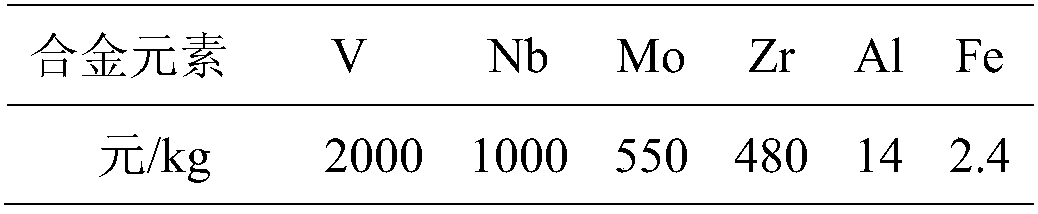

Low-cost high-strength alpha+beta titanium alloy and preparation method thereof

A β-titanium alloy, low-cost technology, applied in the field of titanium alloy processing, can solve the problem of plastic elongation reduction, etc., to achieve the effect of low cost, uniform alloy composition, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

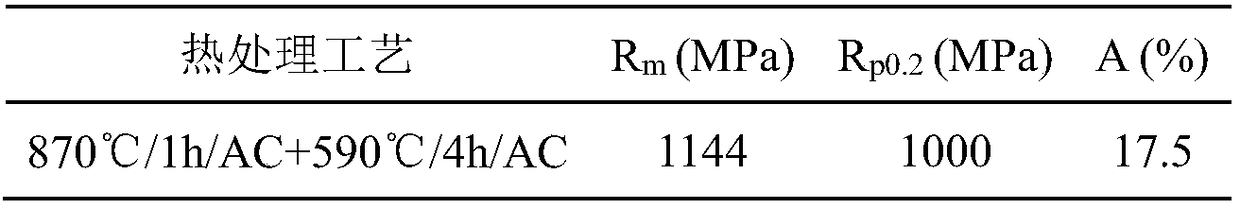

Embodiment 1

[0026] The alloy composition is Ti-3wt%Al-3.5wt%Fe-0.1wt%B(K β =0.7), the temperature of the phase transition point is about 900°C, mix the purchased sponge titanium, Fe-B master alloy, pure iron particles, and pure aluminum particles according to the ratio of 900g for each ingot, and then put them into the cold crucible for suspension In the water-cooled copper crucible of the smelting furnace, a certain amount of high-purity argon gas is introduced after the furnace body is evacuated, and the alloy is first smelted at 1600°C for 10 minutes. After the ingot is fully cooled, turn the ingot upside down and put it into a water-cooled copper crucible for re-melting to homogenize the alloy composition. After repeating this for 3-5 times, the phase transition temperature of the ingot is measured, and then the ingot The blank is forged at 50-200 °C above the change point to form a regular-shaped plate. The plate was kept at 870°C for 1 hour, then air-cooled to room temperature, and...

Embodiment 2

[0032] The alloy composition is Ti-3wt%Al-3wt%Fe-0.1wt%B(K β=0.6), the temperature of the phase transition point is about 908°C, mix the purchased sponge titanium, Fe-B master alloy, pure iron particles, and pure aluminum particles according to the ratio of 900g for each ingot, and then put them into the cold crucible for suspension In the water-cooled copper crucible of the smelting furnace, a certain amount of high-purity argon gas is introduced after the furnace body is evacuated, and the alloy is first smelted at 1600°C for 10 minutes. After the ingot is fully cooled, turn the ingot upside down and put it into a water-cooled copper crucible for re-melting to homogenize the alloy composition. After repeating this for 3-5 times, the phase transition temperature of the ingot is measured, and then the ingot The blank is forged at 50-200°C above the change point to form a regular-shaped plate. The plate was kept at 878°C for 1 hour, then air-cooled to room temperature, and the...

Embodiment 3

[0038] The alloy composition is Ti-3wt%Al-3.5wt%Fe-0.15wt%B(K β =0.7), the temperature of the phase transition point is about 900°C, mix the purchased sponge titanium, Fe-B master alloy, pure iron particles, and pure aluminum particles according to the ratio of 900g for each ingot, and then put them into the cold crucible for suspension In the water-cooled copper crucible of the smelting furnace, a certain amount of high-purity argon gas is introduced after the furnace body is evacuated, and the alloy is first smelted at 1600°C for 10 minutes. After the ingot is fully cooled, turn the ingot upside down and put it into a water-cooled copper crucible for re-melting to homogenize the alloy composition. After repeating this for 3-5 times, the phase transition temperature of the ingot is measured, and then the ingot The blank is forged at 50-200°C above the change point to form a regular-shaped plate. The plate was kept at 870°C for 1 hour, then air-cooled to room temperature, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com