Silver-magnesium-nickel friction ring manufacturing method

A silver-magnesium-nickel and friction ring technology, which is applied in the field of preparation of silver-magnesium-nickel alloy friction rings, can solve the problems of large deviation in mechanical properties, poor batch stability, and easy occurrence of inclusions, etc., and achieve the effect of smooth surface and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

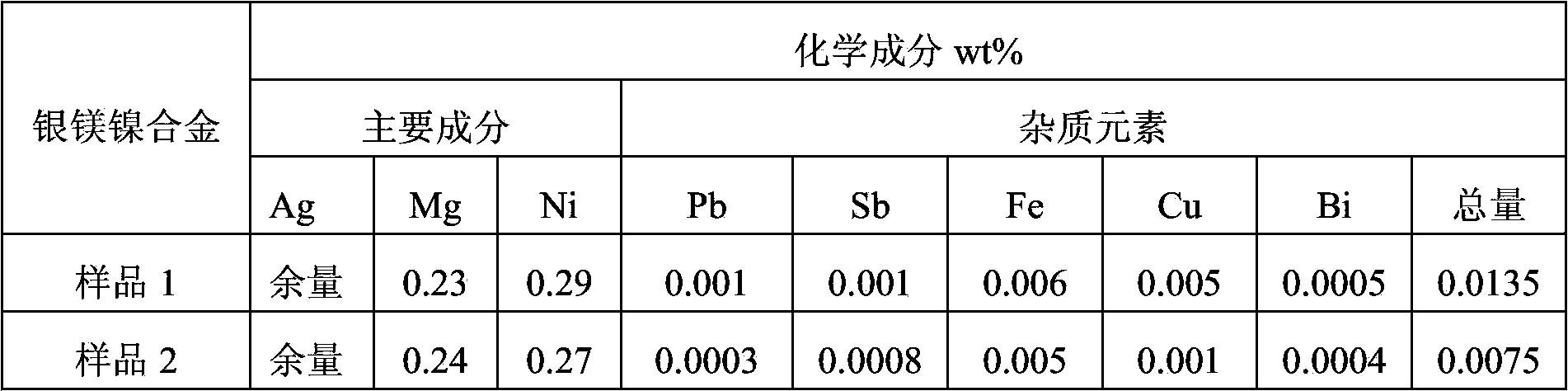

Embodiment 1

[0025] Prepare AgMg0.24Ni0.29 silver-magnesium-nickel alloy friction ring, wherein the weight percentage of each alloy composition is: Mg 0.24%; Ni 0.29%, the balance is Ag, and the specific steps are as follows:

[0026] 1) Clean the melting furnace wall of the vacuum intermediate frequency induction furnace to ensure that there are no other metals or pollutants in the furnace.

[0027] 2) After crushing silver and nickel, soak them in dilute sulfuric acid for 0.5h, then use a copper wire brush to remove surface dirt, rinse with clean water, dehydrate with acetone or alcohol, and air dry.

[0028] 3) Put the silver and nickel into the high-purity graphite crucible of the vacuum intermediate frequency induction furnace for smelting and degassing.

[0029] 4) putting the degassed silver and nickel into a high-purity graphite crucible, and melting under the condition of a vacuum of 5-10 Pa to obtain a silver-nickel master alloy.

[0030] 5) Put the silver-nickel intermediate al...

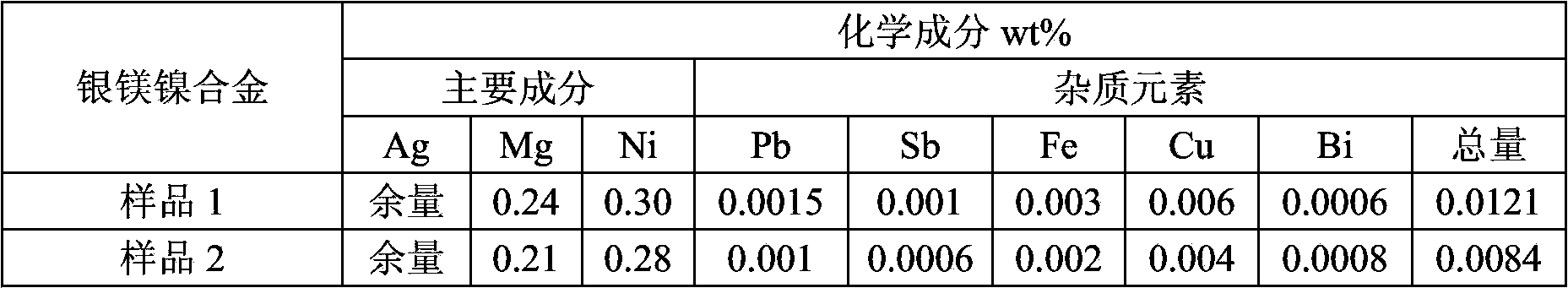

Embodiment 2

[0041] Prepare AgMg0.24Ni0.29 silver-magnesium-nickel alloy friction ring, wherein the weight percentage of each alloy composition is: Mg 0.26%; Ni 0.30%, the balance is Ag, and the specific steps are as follows:

[0042] 1) Clean the melting furnace wall of the vacuum intermediate frequency induction furnace to ensure that there are no other metals or pollutants in the furnace.

[0043] 2) After the silver and nickel are crushed, soak them in degreasing agent for 0.5h, then use a copper wire brush to remove the surface dirt, rinse with clean water, and air dry.

[0044] 3) Putting silver and nickel into different graphite crucibles in a vacuum intermediate frequency induction furnace for melting and degassing.

[0045] 4) putting the degassed silver and nickel into a high-purity graphite crucible, and melting under the condition of a vacuum of 5-10 Pa to obtain a silver-nickel master alloy.

[0046] 5) Put the silver-nickel intermediate alloy into a high-purity graphite cruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com