Water-cooled engine body

A water-cooled engine and airframe technology, applied in engine components, engine cooling, machine/engine, etc., can solve the problems affecting the normal operation of the engine, the overall temperature of the cylinder liner is uneven, and the normal fit clearance change, etc., to ensure the normal fit clearance. , convenient processing and manufacturing, the effect of increasing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

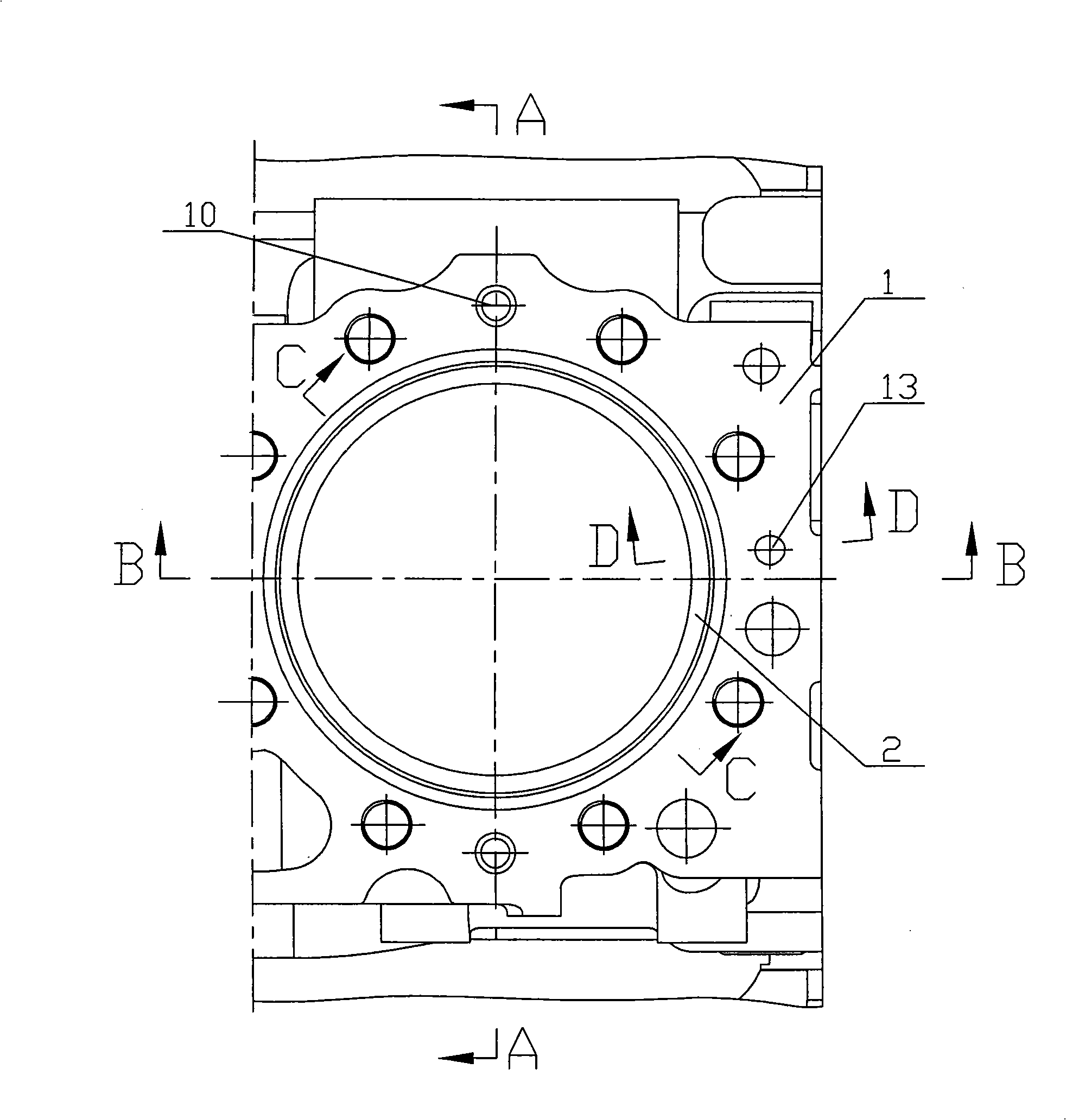

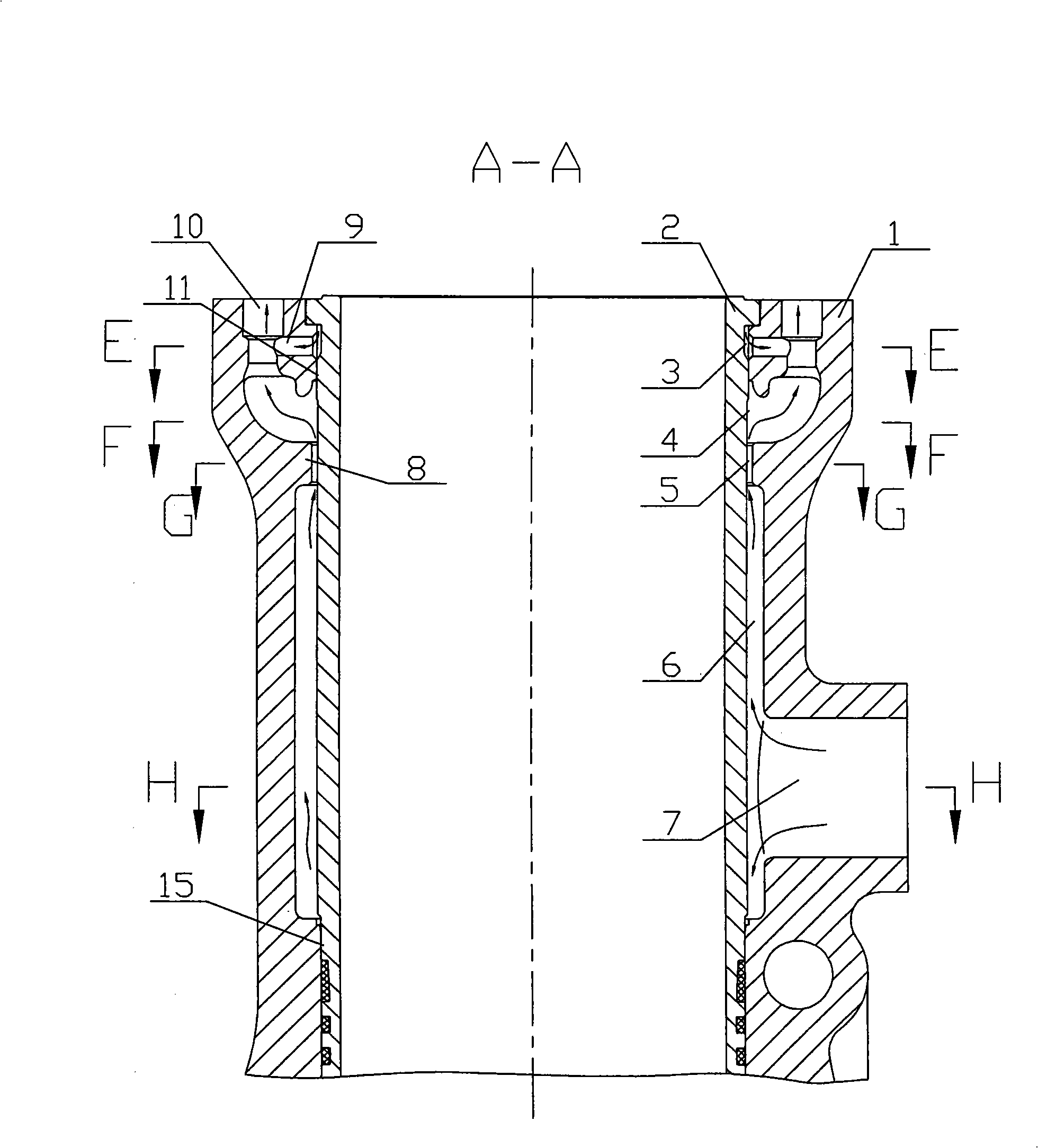

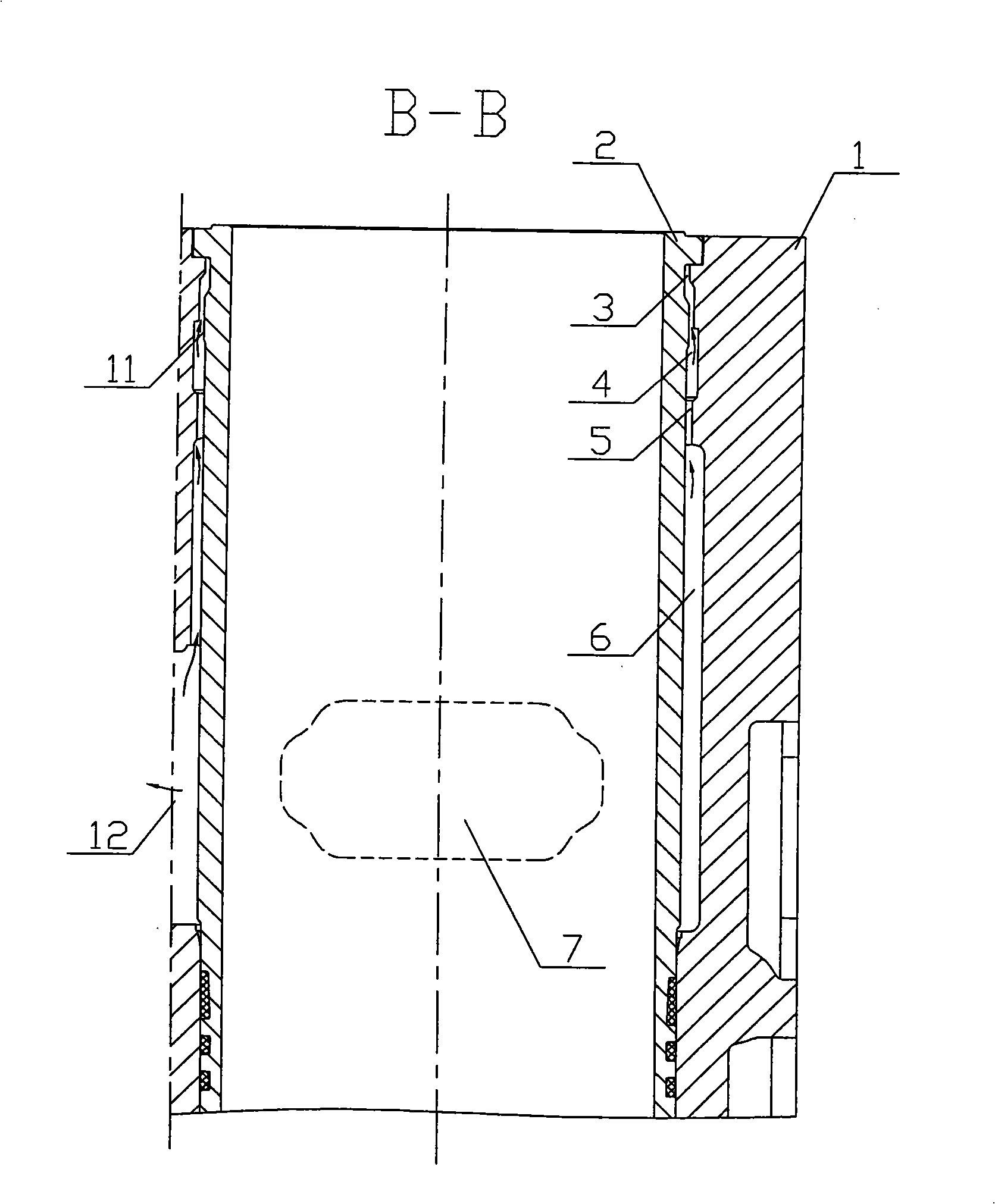

[0026] Figure 1 to Figure 9 As shown, it includes cylinder block 1, cylinder liner 2, third cooling chamber 3, second cooling chamber 4, annular gap 5, first cooling chamber 6, water inlet 7, convex ring 8, water outlet of the third cooling chamber 9. Water outlet 10, upper positioning belt 11, communication port 12, water jacket hole 13, water inlet 14 of the third cooling chamber, lower positioning belt 15. The arrows in the figure indicate the flow direction of the coolant.

[0027] Such as figure 1 Shown is the top view of the last cylinder in the multi-cylinder water-cooled engine block. The invention comprises a cylinder block 1 and a cylinder liner 2; a cooling water passage is provided between the cylinder liner 2 and the cylinder body 1, and a cooling liquid is passed through the cooling water passage to form a cooling water jacket. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com