Patents

Literature

76 results about "Spin casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spin casting, also known as centrifugal rubber mold casting (CRMC), is a method of utilizing centrifugal force to produce castings from a rubber mold. Typically, a disc-shaped mold is spun along its central axis at a set speed. The casting material, usually molten metal or liquid thermoset plastic, is then poured in through an opening at the top-center of the mold. The filled mold then continues to spin as the metal (or thermoset plastic) solidifies.

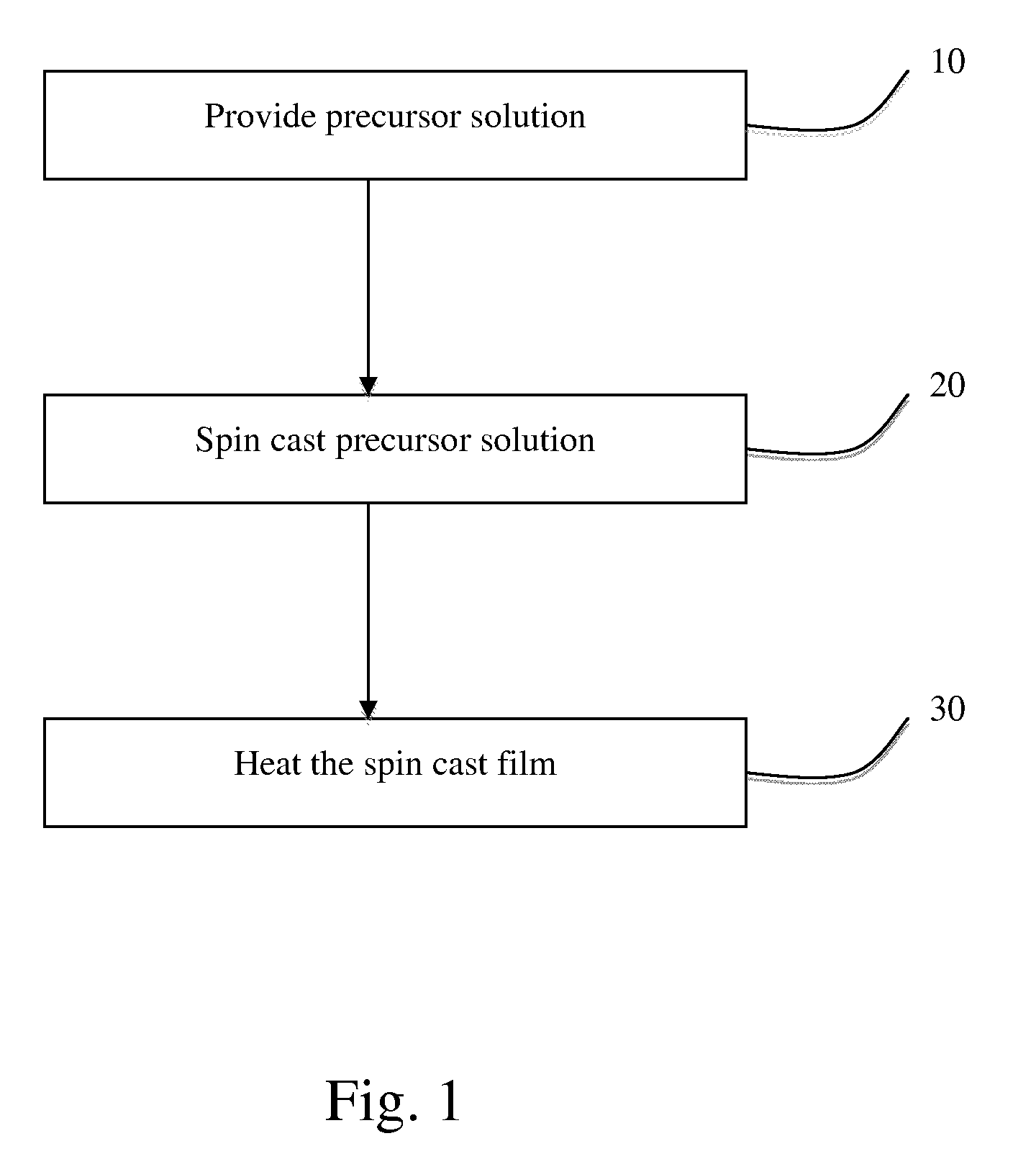

Multiferroic Nanoscale Thin Film Materials, Method of its Facile Syntheses and Magnetoelectric Coupling at Room Temperature

Methods of producing a multiferroic thin film material. The method includes the steps of providing a multiferroic precursor solution, subjecting the precursor solution to spin casting to produce a spin cast film, and heating the spin cast film. The precursor solution may include Bi(NO3)3.5H2O and Fe(NO3)3.9H2O in ethylene glycol to produce a bismuth ferrite film. Further, the thin film may be utilized in varied technological areas, including memory devices for information storage.

Owner:NORTHROP GRUMMAN SYST CORP +1

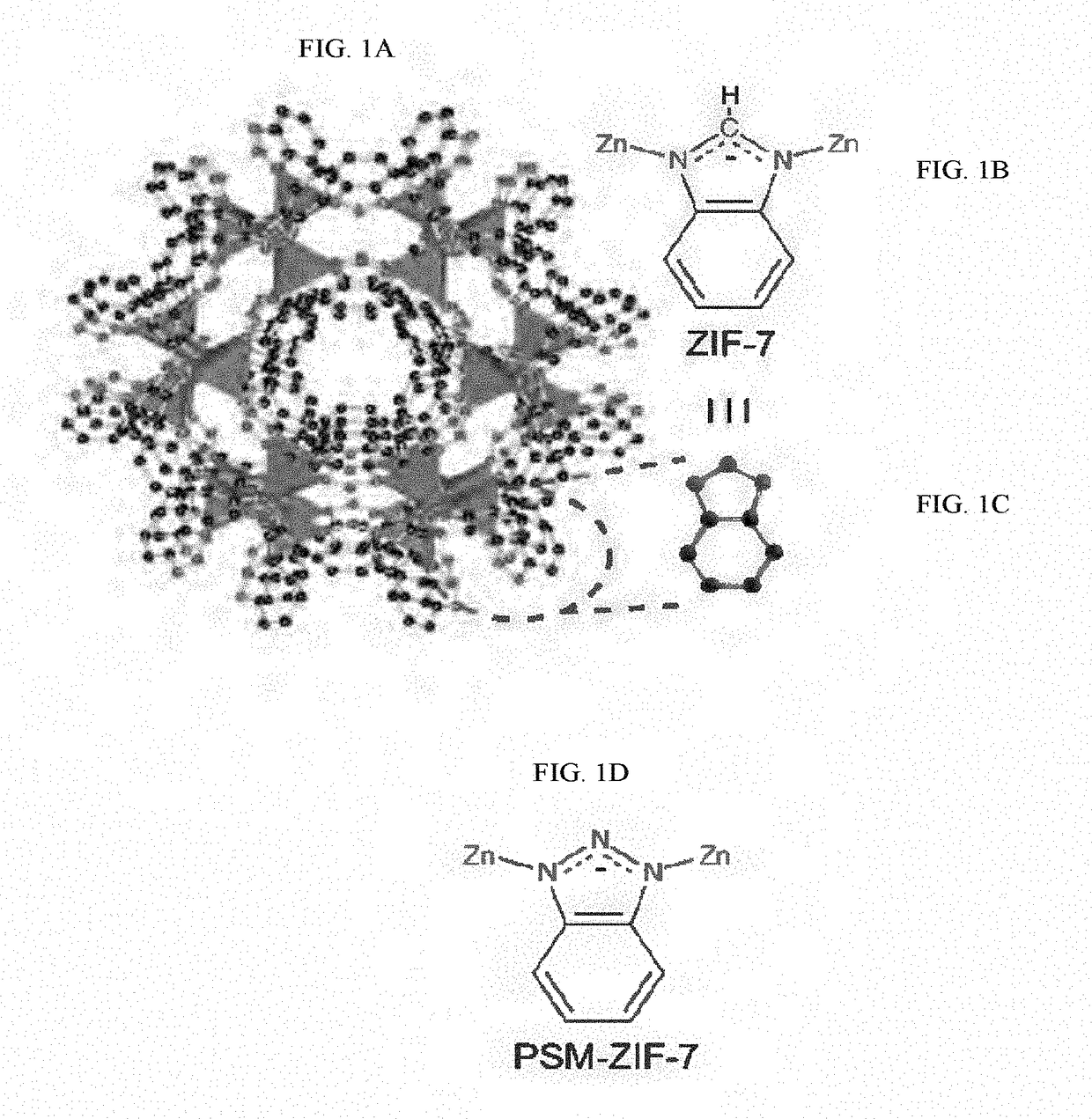

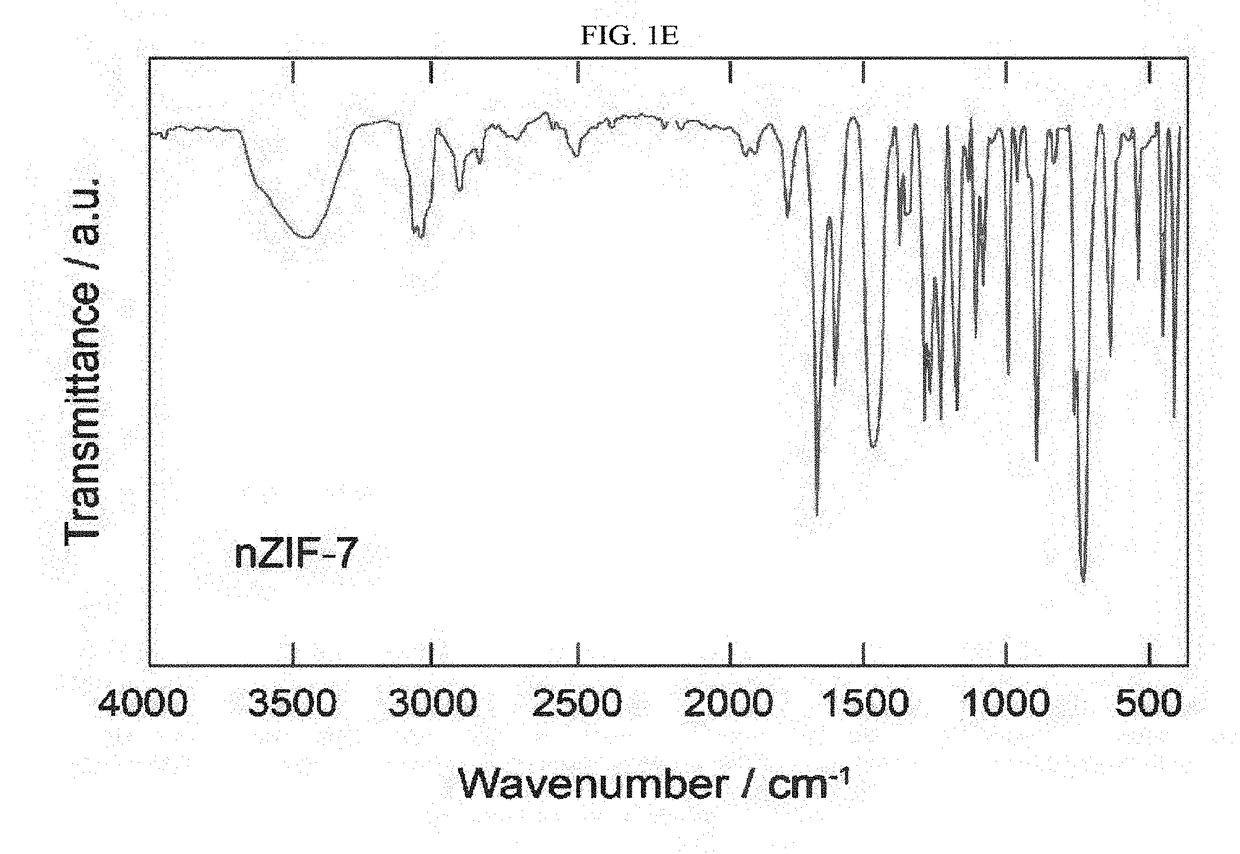

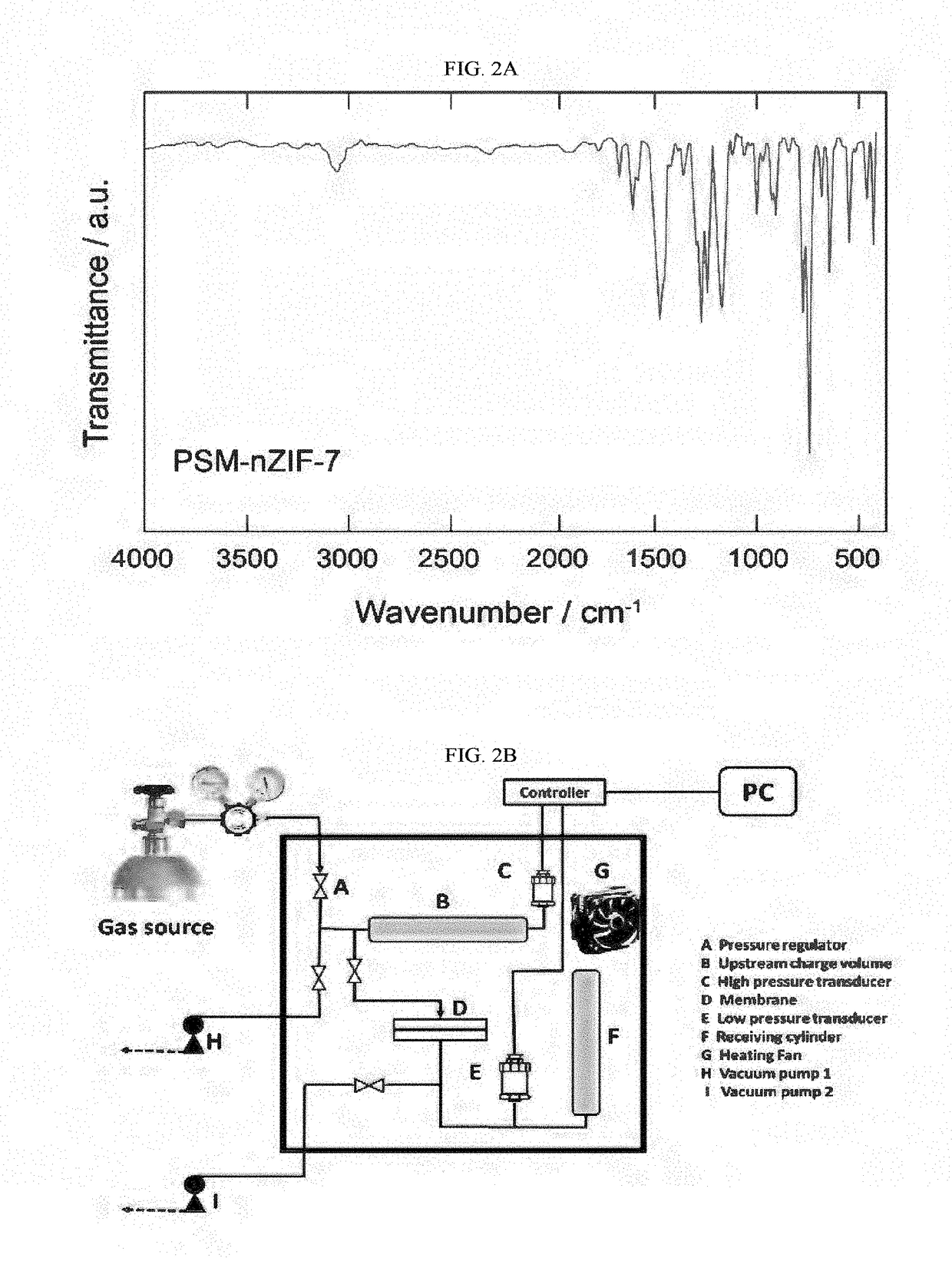

Mixed matrix membrane, a method of making thereof, and a method for gas separation

A mixed matrix membrane which is porous and has a cross section resembling a sponge. The membrane includes nanoparticle fillers which are also porous. The membrane may be freestanding or supported on a substrate. Methods of making the membrane by spin casting or solvent casting are described. Methods of separating a gas / organic vapor using the membrane are described.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

Thermoset in-mold finishing film

This invention relates to the manufacturing of durable thermoset in-mold finishing films (TIMFFs) combining in-mold decorating and in-mold durable exterior grade coating capabilities, to molded articles having TIMFFs adhering to their surfaces and both showing a decoration and providing protection, and to thermosetting resin formulations used in the manufacturing of TIMFFs. In some embodiments, the thermoset is prepared via polyurethane chemistry; the manufacturing process comprises reaction injection molding (RIM) with a specially designed mold; and articles having TIMFFs adhering to their surfaces include graphic panels for durable signage, structural graphics, molded flooring, prefabricated housing, aerospace structures and body panels, automotive structures and body panels, and marine structures and body panels. In addition to RIM, the TIMFF technology is also compatible with other processes, such as injection molding, compression molding, resin transfer molding, spin casting, rotational molding, thermoforming, roll lamination, use of a platen / laminate press, and blow molding.

Owner:ABSOLUTE EXHIBITS

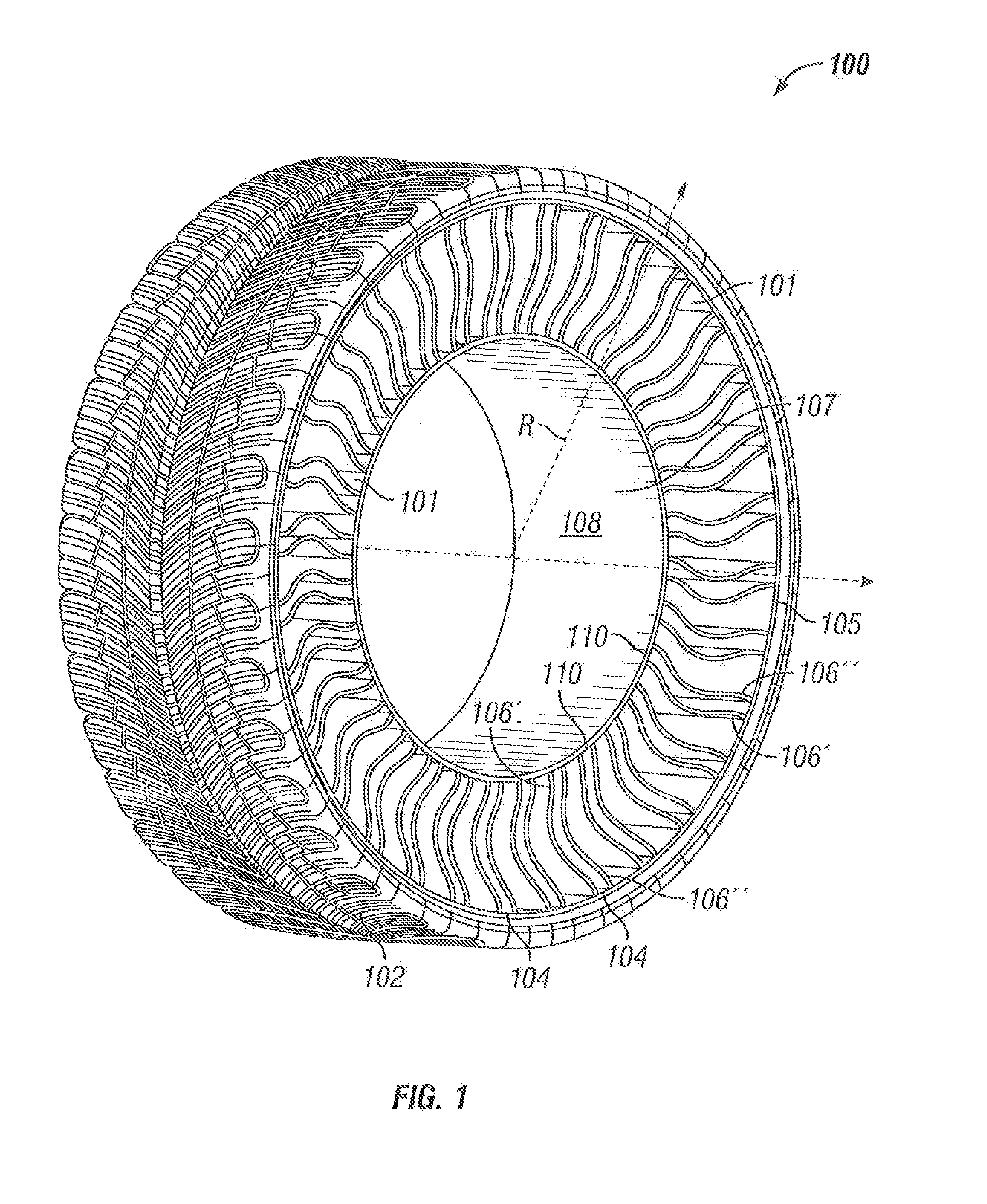

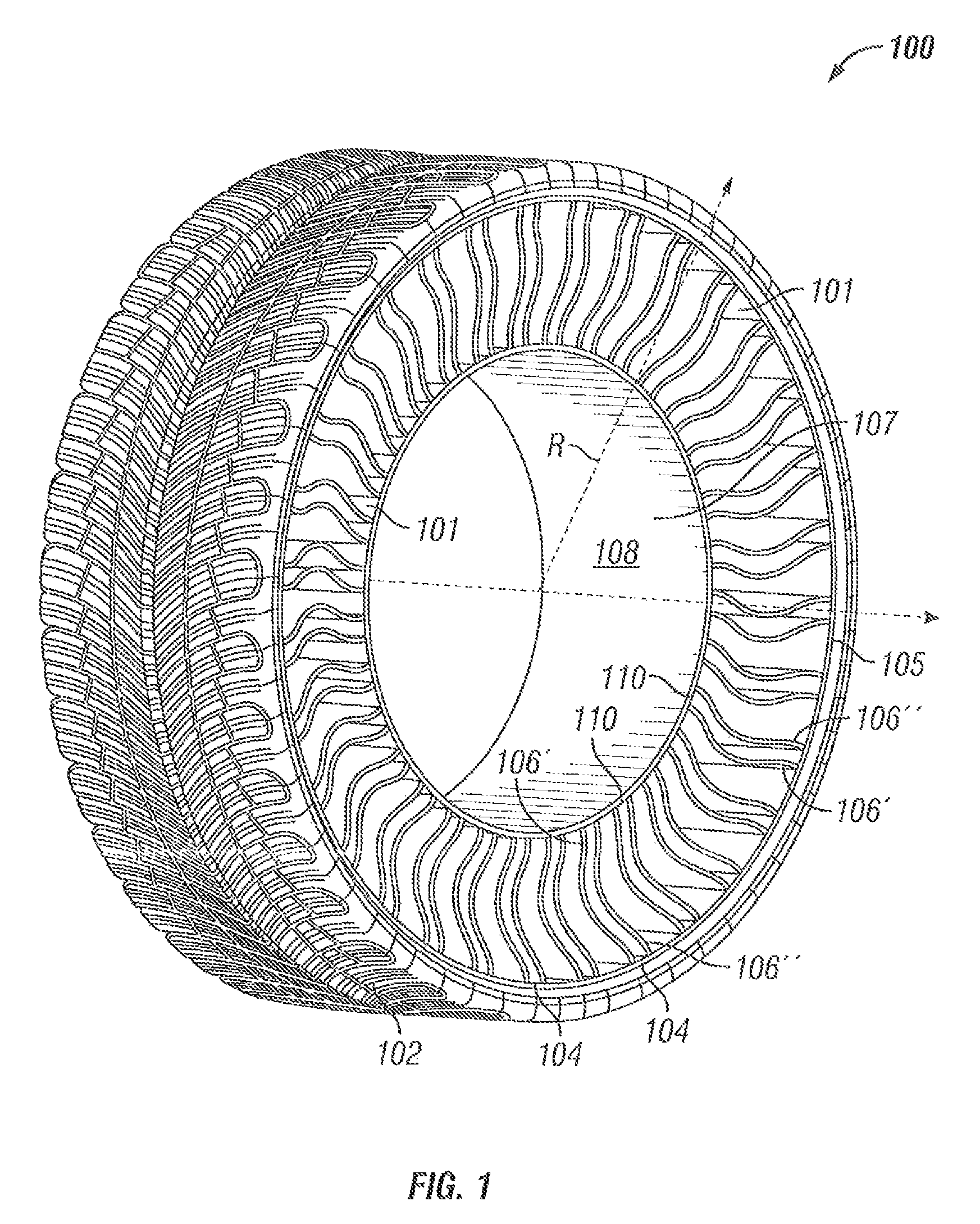

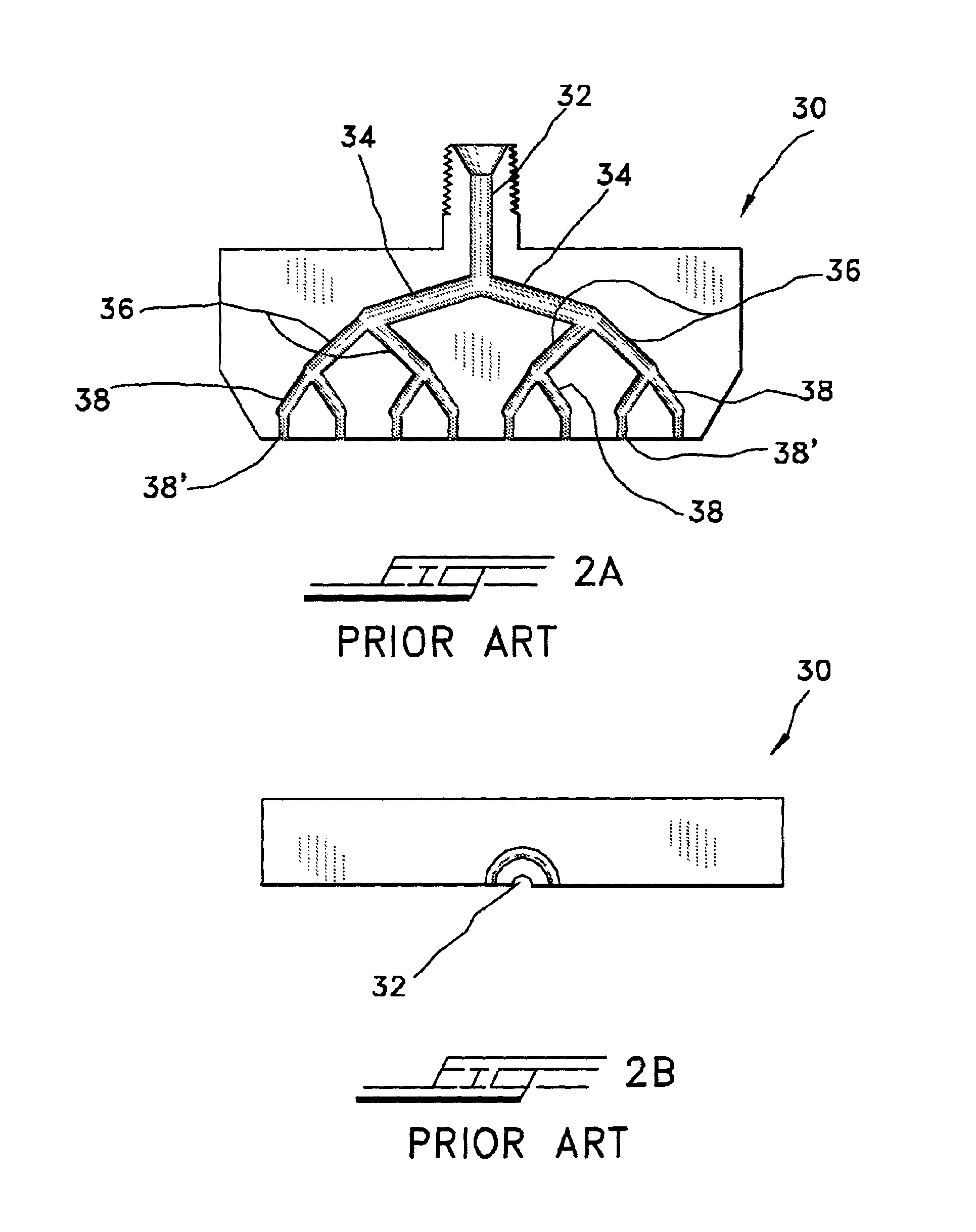

Tire core package for use in manufacturing a tire with belts, plies and beads and process of tire manufacture

InactiveUS6974519B2Conveniently rolled into sectionDesired hardnessWithout cord reinforcementTyresFiberElastomer

A system for manufacturing an elastomeric tire utilizing a separate formation of a package having a tire core shape and containing tire belts, plies and beads. The package is formed by a laying up of layers of pre-cure elastomer intradigitated with sections of porous fabric, where the fabric fibers are placed at desired crossing angles to one another, and the pre-cure elastomer layers are positioned therebetween as a sandwich, with the sandwich then cold rolled into the tire core shape. Inelastic hoop shaped beads are fitted to and encapsulated in the tire core side walls ends and, as required, an inelastic belt is fitted around the tire core tread area that is secured thereto as by cold rolling a layer of pre-cure elastomer thereover, completing the tire core package. The tire core package is fitted into a mold, preferably a spin casting mold, and is supported therein equidistant from the mold cavity walls to receive an elastomer sprayed therein as the mold is spun. During spinning, the exothermic heat of reaction of the sprayed elastomer constituents as is generated as they are mixed and sprayed into the mold, completes the cure of the pre-cure elastomer, providing a homogenous finished tire with the belts, plies and beads optimally positioned therein.

Owner:AMERITIRE

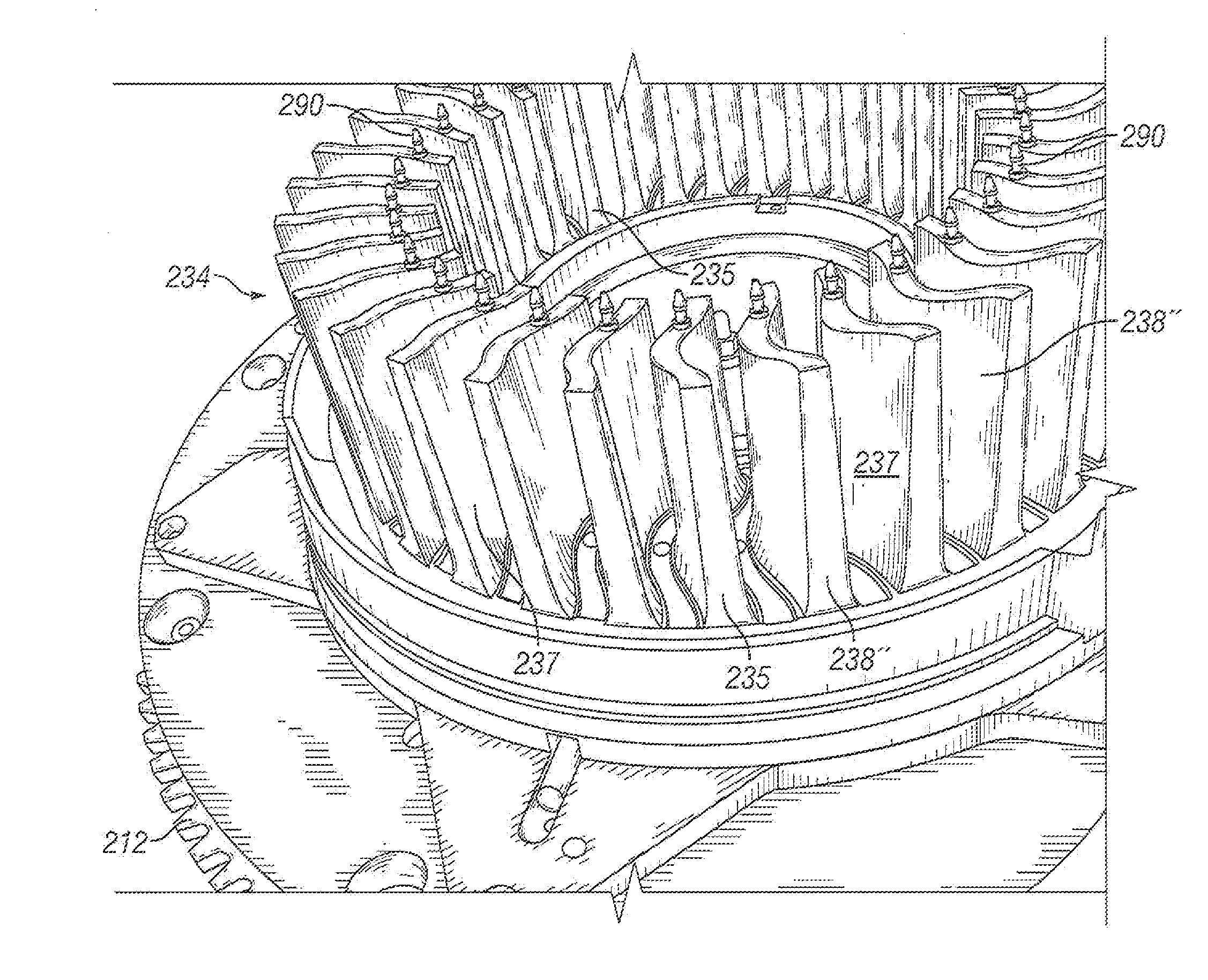

Apparatus for casting a non-pneumatic tire having a floating mold alignment mechanism

Owner:MICHELIN RECH & TECH SA +1

Pre-cast concrete wall system

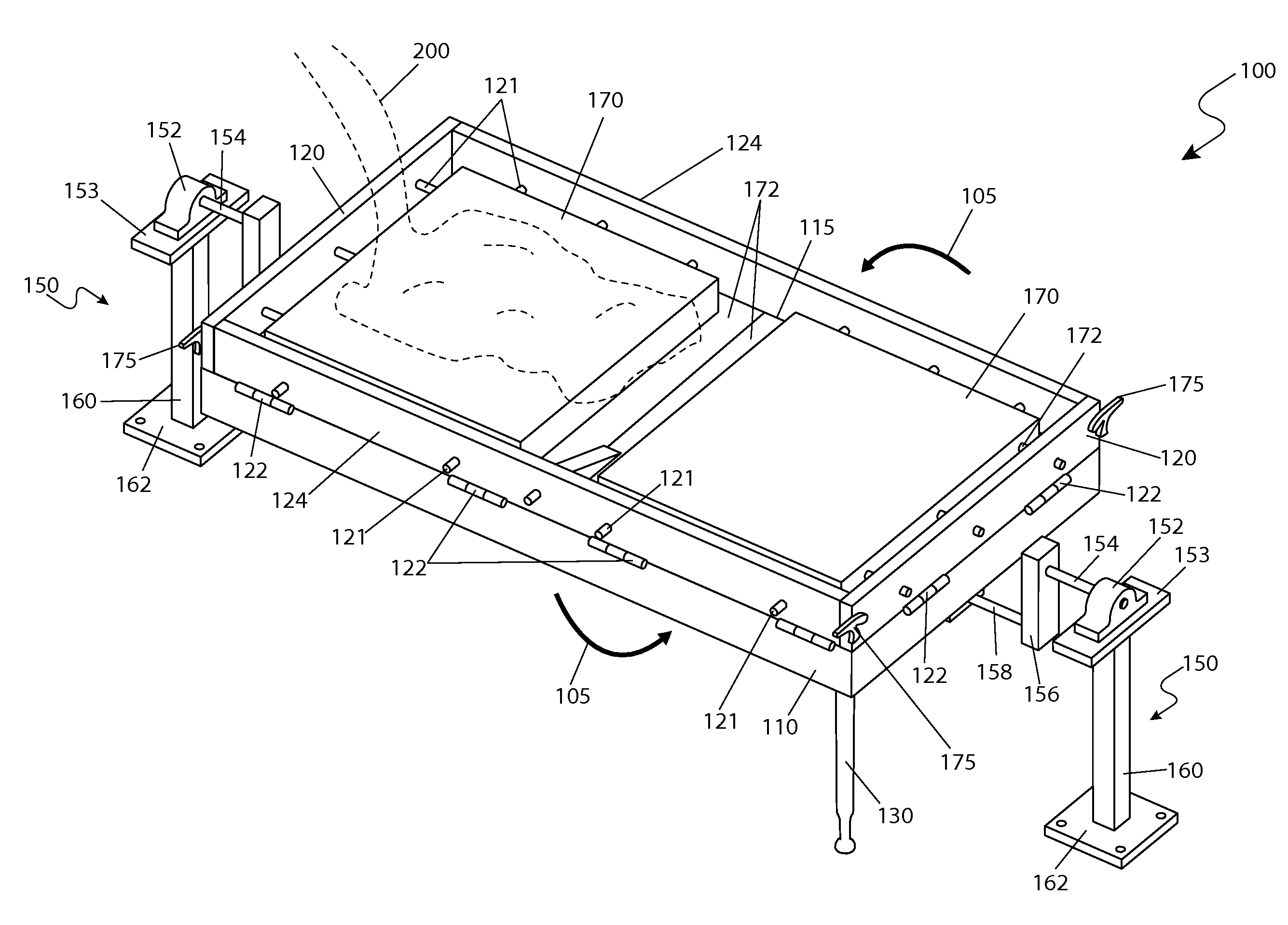

InactiveUS8790109B1Reduce weightReduce material costsMould separation apparatusMouldsSpin castingSubstructure

A pre-cast concrete wall system for crawlspace applications is herein disclosed. The system includes a plurality of interconnected pre-cast concrete wall panels having a recessed area along one side to reduce concrete usage and weight, while maintaining load bearing properties. The wall panels are securely fastened to a substructure, such as footers, using anchors and to each other by opposingly aligned keyways and connecting fasteners. Each wall panel includes at least one (1) pair of leveling bolts which provides for the leveling of the wall panels and correct for any unevenness in the footer. The wall panels are fabricated using a rotating casting table which allows an operator to pour concrete at ergonomic heights and rotate the casting table and cured wall panel member to a vertical position for convenient unloading and transportation of the wall panel to a job site.

Owner:BROWNSON THAD J

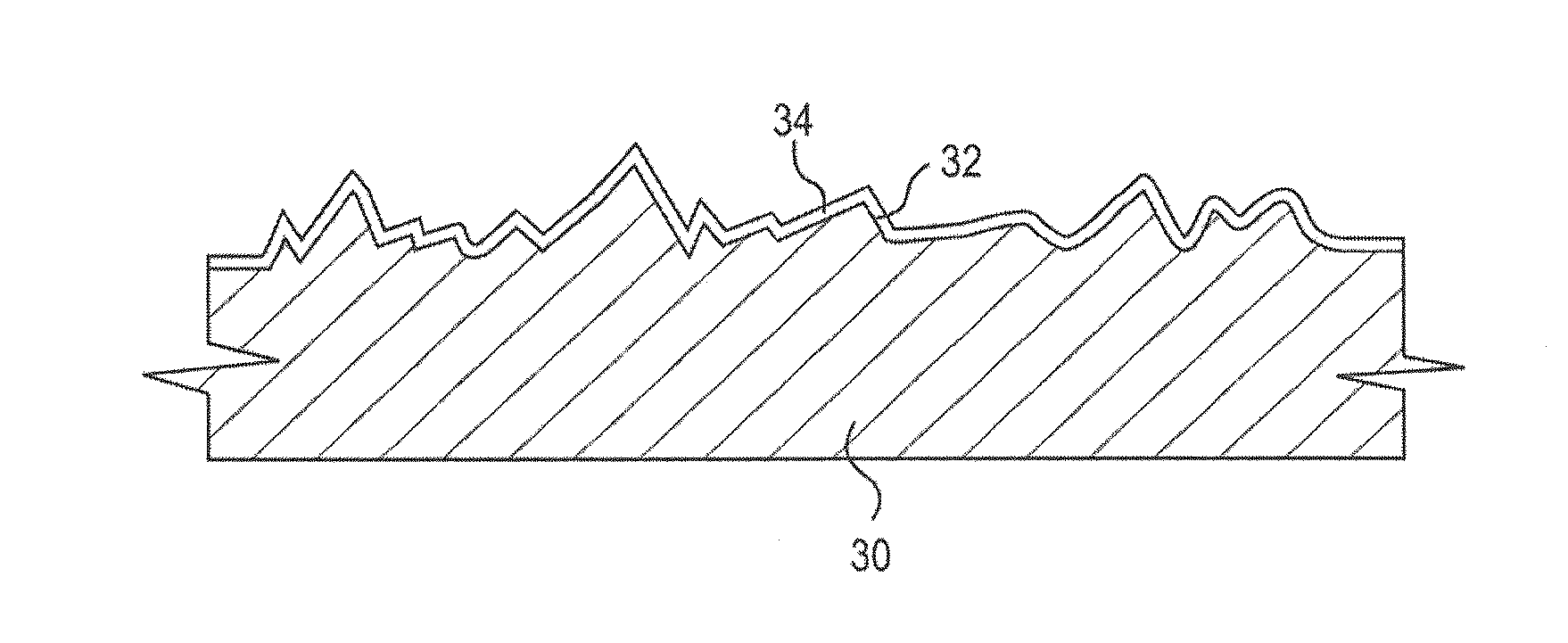

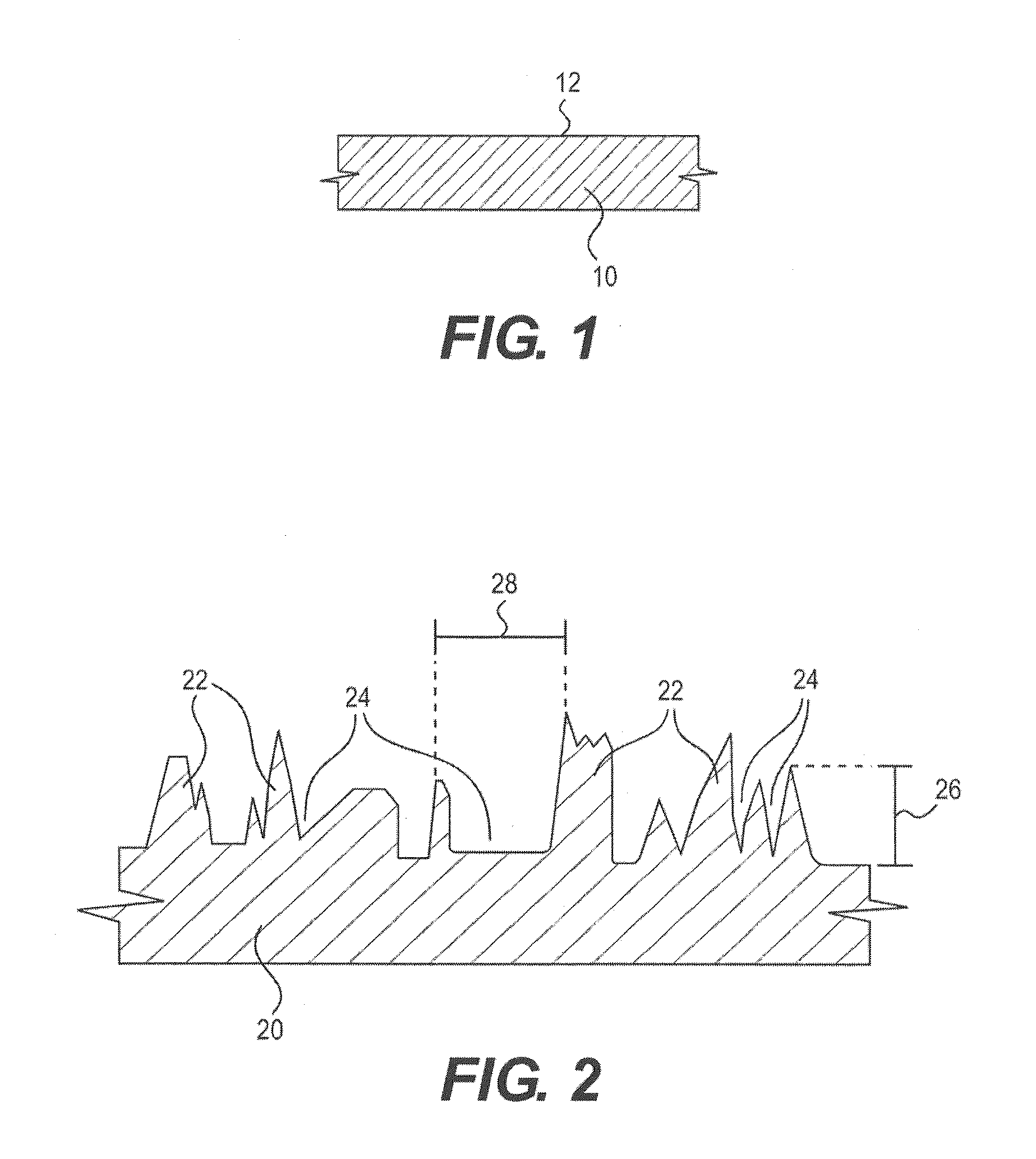

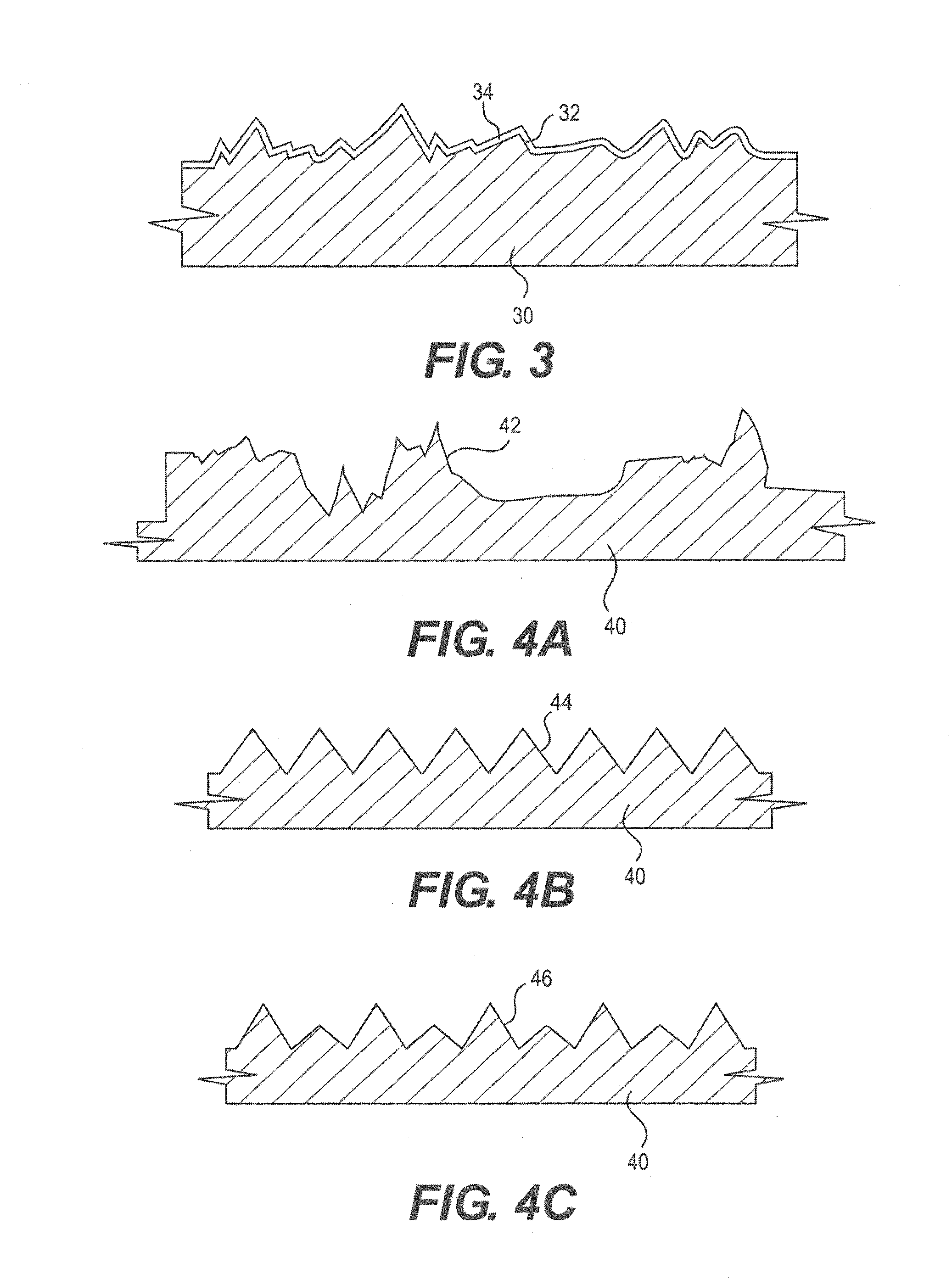

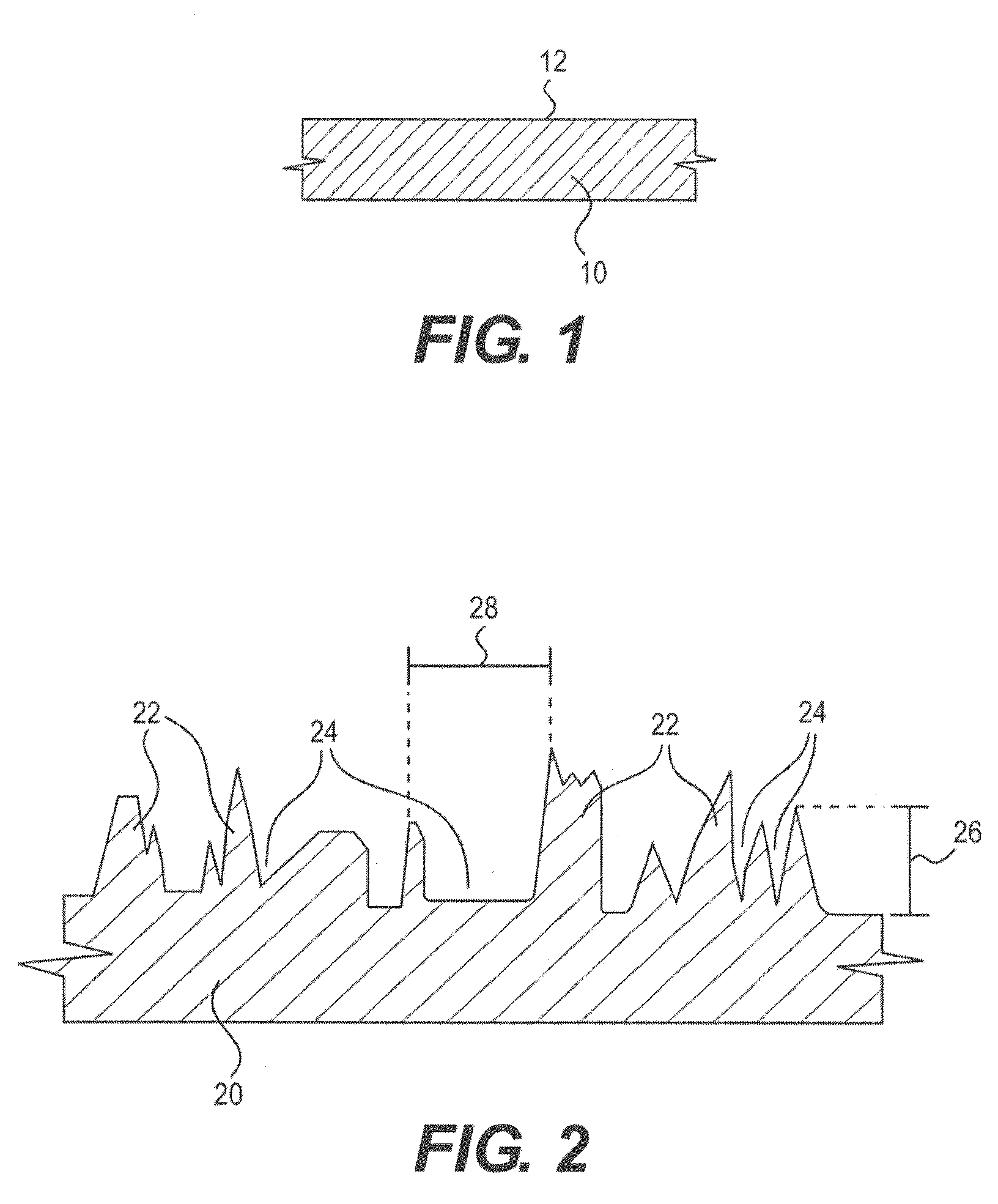

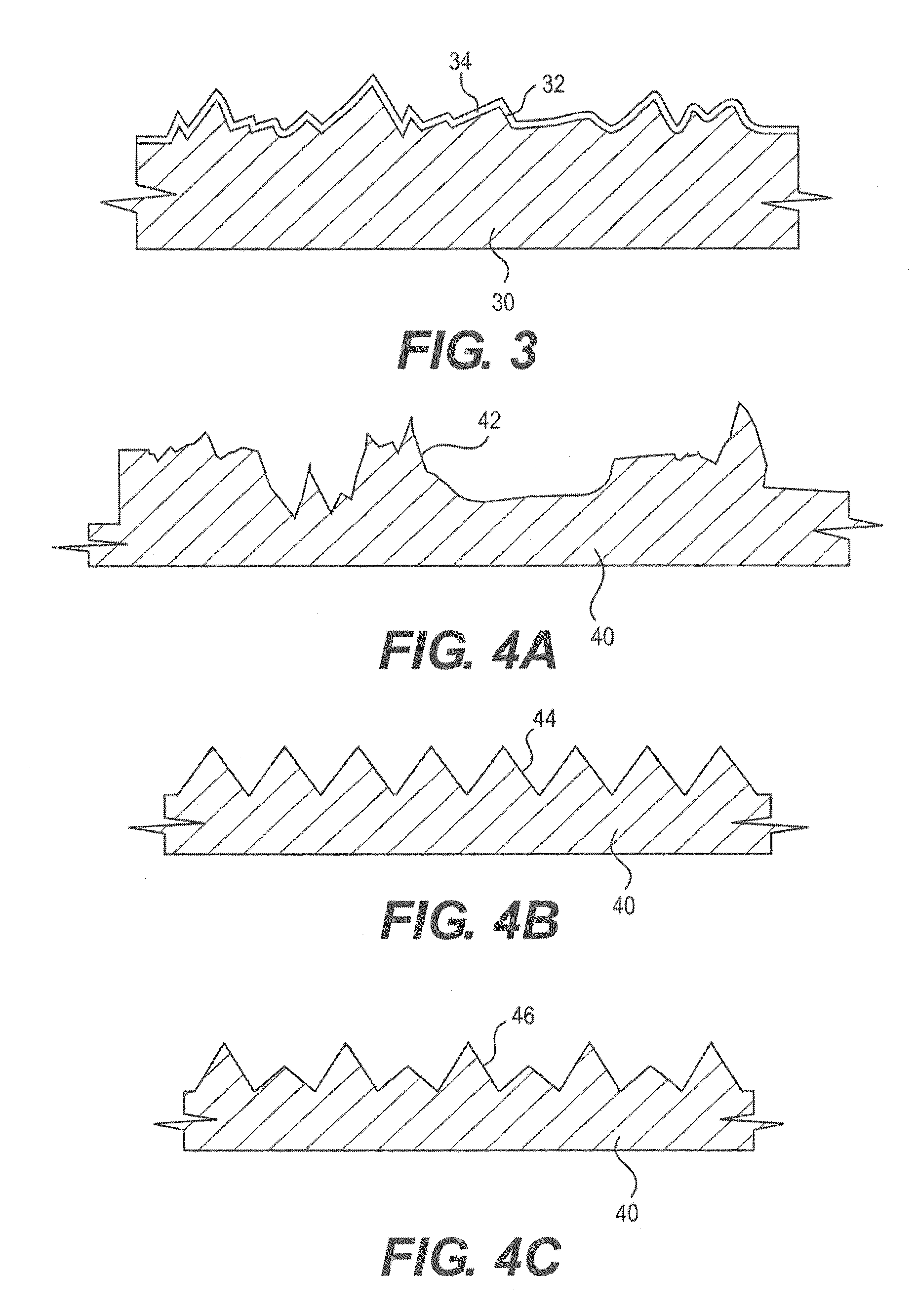

Modified Surface Having Low Adhesion Properties To Mitigate Insect Residue Adhesion

ActiveUS20150251217A1Reduced adhesion surface propertyMitigate insect residue adhesionRadiation applicationsDe-icing equipmentsParticulatesEtching

A process to modify a surface to provide reduced adhesion surface properties to mitigate insect residue adhesion. The surface may include the surface of an article including an aircraft, an automobile, a marine vessel, all-terrain vehicle, wind turbine, helmet, etc. The process includes topographically and chemically modifying the surface by applying a coating comprising a particulate matter, or by applying a coating and also topographically modifying the surface by various methods, including but not limited to, lithographic patterning, laser ablation and chemical etching, physical vapor phase deposition, chemical vapor phase deposition, crystal growth, electrochemical deposition, spin casting, and film casting.

Owner:NASA

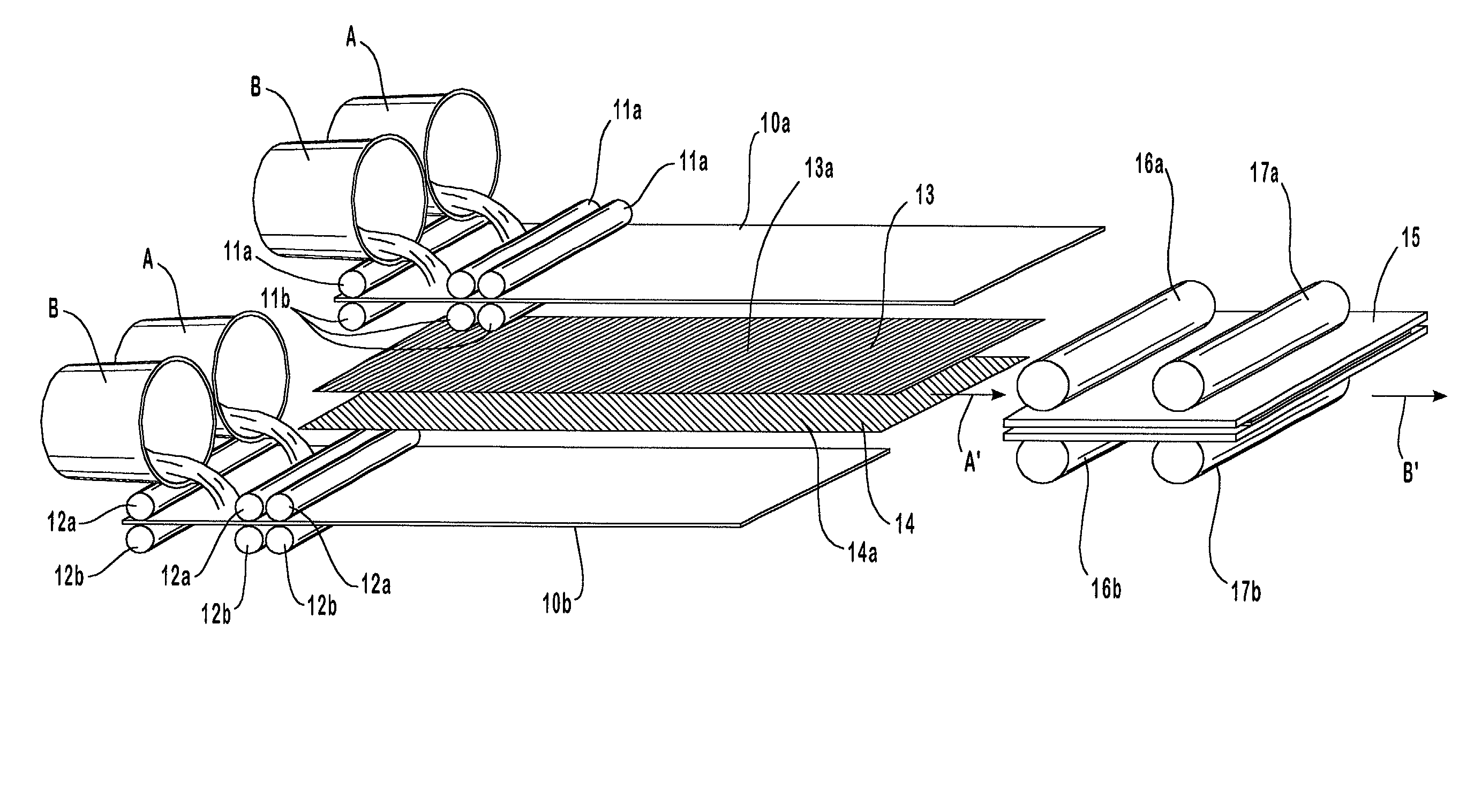

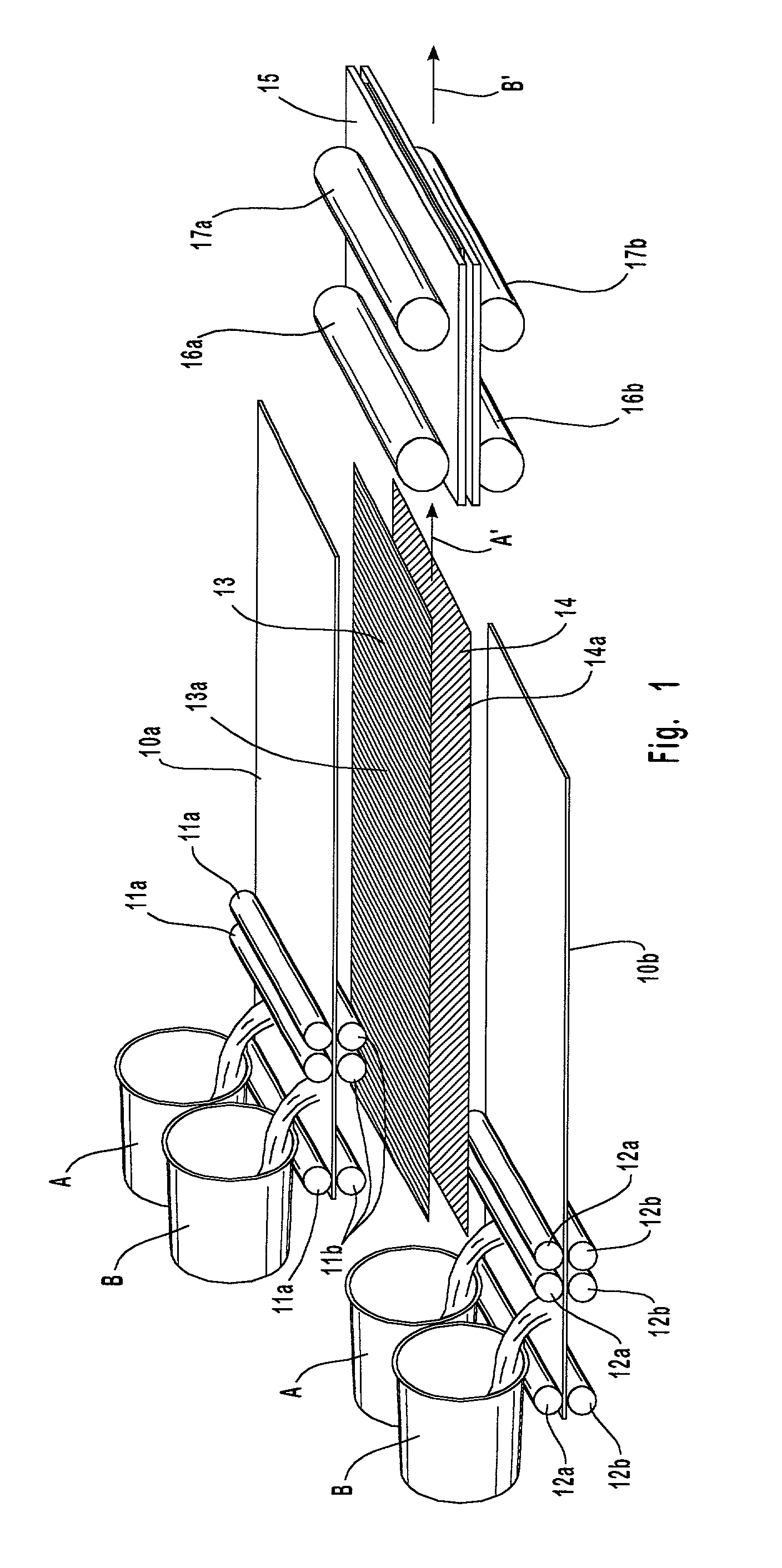

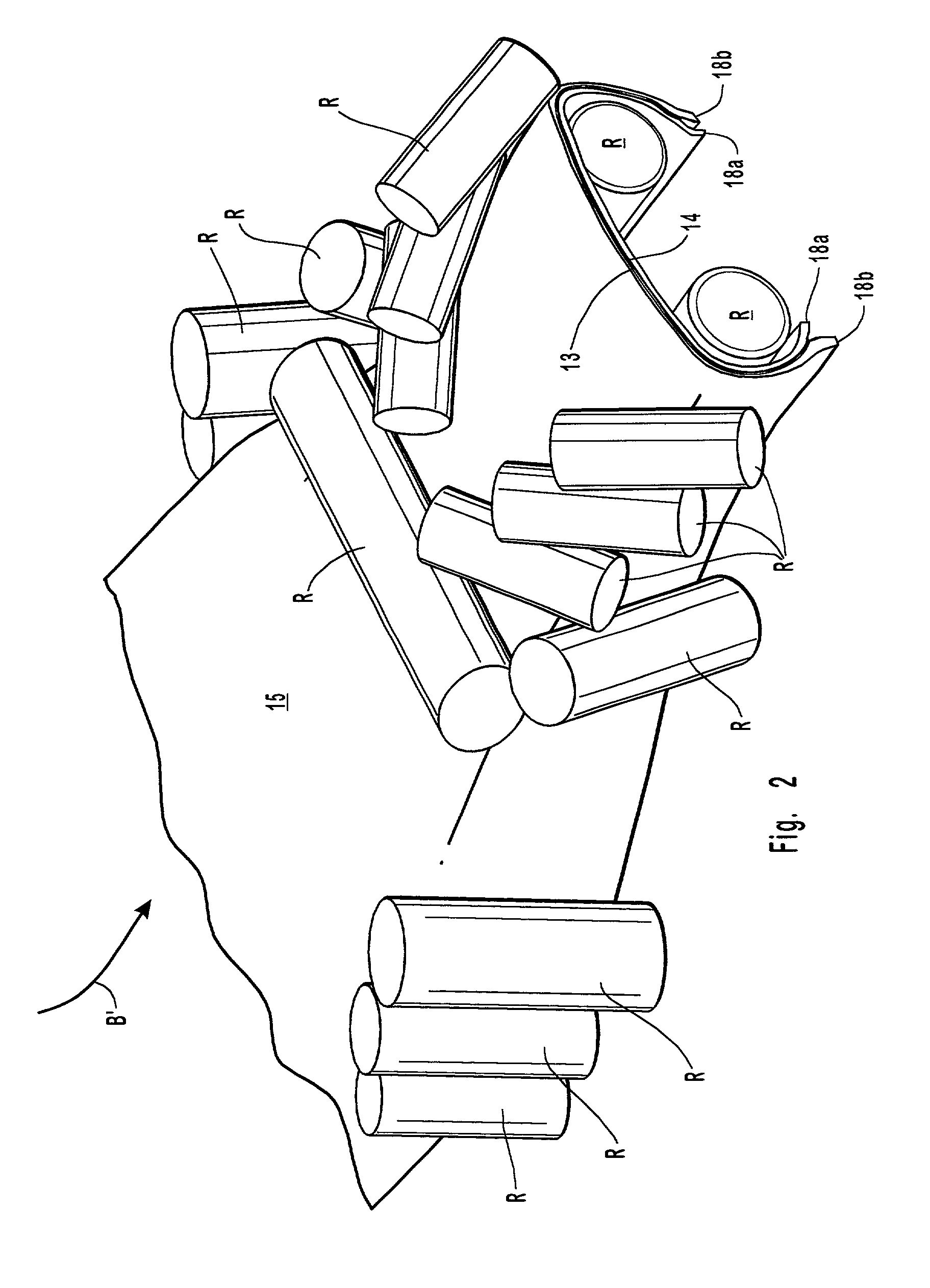

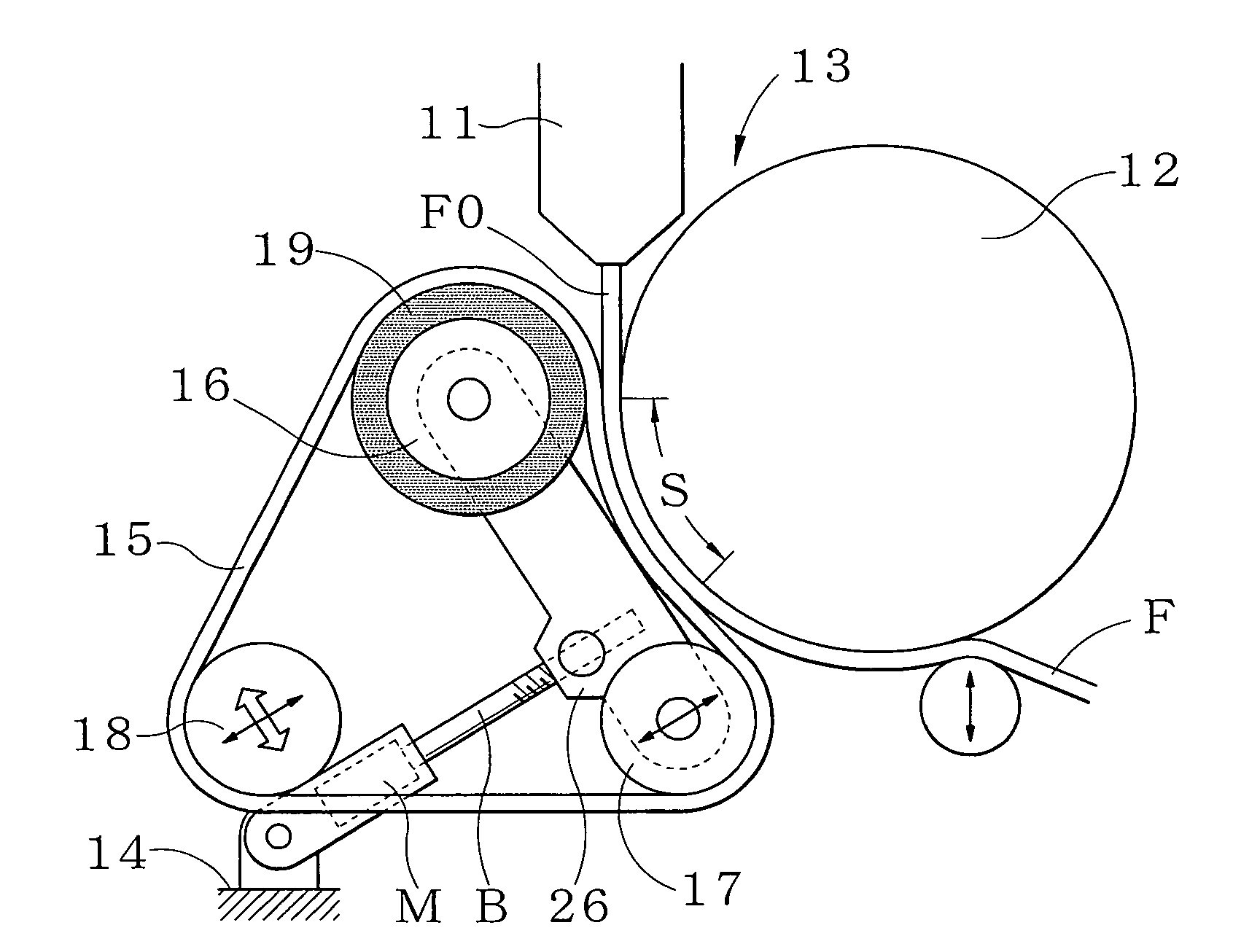

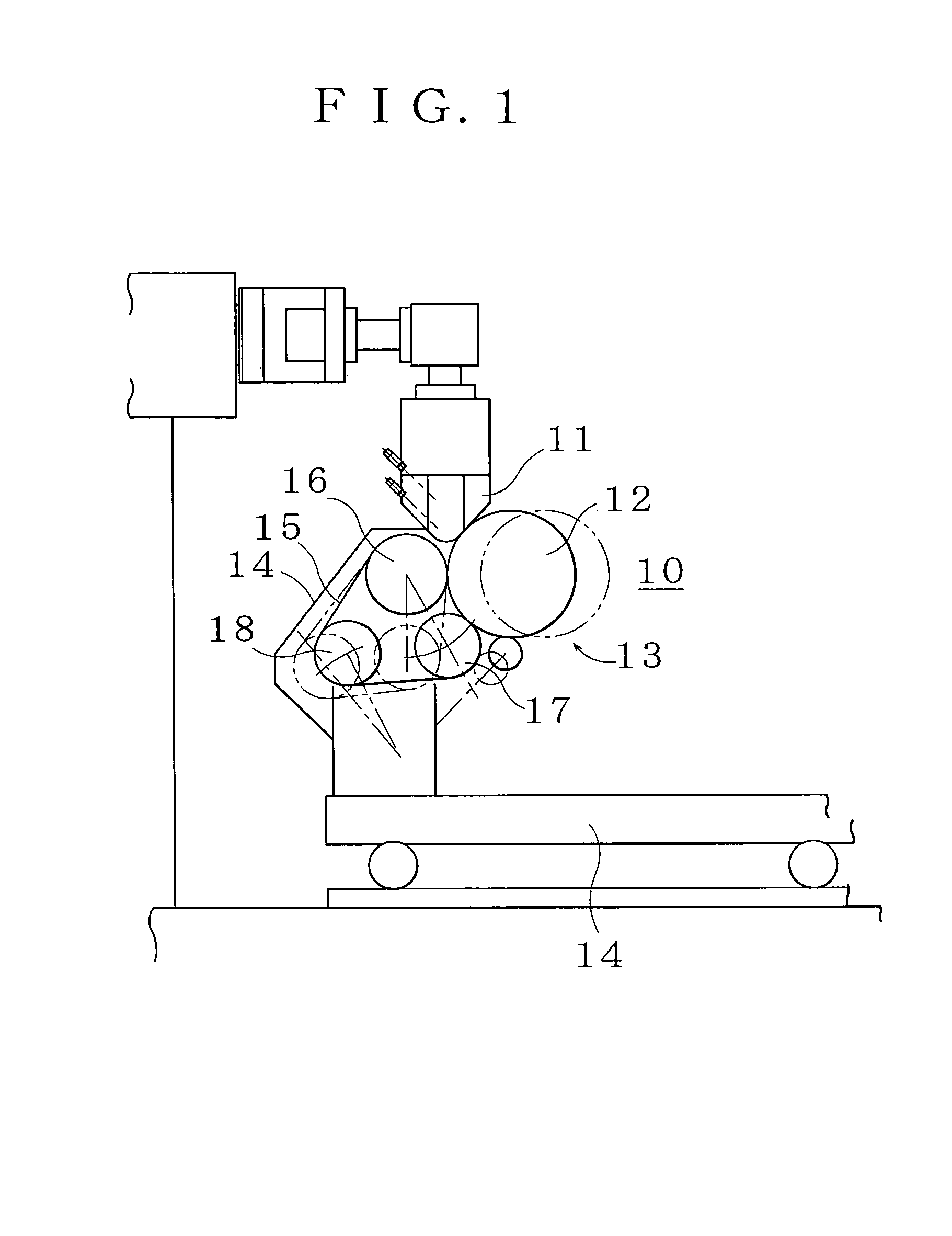

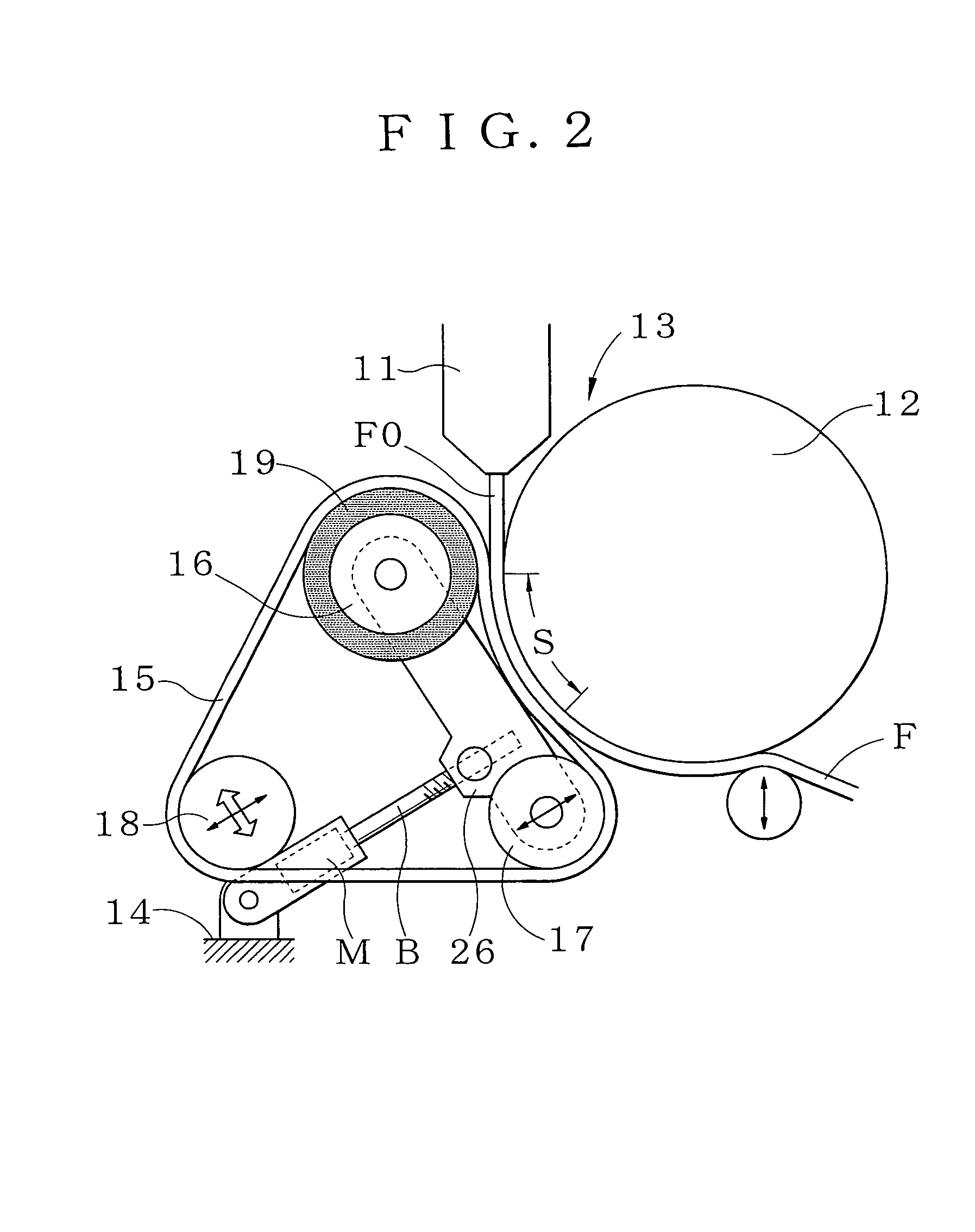

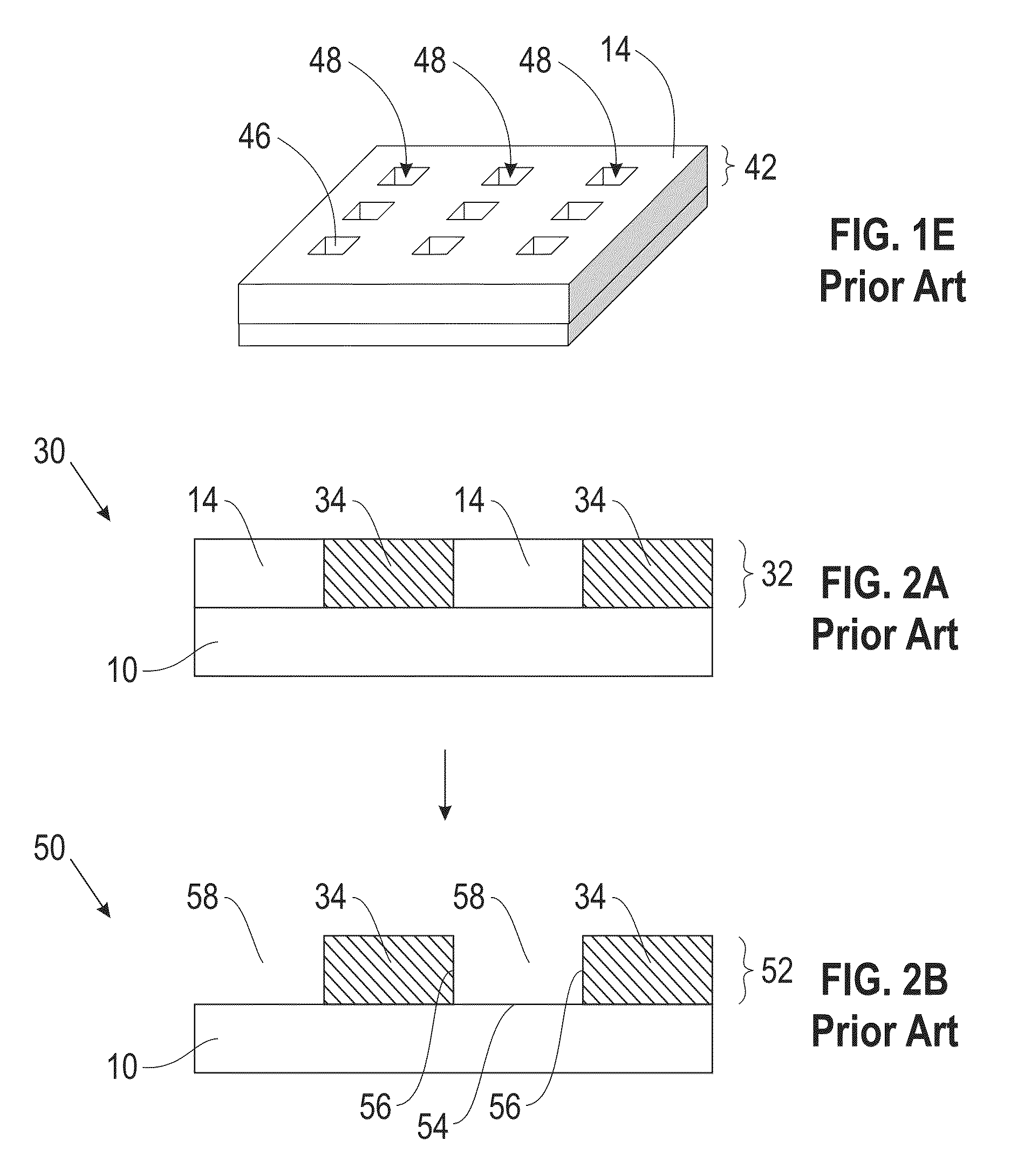

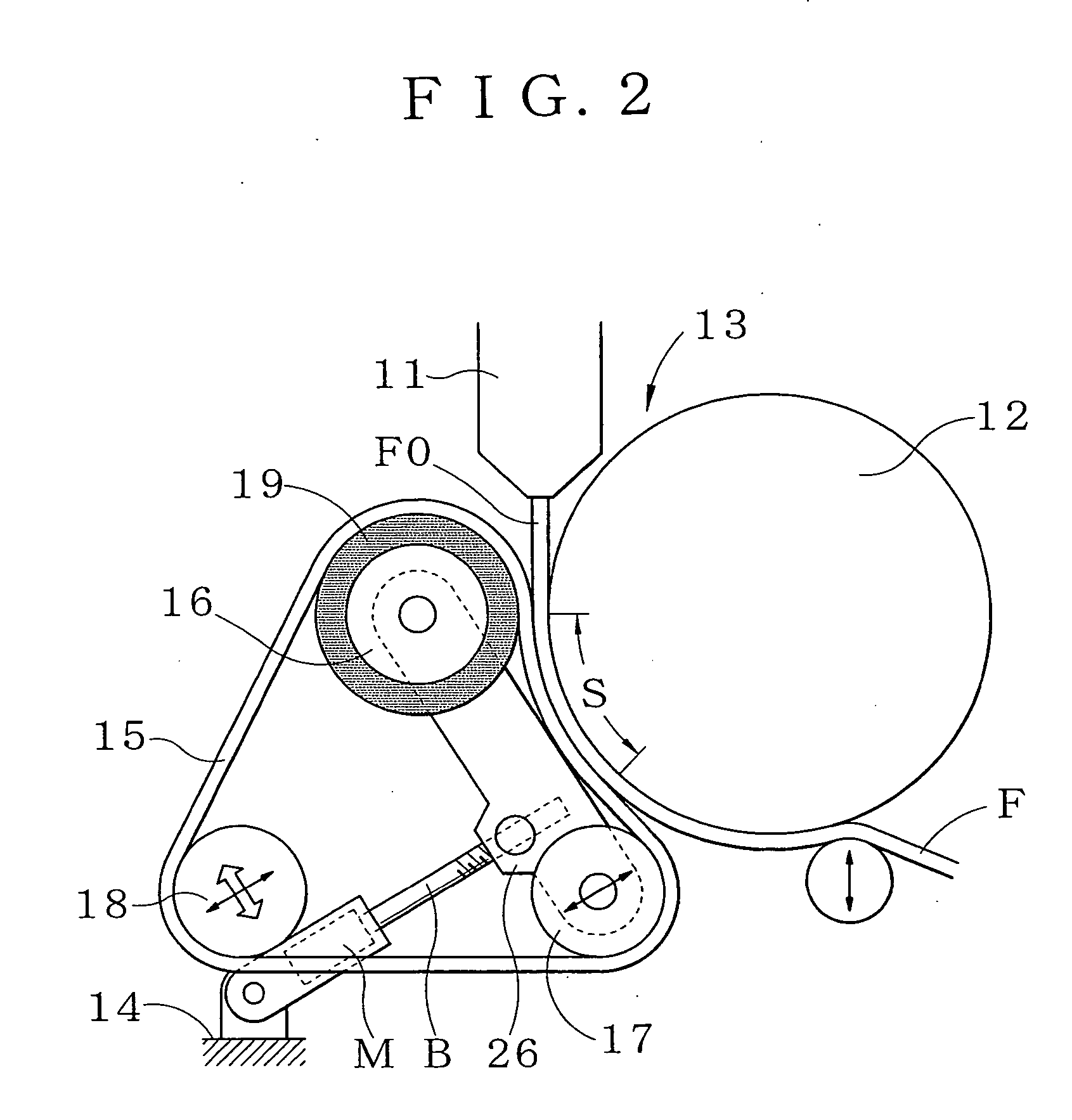

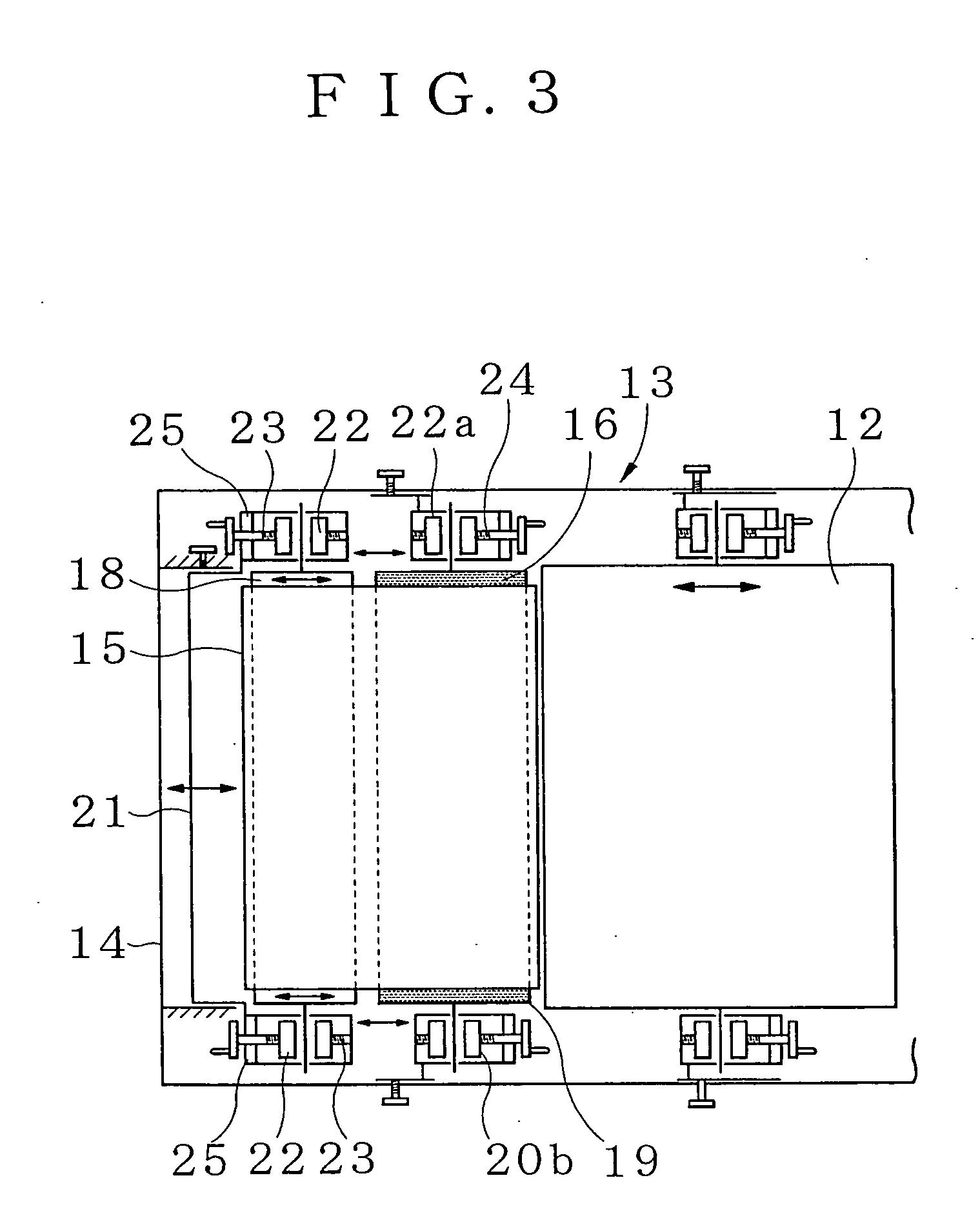

Method and apparatus for producing thermoplastic synthetic resin sheet or film

InactiveUS7427372B2High glossStable continuous productionDough-sheeters/rolling-machines/rolling-pinsConfectioneryRotational axisSpin casting

An apparatus for producing a thermoplastic synthetic resin sheet or film has a casting mechanism having support rollers each mounted to undergo rotation about a corresponding rotational axis and one of which is mounted to undergo non-rotational displacement relative to the other support rollers. A casting sleeve is entrained around the support rollers for rotation therewith. A casting roller is mounted for undergoing rotation relative to the casting sleeve. A synthetic resin material is fed between opposite and confronting outer peripheral surfaces of the casting sleeve and the casting roller while rotating the casting sleeve and the casting roller and while effecting non-rotational displacement of one of the support rollers to holdingly press the synthetic resin material between the casting sleeve and the casting roller and thereby form the synthetic resin material into a thermoplastic synthetic resin sheet or film.

Owner:CTE

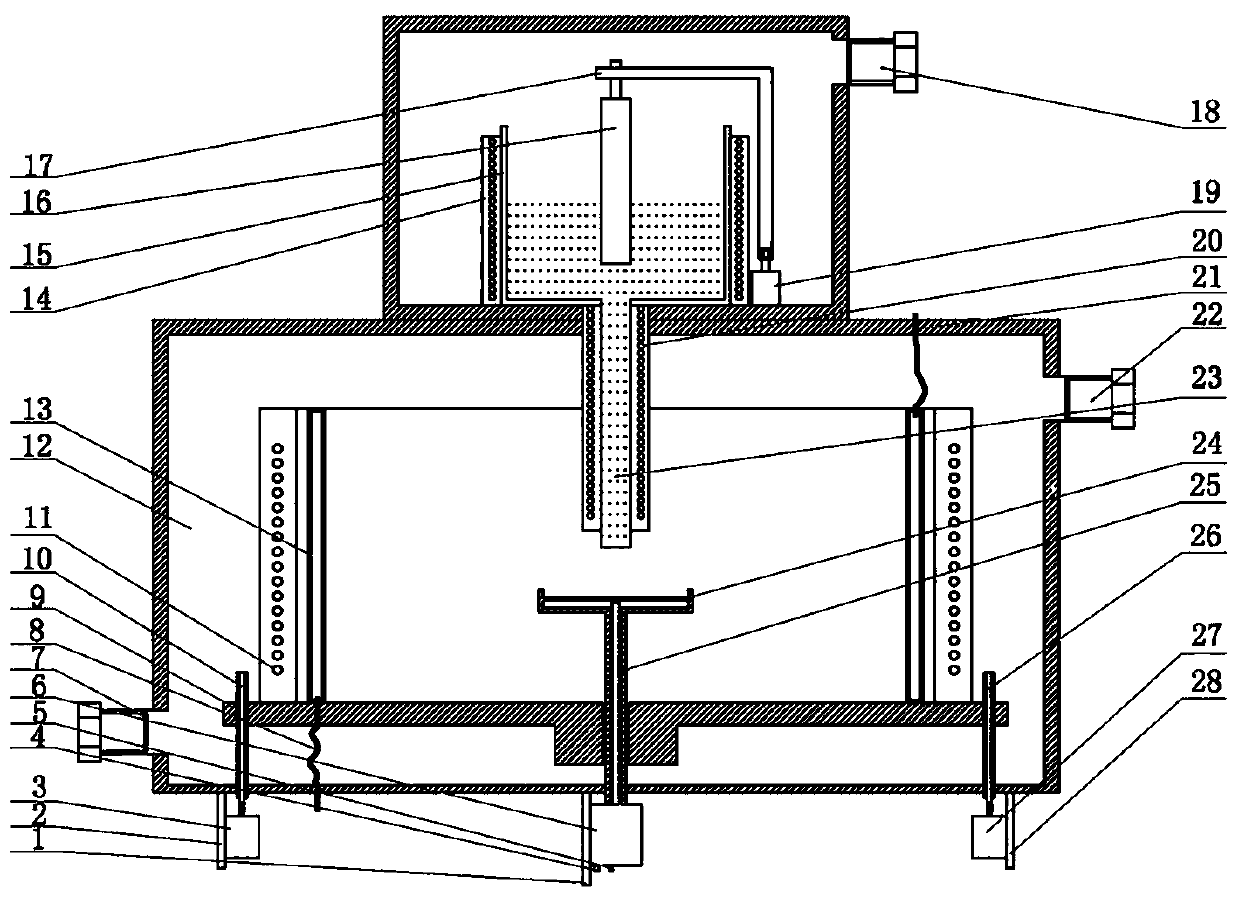

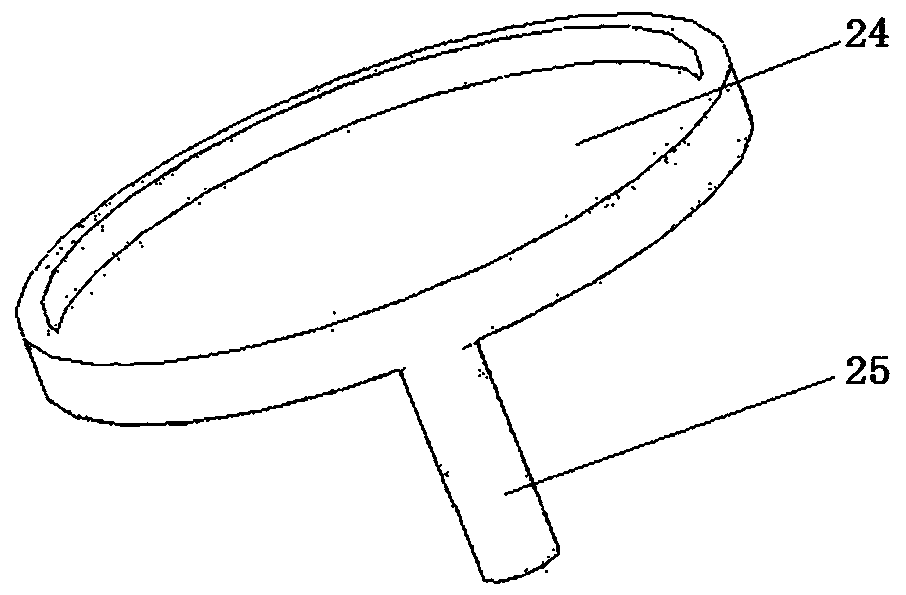

Spin-casting device and spin-casting centrifugal disk

The invention relates to a spin-casting device and a spin-casting centrifugal disk. The spin-casting device comprises a fixed frame, the fixed frame is provided with a crucible for holding metal raw materials in a molten state, a centrifugal disk body is arranged under the crucible, and the centrifugal disk body rotates at a high speed to atomize and throw out the metal raw materials and the metalraw materials are attached to the inner wall of a cylinder-shaped die; and the centrifugal disk body is further provided with a cooling medium flow channel, and a cooling medium can cool the disk surface of a disk body. The cooling medium is led to the cooling medium flow channel of the centrifugal disk body in the centrifugal disk body to cool the disk surface, and when the metal raw materials are poured downwards onto the centrifugal disk body by a flow guide pipe under the crucible, heat exchange is carried out between the metal raw materials and the disk surface, so that heat of the metalraw materials is reduced, cooling can be carried out faster; and in the process of throwing out, the metal raw materials can form semi-solid droplets smoothly, and the phenomenon of sample collapse due to the fact that the atomized particles still keep in a liquid state when colliding with the inner wall of the cylinder-shaped die and the droplets on the die fuse and flow together is avoided, sothat a produced metal hollow ingot has a flat surface, uniform thickness and small grain size.

Owner:HENAN UNIV OF SCI & TECH

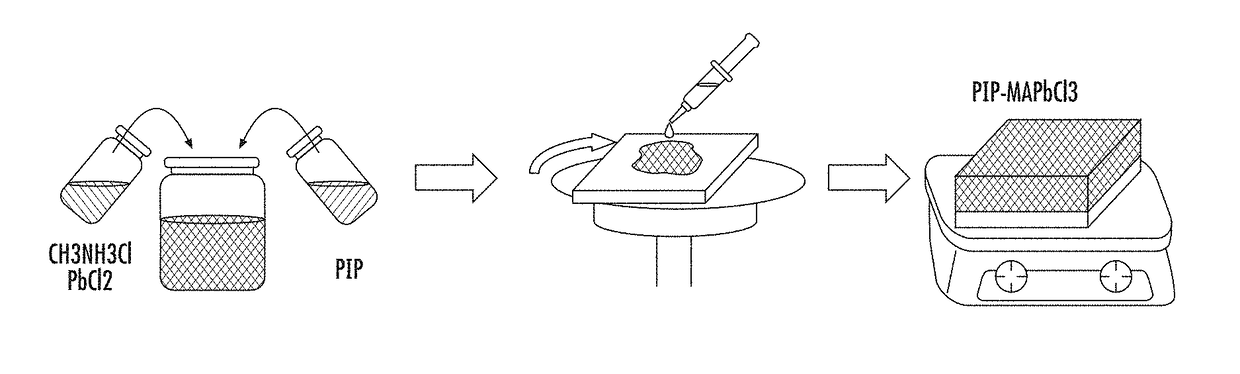

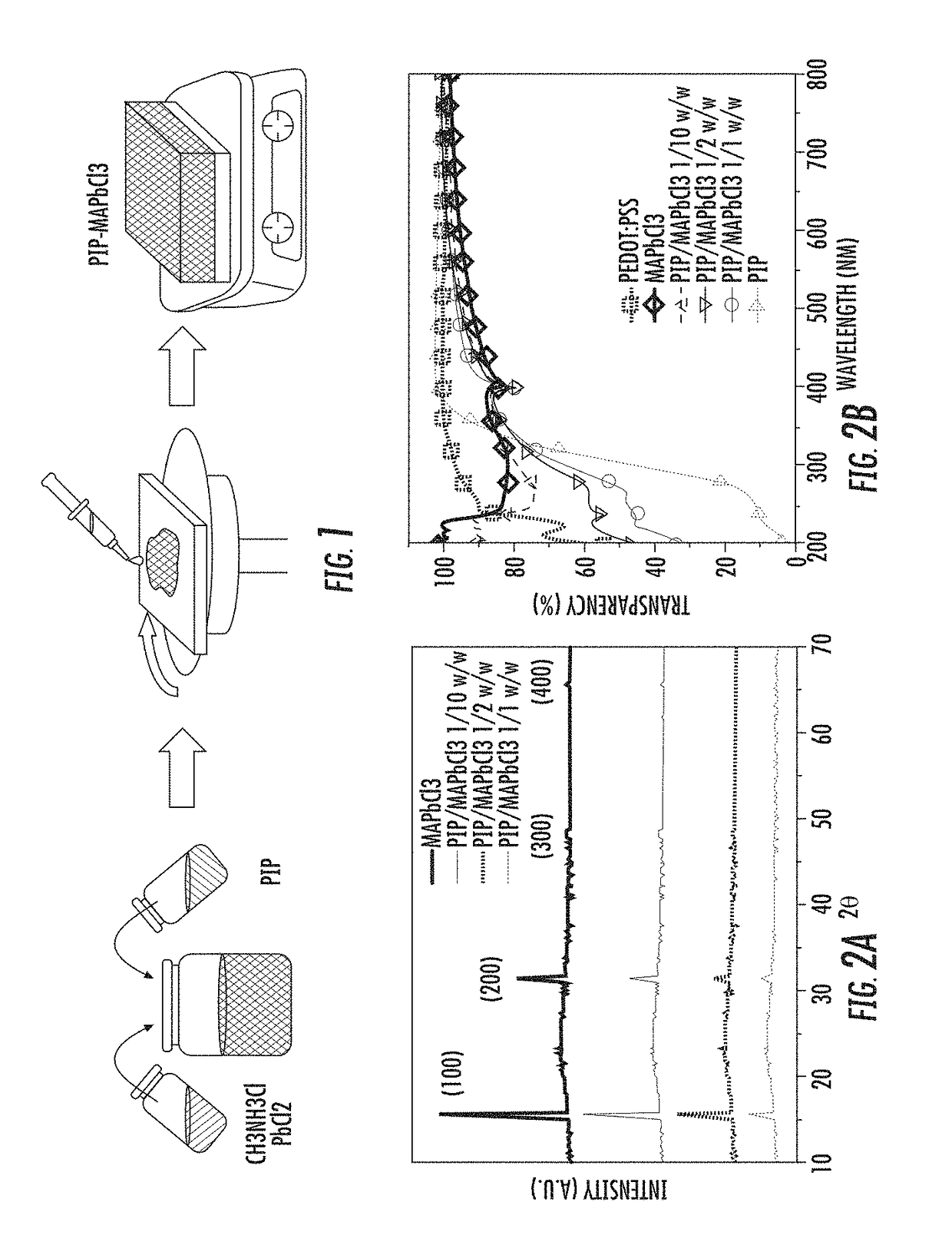

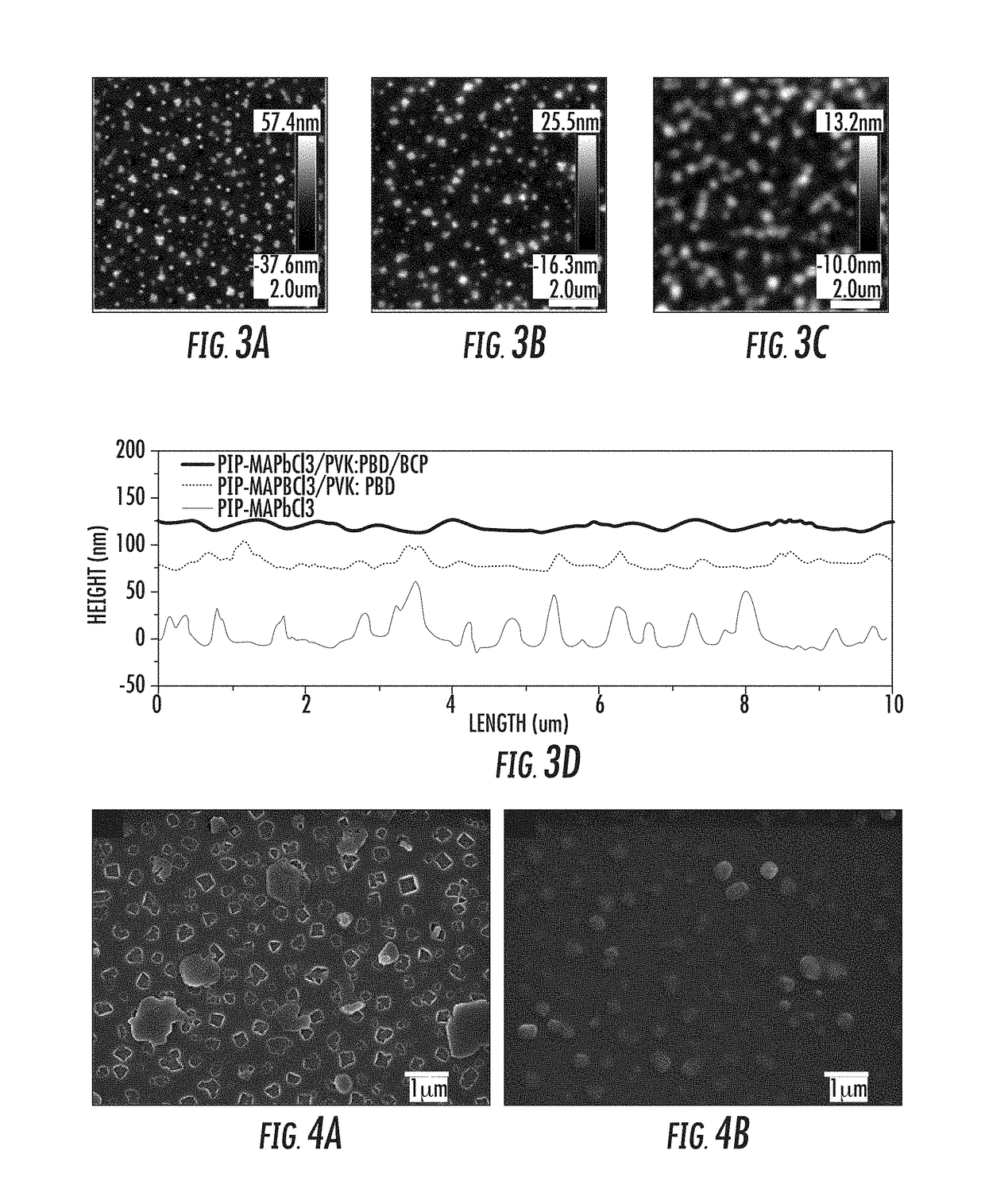

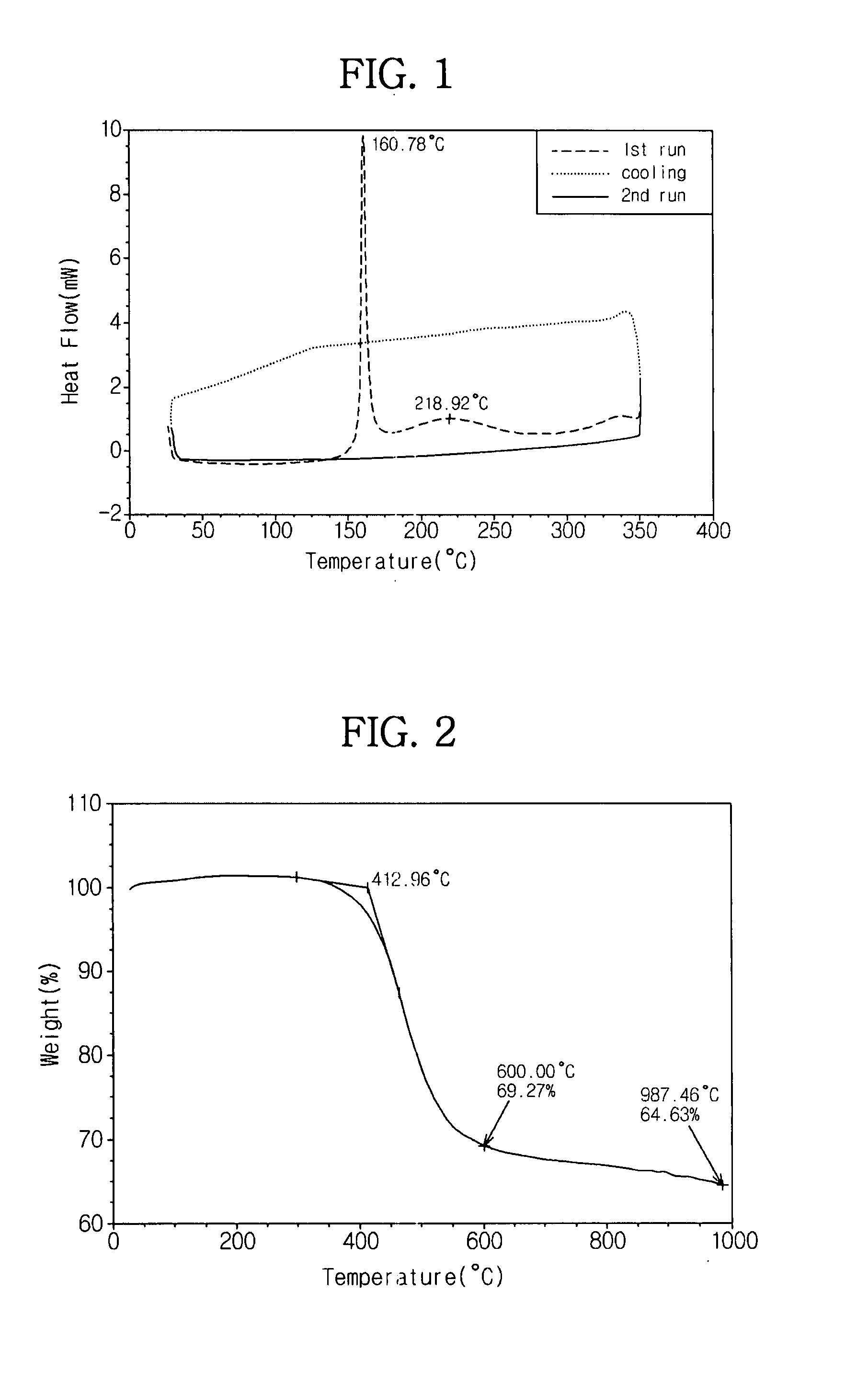

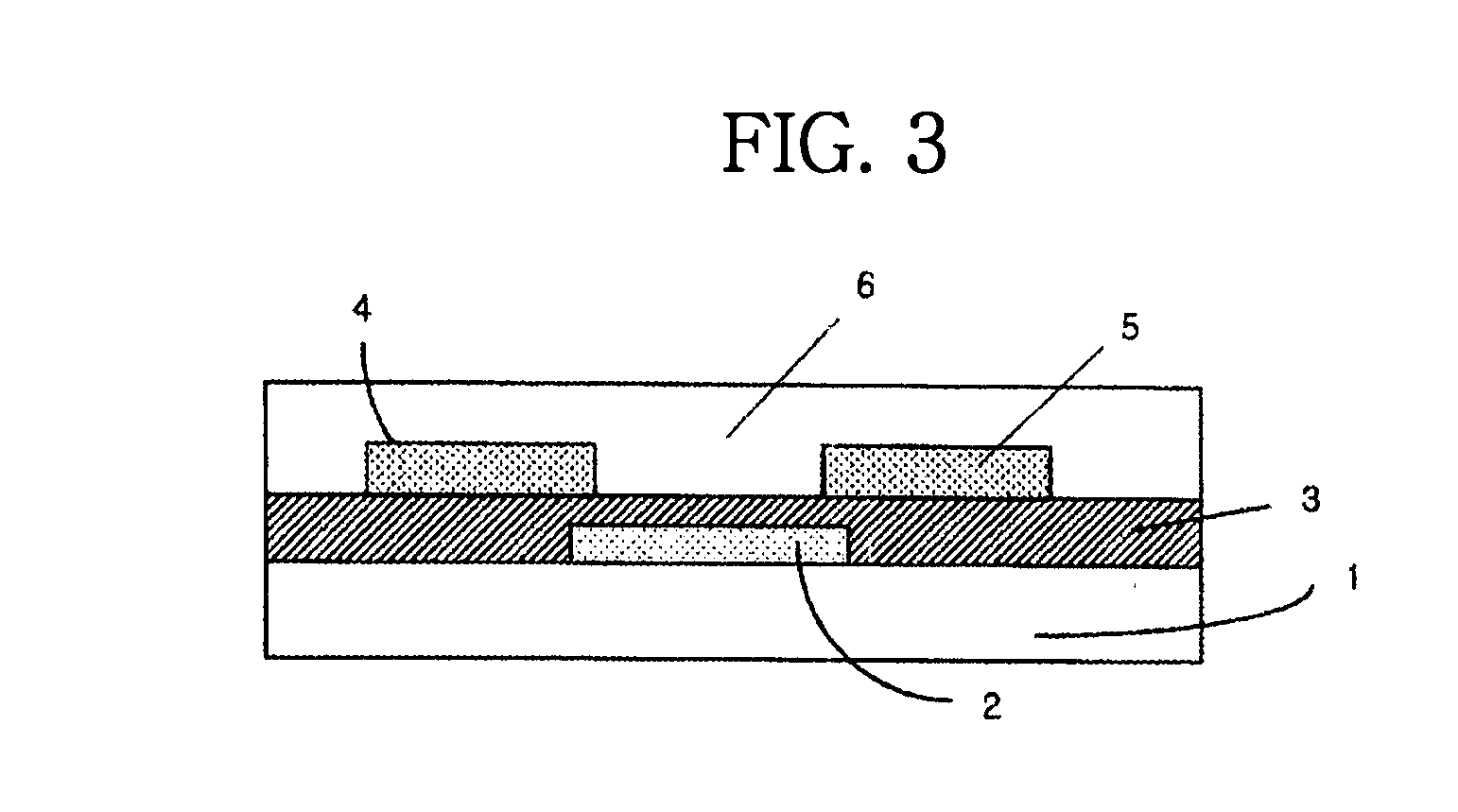

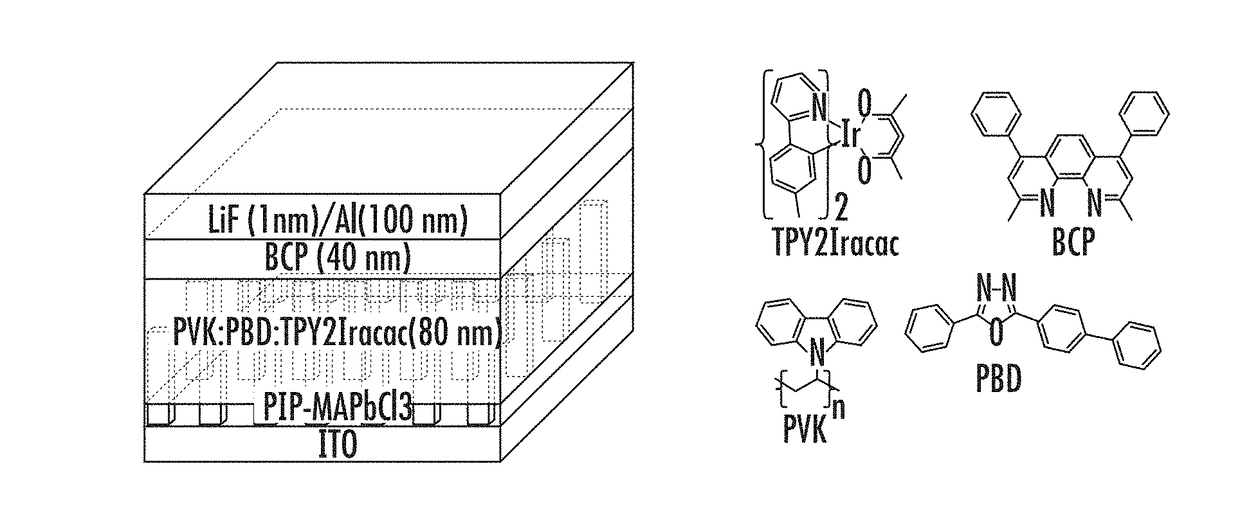

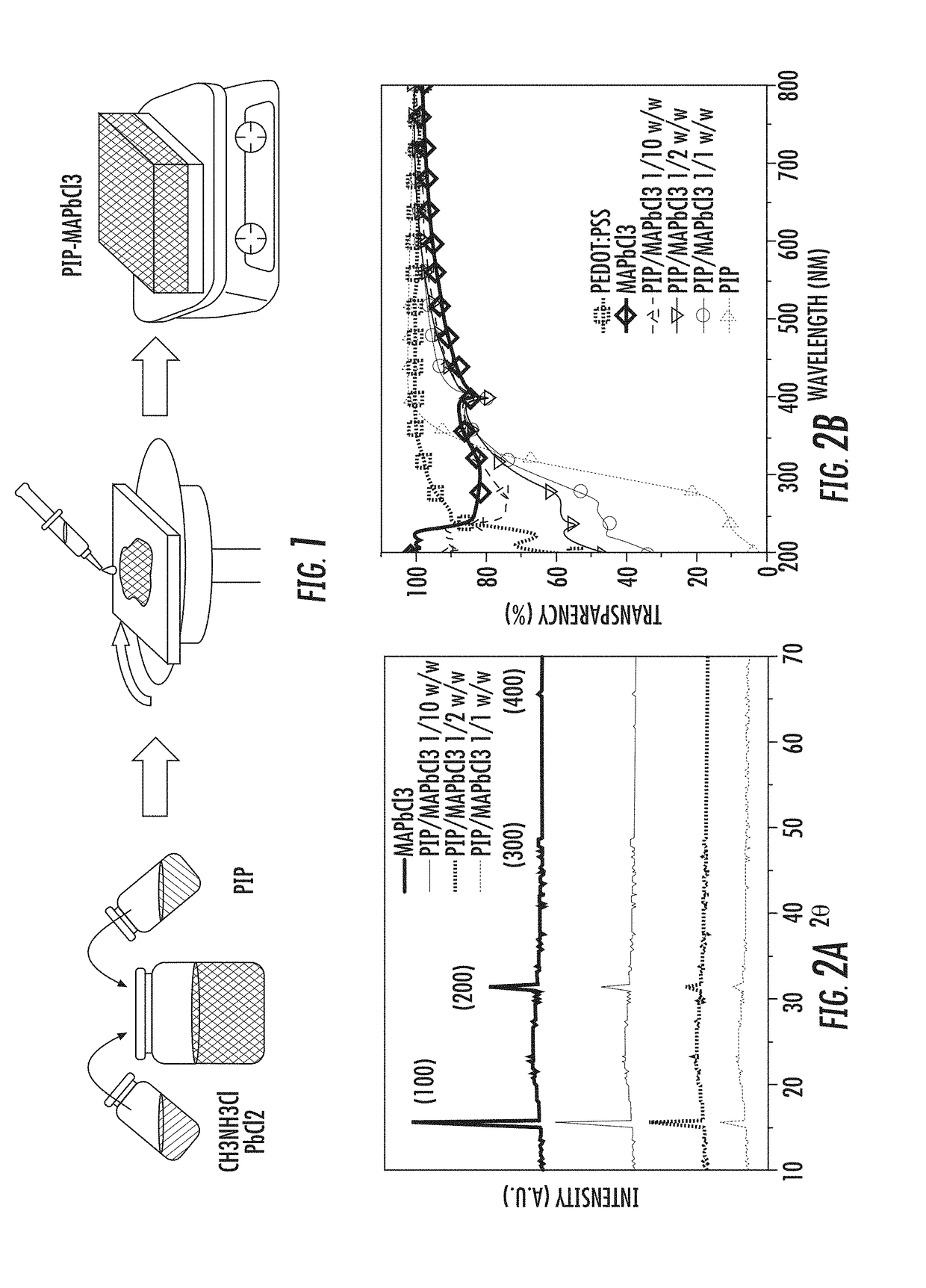

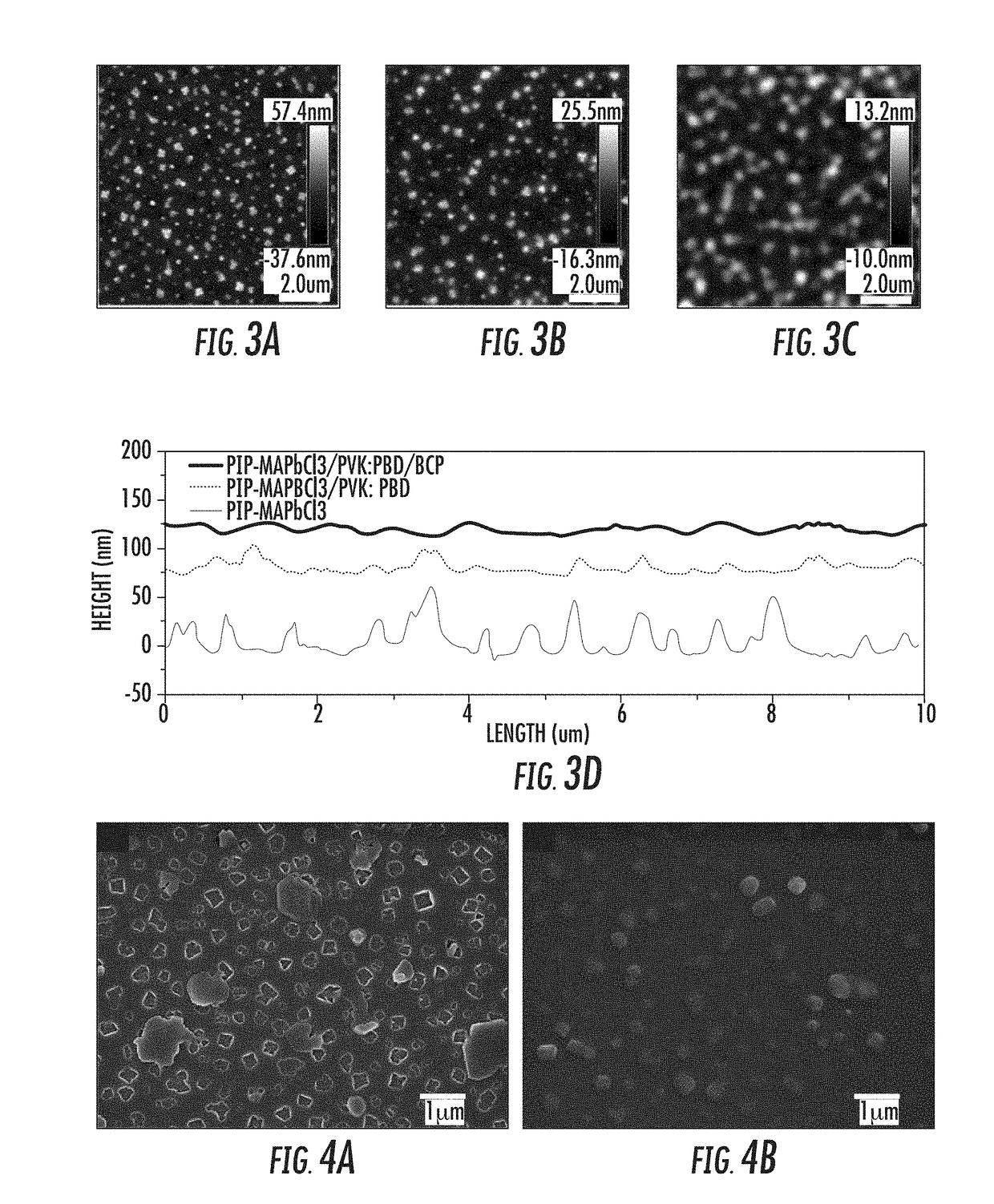

Polymer-perovskite films, devices, and methods

ActiveUS9905765B2Solid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceSpin casting

Provided herein are perovskite-polymer films, methods of forming polymer-perovskite films, and devices including polymer-perovskite films. The polymer-perovskite films may include a plurality of methylammonium lead chloride (CH3NH3PbCl3) nanopillar crystals embedded in a polymer matrix. The devices can be optoelectronic devices, such as light emitting diodes, which include polymer-perovskite films. The polymer-perovskite films of the devices can be hole transport layers in the devices. The methods of making films may include spin casting a precursor solution followed by thermal annealing.

Owner:FLORIDA STATE UNIV RES FOUND INC

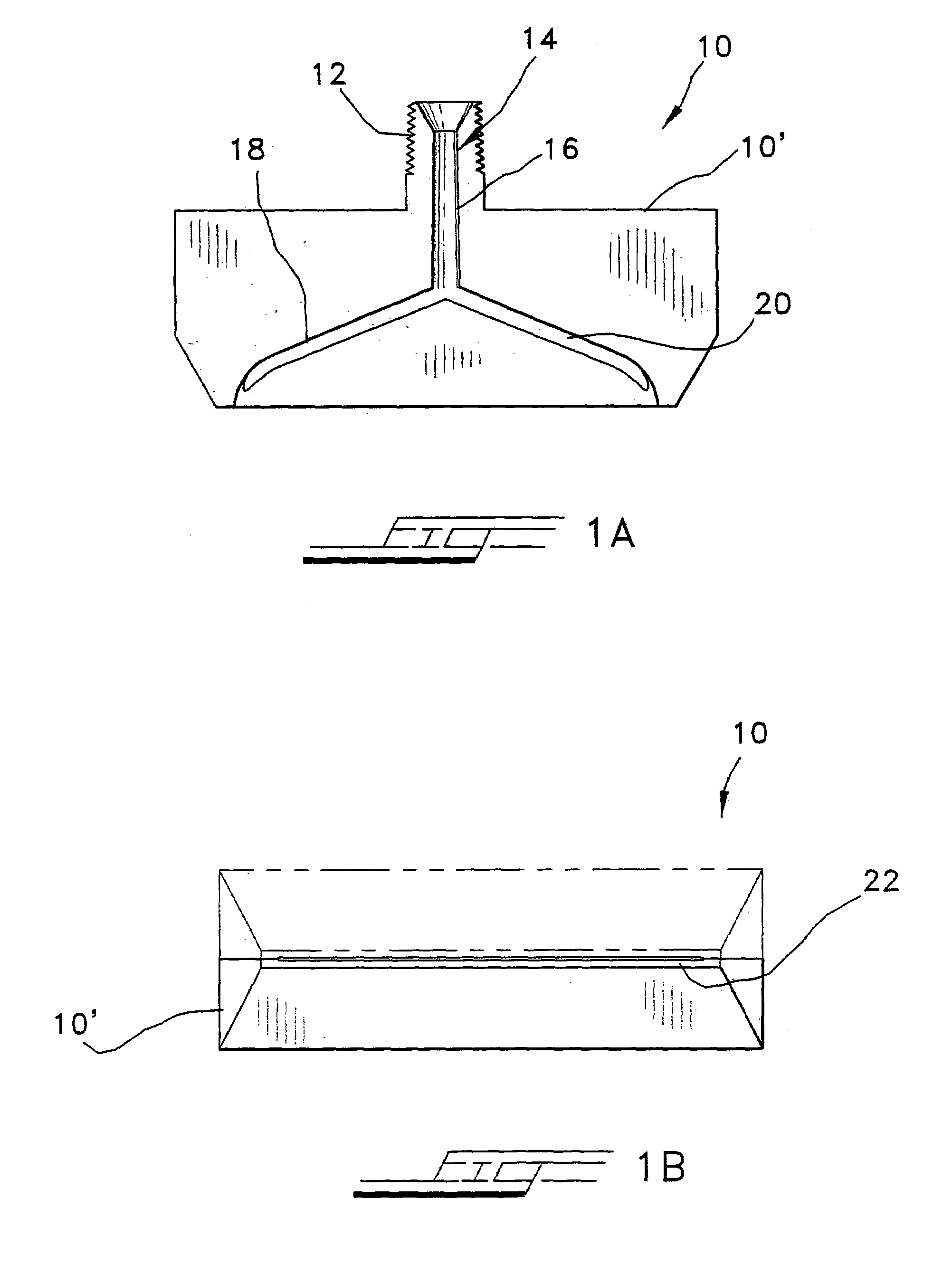

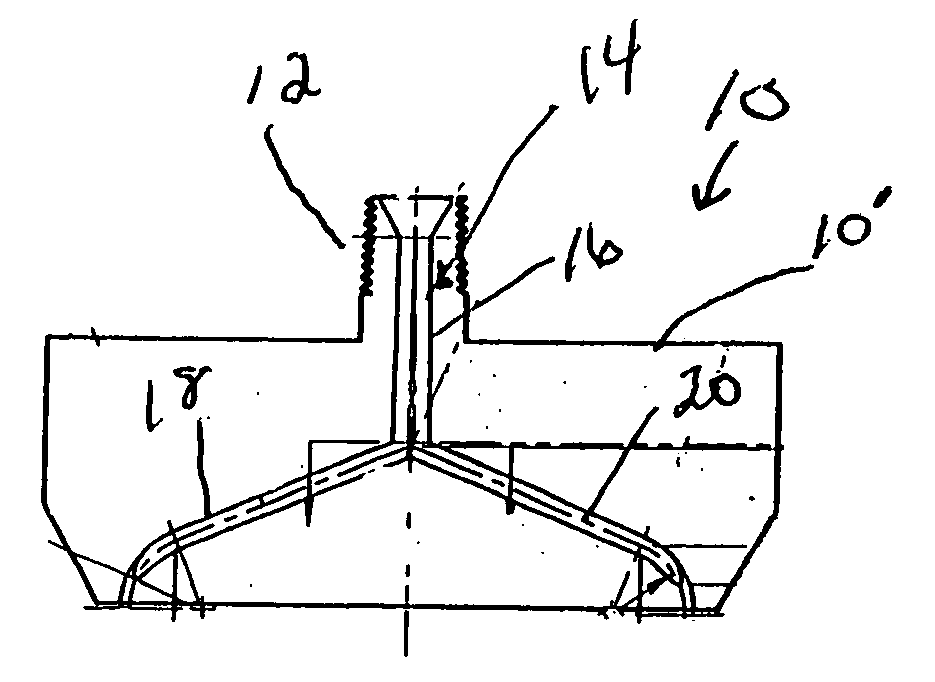

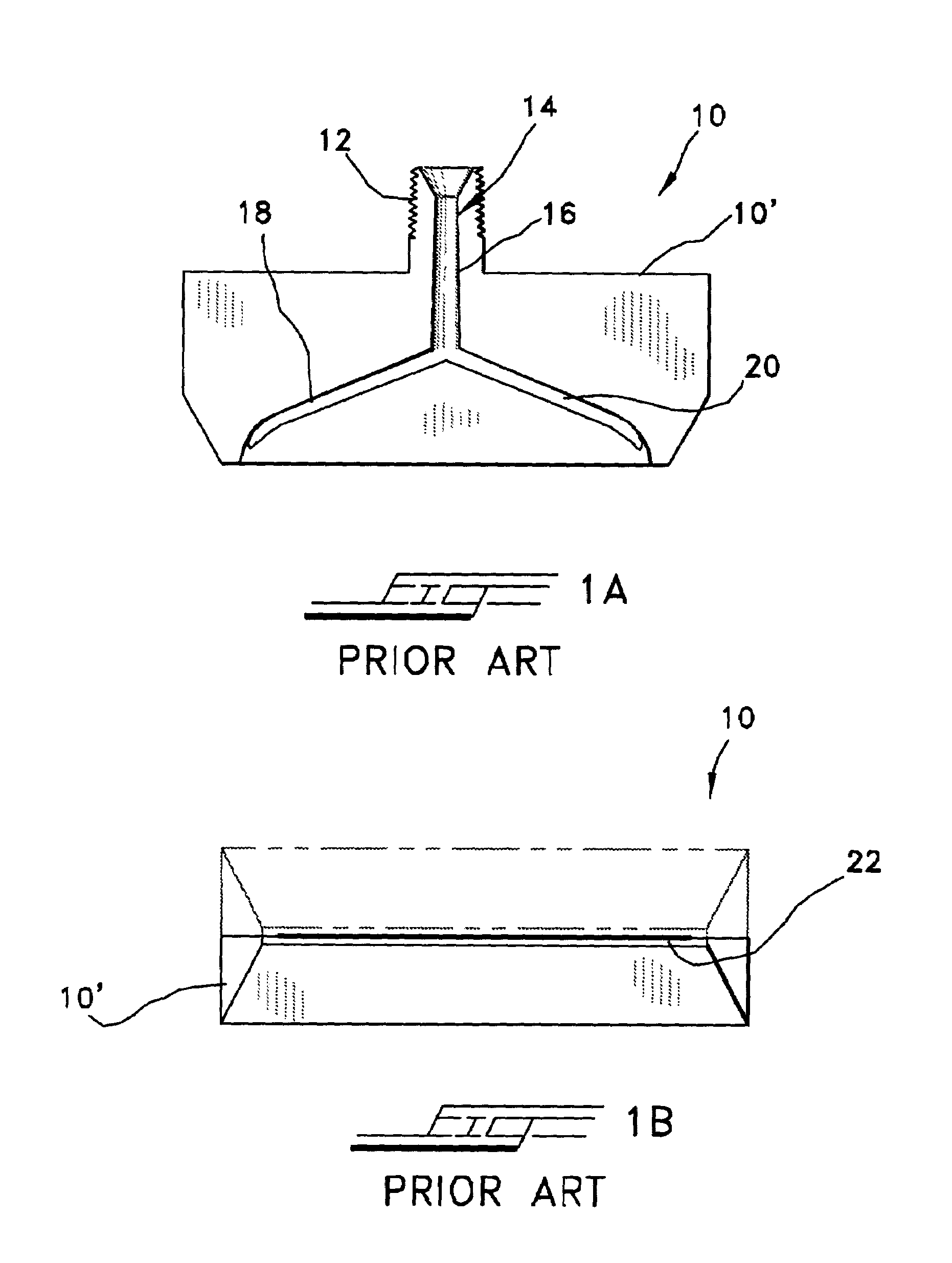

Nozzle for use in rotational casting apparatus

InactiveUS6989061B2Improve productivity and efficiencyEfficient coatingPretreated surfacesSpray nozzlesElastomerSpin casting

For use in a rotational casting machine used for coating a rotating body with elastomer, such as polyurethane, there is provided a nozzle used for dispensing the liquid polyurethane onto the rotating body to be coated. The outlet of the nozzle is a narrow, elongated slit or opening. However, the interior passageway of the nozzle continually changes shape from the inlet to the outlet thereof, in order to ensure a constant cross-sectional area of the interior passageway along the length thereof, and in order to arrive at the desired narrow, elongated outlet-opening, whereby laminar flow of the liquid polyurethane is achieved with the concomitant reduced dwell-time of the liquid polyurethane therein, in order to reduce build up and clogging of the nozzle.

Owner:KASTALON

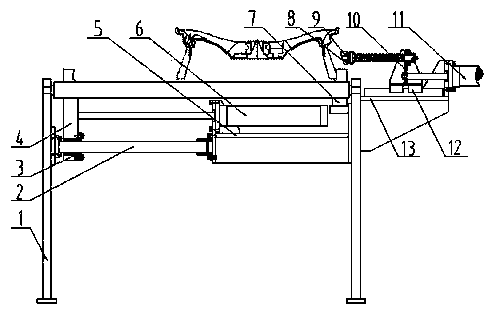

Aromatic enediyne derivative, organic semiconductor thin film, electronic device and methods of manufacturing the same

ActiveUS20080116452A1Group 4/14 element organic compoundsFinal product manufactureManufacturing technologySolar cell

Disclosed are a novel aromatic enediyne derivative, an organic semiconductor thin film using the same, and an electronic device. Example embodiments pertain to an aromatic enediyne derivative which enables the formation of a chemically and electrically stable and reliable semiconductor thin film using a solution process, e.g., spin coating and / or spin casting, at about room temperature when applied to devices, an organic semiconductor thin film using the same, and an electronic device including the organic semiconductor thin film. A thin film having a relatively large area may be formed through a solution process, therefore simplifying the manufacturing process and decreasing the manufacturing cost. Moreover, it is possible to provide an organic semiconductor that may be effectively applied to various fields including organic thin film transistors, electroluminescent devices, solar cells, and memory.

Owner:SAMSUNG ELECTRONICS CO LTD

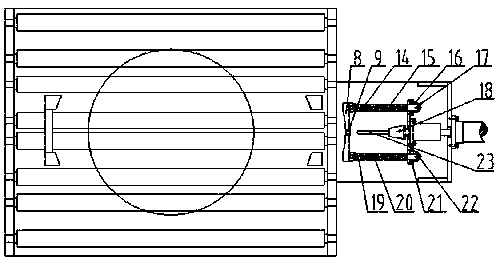

Automatic online drilling device for rim

InactiveCN103862080APrevent frequent breakageHigh degree of automationDrilling/boring measurement devicesWorkpiecesWaste productSpin casting

The invention discloses an automatic online drilling device for a rim. The automatic online drilling device for the rim comprises a rack, an air cylinder, a profiling drilling jig, drilling bushings, a servo electric cylinder, a drilling power drill bit and the like, wherein a sensor carries out locating on a wheel, the air cylinder drives a left clamping block to move rightwards through two guide rods and guide sleeves, the left clamping block tightly clamps the wheel together with a right clamping block, a drilling system gets close to the wheel through the servo electric cylinder, the profiling drilling jig can make good contact with the rim, then the servo electric cylinder continues moving to compress an upper spring and a lower spring, the drilling power drill bit can enter the drilling bushings, a drilling power head drives the drilling power drill bit to rotate at the moment, and drilling carried out on the rim of the wheel begins. When the automatic online drilling device for the rim is used, automatic drilling marking can be carried out on an X-ray waste product of the wheel, and the automatic online drilling device for the rim can adapt to a spin casting blank with the thick rim; due to the guiding function of the drilling bushings, the phenomenon that a drill bit is frequently broken when drilling is carried out on the cambered surface on the outer side of a rim can be effectively avoided.

Owner:CITIC DICASTAL

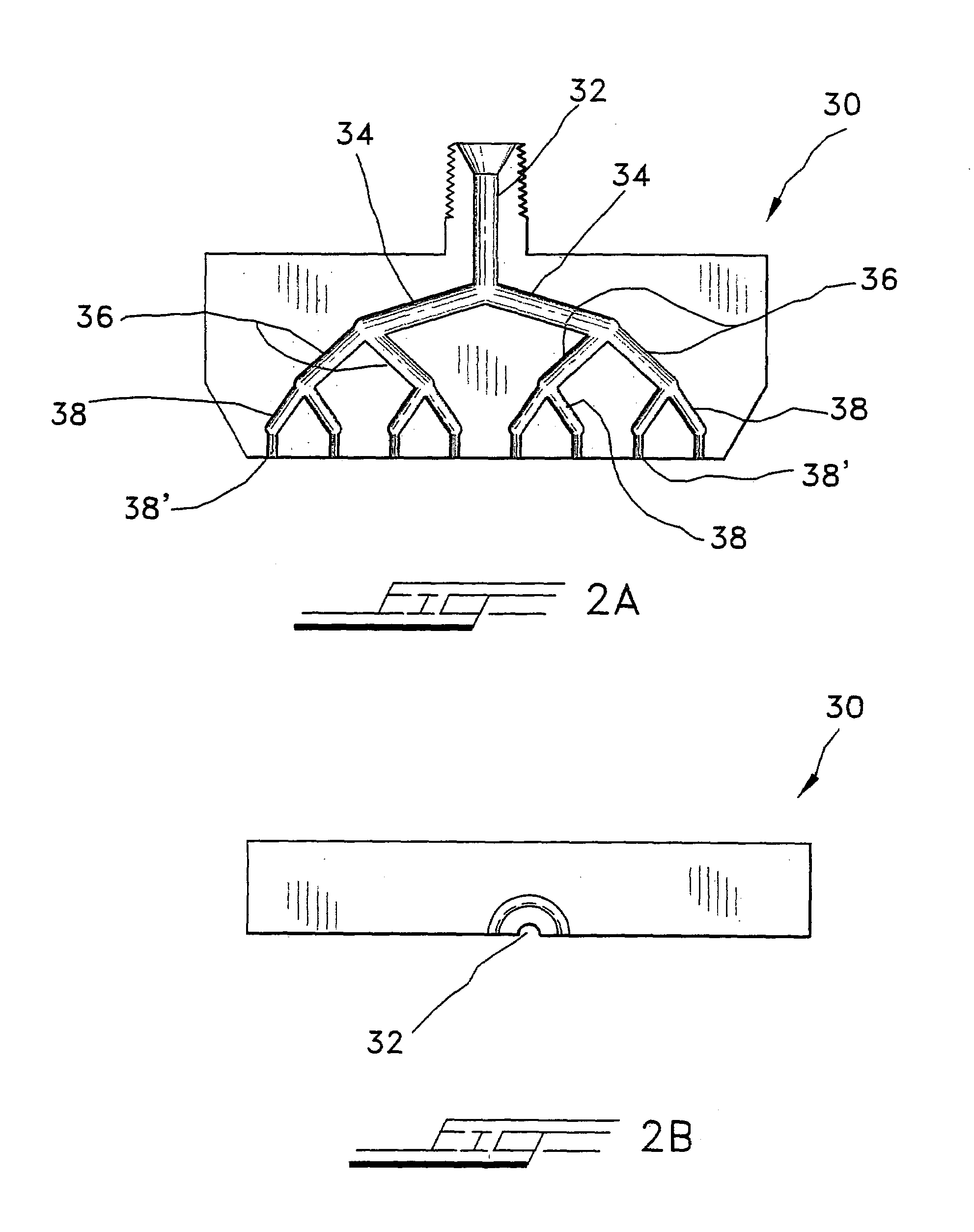

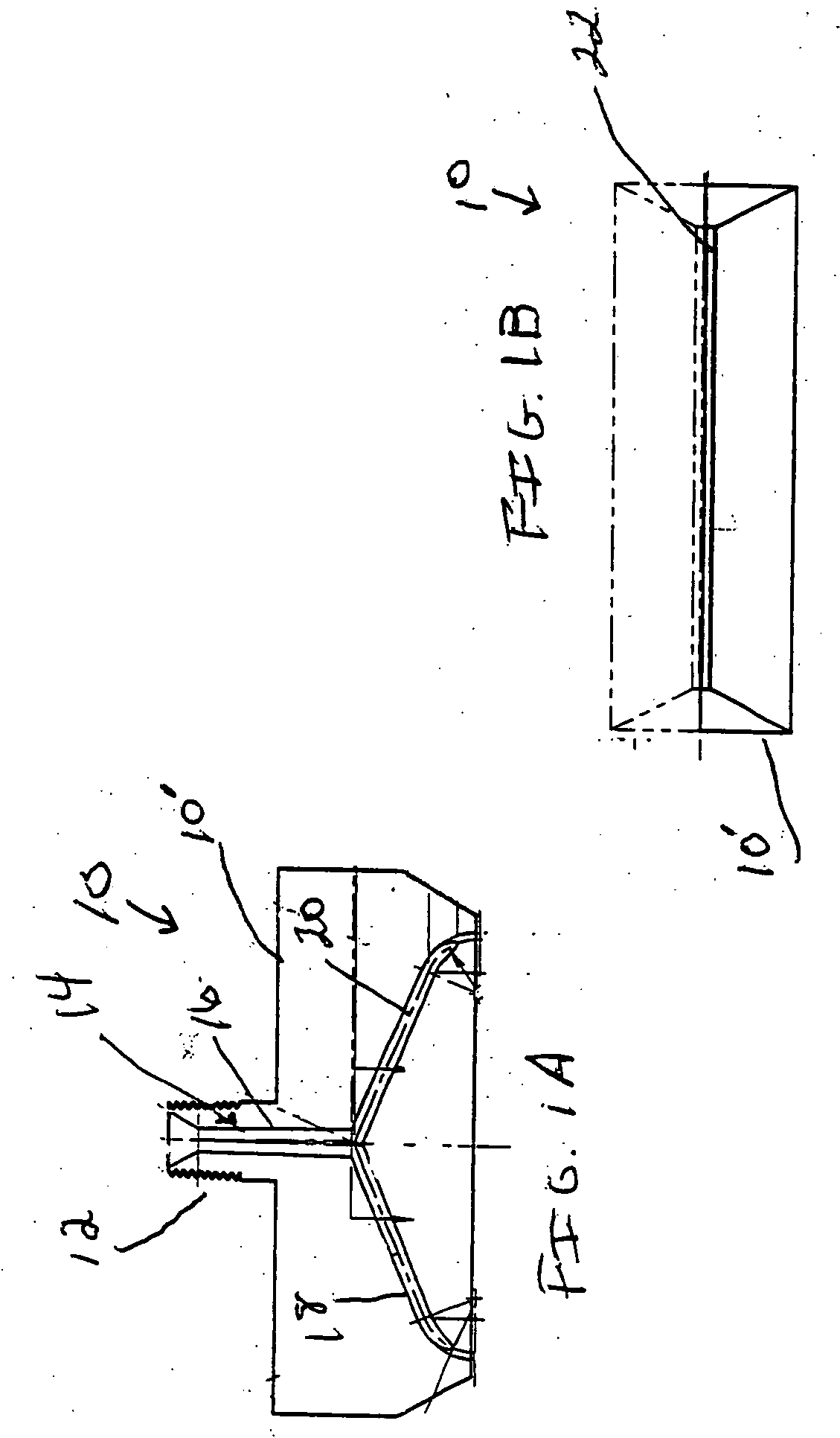

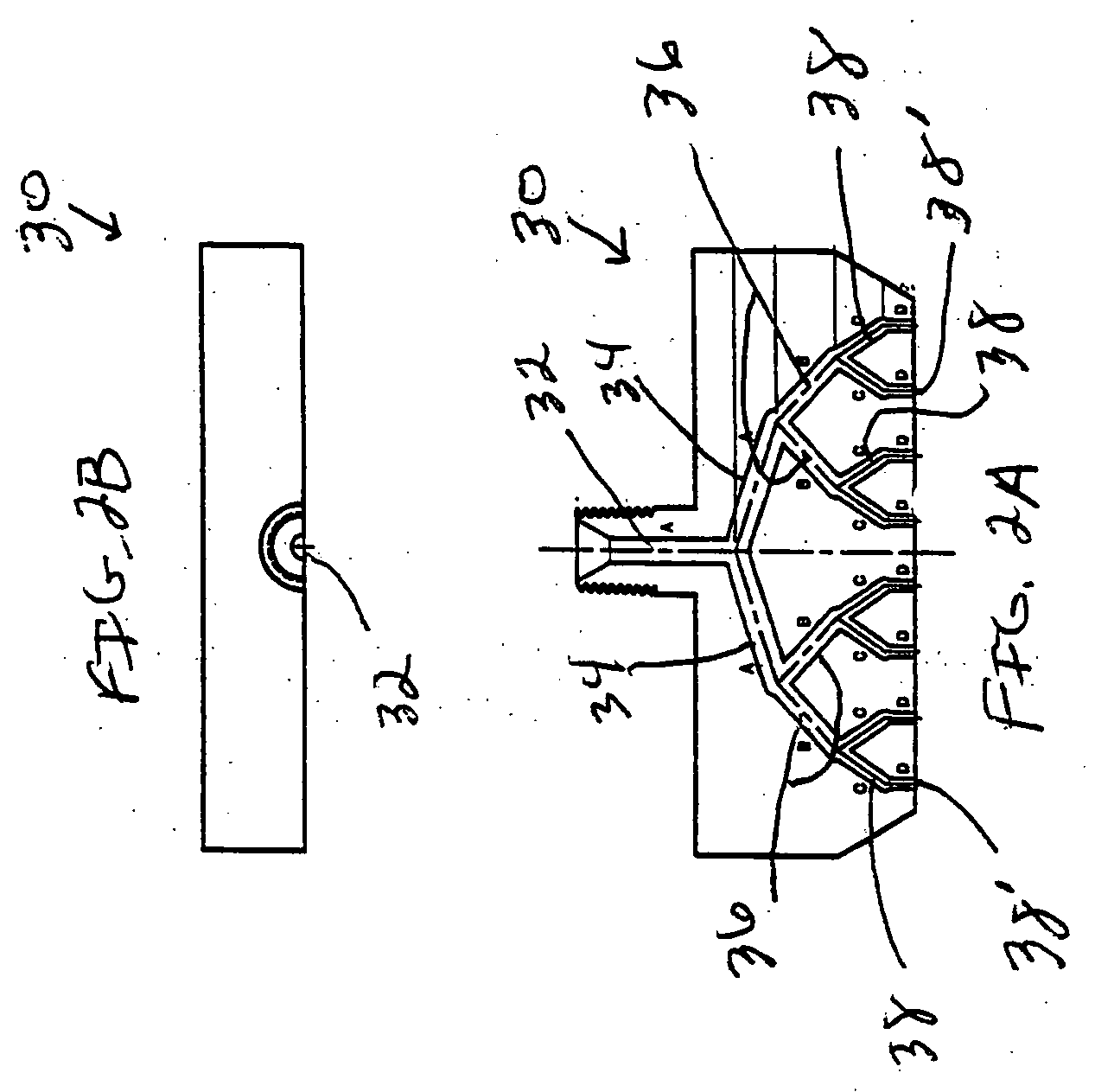

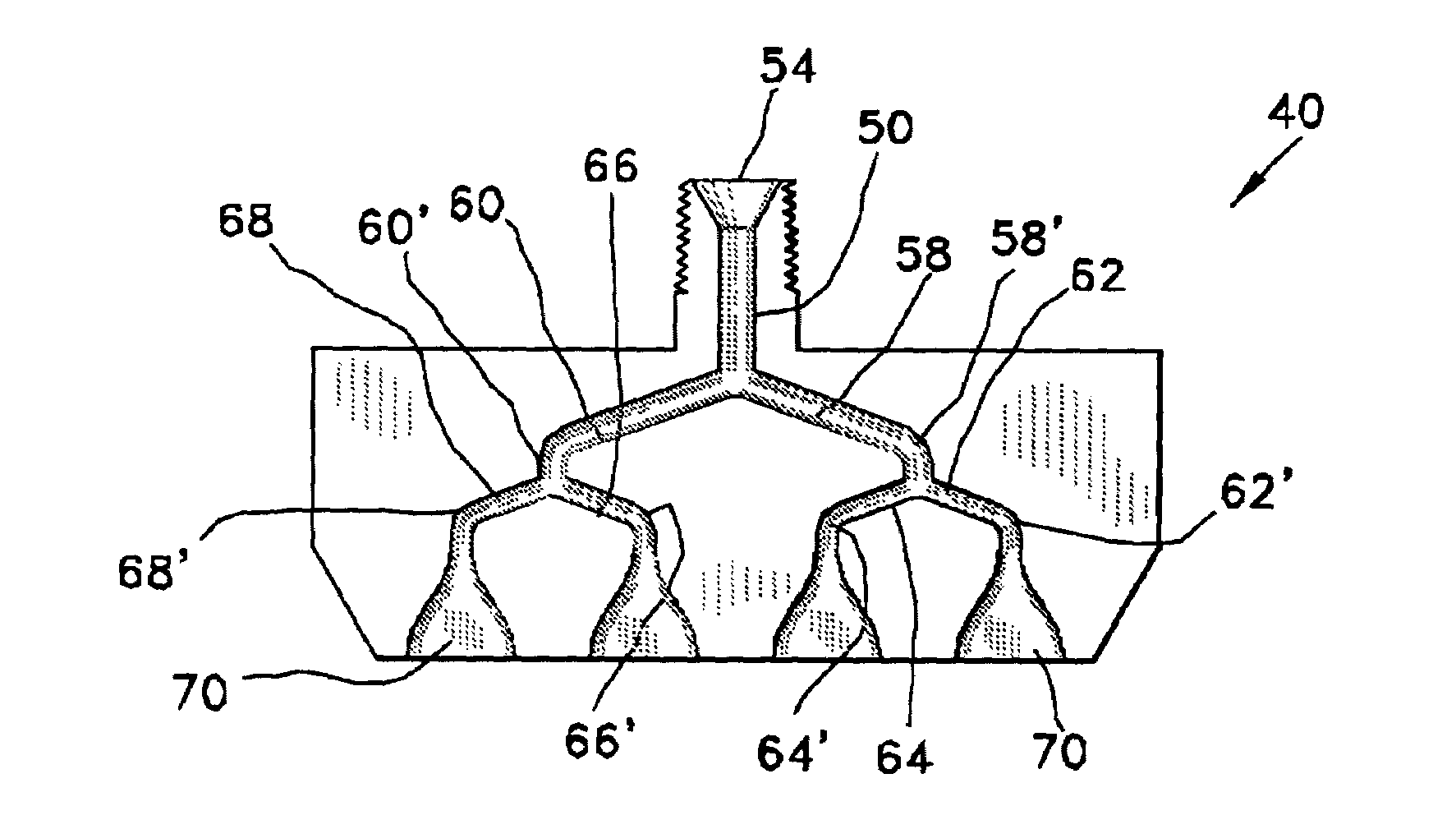

Nozzle for use in rotational casting apparatus

ActiveUS20050268843A1High trafficSpread widelyLiquid surface applicatorsConfectioneryElastomerMain branch

For use in a rotational casting machine used for coating a rotating body with elastomer, such as polyurethane, there is provided a nozzle used for dispensing the liquid polyurethane onto the rotating body to be coated. The nozzle of the invention has a plurality of liquid-flow interior discharge-passageways each of which has an inlet connected to a sub-branch tube, which sub-branch tube is, in turn, is fluidly connected to a main branch that, in turn, is connected to a main inlet-passageway having the inlet that is directly connected to mixing head. Each discharge-passageway, or exit-passageway, changes in cross-sectional shape along the longitudinal axis thereof from its inlet to its outlet such that the cross-sectional area from the inlet to the outlet thereof gradually and minimally increases, whereby at least substantial laminar flow of the liquid is achieved with the concomitant reduced dwell-time of the liquid therein, in order to reduce in-nozzle reaction and subsequent clogging of the nozzle. The exit of the nozzle itself is constituted by the plurality of spaced-apart exit-openings or outlets of the discharge-passageways, where each such exit-opening or outlet is formed as a narrow, elongated slit or opening.

Owner:KASTALON

Polymer-Perovskite Films, Devices, and Methods

ActiveUS20180159041A1Solid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceSpins

Provided herein are perovskite-polymer films, methods of forming polymer-perovskite films, and devices including polymer-perovskite films. The polymer-perovskite films may include a plurality of methylammonium lead chloride (CH3NH3PbCl3) nanopillar crystals embedded in a polymer matrix. The devices can be optoelectronic devices, such as light emitting diodes, which include polymer-perovskite films. The polymer-perovskite films of the devices can be hole transport layers in the devices. The methods of making films may include spin casting a precursor solution followed by thermal annealing.

Owner:FLORIDA STATE UNIV RES FOUND INC

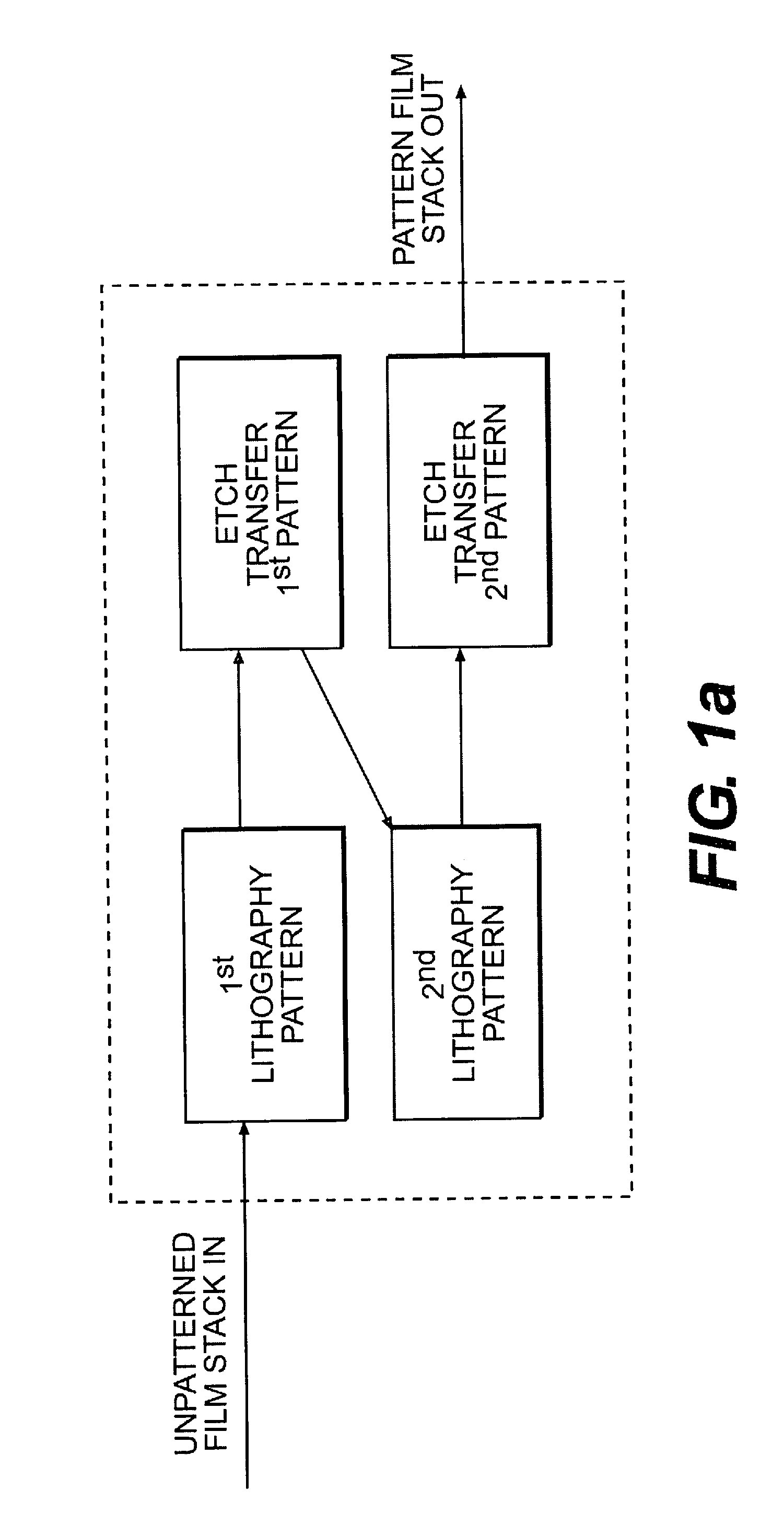

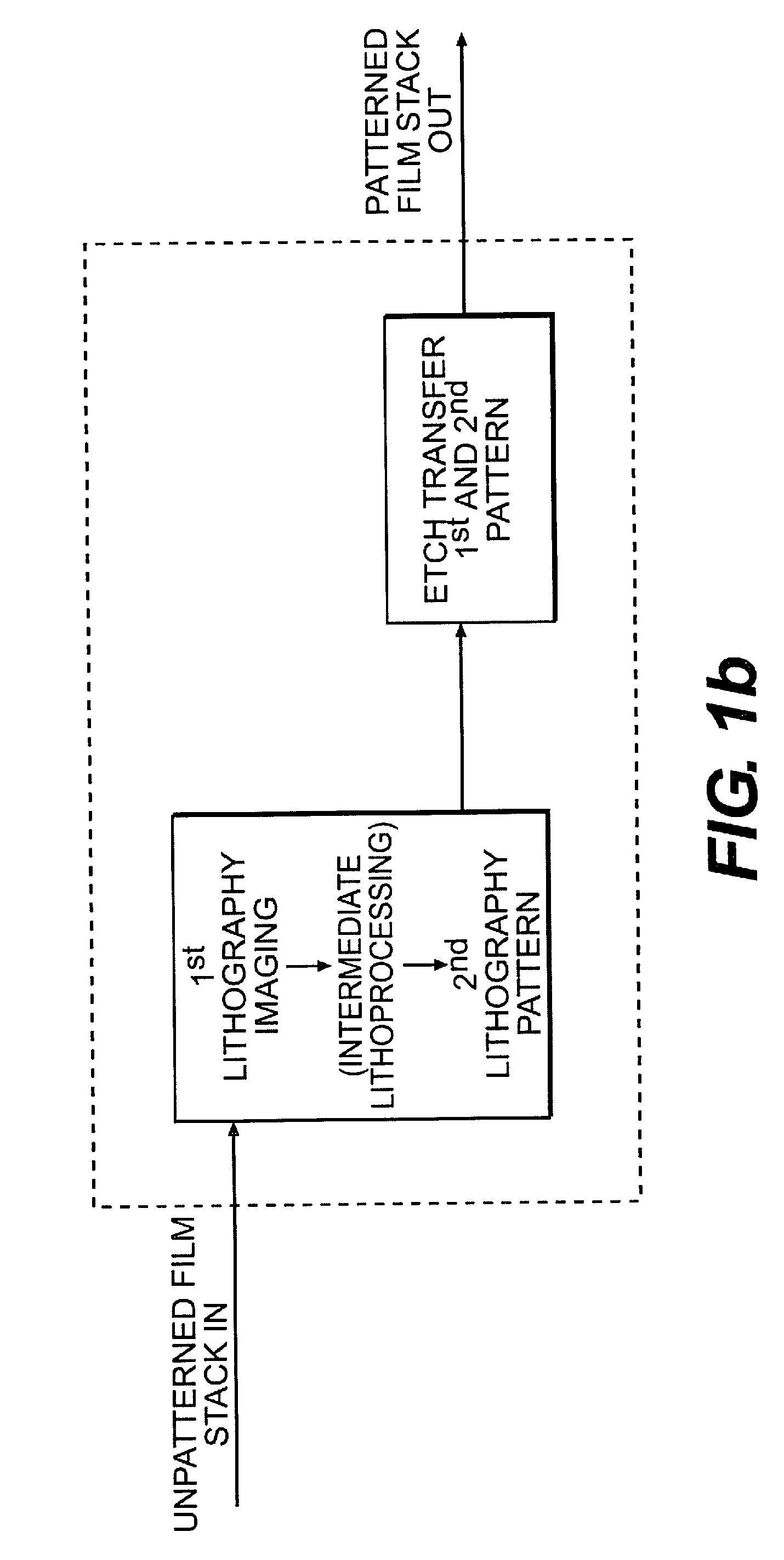

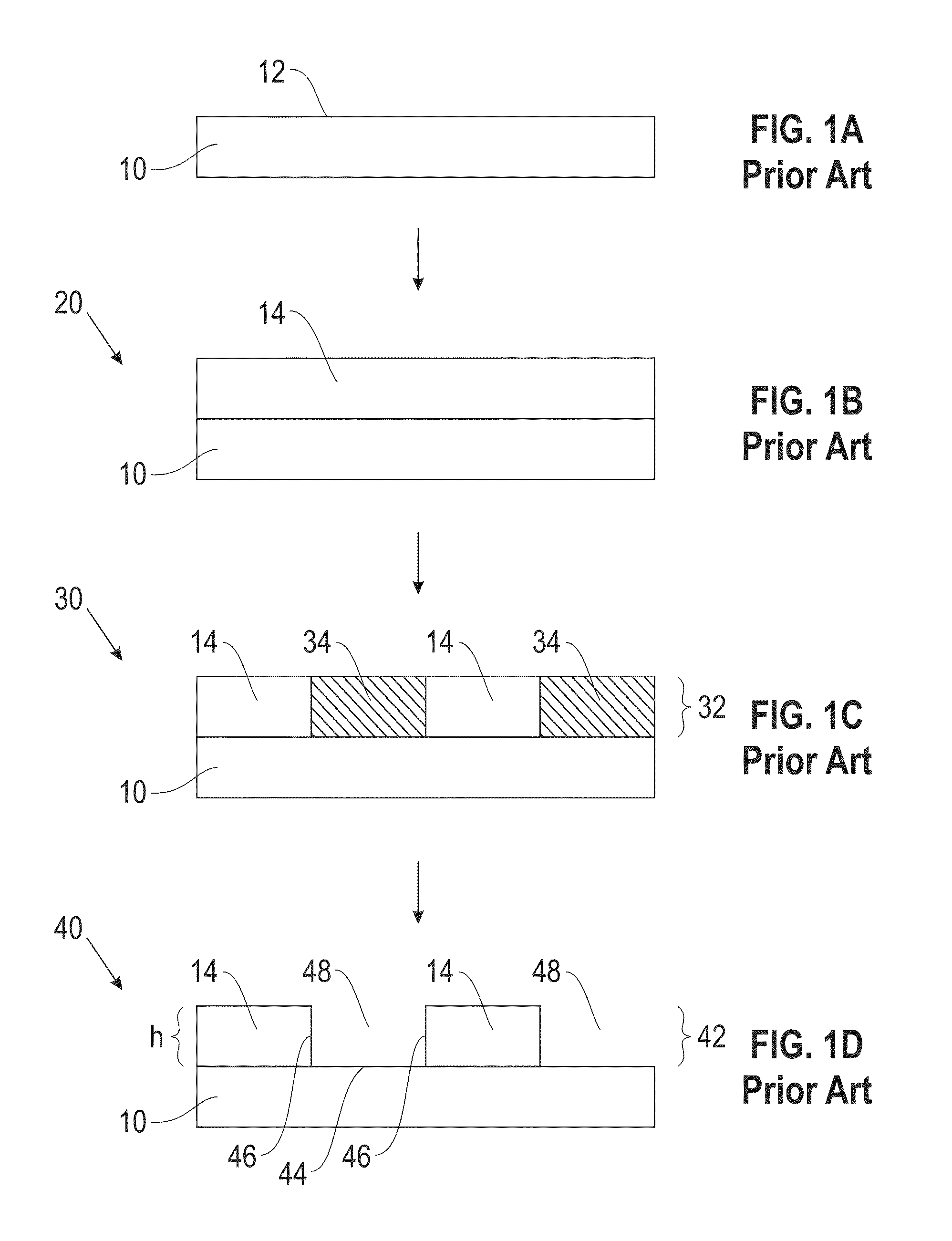

Process of Multiple Exposures With Spin Castable Films

InactiveUS20120214311A1Cost-effectiveAdvanced technologySolid-state devicesSemiconductor/solid-state device manufacturingDecompositionNext-generation lithography

Owner:GLOBALFOUNDRIES INC

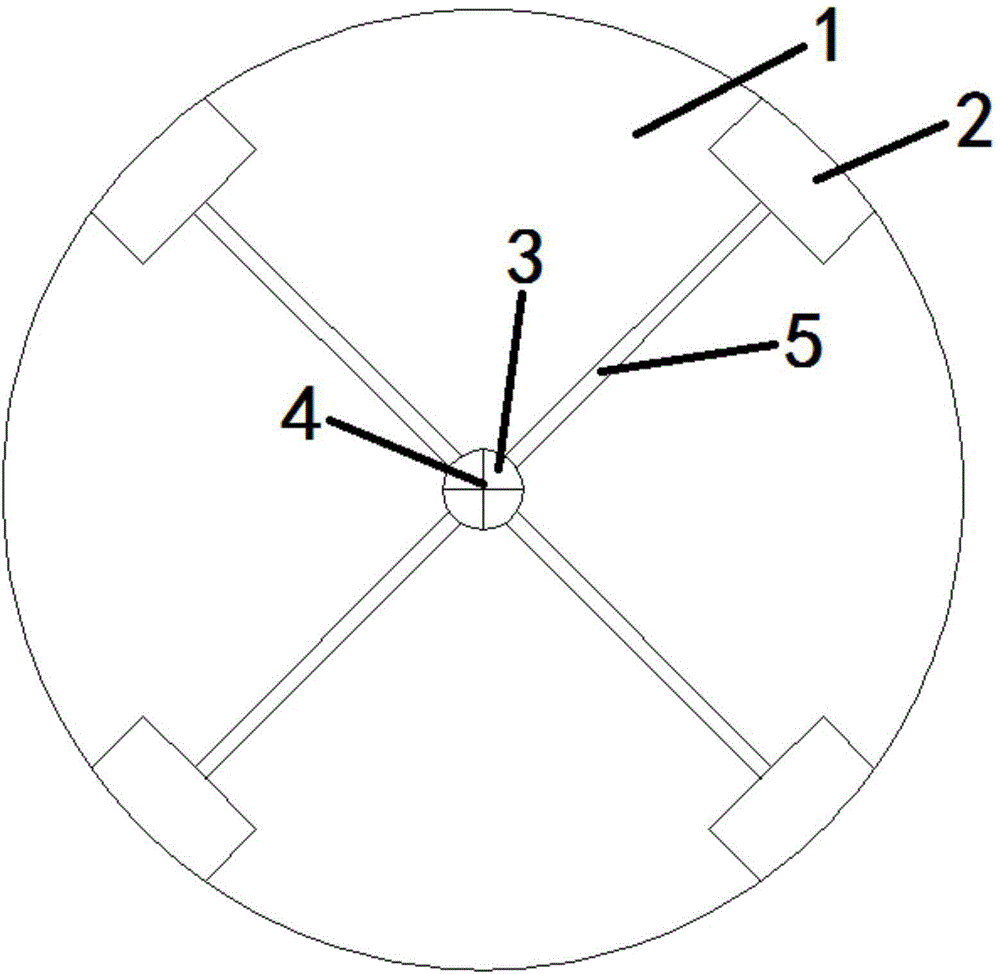

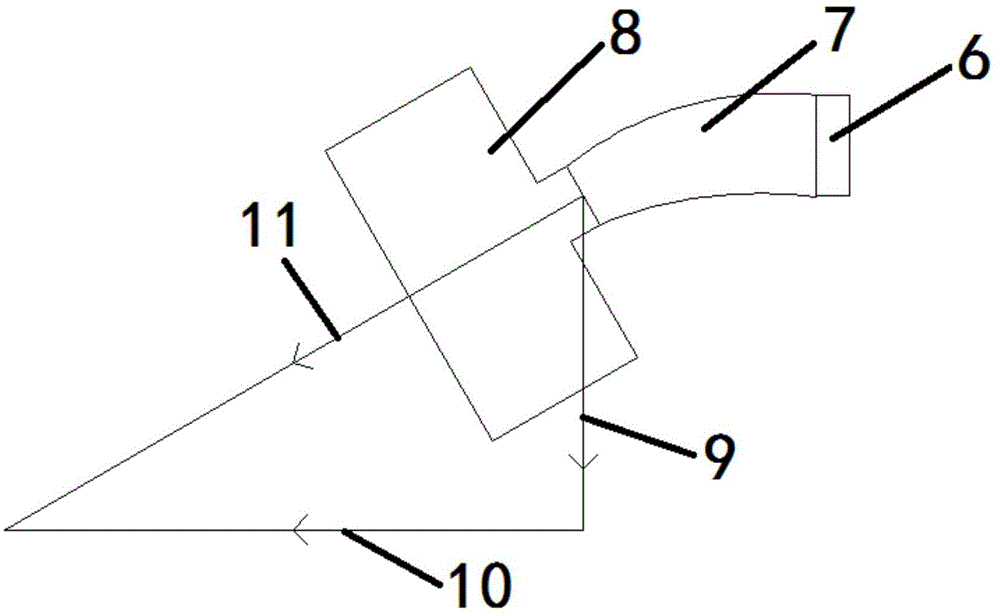

Rotating casting method capable of achieving any mold filling force by virtue of centrifugal force and gravity

The invention discloses a rotating casting method capable of achieving any mold filling force by virtue of centrifugal force and gravity. According to the technical scheme, a rotating disk capable of rotating at any speed is constructed, the center of the rotating disk is a sprue gate around which a horizontal pouring gate is arranged, the outer side of the horizontal pouring gate is a die position, a die is arranged at the die position, and a gate of the die is connected with the tail end of the horizontal pouring gate; during casting, the rotating disk rotates at certain speed, and poured molten metal flows outwards along the pouring gate under the action of the centrifugal force, and is injected into the mold for mold filling. According to the rotating casting method, the limitation of conventional gravity to the mold filling force is broken, complex pressurization equipment is not required, and requirements on the precision of the equipment are greatly lowered; different mold filling pressure can be achieved only by adjusting the rotating speed of the rotating disk, convenience in adjustment, high adjustment speed and adjustment reliability are ensured, and the rotating casting method is a new mold filling pressure-adjustable casting method.

Owner:ANHUI NEOFOUND TECH

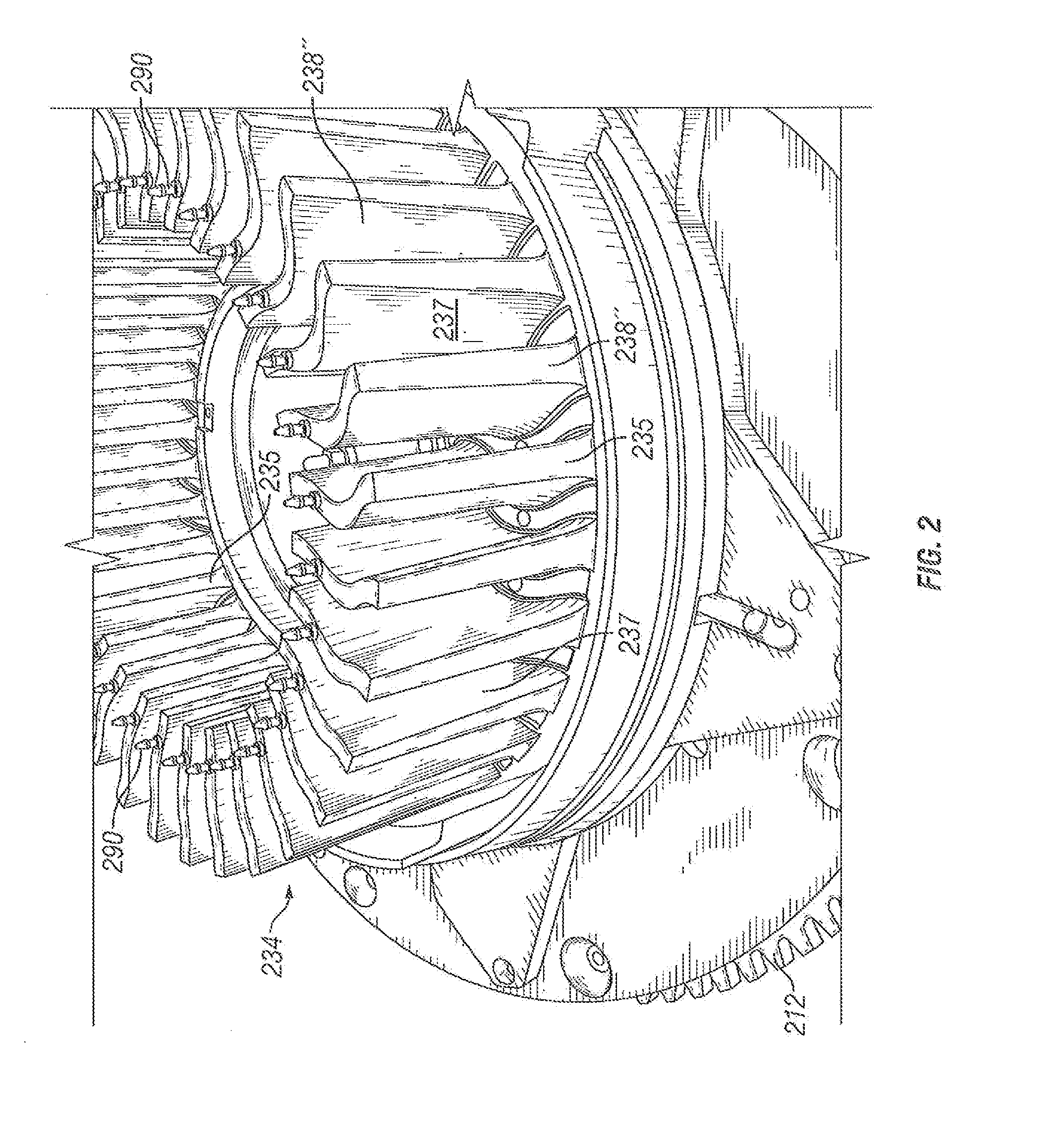

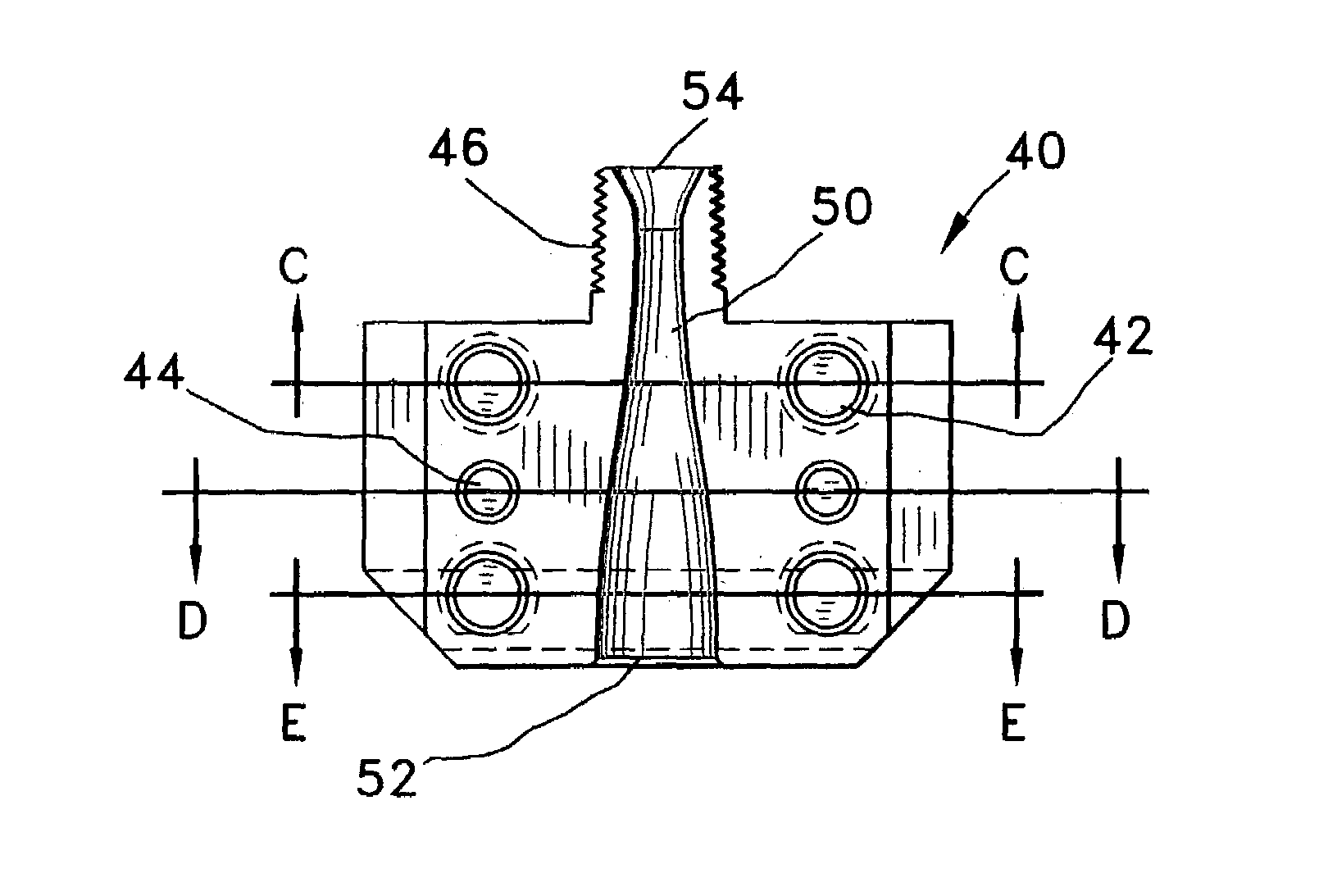

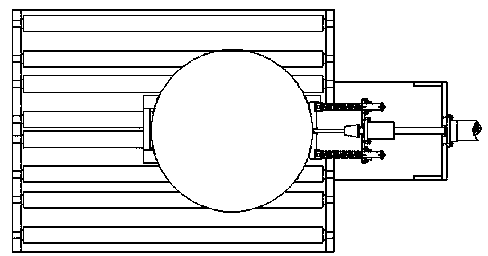

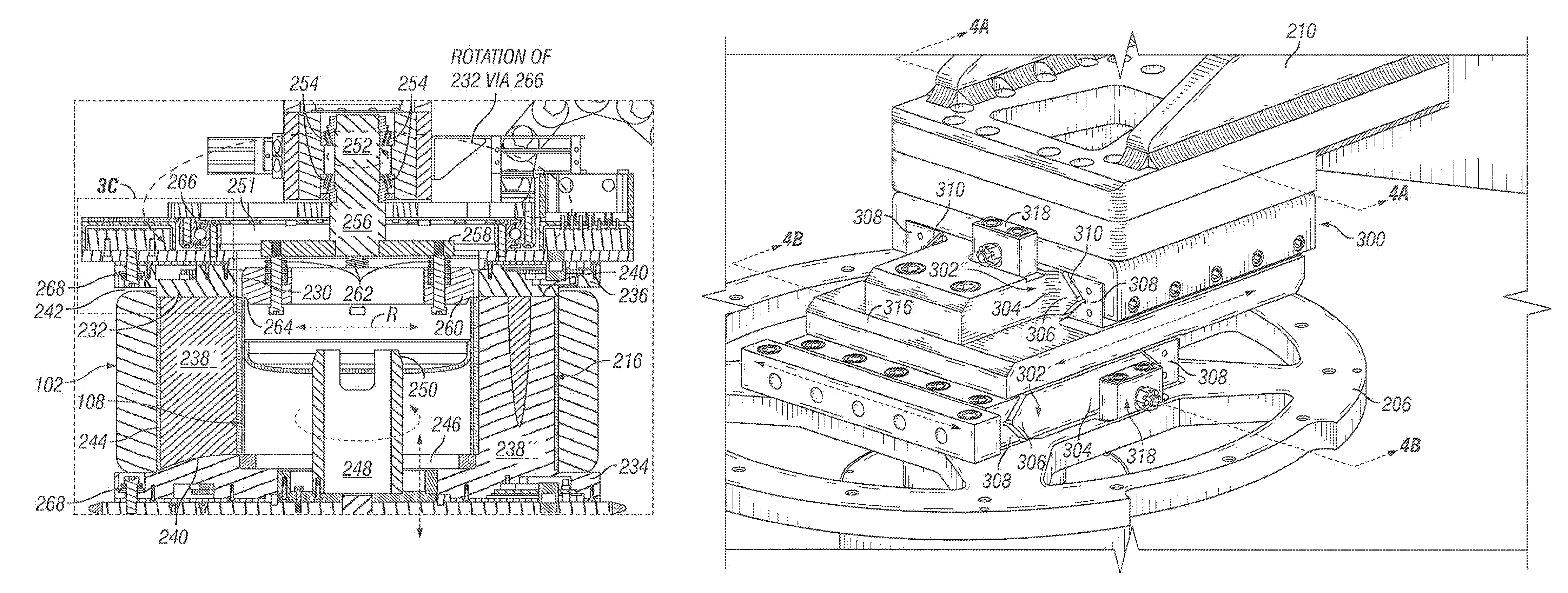

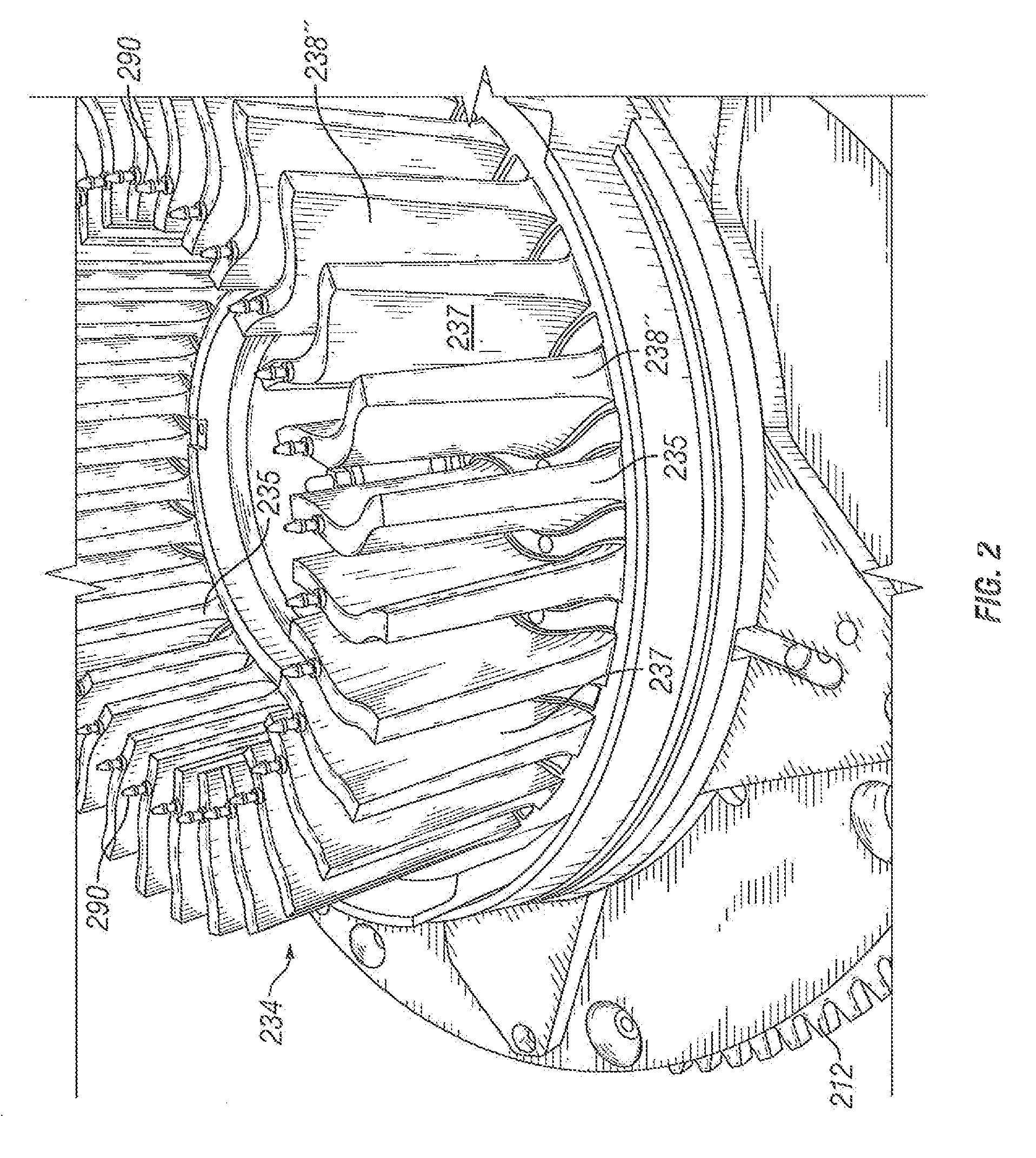

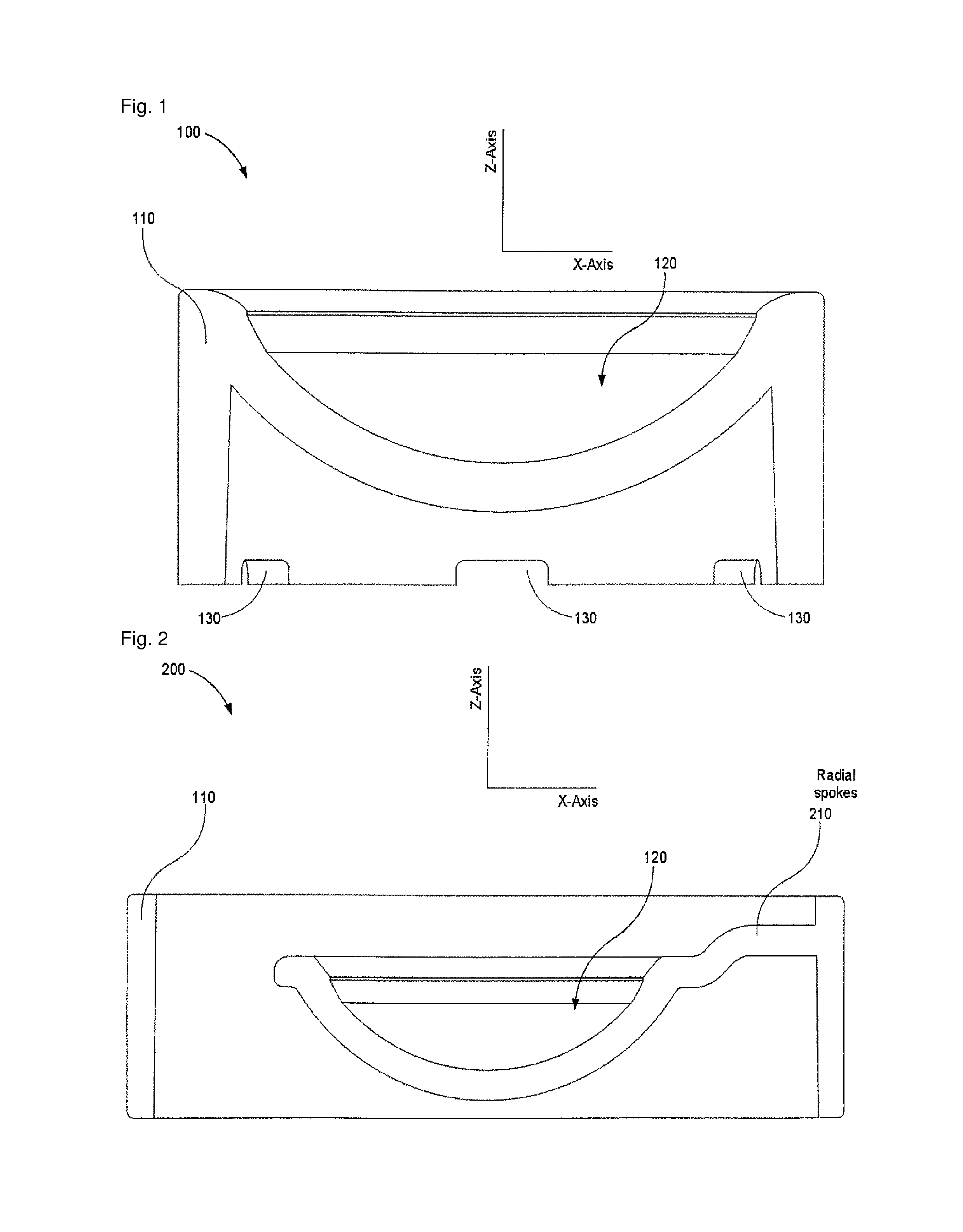

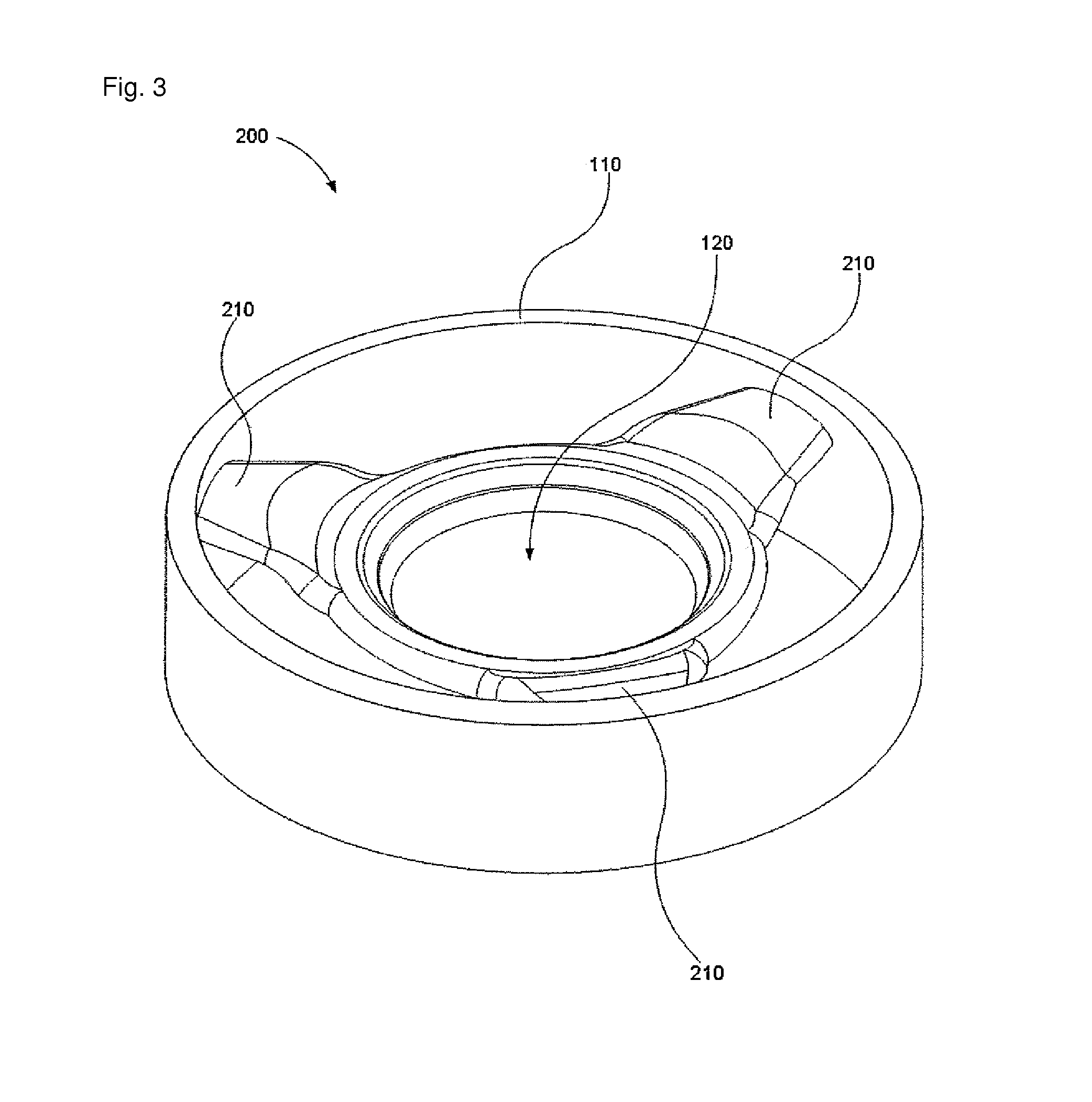

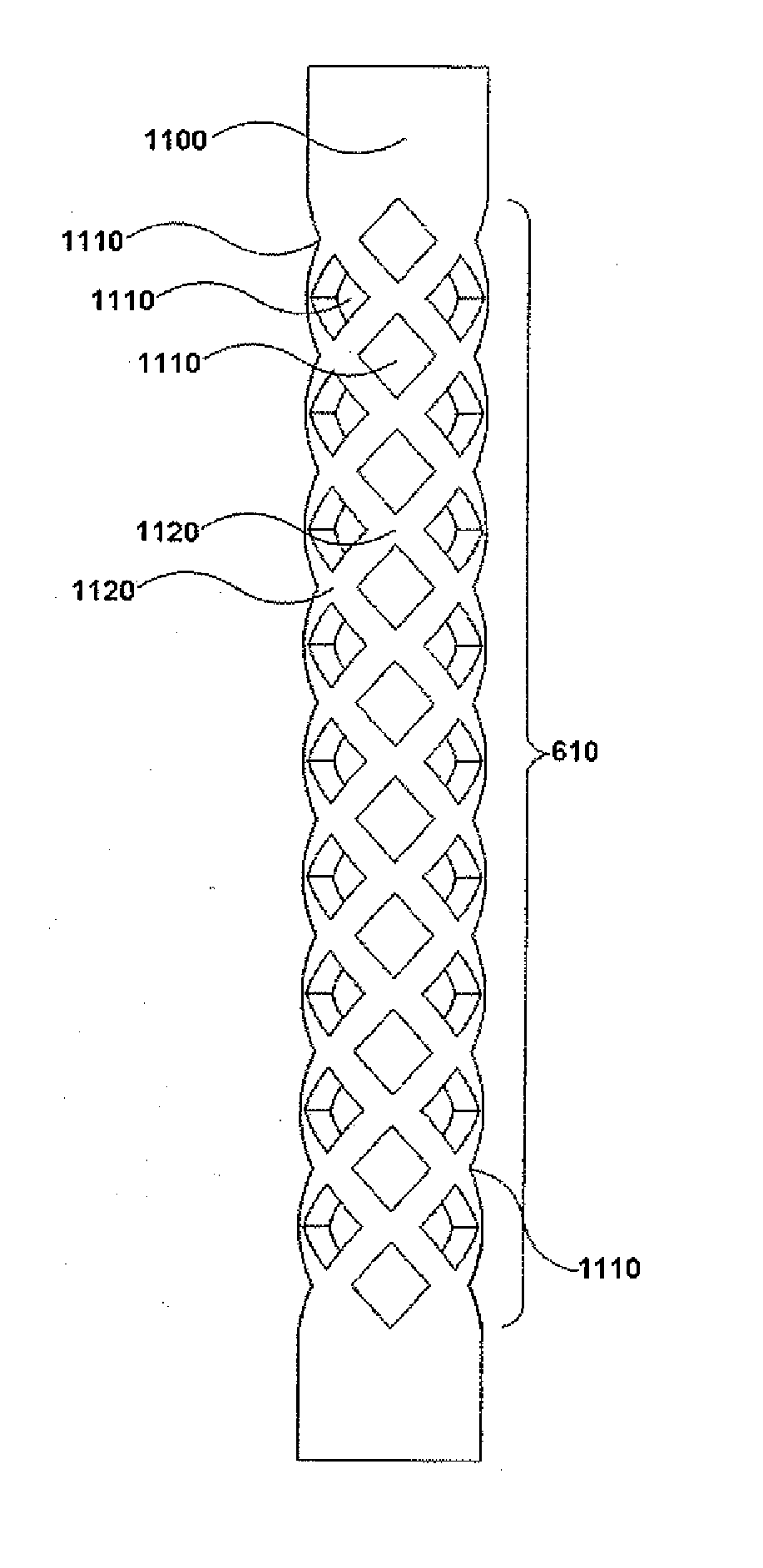

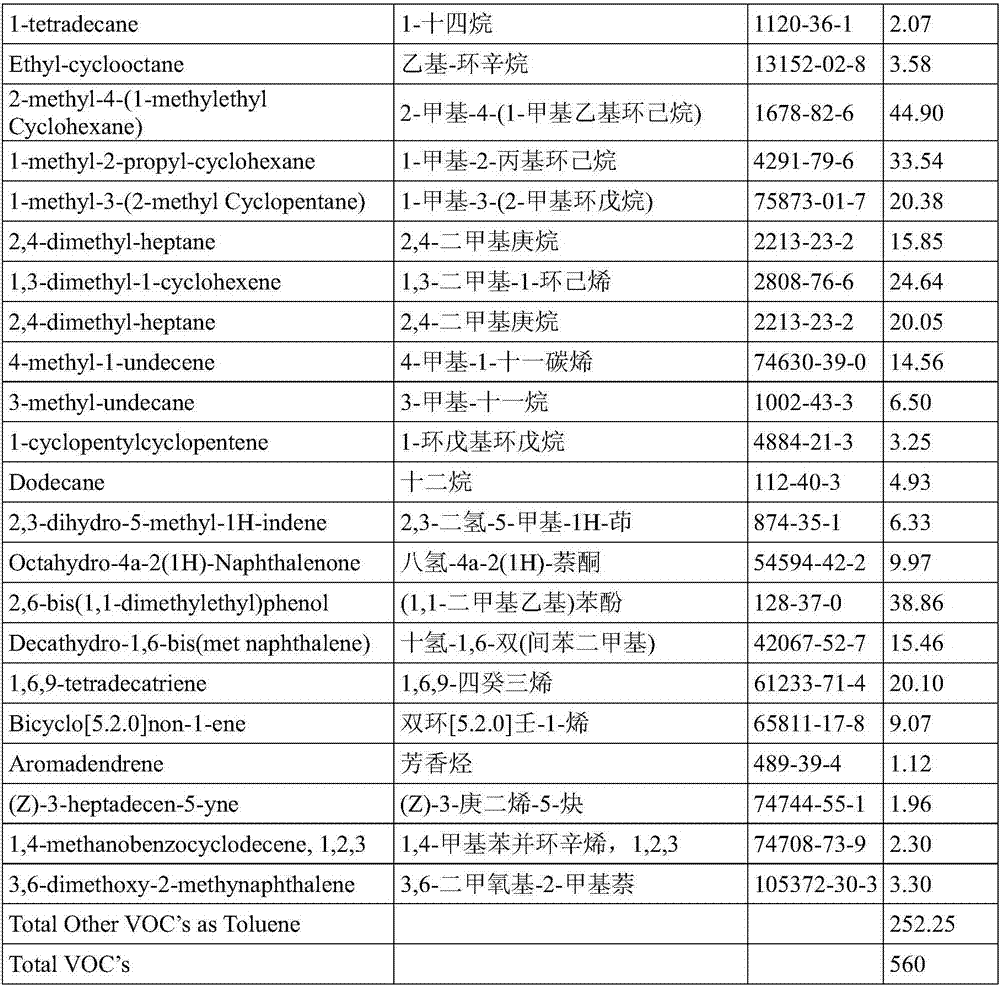

Apparatus for casting a non-pneumatic tire having a floating mold alignment mechanism

This invention relates generally to an apparatus for rotationally casting a portion of a tire, and, more specifically, to an apparatus that has a floating alignment mechanism that allows a portion of a mold to move in the radial direction of the tire, which is at least partially formed by the mold, allowing the molding apparatus to omit the use of tie bars. The mechanism may comprise two set of needle roller bearings that are orthogonally arranged to allow radial movement of a portion of a mold.

Owner:MICHELIN RECH & TECH SA +1

Preparation method of novel polyurethane chain extender

InactiveCN102702011AOrganic compound preparationCarboxylic acid amides preparationElastomerHigh activity

The invention discloses a novel low-viscosity liquid polyurethane chain extender PUCURE which is prepared by taking diamine MDA as a basic raw material. The PUCURE is matched with a polyurethane prepolymer in an MDI system; MDA / NaCl is dispersed in dioctyl adipate (DOA); in the presence of NaCl, the DOA reacts with the MDA at room temperature and an amino group in the DMA can be sealed to lose activity (reactivity); and when the reaction system is heated to 115-160 DEG C, a sealing agent is released and the released high-activity amino group rapidly reacts with the prepolymer to generate a high-strength elastomer product. A mixture of the PUCURE and the corresponding prepolymer can be stored for more than one month at a temperature of below 50 DEG C; compared with the traditional curing agents (MOCA, BDO, etc.), a product cured by the PUCUR has excellent dynamic performance; and the PUCURE has the characteristics of low viscosity and delaying property of the system, so that the PUCURE is applicable to opening pouring, liquid injection molding, spin casting, dipping and other technologies; in addition, the PUCURE is also applicable to production of large-sized products with complicated structures and occasions with requirements on microwave curing, high stability and unfixed operating time.

Owner:LUDONG UNIVERSITY

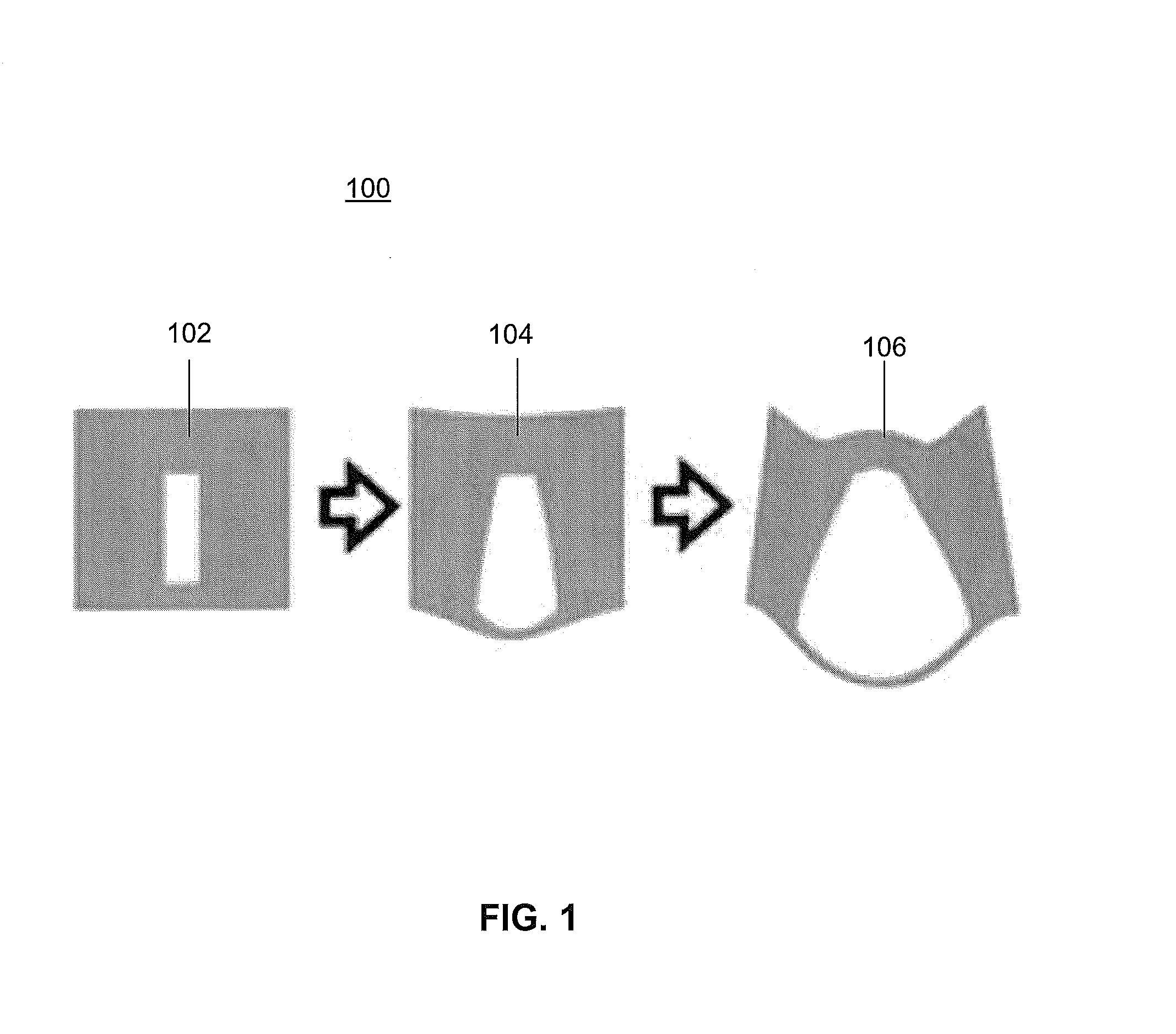

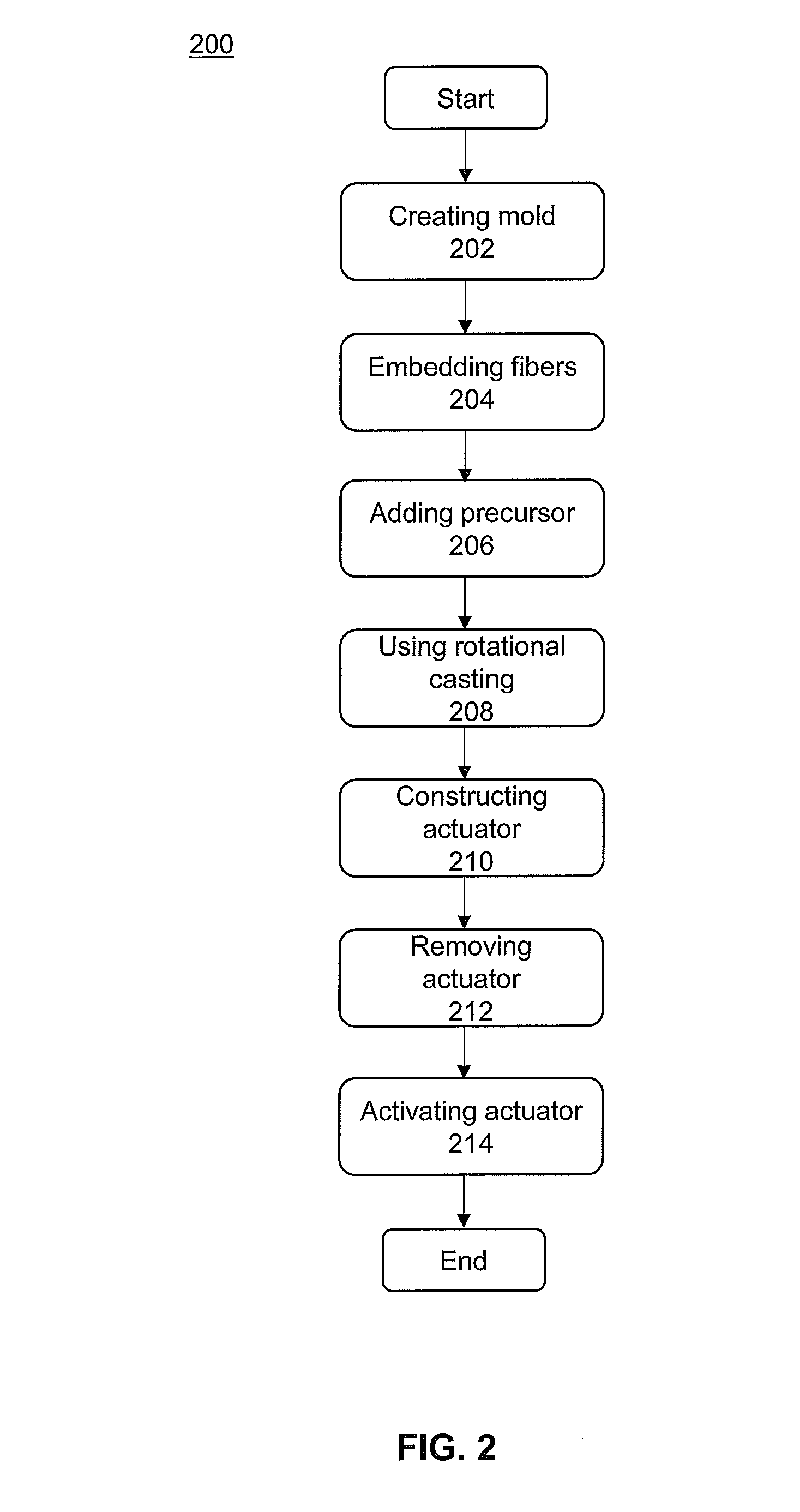

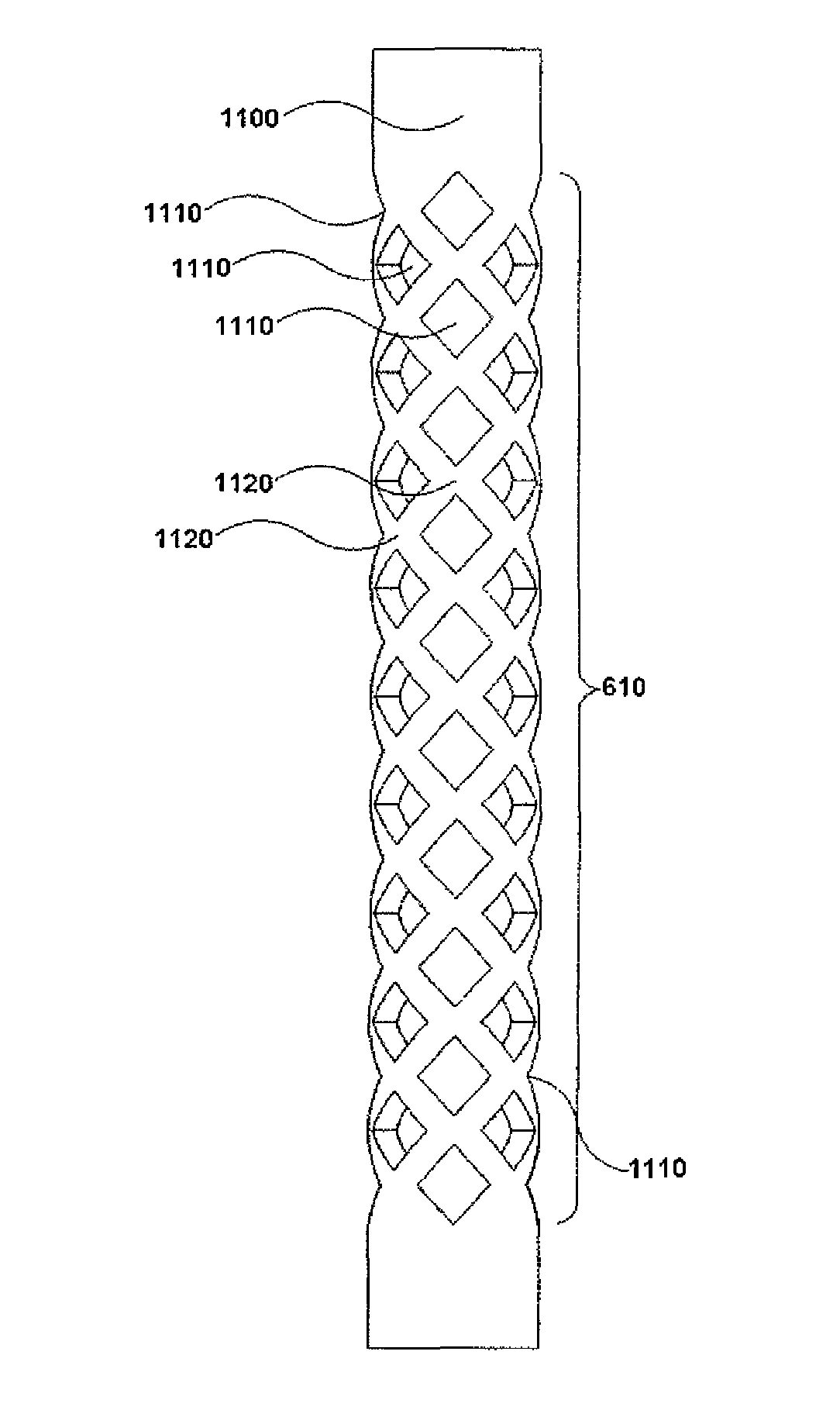

Soft robot device and related fabrication methods

ActiveUS20160250758A1High pressureLarge forceProgramme-controlled manipulatorFluid-pressure actuatorsFiberSpin casting

Owner:CORNELL UNIVERSITY

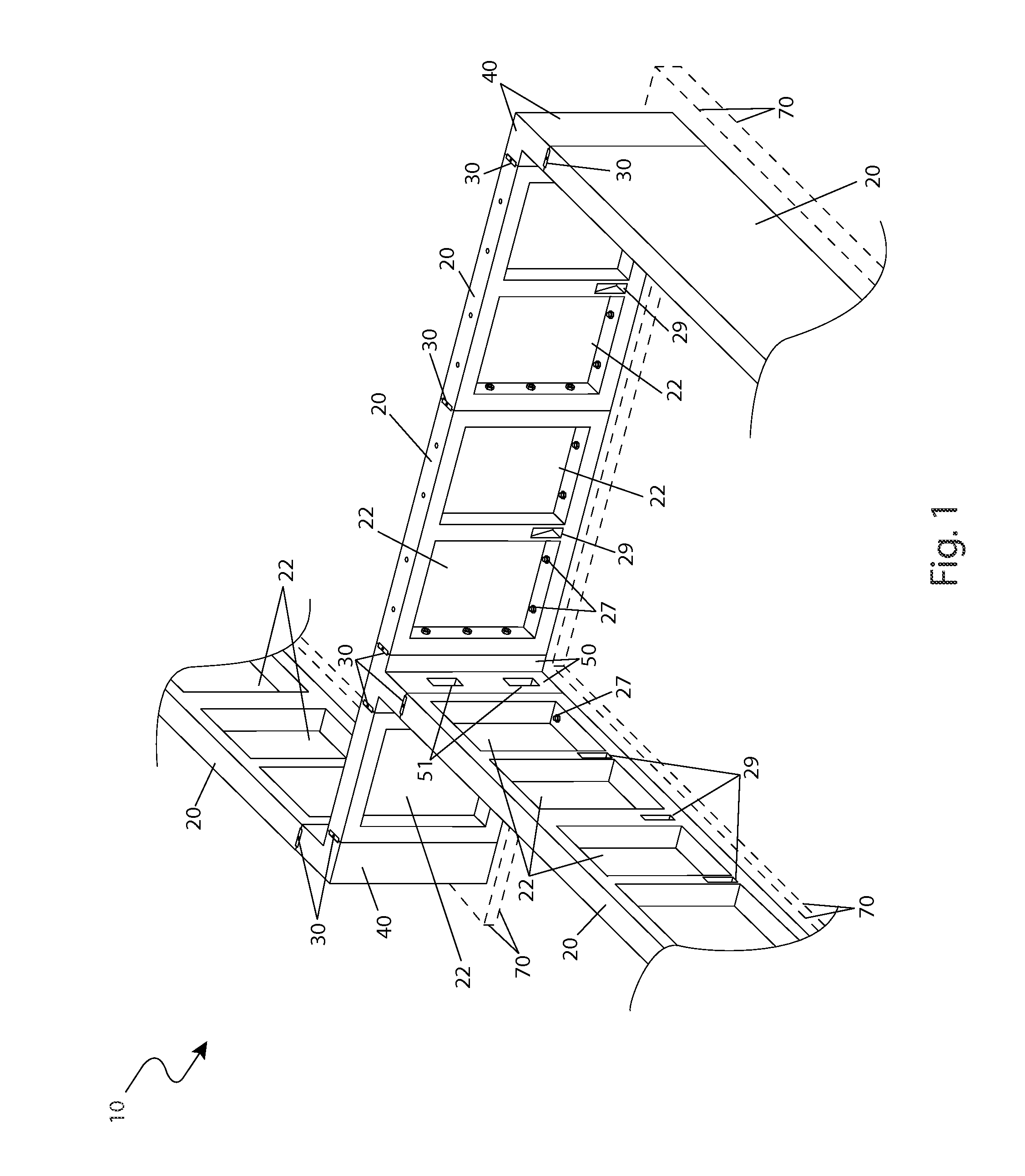

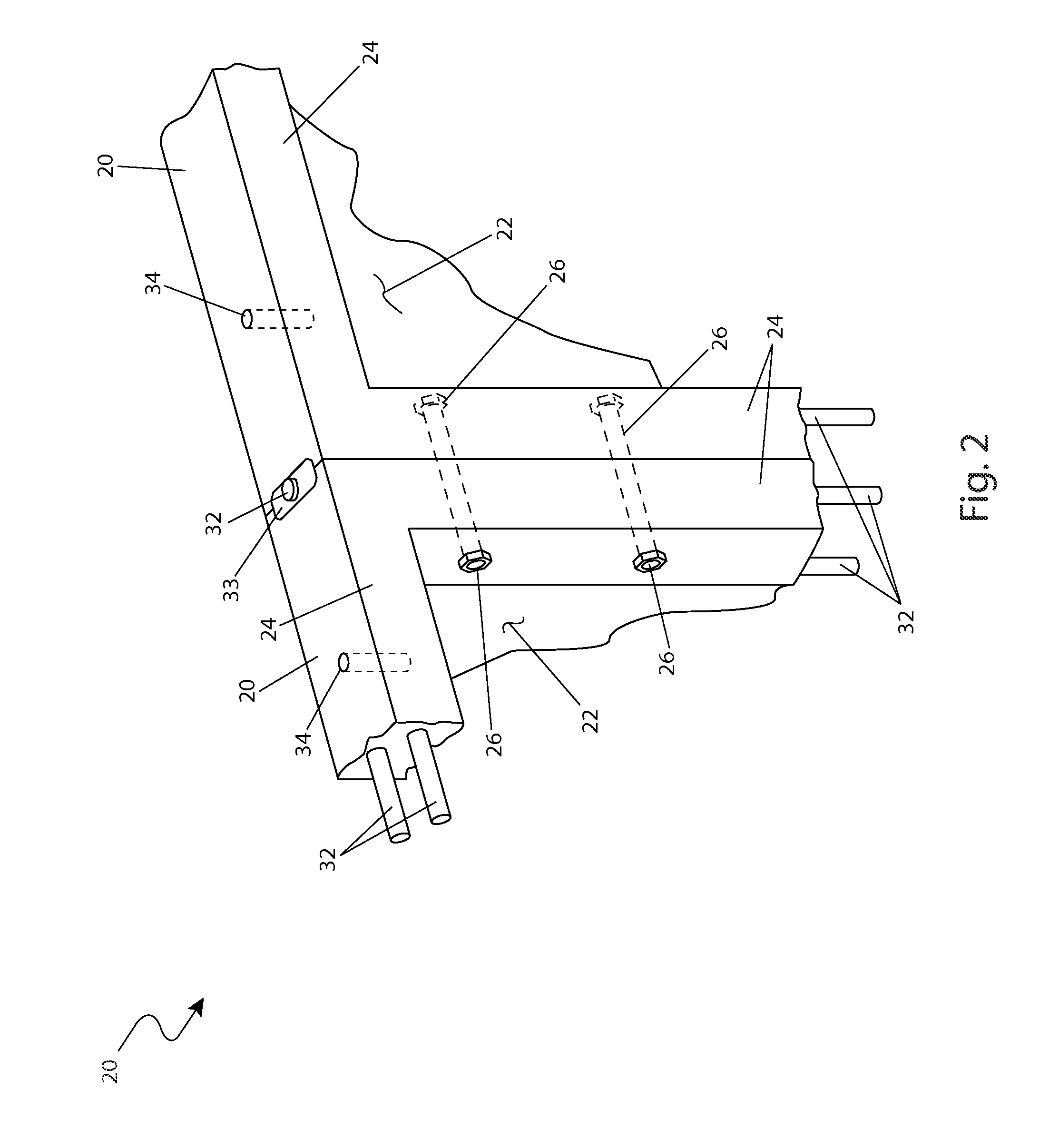

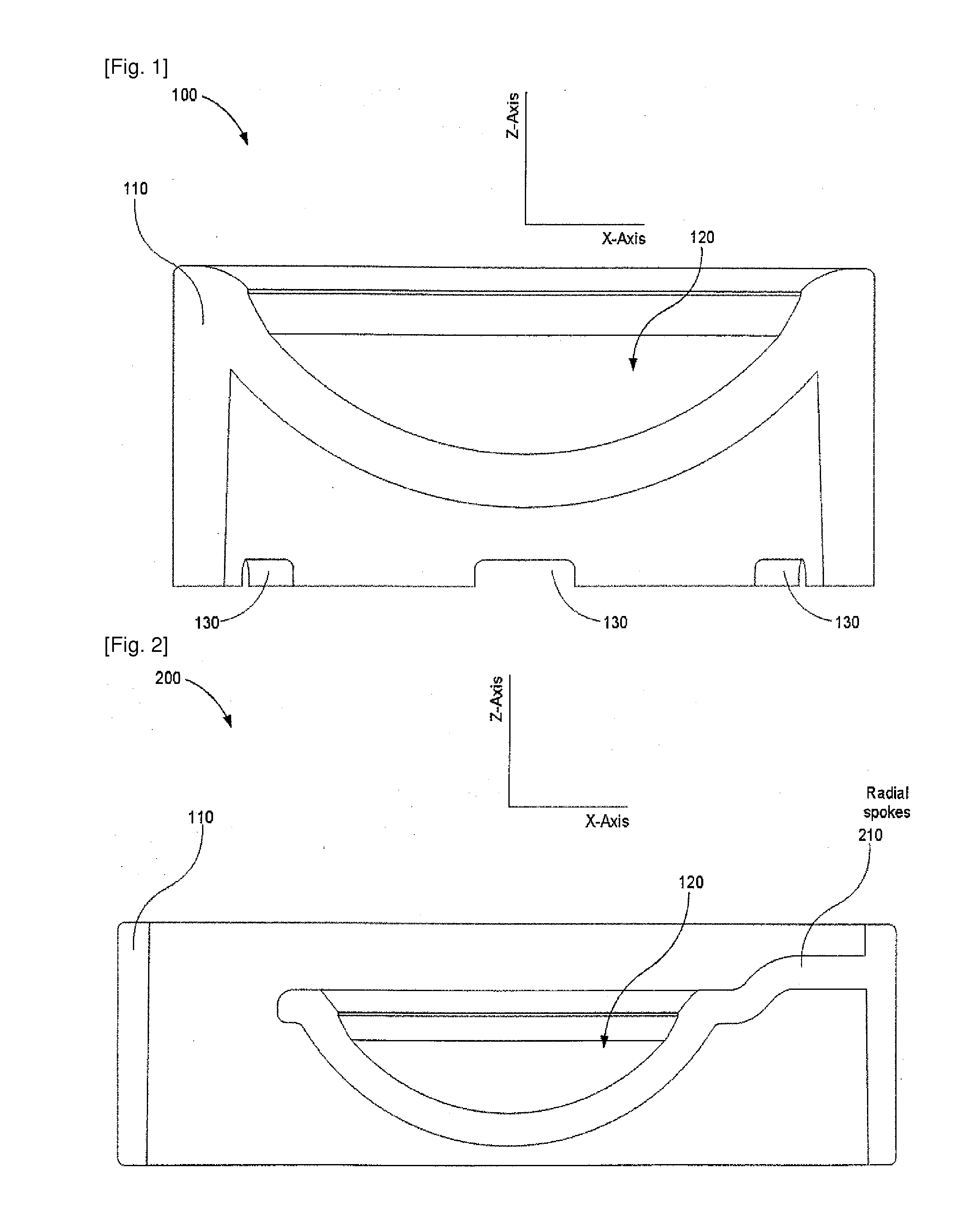

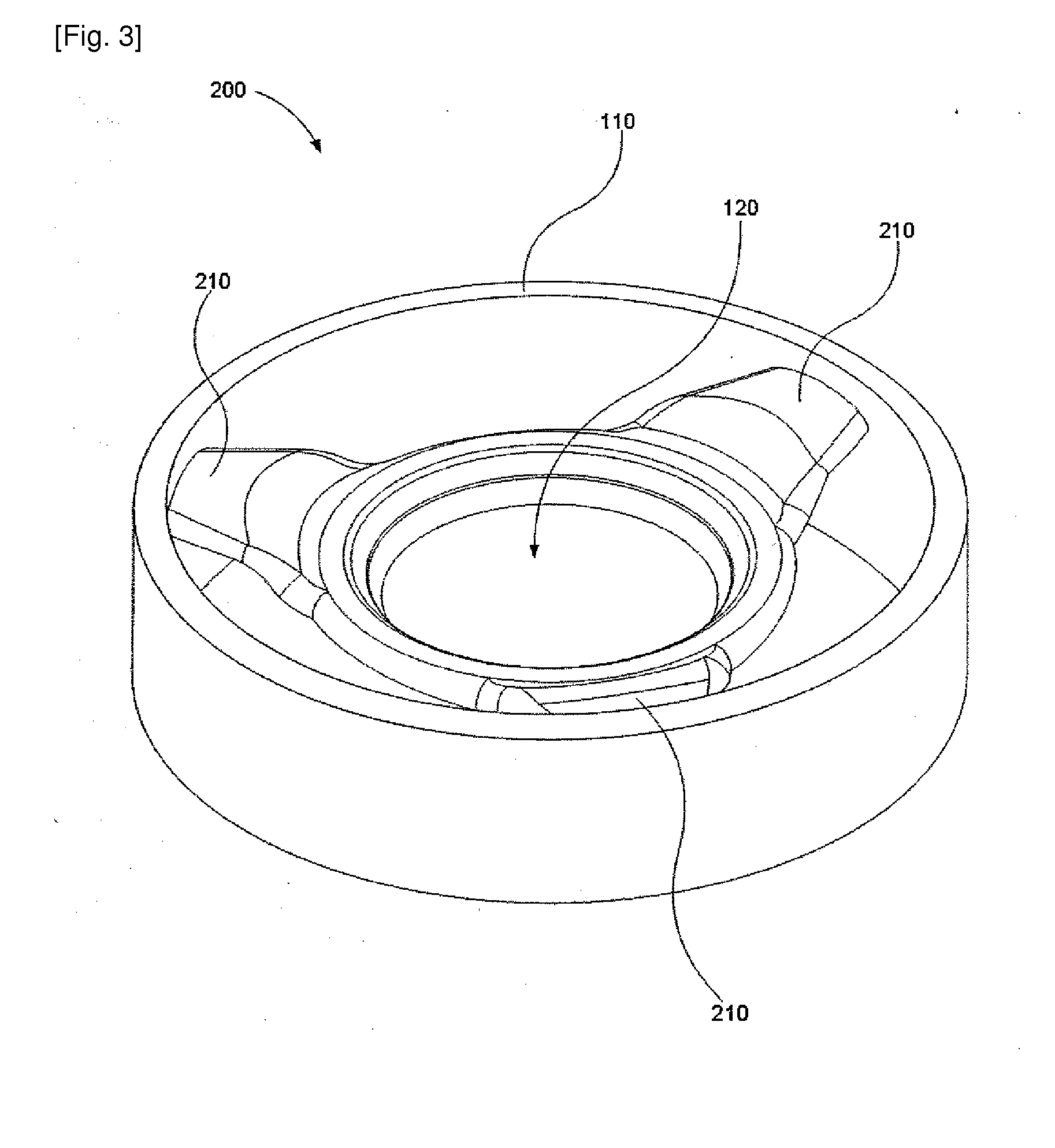

Systems and methods for the production of contact lenses

An apparatus for spin casting lenses includes a rotatable tube, the rotatable tube defining a longitudinal cavity, wherein the longitudinal cavity is configured to receive molds. According to one exemplary embodiment, the rotatable tube is made of metal and includes a plurality of apertures configured to permit the transmission of actinic radiation.

Owner:MENICON SINGAPORE PTE LTD

Nozzle for use in rotational casting apparatus

ActiveUS7270711B2High trafficSpread widelyLiquid surface applicatorsConfectioneryElastomerMain branch

For use in a rotational casting machine used for coating a rotating body with elastomer, such as polyurethane, there is provided a nozzle used for dispensing the liquid polyurethane onto the rotating body to be coated. The nozzle of the invention has a plurality of liquid-flow interior discharge-passageways each of which has an inlet connected to a sub-branch tube, which sub-branch tube is, in turn, is fluidly connected to a main branch that, in turn, is connected to a main inlet-passageway having the inlet that is directly connected to mixing head. Each discharge-passageway, or exit-passageway, changes in cross-sectional shape along the longitudinal axis thereof from its inlet to its outlet such that the cross-sectional area from the inlet to the outlet thereof gradually and minimally increases, whereby at least substantial laminar flow of the liquid is achieved with the concomitant reduced dwell-time of the liquid therein, in order to reduce in-nozzle reaction and subsequent clogging of the nozzle. The exit of the nozzle itself is constituted by the plurality of spaced-apart exit-openings or outlets of the discharge-passageways, where each such exit-opening or outlet is formed as a narrow, elongated slit or opening.

Owner:KASTALON

Systems and methods for the production of contact lenses

An apparatus for spin casting lenses includes a rotatable tube, the rotatable tube defining a longitudinal cavity, wherein the longitudinal cavity is configured to receive molds. According to one exemplary embodiment, the rotatable tube is made of metal and includes a plurality of apertures configured to permit the transmission of actinic radiation.

Owner:MENICON SINGAPORE PTE LTD

Modified surface having low adhesion properties to mitigate insect residue adhesion

A process to modify a surface to provide reduced adhesion surface properties to mitigate insect residue adhesion. The surface may include the surface of an article including an aircraft, an automobile, a marine vessel, all-terrain vehicle, wind turbine, helmet, etc. The process includes topographically and chemically modifying the surface by applying a coating comprising a particulate matter, or by applying a coating and also topographically modifying the surface by various methods, including but not limited to, lithographic patterning, laser ablation and chemical etching, physical vapor phase deposition, chemical vapor phase deposition, crystal growth, electrochemical deposition, spin casting, and film casting.

Owner:NASA

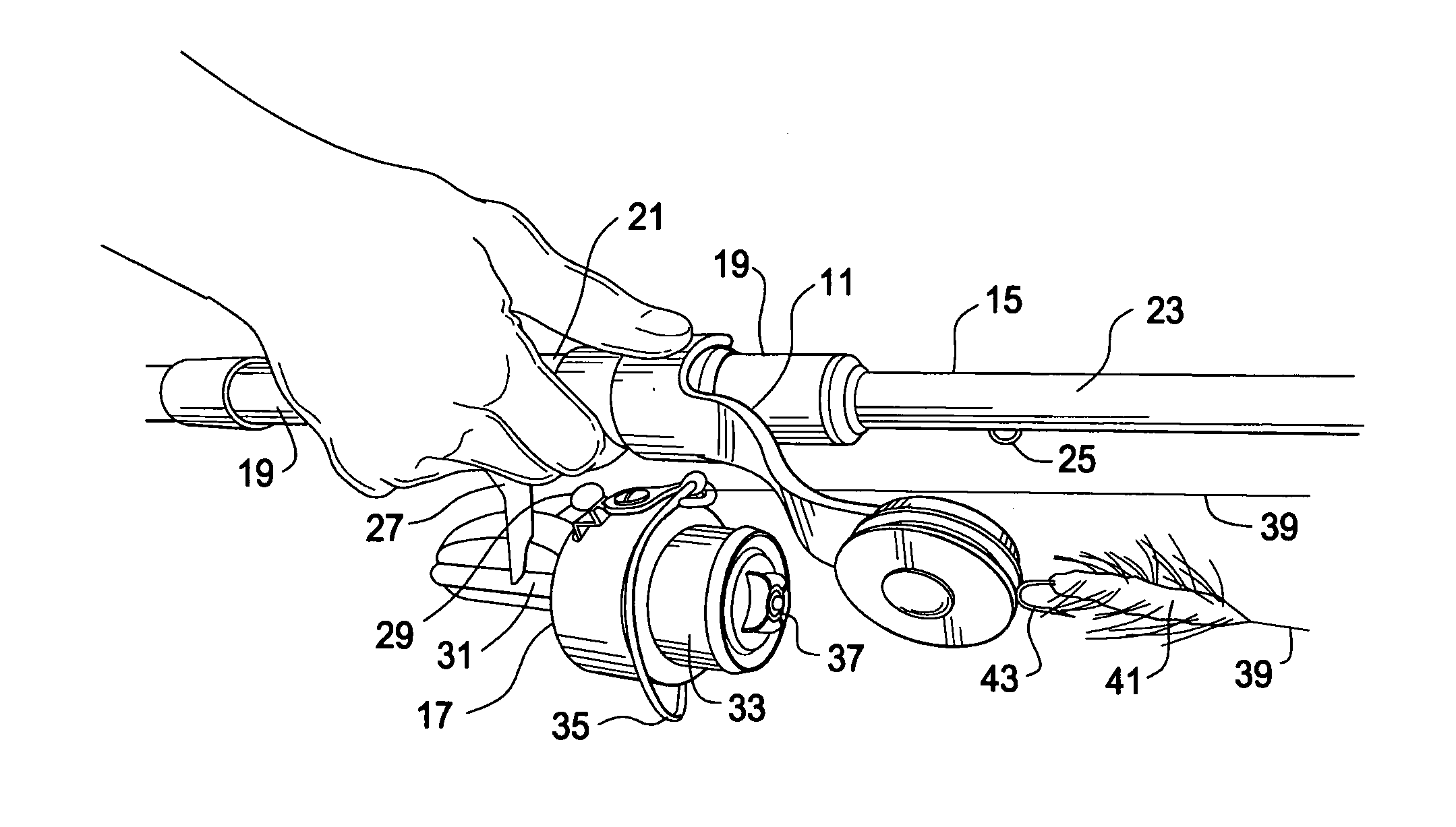

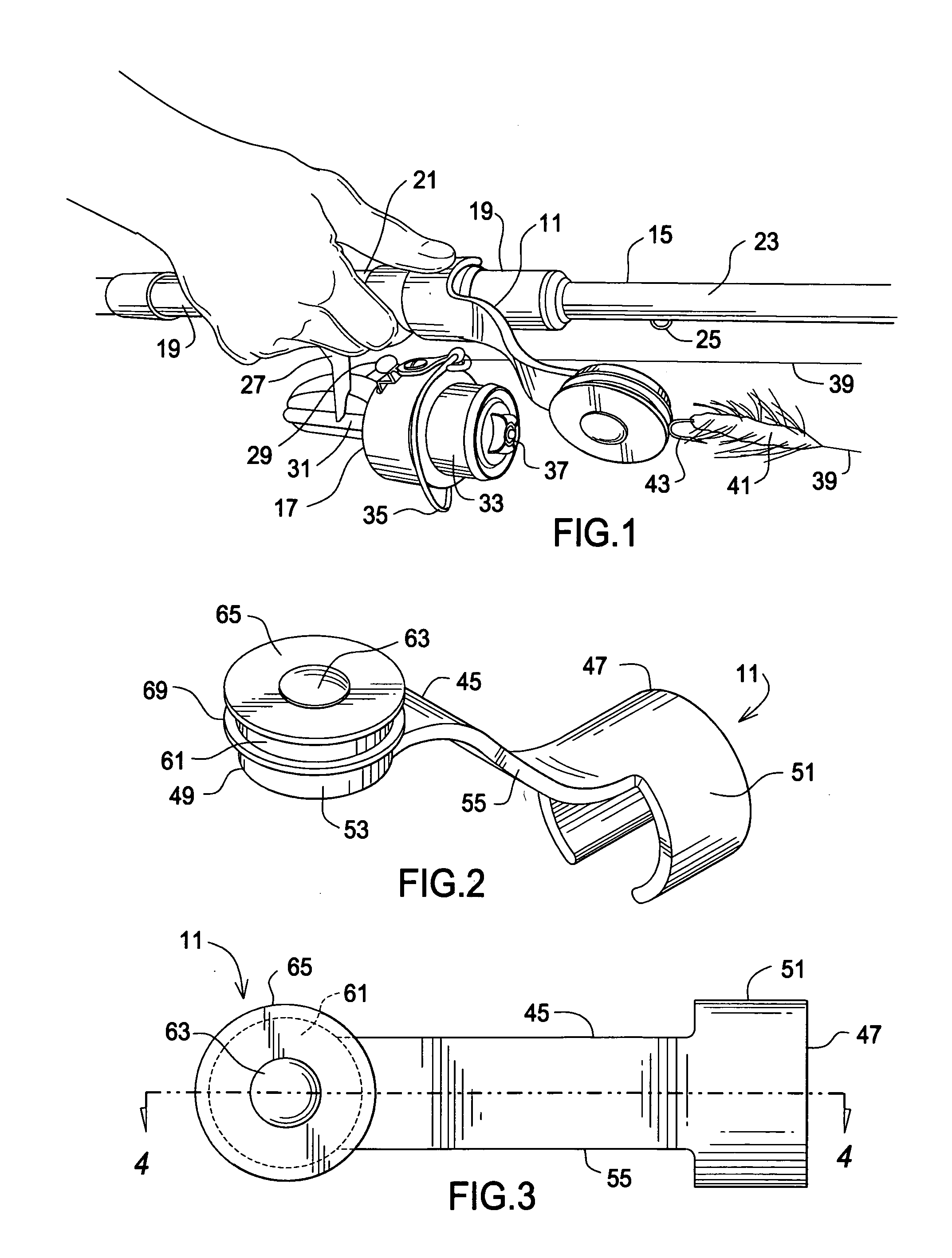

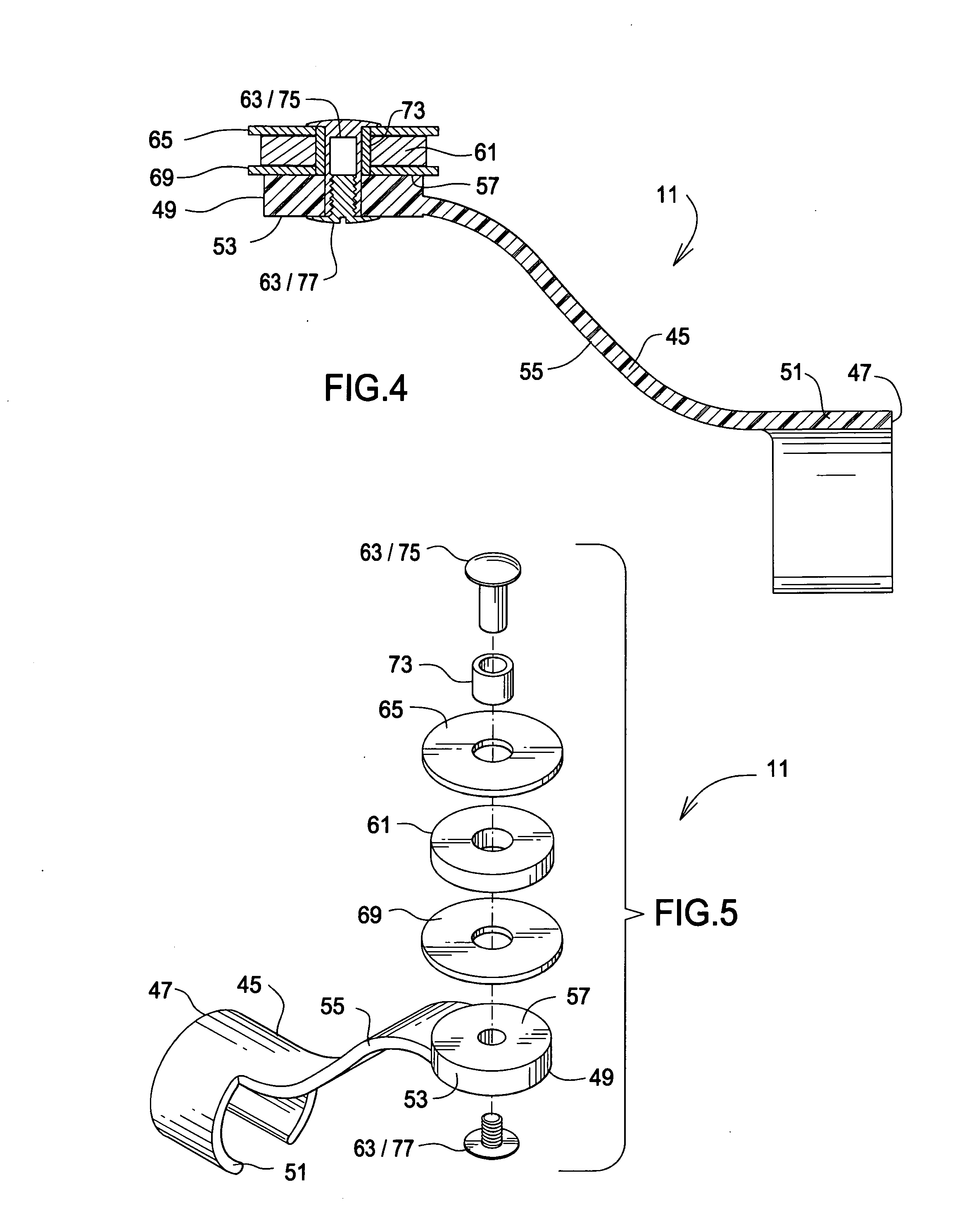

Magnetic line and lure restraint for enhanced casting

InactiveUS20150201600A1Easy to castWithout diminishing overall quality of castFishing netsRodsDecoySpin casting

Apparatus and methods are disclosed for line and lure restraint to enhance spin casting. The apparatus is mountable to a fishing rod adjacent to a line reel maintained on the rod and includes a mount having a positioning arm with a mounting clip at one end and a platform at an opposite end. A neodymium ring magnet with first and second steel washers at opposite sides thereof is located on a bushing. An axial securement rotatably secures this assembly at the platform. The positioning arm is configured to selectively locate the magnate assembly relative to the rod and reel.

Owner:CIARI JAMES R

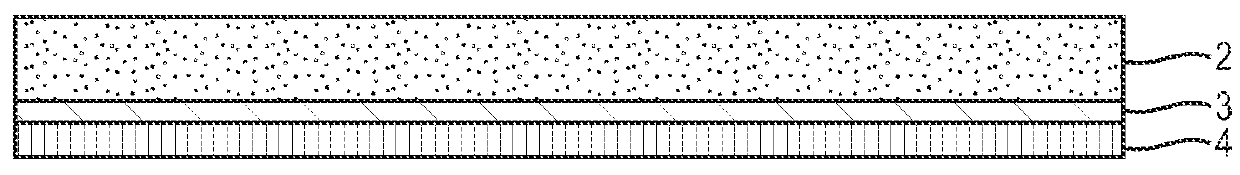

HEPA production method

InactiveCN108001008ASolve the smellDispersed particle filtrationSynthetic resin layered productsSpin castingHot melt

The invention provides a HEPA production method. The method comprises PET molding: preparing PET filaments from two types PET at different melting temperatures and preparing a PET layer from the PET filaments, PP molding: spin-casting PP particles and preparing a PP layer, pasting: applying a hot melt adhesive to the PET layer through a spraying or powder spraying method and pasting the PP layer to the PET layer to obtain a composite layer structure, bending and setting: bending and hot-setting the composite layer structure, and adhesive tape loading: applying an adhesive tape to the bent composite layer structure to obtain HEPA. The production method can reduce the pungent odor of the product after processing and improve user comfort.

Owner:A O SMITH CHINA WATER HEATER CO LTD

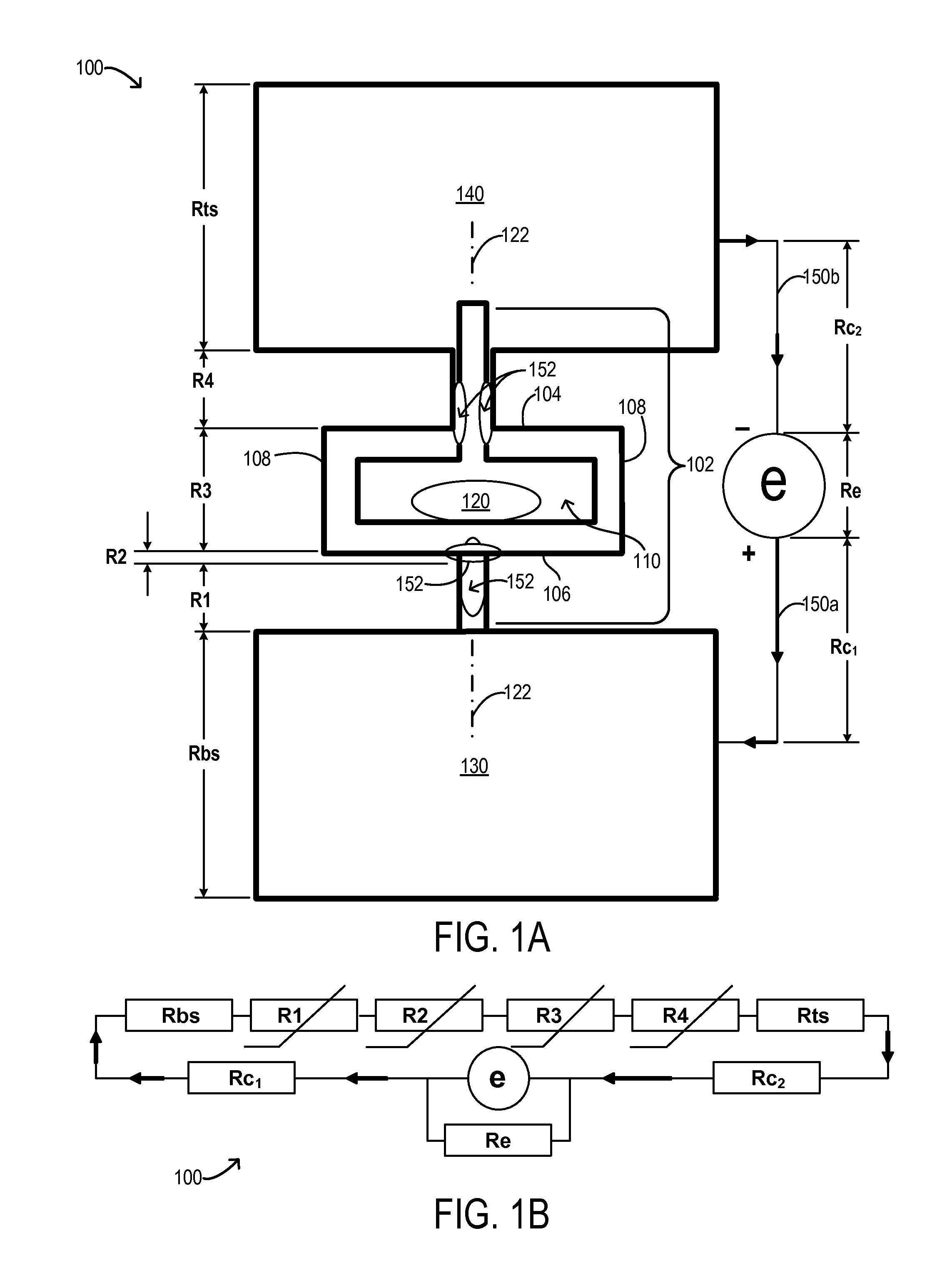

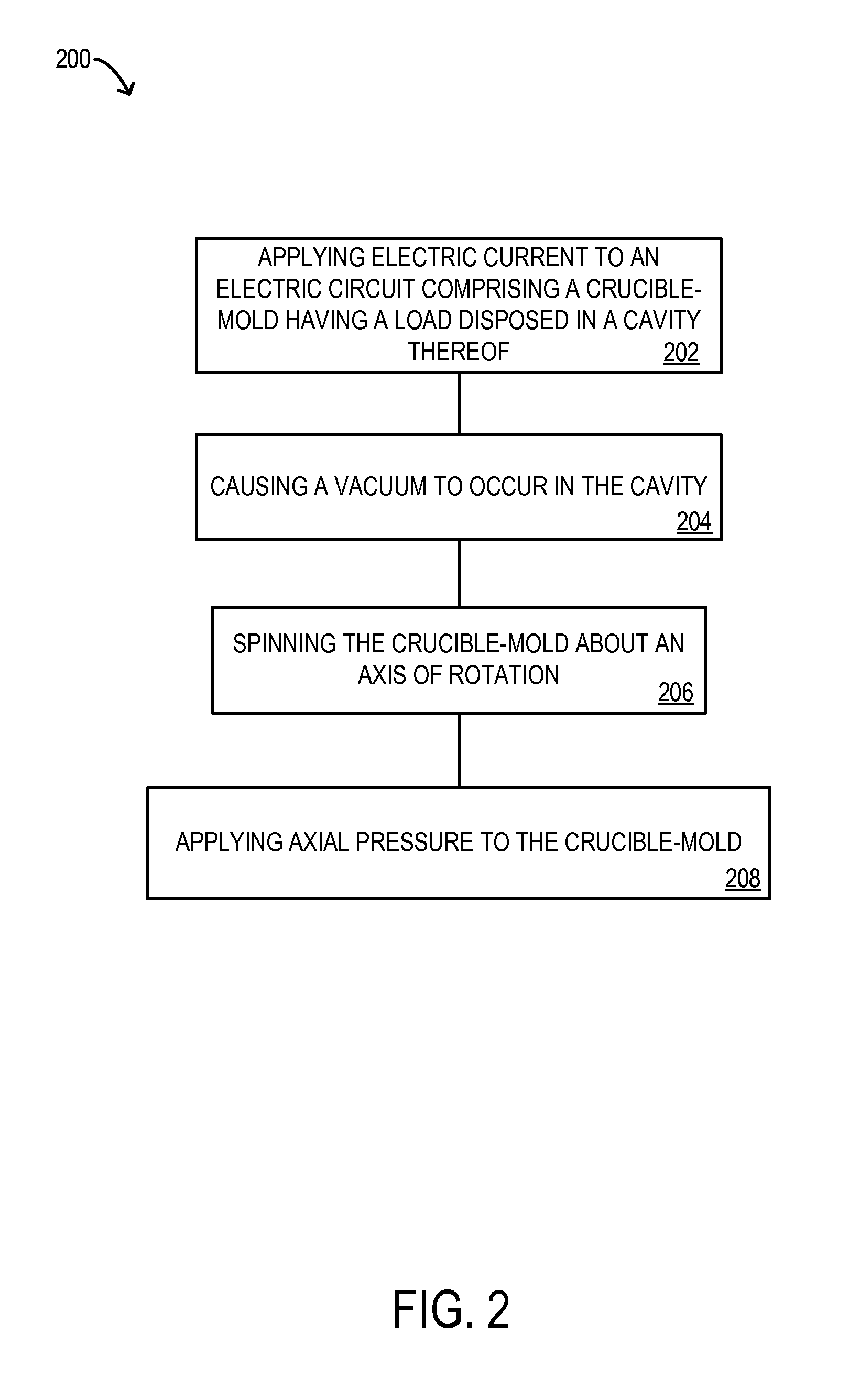

Systems and methods for a thermistor furnace

InactiveUS20120090805A1Moulding machine componentsCasting parameters measurement/indication devicesSpin castingSpins

Systems, apparatus, methods, and articles of manufacture that provide for a thermistor furnace, such as for melting, casting, and / or smelting loads (e.g., precious metals, other metals such as titanium, and / or thermoset plastics), are provided. In some embodiments, the thermistor furnace may comprise a vacuum spin casting apparatus capable of utilizing various types and configurations of molds, such as graphite and / or plaster molds.

Owner:UZIALKO STANISLAW P +1

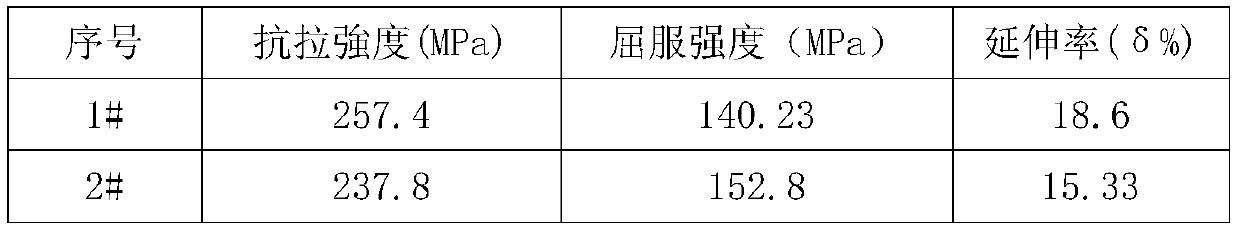

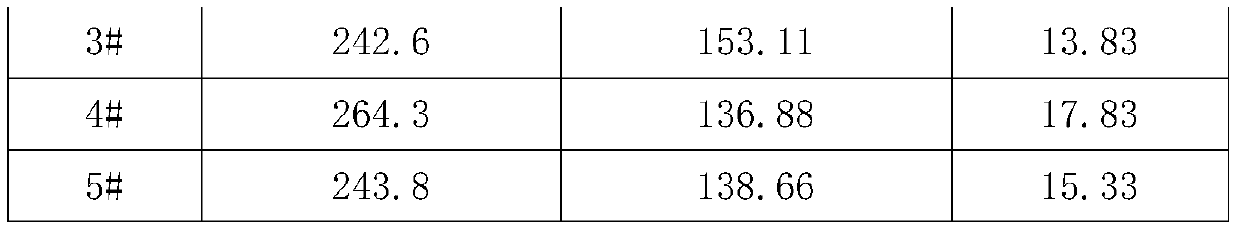

Aluminum alloy hub spinning casting process

The invention belongs to the technical field of metal casting, and relates to an aluminum alloy hub spinning casting process. The process comprises the steps: injecting molten aluminum into a mold cavity, spinning a rim blank out after a wheel disc is cast; carrying out cooling treatment, demolding, and carrying out spinning casting, wherein during the cooling treatment, the blank preheating temperature is 410-450 DEG C, the front surface of the blank is cooled in water at the temperature of 45-55 DEG C for 4-6 s after being discharged from the furnace, no water enters a rim body, the rim bodyis cooled in air, and spinning is started when the temperature of the mold is 200-240 DEG C, the temperature of the front surface of the blank is 180-220 DEG C and the temperature of the rim blank is360-400 DEG C; removing a blank sprue; and carrying out heat treatment, surface shot blasting, machining and surface coating or electroplating treatment on the blank. An optimized cooling method is adopted for the spinning blank, so that the temperatures of all parts of the blank are different, the blank is more suitable for the spinning process, and product deformation and extrusion defects areeffectively reduced; and the proper feeding speed is designed, the rim defects of the product are reduced, and the skin pulling and crack defects of the product can be effectively reduced.

Owner:DARE WHEEL MFG

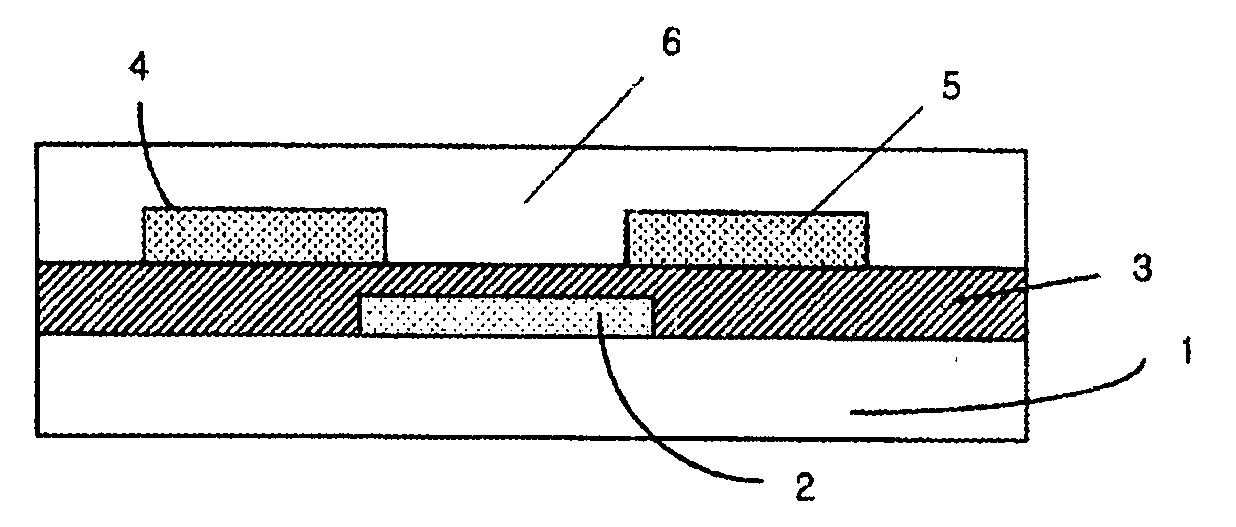

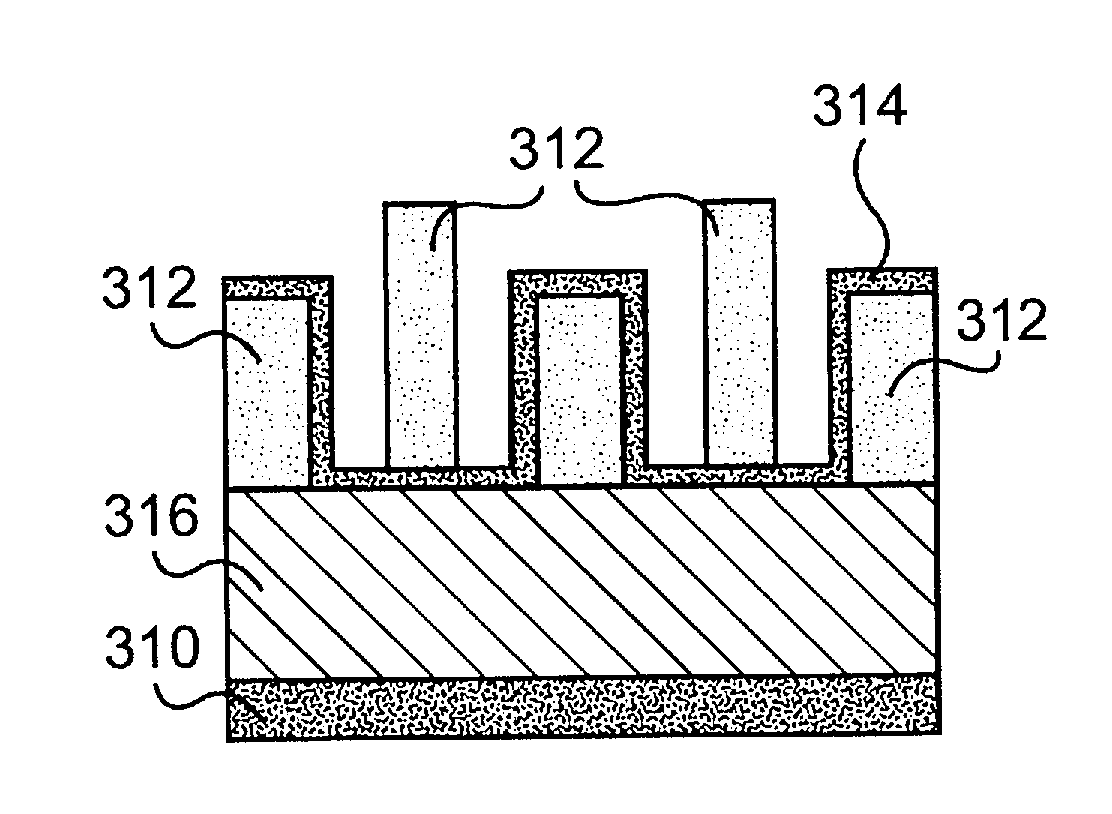

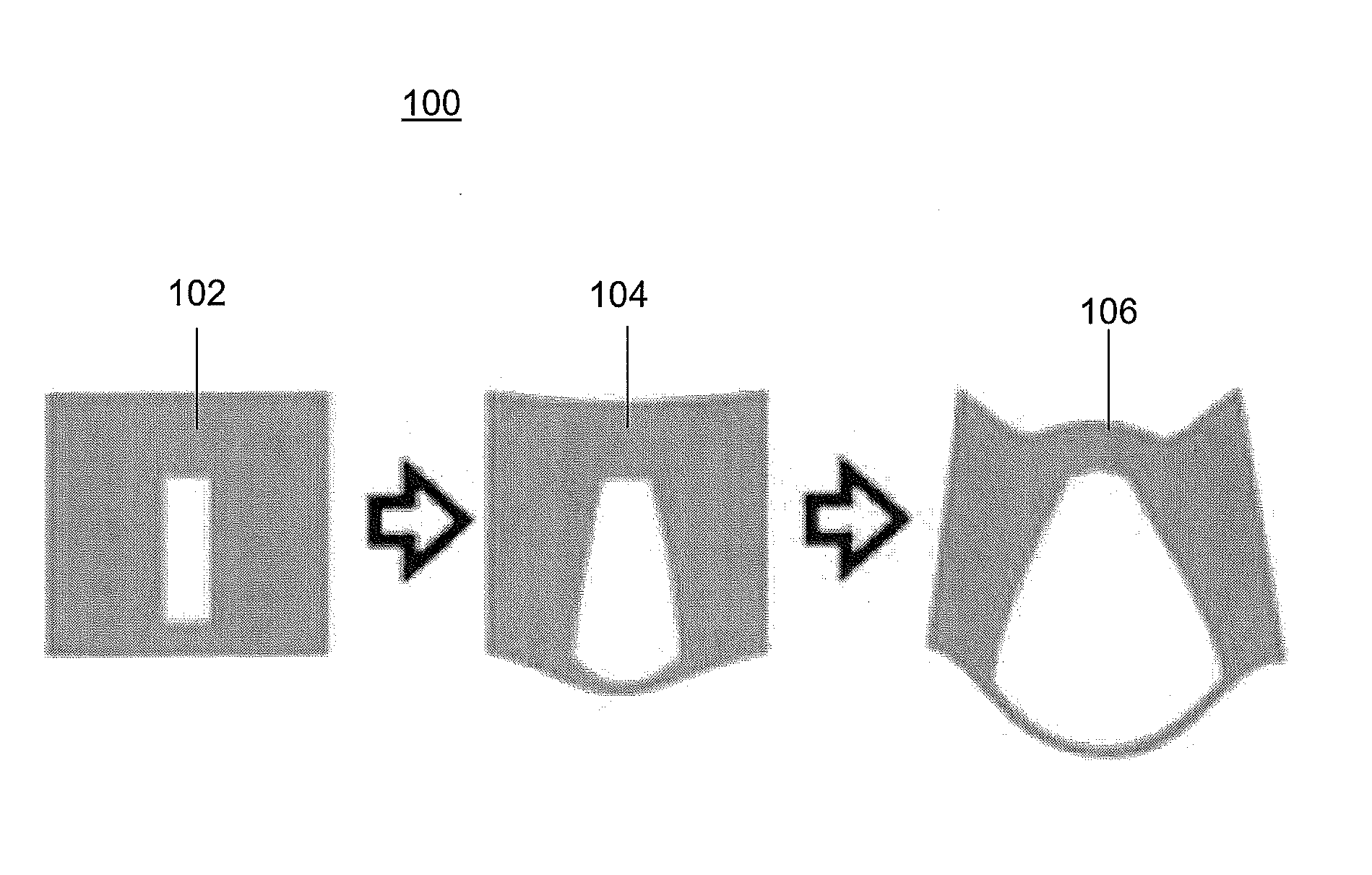

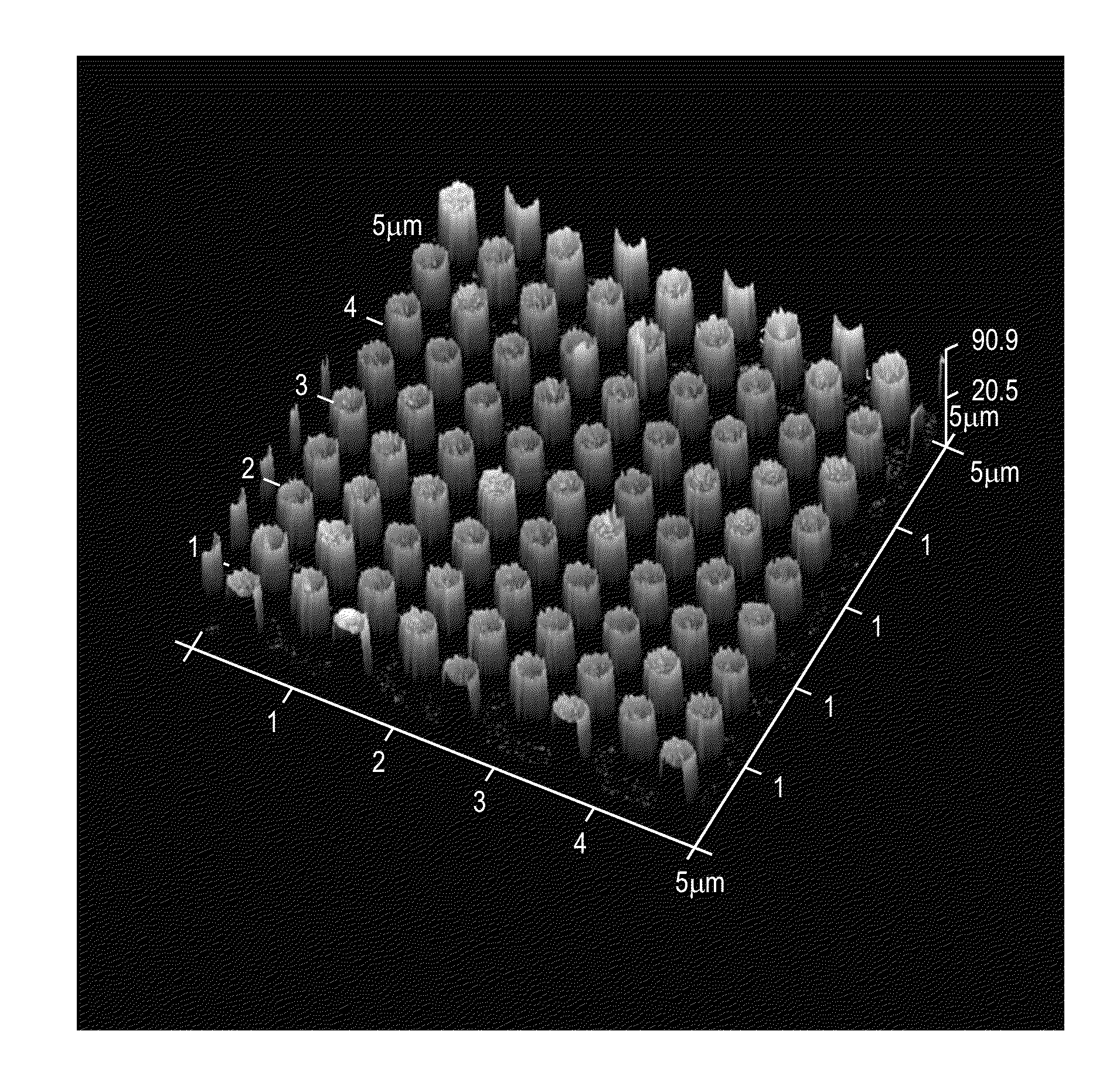

Methods of forming nanoparticles using semiconductor manufacturing infrastructure

A method of preparing particles comprises forming by optical lithography a topographic template layer disposed on a surface of a substrate, which is suitable for spin casting. The template layer comprises a non-crosslinked template polymer having a pattern of independent wells therein for molding independent particles. Spin casting a particle-forming composition onto the template layer forms a composite layer comprising the template polymer and the particles disposed in the wells. The composite layer is removed from the substrate using a stripping agent that dissolves the template polymer without dissolving the particles. The particles are then isolated.

Owner:IBM CORP

Method and apparatus for manufacturing thermoplastic synthetic resin sheet or film

InactiveUS20050173828A1High glossStable continuous productionFlat articlesRotational axisSpin casting

An apparatus for producing a thermoplastic synthetic resin sheet or film has a casting mechanism having support rollers each mounted to undergo rotation about a corresponding rotational axis and one of which is mounted to undergo non-rotational displacement relative to the other support rollers. A casting sleeve is entrained around the support rollers for rotation therewith. A casting roller is mounted for undergoing rotation relative to the casting sleeve. A synthetic resin material is fed between opposite and confronting outer peripheral surfaces of the casting sleeve and the casting roller while rotating the casting sleeve and the casting roller and while effecting non-rotational displacement of one of the support rollers to holdingly press the synthetic resin material between the casting sleeve and the casting roller and thereby form the synthetic resin material into a thermoplastic synthetic resin sheet or film.

Owner:CTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com