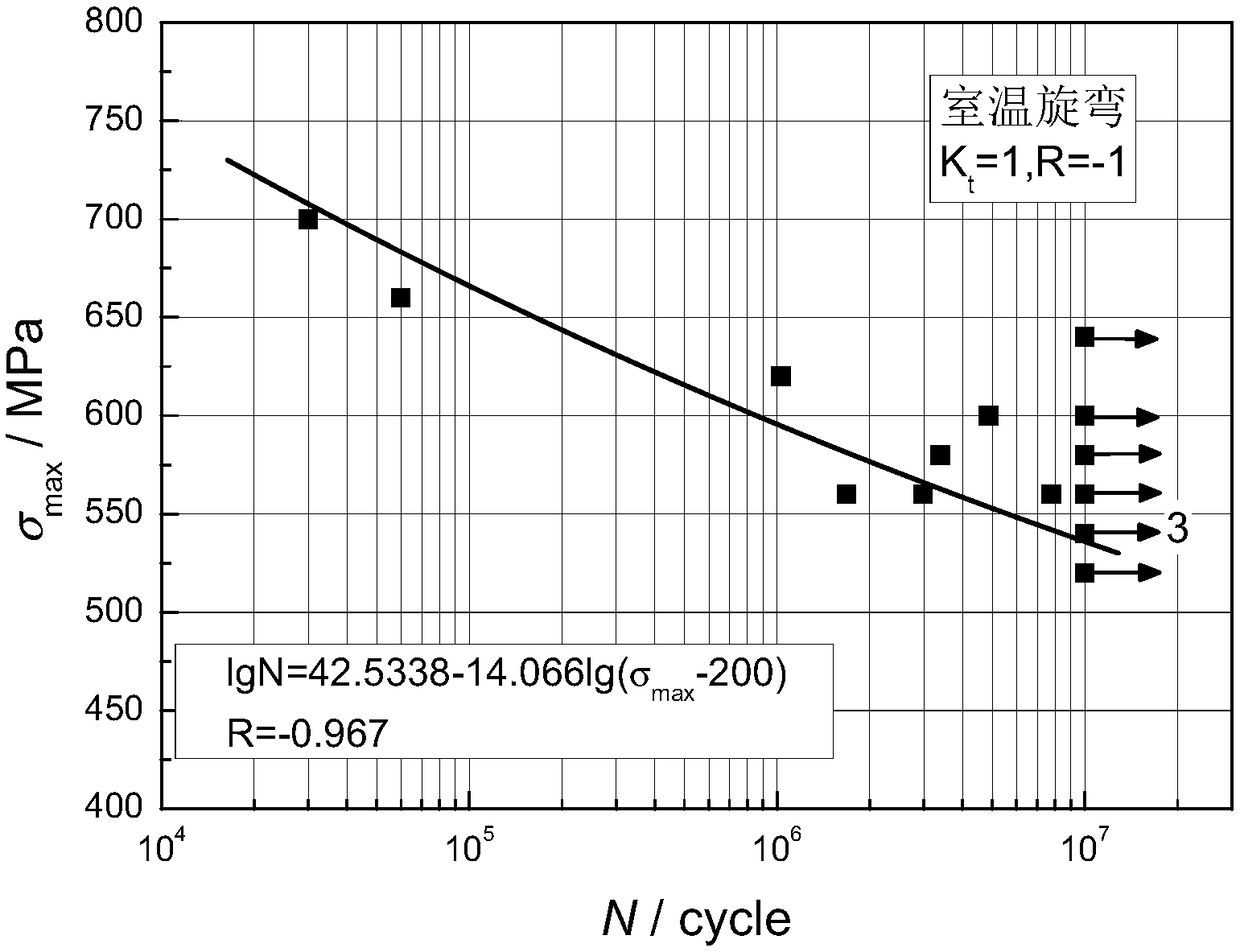

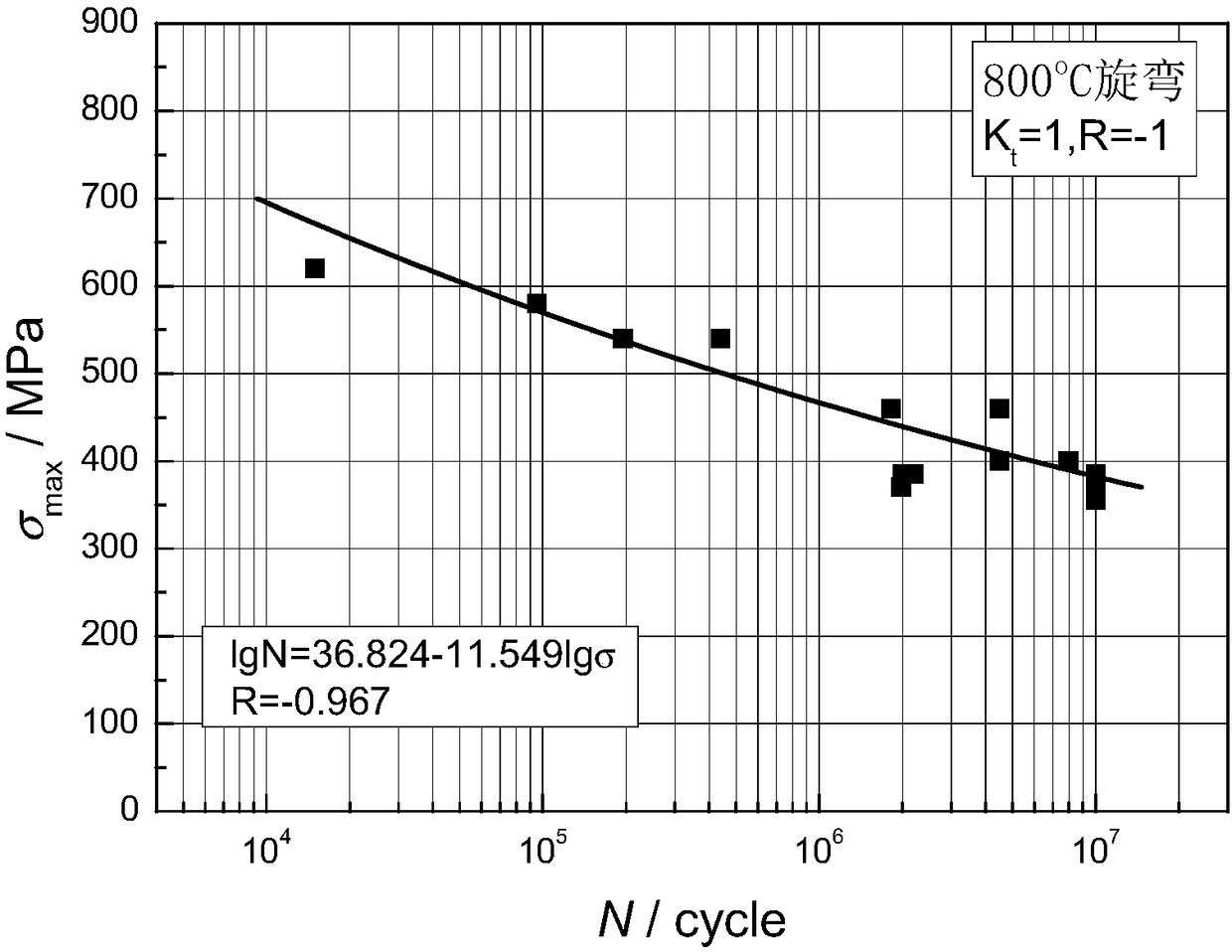

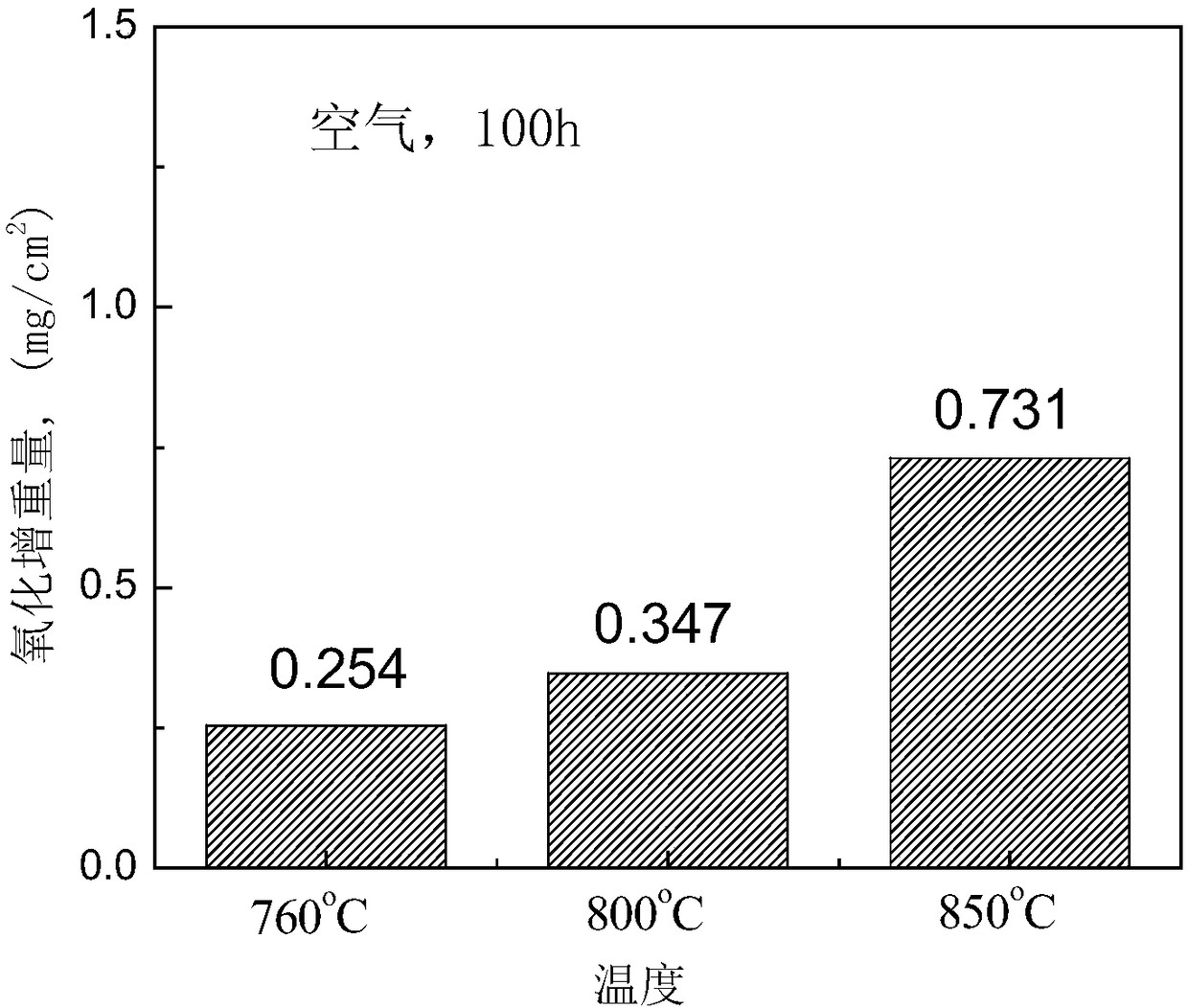

TiAl alloy and preparation method thereof

The invention belongs to the field of TiAl intermetallic compounds, and relates to forging TiAl alloy which is mainly applied to manufacturing of aero-engine blades, can be used for a long time at thetemperature being 700-800 DEG C, and is high in plasticity, high in strength, high-temperature-resistant and fatigue-resistant and a preparation method of the forging TiAl alloy. The TiAl alloy is added with beta stable elements such as Cr, Nb, Ta, W and Mo, and is further added with a small amount of interstitial elements such as B and Si. The forging TiAl alloy is characterized in that the TiAlalloy comprises the following components in percentages by atoms: 42-47% of Al, 3-6% of Nb, 1-2% of Cr, 0.1-0.5% of Ta, 0-0.2% of W, 0-0.2% of Mo, 0-0.2% of B, 0-0.2% of Si and the balance of Ti andinevitable impurities, wherein O content is less than or equal to 0.1 wt%, N content is less than or equal to 0.015 wt%, H content is less than or equal to 0.01 wt%, and Fe content is less than or equal to 0.08 wt%. After the various beta stable elements are combined and matched, the total adding amount is calculated according to a [Nb] equivalent formula and requires to be controlled between 6 and 11. The TiAl alloy can work at the temperature being 700-800 DEG C for a long time, can be used for manufacturing parts such as aero-engine compressor blades and low-pressure turbine blades, can also be used for manufacturing high-temperature-resistant structures such as supersonic aircrafts, and can be used for a short time at the temperature being 900-1000 DEG C.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

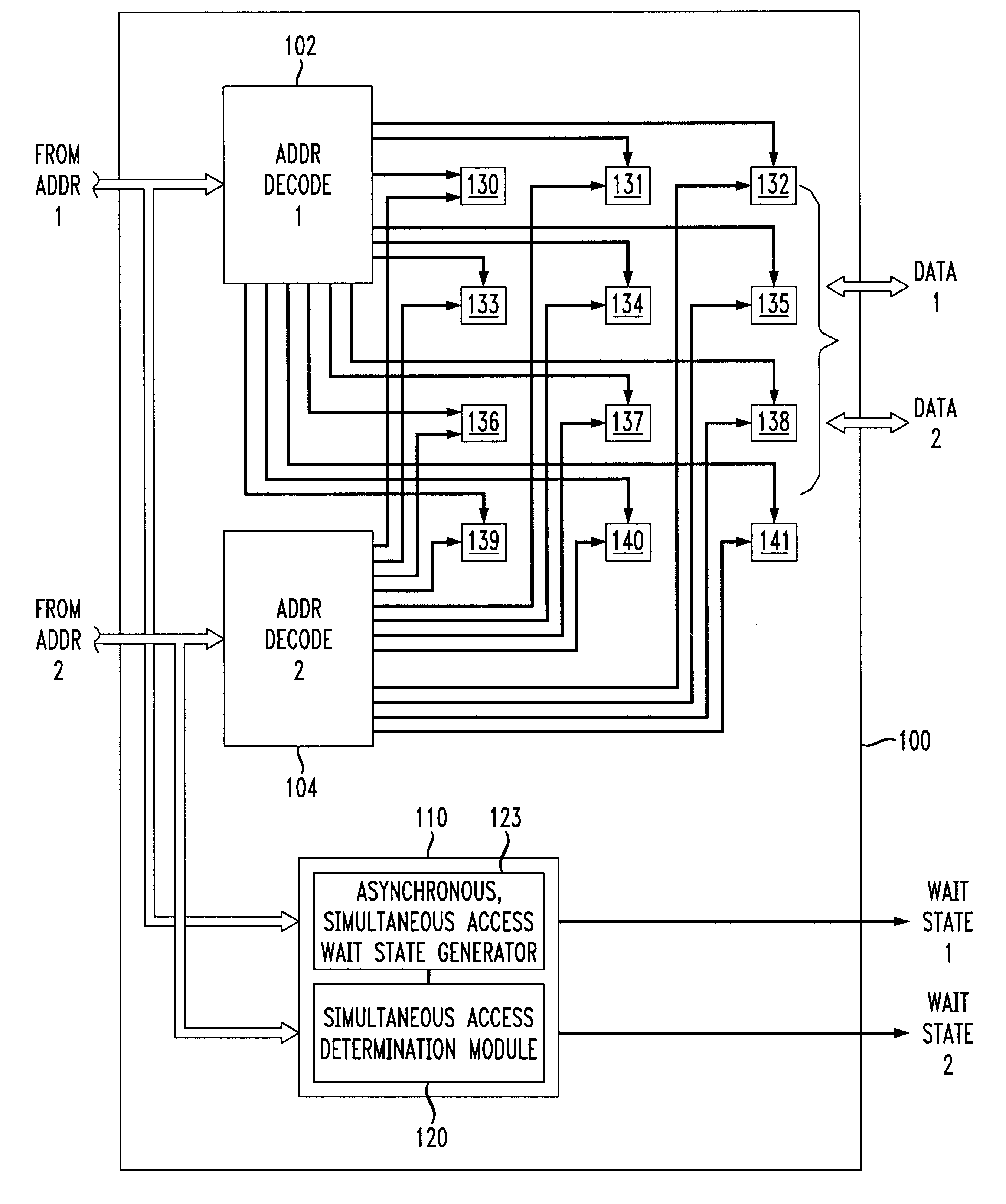

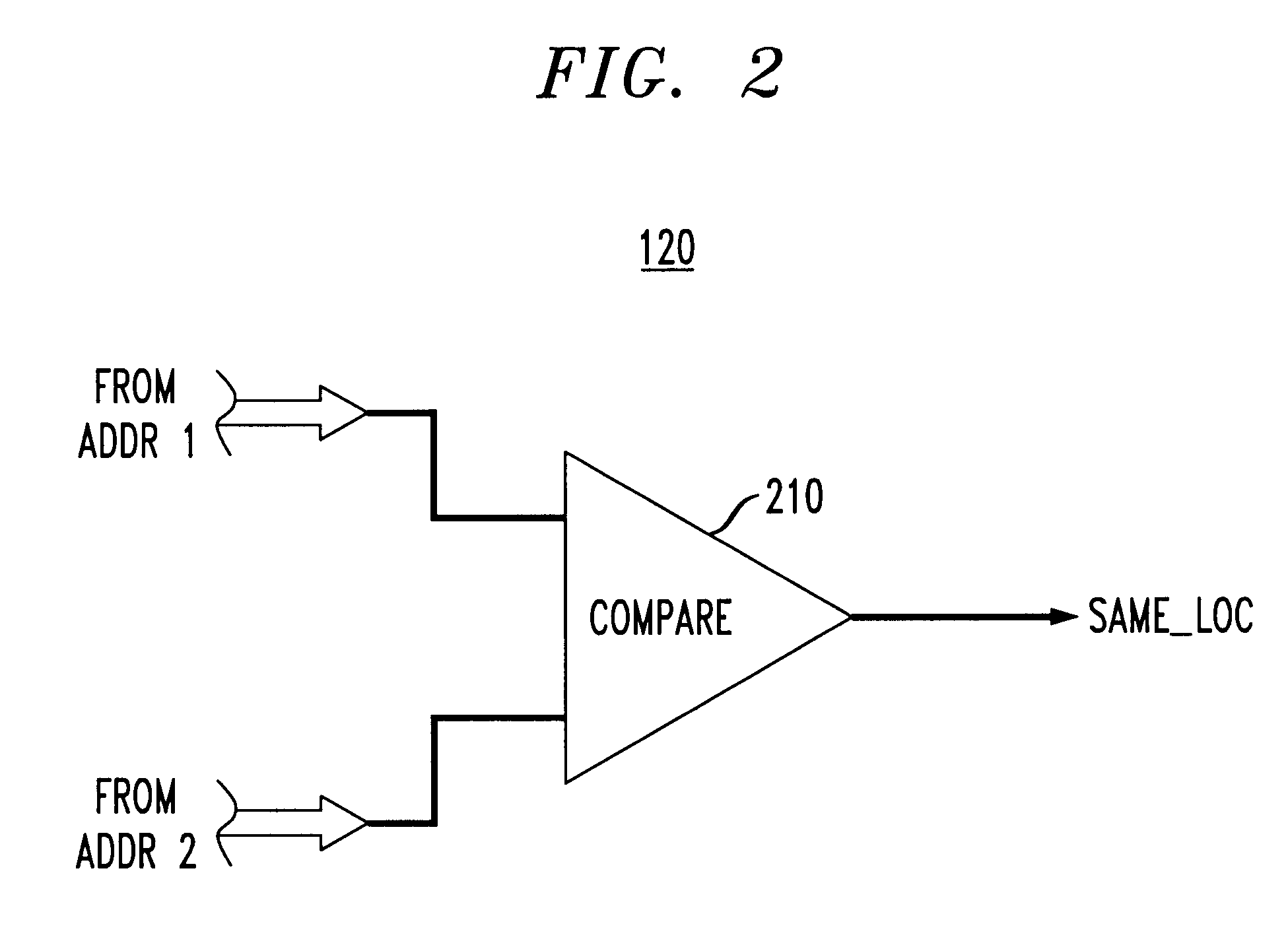

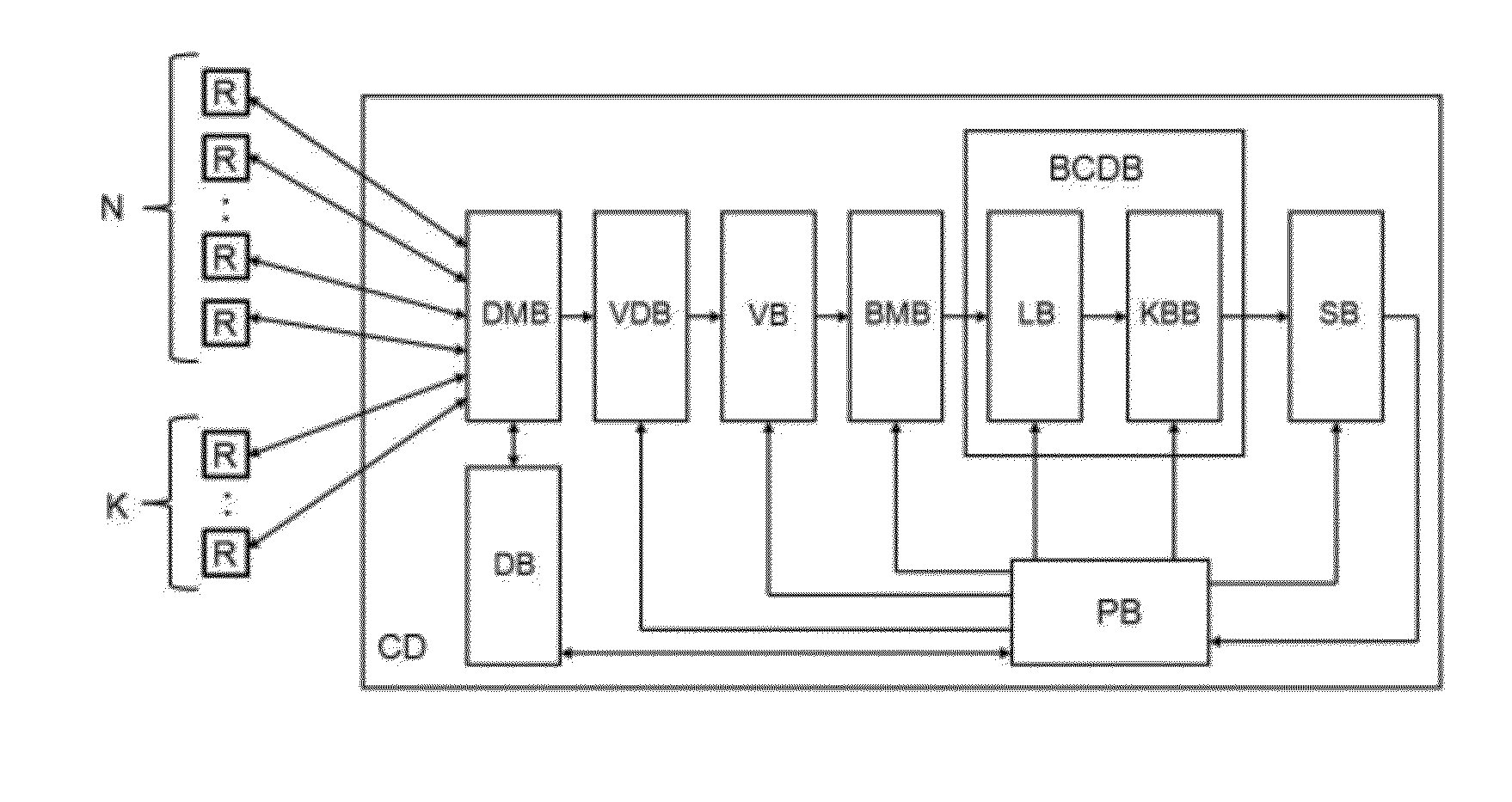

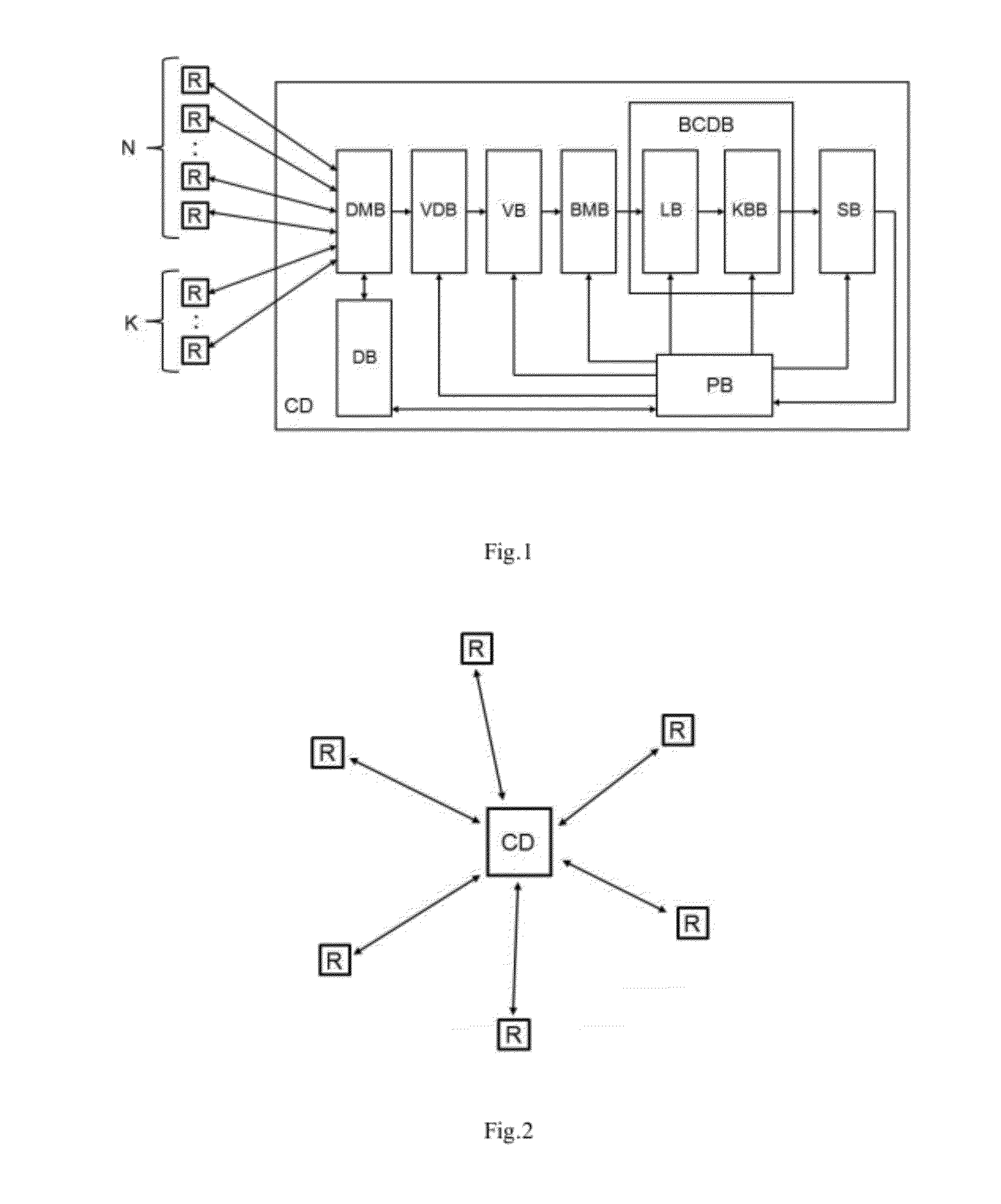

Wait state generator circuit and method to allow asynchronous, simultaneous access by two processors

An asynchronous wait state generator circuit and method is included in a dual port device, e.g., in a dual port memory, to allow the use of separate address decoders and simultaneous access to memory locations from asynchronously operating, separate ports. When an address collision is detected between accesses on both ports of a dual port device, a wait state signal is generated for the relevant port having the later attempt to access the same memory or other addressable location. In the unique event wherein both accesses are initiated at precisely the same time, a meta-stable element is used to resolve the condition and to allow access to a prioritized port. The wait state signals output for the relevant port of the dual port device are preferably synchronized with the clock signal of the relevant port.

Owner:LUCENT TECH INC

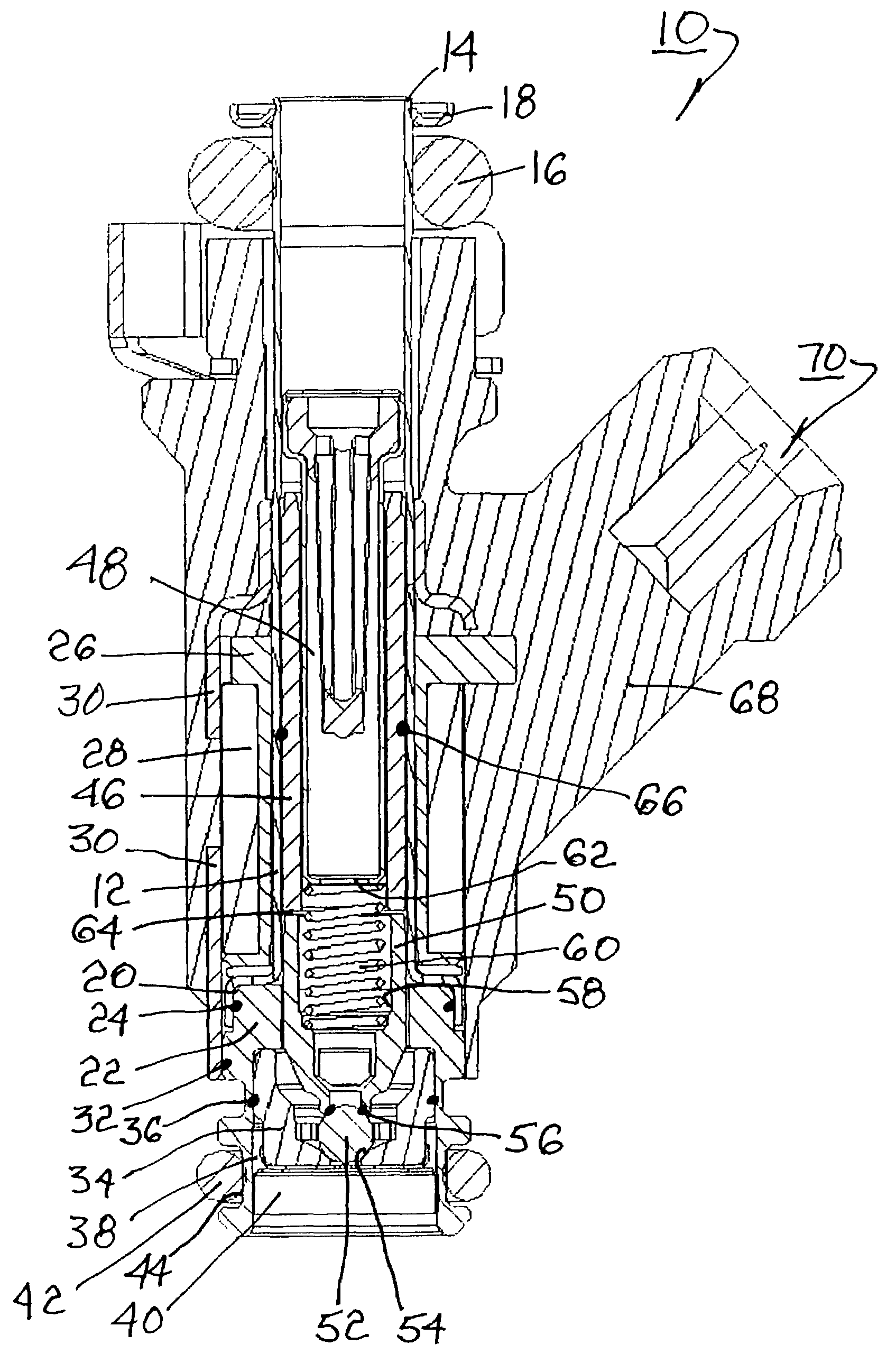

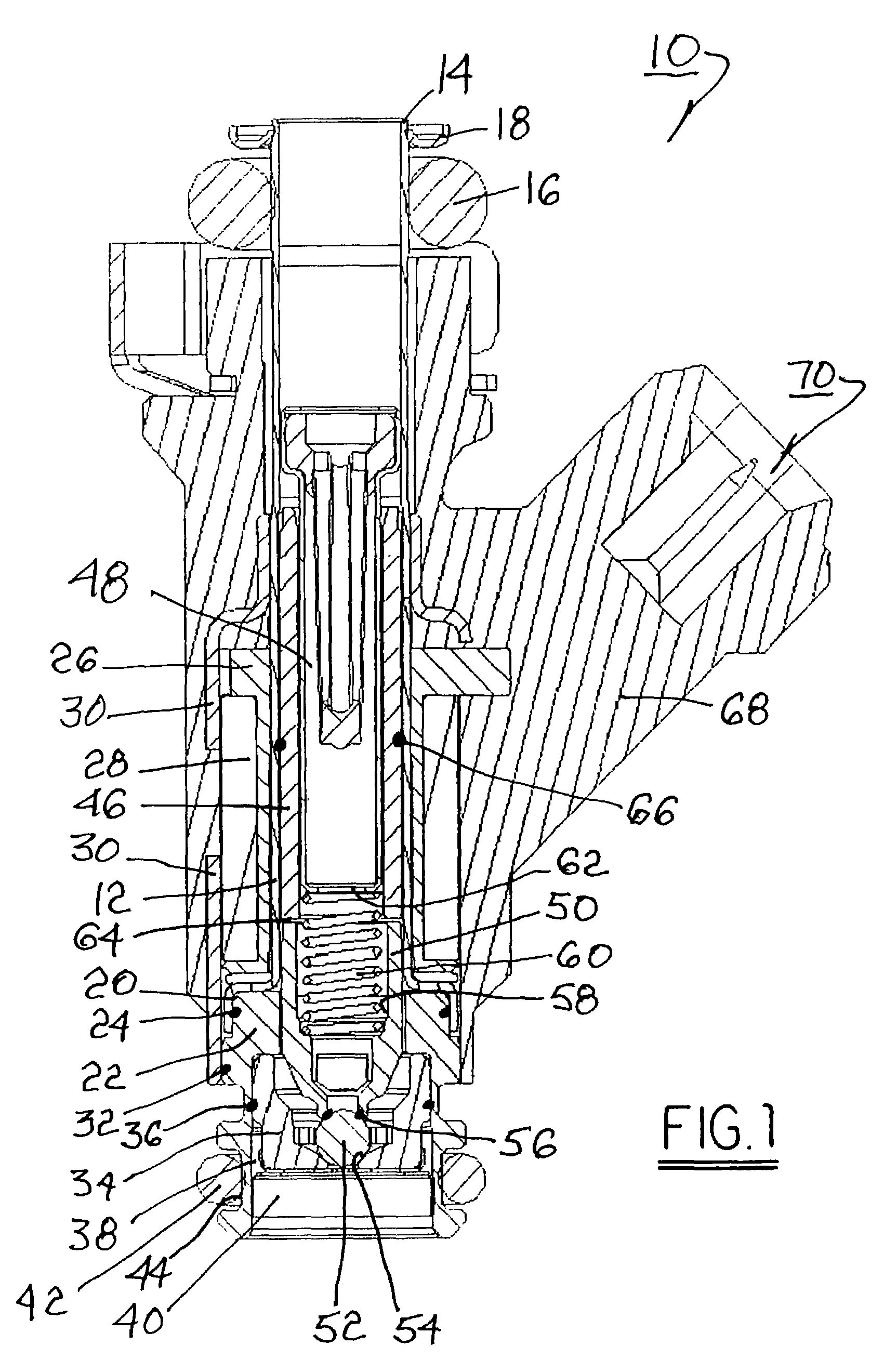

Solenoid-type fuel injector assembly having stabilized ferritic stainless steel components

ActiveUS7252249B2Soft magnetic property strongWith mechanical propertiesOperating means/releasing devices for valvesSpray nozzlesNiobiumPole piece

A solenoid-type fuel injector assembly having at least one component formed of stabilized, solenoid-quality ferritic stainless steel. In a preferred embodiment, an austenitic fuel tube is laser-welded to an injector body and to a solenoid pole piece formed of the subject material. The stabilized, solenoid-quality ferritic stainless steel, preferably a free-machining grade thereof, comprises from about 10% to about 35% chromium, and at least one stabilizing element selected from the group consisting of titanium and columbium. Components thus formed are weldable, exhibit soft magnetic properties sufficiently strong for carrying a magnetic flux in a solenoid pole piece, have desired structural and mechanical properties, and reduce the susceptibility of a solenoid-type fuel injector to metallurgical sensitization and intergranular corrosive attack at weld sites.

Owner:DELPHI TECH IP LTD

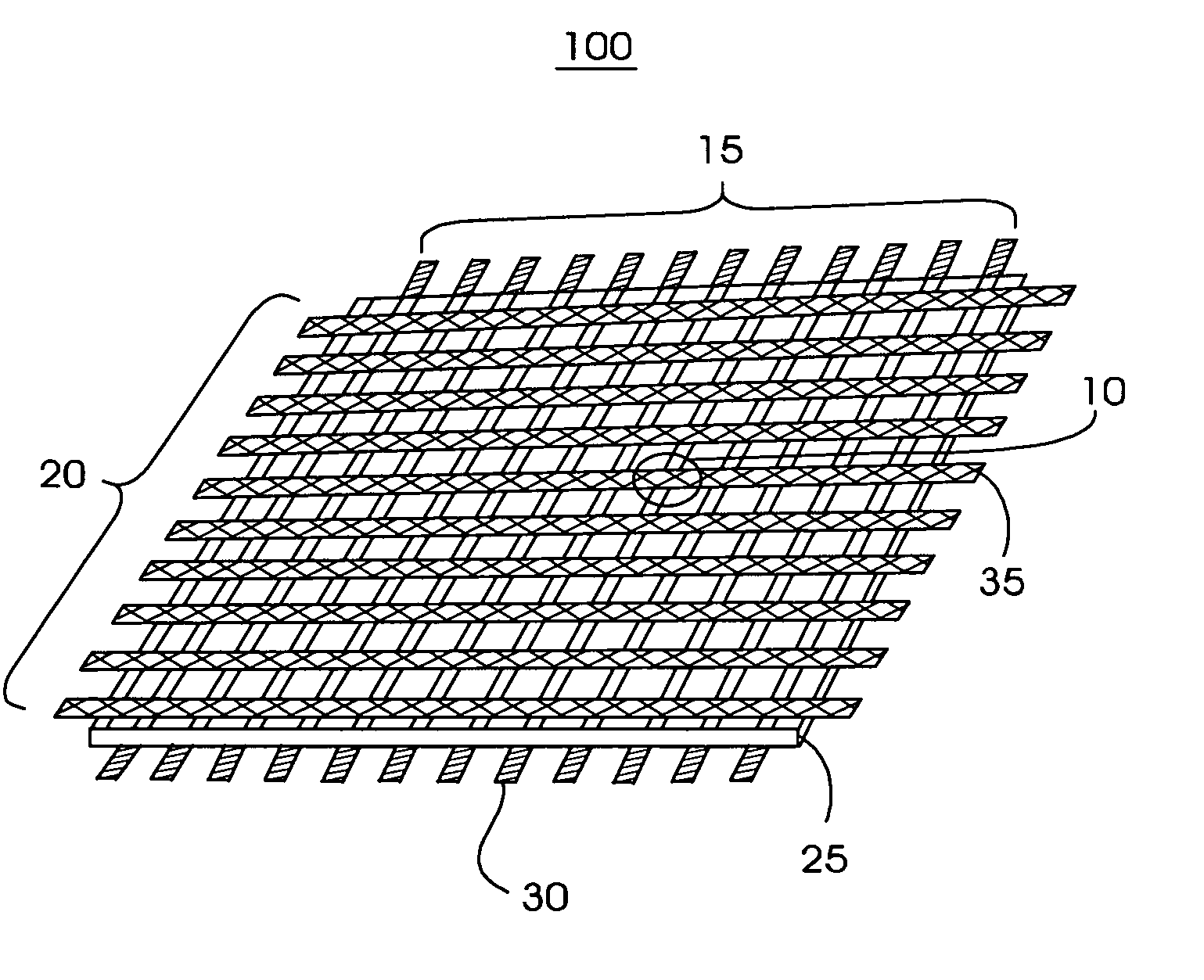

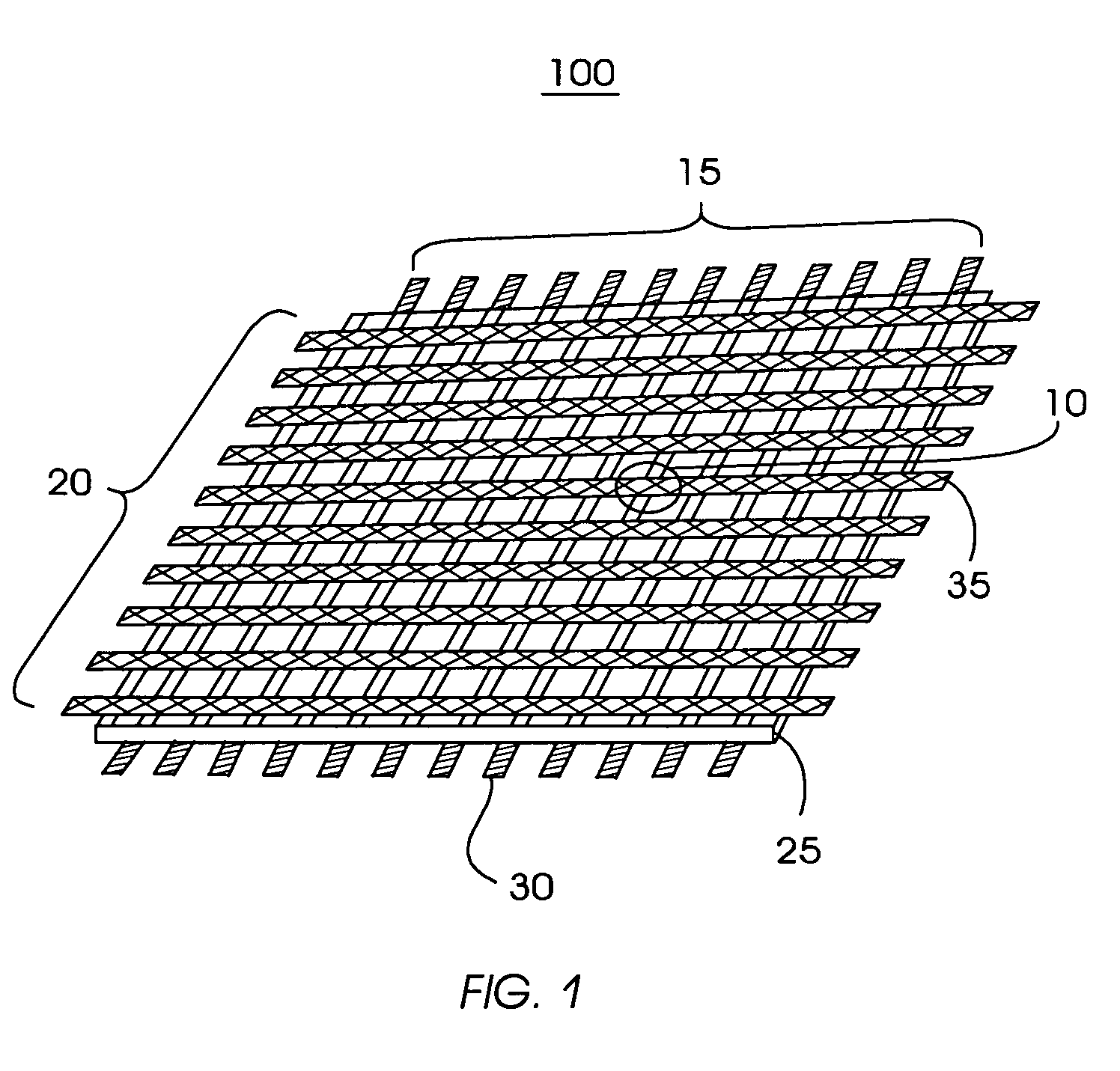

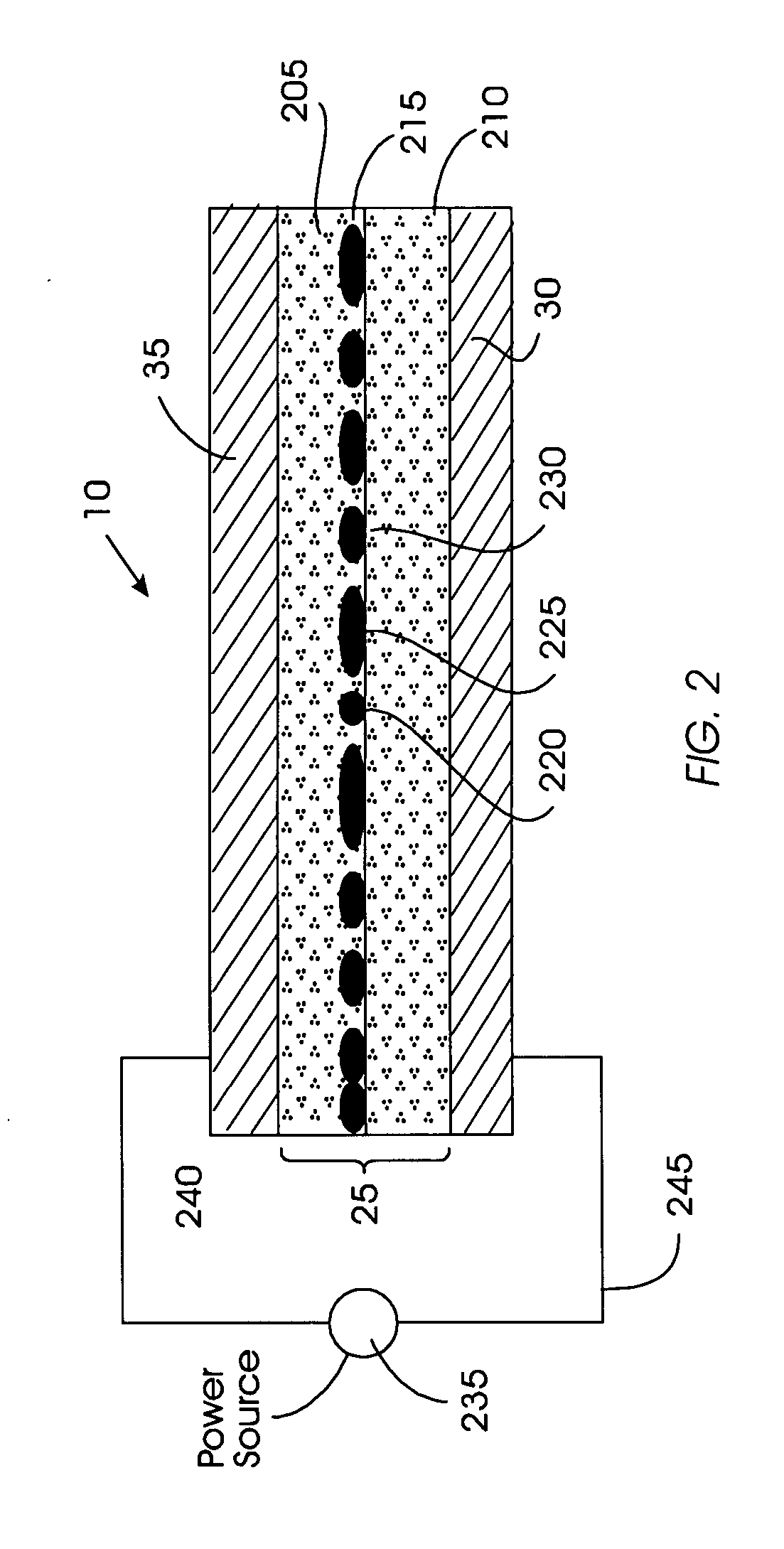

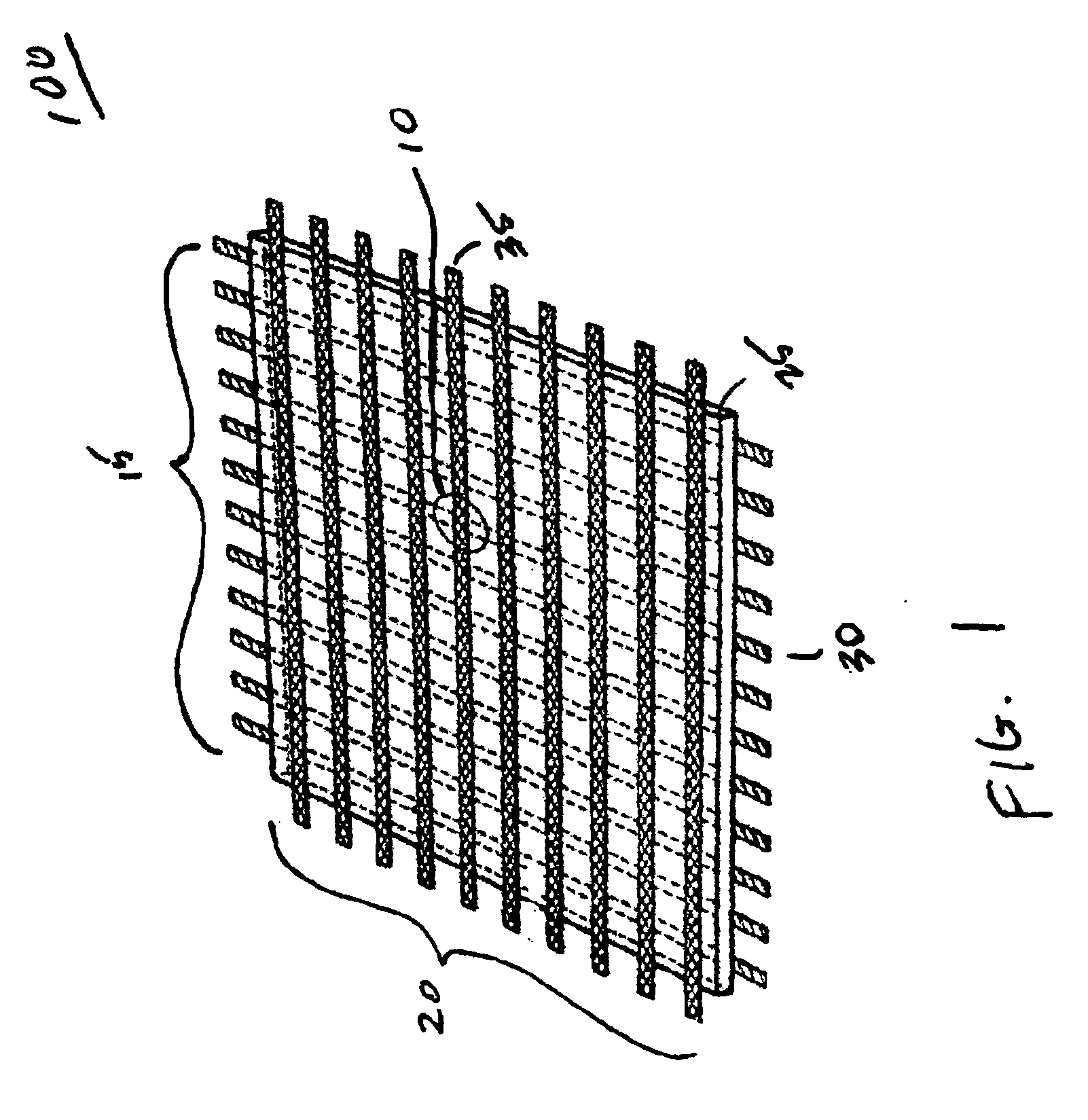

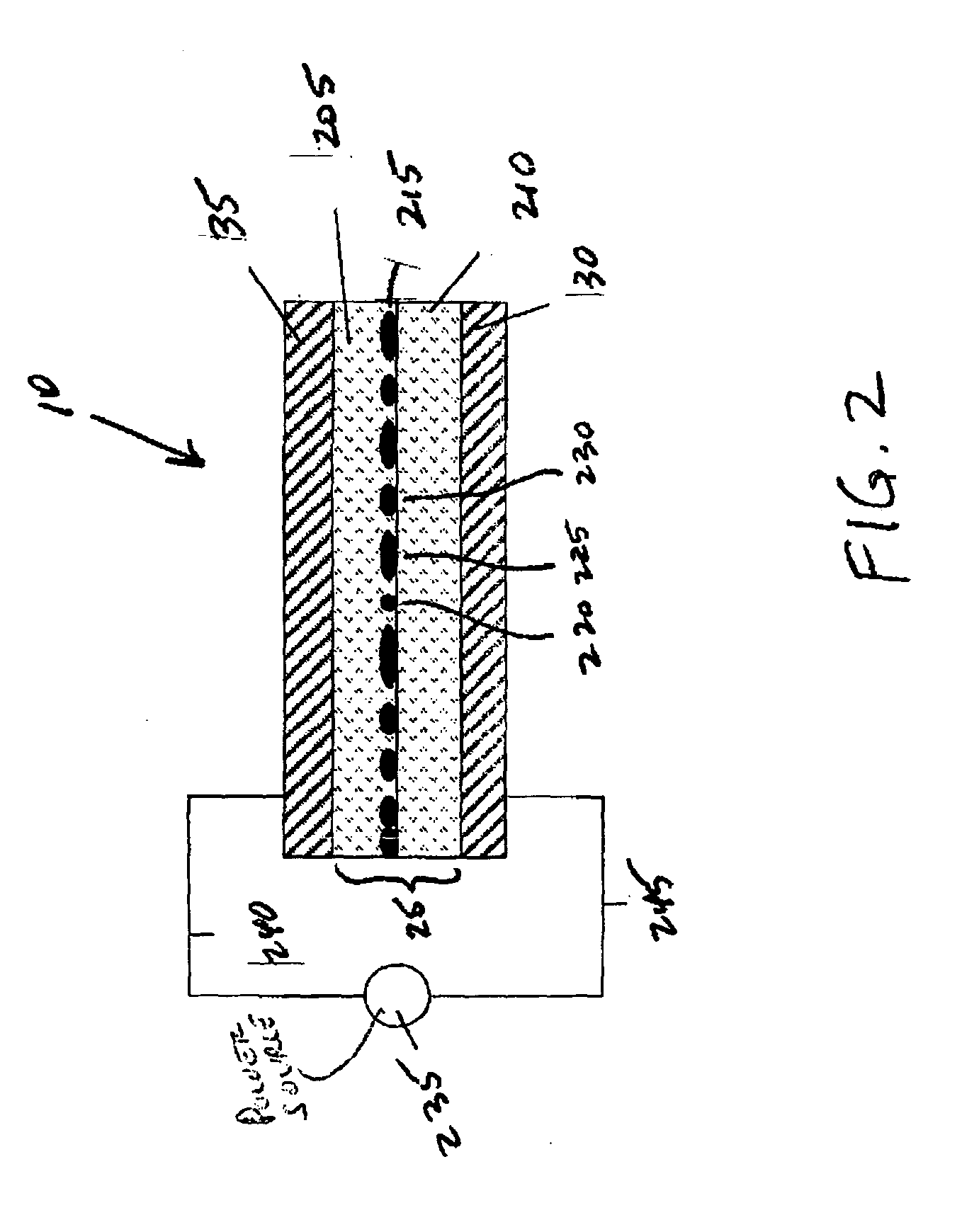

Memory device and method of making the same

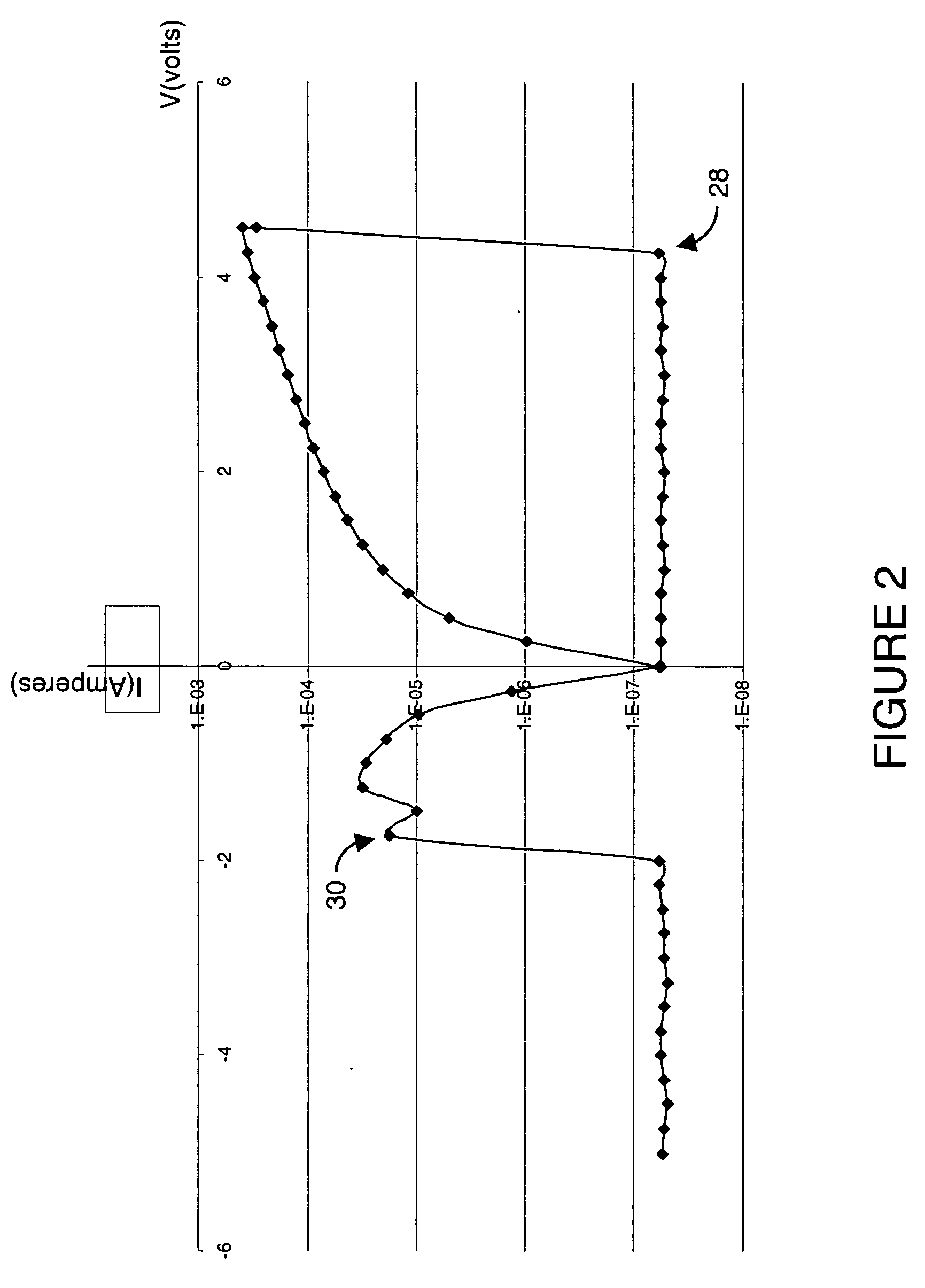

InactiveUS20050237834A1Increase resistanceEasy to adjustMaterial nanotechnologyNanoinformaticsStable stateComposite media

A multi-stable memory or data storage element is used in crosspoint data-storage arrays, as a switch, a memory device, or as a logical device. The general structure of the multi-stable element comprises a layered, composite medium that both transports and stores charge disposed between two electrodes. Dispersed within the composite medium are discrete charge storage particles that trap and store charge. The multi-stable element achieves an exemplary bi-stable characteristic, providing a switchable device that has two or more stable states reliably created by the application of a voltage to the device. The voltages applied to achieve the “on” state, the “off” state, any intermediate state, and to read the state of the multi-stable element are all of the same polarity.

Owner:GLOBALFOUNDRIES US INC

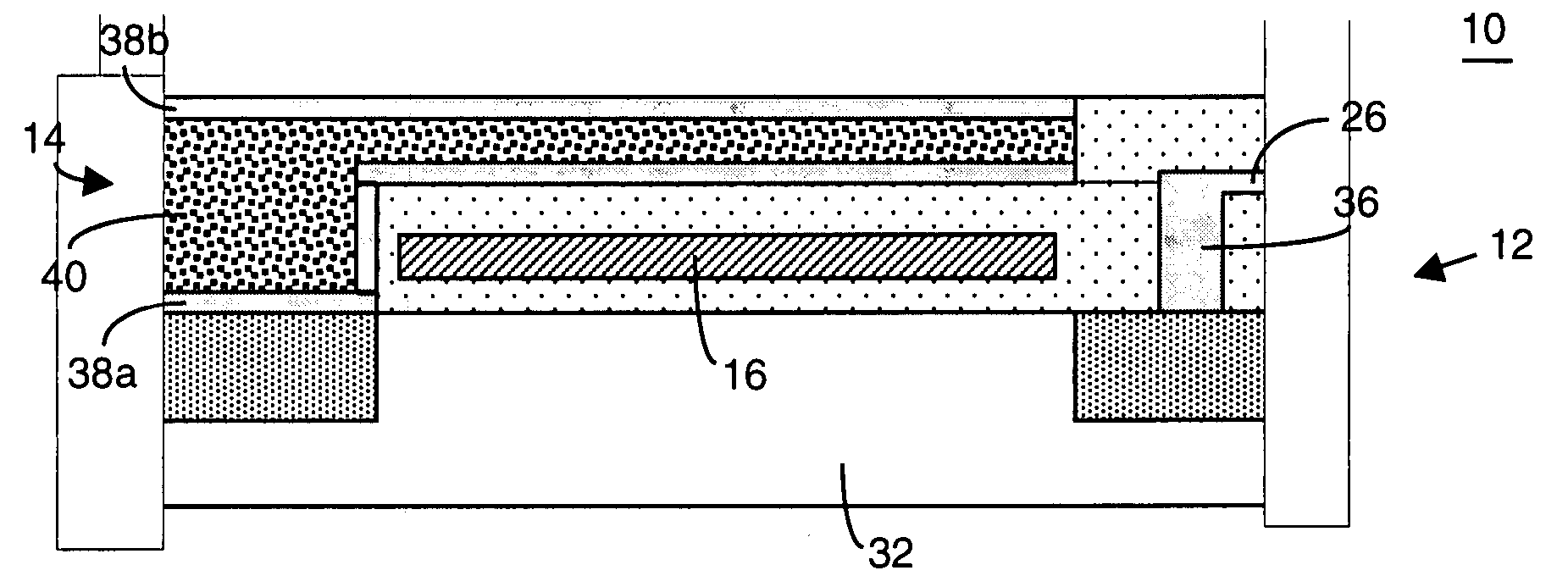

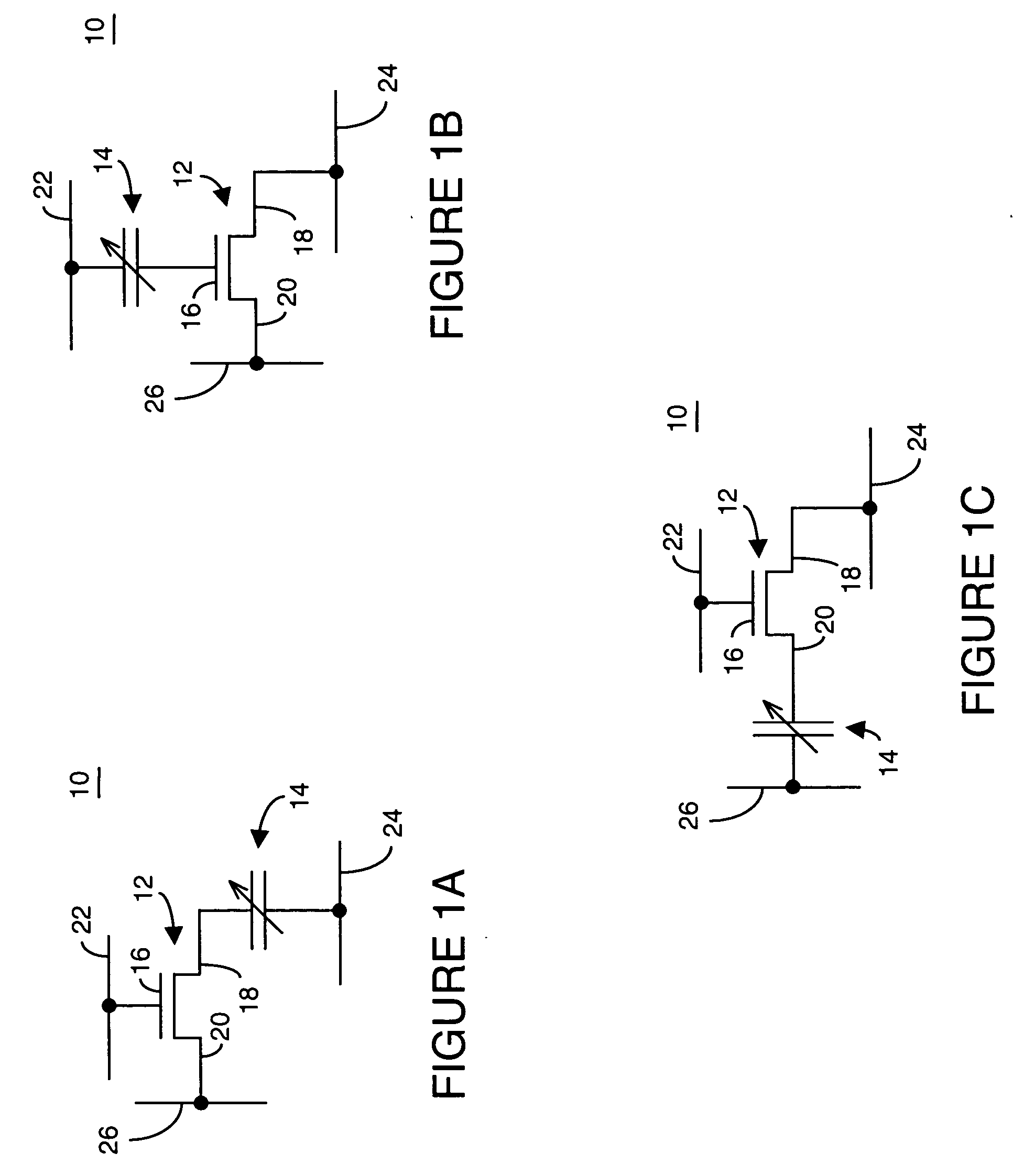

Memory cell having an electric field programmable storage element, and method of operating same

Disclosed is a memory cell having an access transistor and an electric field programmable bi-stable element. The access transistor may be a (N-channel or P-channel) MOSFET transistor having a gate, source or drain region coupled to the electric field programmable bi-stable or multi-stable element (hereinafter collectively, “bi-stable element” unless expressly indicated otherwise). The access transistor facilitates selective and controllable programming and reading of the electric field programmable bi-stable element. Also disclosed is a plurality of memory cells, each having a unique, different and / or distinct electric field programmable bi-stable element and a common access transistor and a common access transistor. In yet another aspect, a differential memory cell having a plurality of memory cells configured to store complementary data states is disclosed. The differential memory cell includes first memory cell and second memory cell wherein the first memory cell maintains a complementary state relative to second memory cell. The first and second memory cells include a common access transistor and unique, different and / or distinct electric field programmable bi-stable element, or each includes an access transistor and an electric field programmable bi-stable element. Finally, a complementary memory cell having an N-channel type memory cell (an N-channel access transistor and an electric field programmable bi-stable element) and a P-channel type memory cell (a P-channel access transistor and an electric field programmable bi-stable element) is disclosed.

Owner:GREER EDWARD C +2

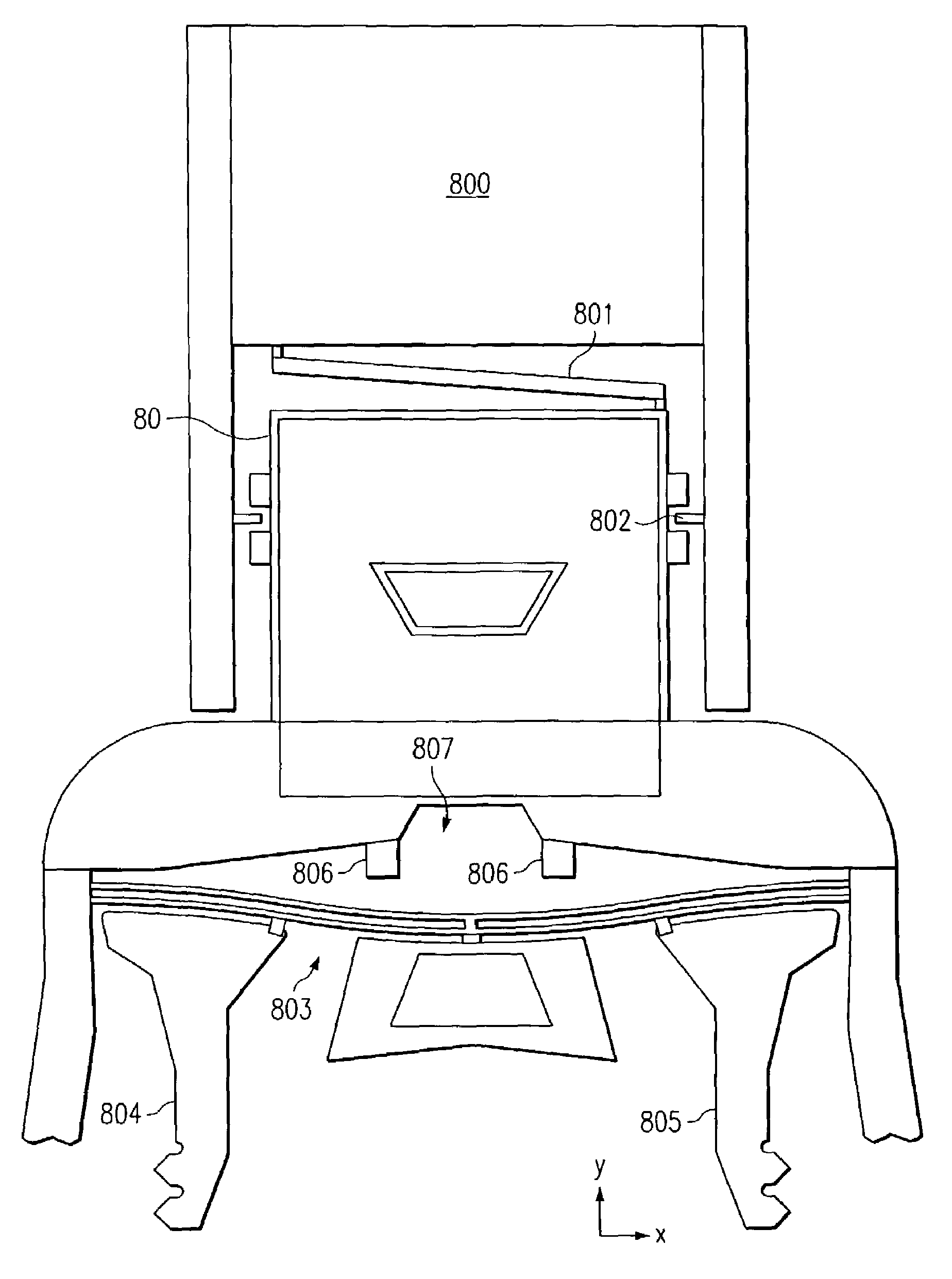

Multi-stable actuation apparatus and methods for making and using the same

InactiveUS20100108922A1Reduce operating costsLess ecologically damaging wasteOperating means/releasing devices for valvesClosed-cycle gas positive displacement engine plantEngineeringAlloy

Actuator apparatus having a multi-stable element actuated by memory alloy actuating elements. In one embodiment, the multi-stable actuator comprises a bistable (two-state) diaphragm element adapted to alternate between two stable configurations via forces exerted on the diaphragm by more than one memory alloy filaments in response to thermal activation. In another embodiment, the bistable diaphragm of the multi-stable actuator transitions from a first to a second stable configuration via forces exerted by a single filament in response to direct or indirect thermal activation. A portion of the assembly is displaced when the assembly is in the second configuration. The bistable diaphragm transitions back to the first stable configuration via application of mechanical force on a portion of the assembly which was displaced. Methods for making and using the bistable actuator apparatus are also disclosed.

Owner:AUTOSPLICE SYST

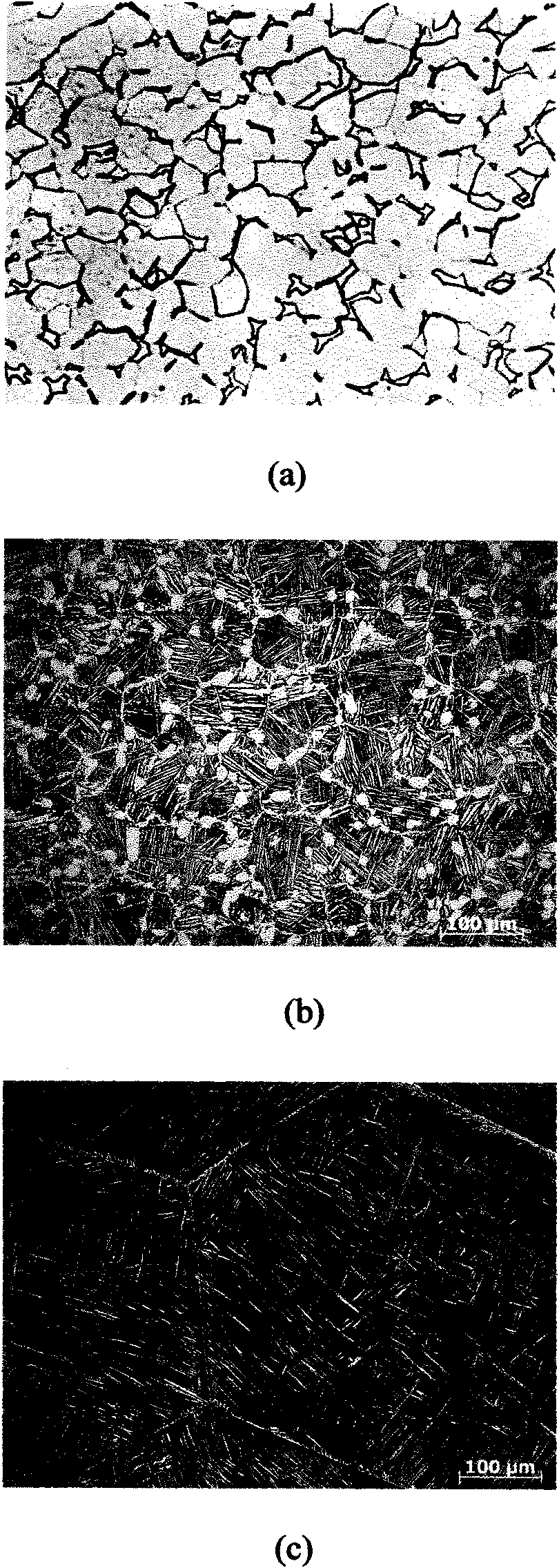

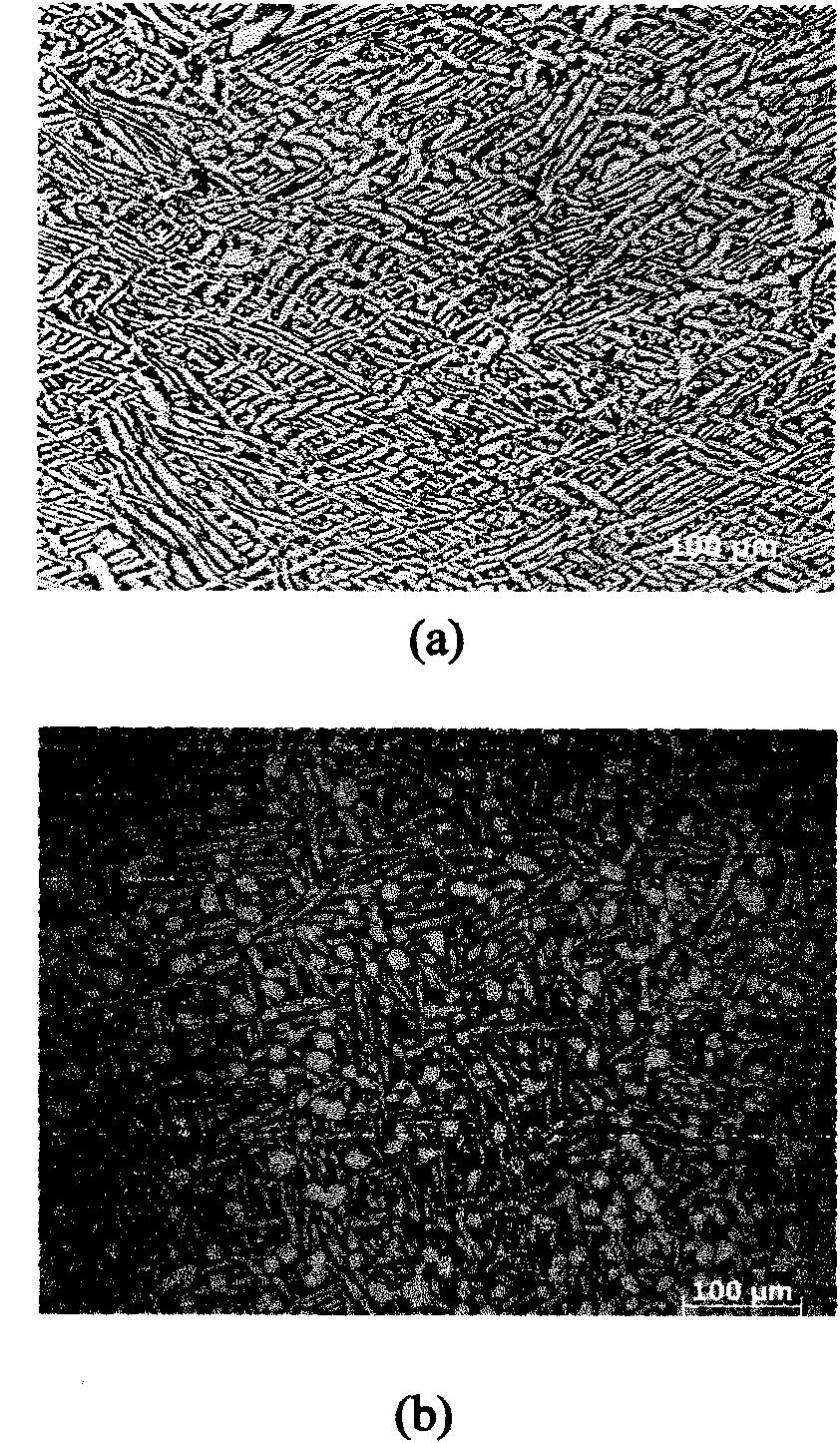

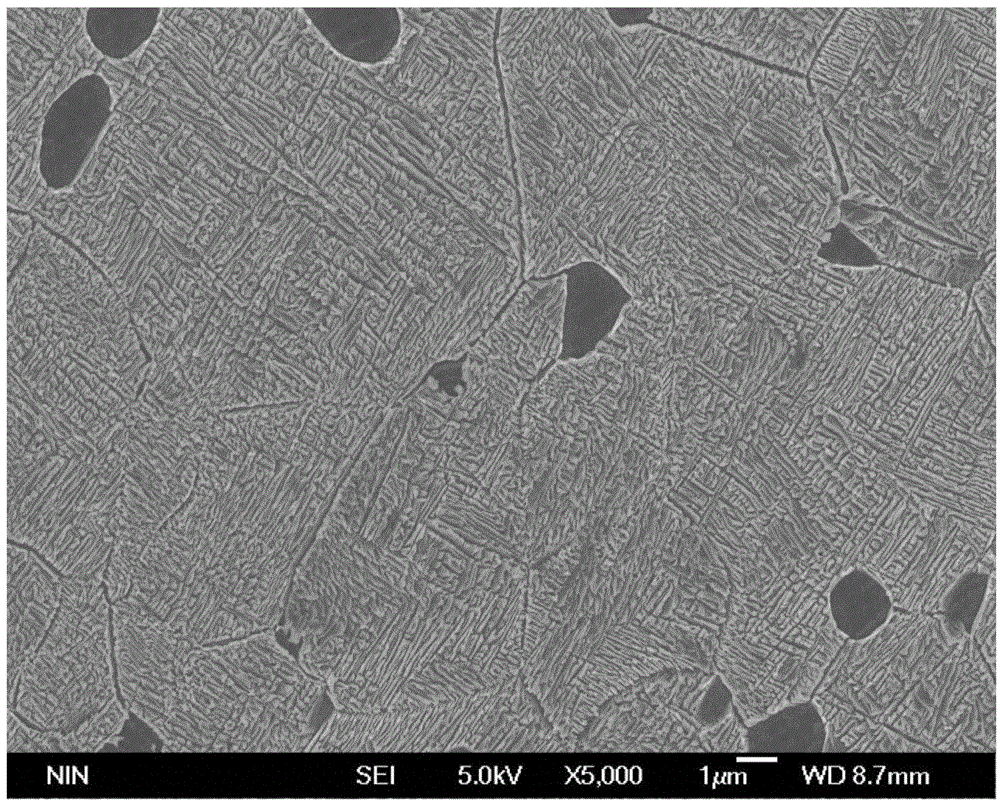

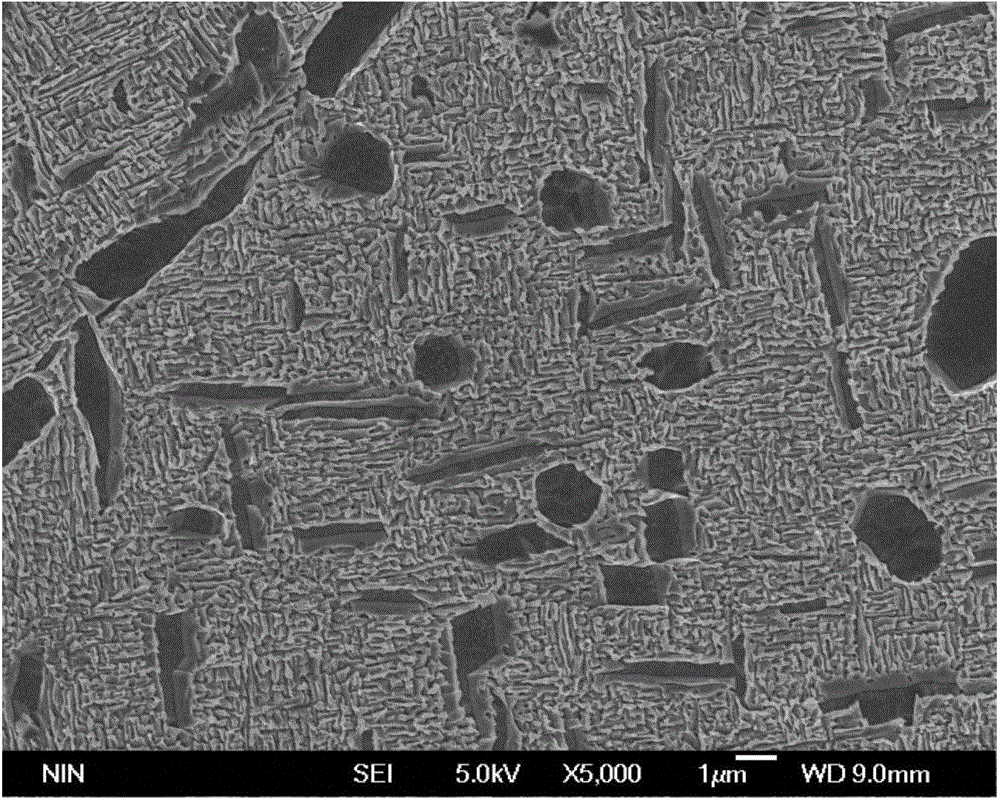

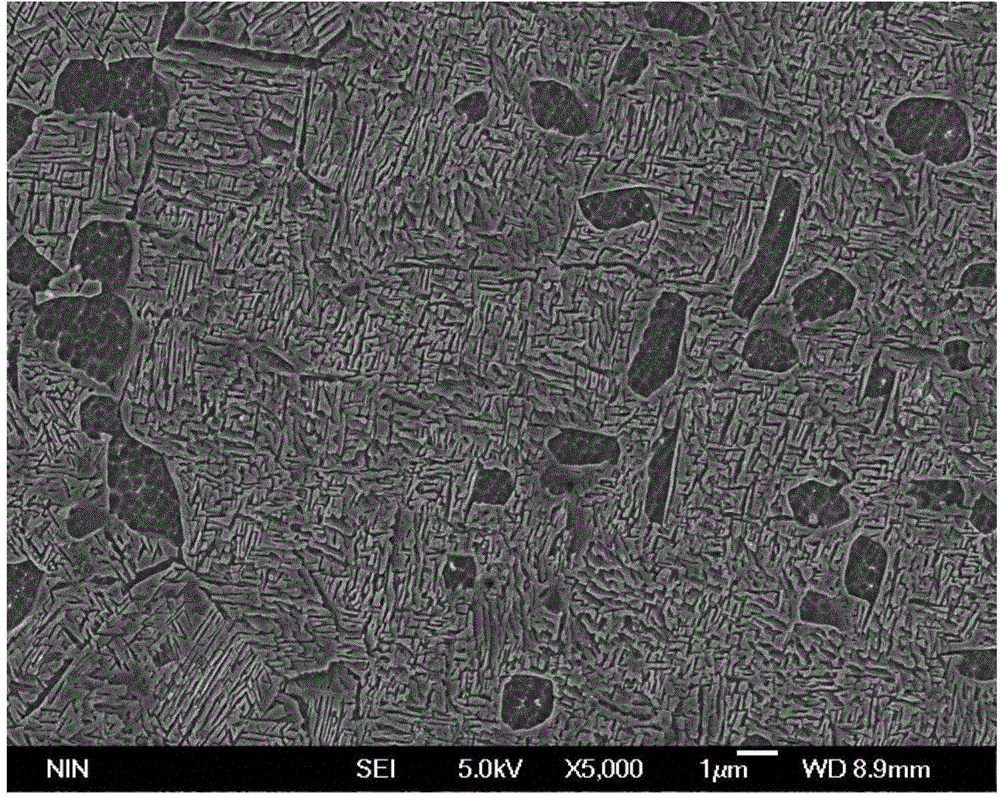

Titanium alloy with thin sheet layer microstructure and manufacturing method thereof

The invention provides a titanium alloy with a thin sheet layer microstructure and a manufacturing method thereof. The titanium alloy is characterized in that: 1) a certain amount of Si element is added into the alloy so that Ti5Si3 or Ti2Si type silicide can be dissolved out from the alloy under a certain condition; 2) controlling the adding amount of alloying elements, namely Zr, Sn and beta stable elements, which affect the dissolving temperature of the silicide so as to guarantee that the alpha + beta / beta transformation temperature of the titanium alloy is lower than the dissolving temperature of the silicide; 3) fully deforming the alloy at the temperature of below the dissolving temperature of the silicide, and finally properly deforming the alloy in the alpha + beta phase area over 1 to 2 fire, wherein the primary beta crystallite dimension of the alloy after thermal treatment is less than 200 mu m and the alloy has a thin sheet lamellar structure. The invention also provides a titanium alloy component and a corresponding smelting, hot working and heat treatment process. The thin sheet layer titanium alloy of which the primary beta crystallite dimension of the alloy after thermal treatment is less than 200 mu m can be prepared by the process. The titanium alloy has relatively high strength and plastic toughness matching, is a high-strength, high-toughness and high-temperature resistant titanium alloy material and is expected to be well popularized and applied in the field of aerospace.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

High-strength high-elasticity modulus titanium alloy

ActiveCN1978681AHigh modulus of elasticityNo significant deterioration of plasticity indexHigh intensityTitanium

The invention relates to a titanium alloy which is alpha + beta two phase one. Its components are as follows: 4.5-9.0wt% aluminum, 0.2-1.5wt% boron, and 0.5-5wt% beta stable element. The titanium alloy of the invention not only has high intensity high elastic modulus, but also cannot worsen its process ability and plasticity index.

Owner:GRIMAT ENG INST CO LTD

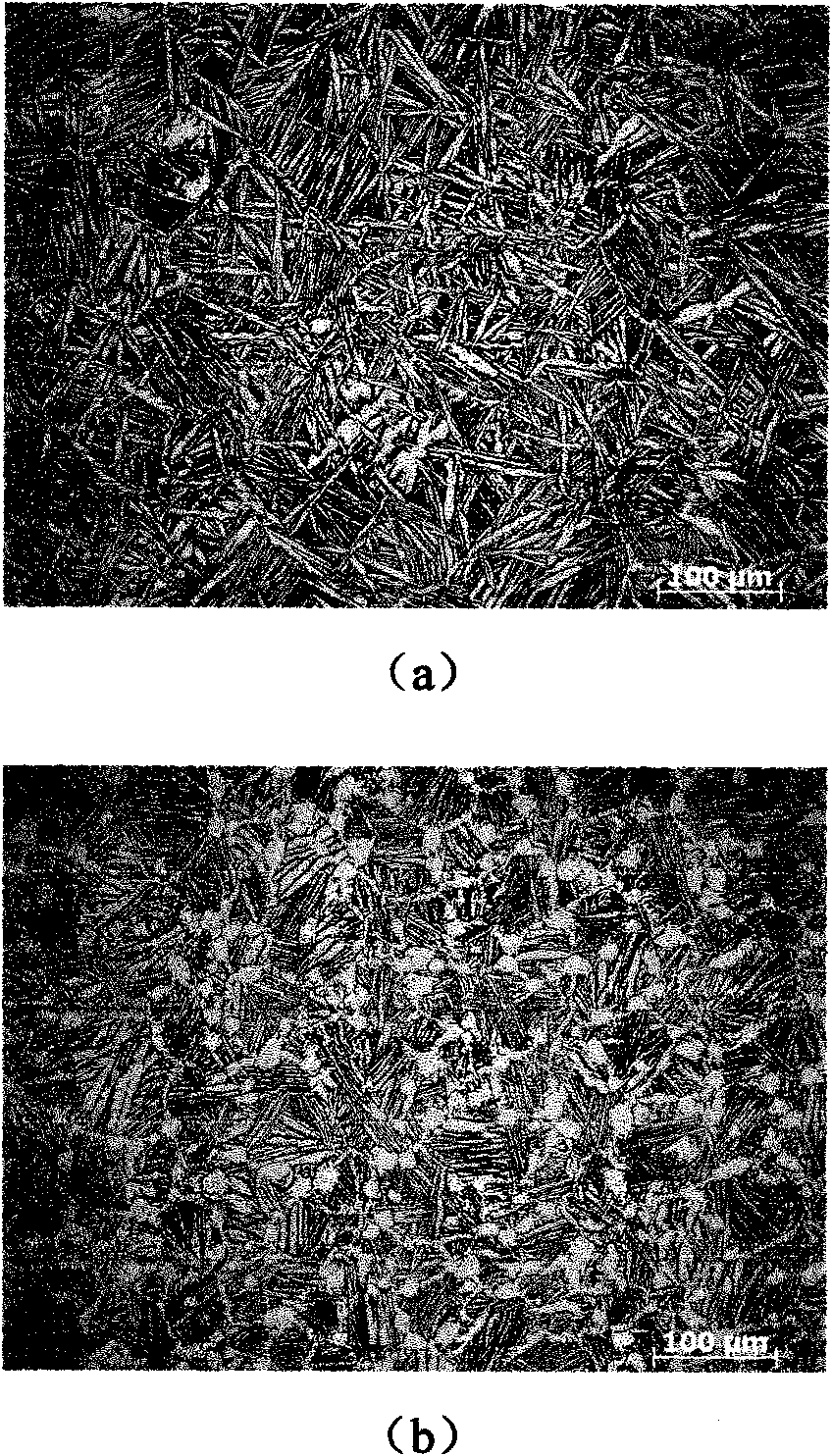

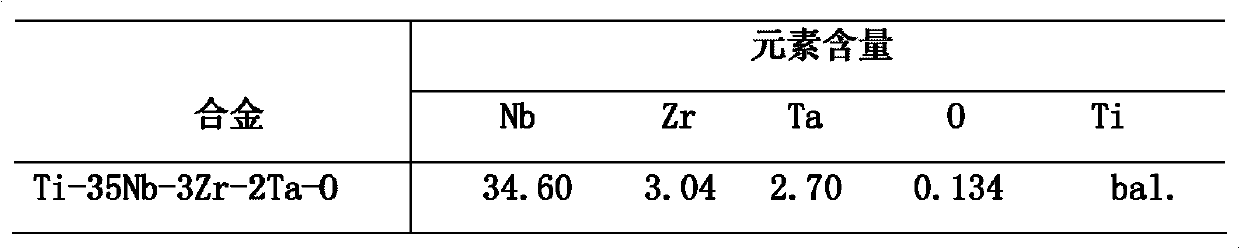

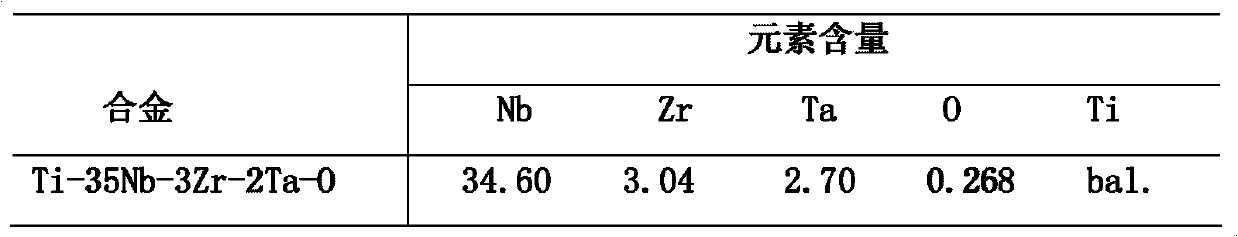

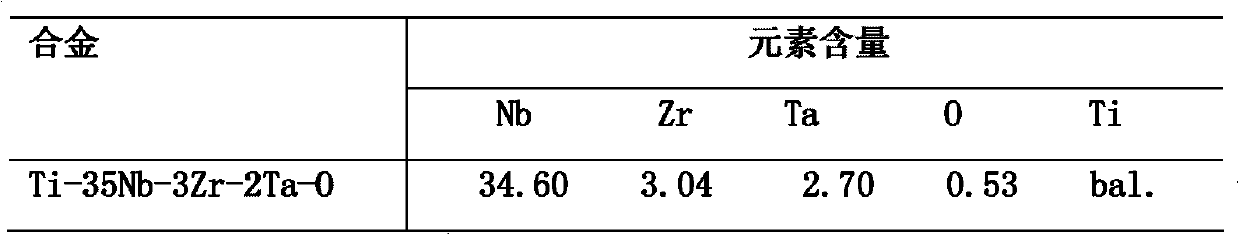

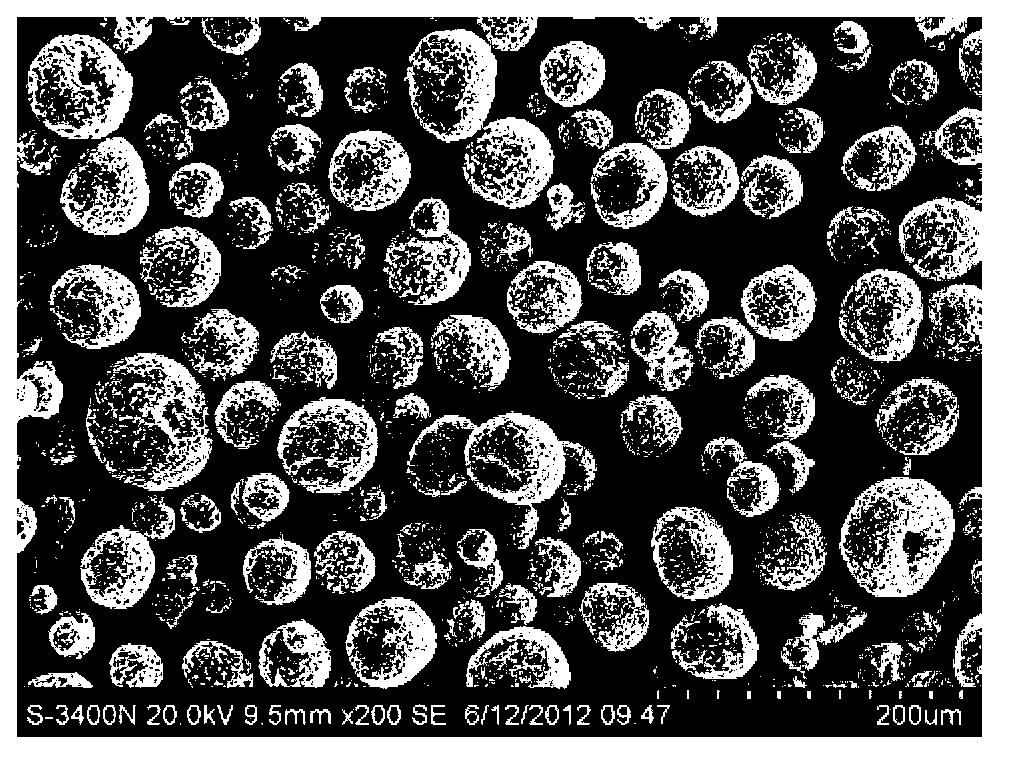

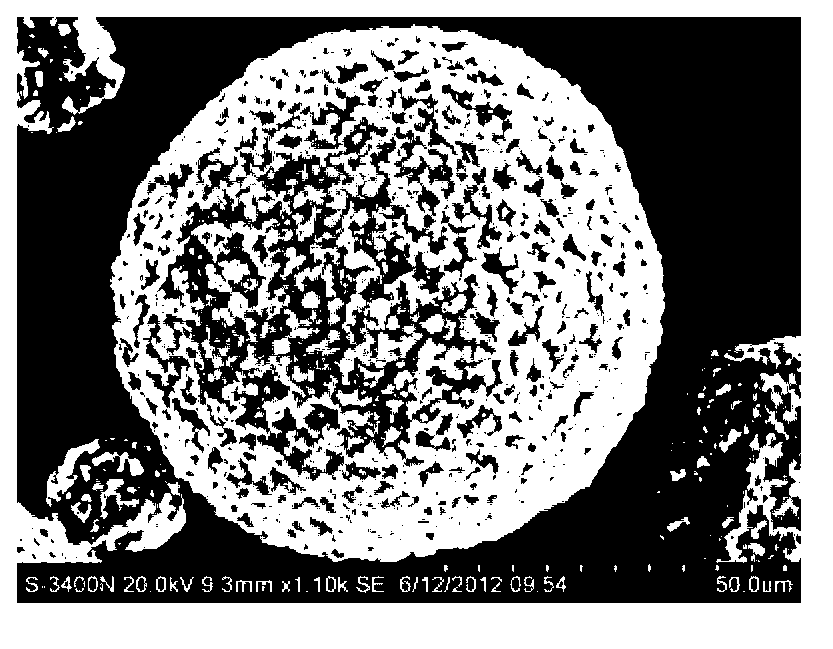

Medicinal oxygen-containing beta titanium alloy for orthopedic implantation and preparation method thereof

The invention relates to a medicinal oxygen-containing beta titanium alloy for orthopedic implantation and a preparation method thereof, which belong to the technical field of medicinal apparatus and instruments. The preparation method comprises the following steps of: performing vacuum self-consuming smelting treatment on alloy ingredients to obtain a titanium-niobium-zirconium-tantalum (Ti-Nb-Zr-Ta) alloy; performing non-consumable smelting treatment on the Ti-Nb-Zr-Ta alloy; and then performing heat treatment and heat processing sequentially to prepare the medicinal beta titanium alloy and obtain the medicinal oxygen-containing beta titanium alloy, wherein the oxygen element accounts for 0.13 to 0.53 weight percent of the medicinal oxygen-containing beta titanium alloy, and the titanium-niobium-zirconium-tantalum alloy comprises the following components in percentage by mass: 60 percent of Ti, 35 percent of Nb, 3 percent of Zr and 2 percent of Ta. In the preparation method, elements with biological safety are selected and a high-content beta stable element is added, so the alloy has high cold machining property; and the alloy is strengthened by increasing the oxygen element content in the alloy and the oxygen element ratio is optimized by adding the oxygen elements with different content, so the alloy has high strength and low elastic modulus.

Owner:SHANGHAI JIAO TONG UNIV

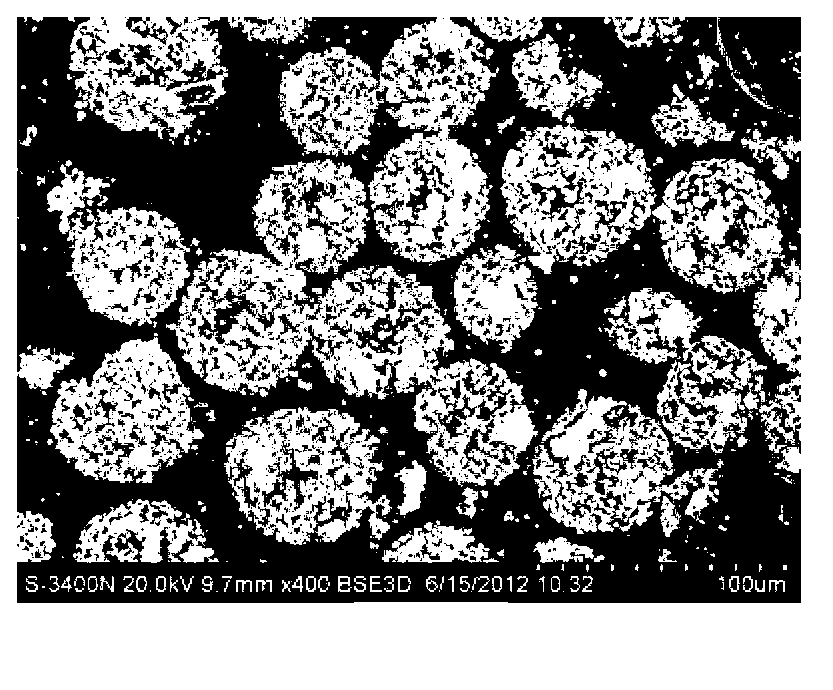

Preparation method of agglomerated composite thermal spraying powder of boride-containing ceramic

The invention provides a preparation method of agglomerated composite thermal spraying powder of boride-containing ceramic, which belongs to the field of powder processing and thermally sprayed composite ceramic coatings. According to requirements on elements of the thermal spraying powder, raw materials are subjected to mixing, ball mixing and sieving; a dispersant and water are added for the ball milling again, an adhesive is added after the materials are uniform, and then material slurry is taken out; the material slurry is subjected to spray drying and granulating by a spray drying device, and then the powder subjected to the spray drying is thermally treated. By adopting the preparation method provided by the invention, uniform and stable element distribution in the material slurry is realized, the viscosity of the material slurry is appropriate, the obtained sphere is good, the density is high, the fluidity is good, the apparent density is high and the granularity distribution is uniform, and the method is applicable to thermally sprayed boride-containing composite ceramic powder.

Owner:BEIJING UNIV OF TECH

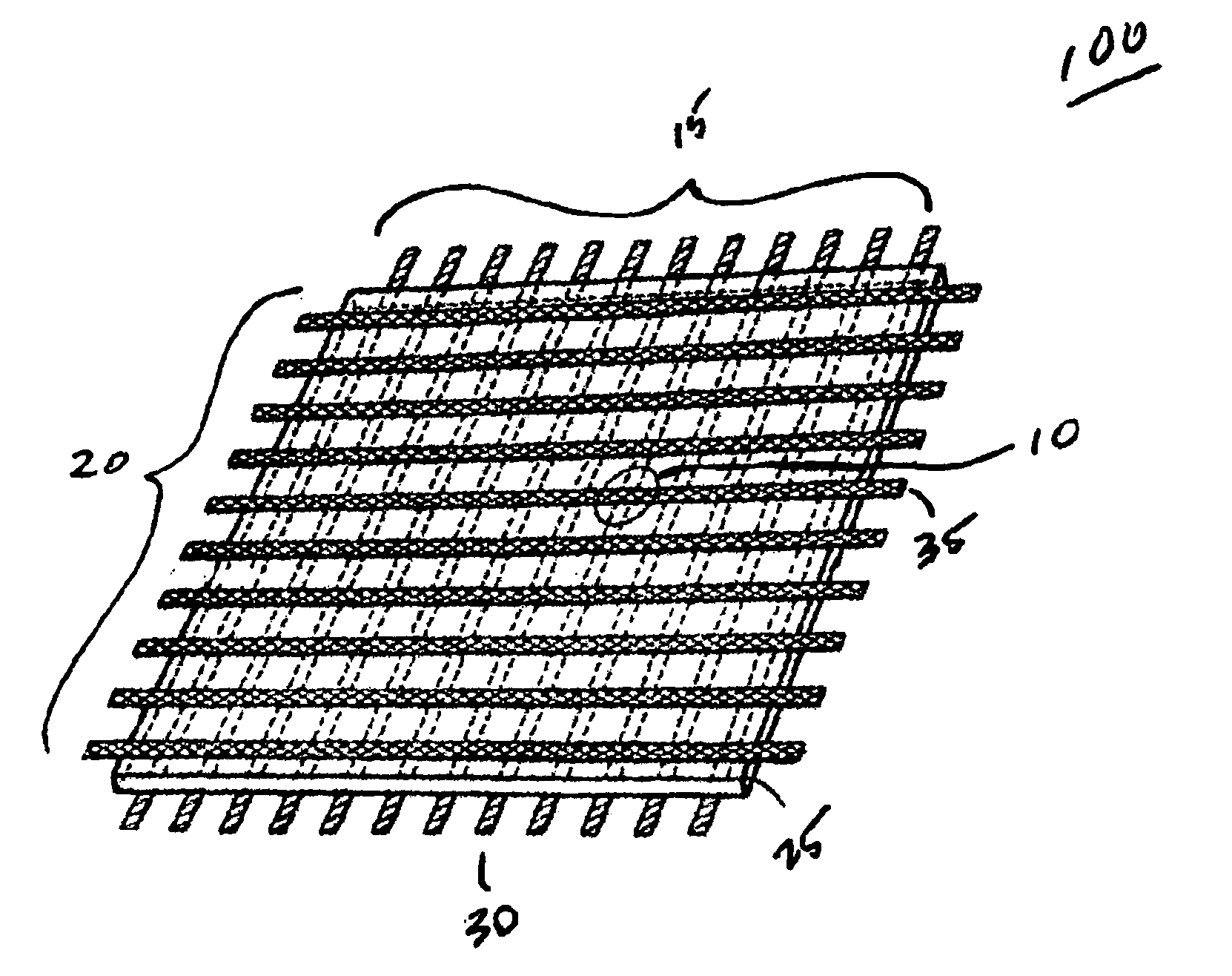

Non-volatile multi-stable memory device and methods of making and using the same

ActiveUS20050040455A1Increase resistanceEasy to adjustMaterial nanotechnologyNanoinformaticsHigh resistanceElectrical resistance and conductance

A multi-stable memory or data storage element is used in crosspoint data-storage arrays, as a switch, a memory device, or as a logical device. The general structure of the multi-stable element comprises a layered, composite medium that both transports and stores charge disposed between two electrodes. Dispersed within the composite medium are discrete charge storage particles that trap and store charge. The multi-stable element achieves an exemplary bi-stable characteristic, providing a switchable device that has two or more stable states reliably created by the application of a voltage to the device. The voltages applied to achieve the “on” state, the “off” state, any intermediate state, and to read the state of the multi-stable element are all of the same polarity. The multi-stable element is stable, cyclable, and reproducible in both the “on” state and the “off” state. The storage medium has a relatively high resistance in both its on and off states. Consequently, a dense array can be fabricated without significant cross-talk between adjacent elements. No patterning of the layer of storage medium is required.

Owner:GLOBALFOUNDRIES US INC

Multi-stable actuation apparatus and methods for making and using the same

InactiveUS8540206B2Reduce energy useCost effectiveOperating means/releasing devices for valvesClosed-cycle gas positive displacement engine plantAlloyEngineering

Actuator apparatus having a multi-stable element actuated by memory alloy actuating elements. In one embodiment, the multi-stable actuator comprises a bistable (two-state) diaphragm element adapted to alternate between two stable configurations via forces exerted on the diaphragm by more than one memory alloy filaments in response to thermal activation. In another embodiment, the bistable diaphragm of the multi-stable actuator transitions from a first to a second stable configuration via forces exerted by a single filament in response to direct or indirect thermal activation. A portion of the assembly is displaced when the assembly is in the second configuration. The bistable diaphragm transitions back to the first stable configuration via application of mechanical force on a portion of the assembly which was displaced. Methods for making and using the bistable actuator apparatus are also disclosed.

Owner:AUTOSPLICE SYST

Memory alloy-actuated apparatus and methods for making and using the same

InactiveUS8851443B2Reduce energy useCost effectiveDiaphragm valvesOperating means/releasing devices for valvesValve actuatorShape-memory alloy

Actuator apparatus having a multi-stable element actuated by memory alloy actuating elements. In one embodiment, the multi-stable actuator comprises a bistable (two-state) diaphragm element adapted to alternate between two stable configurations via forces exerted on the diaphragm by more than one memory alloy filaments in response to thermal activation. The bistable diaphragm element is coupled to a magnetic actuator element resident on a dry portion of a valve fitting, while a plunger actuated by the magnetic actuator element is resident on a wet portion of a valve fitting. Methods for making and using the bistable actuator apparatus are also disclosed.

Owner:AUTOSPLICE SYST

Medium-chromium ferrite stainless steel for automobile with high formability and acidic corrosion resistance as well as manufacturing method thereof

ActiveCN101768702AAccelerated corrosionImprove textureTemperature control deviceMetal rolling arrangementsTO-18Stable element

The invention relates to medium-chromium ferrite stainless steel for automobiles with high formability and acidic corrosion resistance, comprising the following components in percentage by weight: not more than 0.015 percent of C, not less than 0.20 percent and not more than 0.05 percent of Si, not less than 0.20 percent and not more than 0.07 percent of Mn, 16.0 to 18.0 percent of Cr, not more than 0.03 percent of P, not more than 0.002 percent of S, not more than 0.3 percent of Ni, not more than 0.015 percent of N, not more than 0.025 percent of C+N, not more than 0.06 percent of Al, not more than 0.2 percent of Cu, 0.1 to 0.3 percent of Zr, and the balance of Fe and inevitable impurities; one or more of Nb and Ti are also added as stabilizing elements with the following addition amount: Nb single stabilization: 0.5Nb is not less than 0.10 percent and not more than 0.20 percent by weight; Ti single stabilization: Ti is not less than 8X(C+N) and not more than 0.30 percent by weight, wherein the 8X(C+N) is not less than 0.20 percent by weight; Nb, Ti dual stabilization: 0.5Nb+Ti is not less than 10X(C+N) and not more than 15(C+N); Nb / Ti is equal to 1.0 to 1.8; and Nb + Ti is not more than 0.40 percent by weight. The medium-chromium ferrite stainless steel adopts different stabilizing modes of Ti single stabilization, Nb single stabilization and Ti + Nb dual stabilization and adds the stabilizing elements with different contents according to different stabilizing modes.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

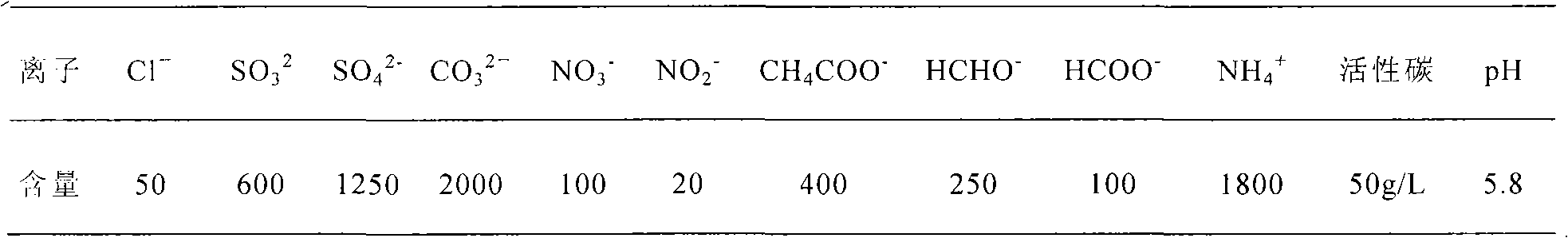

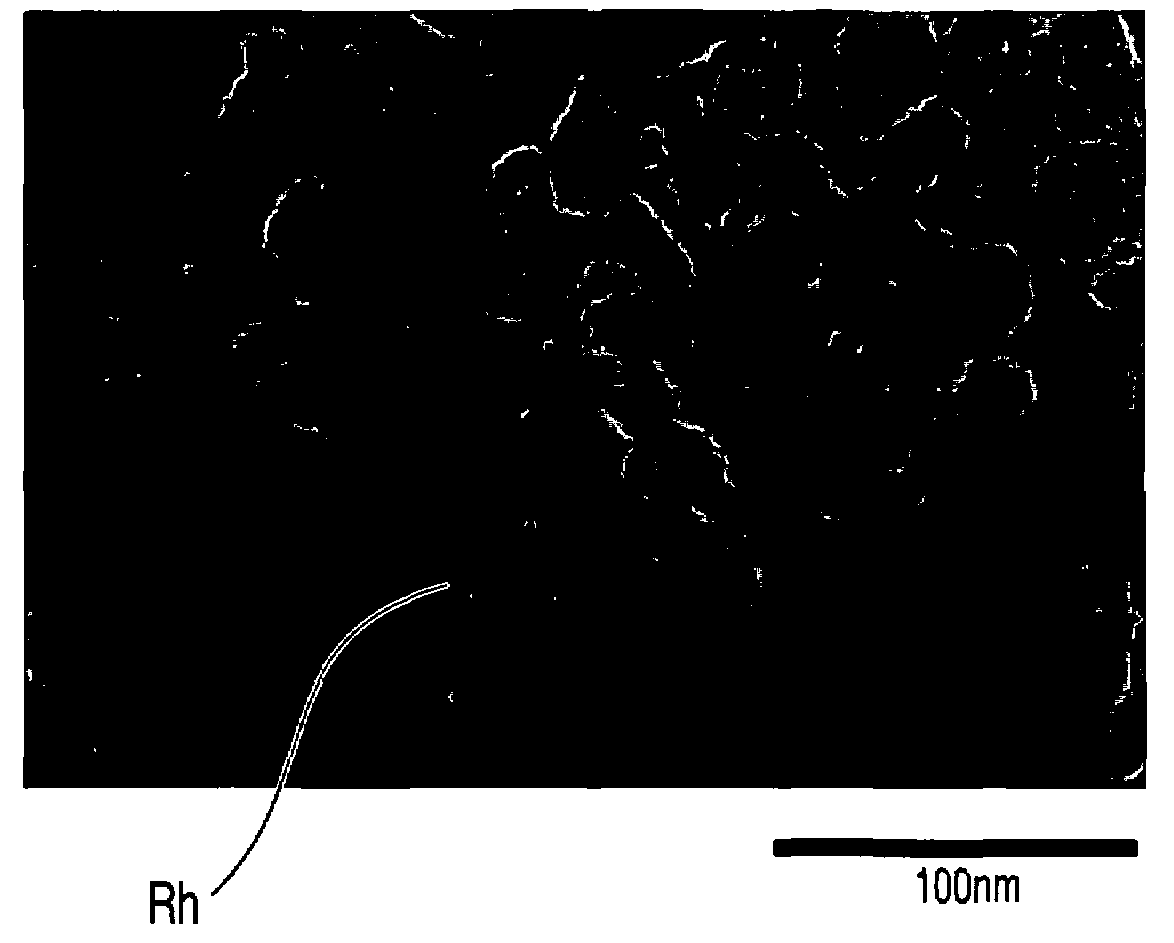

Exhaust gas-purifying catalyst and method of manufacturing the same

InactiveUS7498288B2Reduce catalysisInternal combustion piston enginesExhaust apparatusRare-earth elementActive component

Owner:CATALER CORP

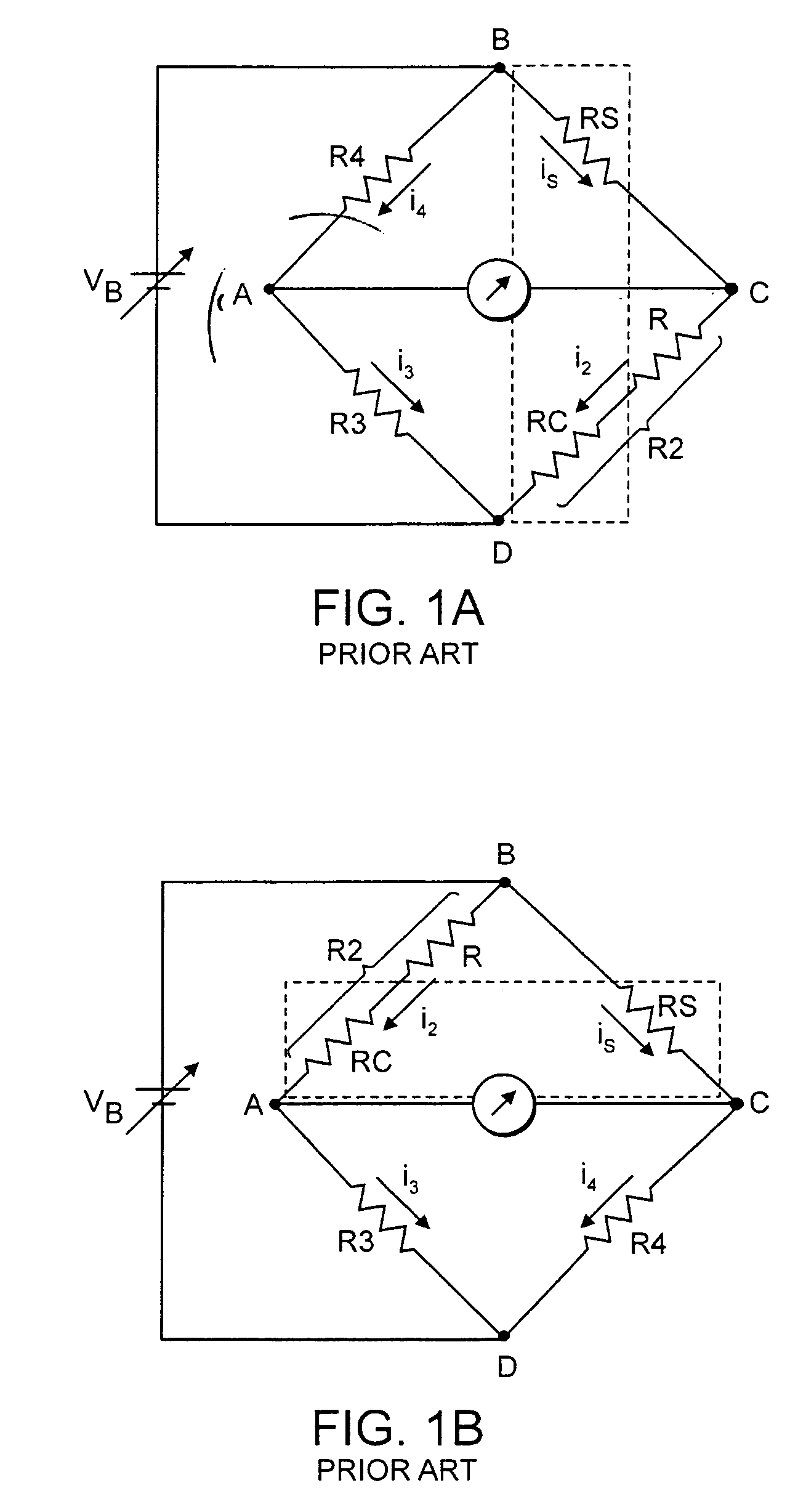

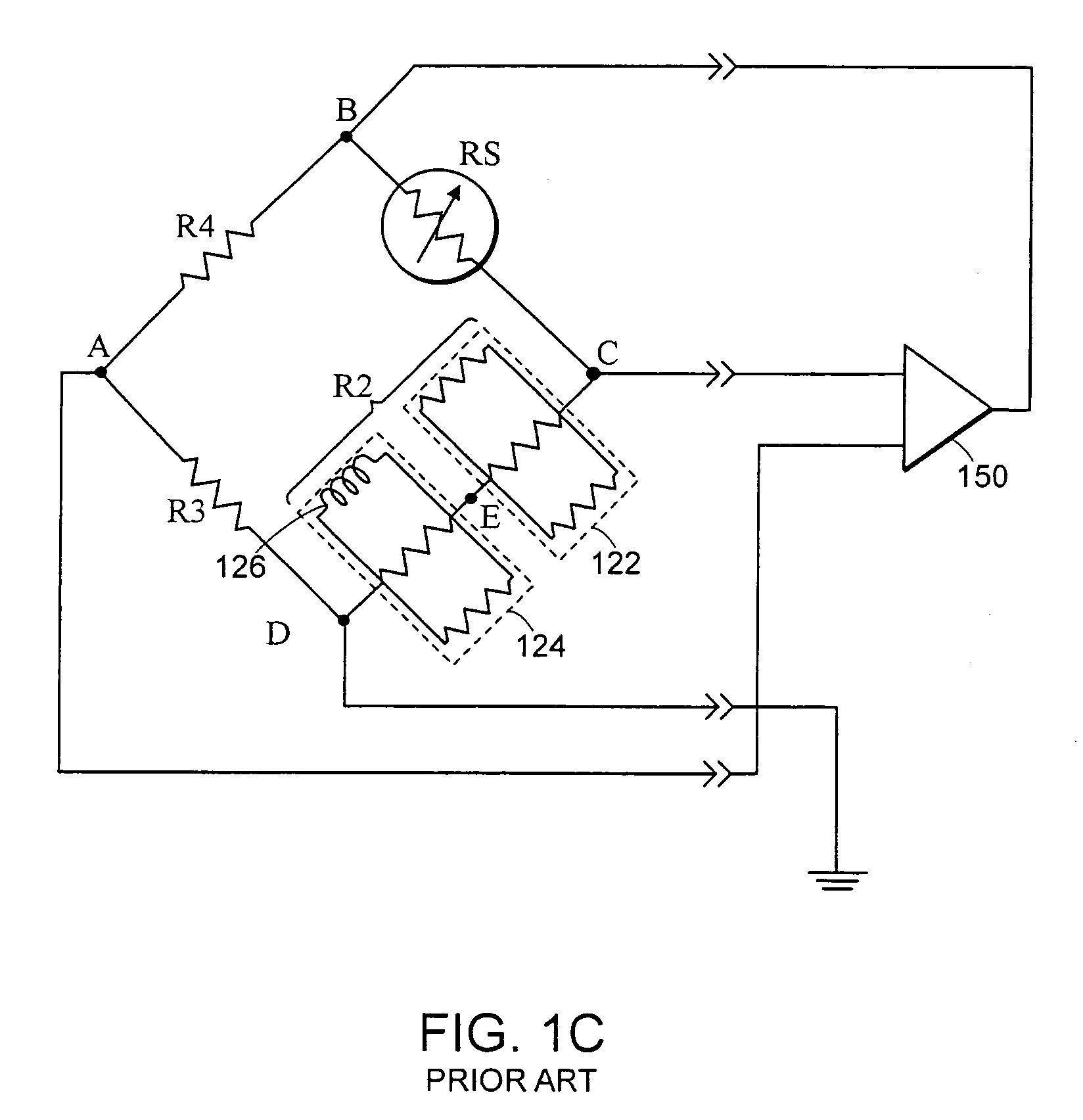

Technique for improving Pirani gauge temperature compensation over its full pressure range

InactiveUS7331237B2Vacuum gauge using heat conductivity variationElectrical resistance and conductanceCurve fitting

A method and apparatus are provided for achieving nearly perfect temperature compensation of a heat-loss vacuum gauge over its full pressure range. A voltage is measured across a sensor leg, a sensor leg and a temperature compensating leg connected together in series, or a sensor leg and a fixed resistive leg coupled together in series. A voltage is also measured across a subleg of the temperature compensating leg. The temperature compensating leg may include a temperature sensitive subleg and a temperature stable subleg connected together in series. The sublegs may include one or more temperature sensitive and / or temperature stable elements. The measured voltages are combined to produce temperature independent pressure indications over a pressure range. Three-dimensional curve-fitting or similar techniques may be used to combine the measured voltages.

Owner:MKS INSTR INC

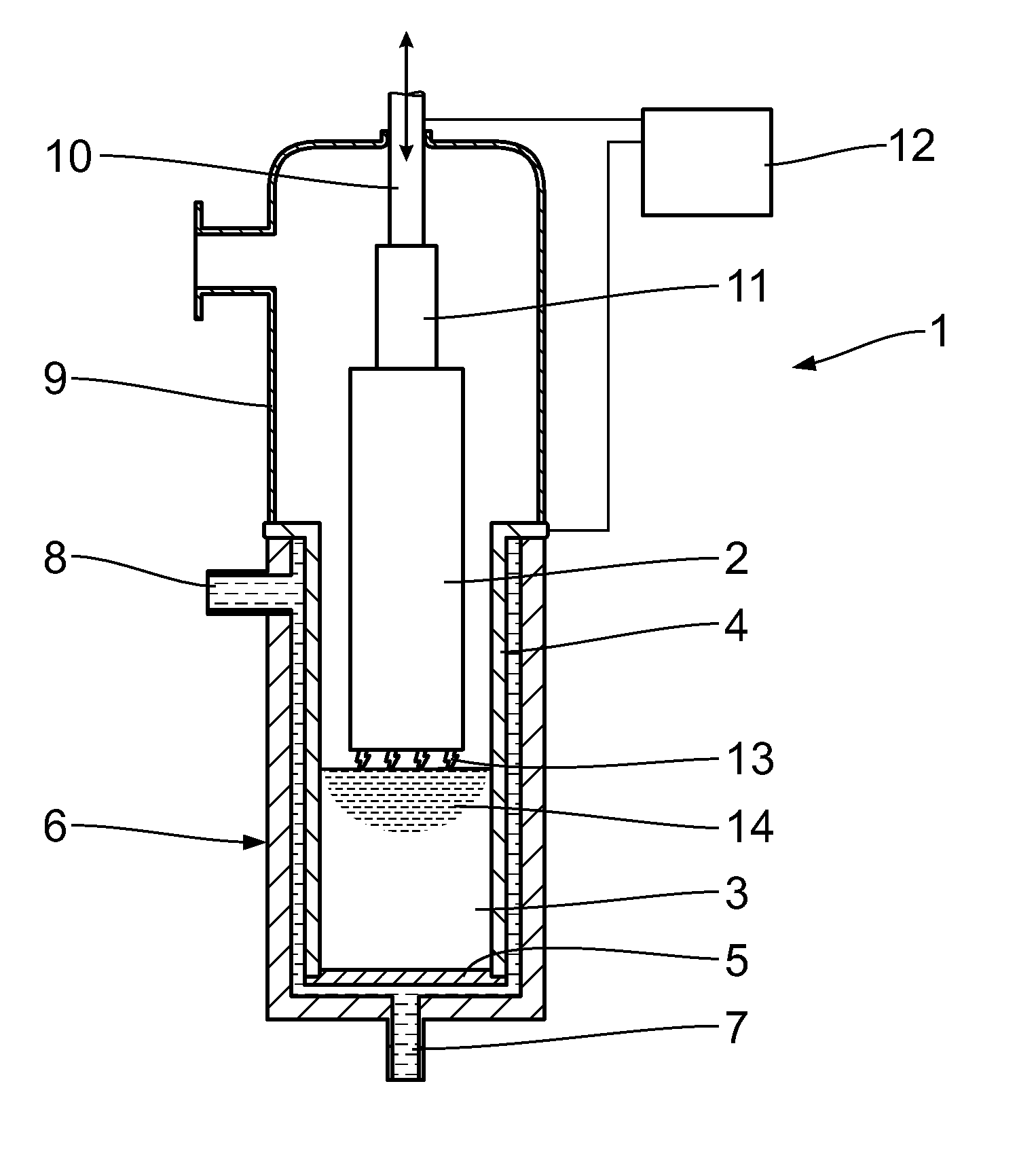

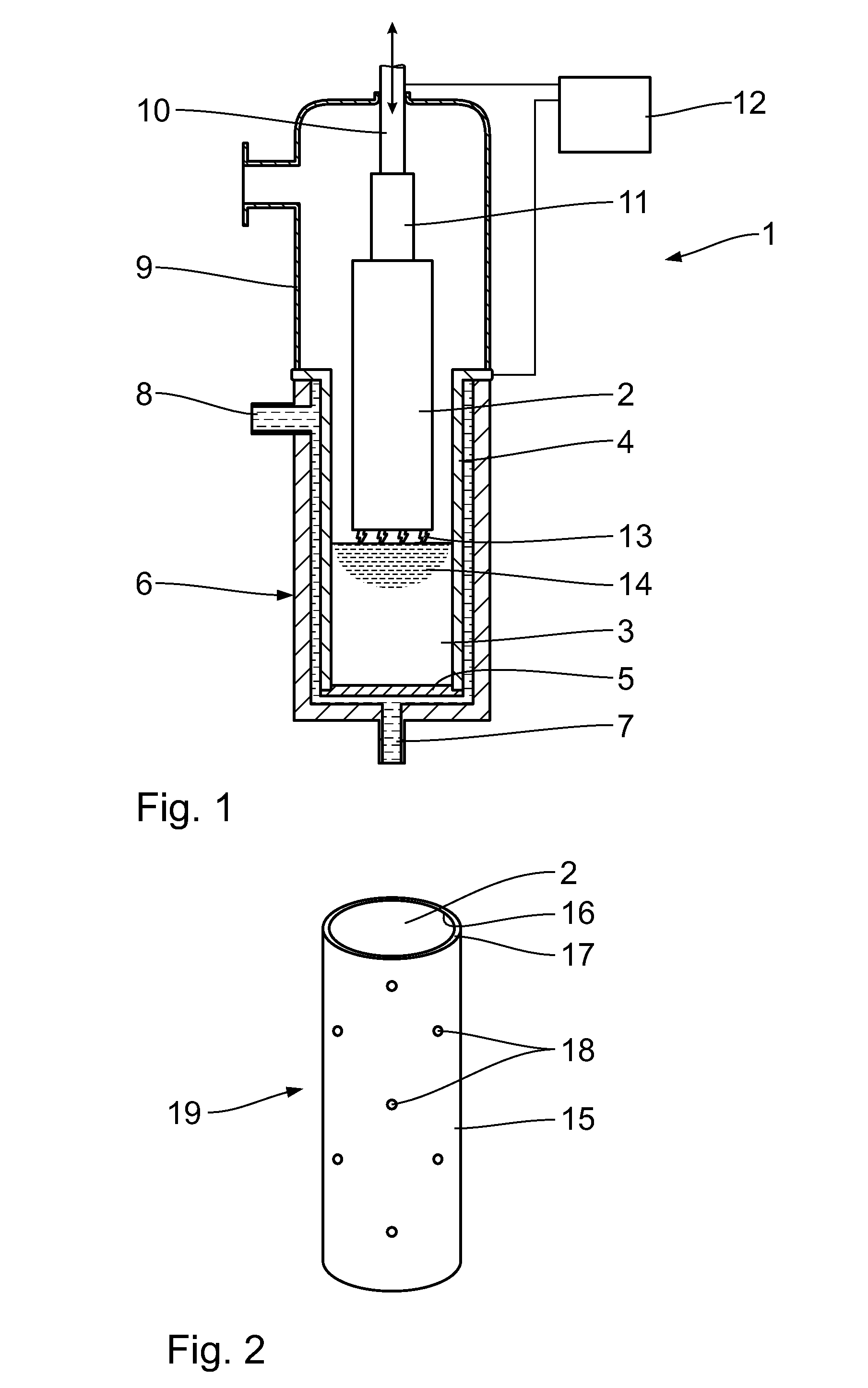

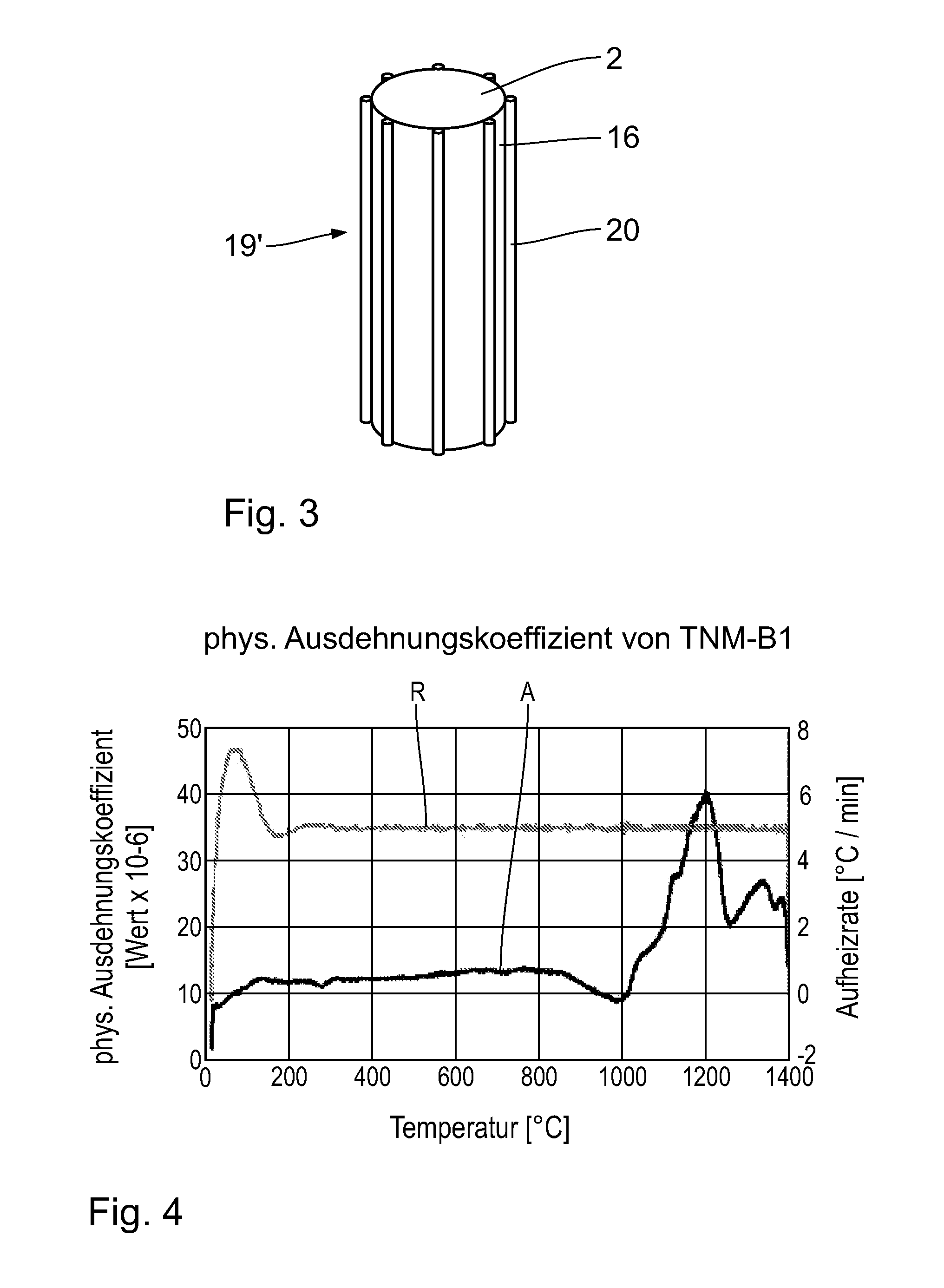

METHOD FOR THE PRODUCTION OF A Ãβ-y-TiAL BASE ALLOY

A method for the production of a γ-TiAl base alloy by vacuum arc remelting, which γ-TiAl base alloy solidifies via the (β-phase (β-γ-TiAl base alloy), comprises the following method steps:forming a basic melting electrode by melting, in at least one vacuum arc remelting step, of a conventional γ-TiAl primary alloy containing a lack of titanium and / or of at least one (β-stabilising element compared to the (β-γ-TiAl base alloy to be produced;allocating an amount of titanium and / or (β-stabilising element to the basic melting electrode, which amount corresponds to the reduced amount of titanium and / or (β-stabilising element, in an even distribution across the length and periphery of the basic melting electrode;adding the allocated amount of titanium and / or (β-stabilising element to the basic melting electrode so as to form the homogeneous (β-γ-TiAl base alloy in a final vacuum arc remelting step.

Owner:GFE METALLE & MATERIALIEN GMBH +1

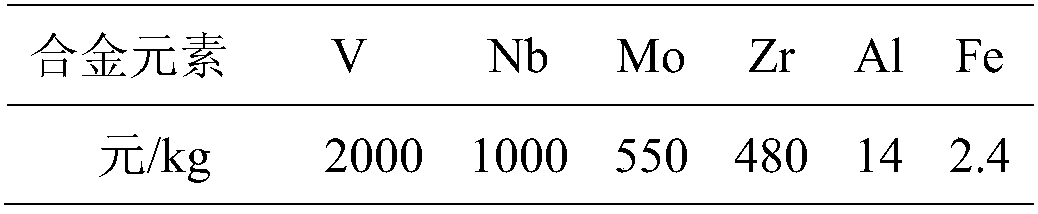

Low-cost high-strength alpha+beta titanium alloy and preparation method thereof

The invention provides low-cost high-strength alpha+beta titanium alloy. The titanium alloy takes titanium as a main body element, and takes alpha stable elements, namely, Al and B, and beta stable element, namely, Fe, as alloy elements; and the titanium alloy is prepared from the following components in percentage by weight: 2.5 to 4.5 percent of Al, 2.5 to 4 percent of Fe, 0.05 to 0.2 percent ofB, and the balance of titanium and unavoidable impurities. The invention also provides a preparation method of the low-cost high-strength alpha+beta titanium alloy; the preparation method comprises the following steps: adding raw materials into a water-cooled crucible suspension melting furnace into which argon gas is introduced according to a designed proportion alloy component proportion; obtaining an ingot casting after repeated melting; cogging and forging above a phase transition point; sampling a forged alloy and performing heat treatment; and finally, characterizing tissue structures and performance. The prepared titanium alloy is uniform in alloy components and fine in tissues; the tensile strength is greater than or equal to 1,000 MPa, and the plastic elongation percentage is greater than or equal to 15 percent; and the alloy has the advantages of low cost and high strength, and can replace part expensive titanium alloys in certain fields.

Owner:NANJING UNIV OF TECH

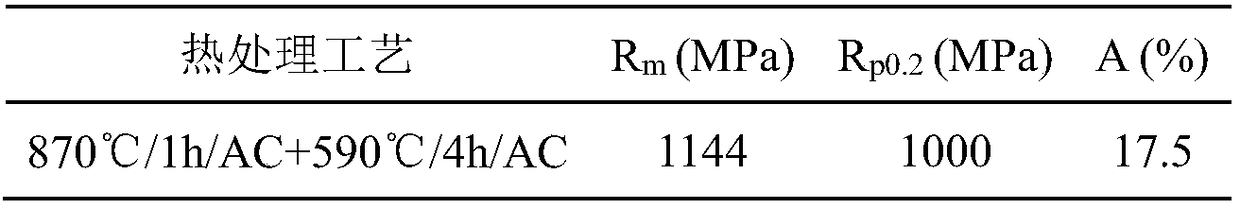

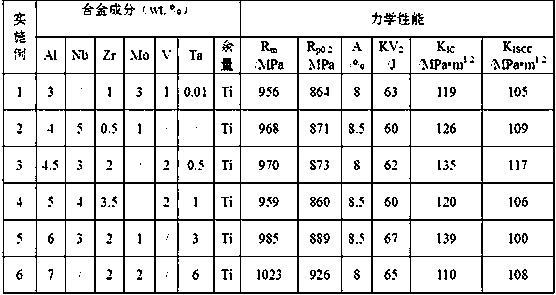

High-intensity, high-toughness and corrosion-resistant titanium alloy and preparation method thereof

ActiveCN109161726AGood cold and hot processing performanceGood technical applicationHigh intensityStable element

The invention relates to a high-intensity, high-toughness and corrosion-resistant titanium alloy and a preparation method thereof, and belongs to the field of alloys. The titanium alloy is prepared from the following element components (in percentage by mass): 3.0 to 7.0 percent of Al; 2.0 to 6.0 percent of a beta-stable element (Mo+Nb+V), 0.01 to 6.0 percent of Ta, 0.5 to 3.5 percent of Zr and the balance of Ti and unavoidable impurities. The performance of the alloy is as follows: Rp0.2 is greater than or equal to 840 MPa, Rm is greater than or equal to 940 MPa, A is greater than or equal to8 percent, KIC is greater than or equal to 110 MPa.m<1 / 2>, KISCC is greater than or equal to 100 MPa.m<1 / 2>, and KV2 is greater than or equal to 60J. The alloy has good technology application and market prospects in the field of ship, marine engineering and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Super-high strength and high-plasticity titanium alloy

ActiveCN104862529AGood heat treatment strengthening effectImprove plasticityRoom temperatureStable element

The invention discloses a super-high strength and high-plasticity titanium alloy, which is prepared from the following components in percentage by weight: 4%-6% of Al, 8%-11% of Mo, 2%-6% of V, 2%-5% of Cr, and the balance of Ti and inevitable impurities, wherein the tensile strength Rm of the super-high strength and high-plasticity titanium alloy at a room temperature is greater than or equal to 1500MPa; and the ductility A is greater than or equal to 10%. The titanium alloy disclosed by the invention contains a beta isomorphous stable element Mo with relatively high mass percent; the diffusion speed of the element Mo in the titanium alloy is slow, so that the size of a precipitated phase in the titanium alloy is small, and the titanium alloy has a relatively good heat treatment strengthening effect; an alpha phase can be dissolved and strengthened by the element V; meanwhile, the c / a ratio of the alpha phase is reduced; slippage of the alpha phase is facilitated; and the titanium alloy has relatively low creep resistance and good plasticity.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Metal refiner for magnesium alloy and preparation method thereof

The invention relates to a metal refiner for a magnesium alloy and is characterized in that the refiner adopts magnesium as the basal body and contains strontium, neodymium and lanthanum elements. The mass percentage for the alloy elements is as follows: Sr more than or equal to 5 percent and less than or equal to 30 percent, Nd more than or equal to 0.3 percent and less than or equal to 0.6 percent, La more than or equal to 0.3 percent and less than or equal to 0.6 percent and the rest is magnesium. The submicron phases of the magnesium strontium compound with a length of 0.1 to 0.8 micrometer are distributed on the basal body of the alloy. The refiner preparing method of the invention has simple technique, stable elements, no environmental pollution and low manufacturing cost. The refiner obtained from the method has an excellent service effect, which has a refining effect is 3 to 5 times of that of a common refiner under the same adding condition.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

Monitoring Method of Vertical Displacement and Vertical Deflection Change of Building Construction Elements, Especially of the Roof, and a System for Realization of this Method

InactiveUS20120166136A1Management processDigital computer detailsSpeed measurement using gyroscopic effectsVertical deflectionArchitectural engineering

The invention relates to a monitoring method of vertical displacement of selected points of building construction elements, especially roof construction elements or their parts, and vertical deflection change in these points, wherein a distance, preferably vertical, between each of monitored points of construction elements and the stable elements or stable floor is measured, and then a value of vertical displacement of each monitored point, which occurred from the moment of monitoring initiation, is calculated, and then for each monitored construction element the value of vertical deflection change in the monitored point is calculated. The invention relates also to a system for monitoring of vertical displacement of monitored points as well as vertical deflection change in these points of building construction elements.

Owner:WISENE Z O O

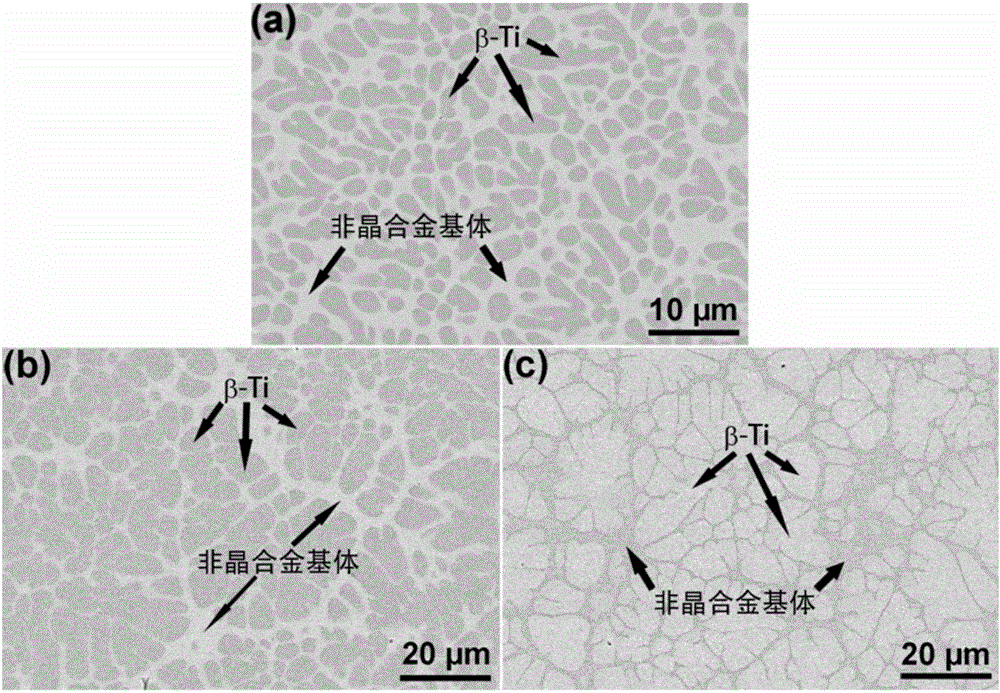

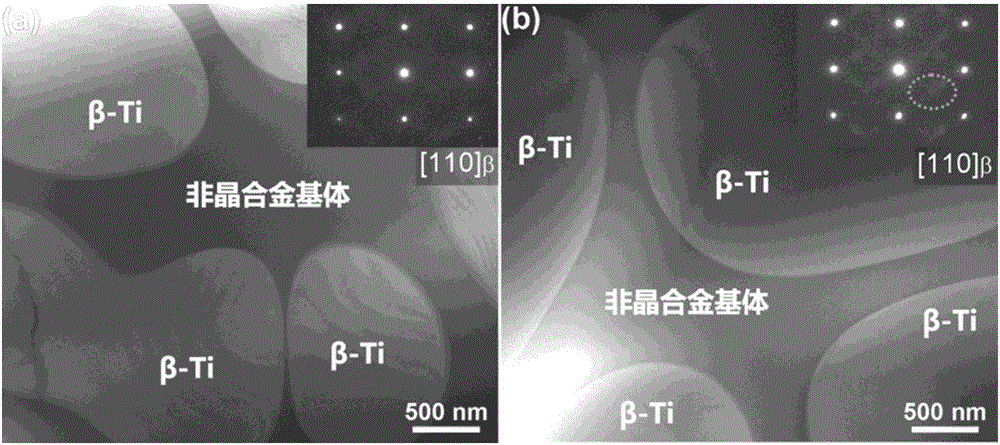

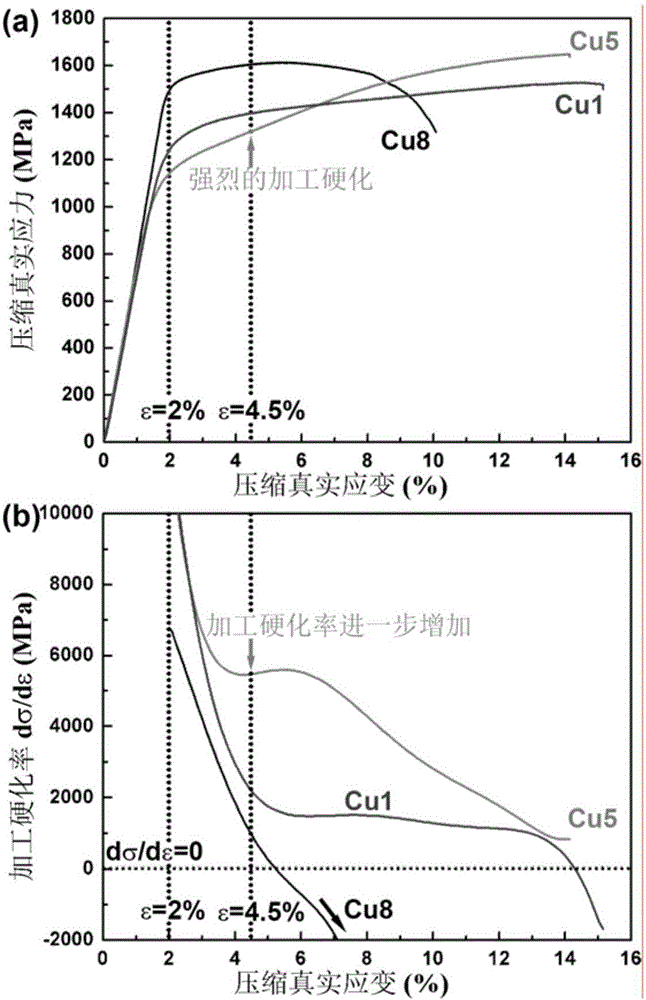

Method for enhancing work hardening capacity of beta-type amorphous alloy endogenous composite material

The invention discloses a method for enhancing work hardening capacity of a beta-type amorphous alloy endogenous composite material and belongs to the technical field of an amorphous alloy composite material. According to the method, content of beta-phase stable element in the chemical components of the beta-type amorphous alloy endogenous composite material is adjusted such that the beta-phase has proper structural metastability. Then, an obtained sample can undergo deformation-induced martensitic transformation and / or twinning so as to enhance work hardening capacity of the beta-type amorphous alloy endogenous composite material. The key of the method is to regulate and control structural metastability of the in-situ precipitated beta-phase. The method has important value for designing and developing the beta-type amorphous alloy endogenous composite material with excellent mechanical properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Forging forming method of high-toughness titanium ring

InactiveCN107803454AIncrease confusionImprove high temperature strengthForging press drivesMetal rollingStable elementForging

The invention discloses a forging forming method of a high-toughness titanium ring. The forging forming method of the high-toughness titanium ring is carried out according to the following steps that1, a titanium alloy is blanked into a bar; 2, a titanium alloy pre-rolling ring blank is obtained; 3, the ring blank is subjected to rolling forming; 4, double annealing is conducted; 5, coarse grainsof the ring blank are broken; 6, the coarse broken grains are refined and uniformized; 7, the grains at a beta area of a forging structure are refined; 8, constant-temperature correction is conducted; and 9, low-temperature heat treatment is conducted, and air cooling is conducted to the indoor temperature. The forging forming method is simple, clear and convenient to apply; the content of the alpha stable is increased appropriately, and the content of the beta stable element is decreased appropriately, so that the number of alpha strips in the titanium alloy is increased; and therefore, after subsequent forging, a mesh basket structure with the high confusion degree can be obtained for improving the high-temperature strength of a forging, and meanwhile, the high-temperature tensile strength of the forging is improved.

Owner:陕西海恩得工贸股份有限公司

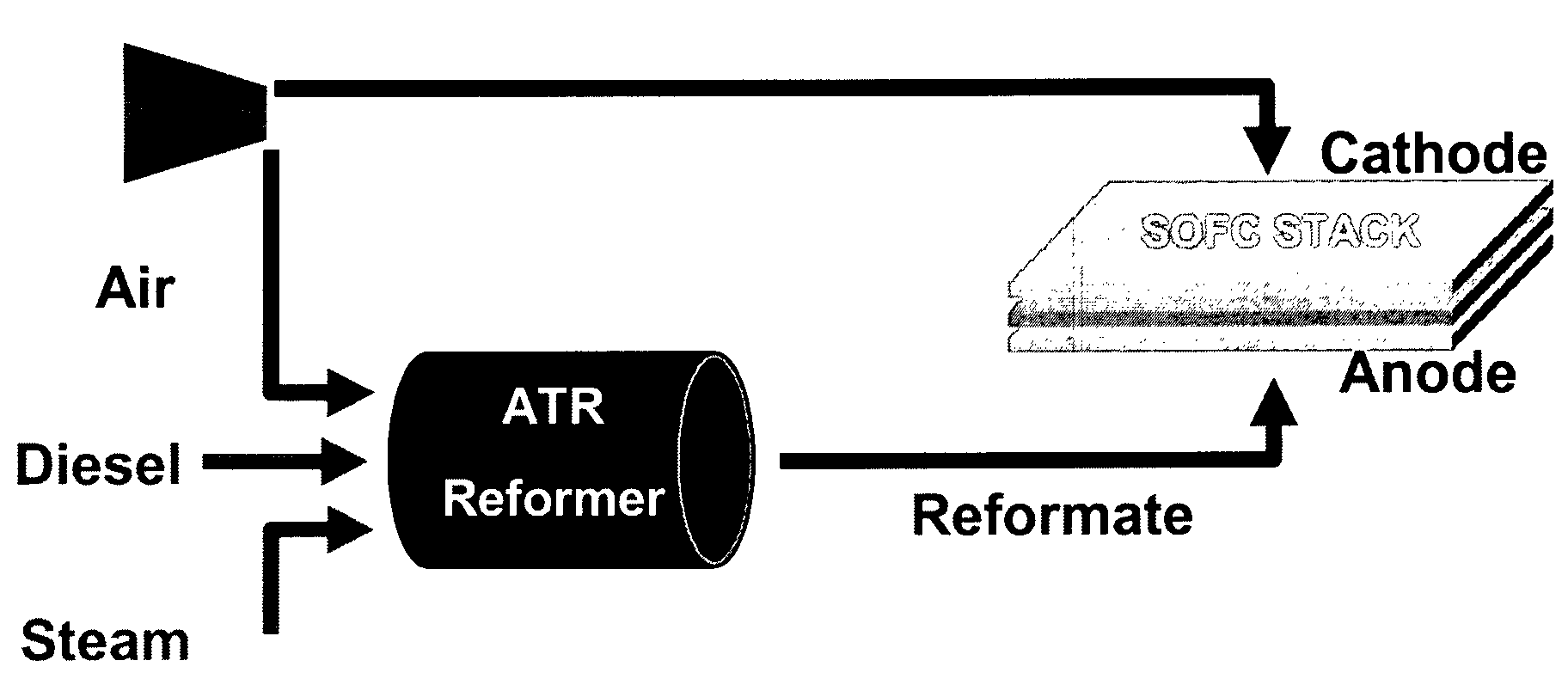

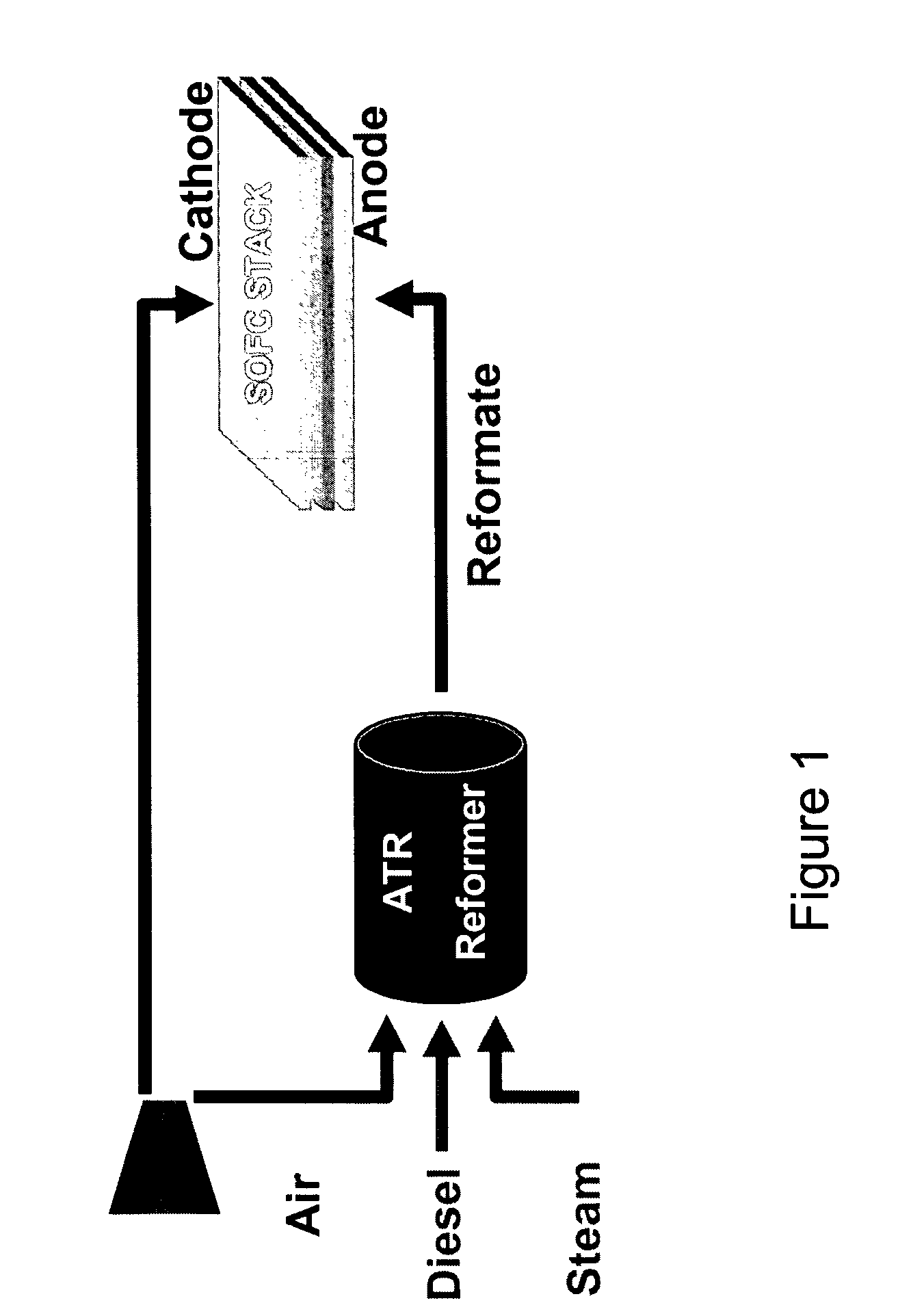

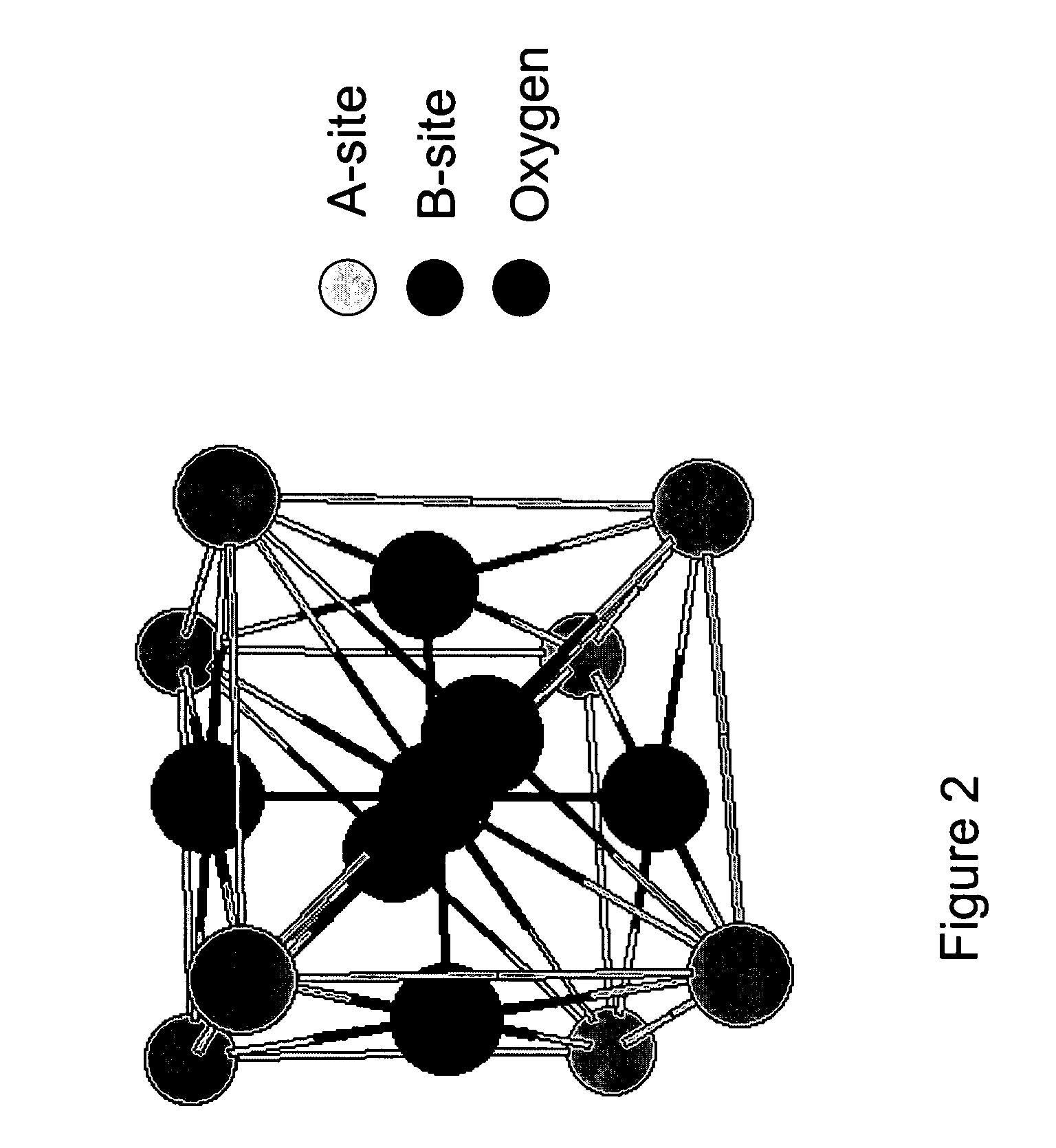

Autothermal reforming catalyst having perovskite structure

InactiveUS7507690B2High yieldLow reformingHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementEngineering

The invention addressed two critical issues in fuel processing for fuel cell application, i.e. catalyst cost and operating stability. The existing state-of-the-art fuel reforming catalyst uses Rh and platinum supported over refractory oxide which add significant cost to the fuel cell system. Supported metals agglomerate under elevated temperature during reforming and decrease the catalyst activity. The catalyst is a perovskite oxide or a Ruddlesden-Popper type oxide containing rare-earth elements, catalytically active firs row transition metal elements, and stabilizing elements, such that the catalyst is a single phase in high temperature oxidizing conditions and maintains a primarily perovskite or Ruddlesden-Popper structure under high temperature reducing conditions. The catalyst can also contain alkaline earth dopants, which enhance the catalytic activity of the catalyst, but do not compromise the stability of the perovskite structure.

Owner:UCHICAGO ARGONNE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com