Preparation process for extracting active ingredient of natural plant by supersonic

A technology of natural plants and active ingredients, applied in food preparation, food science, application, etc., can solve the problems of long total extraction time, loss of heat-sensitive active ingredients, cumbersome operation process, etc., and achieve less loss of heat-sensitive active ingredients and effective heat sensitivity. The effect of less loss of components and improved extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

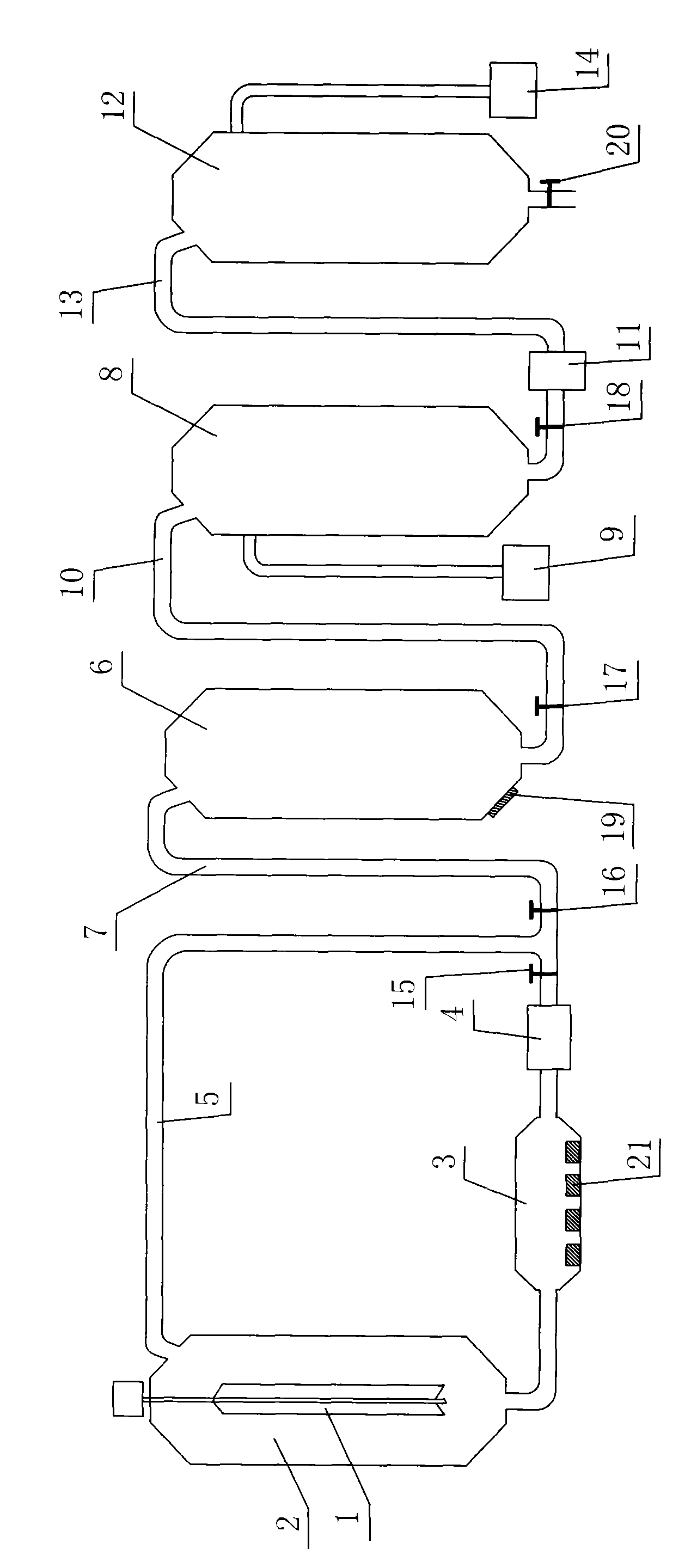

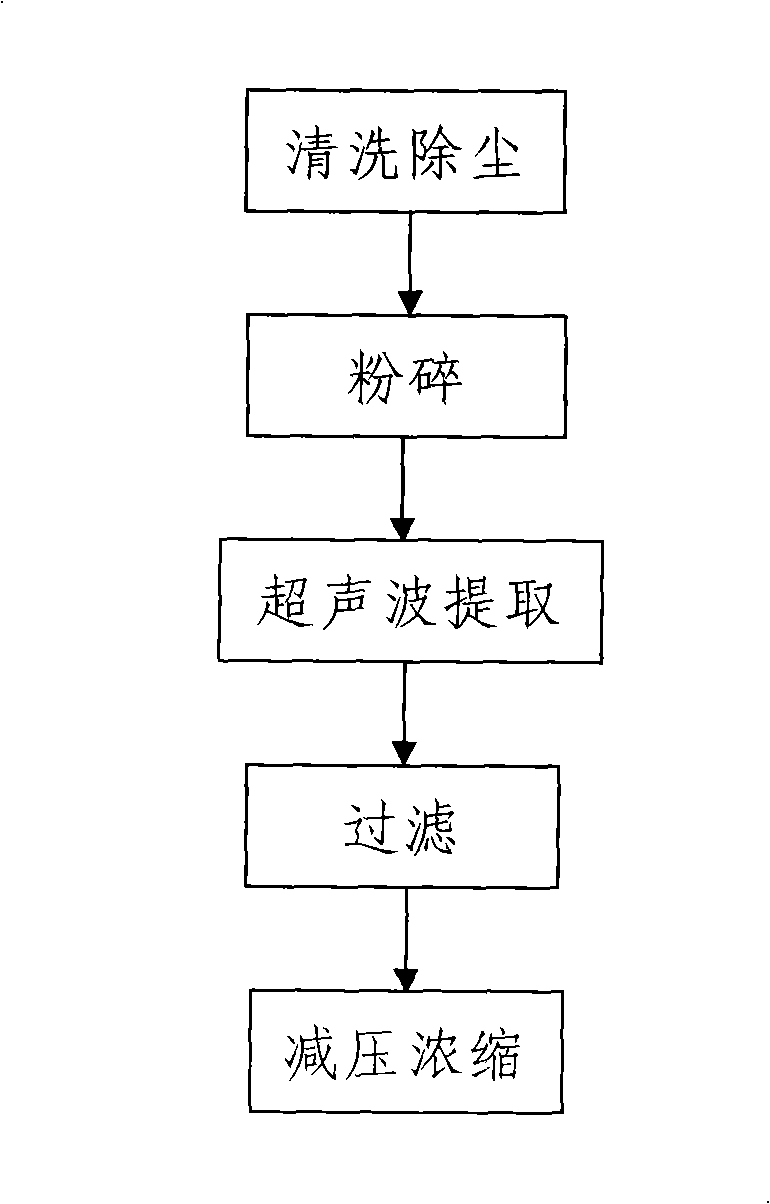

[0031] Such as figure 1 , figure 2 As shown, the preparation process of ultrasonically extracting active ingredients from natural plants of the present invention includes the following steps:

[0032] Step 1. Cleaning and dust removal: the natural plants to be extracted that have passed the inspection are cleaned and dusted and dried or dried. The cleaning method is dry cleaning by a dry cleaning machine.

[0033] In this embodiment, the Zanthoxylum bungeanum is taken as an example for description. First, 100 kg of Zanthoxylum bungeanum raw materials that have passed the inspection are subjected to dry cleaning and dust removal by a dry cleaning machine.

[0034] Step 2: Crushing: the natural plants to be extracted after being cleaned and dusted are put into a crusher with a built-in 20-60 mesh screen for crushing.

[0035] In this embodiment, the sieve installed inside the pulverizer is a 40-mesh sieve, that is to say, in this step, 100 kg of prickly ash raw material that has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com