Patents

Literature

53 results about "Cunife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cunife is an alloy of copper (Cu), nickel (Ni), iron (Fe), and in some cases cobalt (Co). The alloy has the same linear coefficient of expansion as certain types of glass, and thus makes an ideal material for the lead out wires in light bulbs and thermionic valves. Fernico exhibits a similar property. It is a magnetic alloy and can be used for making magnets.

High-thermal-conductivity graphite-aluminium composite material reinforced by diamond particles in hybrid manner and preparation process for same

ActiveCN103343274AImprove mechanical propertiesImprove thermal conductivityAxial pressurePolyvinyl alcohol

Owner:SHANGHAI JIAO TONG UNIV

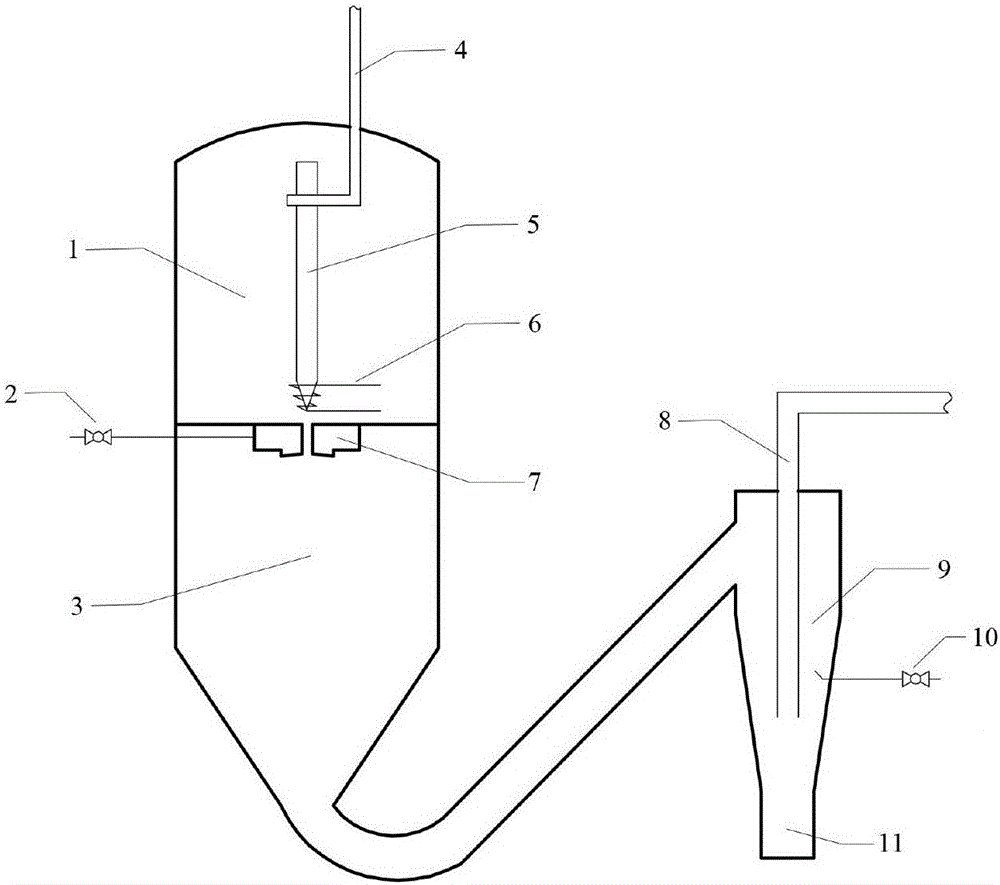

Method for preparing RE-Mg-Ni-M series hydrogen storage alloy

The invention relates to a preparation method of RE-Mg-Ni-M based hydrogen storage alloy. Under the protection of inert gases, the as-cast condition products of the RE-Mg-Ni-M based hydrogen storage alloy are smelted through using a cold-crucible magnetic-suspension furnace; heat-treated products are obtained by heat treatment of the as-cast condition products. The method has the steps that: (1) material is prepared; (2) metal Ni and M are smelted together; (3) metal RE is smelted; (4) the casting ingots obtained from step (2) and step (3) are smelted; (5) the ingot obtained from step (4) is overturned and smelted to obtain alloy solution, then master alloy of magnesium is added into the alloy solution to obtain the as-cast condition products of the RE-Mg-Ni-M based hydrogen storage alloy by cooling; (6) heat treatment is carried out to the as-cast condition products to get the heat-treated product. The single weight of the as-cast condition products and heat-treated products is 50-1000g; the content of magnesium in the products is close to designed content; the components of the as-cast condition products are uniform and have high hydrogen storage capacity; the structure and components of the heat-treated products are uniform and also have high hydrogen storage capacity and long cycling life.

Owner:GRIMAT ENG INST CO LTD

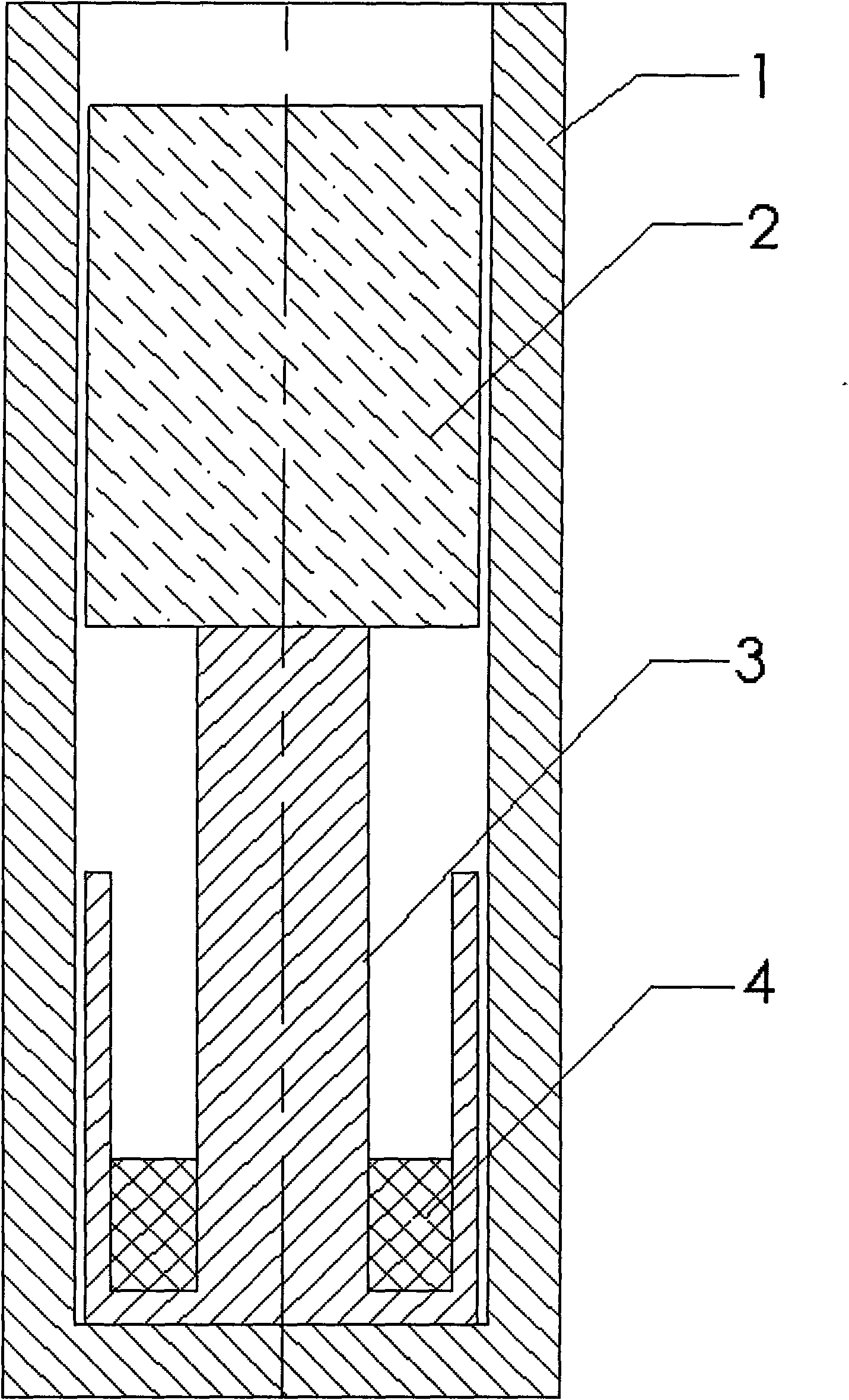

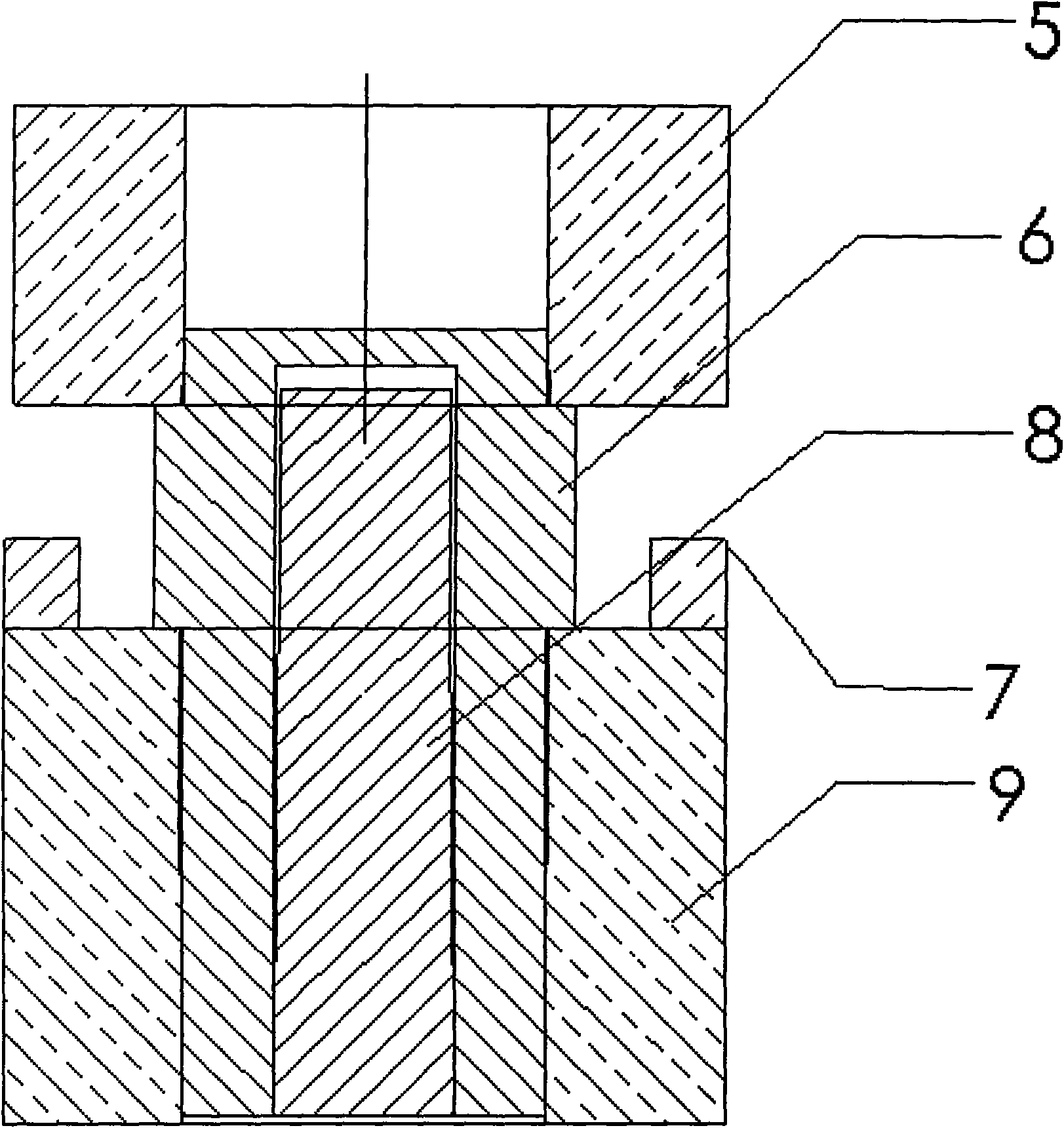

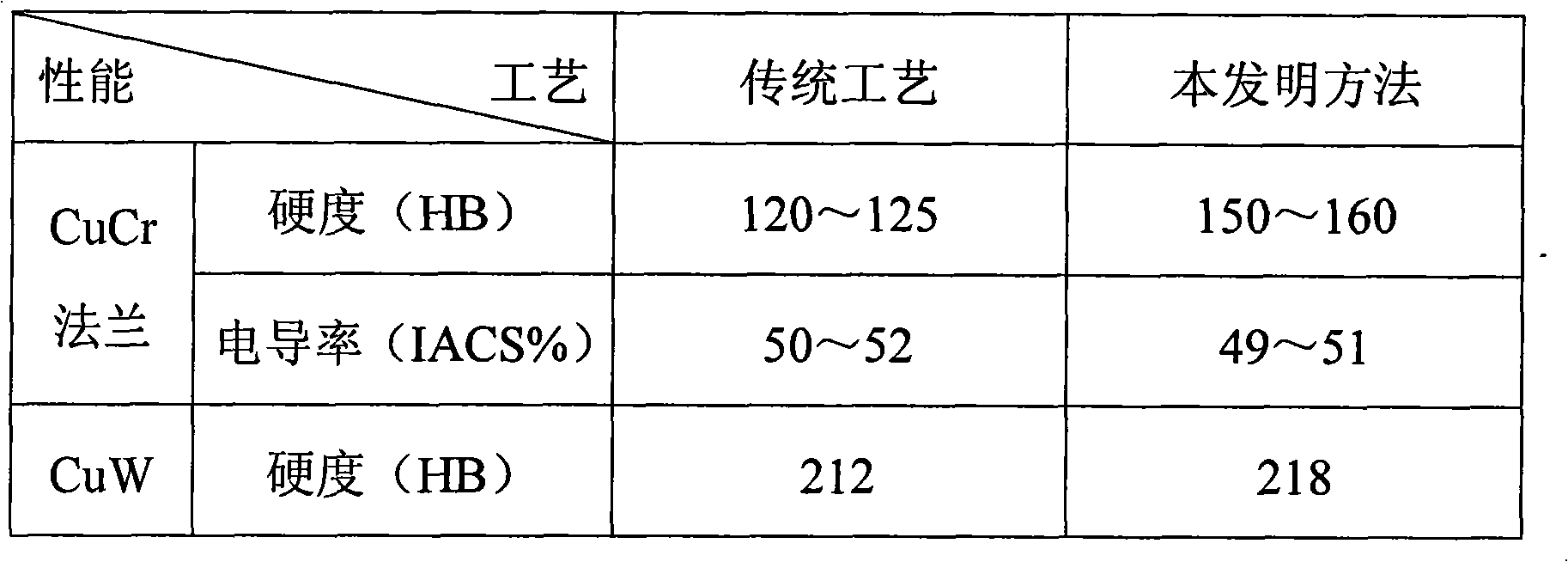

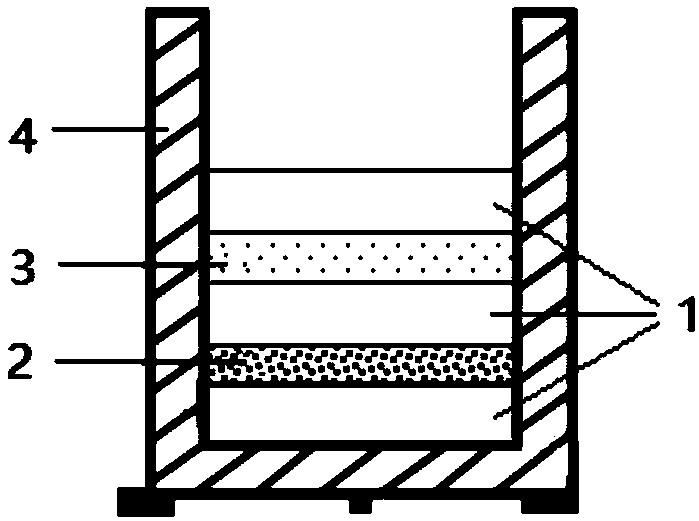

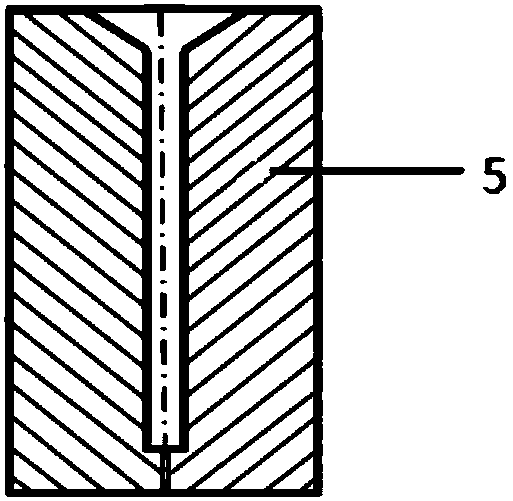

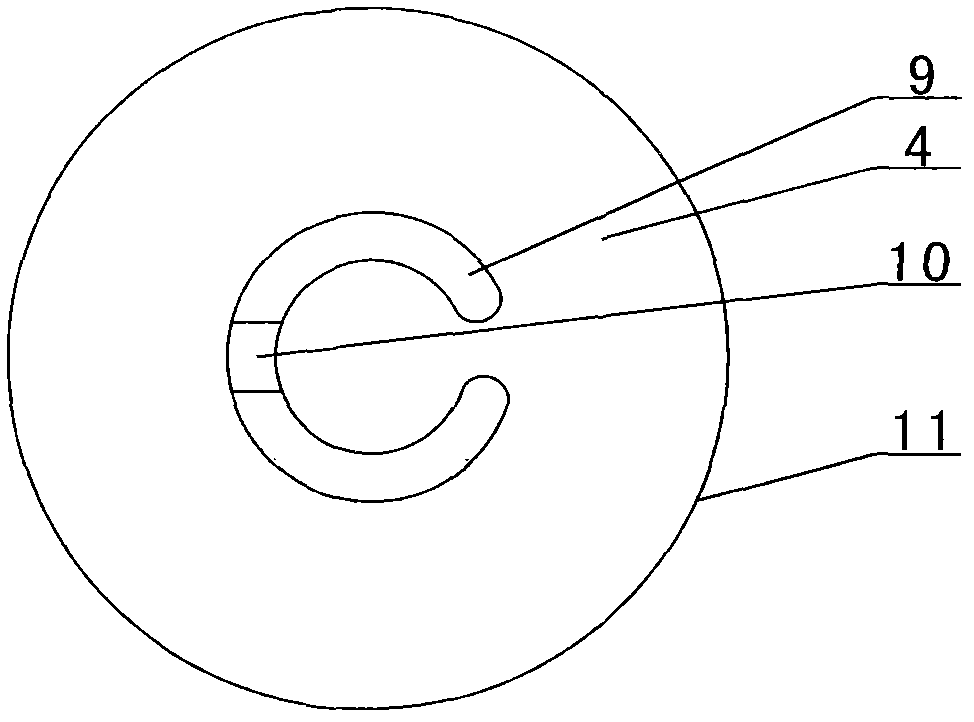

Preparation method of CuW/CrCu integral high-voltage electrical contacts

The invention discloses a preparation method of CuW / CrCu integral high-voltage electrical contacts, which includes the following steps of: firstly taking and mixing CuW powder and CrCu powder with the mass percentage of 1 to 1.5:0.001 to 0.01 and then adopting a cold mold and a hot mold; wherein the cold mold comprises an upper mold and a lower mold which are separated and have a cavity in the interior; a dismountable gasket is arranged between the upper mold and the lower mold; a dismountable mold core b is arranged in the interior cavity of the lower mold; a tungsten skeleton is pressed in the cold mold and the infiltration and sintering are carried out in a cylindrical pot; the hot mold comprises an external mold with a cavity in the interior, and a dismountable mold core a is arranged in the cavity of the interior of the external mold, infiltrated and sintered in the hot mold and then is put into the cold mold for pressing a flange; and then the CuW / CrCu integral high-voltage electrical contacts are obtained after machining. The preparation method of CuW / CrCu integral high-voltage electrical contacts uses the hot mold and cold mold with the mold core structure in sintering with no need of being machined after being processed into entity, thus achieving the purpose of saving materials.

Owner:XIAN UNIV OF TECH

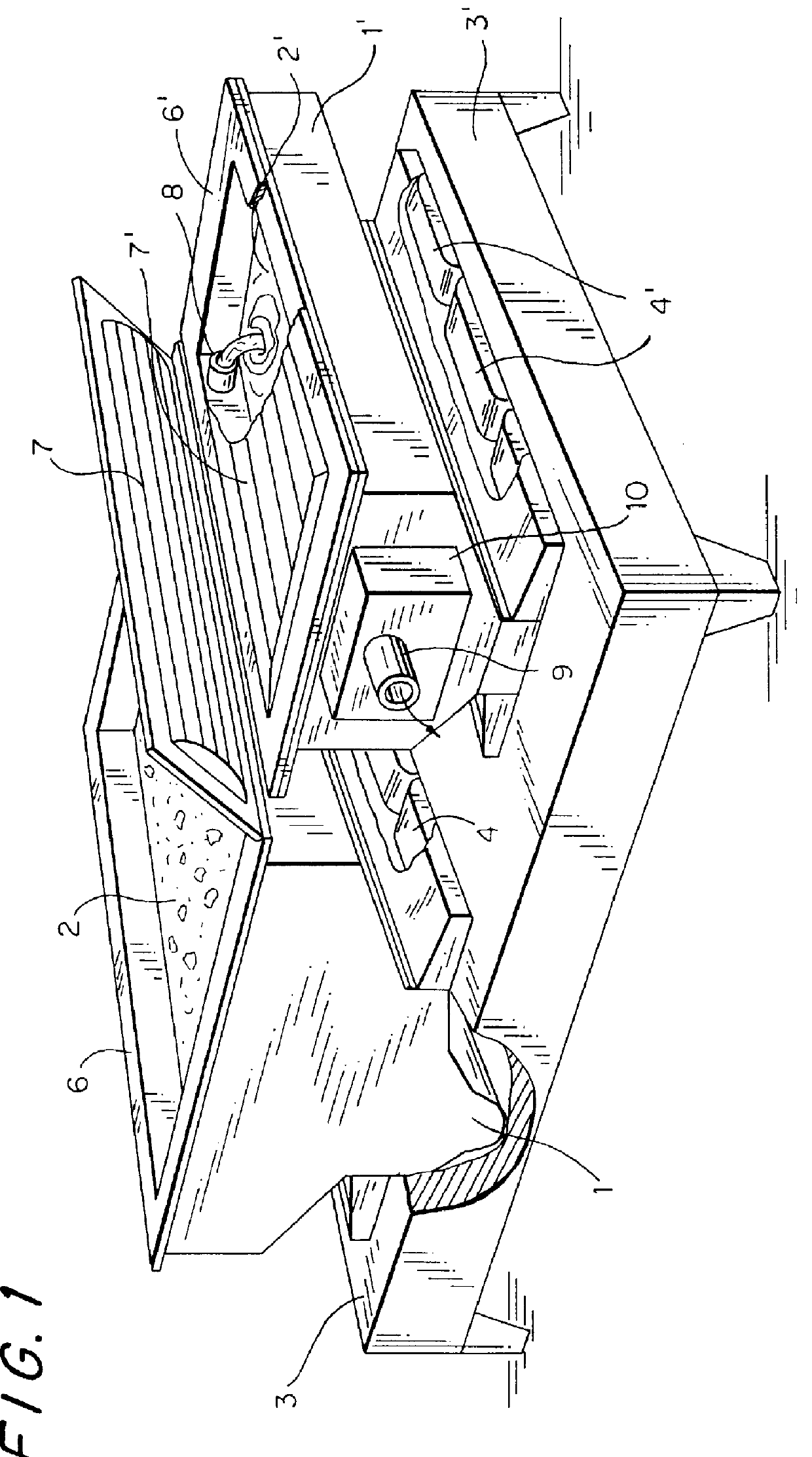

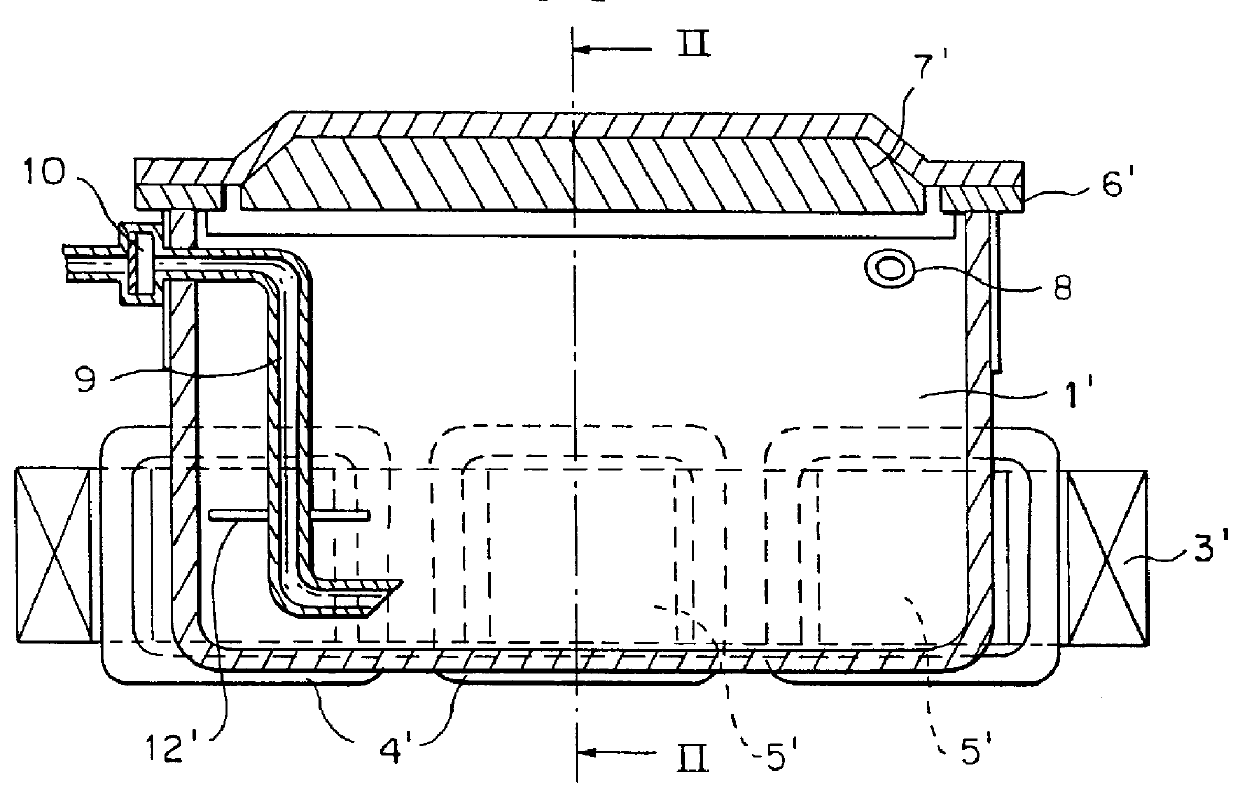

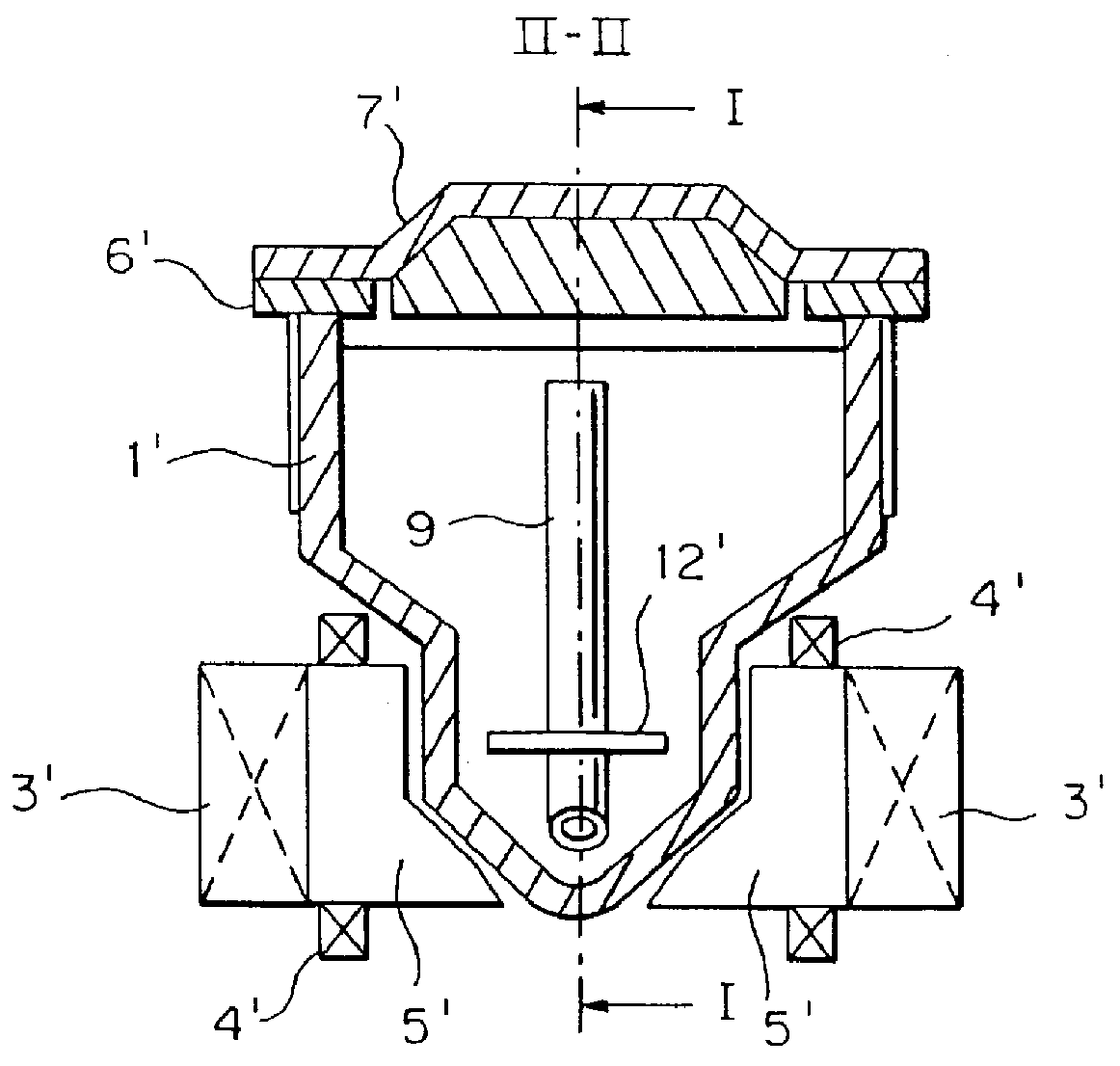

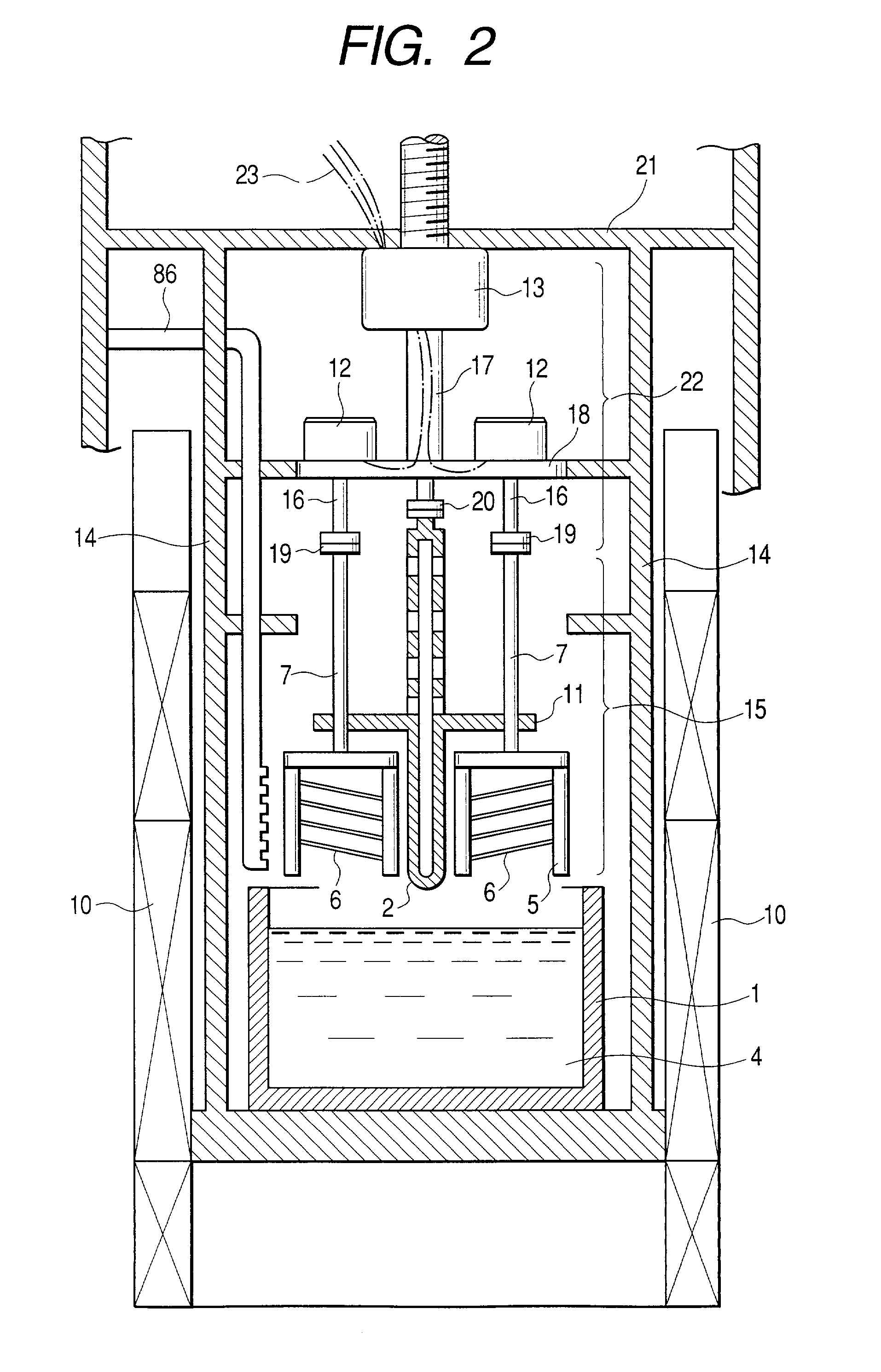

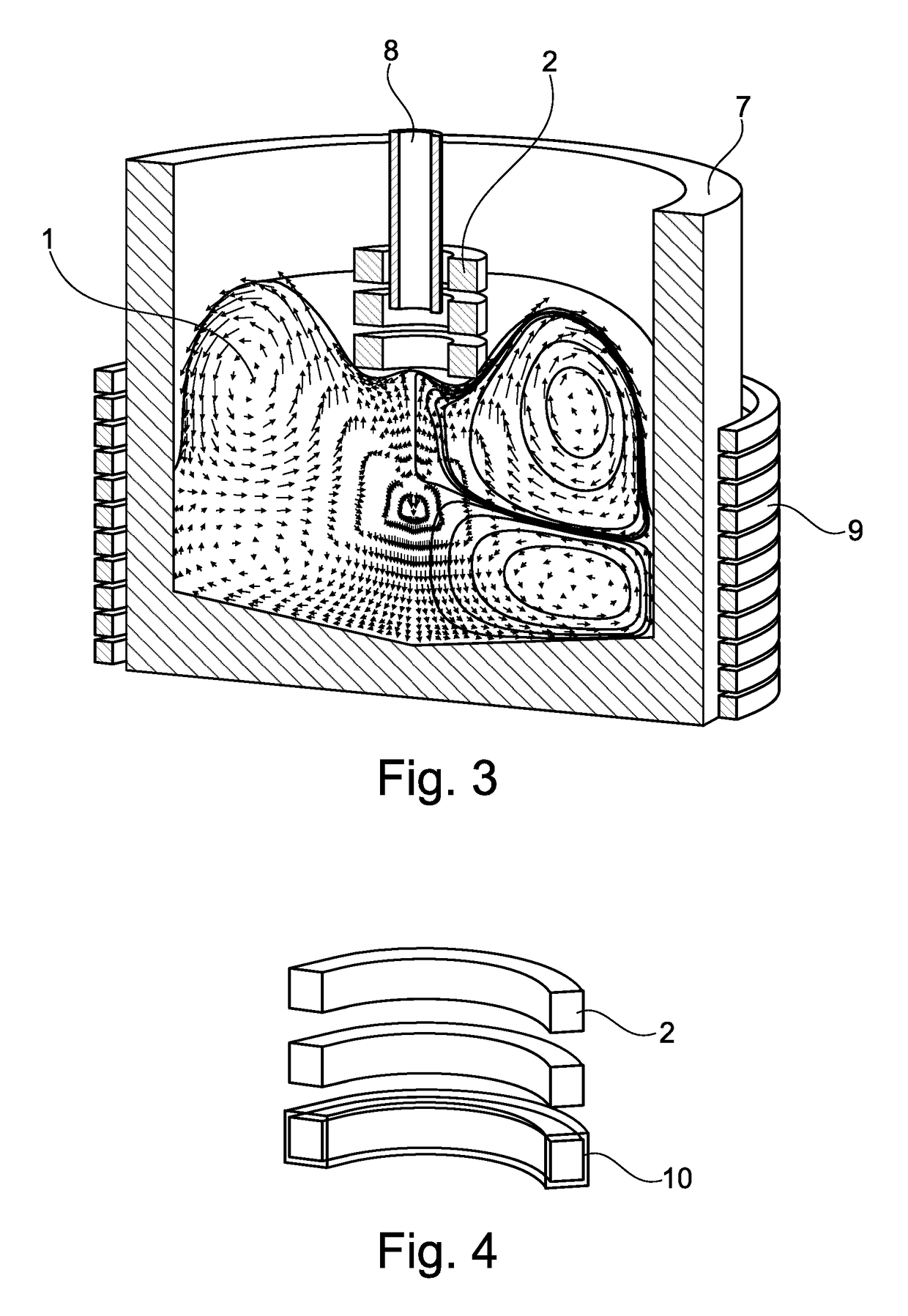

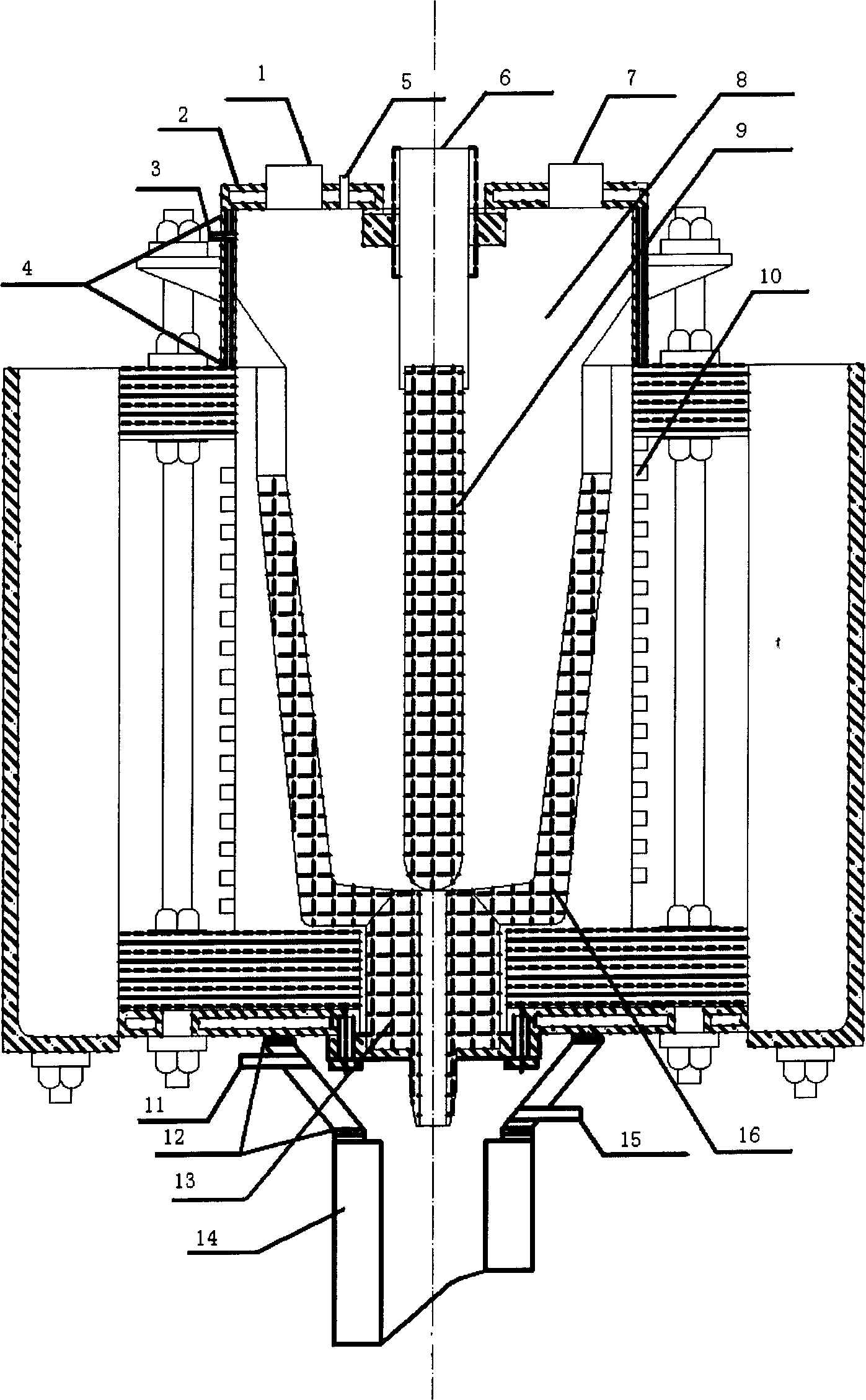

Apparatus for the process of melting and purification of aluminum, copper, brass, lead and bronze alloys

InactiveUS6010552AReduce riskReduced effectivenessTransportation and packagingMixersFiltrationElectromagnetic induction

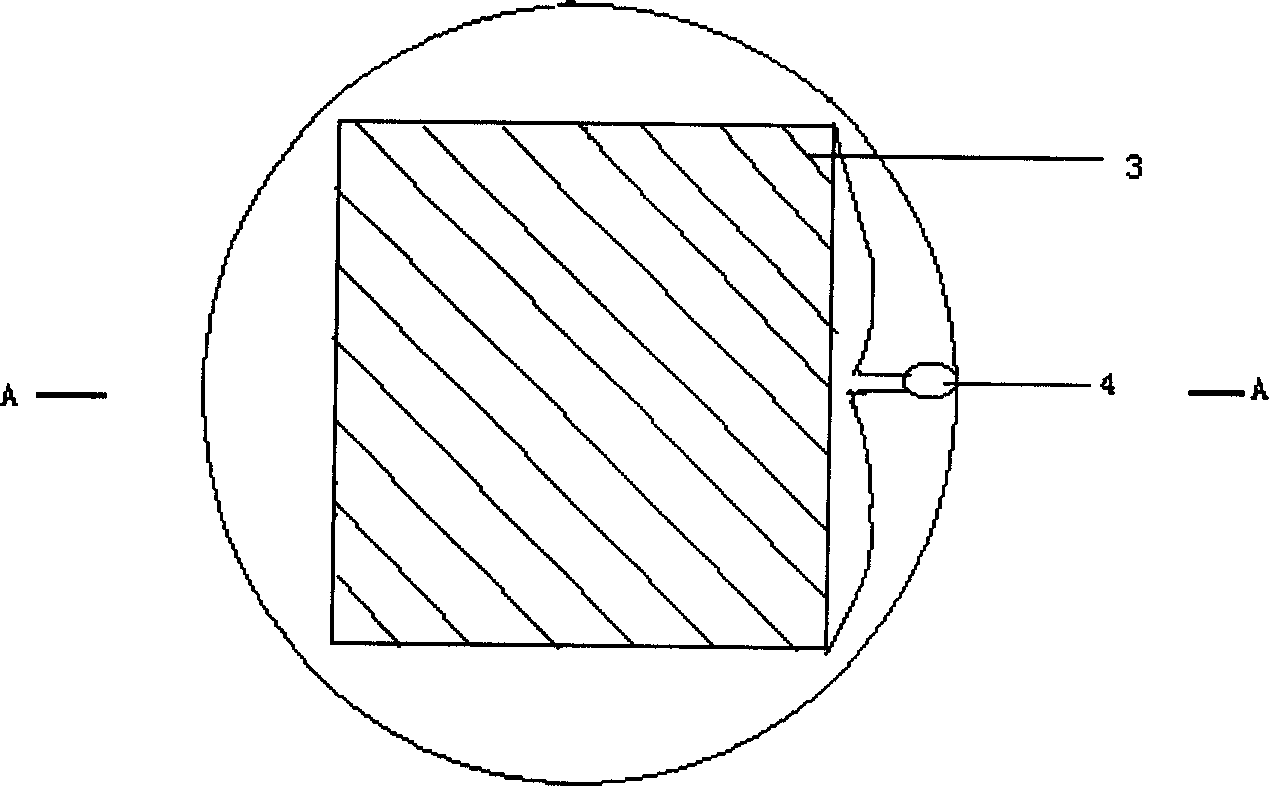

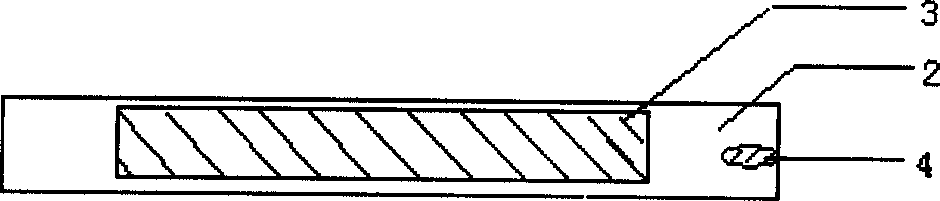

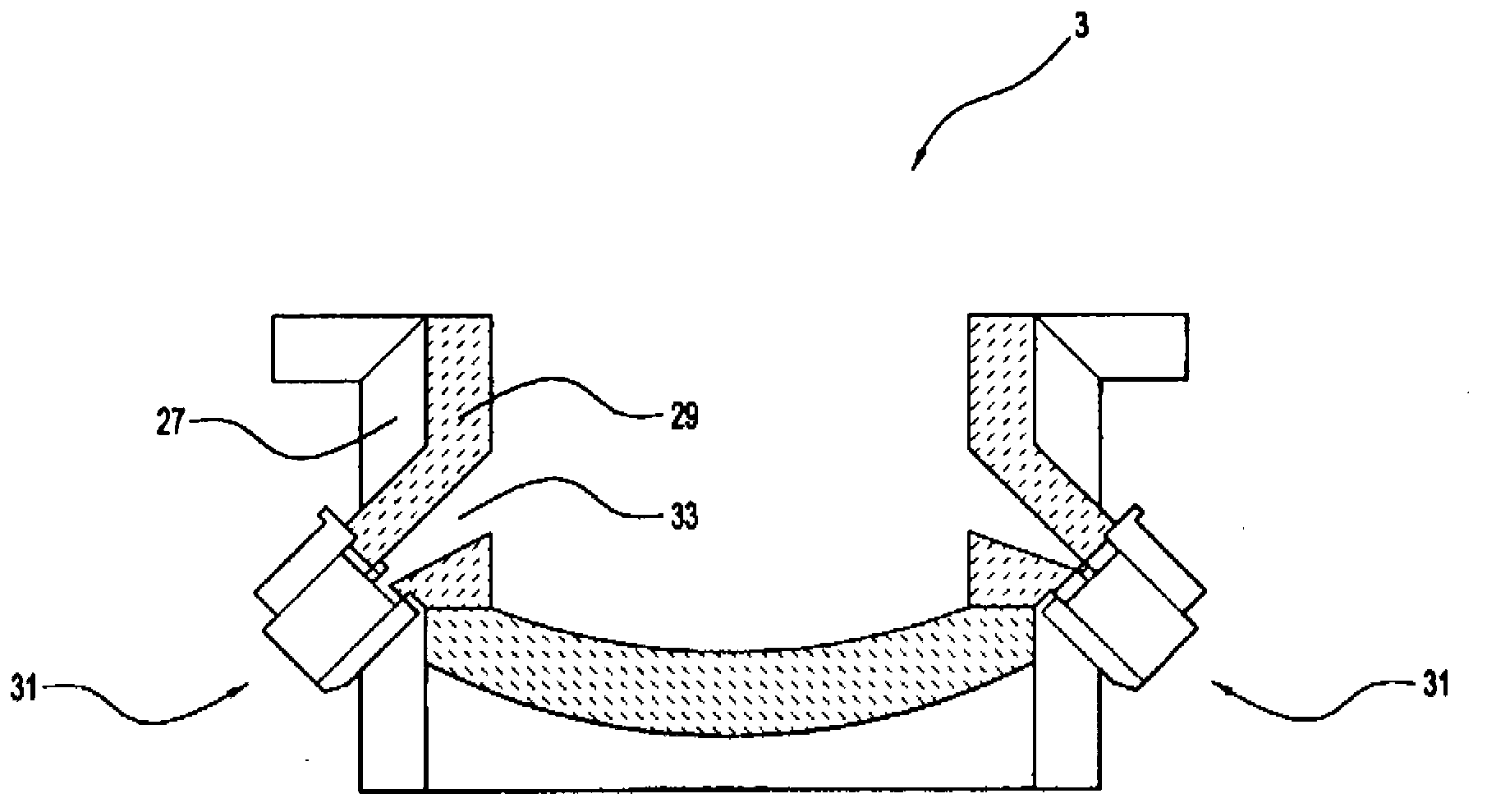

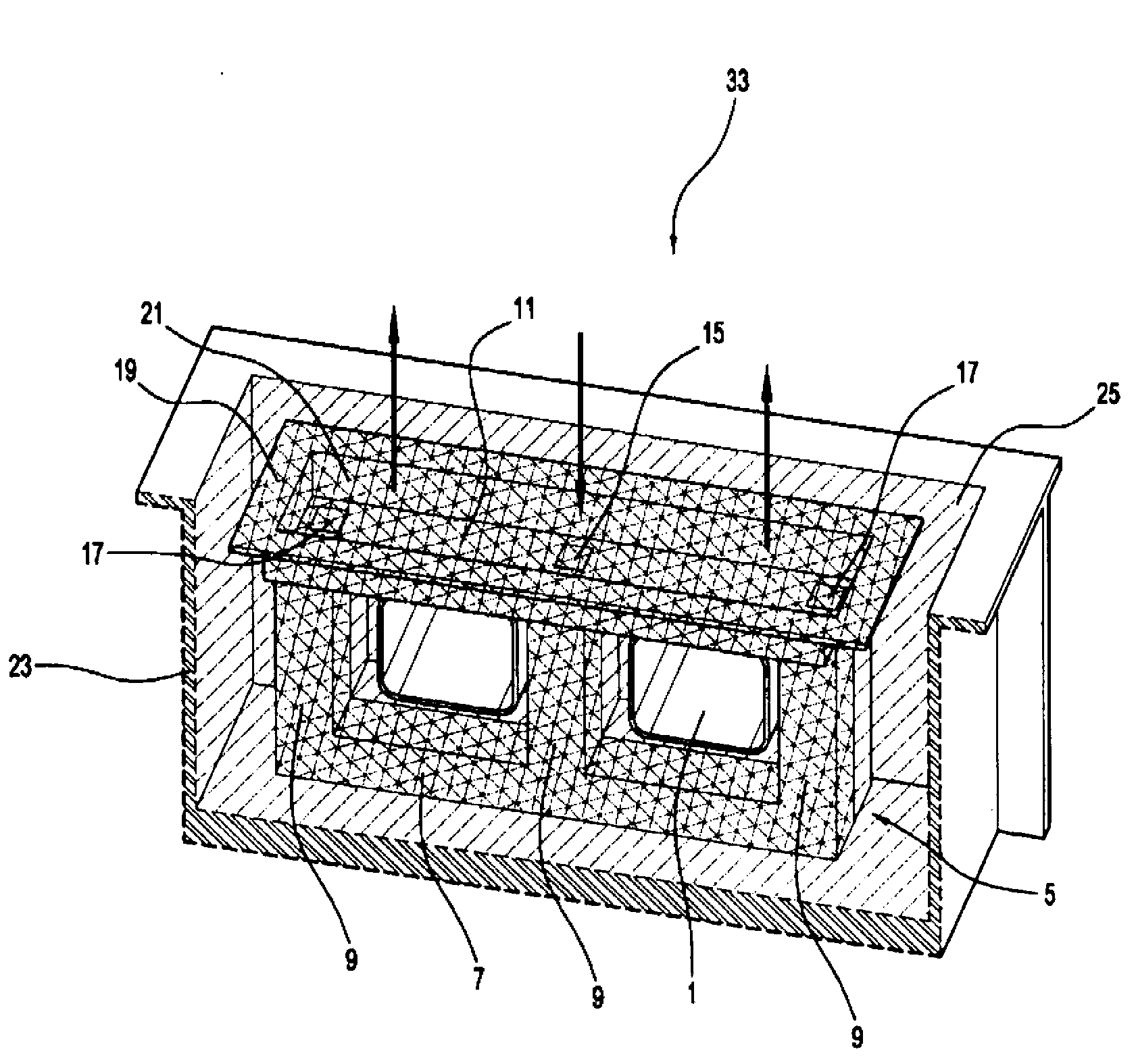

The present apparatus is comprised by two magnetic induction sets, one for melting of the raw material and the second for purification of molten metal; each set comprises a pot or crucible (1, 1'), an electromagnetic device, a filter (11) and a power supply; each crucible (1, 1') is surrounded in the lower part by a hollow permanent magnet (3, 3') in which three pairs of electromagnets facing each other are arranged; the process consists of the following stages: a) charging of metallic raw material inside a crucible (1); b) electromagnetic induction heating to melt the metallic raw material (2) inside crucible (1) through a three-phase magnetic system creating a horizontal travelling or pules magnetic field which builds a turbulent flux inside the melt (2'); c) whirling stirring of melt (2') by electromagnetic induction and purification of it via extraction of hydrogen and of non-electroconductive inclusions by coagulation of them in agglomerates; d) discharging of purified melt (2') by a magneto-hydrodynamic pump effect for the next treatment or technological actions such as the continuous or periodical casting through a filter for the mechanical filtration of the agglomerates.

Owner:S E TRI

Preparation method for high-strength high-conductivity copper alloy bar

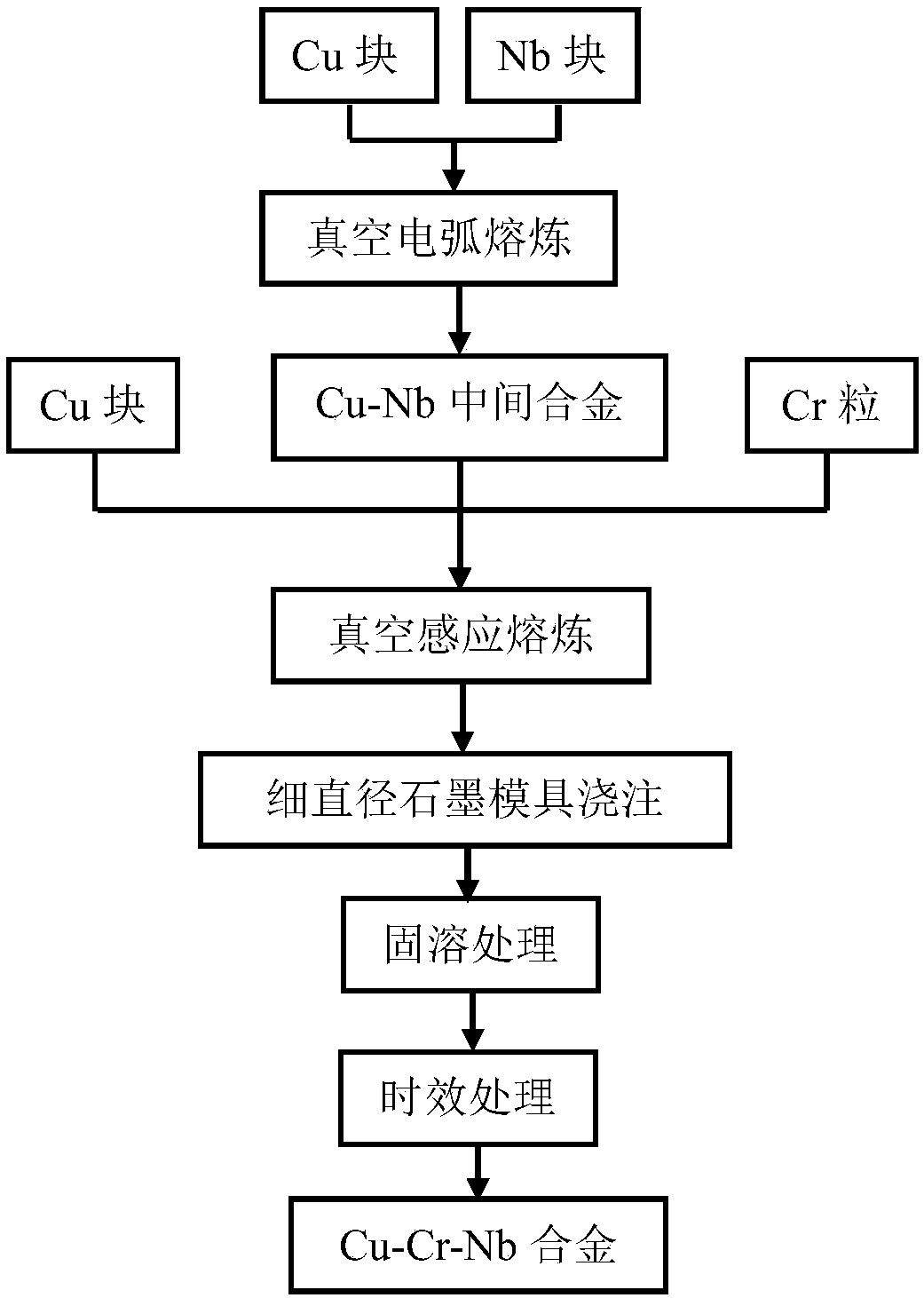

The invention discloses a preparation method for a high-strength high-conductivity copper alloy bar. The preparation method comprises the following concrete steps: placing Cu-Nb intermediate alloy, Crparticles and Cu blocks in a crucible, and carrying out melting in an induction melting furnace protected by argon so as to obtain Cu-Cr-Nb alloy liquid; subjecting the Cu-Cr-Nb alloy liquid to casting and cooling in a fine-diameter graphite mold so as to obtain a Cu-Cr-Nb alloy bar; and putting the bar into a heat treatment furnace for solutionizing and aging heat treatment, and carrying out mechanical processing so as to obtain the finished Cu-Cr-Nb alloy bar. According to the invention, the Cu-Cr-Nb alloy is prepared by using a fine-diameter graphite mold casting and cooling method, so thecooling rate of the alloy is improved, the structure of the alloy is refined, and the solid solubility of elemental Cr and Nb in a Cu substrate is greatly improved; and through the aging treatment, dispersed fine second-phase particles are precipitated from the copper substrate, so the performance of the alloy is improved.

Owner:XIAN UNIV OF TECH

Silver-copper-tin alloy, silver-copper-tin alloy brazing wire and preparation method for same

ActiveCN103567657ALower melting temperatureAvoid failureWelding/cutting media/materialsSoldering mediaCunifeIngot

The invention provides silver-copper-tin alloy, a silver-copper-tin alloy brazing wire prepared by using the silver-copper-tin alloy and a preparation method for the silver-copper-tin alloy brazing wire. The silver-copper-tin alloy consists of the following ingredients in percent by weight: 25-35wt% of copper, 5-18wt% of tin and the balance silver. The silver-copper-tin alloy brazing wire is excellent in welding performance, and is an important intermediate-temperature brazing wire for an electric vacuum device; and the problem that an electronic device is failed due to over high brazing temperature is effectively solved. The preparation method comprises the following steps of selecting high-purity silver, oxygen-free copper and high-purity tin; calculating the required quantities of the high-purity silver, the oxygen-free copper and the high-purity tin according to a matching range; preparing materials; placing matched furnace materials in a crucible of a double-vacuum continuous casting machine; refining the furnace materials after the furnace materials are totally melted; regulating the temperature to 730-760 DEG C; beginning to perform casting at the speed of 1.5mm / s after standing for a moment; stopping 2 seconds after performing casting for 1 second; performing multi-pass rotary swaging and online annealing on cast ingots; enabling the diameters of the cast ingots to be reduced to 3.4 mm from 8mm by rotary swaging; and performing wiredrawing, vacuum annealing, peeling treatment and cleaning so as to obtain a threadlike finished product with the diameter of 0.5mm. The preparation method is simple; and the problem that the silver-copper-tin alloy is quite easy to oxidize in a machining and forming process is solved.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

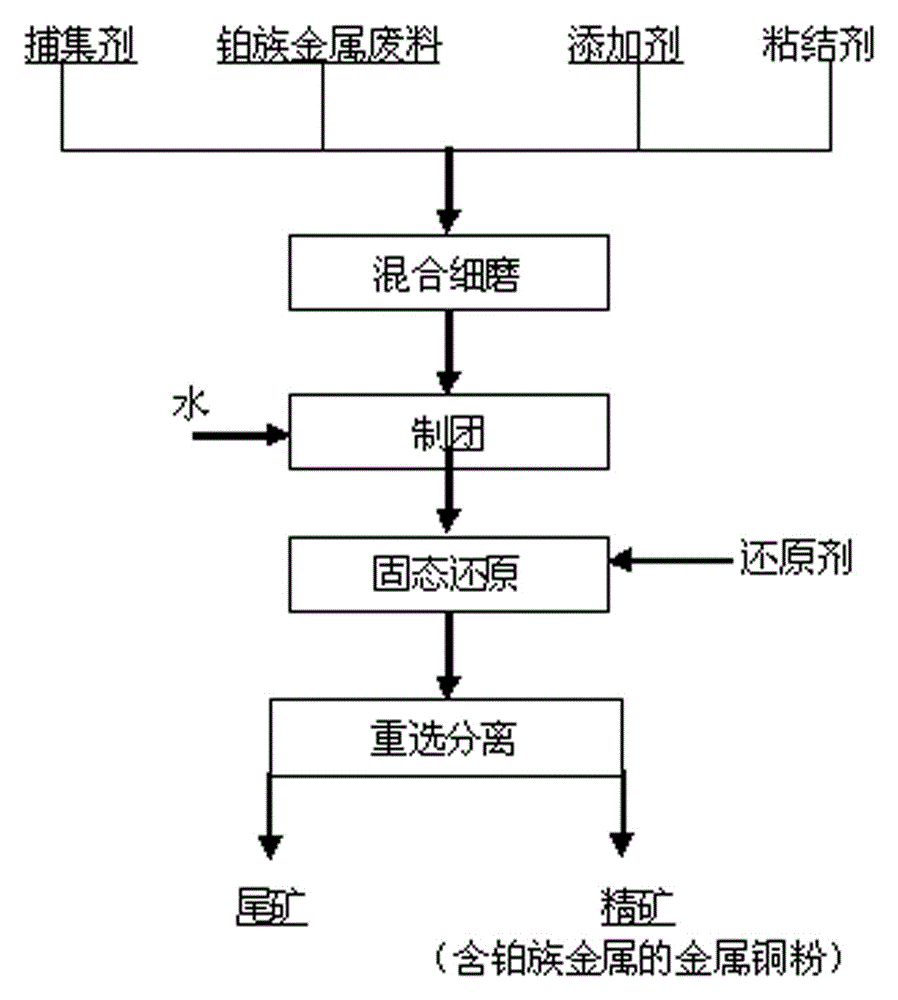

Method of recovering platinum group metals based on copper capture

InactiveCN104988314AEfficient recyclingHigh recovery rateProcess efficiency improvementPetrochemicalMetal recycling

The invention discloses a method of recovering platinum group metals based on copper capture. The method comprises the steps that platinum group metal contained waste is proportionally mixed with a copper capturing agent, an additive and a binding agent, and is subjected to fine grinding and then water adding to be pelletized, dried, placed in a crucible, and reduced at a certain temperature after certain reducing coal is added; metallized pellets obtained by reduction are broken, and the broken metalized pellets are subjected to ball milling and then gravity separation; and obtained ore concentrate is metal copper powder containing the platinum group metals, thereby realizing the recovery of the platinum group metals. The method is simple in technological process; and the reduction temperature is low; used equipment is conventional metallurgy and ore-dressing equipment, so that the method is easy to implement; a recovery rate of the platinum group metals is greater than 99%; the content of the platinum group metals in gravitation separation tailings is less than 10g / t; with the adoption of the method, the platinum group metals can be effectively recovered from spent auto-catalysts, catalysts for petrochemical industry and catalysts for fine chemicals; no harmful gas is discharged; the tailings can serve as raw building materials; and the whole process is clean and pollution-free.

Owner:KUNMING INST OF PRECIOUS METALS

Rare earth magnesium-alloy material for 3D printing and preparation method of same

ActiveCN104762541AImprove flame retardant performanceMicrostructureAdditive manufacturing apparatusRare-earth elementSlag

The invention belongs to the technical field of 3D printing materials and discloses a rare earth magnesium-alloy material for 3D printing and a preparation method of the same. The preparation method particularly comprises following steps: (1) weighing raw materials according to element mass ratio of Mg:Mn:Re being 85-97:2-10:1-5; (2) adding pure magnesium, pure manganese and magnesium alloy into a pre-heated crucible, adding a cover agent and smelting the mixture under atmospheric conditions; (3) after the mixture smelted completely, adding an Mg-Re intermediate alloy and pure rare earth elements, melting the components with stirring uniformly and increasing the temperature to 700-750 DEG C; (4) adding a refining agent for refining the alloy for 2-25 min, allowing the refined alloy to stand, removing floated slag, adding the refined alloy into a sand mould trough to obtain a rare earth magnesium alloy base metal; and (5) smelting and atomizing the base metal to obtain the rare earth magnesium-alloy material. The rare earth magnesium-alloy material is excellent in flame retarding performance, is easy to control in powder shape and particle size, can be smelted without protective gas so that a problem of flammability during preparation of the magnesium alloy powder through an atomization method is solved, and can be used for laser 3D printing.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

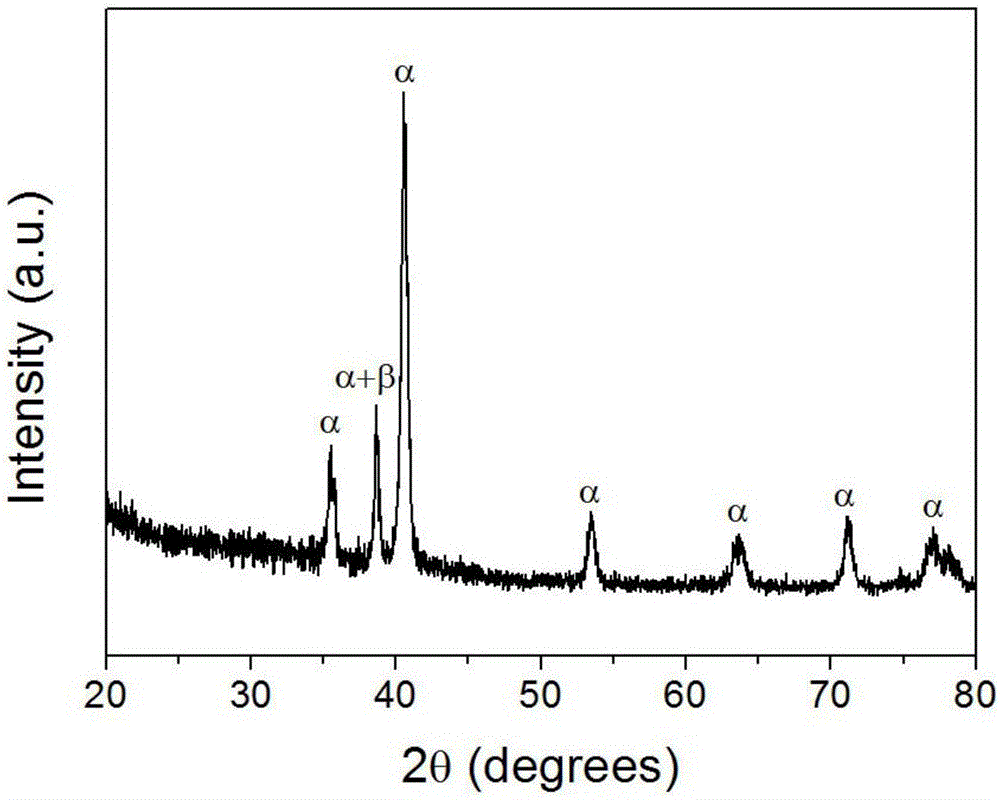

Low-cost high-strength alpha+beta titanium alloy and preparation method thereof

The invention provides low-cost high-strength alpha+beta titanium alloy. The titanium alloy takes titanium as a main body element, and takes alpha stable elements, namely, Al and B, and beta stable element, namely, Fe, as alloy elements; and the titanium alloy is prepared from the following components in percentage by weight: 2.5 to 4.5 percent of Al, 2.5 to 4 percent of Fe, 0.05 to 0.2 percent ofB, and the balance of titanium and unavoidable impurities. The invention also provides a preparation method of the low-cost high-strength alpha+beta titanium alloy; the preparation method comprises the following steps: adding raw materials into a water-cooled crucible suspension melting furnace into which argon gas is introduced according to a designed proportion alloy component proportion; obtaining an ingot casting after repeated melting; cogging and forging above a phase transition point; sampling a forged alloy and performing heat treatment; and finally, characterizing tissue structures and performance. The prepared titanium alloy is uniform in alloy components and fine in tissues; the tensile strength is greater than or equal to 1,000 MPa, and the plastic elongation percentage is greater than or equal to 15 percent; and the alloy has the advantages of low cost and high strength, and can replace part expensive titanium alloys in certain fields.

Owner:NANJING UNIV OF TECH

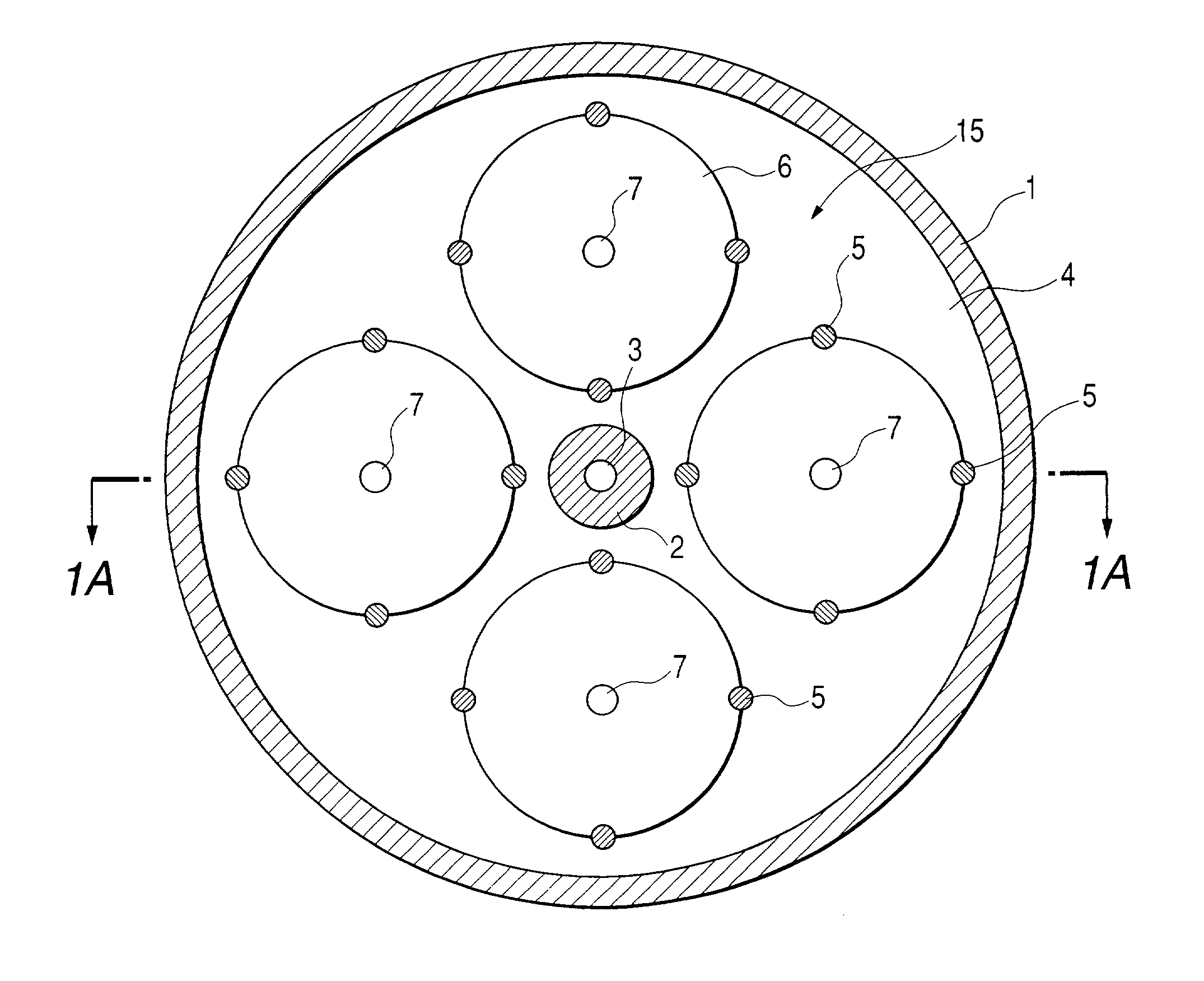

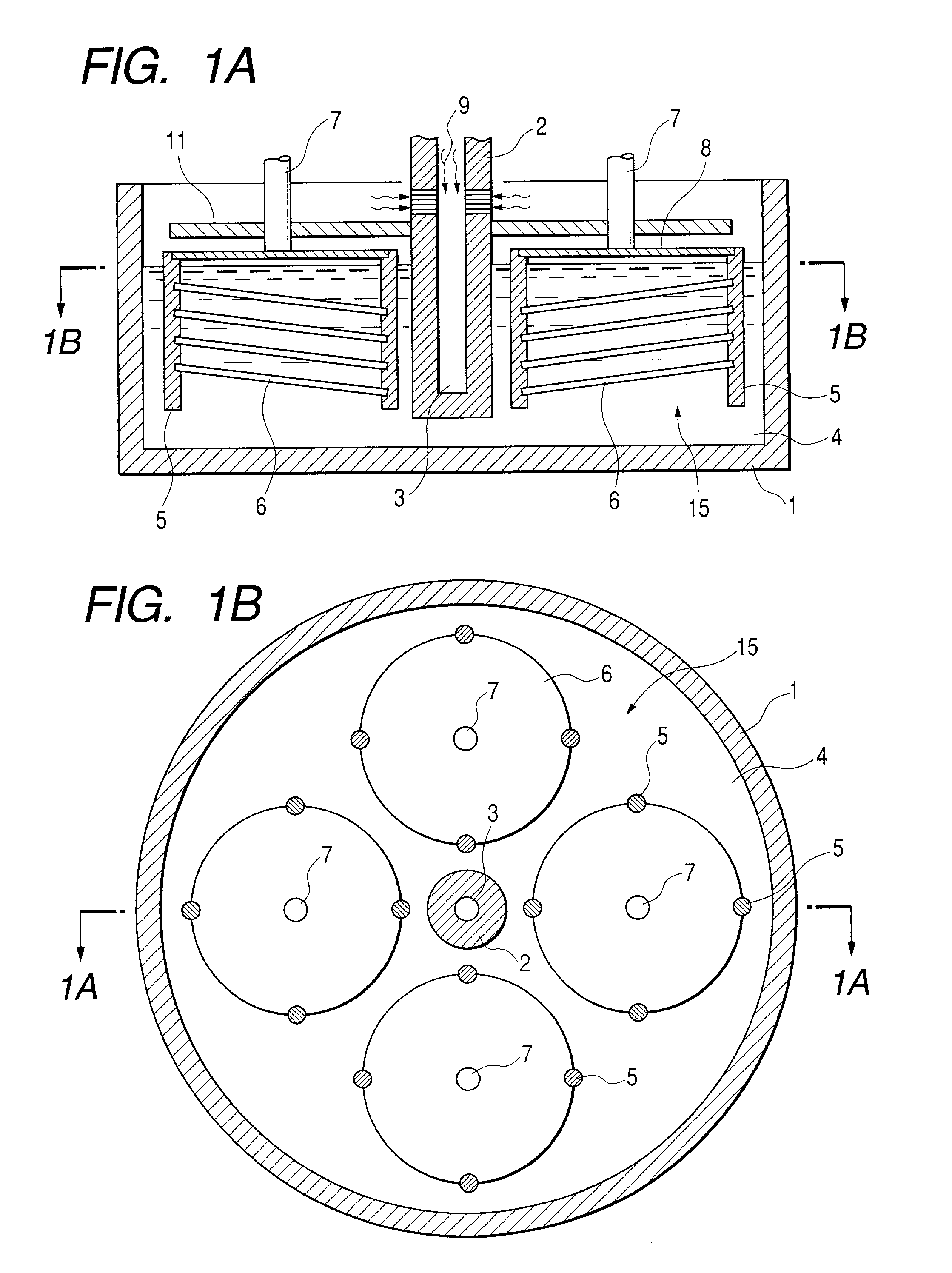

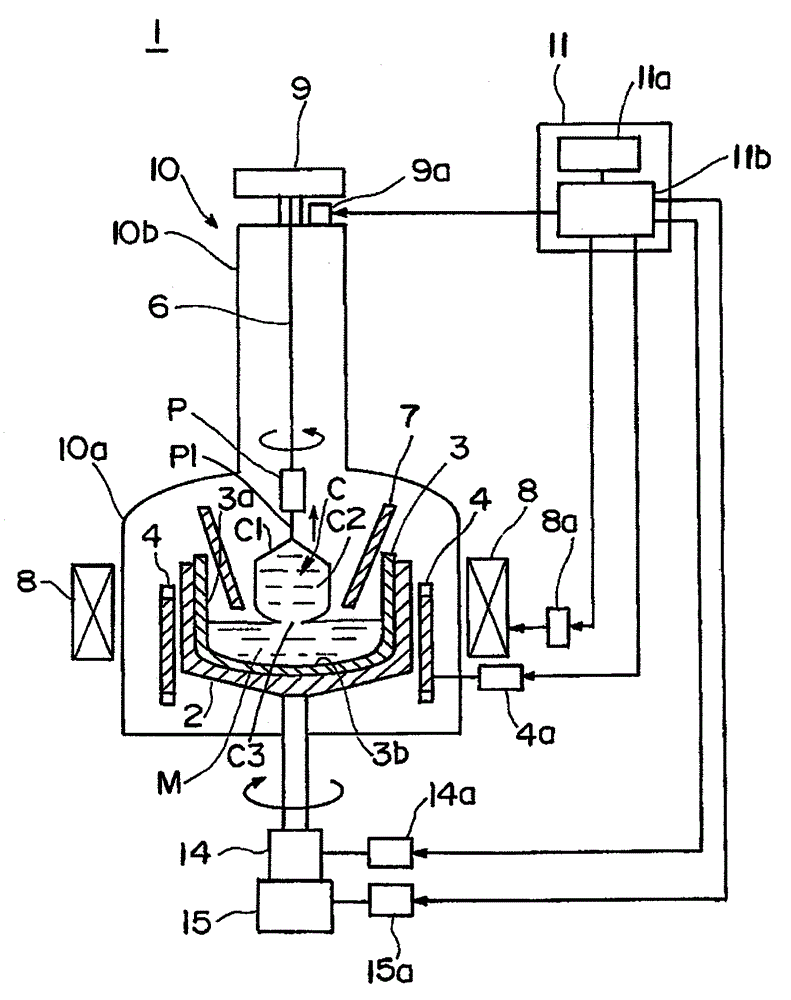

Liquid phase growth methods and liquid phase growth apparatus

InactiveUS20020108559A1Polycrystalline material growthLiquid-phase epitaxial-layer growthCunifeTemperature difference

Provided are a liquid phase growth method including a step of immersing a substrate in a crucible storing a solvent having a growth material dissolved therein; and a step of cooling the solvent from an interior thereof, and a liquid phase growth apparatus for use in the method, by which a temperature difference of a solution is decreased and by which a deposited film is formed in a uniform thickness.

Owner:CANON KK

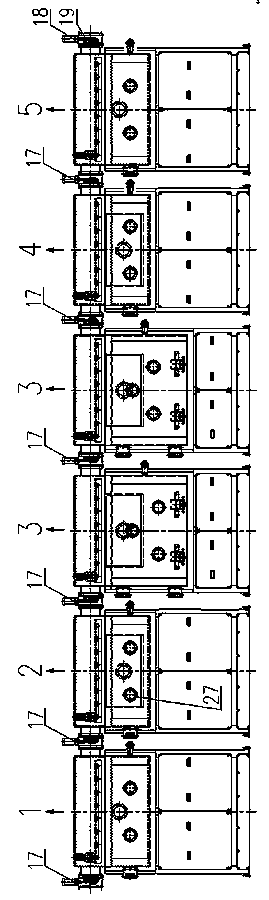

Large solar thin film battery piece assembly production process and equipment

InactiveCN103560169AFlexible controlGuaranteed cleanlinessFinal product manufacturePhotovoltaic energy generationAluminum doped zinc oxideEngineering

The invention discloses a large solar thin film battery piece assembly production process and equipment. The process includes the steps of thin film layer manufacturing, line marking, junction, piece compositing, solidification through an autoclave and the like. Under high vacuum or ultrahigh vacuum environment, copper indium gallium selenide (CIGS) is manufactured through electron beam evaporation, an ion source and a correction plate device so as to manufacture a solar thin film battery piece assembly. According to the method, the non-reactive ion source is used, inert gas is added into the vacuum environment to serve as working gas, and the electron beam evaporation mode of vacuum deposition is used for manufacturing a large-area battery piece. A multi-position crucible is used for carrying out time-sharing one-time vacuum evaporation of cadmium sulfide (CdS) or zinc sulfide (ZnS) on a buffering layer and intrinsic zinc oxide (i-ZnO) of a window layer and aluminum-doped zinc oxide (AZO) on a battery substrate to manufacture a copper indium gallium selenide (CIGS) thin film solar battery.

Owner:JINAN JINGLI NEW ENERGY TECH

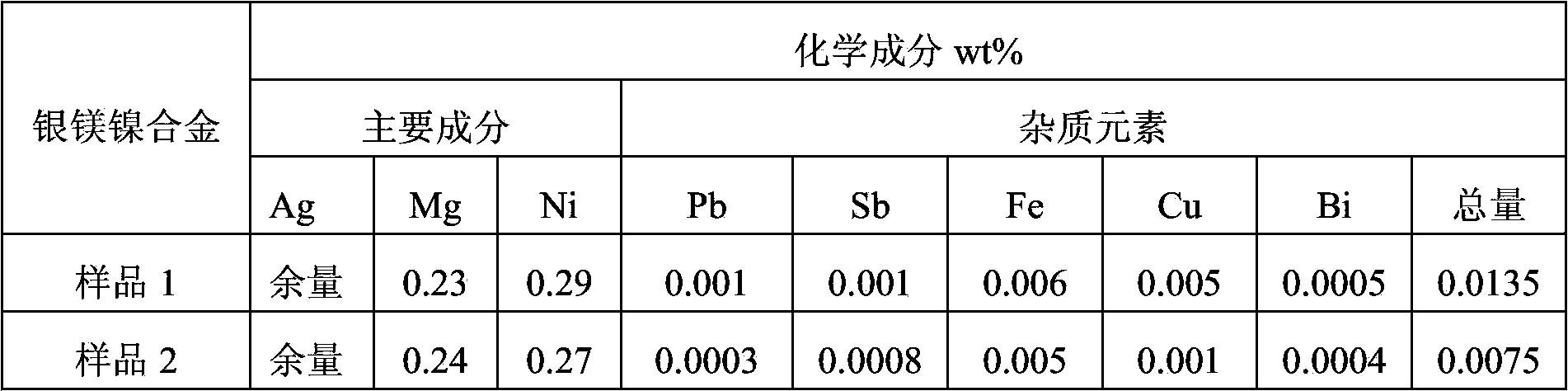

Silver-magnesium-nickel friction ring manufacturing method

The invention provides a silver-magnesium-nickel friction ring manufacturing method. The method includes the following steps: cleaning the furnace wall of a vacuum intermediate-frequency sensing furnace and raw materials; subjecting the raw materials to smashing and degassing; smelting under the condition of 5-10Pa in vacuum degree to obtain silver-nickel intermediate alloy; using a silver piece to coat magnesium, using a silver wire to bind the silver-nickel intermediate alloy at the upper end of a crucible, and smelting to obtain silver-magnesium-nickel alloy ingots; using a dilute sulfuric acid solution to remove an oxidation film on the surface of each ingot, processing the ingots whose ingredients, interiors and surfaces are all qualified, using a hydraulic press to flattening a plate after being rolled and cogged, and performing cold forging or hot forging on a bar for many times to enable the bar to meet hardness requirements; adopting wire-electrode cutting and a milling machine to process the plate and the bar into blank rings respectively, using a turning lathe to process the blank rings to be in the size of finished products, and adopting ultrasonic waves and X-ray lossless detection to perform product interior quality detection. A silver-magnesium-nickel friction ring obtained by the method is smooth and flat in surface and free of defects like cracking, peeling and corrosion discoloring.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Biodegradable metal alloys

The invention relates to biodegradable, metal alloy-containing compositions, methods for their preparation and applications for their use. The compositions include magnesium and other components, such as yttrium, calcium, silver, cerium, and zirconium; or zinc, silver, cerium, and zirconium; or aluminum, zinc, calcium, manganese, silver, yttrium; or strontium, calcium, zinc. The compositions are prepared by vacuum induction / crucible melting together the components and casting the melted mixture in a preheated mild steel / copper mold. In certain embodiments, the compositions of the invention are particularly useful for forming medical devices for implantation into a body of a patient.

Owner:UNIVERSITY OF PITTSBURGH

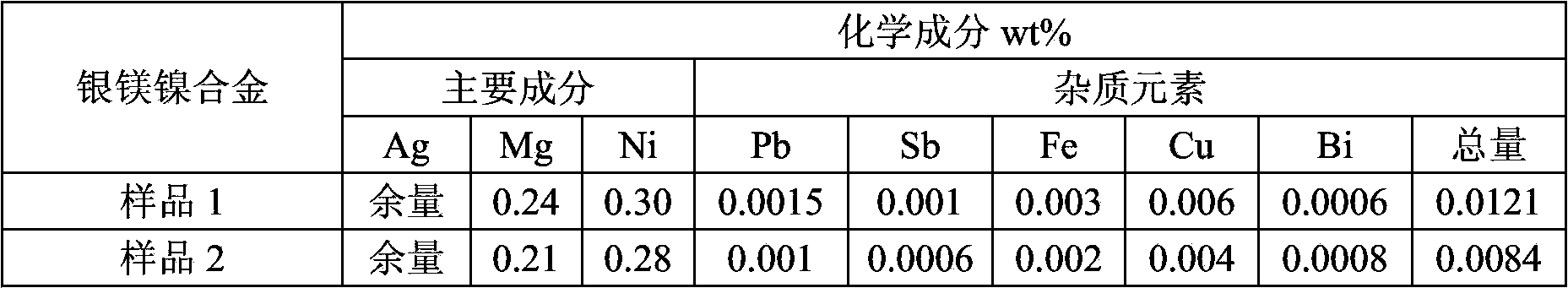

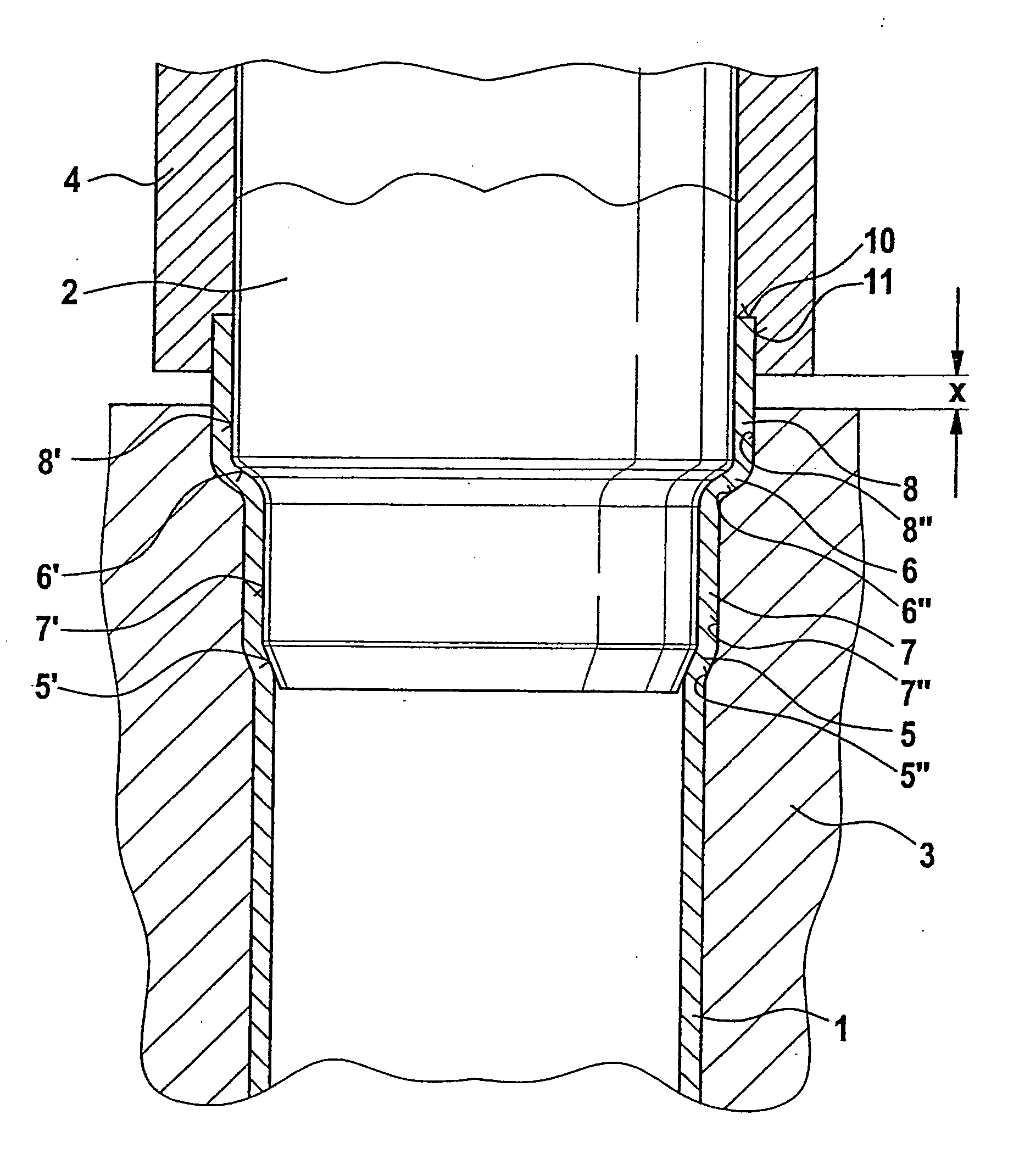

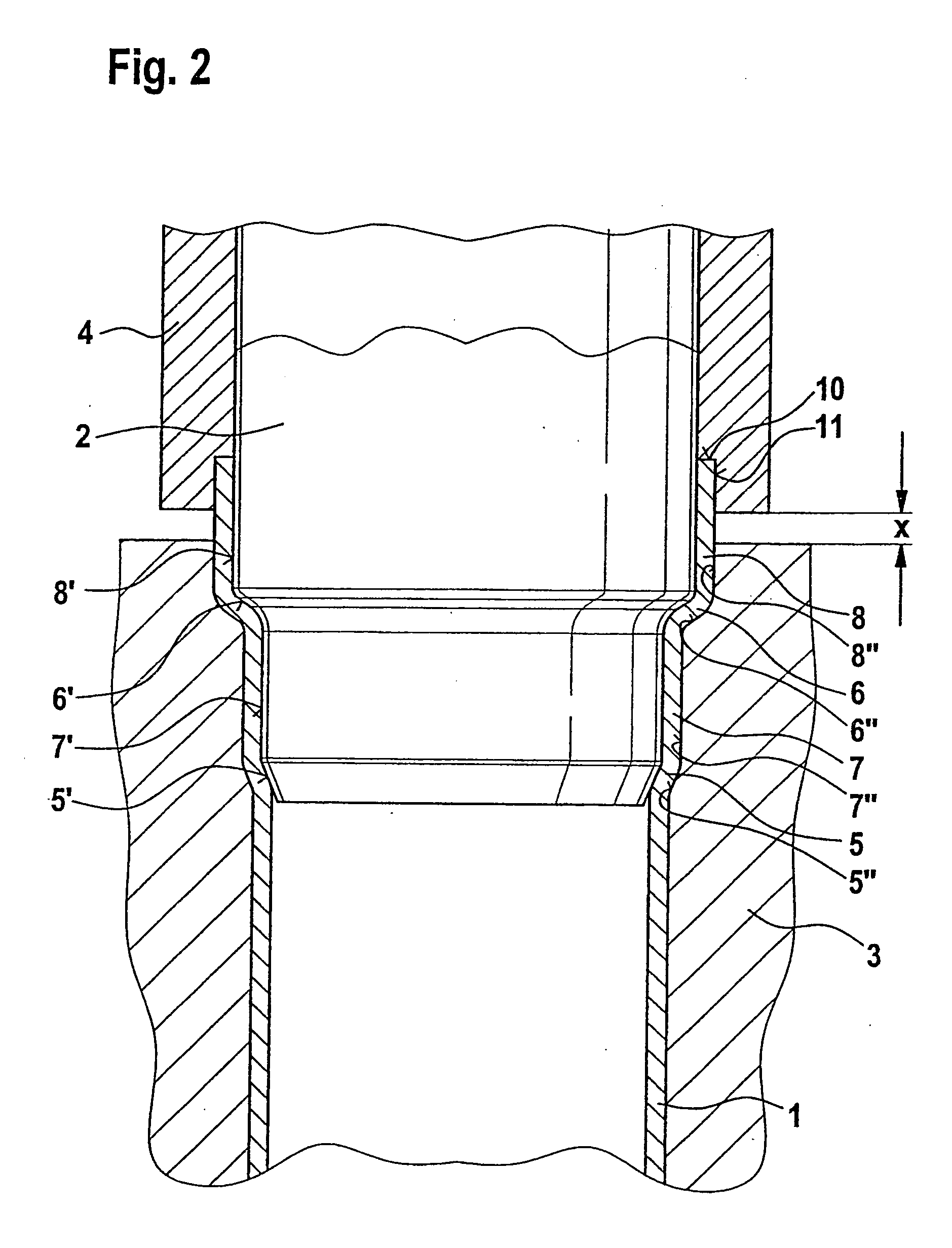

Method for Producing a Coupling on a Pipe and Device for Producing Said Coupling

In a method for producing a coupling on a pipe, preferably consisting of copper or steel or Cu-, Ni-, Fe-alloys, by way of a preferably graduated or one-stage expansion of the pipe end to create a much larger difference in diameter, an expansion tool is introduced axially into the end of the pipe. Once the expansion tool has been introduced into the pipe end, the region of the pipe end that is to be or has been expanded is completely or partially compressed, by a force acting axially on the pipe end, so that the external diameter of the pipe end that is to be processed is delimited by one or more shaping jaws that completely or partially surround the pipe end. The invention also relates to a device for producing a coupling on a pipe end according to the method.

Owner:FFG WERKE +1

Biodegradable metal alloys

The invention relates to biodegradable, metal alloy-containing compositions, methods for their preparation and applications for their use. The compositions include magnesium and other components, such as yttrium, calcium, silver, cerium, and zirconium; or zinc, silver, cerium, and zirconium; or aluminum, zinc, calcium, manganese, silver, yttrium; or strontium, calcium, zinc. The compositions are prepared by vacuum induction / crucible melting together the components and casting the melted mixture in a preheated mild steel / copper mold. In certain embodiments, the compositions of the invention are particularly useful for forming medical devices for implantation into a body of a patient.

Owner:UNIVERSITY OF PITTSBURGH

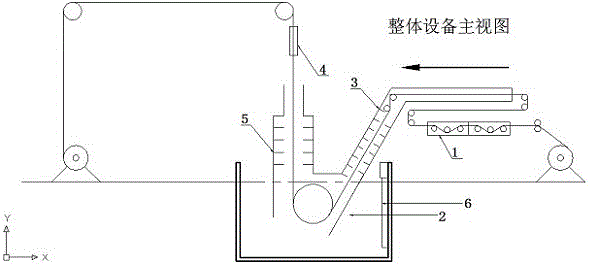

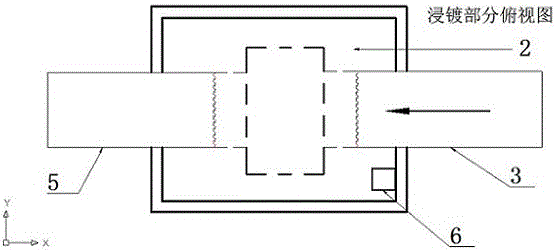

Hot-dipping technological method and device for preparing component gradient alloy material

ActiveCN105839041AImprove efficiencyLow costHot-dipping/immersion processesAlloy coatingLiquid alloy

The invention relates to a hot-dipping technological method and device for preparing a component gradient alloy material. According to the method, the alloy material is directly prepared on the surface of a base material, and the component gradient coating alloy or magnesium alloy is prepared rapidly. The method specifically includes the following steps that (1) a steel (or nickel or copper or other high-melting-point material) wire or band serves as the base material; (2) the alloy is melted in a crucible; (3) after being subjected to surface treatment, the base material penetrates through molten alloy for hot dipping; (4) alloy elements are added to change the components of the molten metal; and (5) the alloy material with the components varying in the motion direction of the base material is obtained. By means of the method, a large number of component gradient alloy coatings within a certain component range can be prepared within a short period, and the prepared finished products can be used as samples for a high-throughput experiment. Compared with other preparation methods for samples of the high-throughput experiment, the method is high in efficiency and low in cost, and the prepared material can be subjected to subsequent machining.

Owner:SHANGHAI UNIV

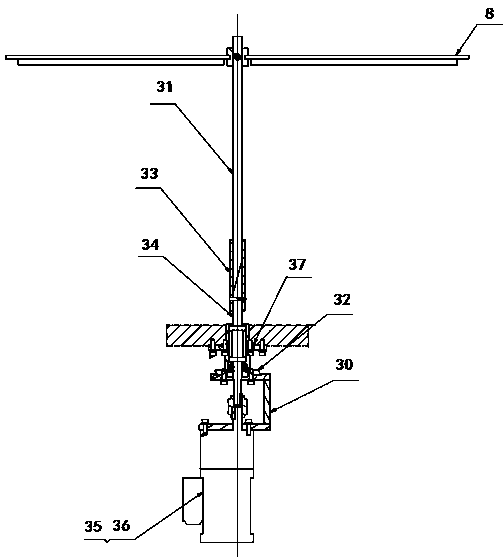

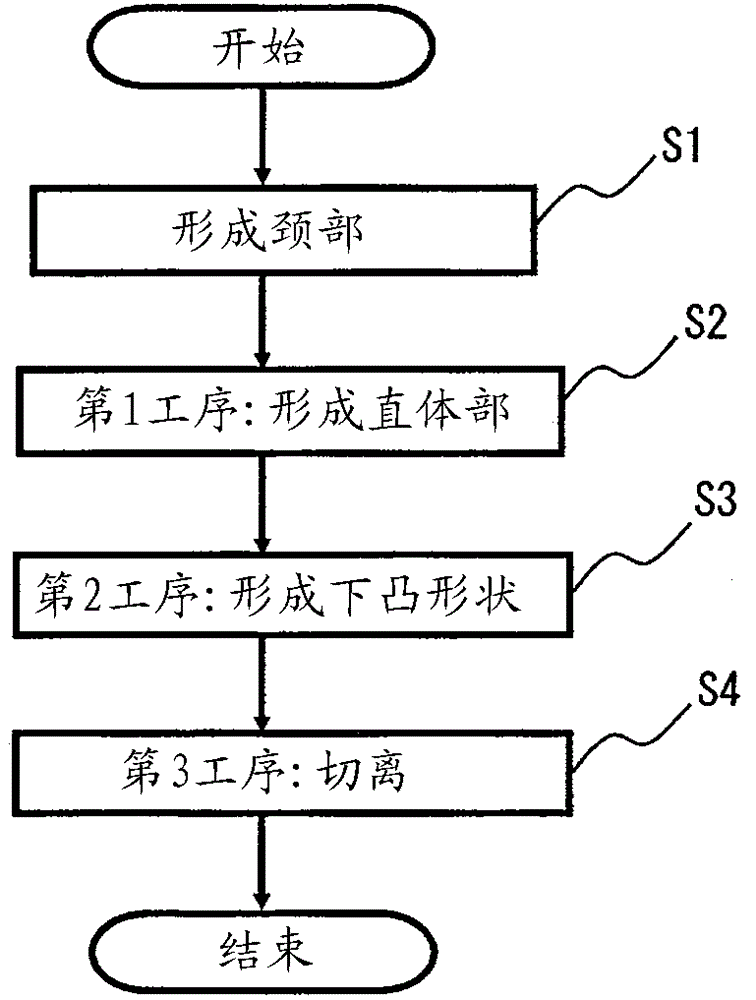

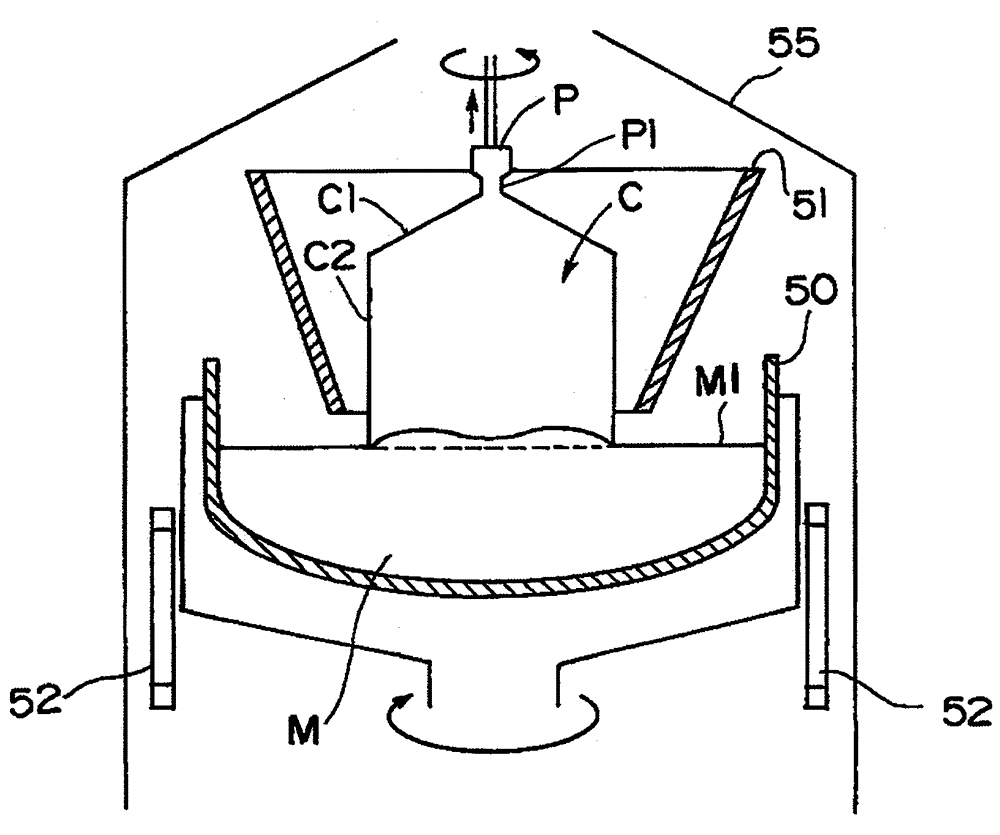

Single crystal extraction method

ActiveCN105040099AReduce extraction timeImprove yieldPolycrystalline material growthBy pulling from meltCrystal rotationCunife

The single crystal extraction method is used for shortening the extraction time from the forming of a straight body part to crystal excision from a meltwater, extracting single crystal and improving a rate of finished products. The method comprises a first process, a second process and a third process. The first process forms the straight body part (C2), and the second process is behind the first process. In the final process of forming the straight body part, a lower protruded shape (C3) protruded downwards is formed at the lower end of the crystal, and the third process is configured to cut the lower protruded shape formed in the second process from the silicon meltwater. In the second process, the field density of the horizontal magnetic field is controlled lower than the first process in the range of 800 to 1000 gausses, the crystal extract speed is controlled lower than the first process in the range of 0.2 to 0.5 mm / min, the crystal rotation speed is controlled lower than the first process in the range of 1 to 3 rpm, and the crucible rotation speed is controlled in the range of 0.5 to 5 rpm.

Owner:GLOBALWAFERS JAPAN

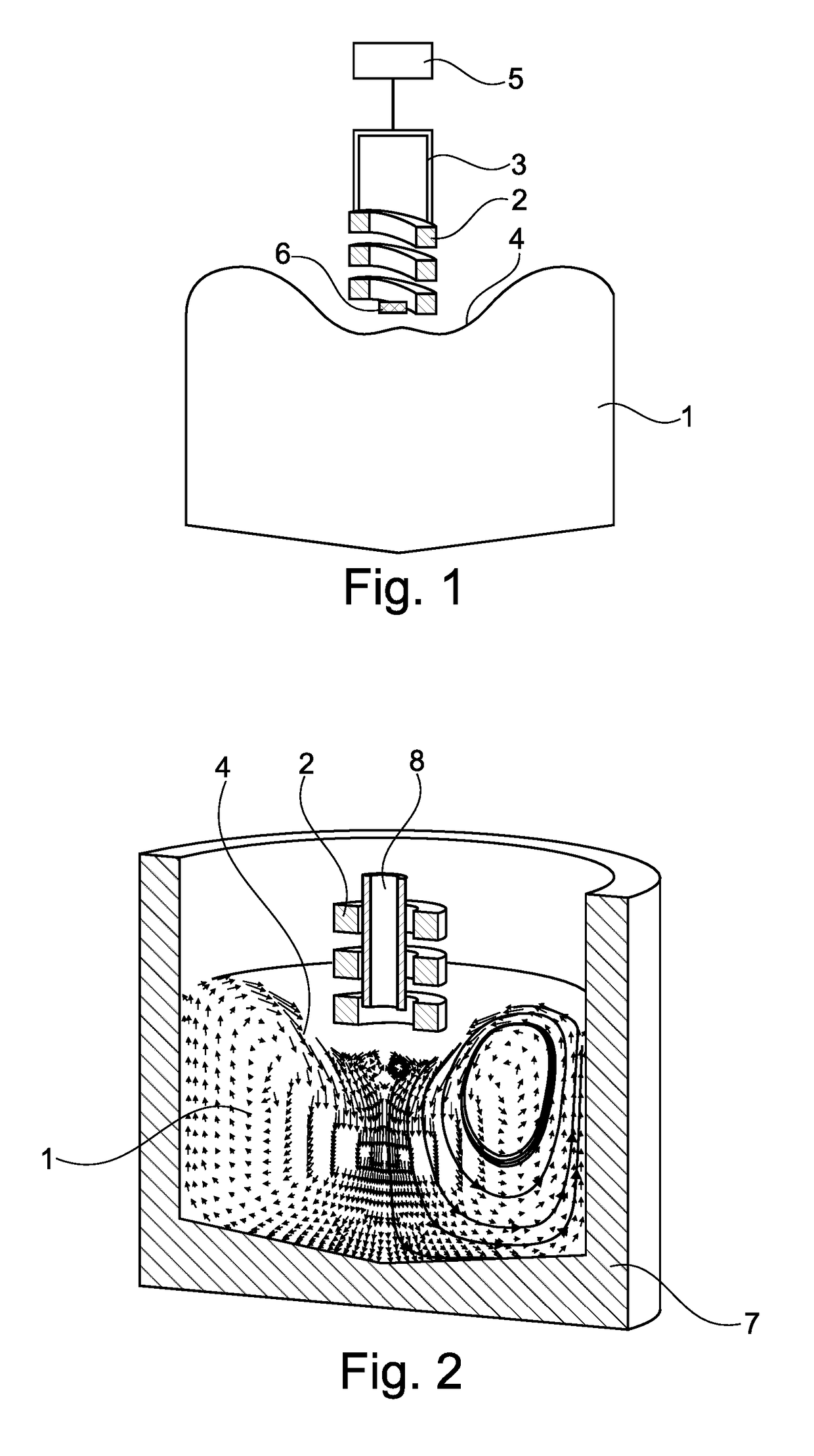

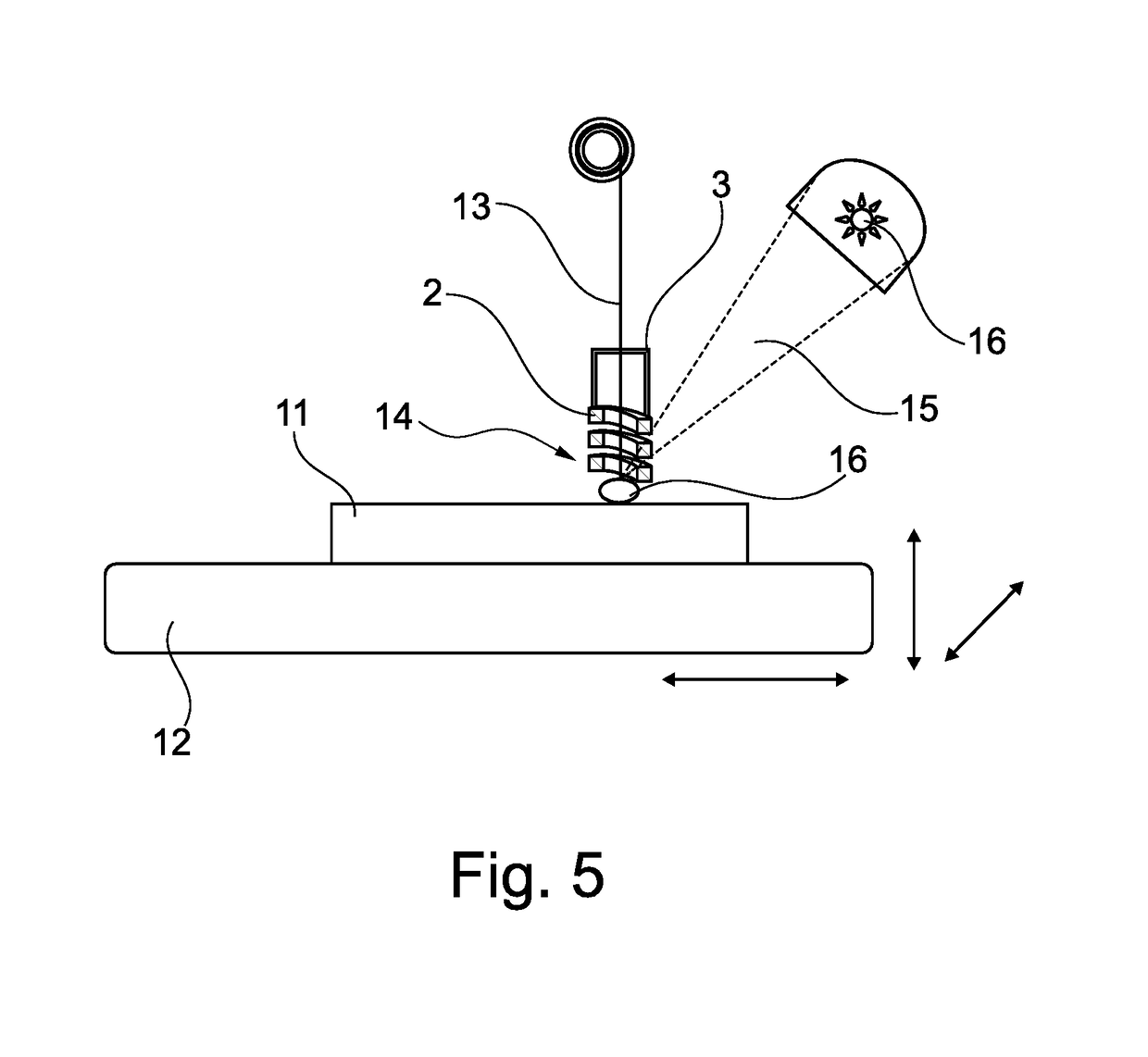

Manufacturing of a metal component or a metal matrix composite component involving contactless induction of high-frequency vibrations

ActiveUS10207321B2Microstructure of a component can more efficiently be controlled and optimisedEvenly distributedMaterial nanotechnologyAdditive manufacturing apparatusMetallurgyMaterials science

The present invention relates to a system for contactless induction of high-frequency vibrations in a volume of molten metal during the manufacturing of a metal component or a metal matrix composite component. The system includes a moveably arranged electromagnetic primary coil, adjustment means for adjusting the position of the primary coil, and a control unit for controlling the position of the primary coil to a predefined distance above, but not in contact with, an upper free surface of the molten metal. The molten metal may be contained in a foundry crucible during manufacturing. The system can be used as an additive manufacturing system, with the primary coil arranged above the melt pool. A secondary low-frequency electromagnetic coil may be arranged around and at a distance from the molten metal to induce flow and / or vibrations in the molten metal.

Owner:EUROPEAN SPACE AGENCY

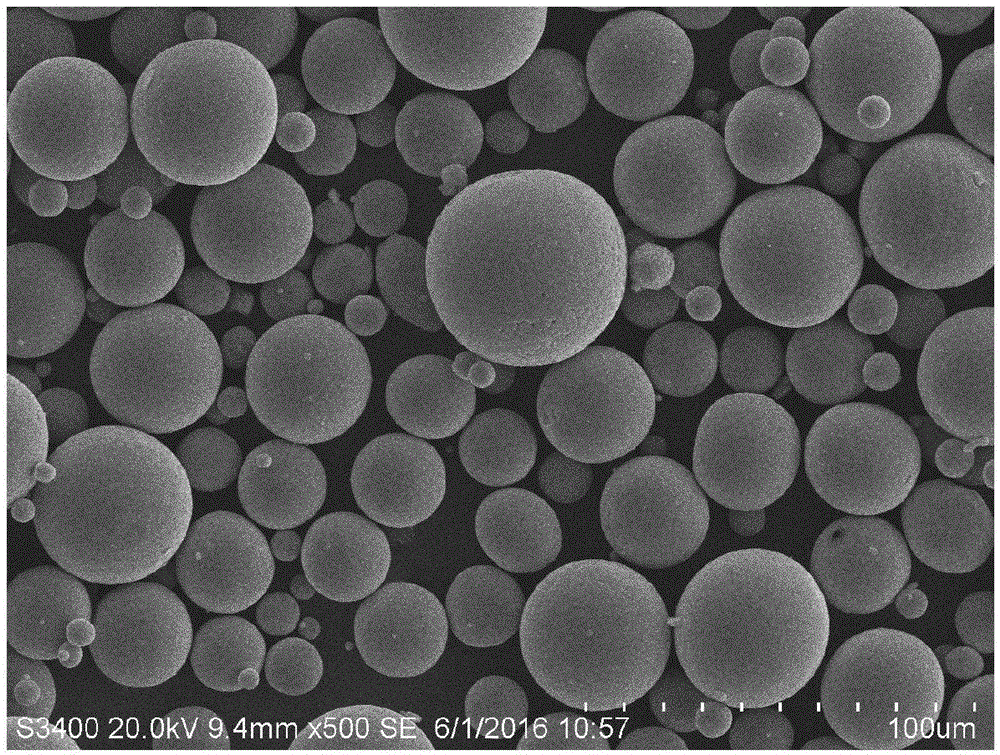

Preparation method of titanium or titanium alloy powder with micro-hydrogenated surface

ActiveCN106623952AReduce the temperatureReduce the rate of hydrogen uptakeAdditive manufacturing apparatusShielding gasTitanium alloy

The invention relates to a preparation method of titanium or titanium alloy powder with micro-hydrogenated surface. The method comprises the following steps: (1) a titanium or titanium alloy bar with low pollution and specific size is prepared in advance; (2) an atomizing unit is pre-vacuumized and then filled with high-purity inert gas as shielding gas; (3) the lower end of the titanium or titanium alloy bar is heated to be melted by an induction coil, and atomized power preparation is performed; (4) titanium or titanium alloy powder obtained after atomization enters a cyclone separator, hydrogen is introduced into the cyclone separator, and low-temperature surface micro-hydrogenation treatment is finished in the cyclone separator; (5) after the powder is cooled completely, the titanium or titanium alloy powder with micro-hydrogenated surface is taken from a powder collecting tank. Aiming at the problem of high probability of oxidation of titanium or titanium alloy powder surface, crucible-free atomization and low-temperature surface micro-hydrogenation are combined, and the titanium or titanium alloy powder with the micro-hydrogenated surface, little pollution and excellent oxidation resistance for 3D printing is prepared.

Owner:NANJING UNIV OF SCI & TECH +3

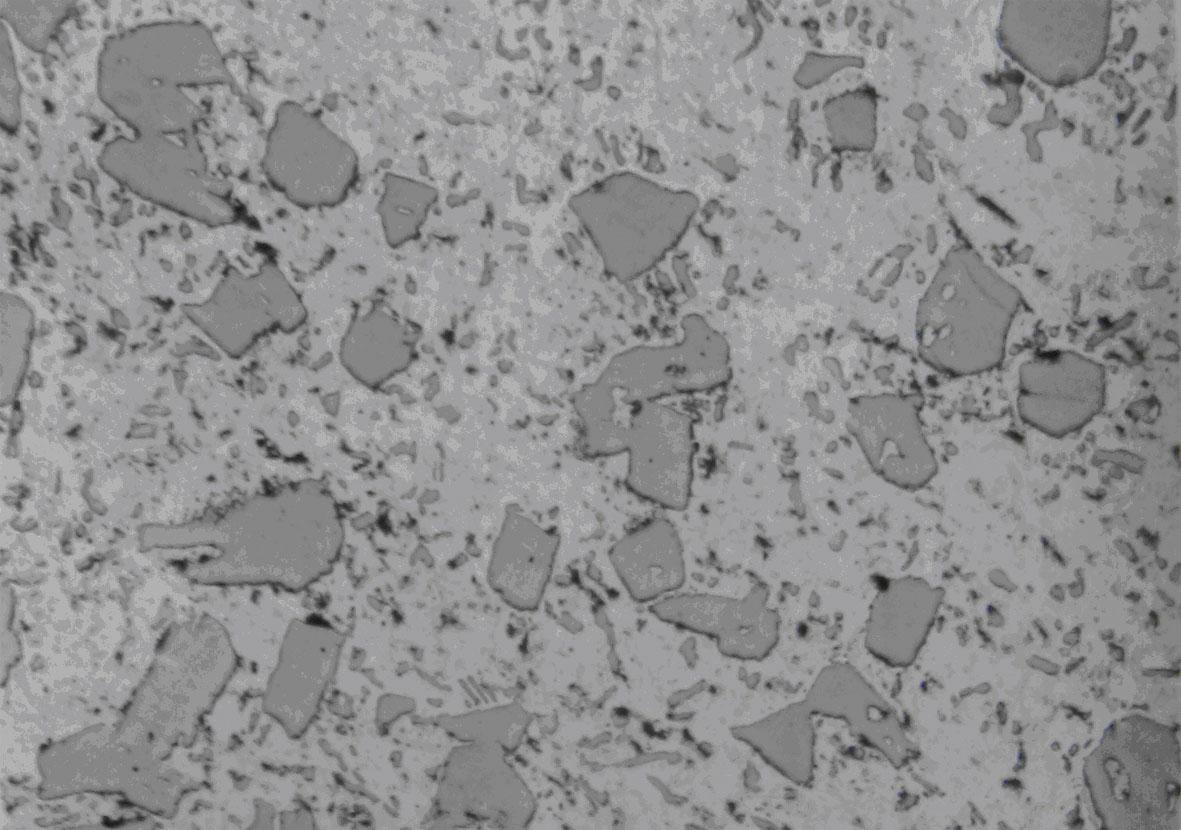

Preparation method of hypereutectic aluminum-silicon alloy casting

The invention discloses a preparation method of a hypereutectic aluminum-silicon alloy casting. The preparation method comprises the following steps of: (1) preheating a crucible, putting AlSi alloy, AlCu alloy and AlNi alloy into the crucible, heating the alloys, and pressing metallic magnesium into the molten materials; (2) pressing inoculant into the alloy melt, stirring the melt uniformly, and then preserving the heat; (3) pressing ZnCl2 into the alloy melt, removing slag after heat preservation and degassing, and casting the melt into a casting blank; and (4) performing heat treatment on the casting blank, and thus obtaining the hypereutectic aluminum-silicon alloy casting. The mechanical property of the product prepared by the method is superior to that of a similar hypereutectic aluminum alloy product; and the method is simple, easy to realize industrialization and low in preparation cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Heatproof magnesium sannum silver alloy and preparation method thereof

InactiveCN102358929APotential for high temperature and high strength applicationsImprove thermal stabilityElemental compositionManganese

The invention relates to heatproof magnesium stannum silver alloy and a preparation method thereof, which belongs to metal structural materials and the field of preparation technology. The ingredient of the magnesium stannum silver alloy is composed of four elements of magnesium, stannum, silver and manganese or five elements of magnesium, stannum, silver, manganese and zinc. The mass percentage of the content of each ingredient is stannum (Sn) of 6% to 7%, silver (Ag) of 1% to 2%, manganese (Mn) of 0.2 % to 0.5%, zinc (Zn) of 0% to 1.0% and magnesium of the rest. The preparation method comprises steps of sequentially placing all ingredients in a crucible, heating, stirring, standing to form alloy liquid, pouring into cold molds to form blanks of the magnesium stannum silver alloy, heating in the air, quenching in cold water to obtain homogenized magnesium stannum silver alloy and finally performing aging hot treatment in the air and quenching in cold water to achieve the heatproof magnesium stannum silver alloy. The magnesium stannum silver alloy is small in content of elements and simple in smelting technology. Under 200 DEG C, the aging peak value can reach more than 84 HV. Aging of 700 hours, hardness can keep above 77 HV. Thus, high temperature tissues are stable, and commercial potentiality is provided.

Owner:TSINGHUA UNIV

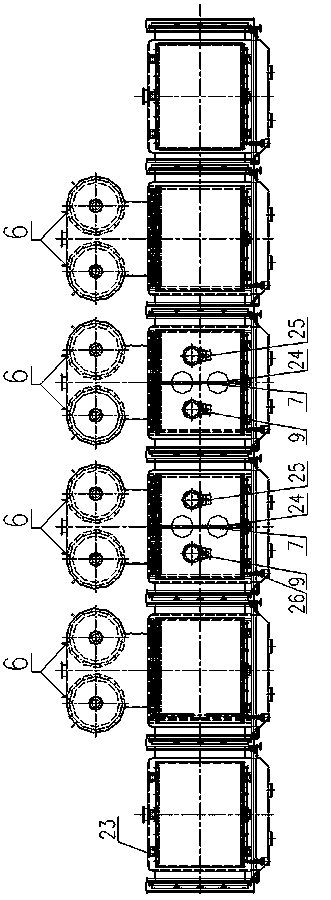

Drawing method for C-shaped silicon core

InactiveCN103160914AOvercome the disadvantages of smaller diameterGrow fastPolycrystalline material growthBy pulling from meltCunifeSilicon

The invention discloses a drawing method for a C-shaped silicon core, wherein in the method, a crucible (5) and a heating sleeve (6) used for melting a crystal (7), and a die plate (11) structure for drawing the C-shaped silicon core (2) are provided. The drawing method comprises the following steps of: A, previous preparation, B, melting for the materials of the crystal (7), C, control for the silicon core, and D, finishing for the C-shaped silicon core (2), wherein many times of drawing for the C-shaped silicon core (2) of a crystal drawing process can be realized by repeating the steps aforementioned. During the subsequent use of the drawing method disclosed by the invention, the disadvantage of small diameter of the existing solid square silicon core or circular silicon core is effectively overcome; the purpose of rapidly growing a polycrystalline rod is realized by the C-shaped silicon core having a weight which is equal to or slightly greater than the weight of the solid silicon core; and the method for drawing the silicon core disclosed by the invention is simple to cost, and capable of greatly saving enterprise cost.

Owner:LUOYANG JINNUO MECHANICAL ENG

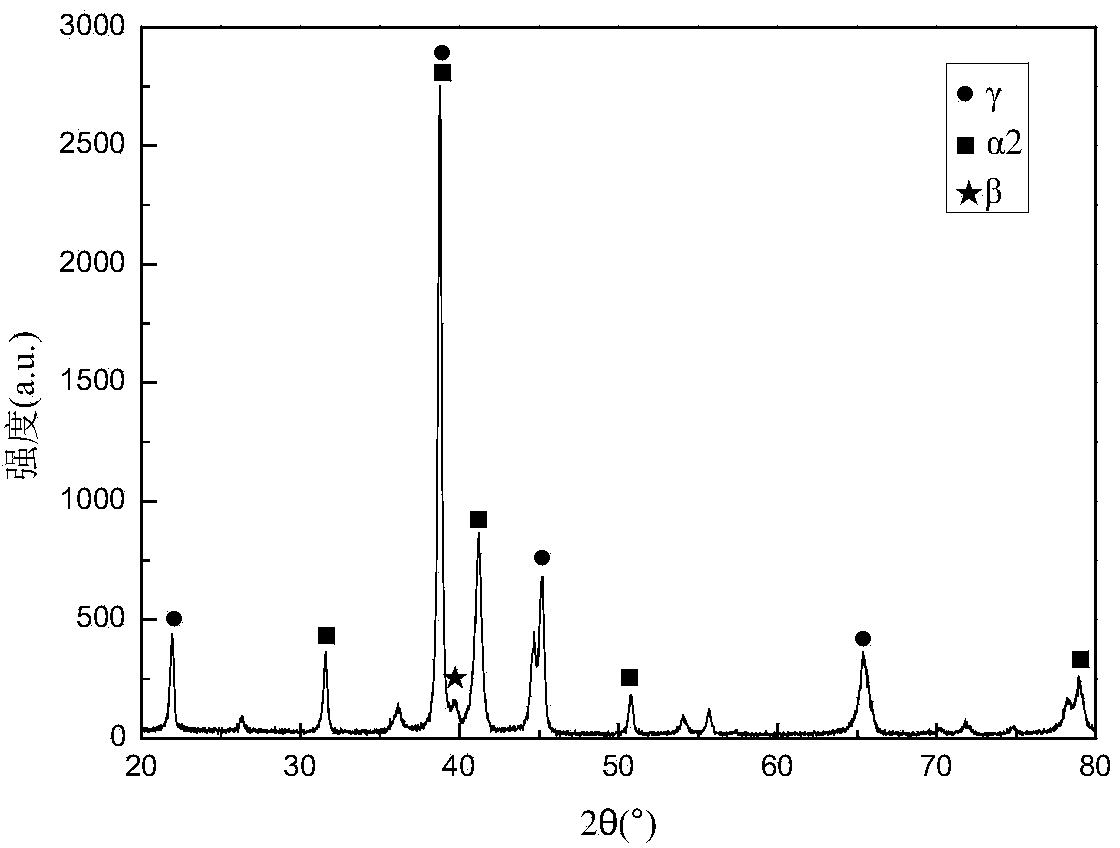

Multi-alloying beta-phase-solidified high Nb-TiAl alloy and preparation method thereof

The invention provides a multi-alloying beta-phase-solidified high Nb-TiAl alloy and a preparation method thereof, and belongs to the technical field of alloy. The alloy comprises the following elements in molar percentage: 43-45% of Al, 5-15% of Nb, no greater than 0.2% of W, no greater than 0.5% of Cr, and the balance of Ti and inevitable impurities; raw materials are formed by briquetting according to the ratio; firstly, a titanium sponge is placed on the inner edge of a mold; secondly, a high pure aluminium layer, an aluminium niobium middle alloy layer, an electrolyzed chromium piece, an aluminium tungsten niobium middle alloy layer, and a titanium sponge layer are arranged sequentially from the bottom up respectively; the briquetting is placed a water cooled copper crucible vacuum induction suspend smelting furnace capable of realizing centrifugal casting; the melt is obtained through smelting under vacuuming, and is mixed uniformly; the melt is cast into a metal mold which is preheated and perform centrifugal rotation for performing centrifugal rotation,, and is cooled along with the furnace. According to the method, the uniform fine TiAl alloy without obvious segregation is obtained.

Owner:BEIJING UNIV OF TECH

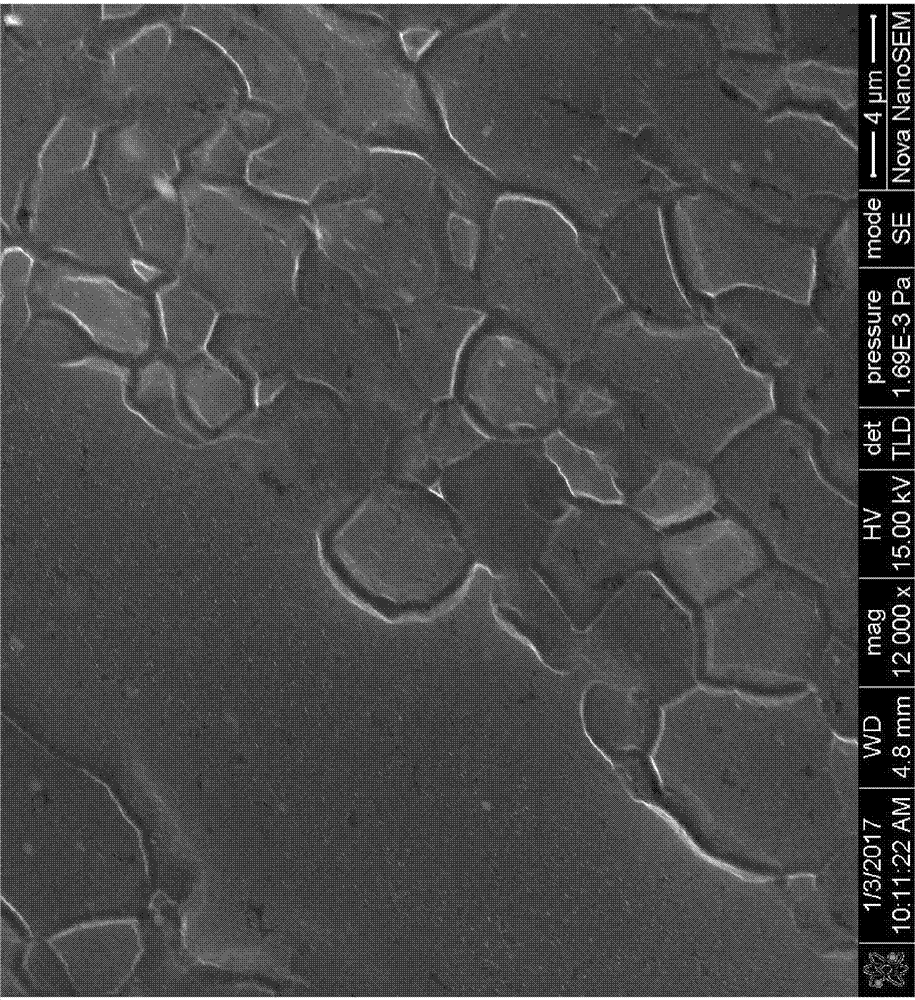

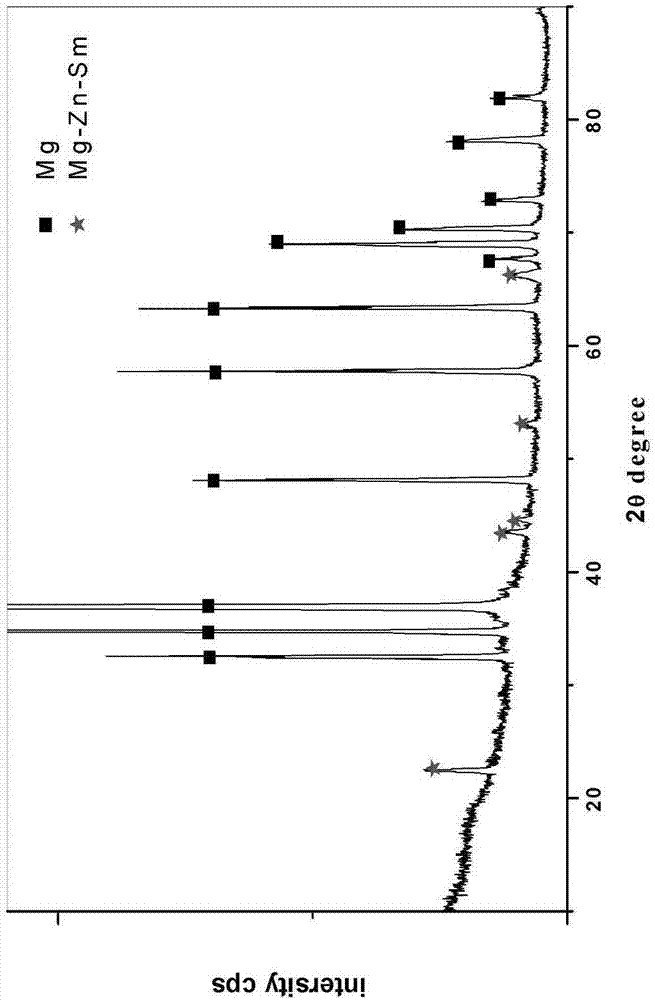

High-thermal-conductivity rare-earth magnesium alloy and preparation method thereof

The invention belongs to the field of metal materials, aims at the technical problem that high strength and high thermal conductivity cannot be both considered in an existing magnesium alloy, and specifically discloses a high-thermal-conductivity rare-earth magnesium alloy. The magnesium alloy contains 2.5-3.5wt.% of zinc, 0.15-0.35wt.% of zirconium, 0-1.5wt.% of samarium and the balance magnesium and inevitable impurities. The invention further discloses a preparation method for a high-thermal-conductivity rare-earth magnesium alloy. The preparation method comprises the following steps: 1) weighing a pure magnesium ingot, pure zinc particles, an Mg-Zr intermediate alloy and an Mg-Sm intermediate alloy according to the required component contents for standby; 2) drying and preheating the raw materials weighed in the step 1) at 200 DEG C for 2h separately for standby; 3) placing the pure magnesium ingot preheated in the step 2) in a stainless steel crucible, and heating the pure magnesium ingot under the shield of a protective gas; and 4) carrying out hot extrusion deformation on the magnesium ingot in the step 3), thereby obtaining the deformed magnesium alloy.

Owner:GANNAN NORMAL UNIV

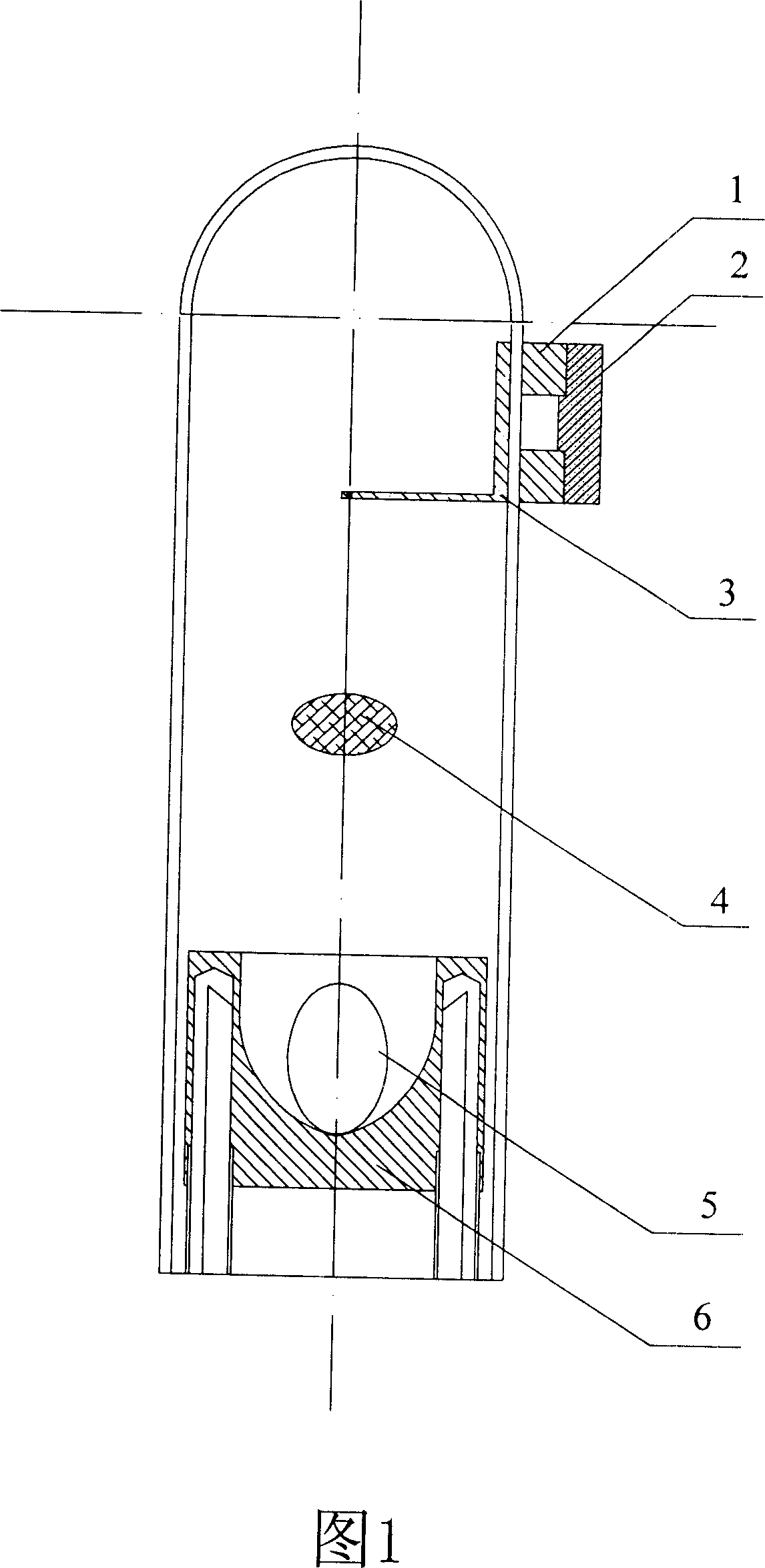

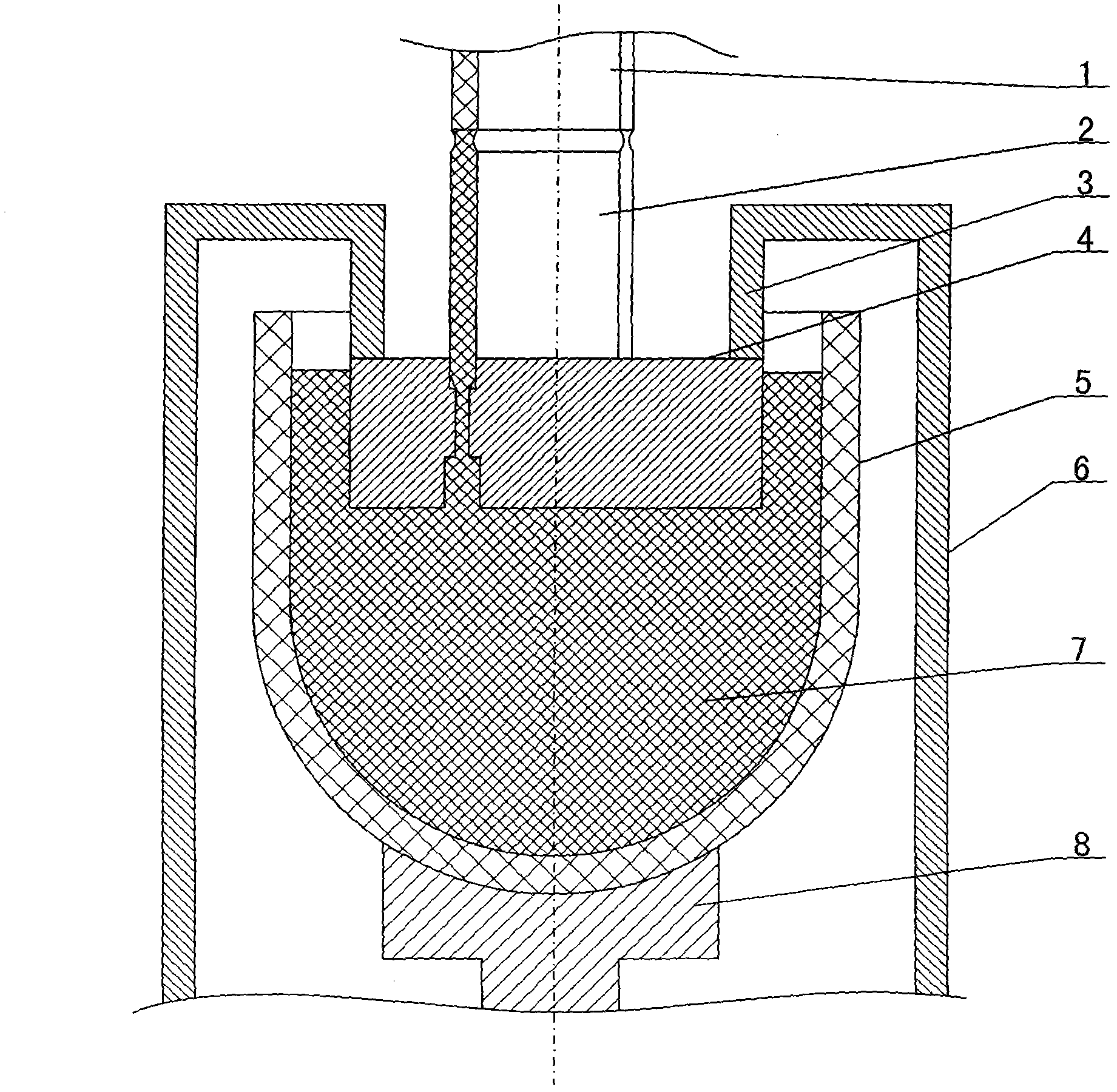

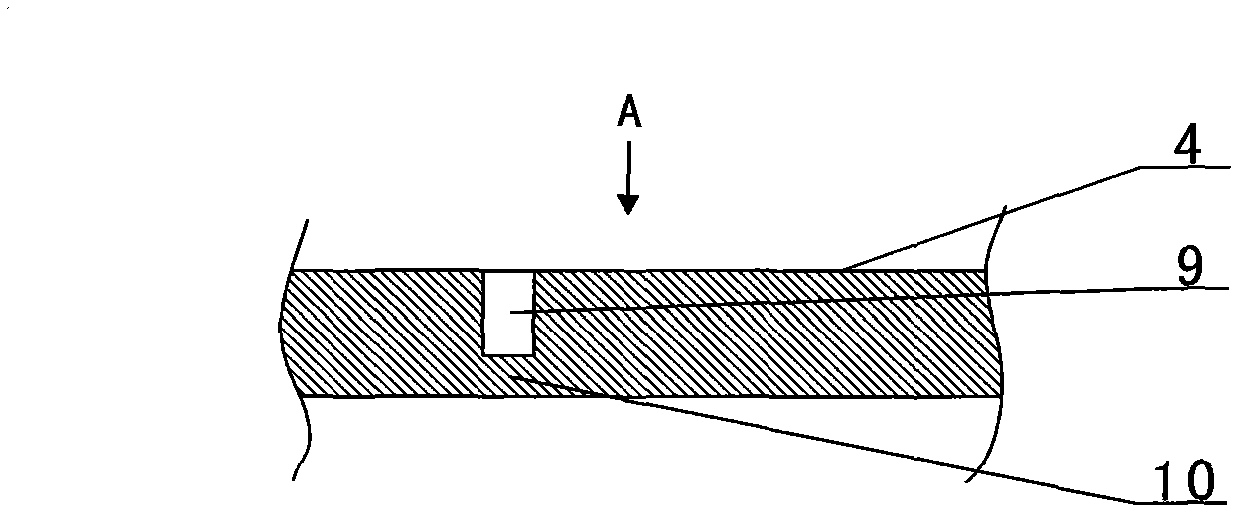

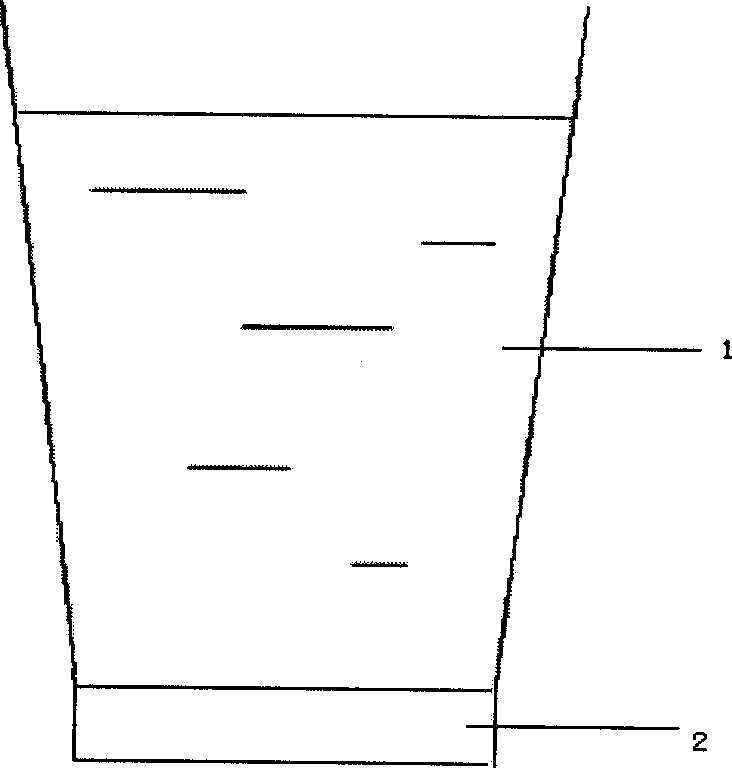

Equipment of non-vacuum smelting easy oxidation metal and alloy

InactiveCN1869564AReduce partial pressureFacilitated DiffusionCasting plantsCrucible furnacesLoss rateCunife

The invention provides a device for non-vacuum smelting easy- to-oxidize metals and alloys, and its main parts comprise furnace body and furnace cover, where the furnace body is equipped with a heater, and a pot is placed inside the furnace body; and the furnace cover has an gas inlet, an gas outlet and a feed inlet and is equipped with a cooling mechanism; the bottom of the hearth is equipped with a bottom pouring orifice, a vertical stopper is arranged inside the furnace body, the lower end of the stopper is connected with the bottom pouring orifice, the upper end of the stopper is equipped with an adjustment mechanism which adjusts the vertical position of the stopper to prevent metal melt from flowing down in the smelting course; the lower side of the furnace body is directly connected with a crystallizer or iron mold, it adopts a down-pouring mode and the connecting channel is made with an gas inlet and an gas outlet. And its whole smelting and casting course is performed in the industrial pure protective gas, having low melting loss rate and good deoxidizing and dehydrogenating effects, easy to implement large-scale continuous operation and obviously improving the pouring quality.

Owner:苏州有色金属研究院有限公司

Luminous container

InactiveCN1545961ASimple structureReduce volumeDrinking vesselsRigid containersThermoelectric materialsCunife

The invention provides a luminous container for realizing luminescent function by means of thermoelectric materials, wherein a sealed luminescent device is arranged on the outer surface of the container, the luminescent device includes a thermoelectric converter and a luminescent unit, the electrodes of the luminescent device is connected with the luminescent unit, thus forming a current loop.

Owner:ZHEJIANG UNIV

Production method of low-price rapidly quenched magnetic powder containing lanthanum and cerium

ActiveCN107123538AMelted just rightLow costInductances/transformers/magnets manufactureMagnetic materialsCeriumLanthanum

The invention provides a production method of low-price rapidly quenched magnetic powder containing lanthanum and cerium. The method comprises the following steps of loading raw materials into a crucible according to the order of a first layer of iron, zirconium, ferroboron, a second layer of iron, lanthanum cerium and praseodymium neodymium; starting a smelting furnace for preheating and discharging an adsorbed gas in the raw materials; further increasing power until the raw materials are completely melted, pouring and obtaining a uniform alloy; carrying out rapid quenching treatment on the alloy to obtain an alloy strip; finally carrying out crystallization treatment on the alloy strip, wherein the composition formula of the magnetic powder is (LaCe+PuNd)<x>(FeZr)<84.5-x>B<6.5>, wherein X is 9-11 and the ratio of LaCe:PuNd is 1:(0.2-4). One part of praseodymium neodymium is replaced with the lanthanum cerium, so that the residual magnetic flux density Br of the prepared magnetic powder is (5-7.5)kGs, the intrinsic coercive force Hcj is (6-9.5)kOe and the maximum magnetic energy product BH is (6-12)MGOe. The magnetic powder is suitable for the market requirements, the cost of the raw materials is reduced and a new application way is opened up for highly abundant rare earth.

Owner:温强 +1

Ceramic lined channel inductor

A channel inductor of a channel induction furnace is disclosed. The channel inductor comprises a channel liner that defines a channel for a molten metal to flow through the channel inductor. The channel liner comprises an inlet and an outlet for the molten metal and a flange for mounting the channel liner to a refractory material lining of a pot of the channel inductor furnace. The channel liner being formed from a ceramic material that is resistant to chemical attack by the molten metal in the channel, whereby in use of the channel induction furnace direct contact between the molten metal and the channel inductor is limited to contact with the channel liner (including the flange) only and molten metal does not contact other parts of the channel inductor.

Owner:BLUESCOPE STEEL LTD

Method for preparing copper-chromium composite contact material through electron beam cladding process

InactiveCN106676517AUniform and small sizeAvoid inclusionsMetallic material coating processesAlcoholCunife

The invention discloses a method for preparing a copper-chromium composite contact material through an electron beam cladding process. The method comprises the following steps: (1) preparation of a base body material; (2) preparation of cladding powder: mixing copper powder and chromium powder according to a ratio, then adding absolute ethyl alcohol, and carrying out ball grinding on the mixed powder through a copper ball to obtain the cladding powder; (3) spreading: spreading the cladding powder on the surface of an oxygen-free copper block; (4) pressing: pressing the cladding layer with a press, and carrying out natural airing or drying; (5) vacuumizing: putting a pressed sample into electronic beam equipment, and vacuumizing to 10<-2> pa or below; (6) electron beam scanning: melting the cladded copper-chromium powder through electron beam scanning, and enabling the surface of an oxygen-free copper base body to be slightly melted to form metallurgical bonding between the copper-chromium powder and the oxygen-free copper base body. According to the preparation method disclosed by the invention, the raw materials are not in contact with a crucible, so that inclusions caused by falling of the crucible and relatively high product gas content caused by crucible degassing are avoided; and meanwhile, by rapid cooling, the particle size of a product from the edge part to the heart part is uniform and fine.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Method for preparing spherical nickel base alloy materials for manufacturing steel teeth

The invention discloses a method for preparing spherical nickel base alloy materials for manufacturing steel teeth, which relates to the technical field of alloy material. The invention is characterized in that the nickel base alloy material comprises the following chemical compositions in percentage by weight: 10 to 15 percent of copper, 3 to 7 percent of chromium, 4 to 8 percent of tin, 2 to 5 percent of silicon, 0.1 to 0.5 percent of cobalt, 0.5 to 2 percent of boron, and the rest for nickel; and the method comprises the following steps: putting the chemical compositions above into a high-temperature crucible, and heating the chemical compositions in a high frequency or medium frequency furnace to melt the compositions; evenly mixing the obtained high-temperature melting liquid for 5 to 10 seconds; and pouring the high-temperature melting liquid subjected to even mixing into a cooling device to carry out centrifugal cooling treatment so as to form spherical particles (particle size: 5 to 8mm). The method is simple and the smelting process does not need to be carried out in a vacuum environment or an atmosphere protection environment by the method.

Owner:LUOYANG BEIYUAN SPECIAL CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com