Single crystal extraction method

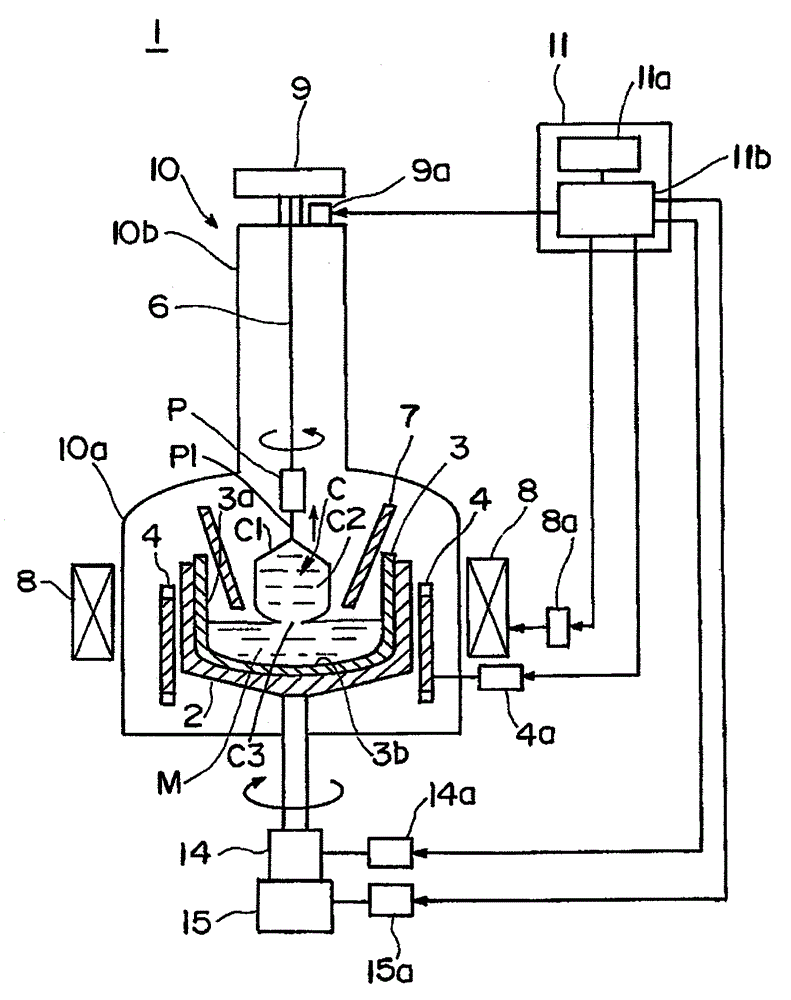

An extraction method, single crystal technology, applied in the field of single crystal extraction, can solve problems such as single crystal slip dislocation, dislocation, crystal dislocation, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

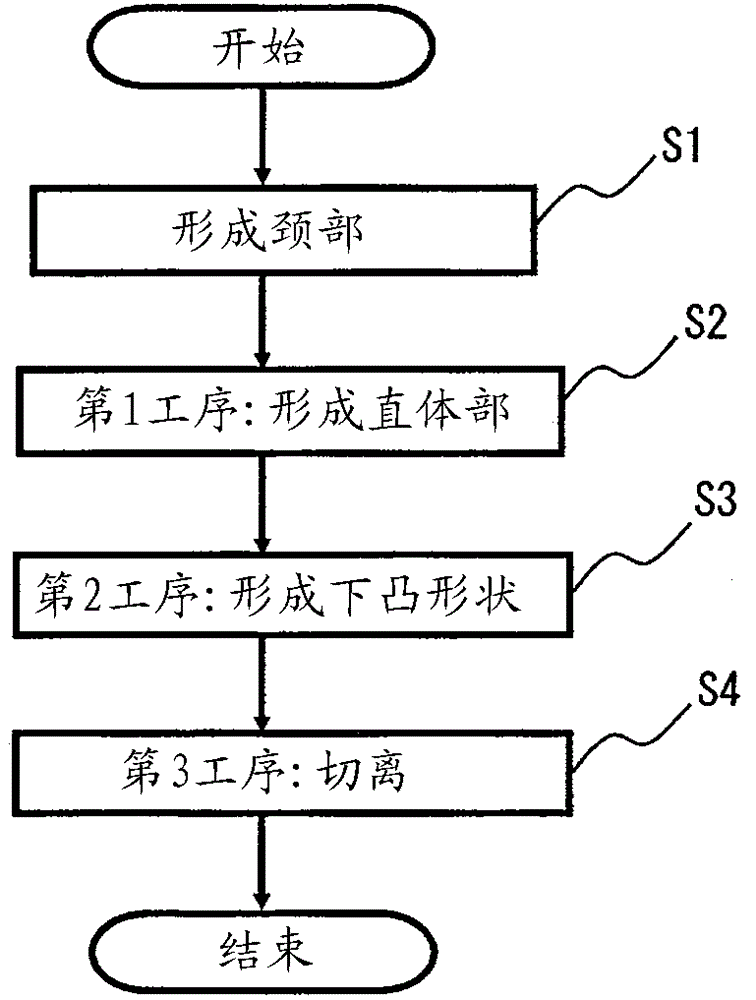

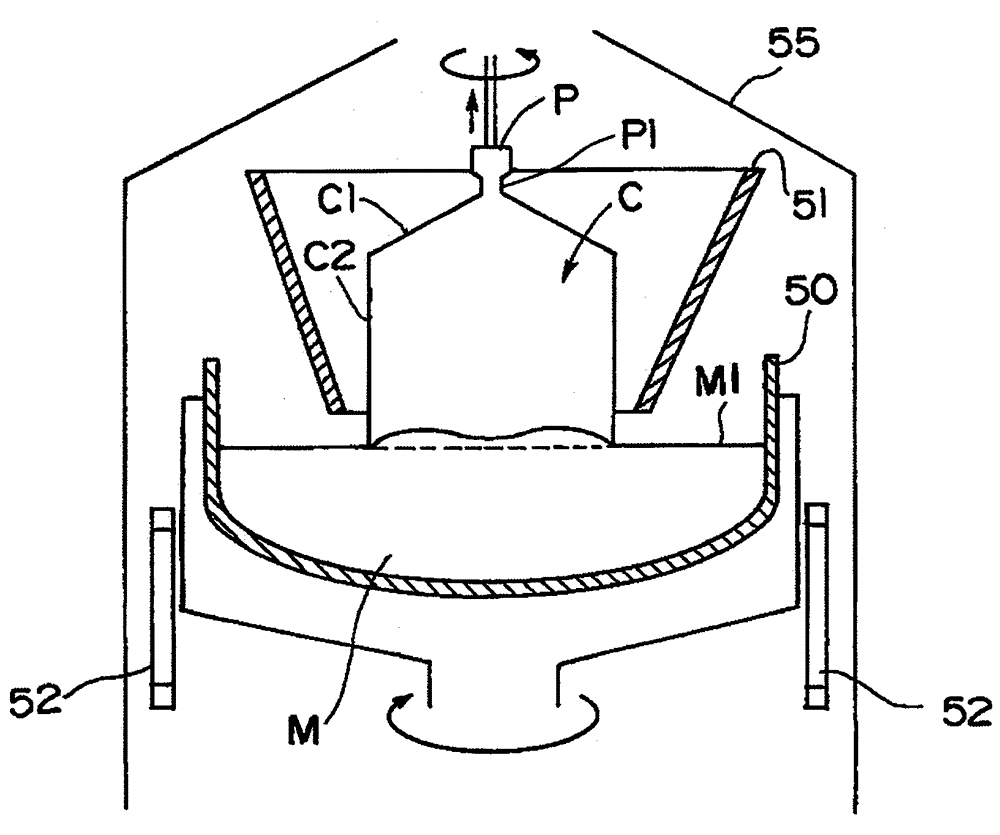

Method used

Image

Examples

Embodiment

[0054] The single crystal extraction method related to the present invention will be further described based on examples. In this example, single crystal extraction was performed using the single crystal extraction apparatus described in the foregoing embodiments, and the extracted crystal was verified.

[0055] Specifically, after the first step of forming the straight body part, in the second step (when the solidification rate is 0.77), which is the final step of forming the straight body part, according to the magnetic flux density, crystal extraction speed, crystal rotation speed, crucible Examples 1-8 and Comparative Examples 1-13 are classified according to each condition of rotation speed. Then, with regard to the extracted crystal, it was judged whether or not extraction can be performed without dislocation, whether or not there is deformation, and the length of the convex shape. The diameter of the single crystal to be cultivated is 390 mm, and 350 kg of silicon crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com