High-thermal-conductivity rare-earth magnesium alloy and preparation method thereof

A technology of rare earth magnesium and high thermal conductivity, which is applied in the field of metal materials, can solve the problems that magnesium alloys cannot take into account high strength and high thermal conductivity, etc., and achieve the goals of improving thermal conductivity and mechanical properties, good thermal conductivity, and improving thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

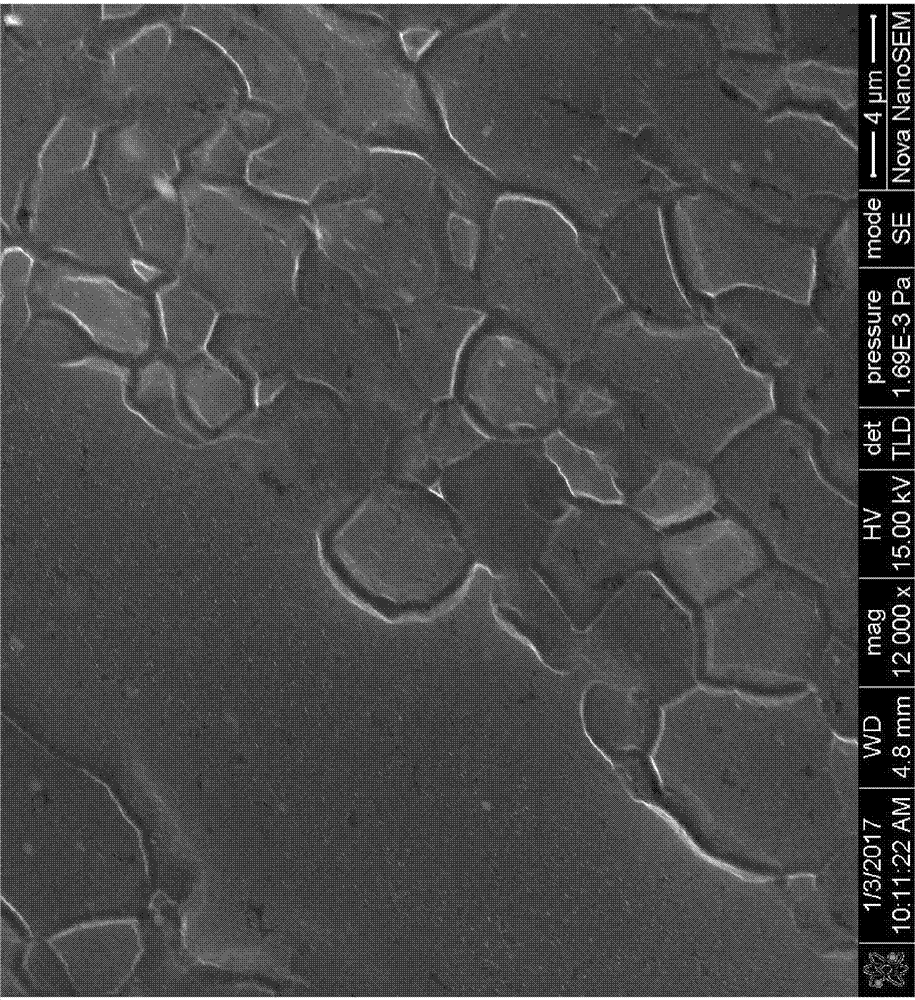

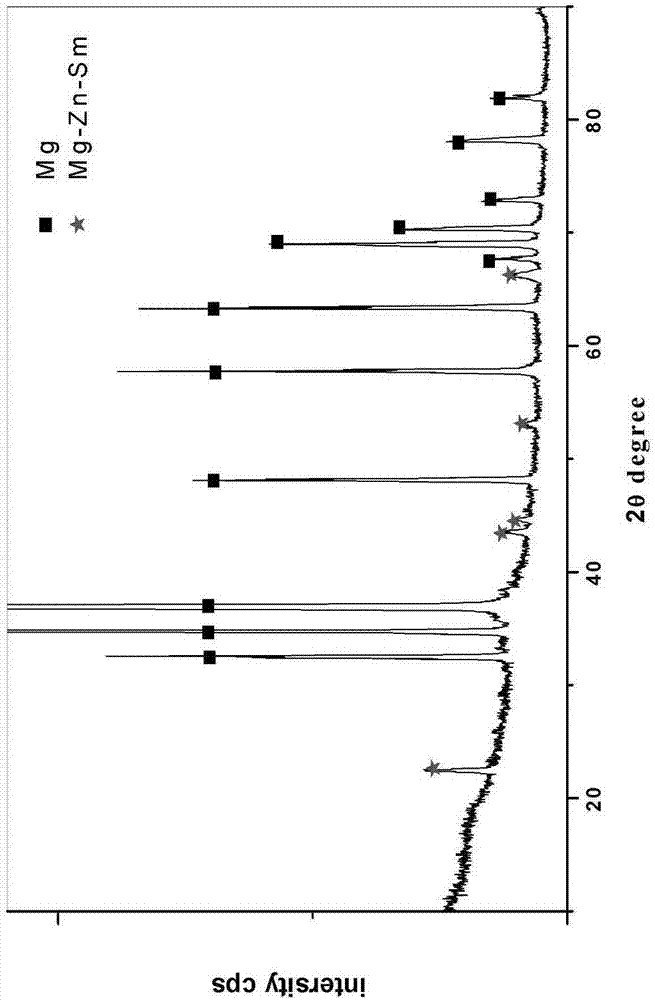

Image

Examples

Embodiment 1

[0031] A rare earth magnesium alloy with high thermal conductivity, the magnesium alloy contains 2.5wt.% of zinc; 0.15wt.% of zirconium; 0.05wt.% of samarium; the rest is magnesium and unavoidable impurities.

[0032] The magnesium alloy is prepared by the following method, and the preparation method includes the following steps:

[0033] 1) Weigh pure magnesium ingots, pure zinc particles, Mg-Zr master alloy, Mg-Sm master alloy according to the composition content containing zinc 2.5wt.%, zirconium 0.15wt.%; samarium 0.05wt.%.

[0034] 2) The raw materials weighed in step 1) were dried and preheated at 200°C for 2 hours respectively, and set aside;

[0035] 3) Put the preheated pure magnesium ingot in step 2) into a stainless steel crucible, heat up under the protection of a protective gas, and the protective gas is CO 2 and SF 6 Mixed gas, CO in protective gas 2 with SF 6 The volume of the gas is 99︰1. After the magnesium is completely melted, add step 2) preheated pure ...

Embodiment 2-7

[0040] Compared with Example 1, the only difference is that only the content of samarium in the magnesium alloy is different. The specific content is shown in the table below:

[0041] Zinc content (wt.%) Zirconium content (wt.%) Samarium content (wt.%) Example 2 2.5 0.15 0.1 Example 3 2.5 0.15 0.15 Example 4 2.5 0.15 0.25 Example 5 2.5 0.15 0.36 Example 6 2.5 0.15 1.44 Example 7 2.5 0.15 1.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com