Preparation method of CuW/CrCu integral high-voltage electrical contacts

A high-voltage, contact technology, applied in contacts, circuits, electrical switches, etc., can solve problems such as waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

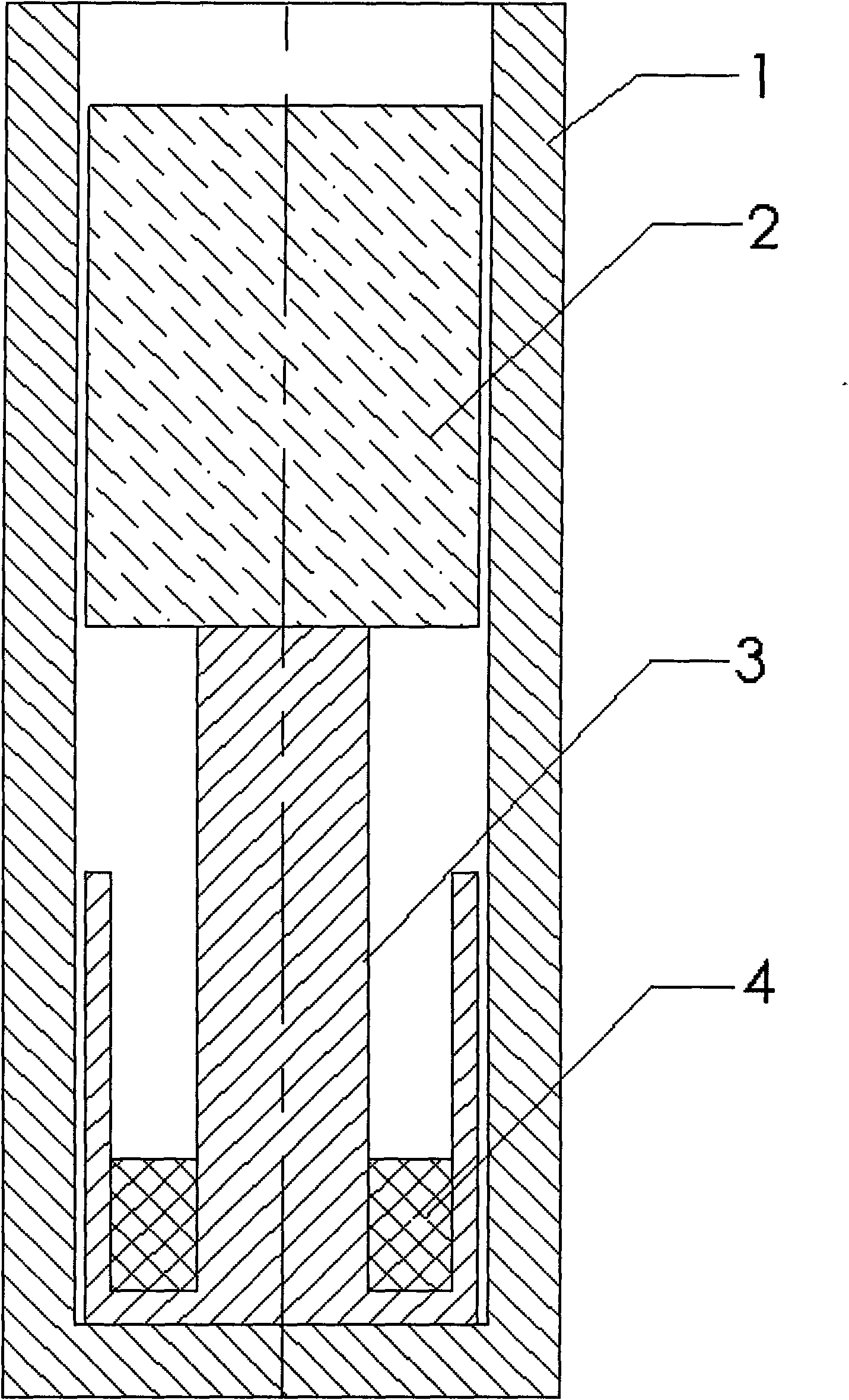

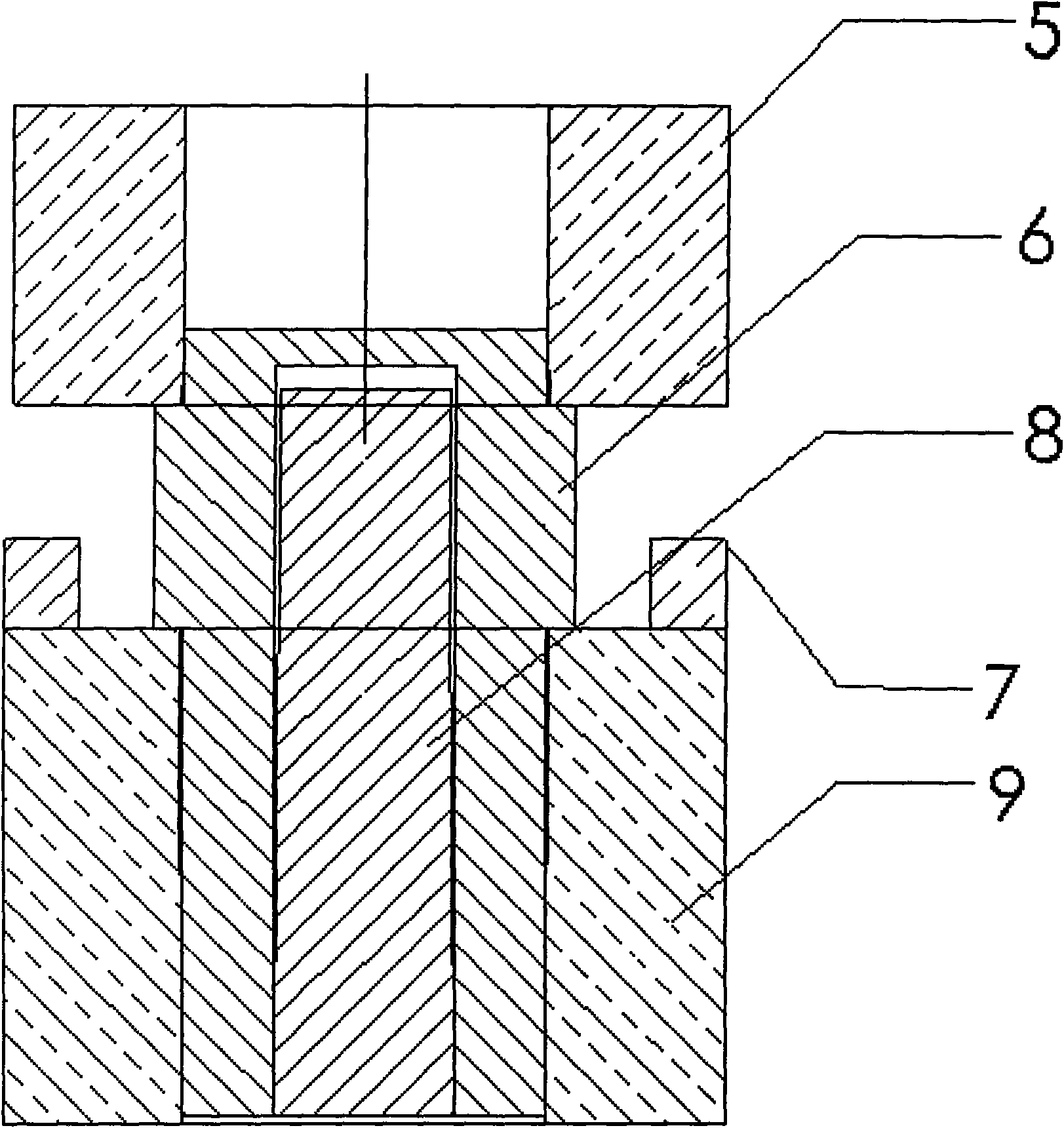

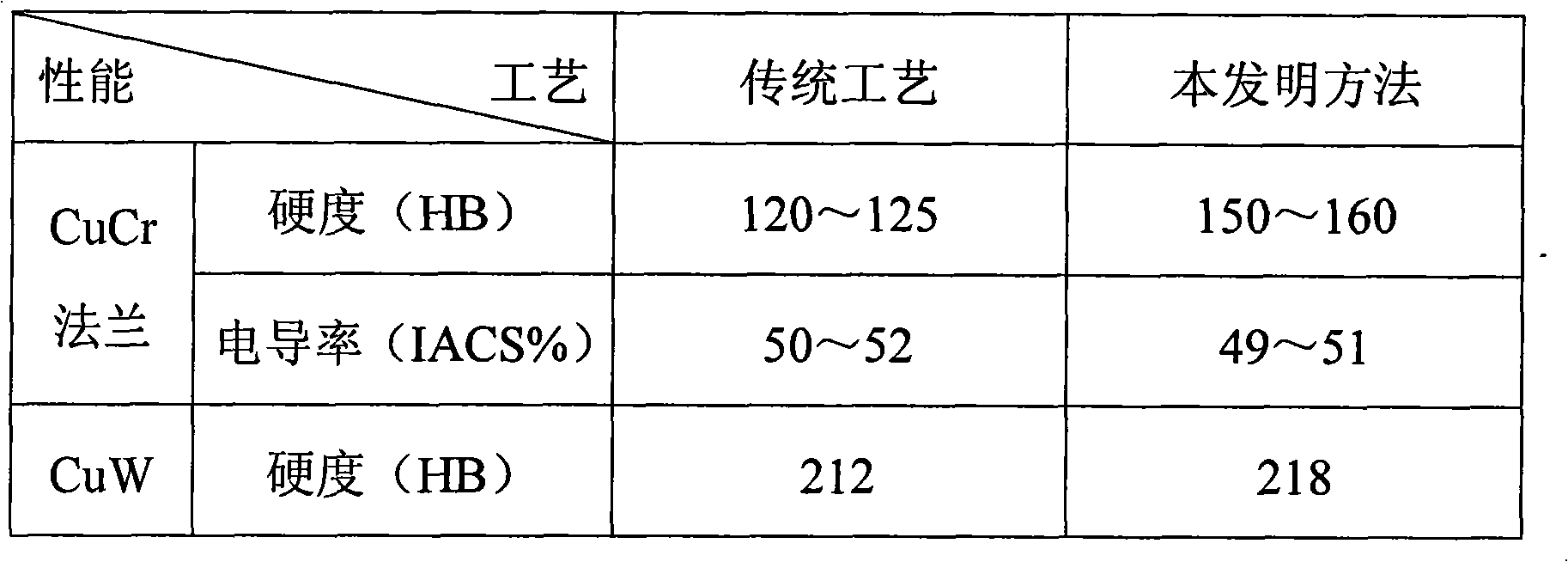

[0031] Take the CuW powder and CrCu powder according to the mass percentage of 1:0.001 and place them in the mixer, and mix the powders at a speed of 120 rpm for 3 hours to obtain a uniformly mixed powder; a cold mold including a phase-separated internal The cavity upper mold 5 and the lower mold 9 with a cavity inside, a detachable gasket 7 is arranged between the upper mold 5 and the lower mold 9, and a detachable cylindrical core is arranged in the inner cavity of the lower mold 9 b8, the size of the core b8 and the electrical contact to be prepared are matched, the mixed powder is poured into the cavity between the lower mold 9 and the core b8 in the cold mold, and then the lower mold 9 containing the powder Place it on a hydraulic press to form a hollow cylindrical tungsten skeleton with a pressure of 5MPa and hold the pressure for 45s; put the tungsten skeleton in a cylindrical crucible, and place a pure copper block on the tungsten skeleton, and perform infiltration sinteri...

Embodiment 2

[0033]Take the CuW powder and CrCu powder according to the mass percentage of 1.5:0.01 and put them in the mixer, and mix the powder for 8 hours at a speed of 120 rpm to obtain a uniformly mixed powder; a cold mold is used, including a phase-separated inner part The cavity upper mold 5 and the lower mold 9 with a cavity inside, a detachable gasket 7 is arranged between the upper mold 5 and the lower mold 9, and a detachable cylindrical core is arranged in the inner cavity of the lower mold 9 b8, the size of the core b8 and the electric contact to be prepared are matched, the mixed powder is poured into the cavity between the lower mold 9 and the core b8 in the cold mold, and then the lower mold 9 containing the powder Place it on a hydraulic press to form a hollow cylindrical tungsten skeleton with a pressure of 10 MPa and hold the pressure for 30 s; place the tungsten skeleton in a cylindrical crucible, and place a pure copper block on the tungsten skeleton, and perform infiltrat...

Embodiment 3

[0035] Take the CuW powder and CrCu powder according to the mass percentage of 1.3:0.005 and place them in the mixer, and mix the powders at a speed of 120 rpm for 5 hours to obtain a uniformly mixed powder; a cold mold is used, including a phase-separated inner part The cavity upper mold 5 and the lower mold 9 with a cavity inside, a detachable gasket 7 is arranged between the upper mold 5 and the lower mold 9, and a detachable cylindrical core is arranged in the inner cavity of the lower mold 9 b8, the size of the core b8 and the electric contact to be prepared are matched, the mixed powder is poured into the cavity between the lower mold 9 and the core b8 in the cold mold, and then the lower mold 9 containing the powder Place it on a hydraulic press to form a hollow cylindrical tungsten skeleton with a pressure of 7MPa and hold the pressure for 35s; place the tungsten skeleton in a cylindrical crucible, and place a pure copper block on the tungsten skeleton, and perform infiltr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com