Preparation method for high-strength high-conductivity copper alloy bar

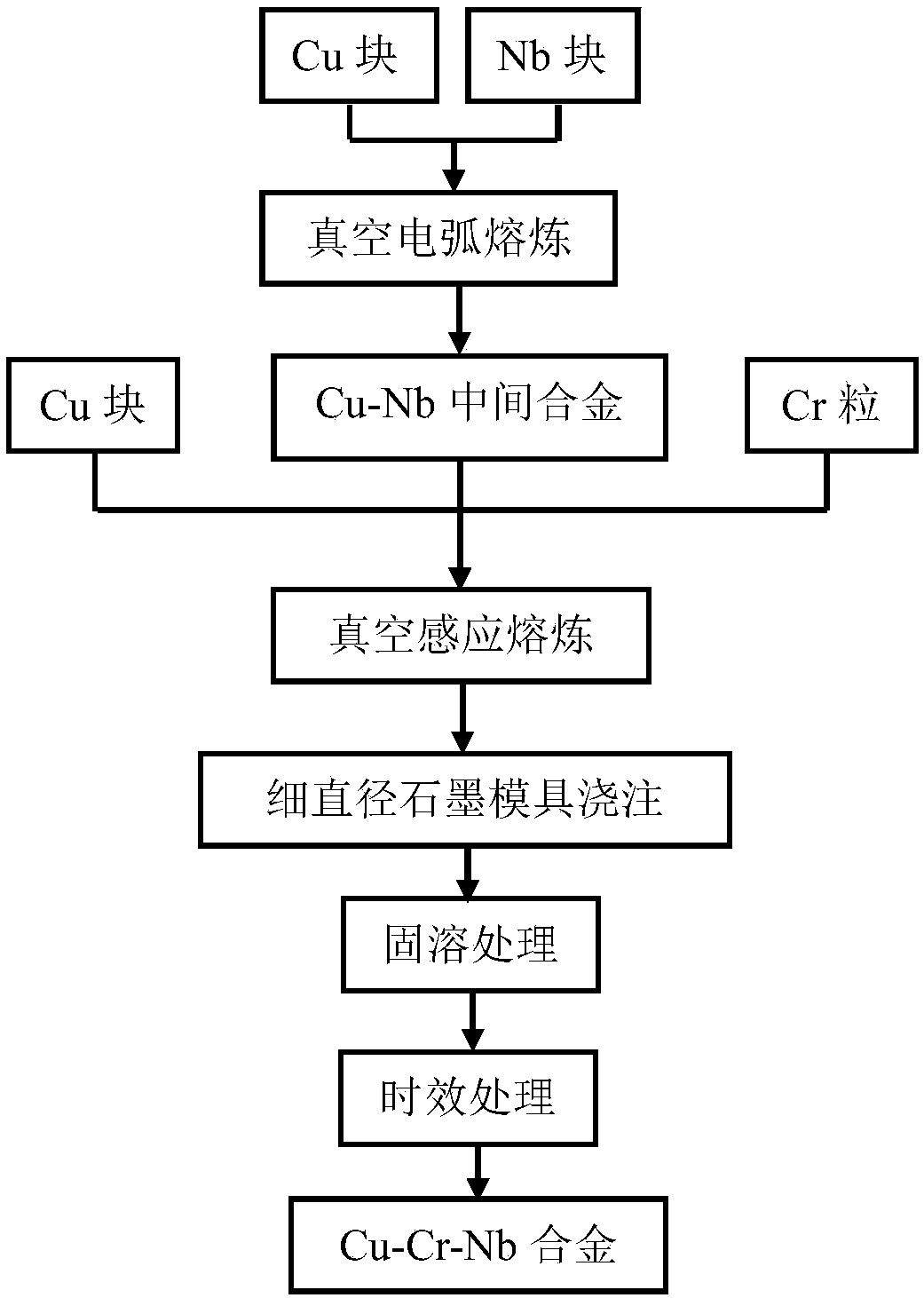

A technology of alloy rods and copper alloys, which is applied in the field of preparation of high-strength and high-conductivity copper alloy rods, can solve the problems affecting the improvement of alloy properties, small alloy thickness, and increased production costs, so as to increase cooling rate, improve alloy properties, The effect of tissue refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

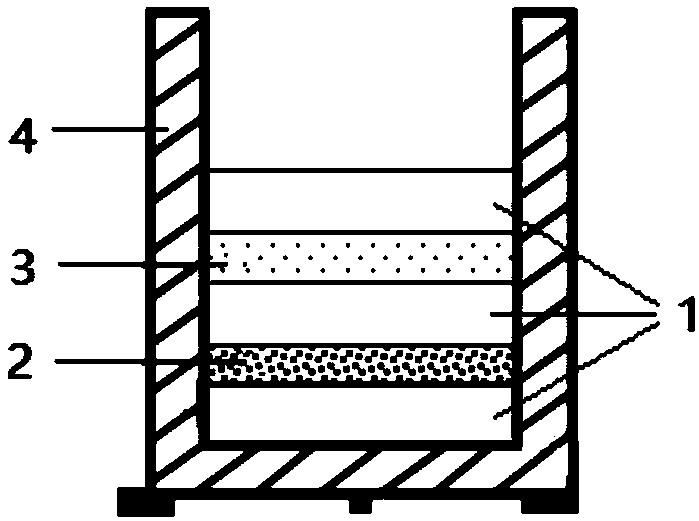

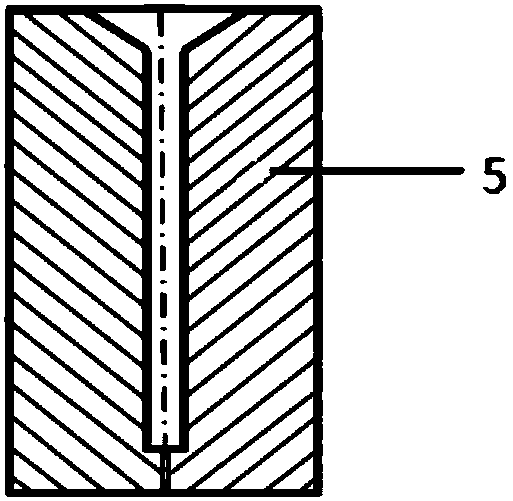

[0037] Put the polished Cu blocks and Nb blocks into the vacuum arc melting furnace in order from bottom to top, and vacuumize to 1×10 -3 , argon gas is used as protective gas, the current should be controlled at 250 amperes during the smelting process, and the smelting is repeated 4 times to obtain a Cu-5%Nb master alloy. The alloy with the target composition of Cu-1.2Cr-0.3Nb was prepared, and the calculated and weighed Cu-Nb master alloy, Cr grains and Cu blocks were figure 2 The filling method is placed in a crucible and evacuated to 4 × 10 -3 Pa or more, a small amount of Ar gas is charged. First, the alloy was rapidly heated to 1150°C, held for 3 minutes, then heated to 1350°C, held for 25 minutes, and then cooled to 1280°C and held for 2 minutes. The alloy liquid was slowly poured into the lower graphite mold with an outer diameter of 100 mm and an inner diameter of 5 mm with the furnace to obtain a Cu-Cr-Nb alloy rod. The obtained alloy bar is put into a heat treat...

Embodiment 2

[0039] Put the polished Cu blocks and Nb blocks into the vacuum arc melting furnace in order from bottom to top, and vacuumize to 1×10 - 3 Above Pa, argon gas is used as protective gas, the current should be controlled at 250 amperes during the smelting process, and the smelting is repeated 4 times to obtain a Cu-25%Nb master alloy. The alloy with the target composition of Cu-0.7Cr-0.1Nb was prepared, and the calculated and weighed Cu-Nb master alloy, Cr grains and Cu blocks were calculated according to figure 2 The filling method is placed in a crucible and evacuated to 4 × 10 -3 Pa or more, a small amount of Ar gas is charged. First, the alloy was rapidly heated to 1080°C, held for 4 minutes, then slowly heated to 1450°C, held for 30 minutes, and then cooled to 1200°C and held for 3 minutes. The alloy liquid is poured into a graphite mold with an outer diameter of 90 mm and an inner diameter of 15 mm with the furnace at a slow speed first and then a fast speed to obtain ...

Embodiment 3

[0041] Put the polished Cu blocks and Nb blocks into the vacuum arc melting furnace in order from bottom to top, and vacuumize to 1×10- 3 Above Pa, argon gas is used as protective gas, the current should be controlled at 250 amperes during the smelting process, and the smelting is repeated 4 times to obtain a Cu-20%Nb master alloy. The alloy with the target composition of Cu-1.5Cr-0.5Nb was prepared, and the calculated and weighed Cu-Nb master alloy, Cr grains and Cu blocks were figure 2 The filling method is placed in a crucible and evacuated to 4 × 10 -3 Pa or more, a small amount of Ar gas is charged. First, the alloy was rapidly heated to 1050°C, held for 5 minutes, then slowly heated to 1500°C, held for 18 minutes, and then cooled to 1250°C and held for 4 minutes. The alloy liquid is poured into a graphite mold with an outer diameter of 100 mm and an inner diameter of 10 mm with the furnace at a speed of first fast and then slow to obtain a Cu-Cr-Nb alloy rod. The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com