Patents

Literature

51results about "Without cord reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

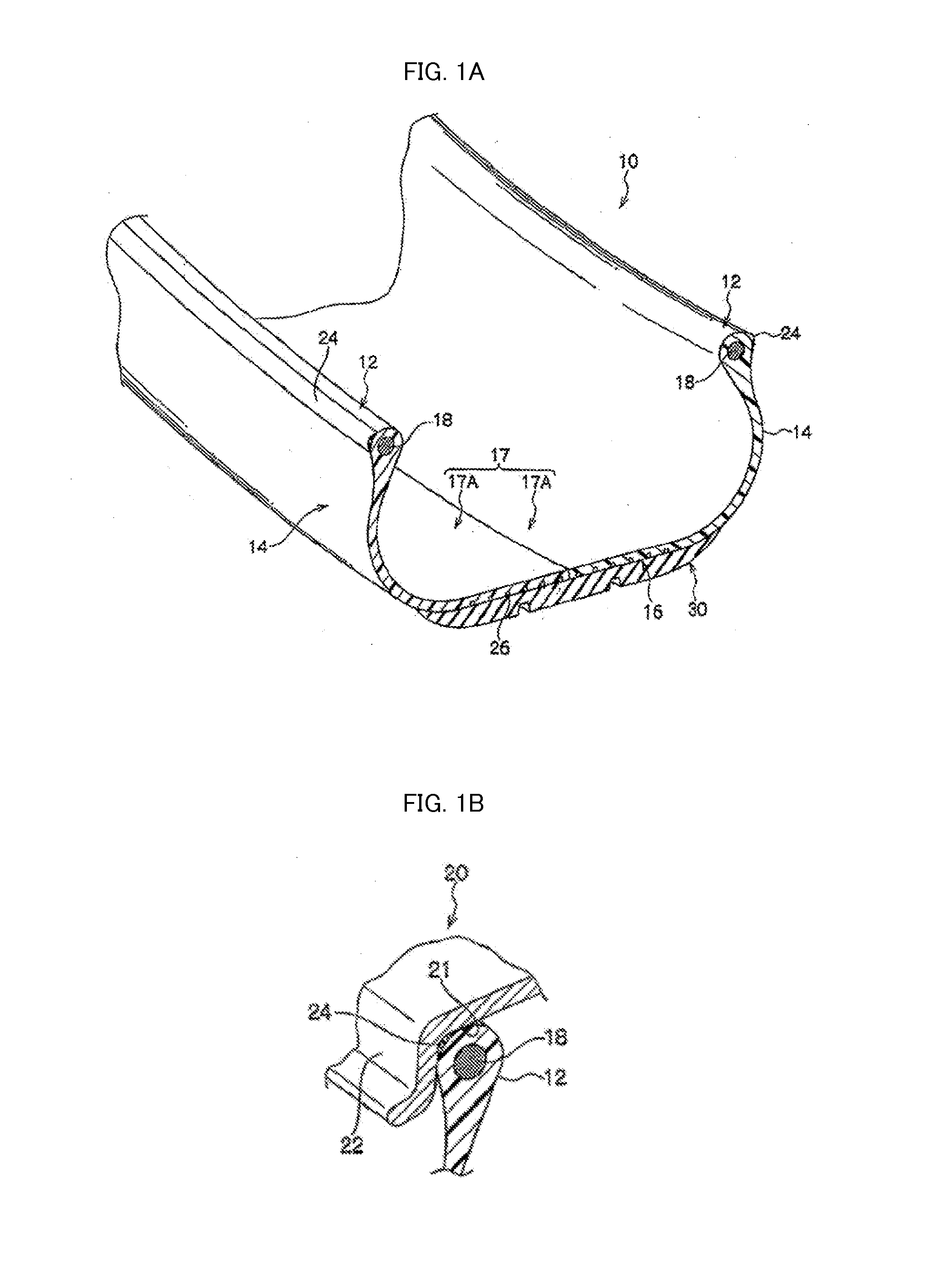

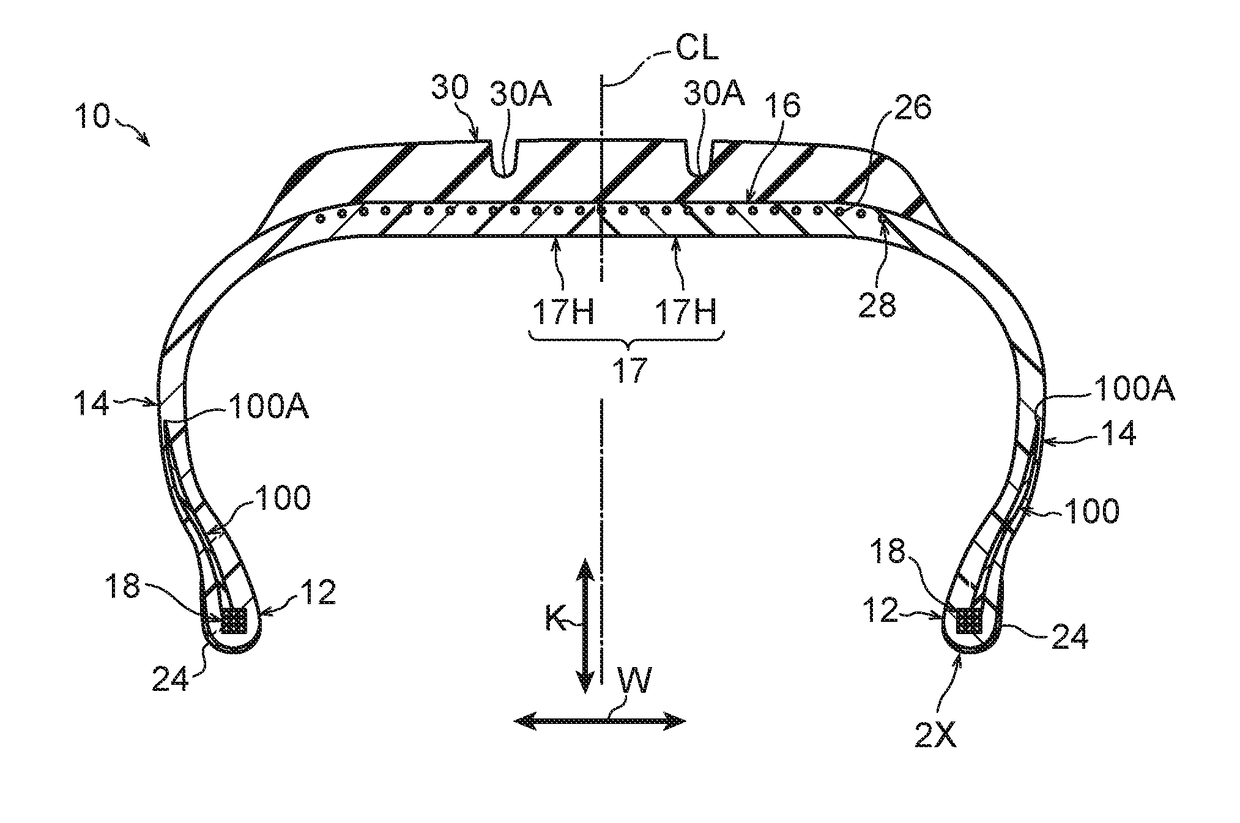

Tire and tire manufacturing method

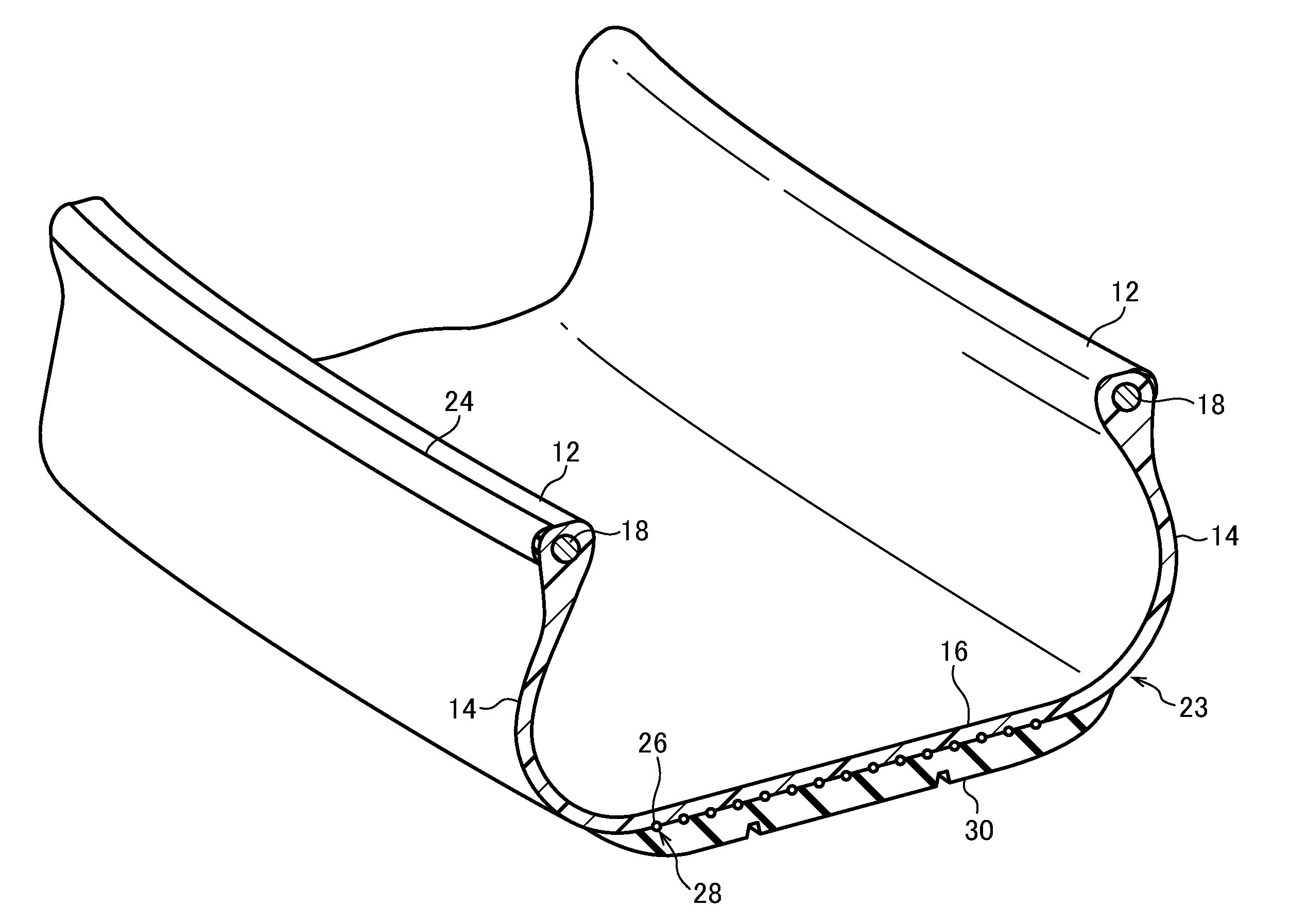

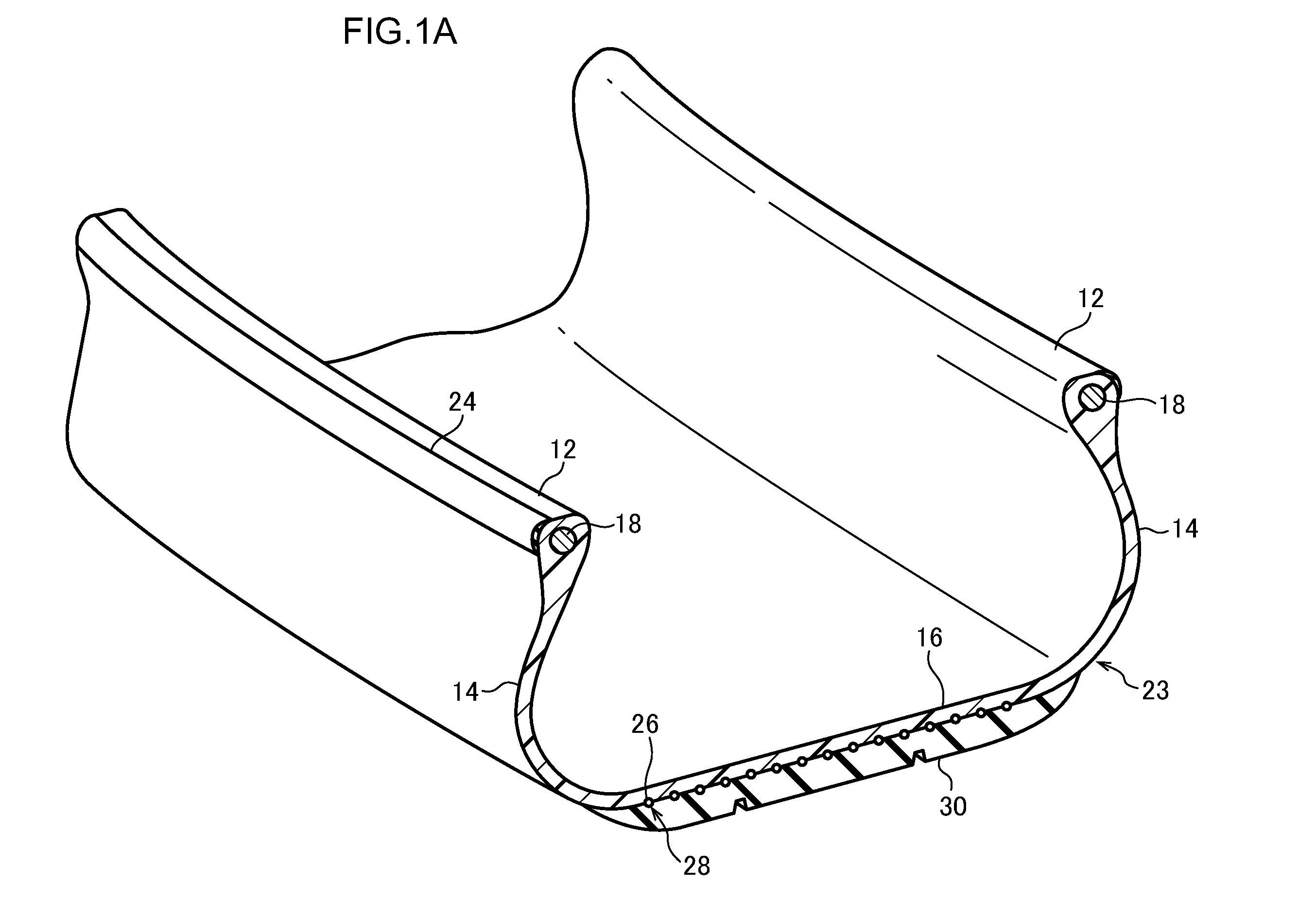

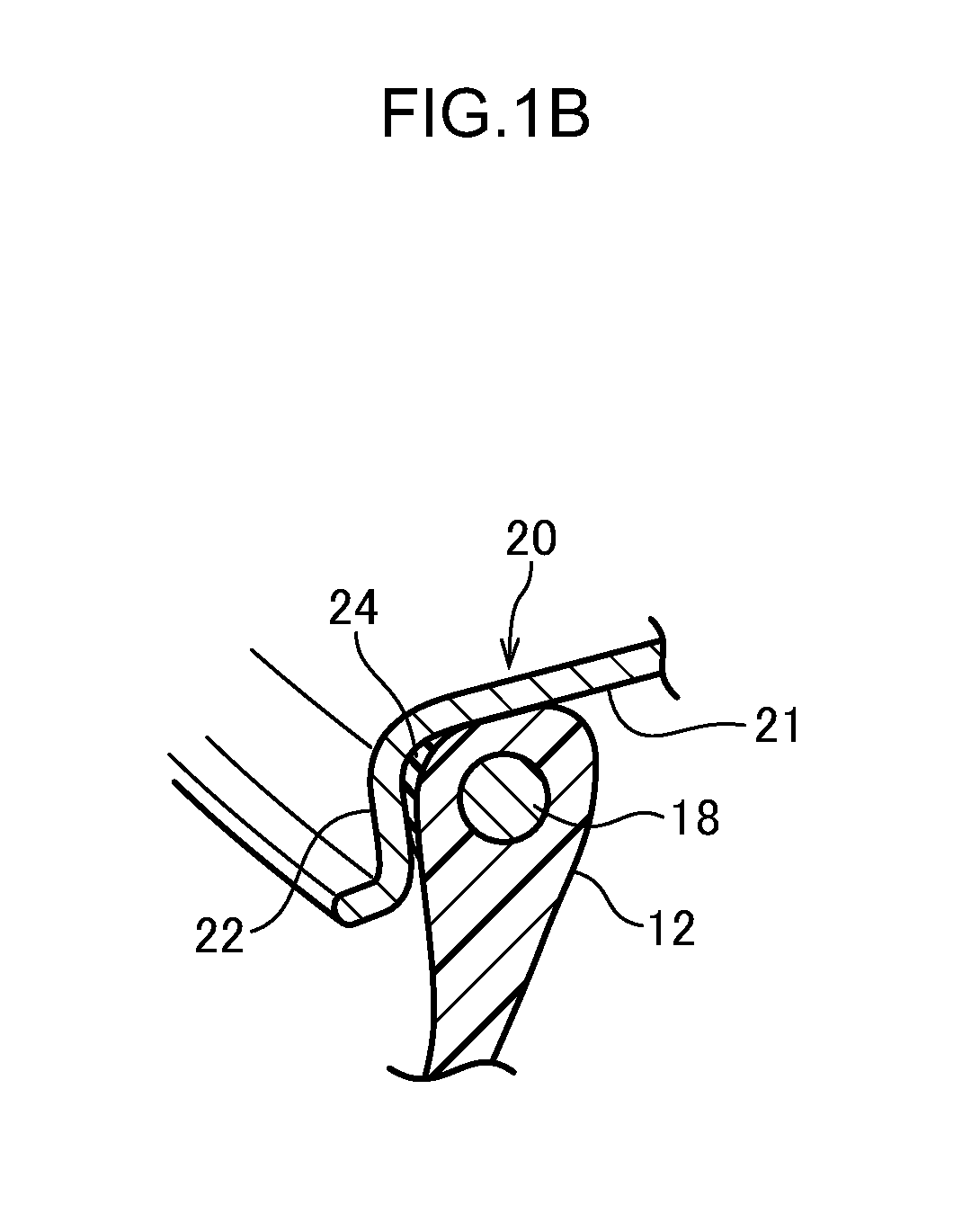

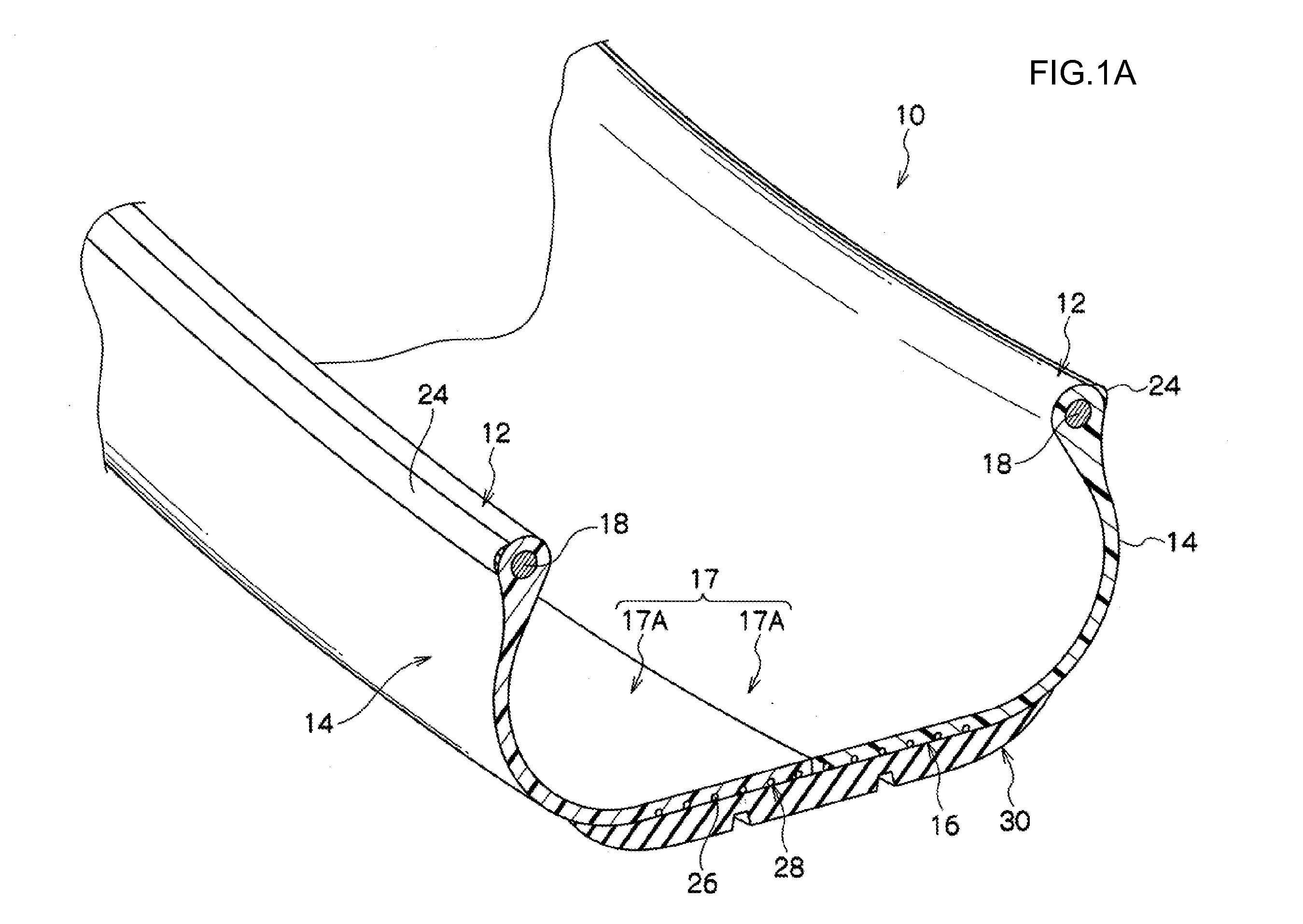

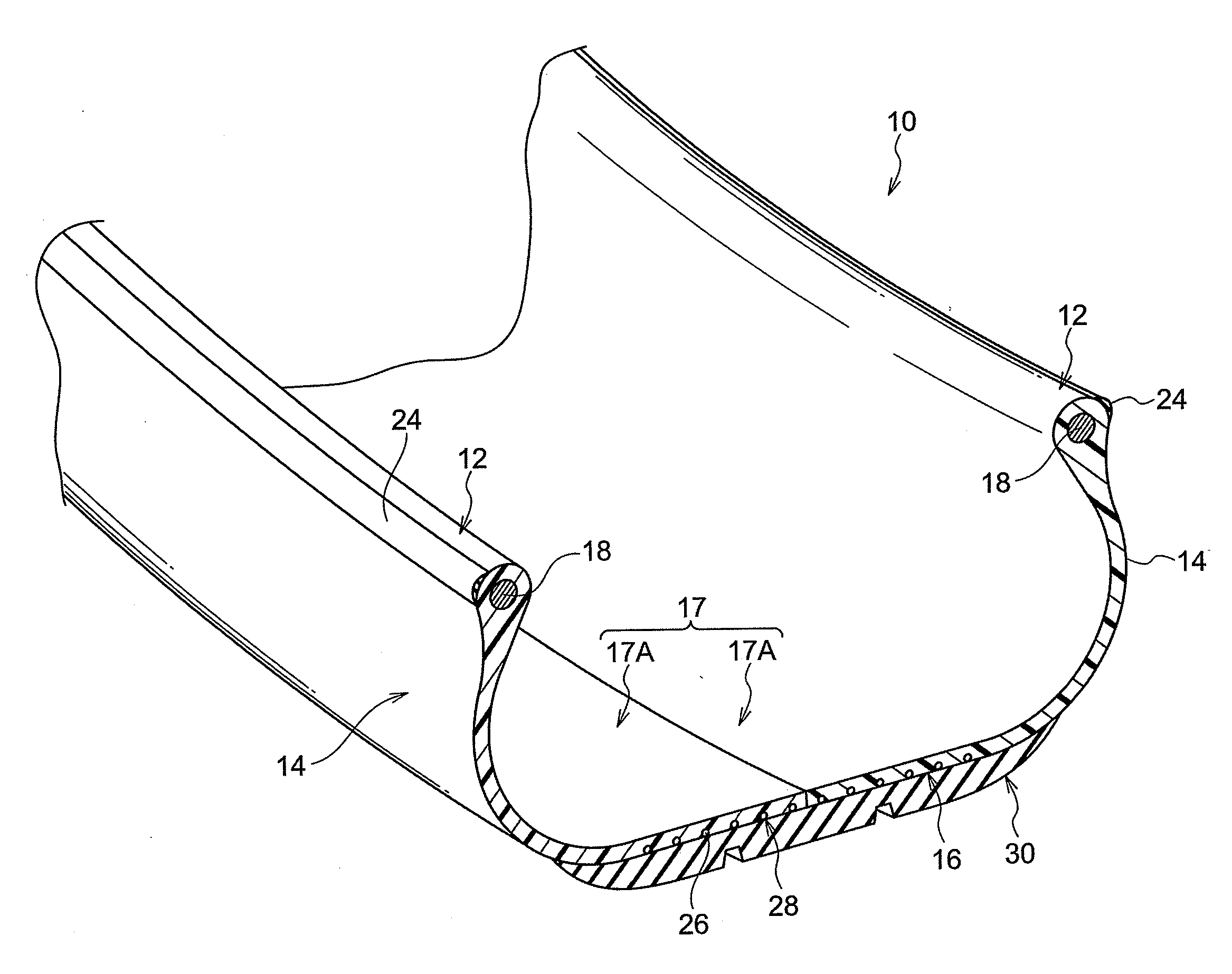

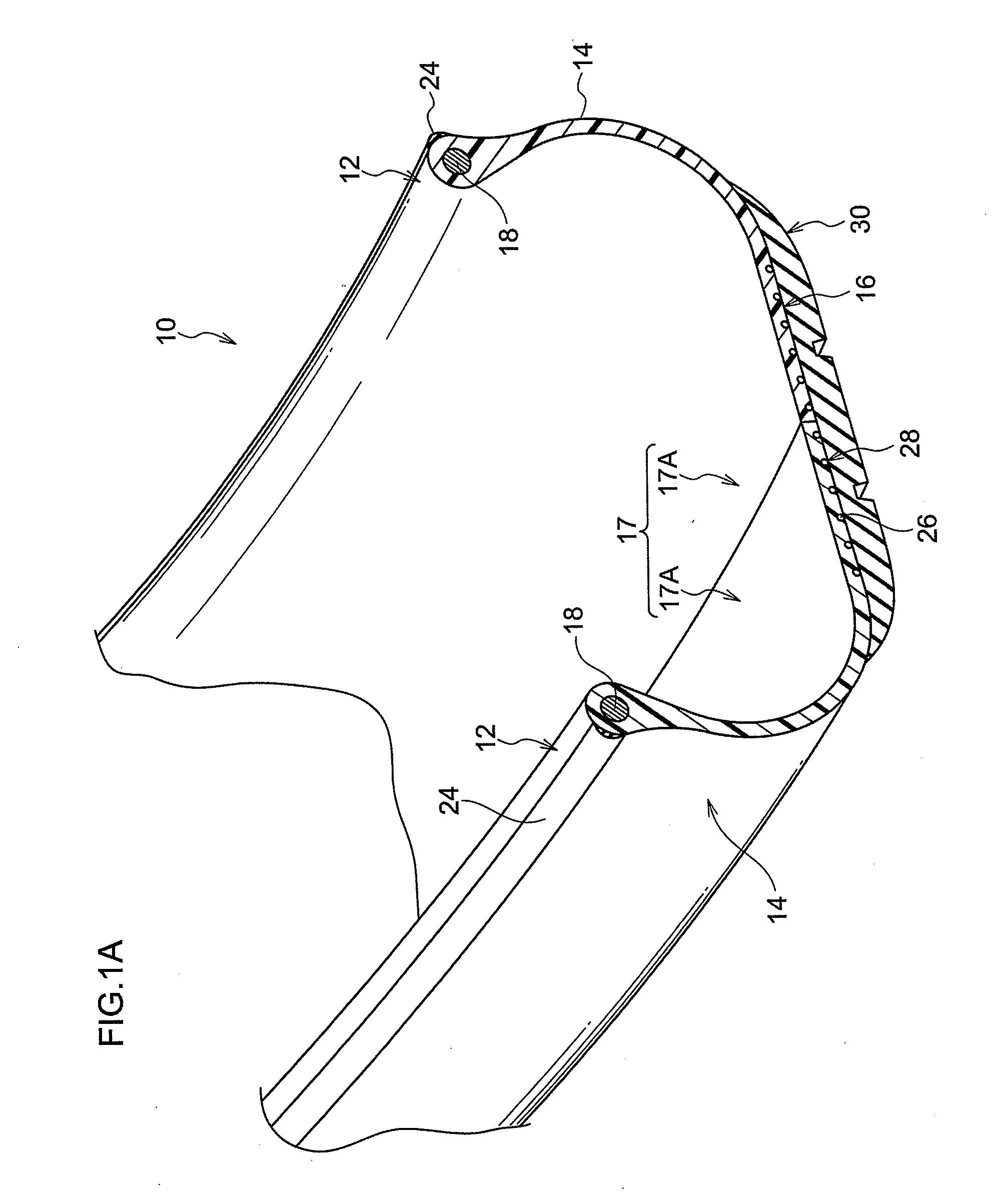

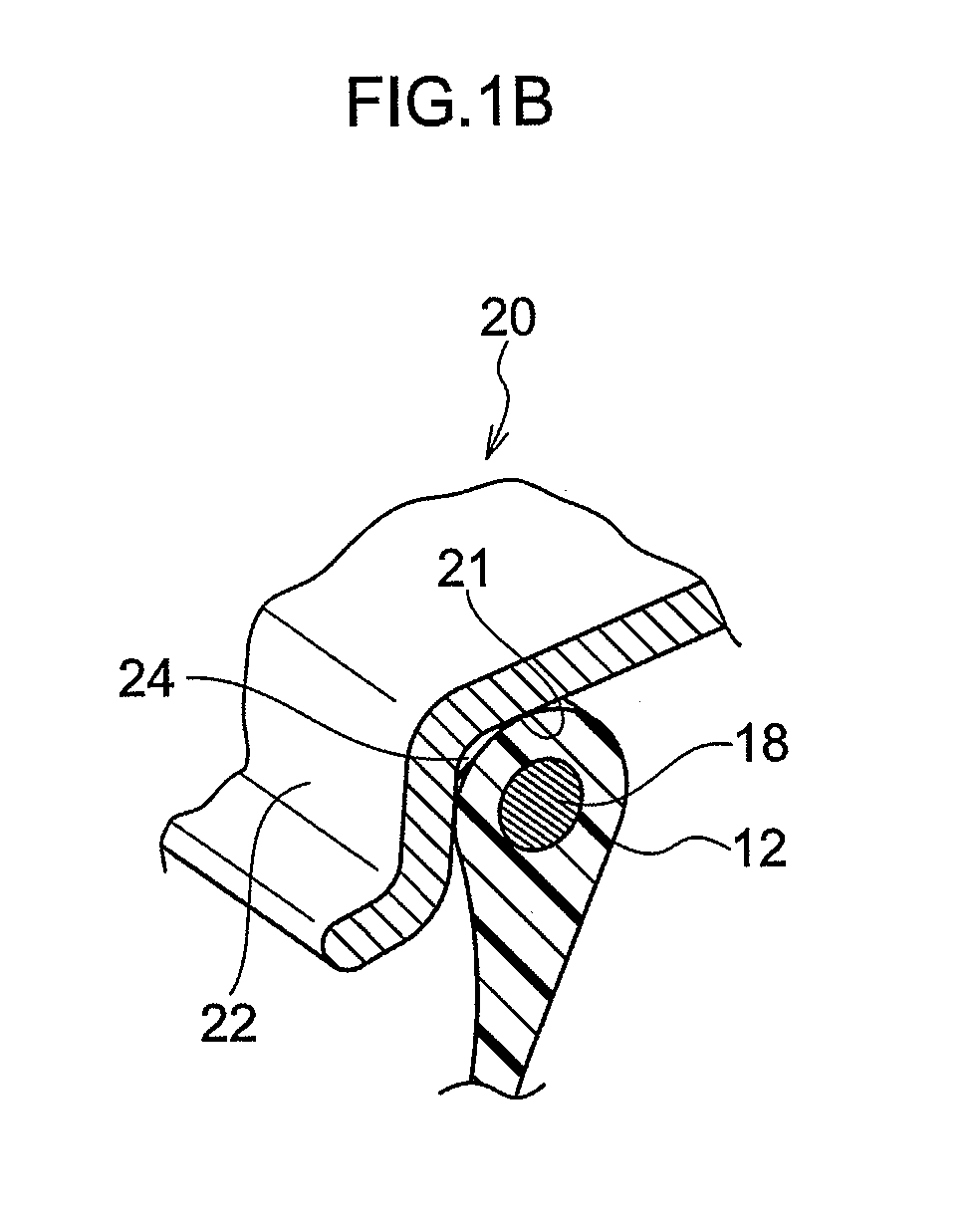

ActiveUS20110297289A1Suppresses airIncreased durabilityWithout cord reinforcementWith separate inflatable insertsMechanical engineeringPlastic property

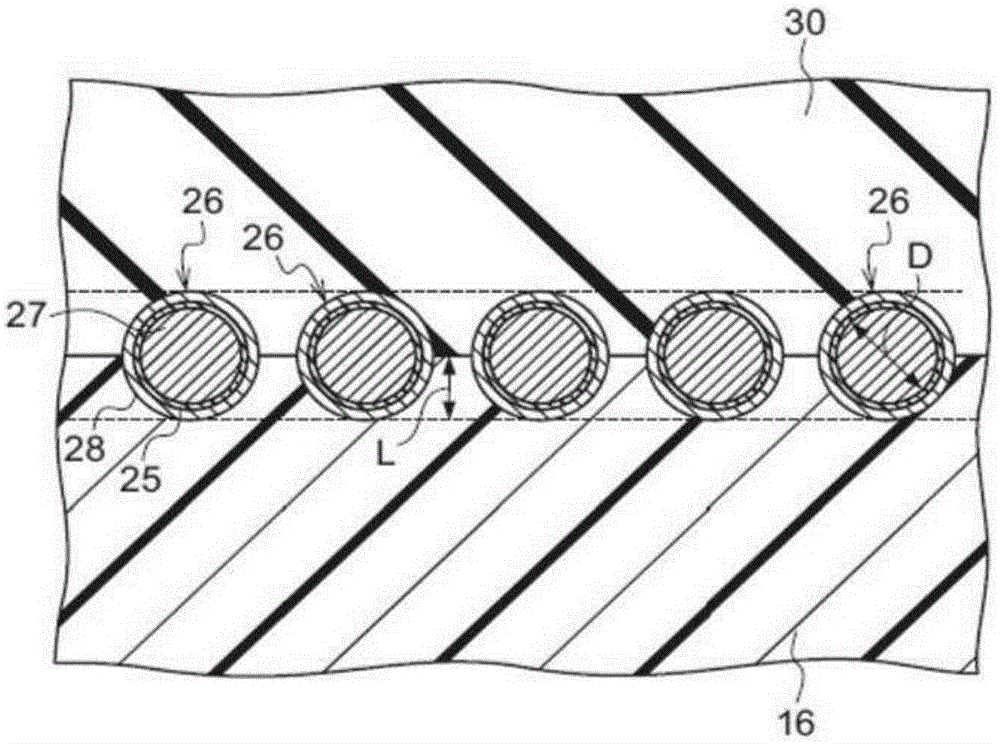

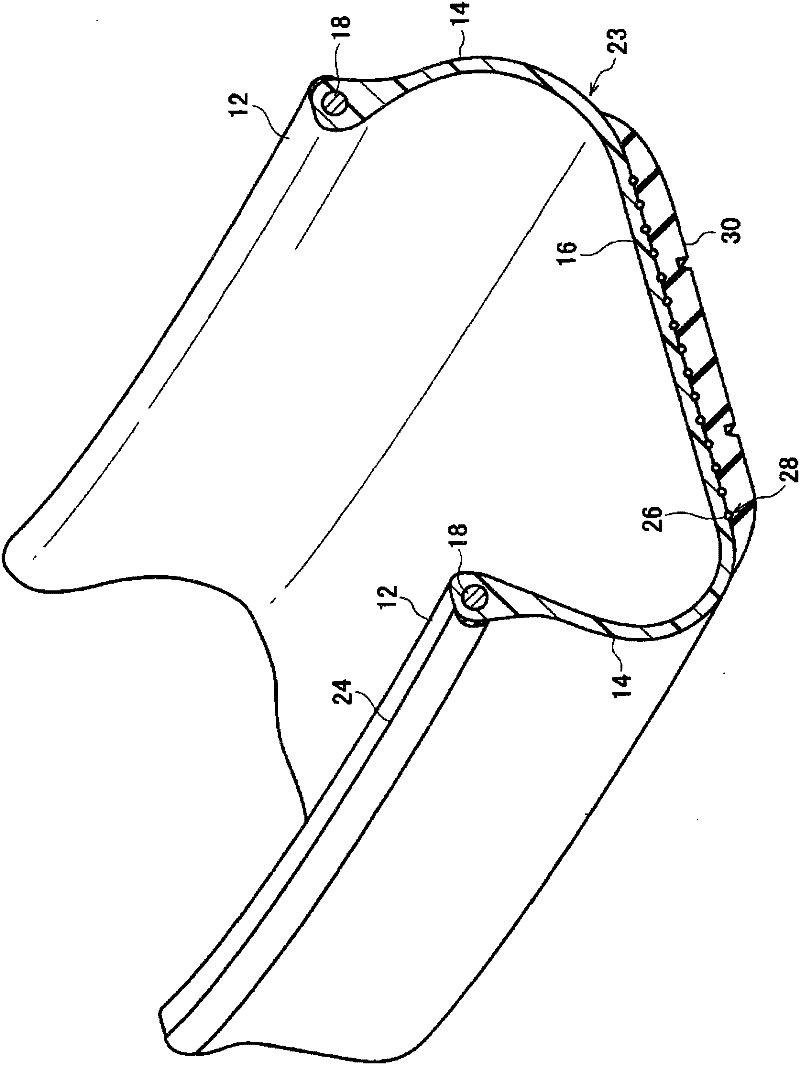

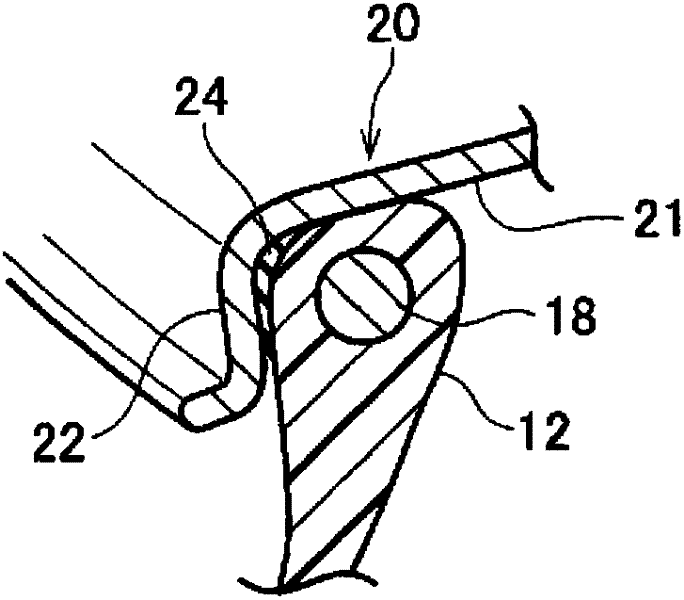

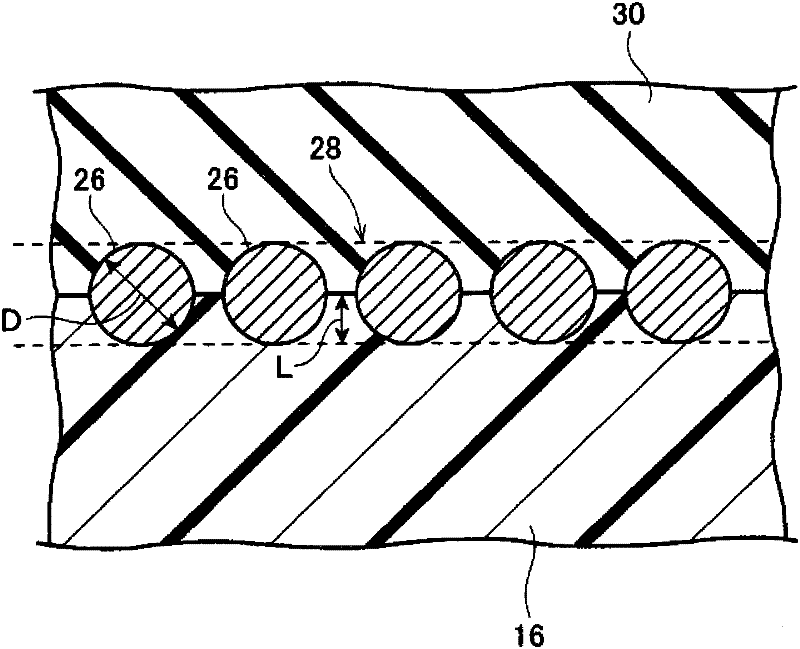

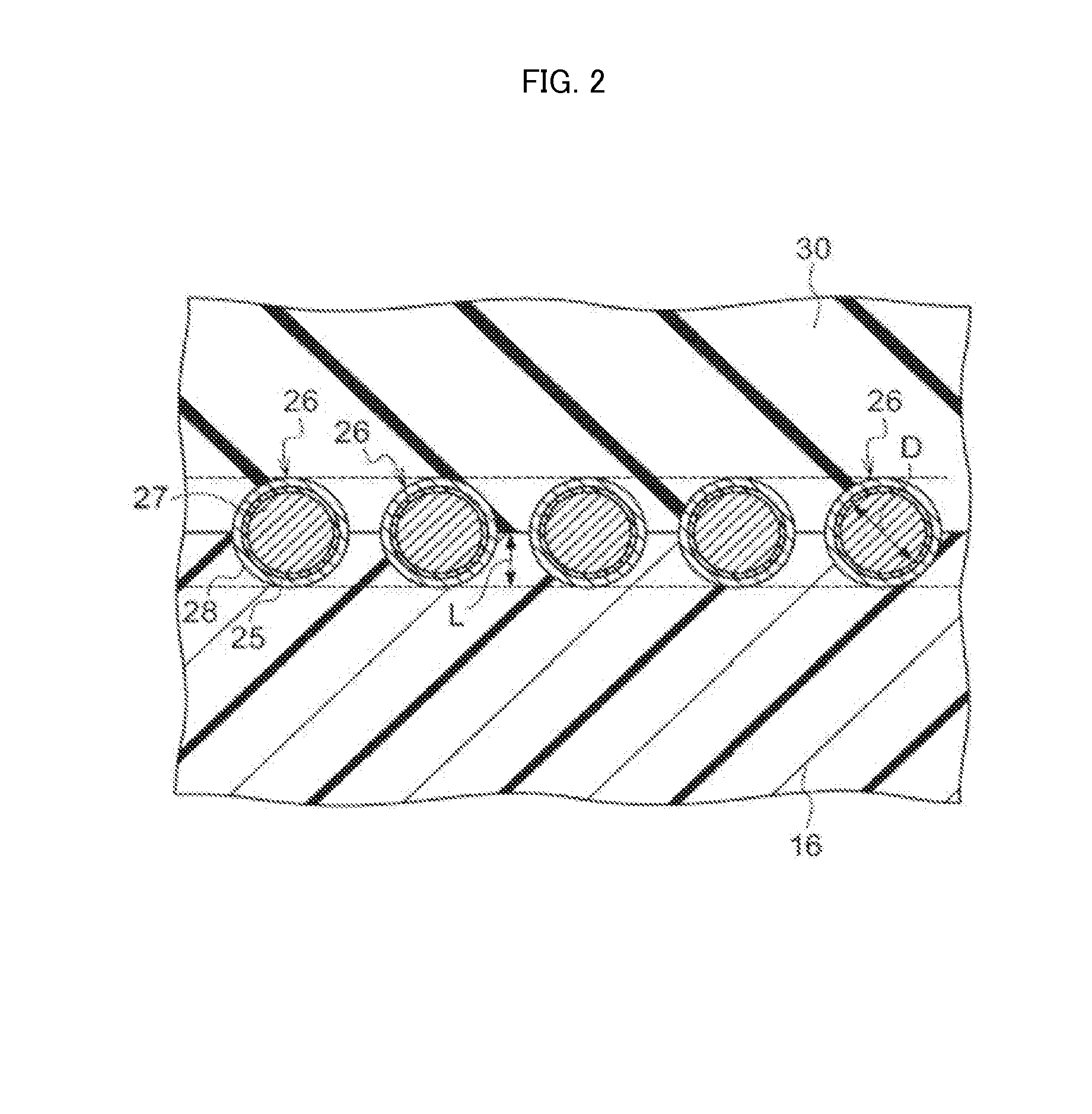

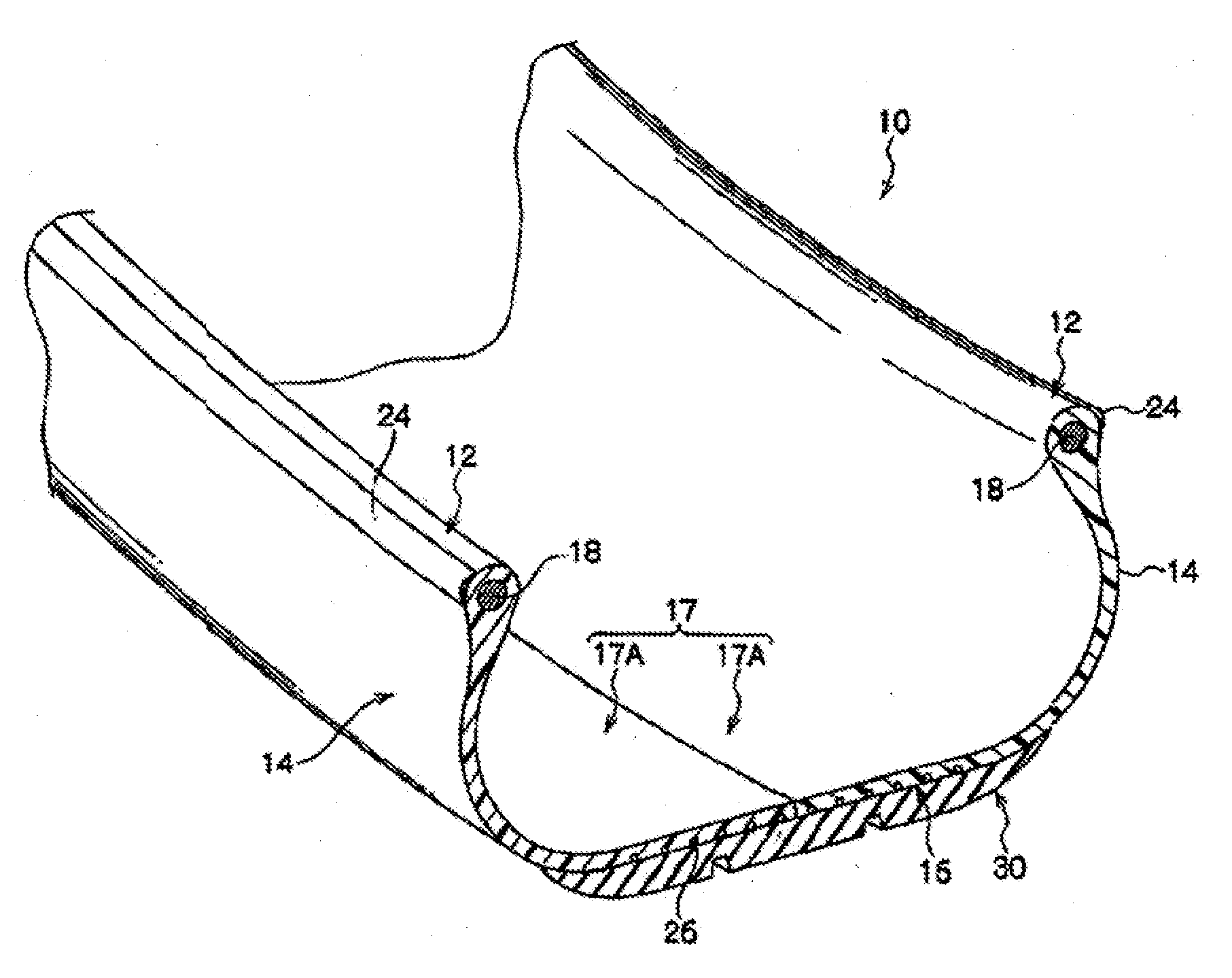

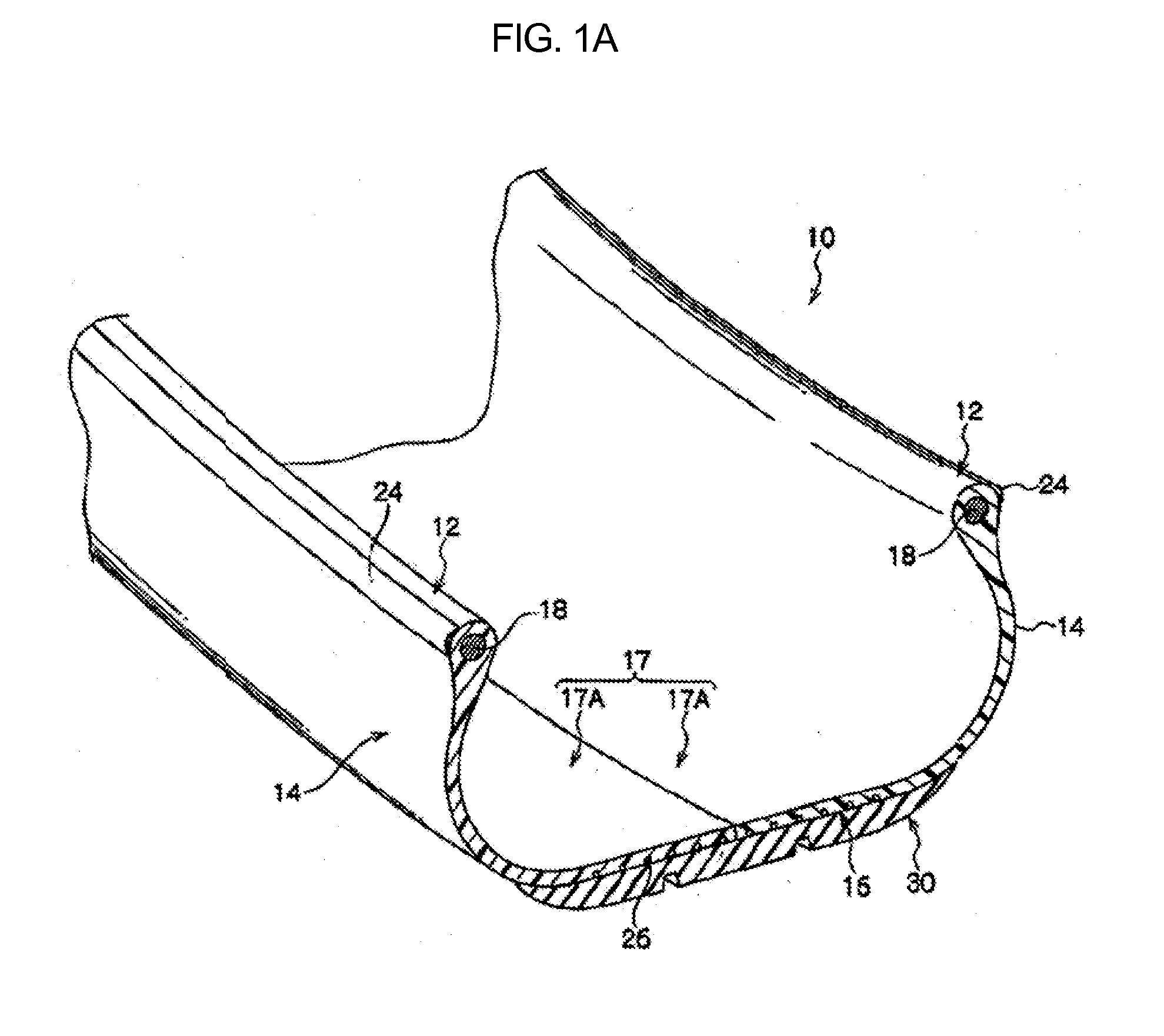

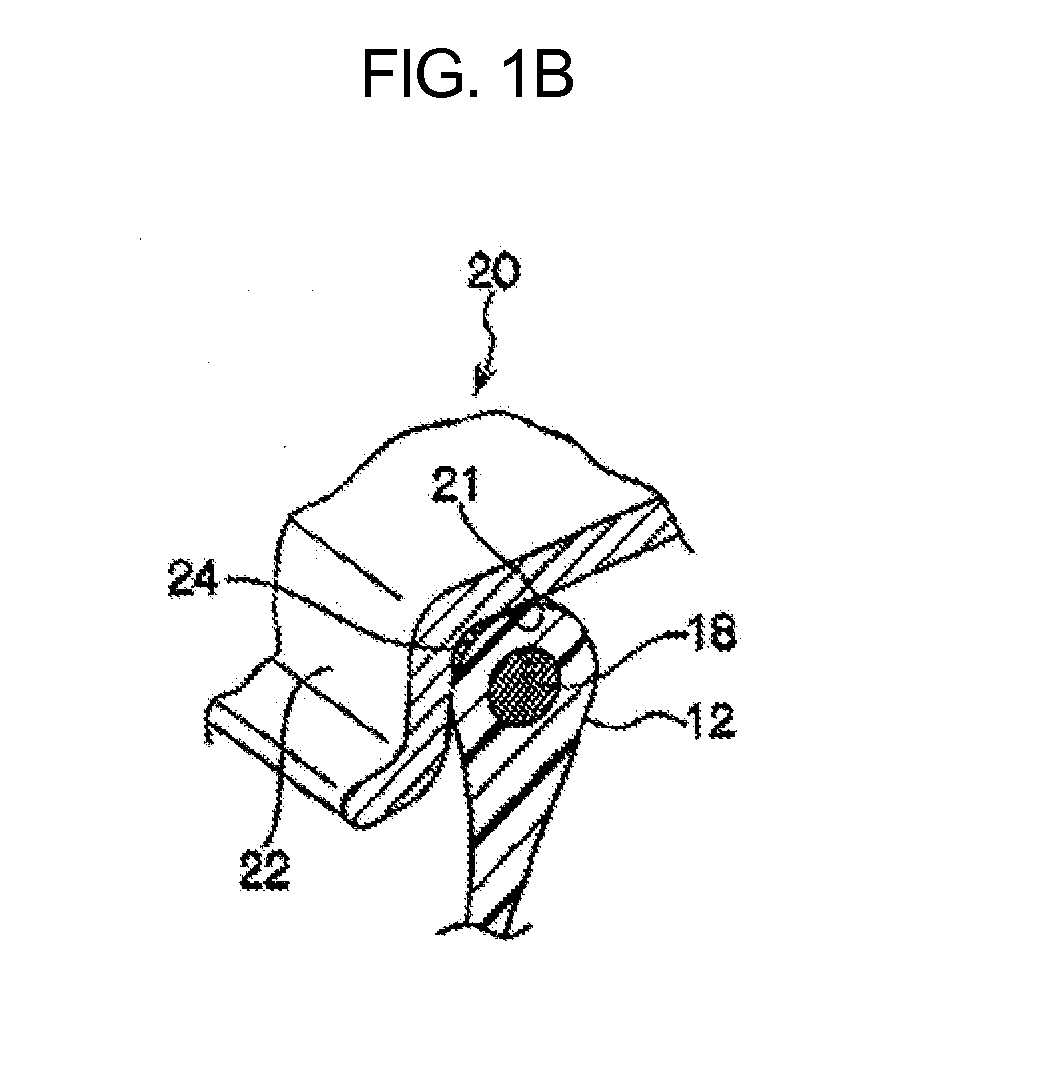

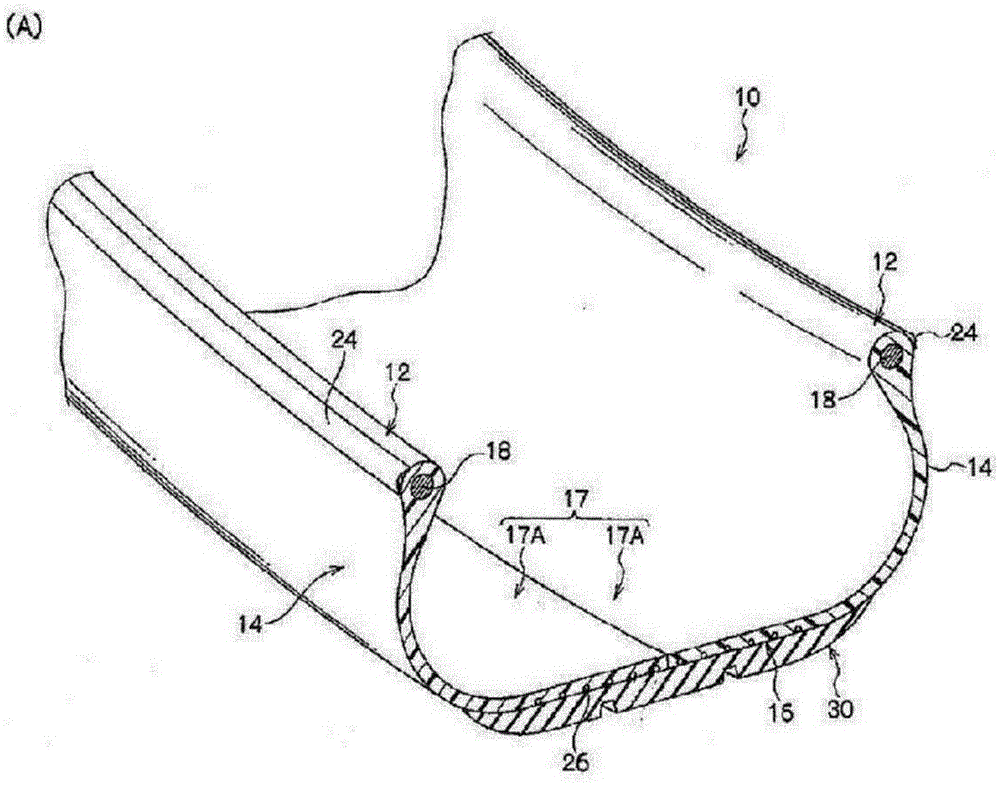

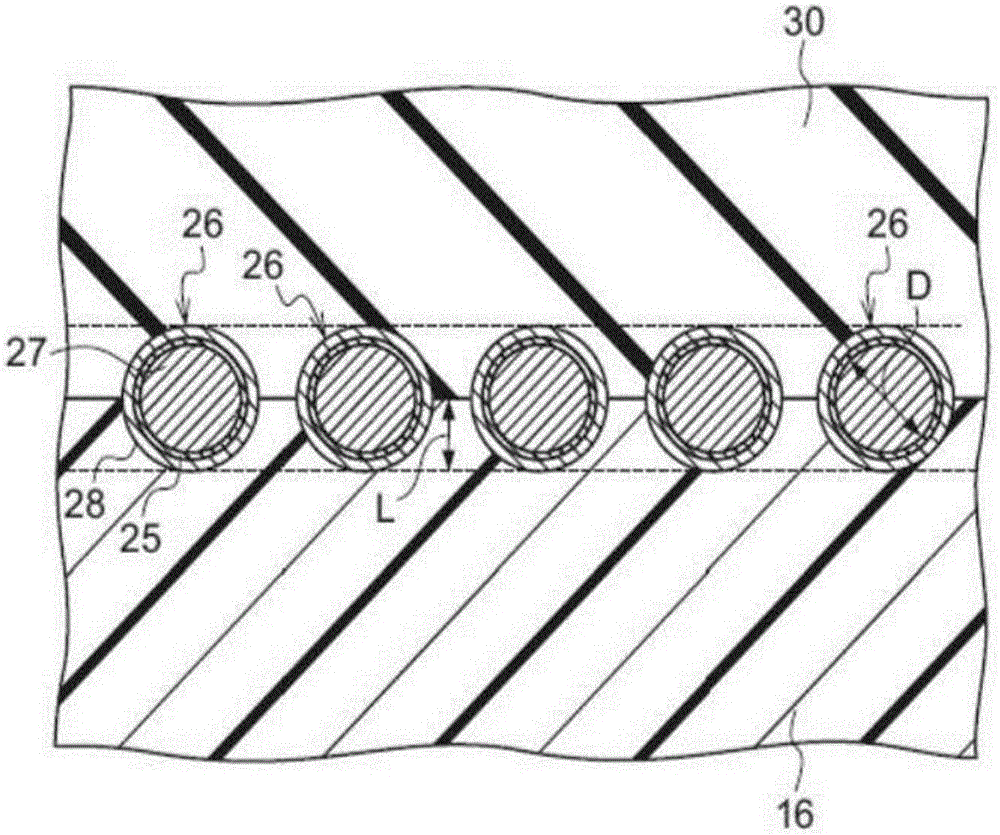

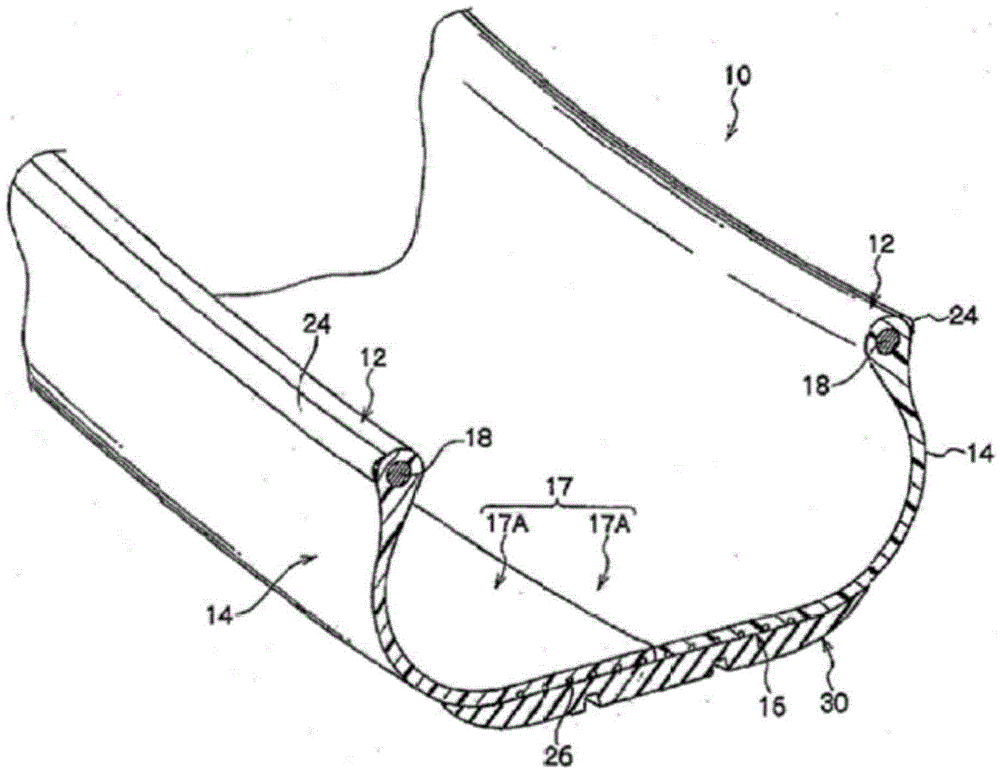

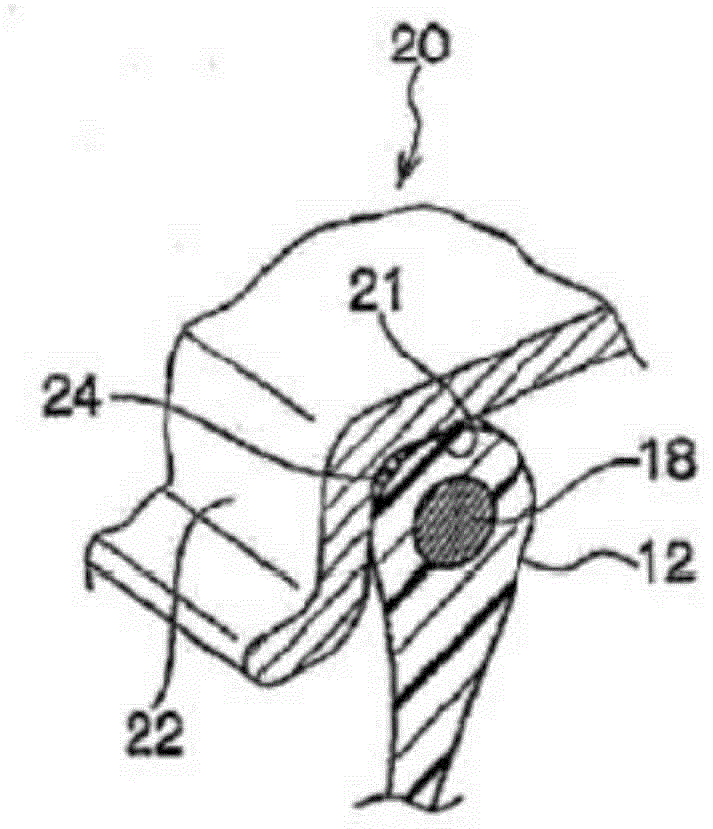

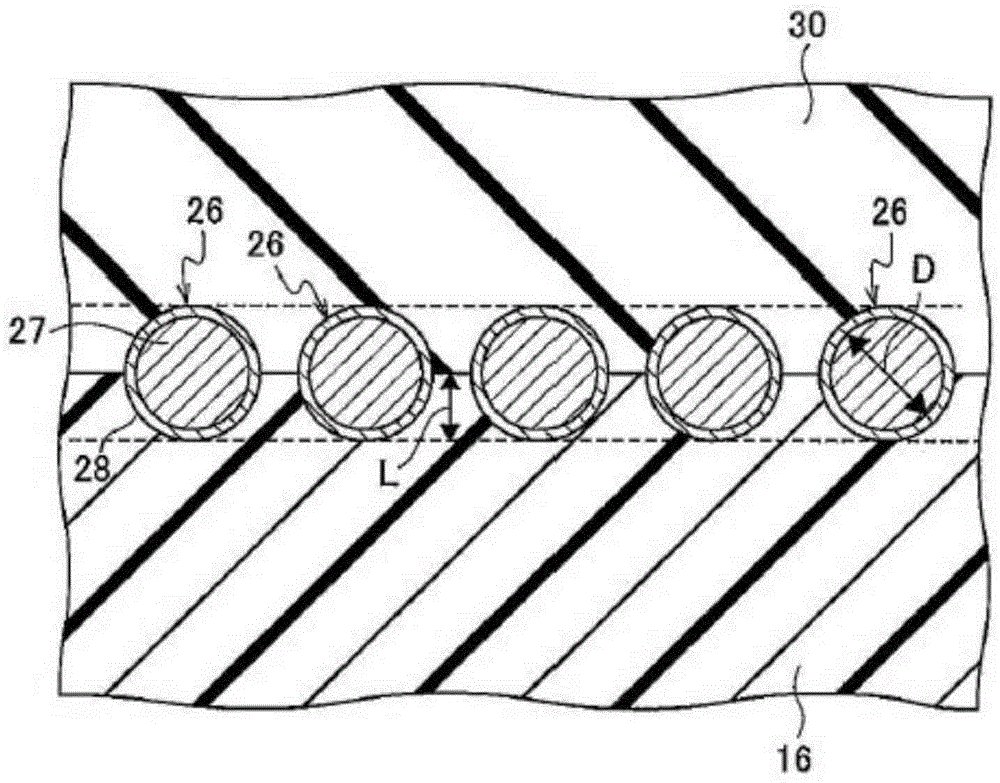

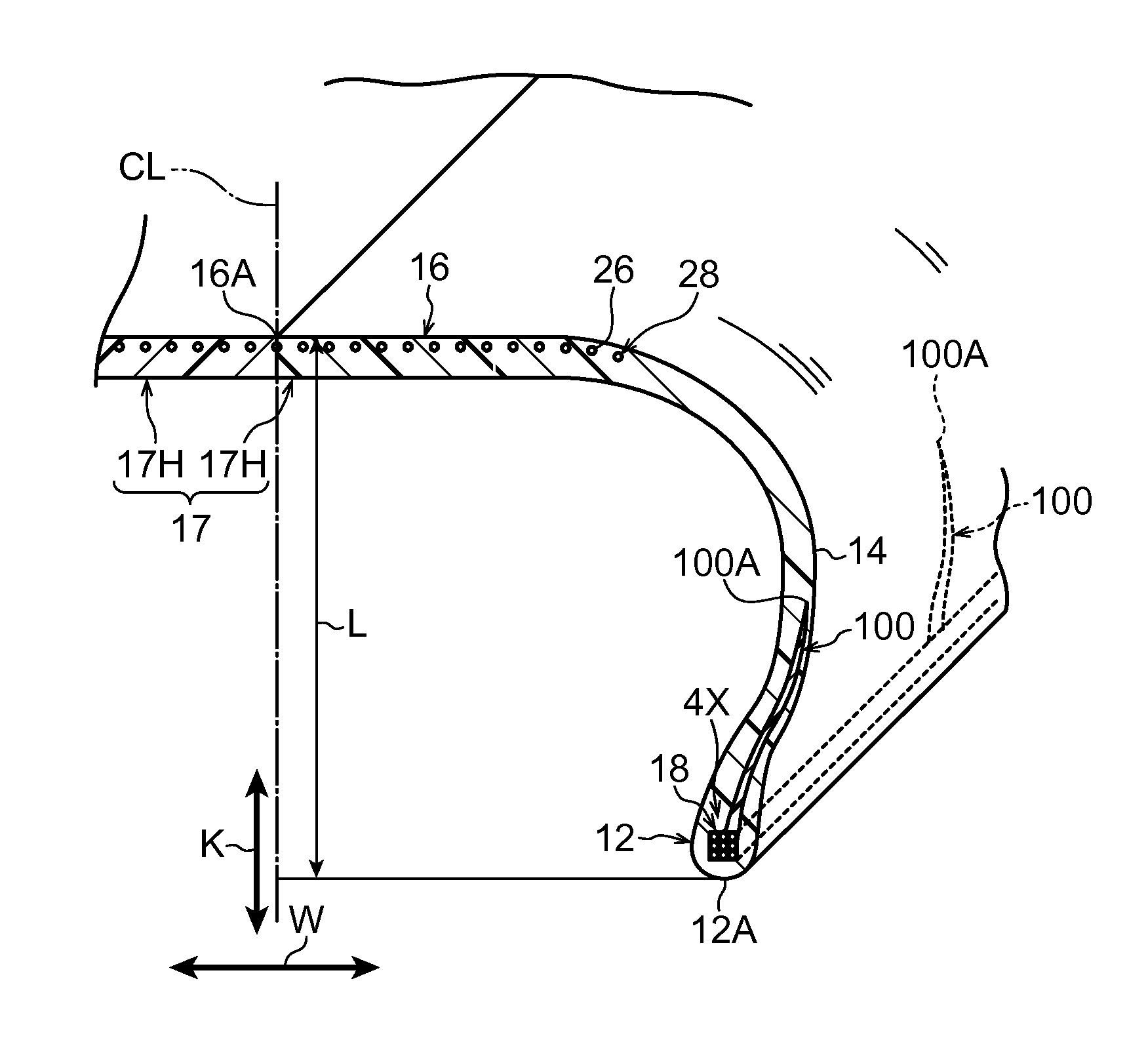

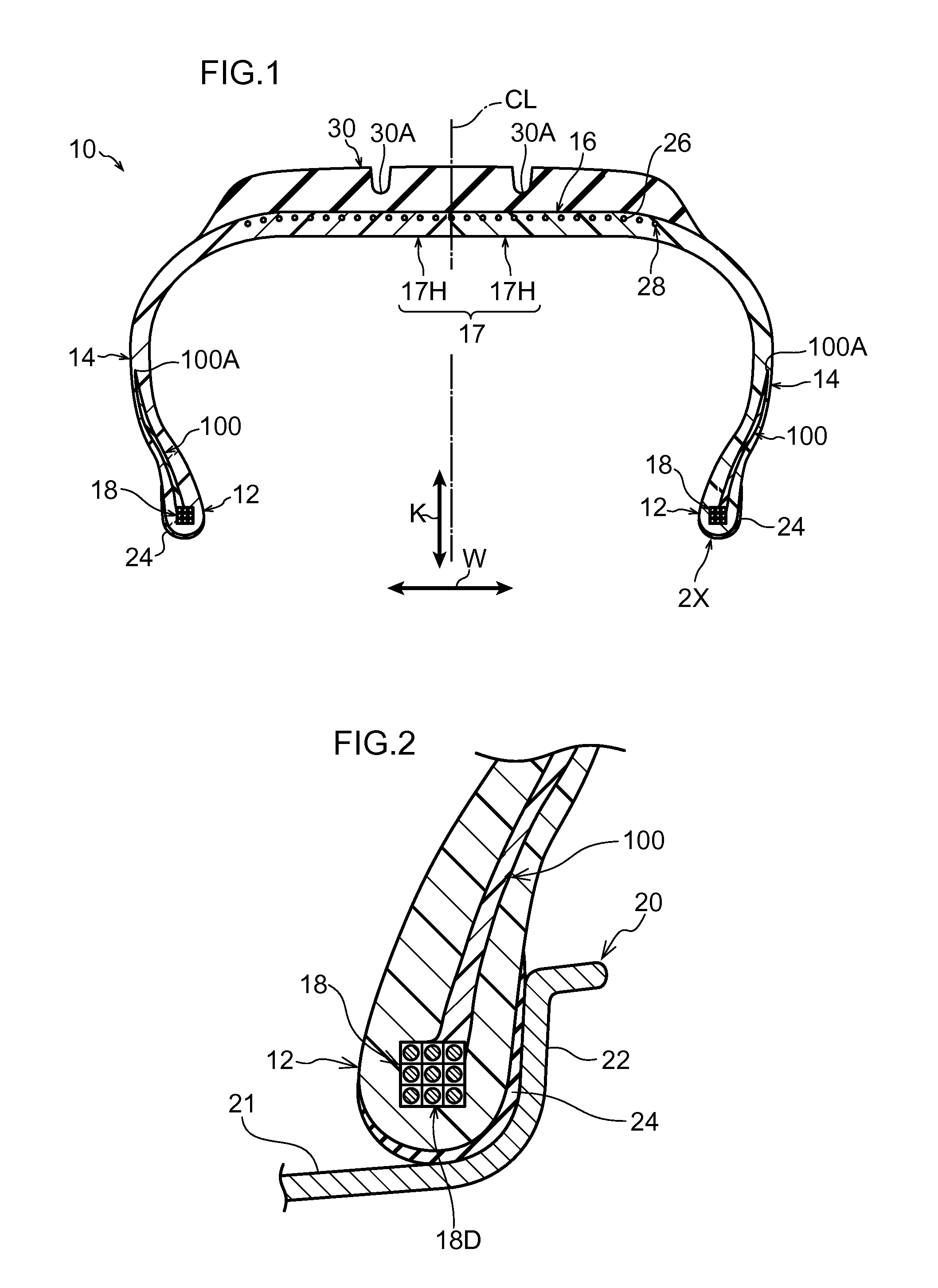

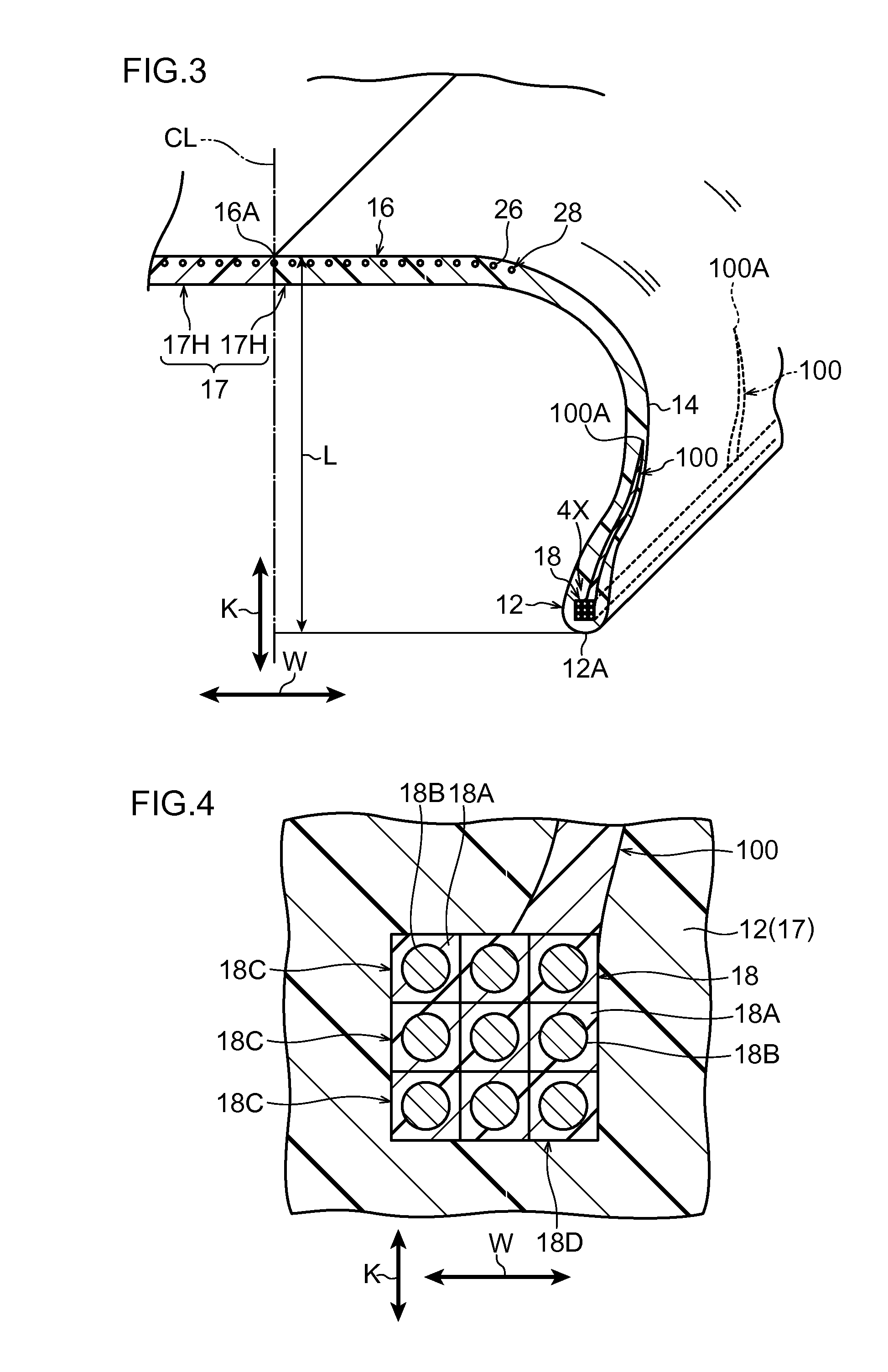

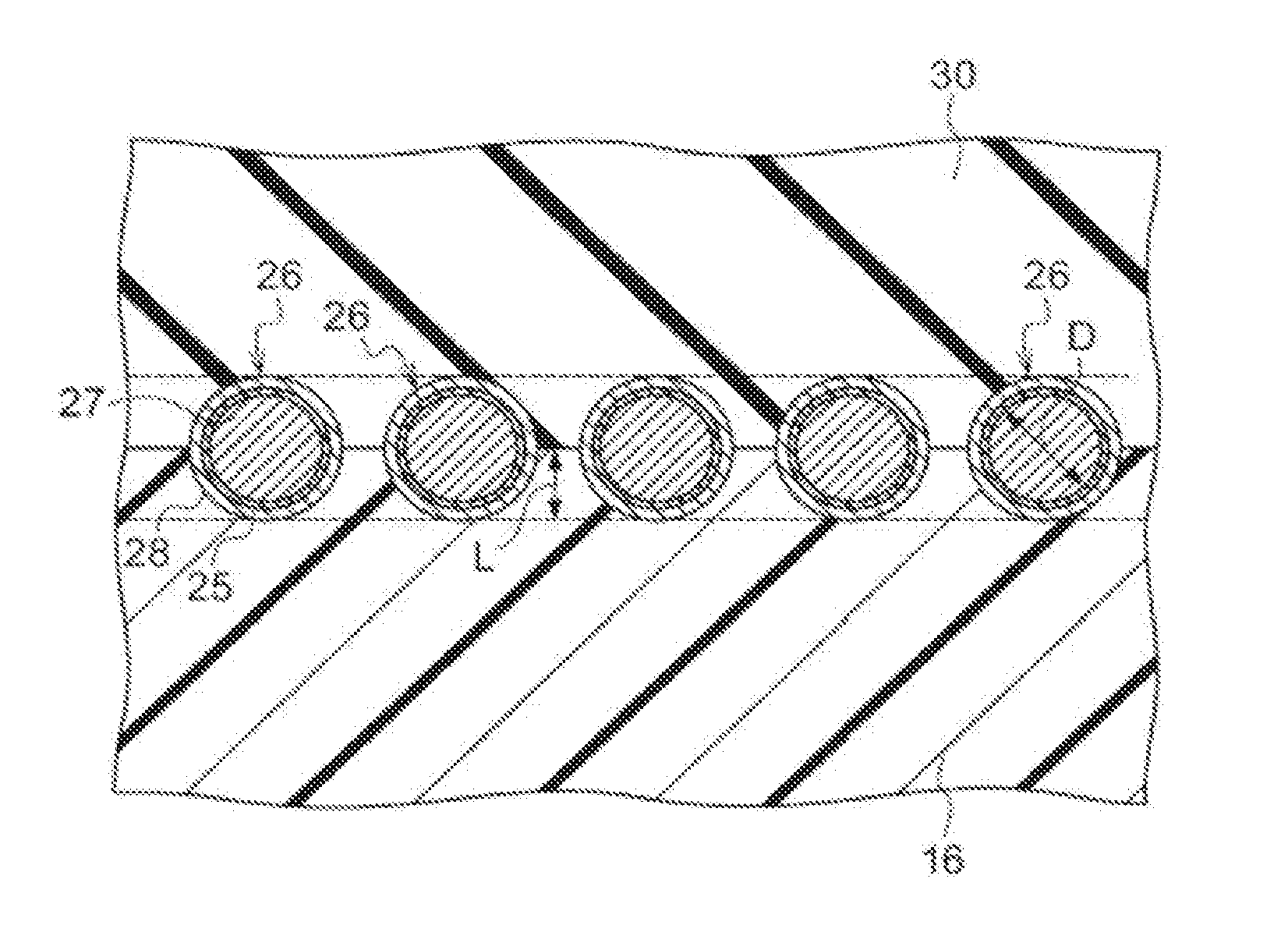

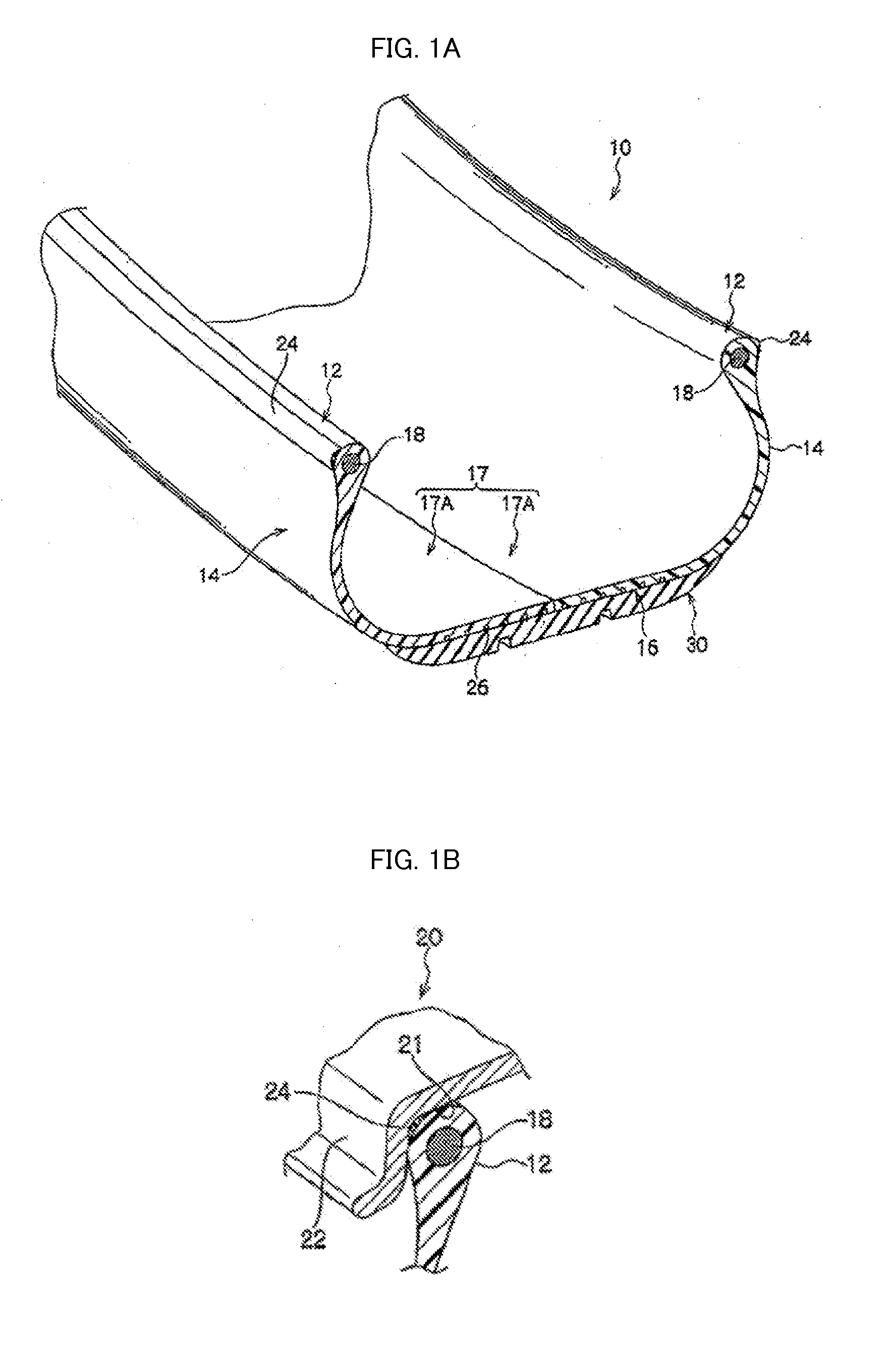

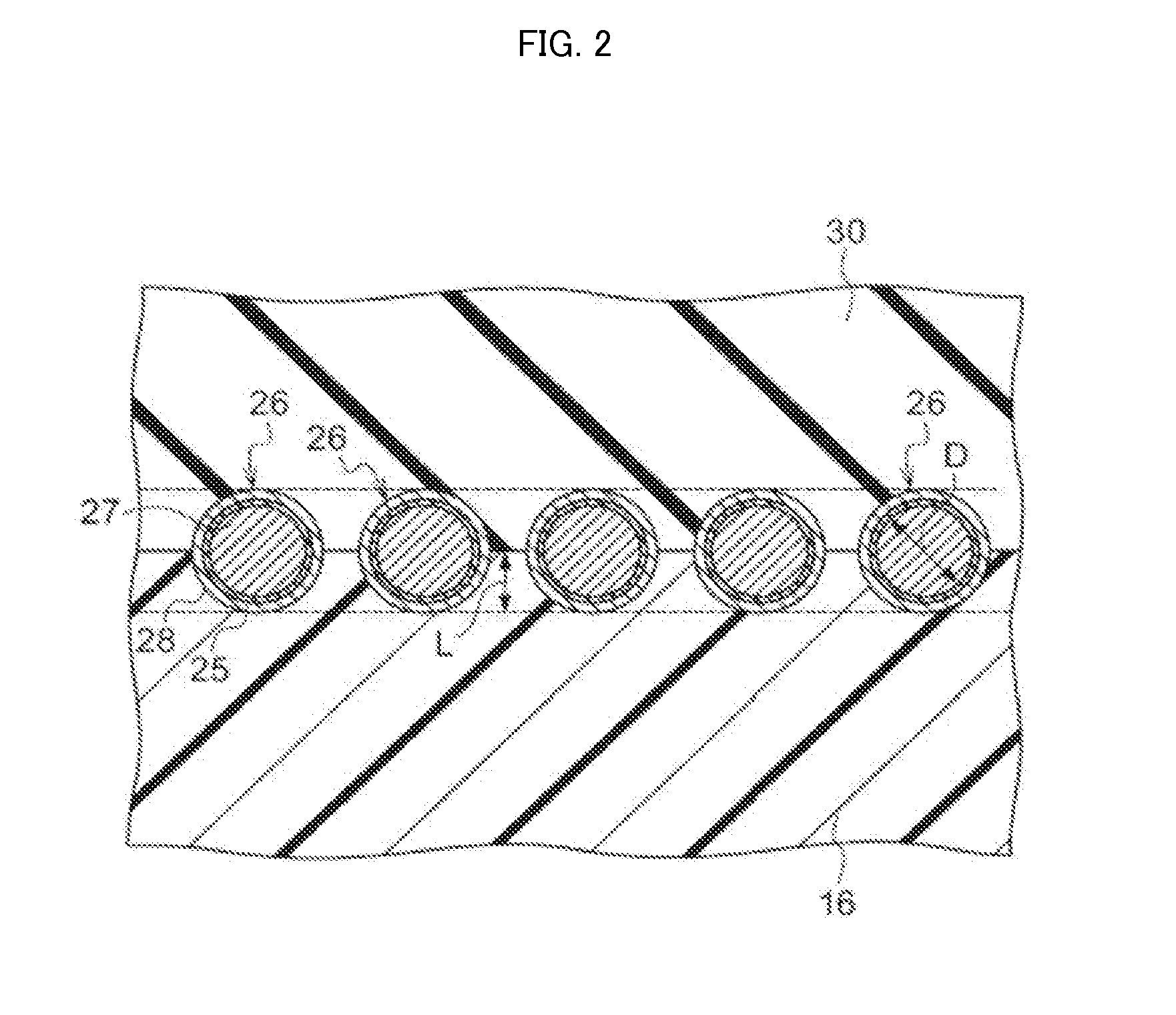

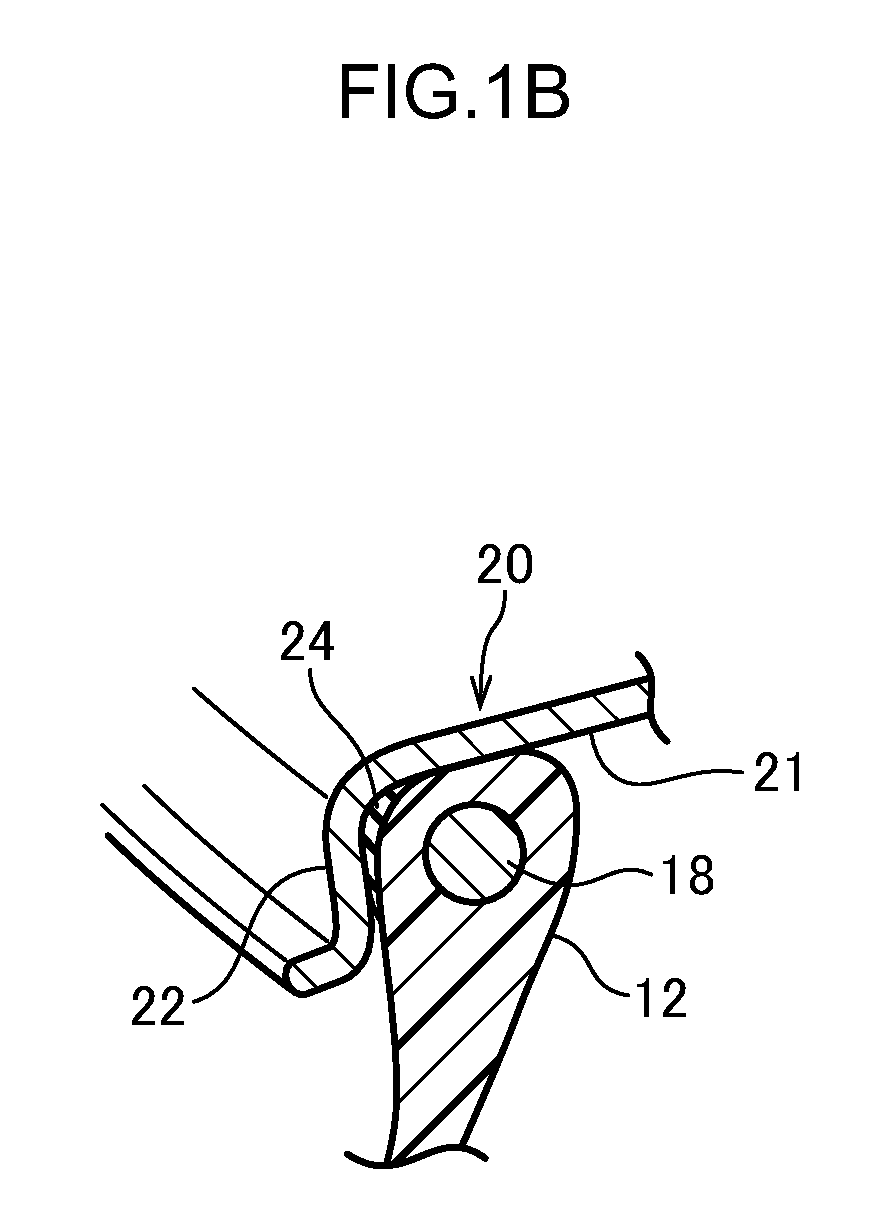

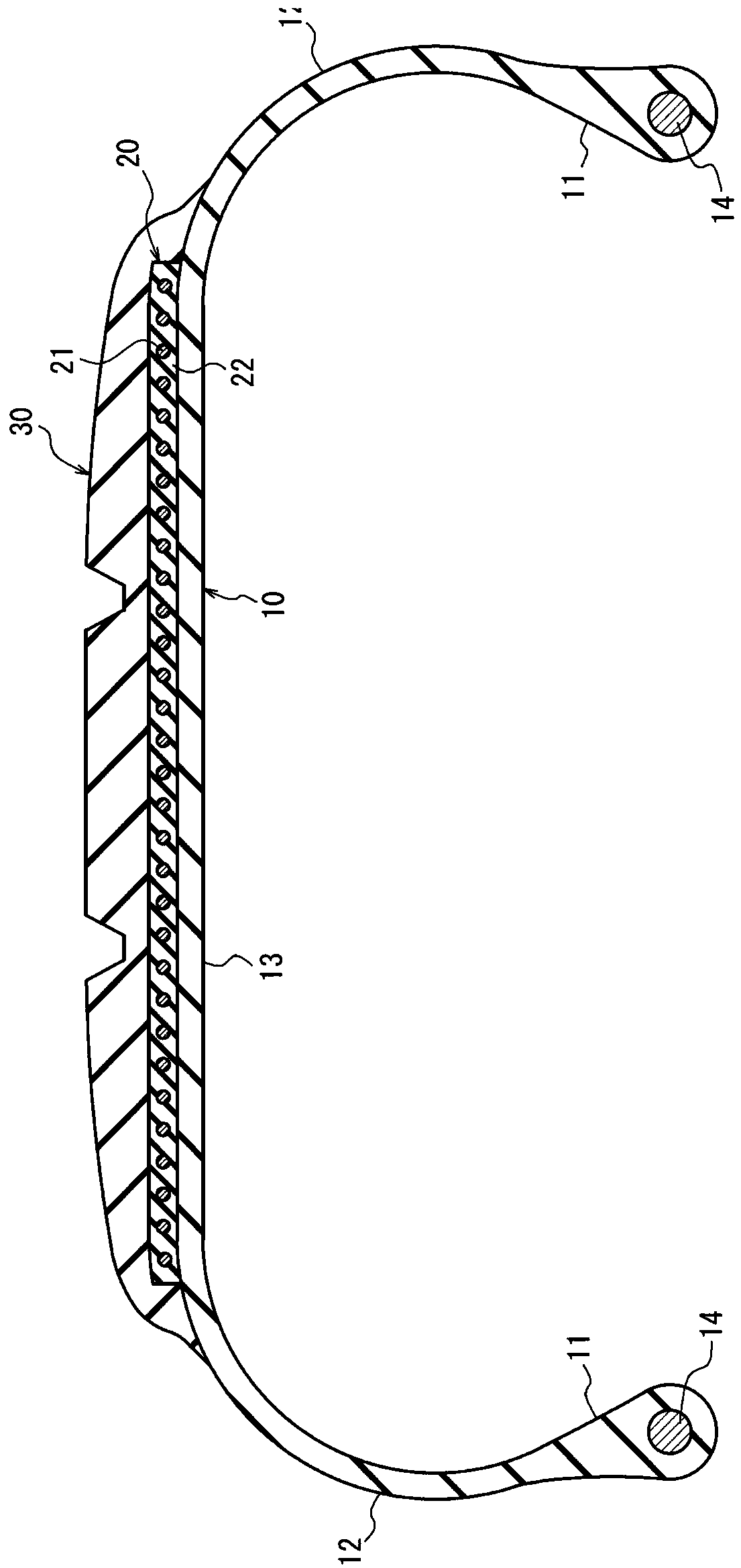

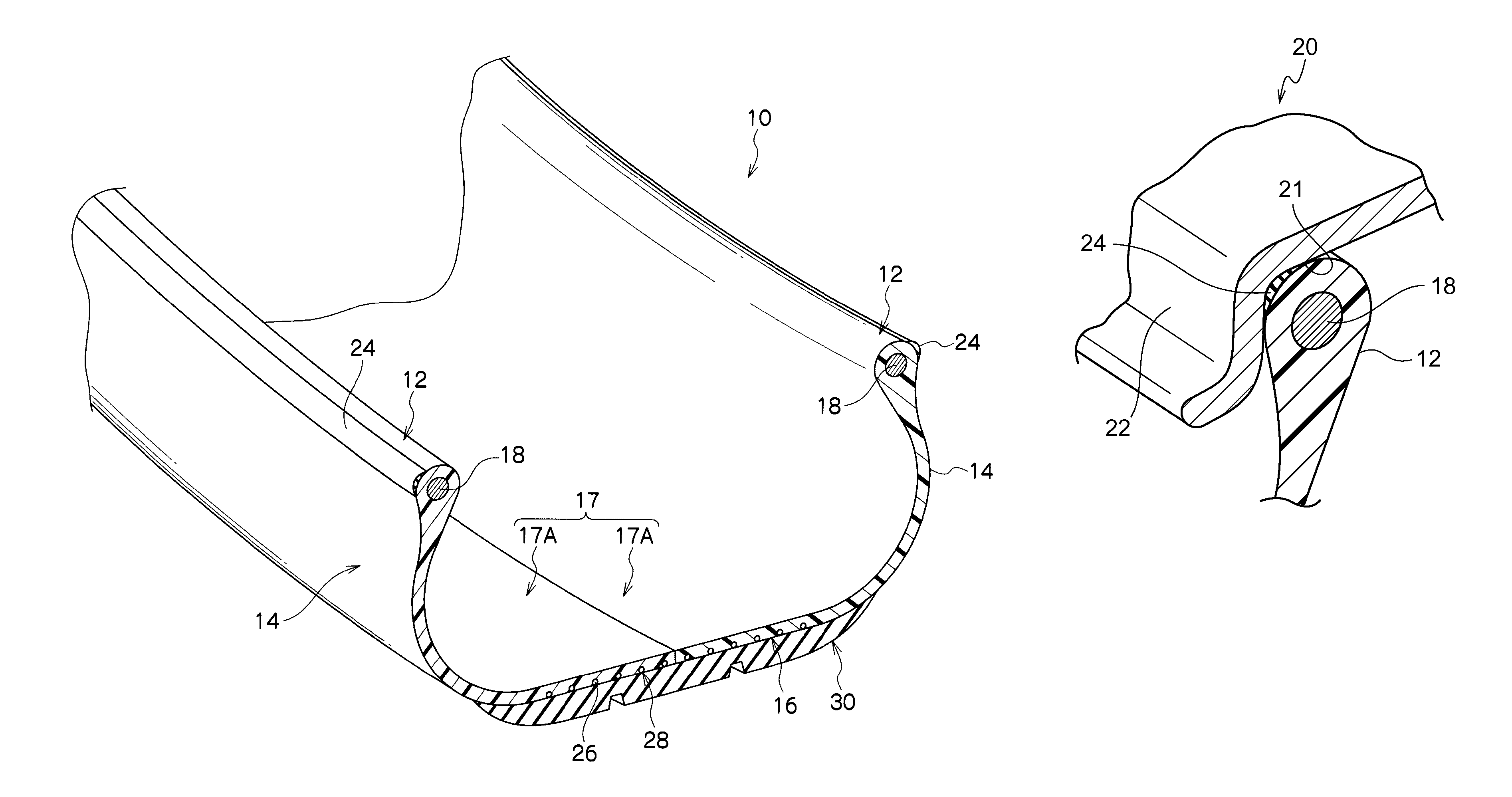

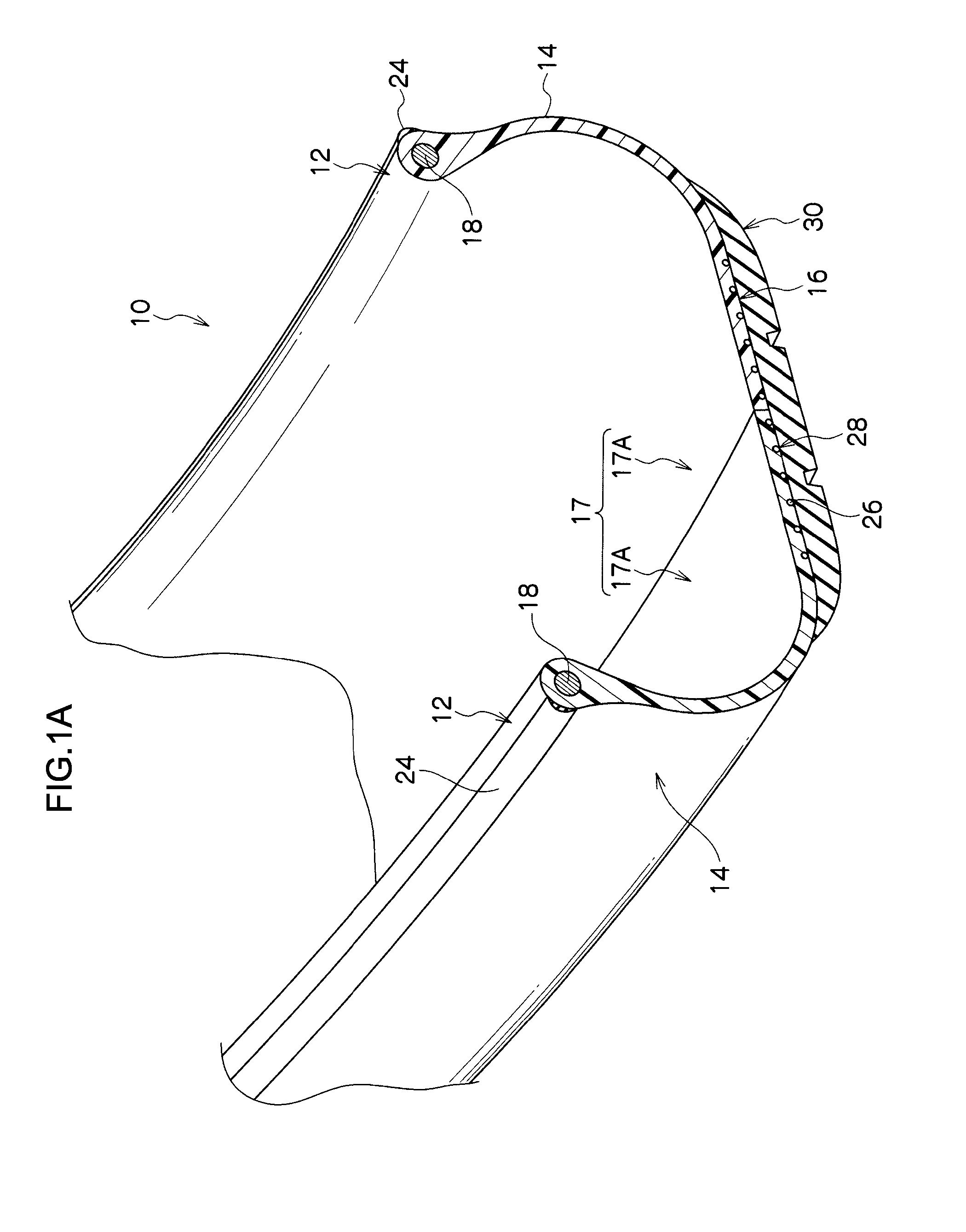

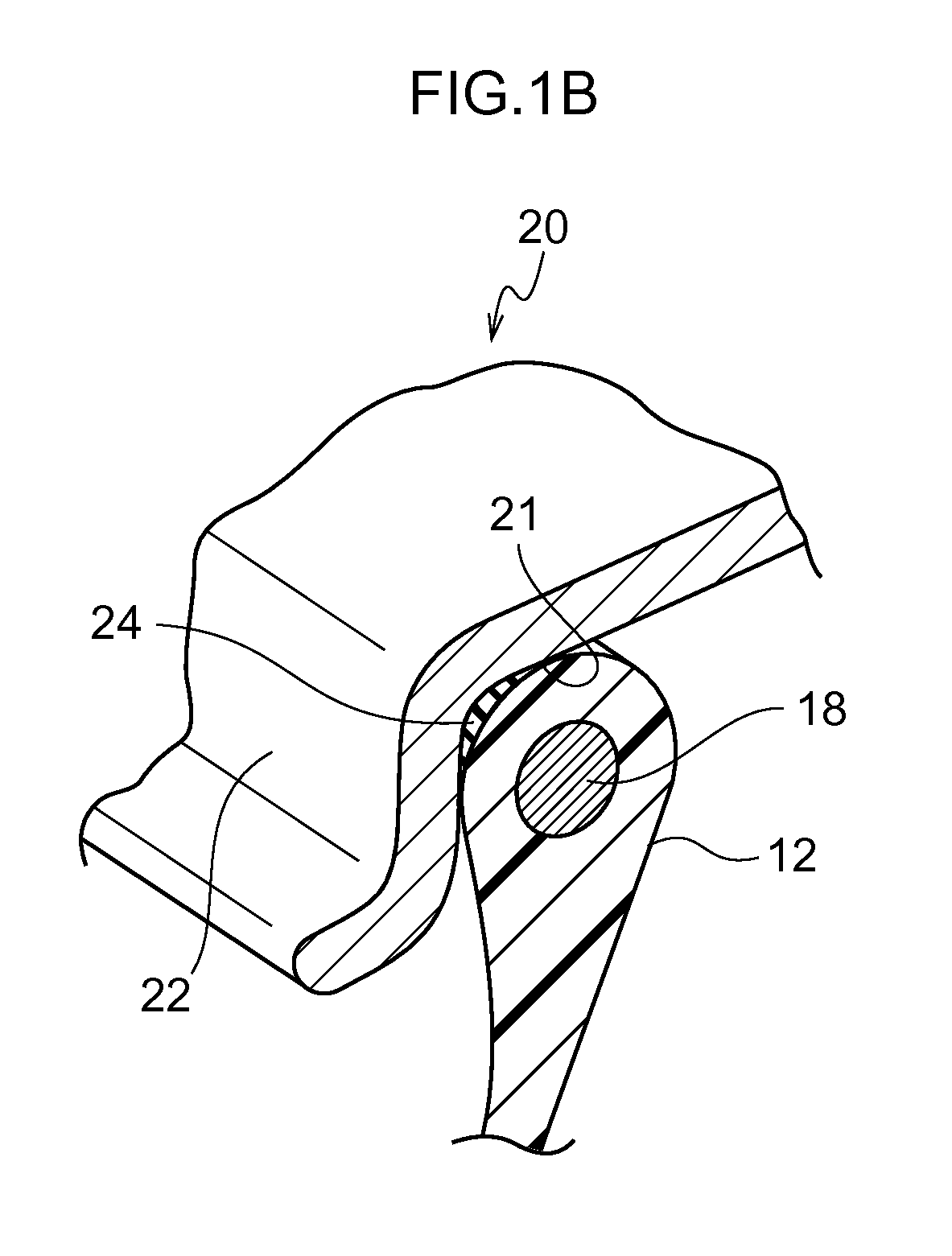

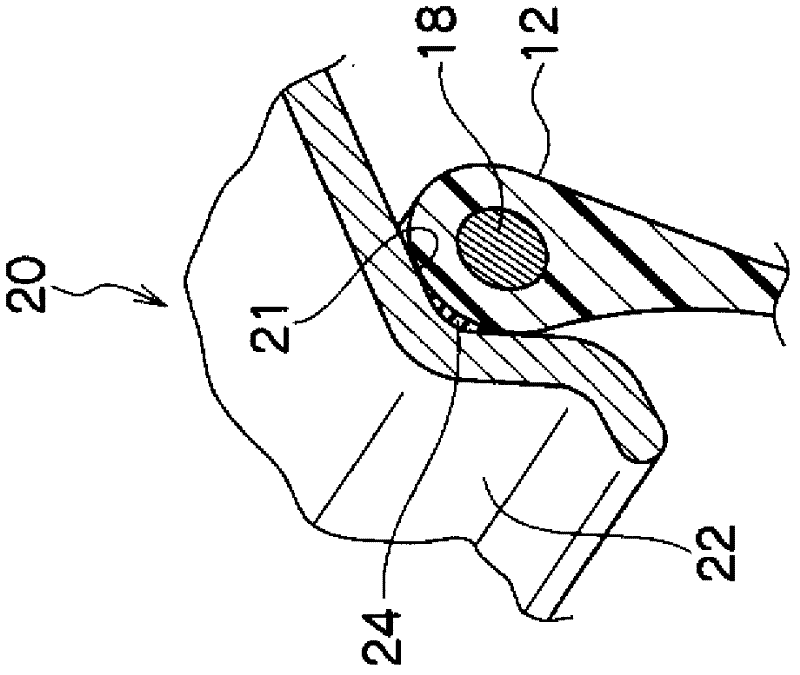

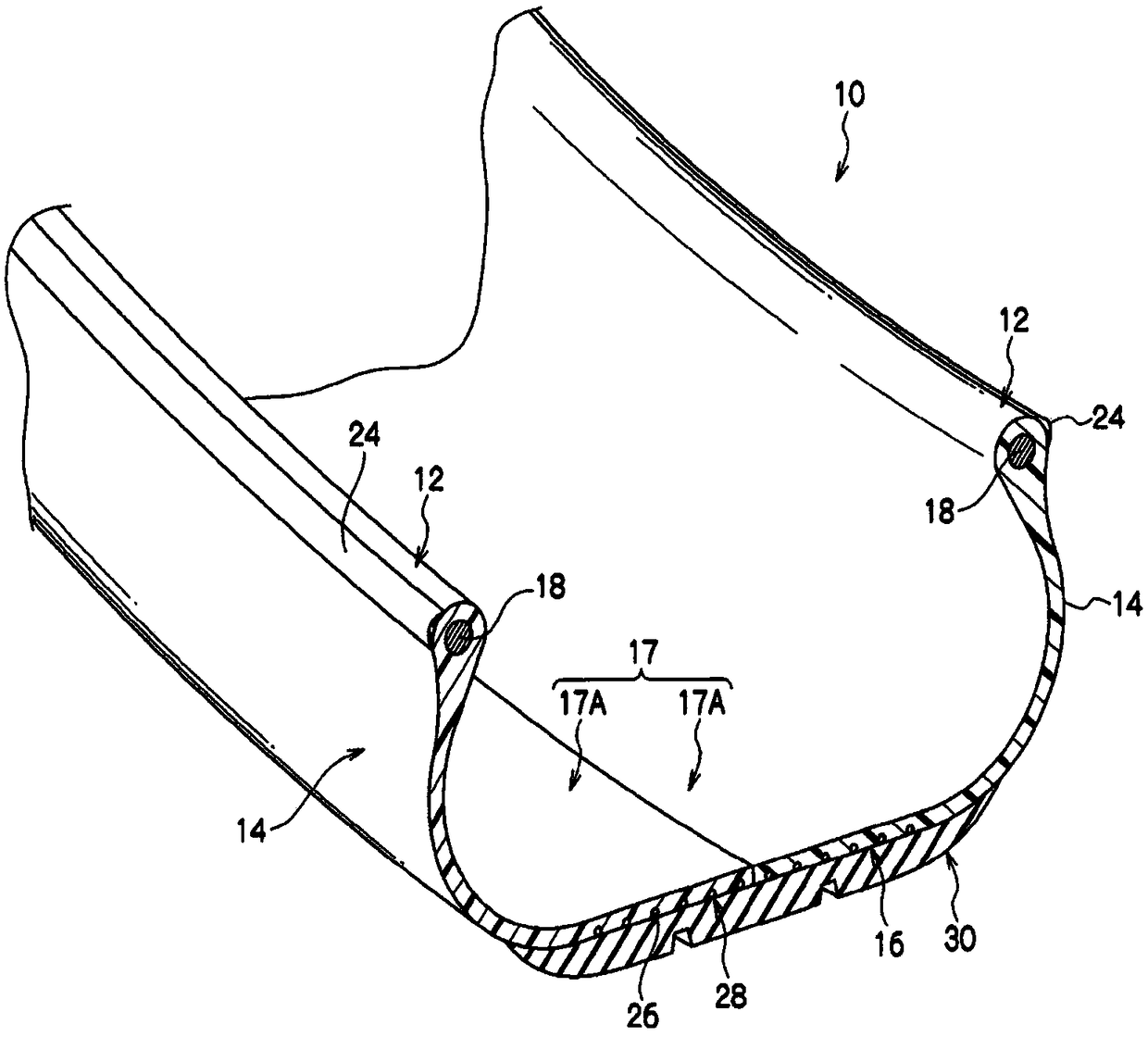

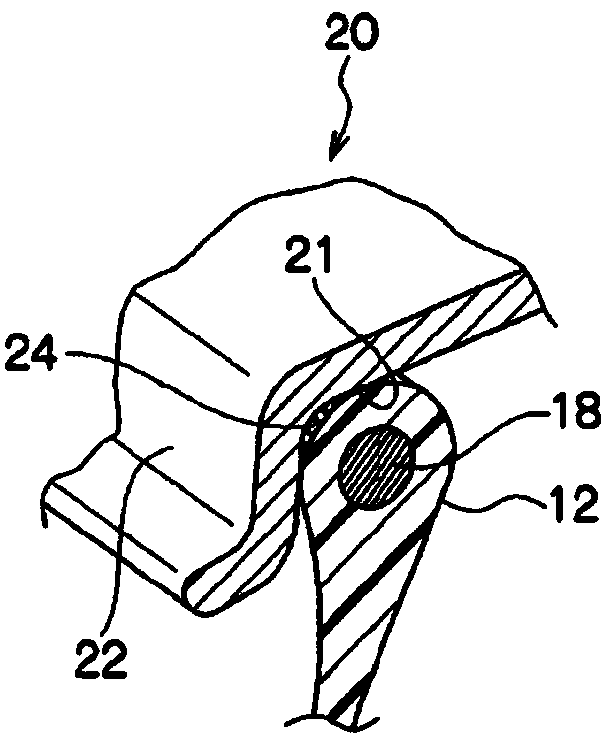

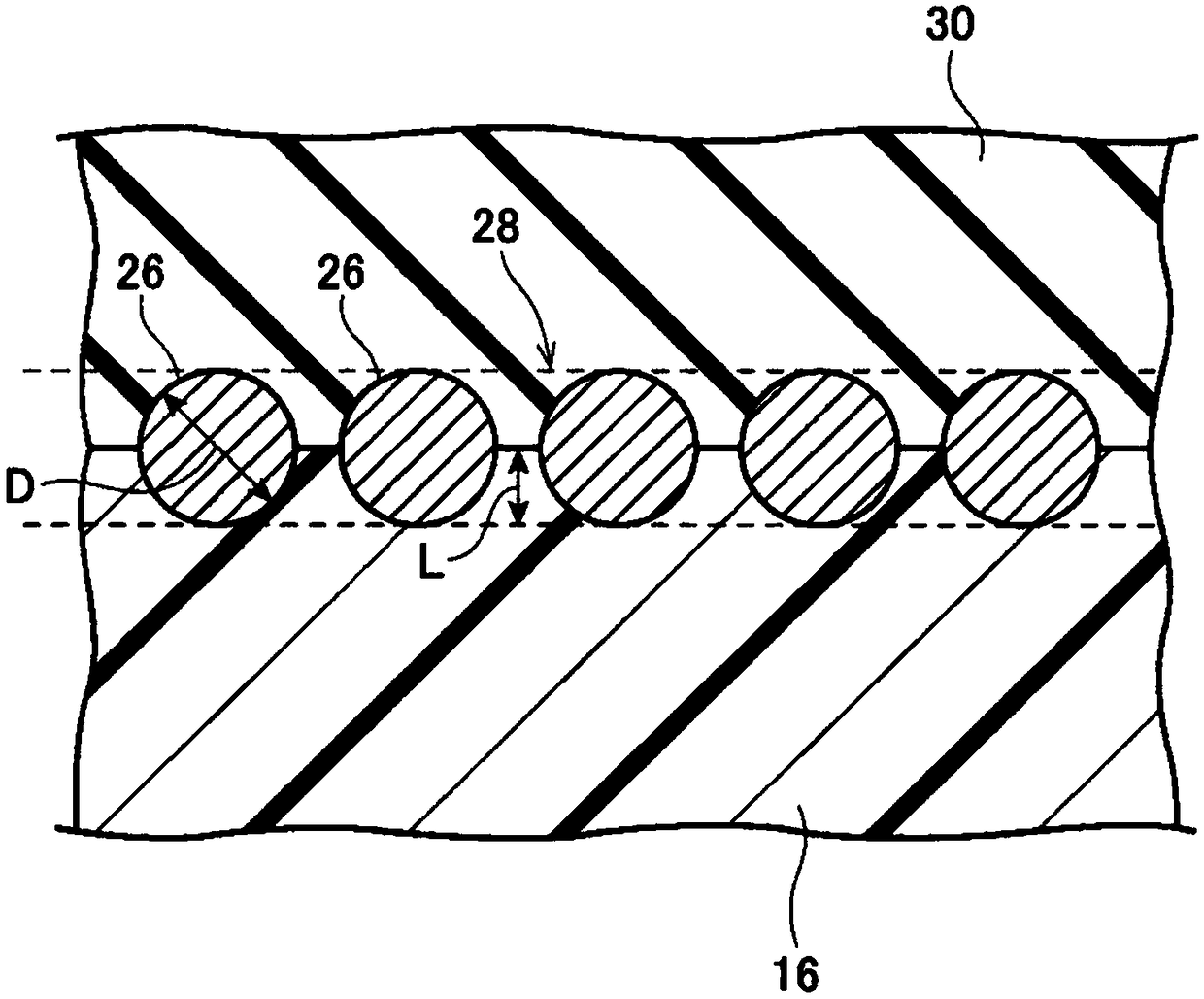

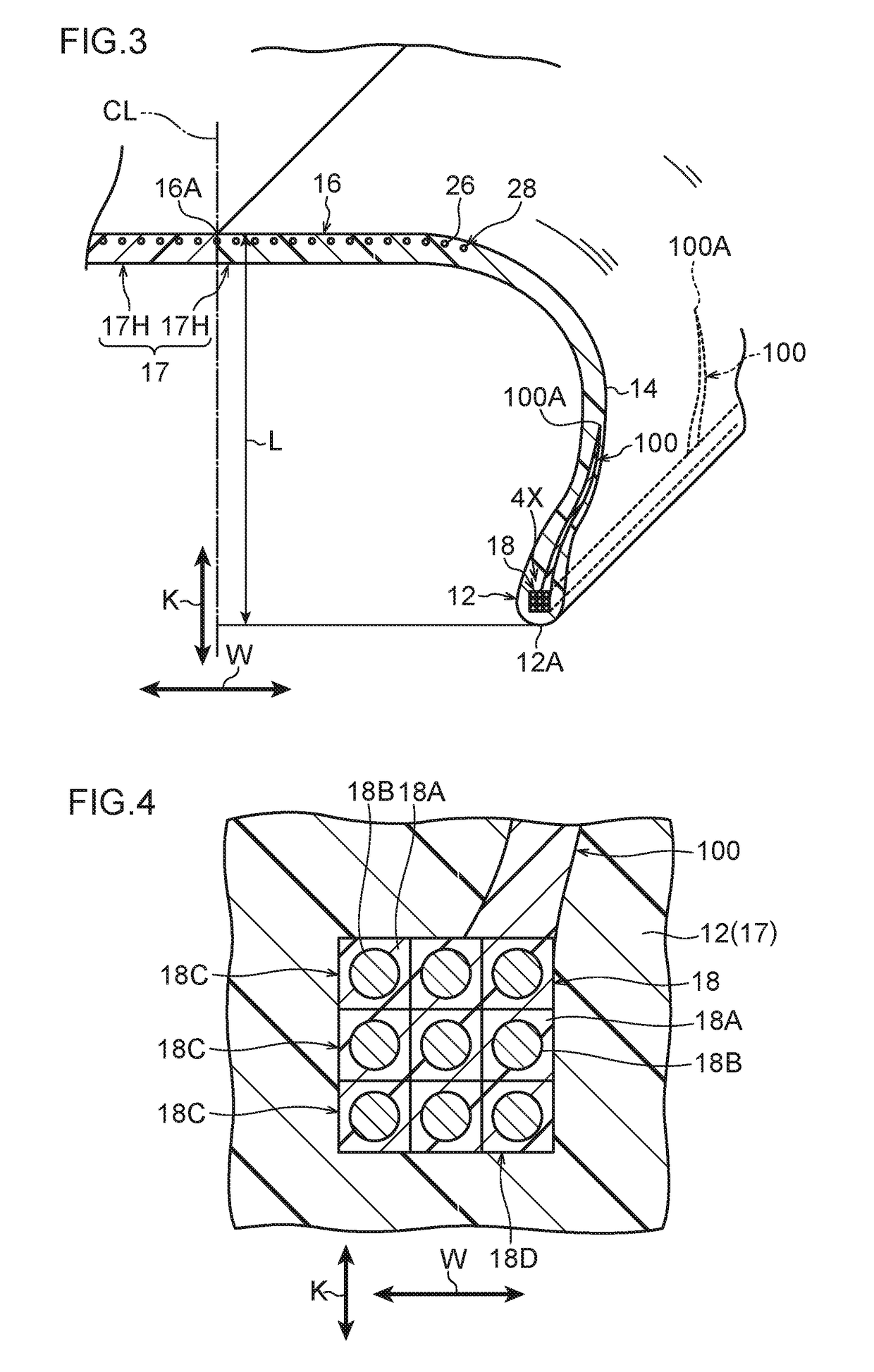

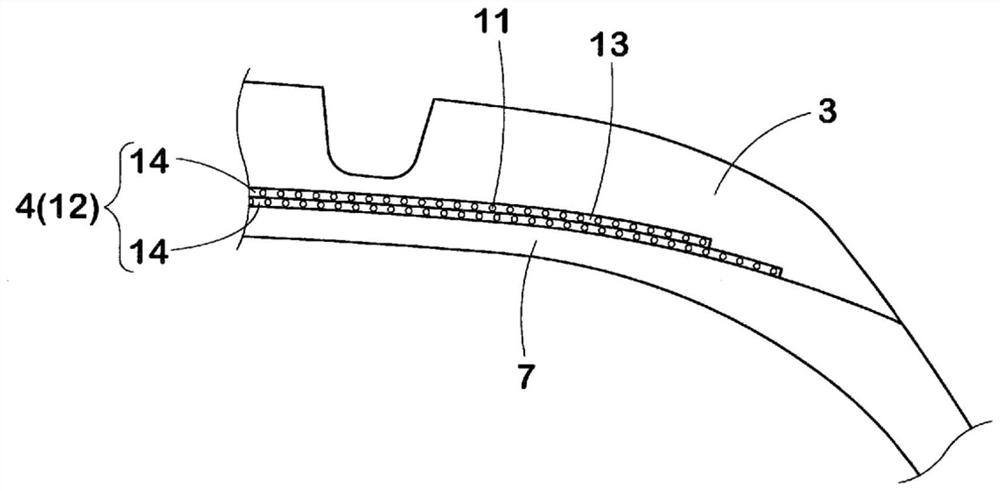

An object is to both provide a tire that is formed from a resin material, and in particular a thermoplastic material, and to also suppresses incorporation of air, raising durability. A tire 10 includes: a ring shaped tire case 23 formed from a resin material; a reinforcement cord 26 having a higher rigidity that that of the resin material, wound in a spiral shape on the outer peripheral section of the tire case 23 and having at least a portion of the reinforcement cord 26 embedded in and making close contact with the outer peripheral section of the tire case 23 when viewed in a cross-section along the axial direction of the tire case 23; and a tread 30 provided on the radial direction outside of a reinforcement cord layer 28 formed by the reinforcement cord 26. Accordingly air can be suppressed from being incorporated and durability can be raised.

Owner:BRIDGESTONE CORP

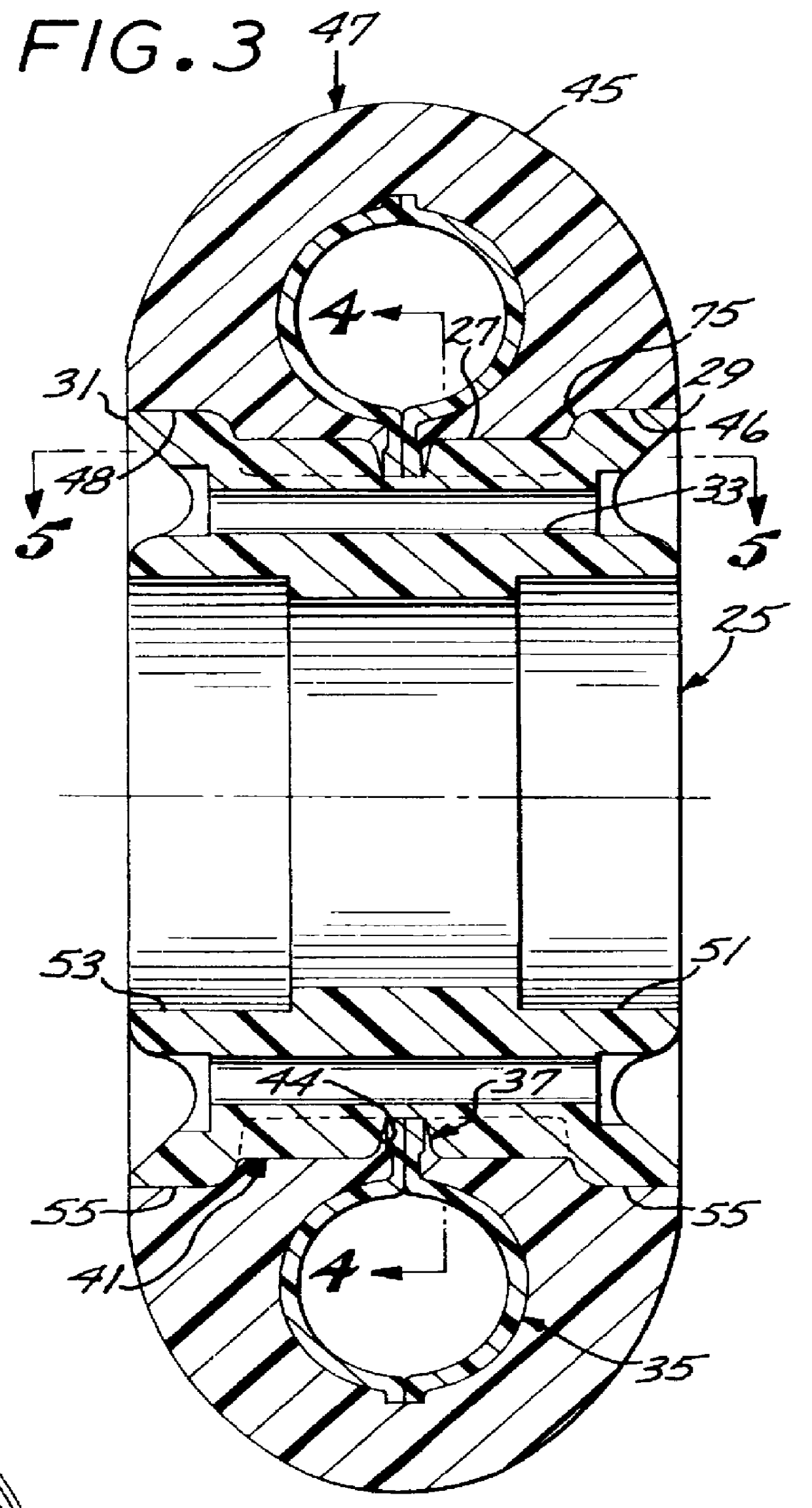

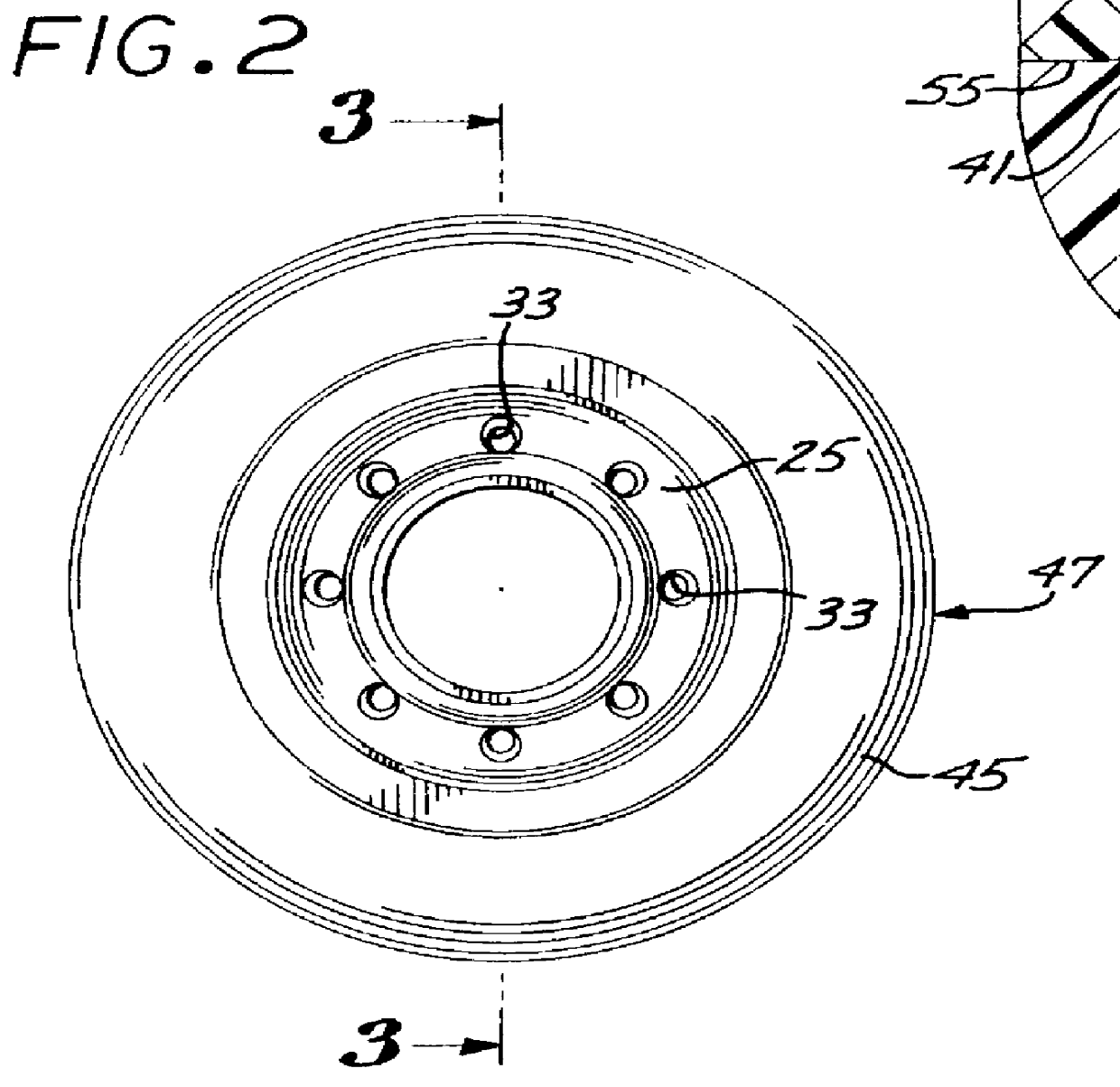

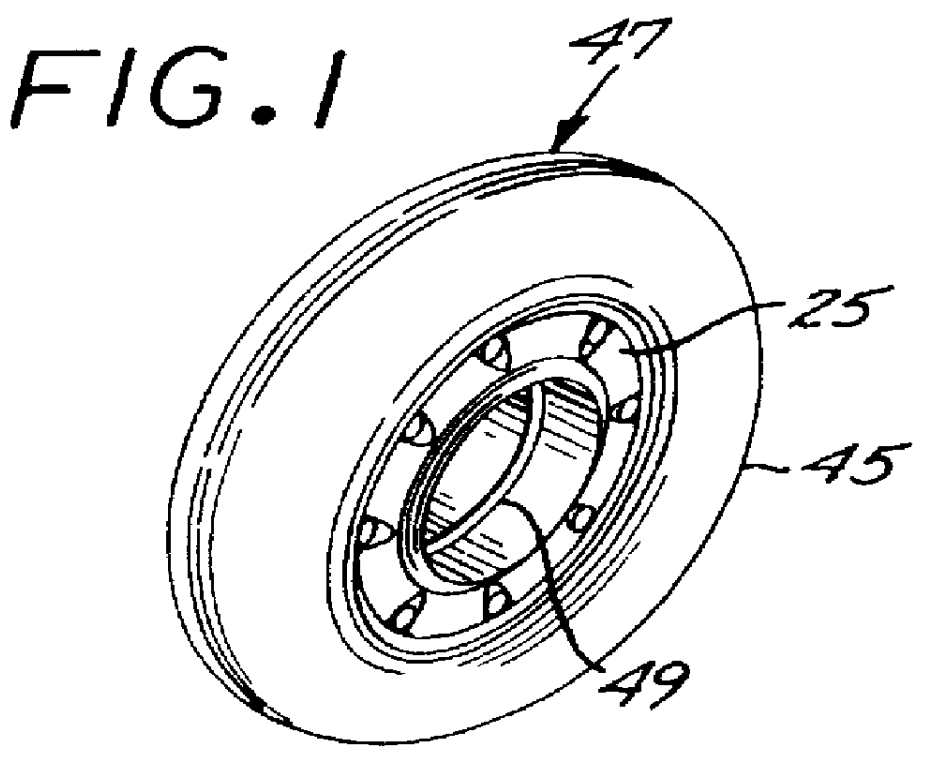

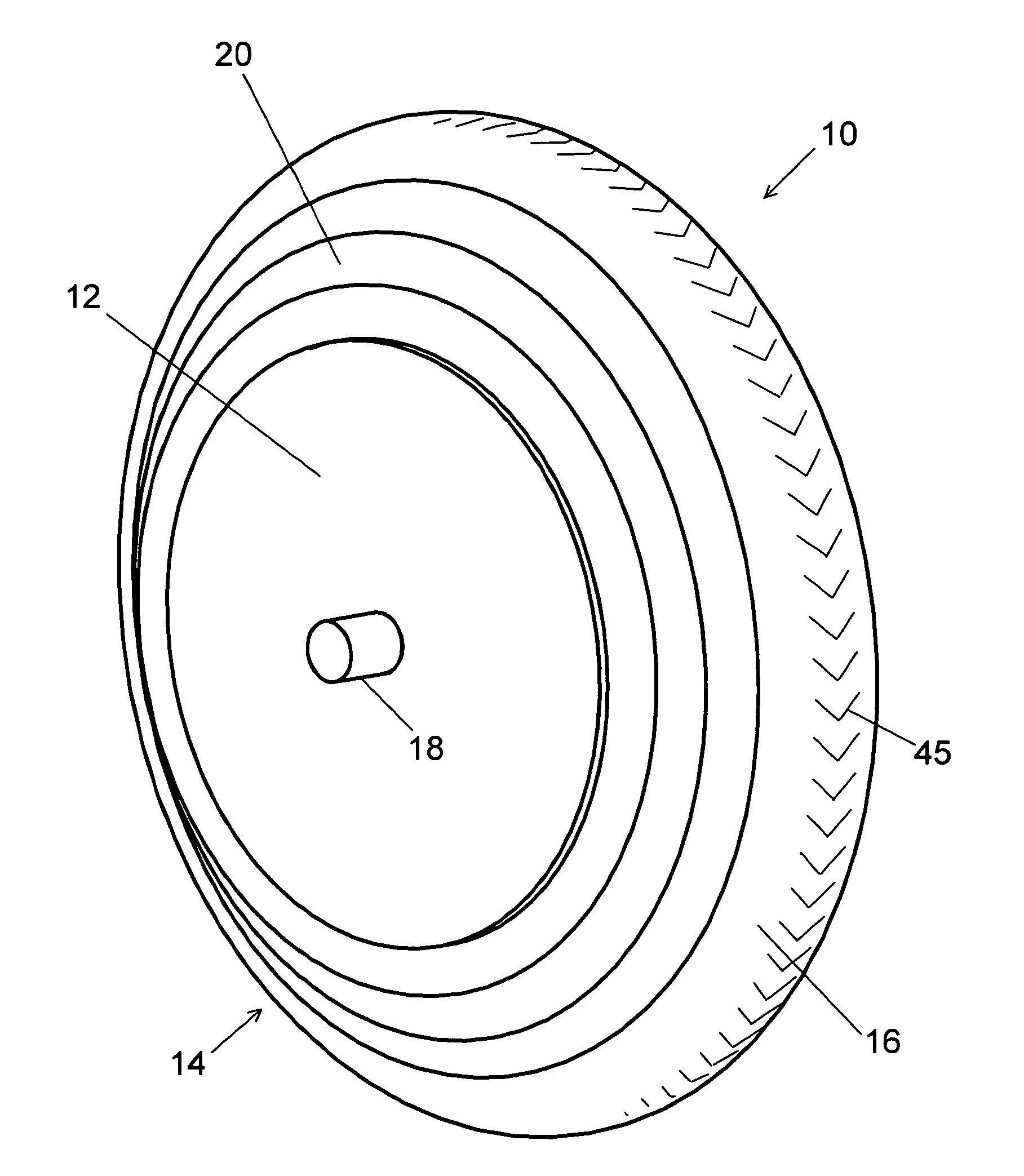

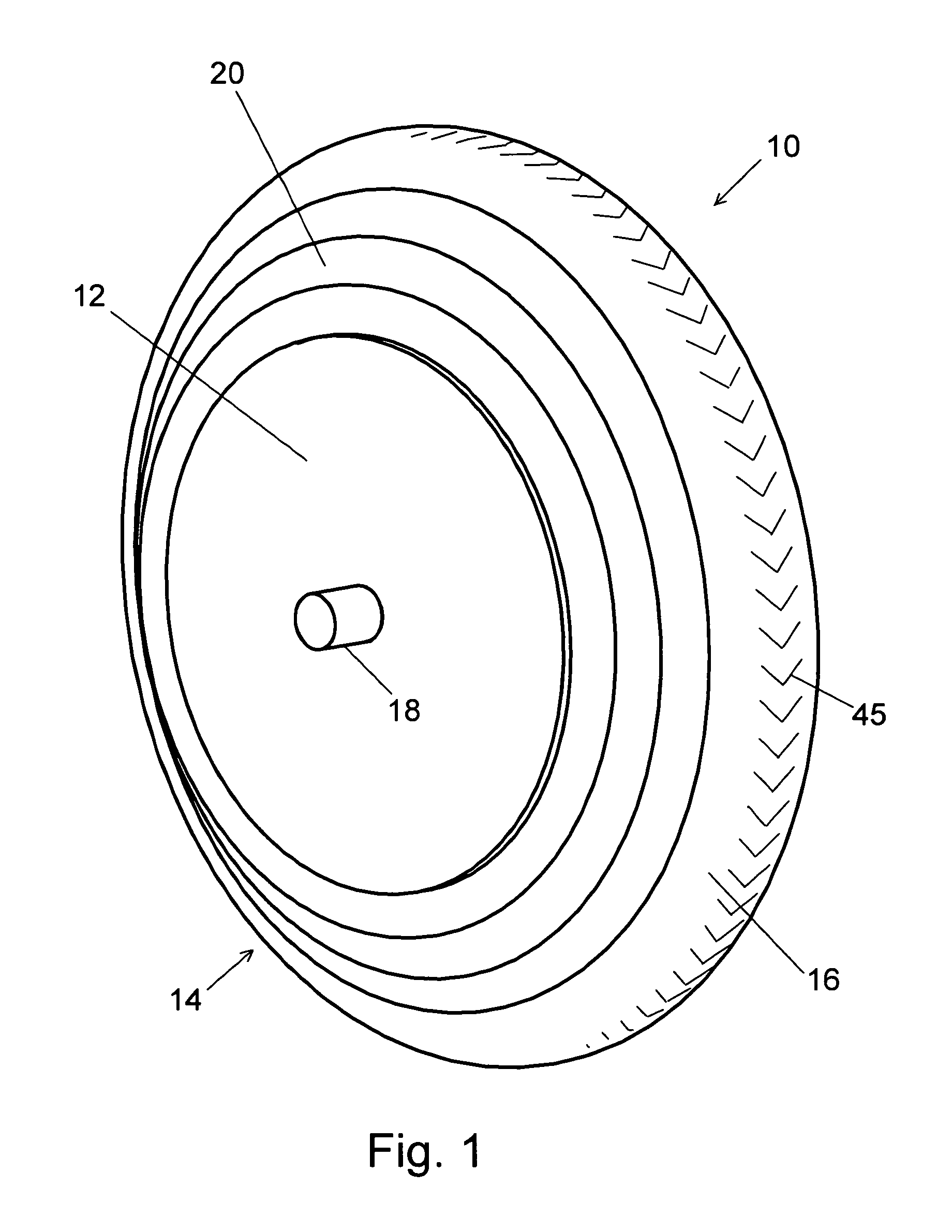

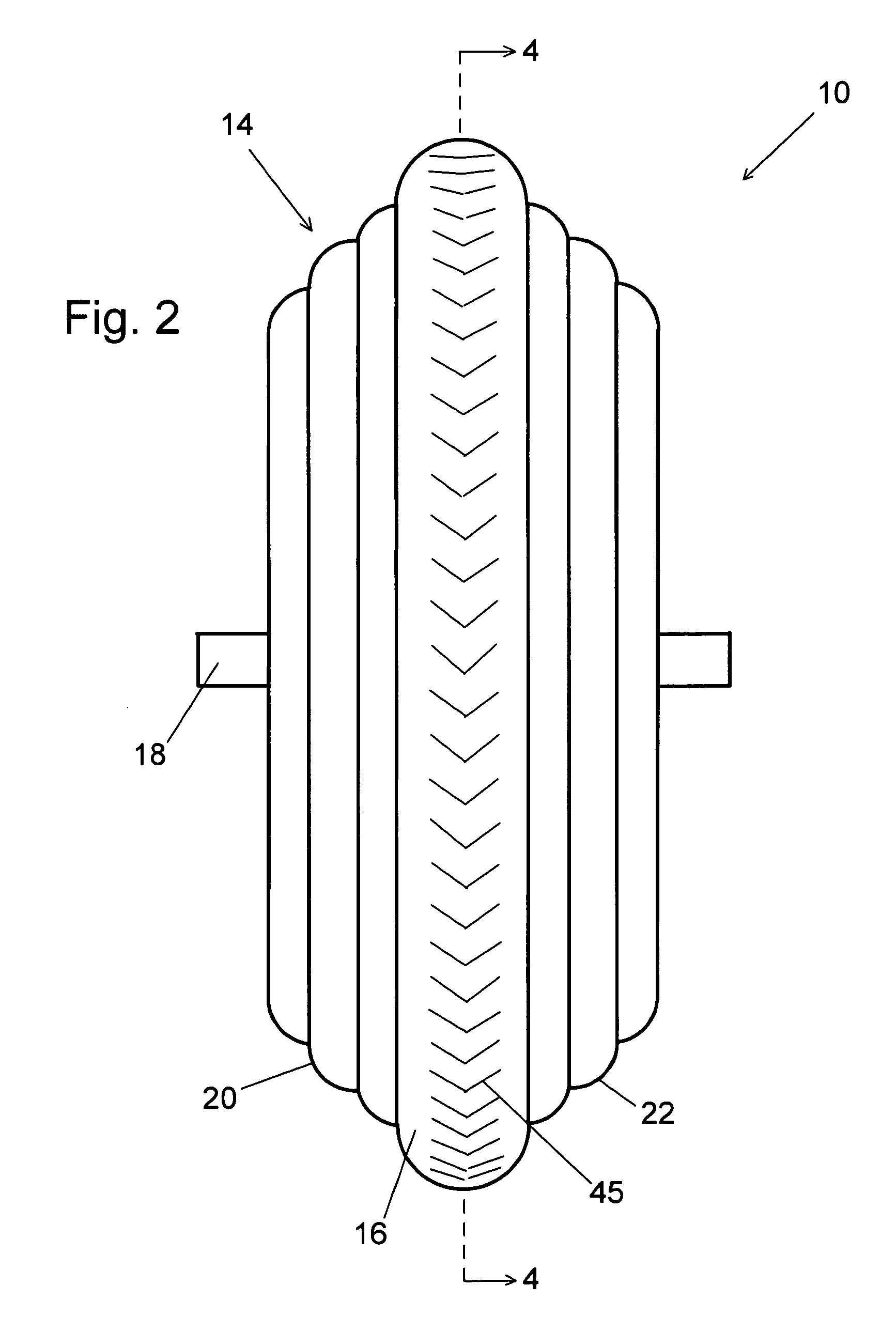

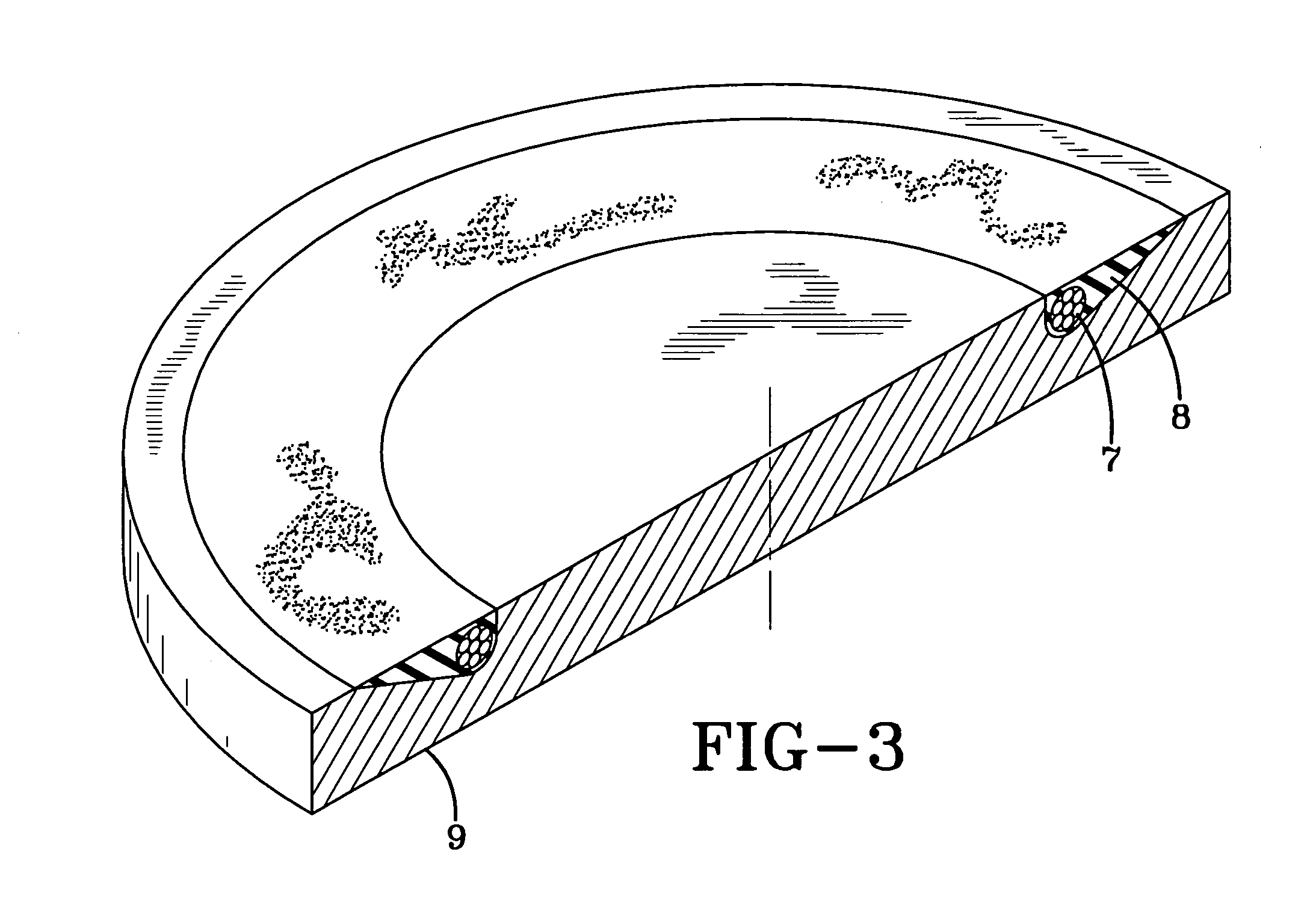

Hollow core pneumatic wheel having contour conforming polyurethane wall

A urethane wheel including a hard urethane hub formed with a rim facing radially outward, and including stand-off ribs spaced equidistant thereabout. The stand-off ribs having centering notches opening radially outward. A thin wall polyurethane annular bladder with an interior annular stand-off skirt facing radially inward, contacting the centering notches of the stand-off ribs, and cooperating to position the bladder both radially and axially about the rim. The tire body is formed of soft polyurethane which surrounds the rim, encapsulates the bladder creating and integral cavity, and forms a contoured surface. A method of manufacturing the wheel which includes selecting a pressurized annular bladder, locating the bladder both axially and radially about the rim, forming a concentric bridge space having axial communication channels between the rim and bladder, and then pouring liquid urethane in a mold to form the tire.

Owner:PNC BANK NAT ASSOC +1

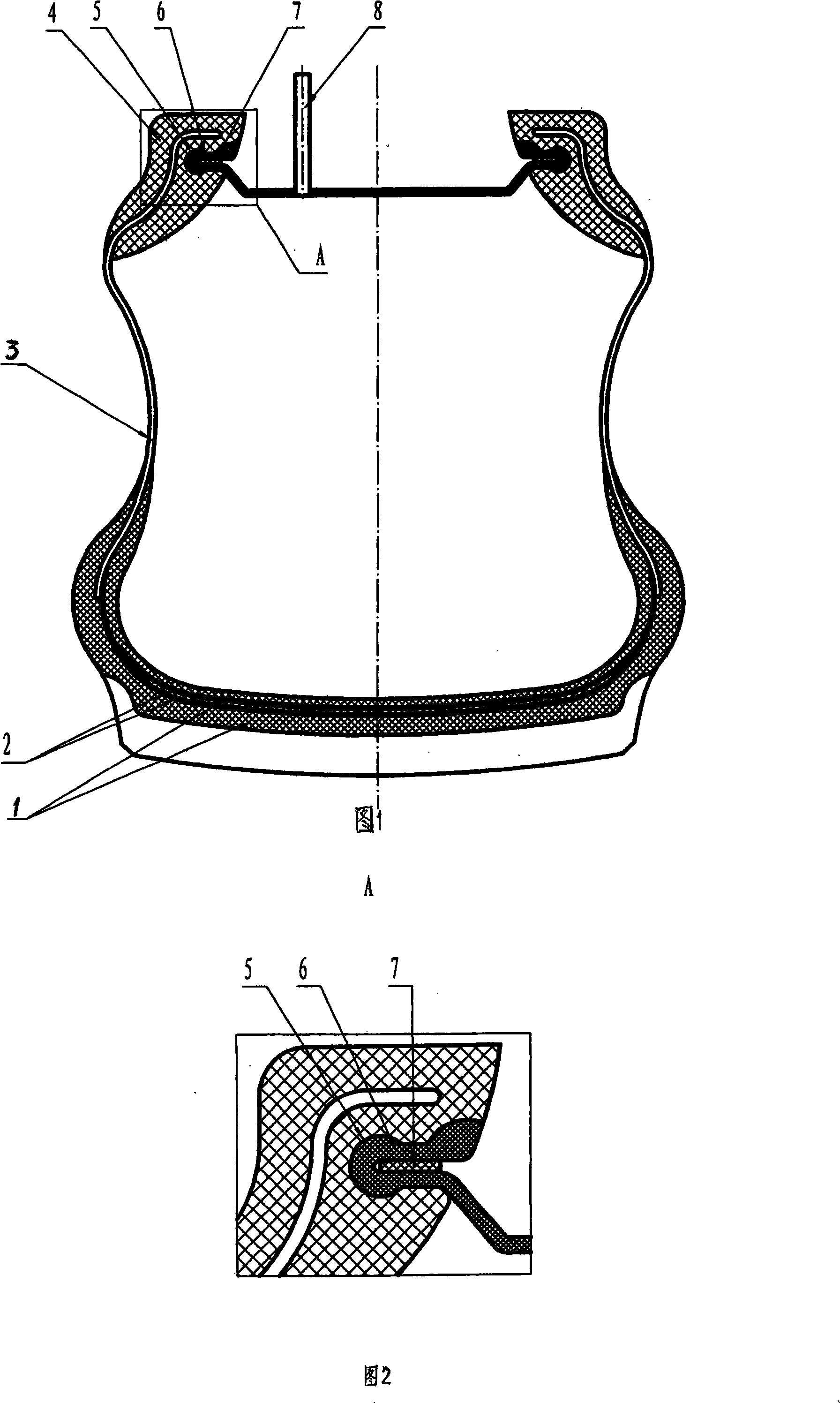

Tire

ActiveCN105163957AIncreased durabilityWithout cord reinforcementSpecial tyresThermoplastic elastomerEngineering

This tire (10) has: an annular tire frame body (17) formed from a resin material; and a reinforcing metal cord member (27) wound at the outer peripheral portion of the tire frame body (17). At least a portion of the reinforcing metal cord member (27) is, with an adhesive layer containing a hot melt adhesive therebetween, covered by a covering composition containing at least one type of thermoplastic material selected from a thermoplastic resin and a thermoplastic elastomer.

Owner:BRIDGESTONE CORP

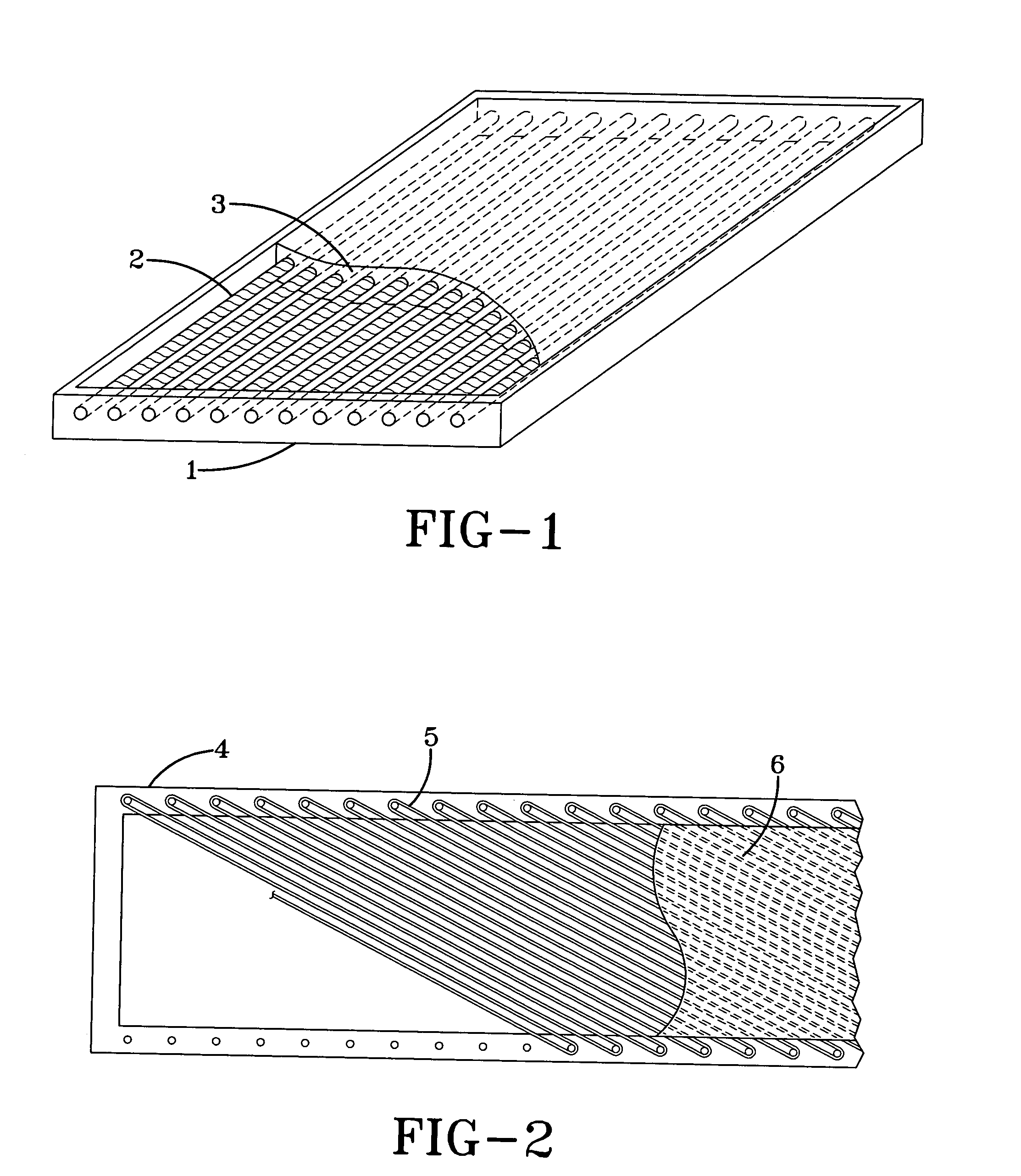

Tire core package for use in manufacturing a tire with belts, plies and beads and process of tire manufacture

InactiveUS6974519B2Conveniently rolled into sectionDesired hardnessWithout cord reinforcementTyresFiberElastomer

A system for manufacturing an elastomeric tire utilizing a separate formation of a package having a tire core shape and containing tire belts, plies and beads. The package is formed by a laying up of layers of pre-cure elastomer intradigitated with sections of porous fabric, where the fabric fibers are placed at desired crossing angles to one another, and the pre-cure elastomer layers are positioned therebetween as a sandwich, with the sandwich then cold rolled into the tire core shape. Inelastic hoop shaped beads are fitted to and encapsulated in the tire core side walls ends and, as required, an inelastic belt is fitted around the tire core tread area that is secured thereto as by cold rolling a layer of pre-cure elastomer thereover, completing the tire core package. The tire core package is fitted into a mold, preferably a spin casting mold, and is supported therein equidistant from the mold cavity walls to receive an elastomer sprayed therein as the mold is spun. During spinning, the exothermic heat of reaction of the sprayed elastomer constituents as is generated as they are mixed and sprayed into the mold, completes the cure of the pre-cure elastomer, providing a homogenous finished tire with the belts, plies and beads optimally positioned therein.

Owner:AMERITIRE

Tire and tire manufacturing method

InactiveCN102317088AIncreased durabilityAvoid enteringWithout cord reinforcementWith separate inflatable insertsEngineeringThermoplastic materials

Disclosed is a tire made from a resin material, particularly a thermoplastic material, and which has reduced air inclusion and increased durability. Air inclusion is reduced and durability is increased in the tire (10) by having an annular tire casing (23) formed from a resin material; a reinforcing cord (26) with a higher rigidity than the resin material which winds helically around the circumference of the tire casing (23) and has at least one portion embedded in the circumference in close adherence to the resin material in a cross-sectional view of the tire casing (23) in the direction of the axle; and a tread (30) provided radially outward from a reinforcing cord layer (28) formed from the reinforcing cord (26).

Owner:BRIDGESTONE CORP

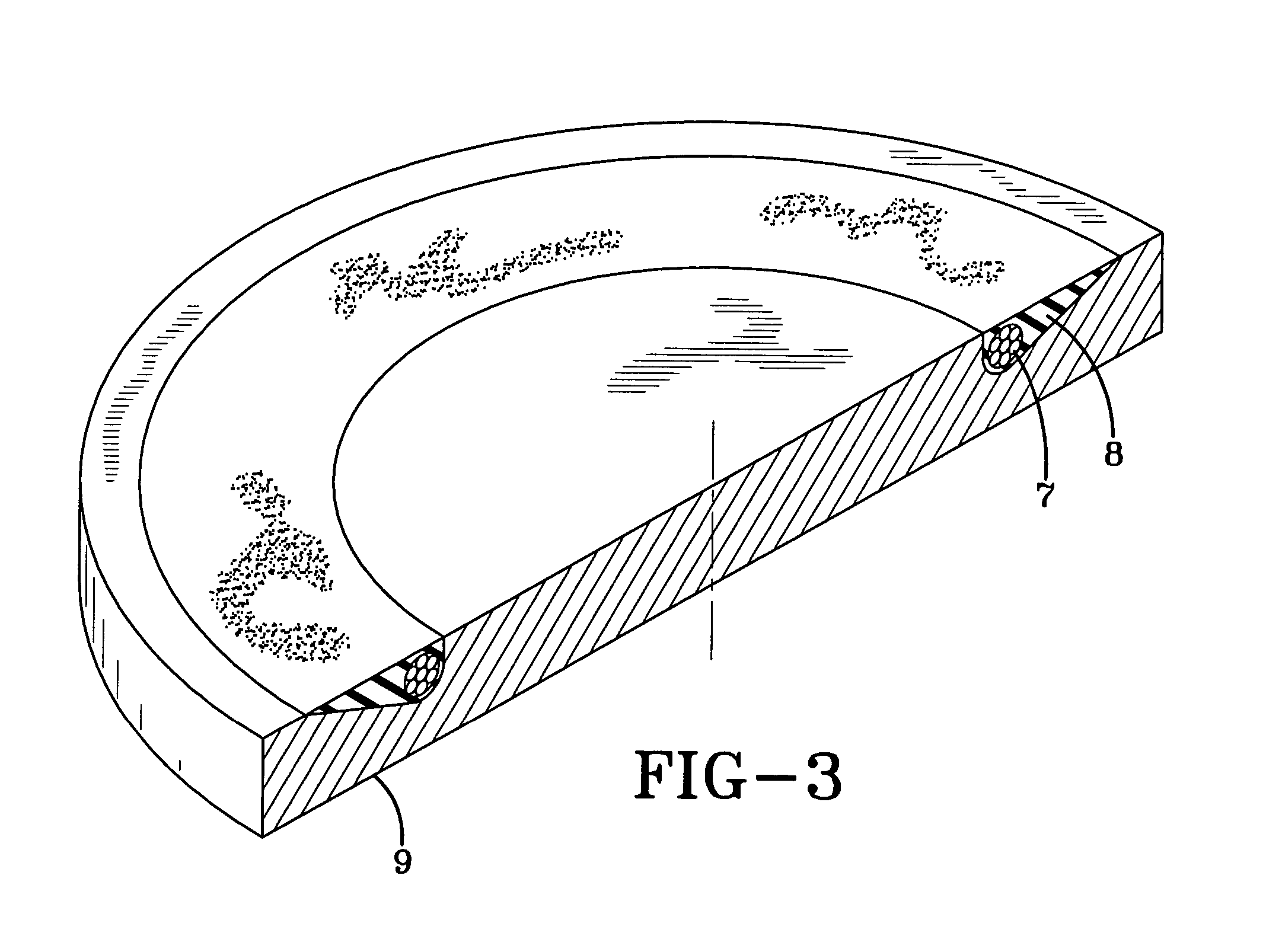

Air no air elastomeric tire

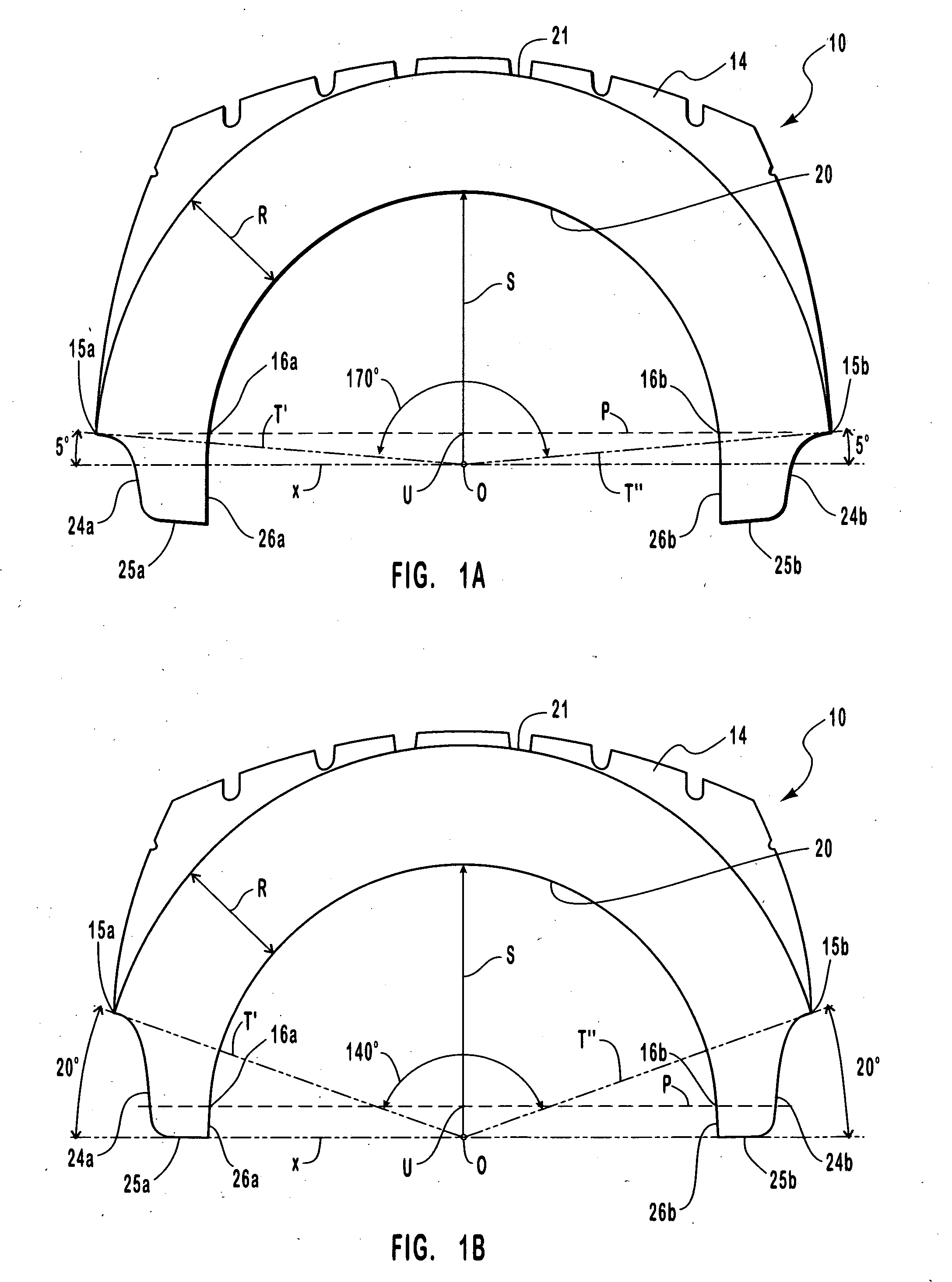

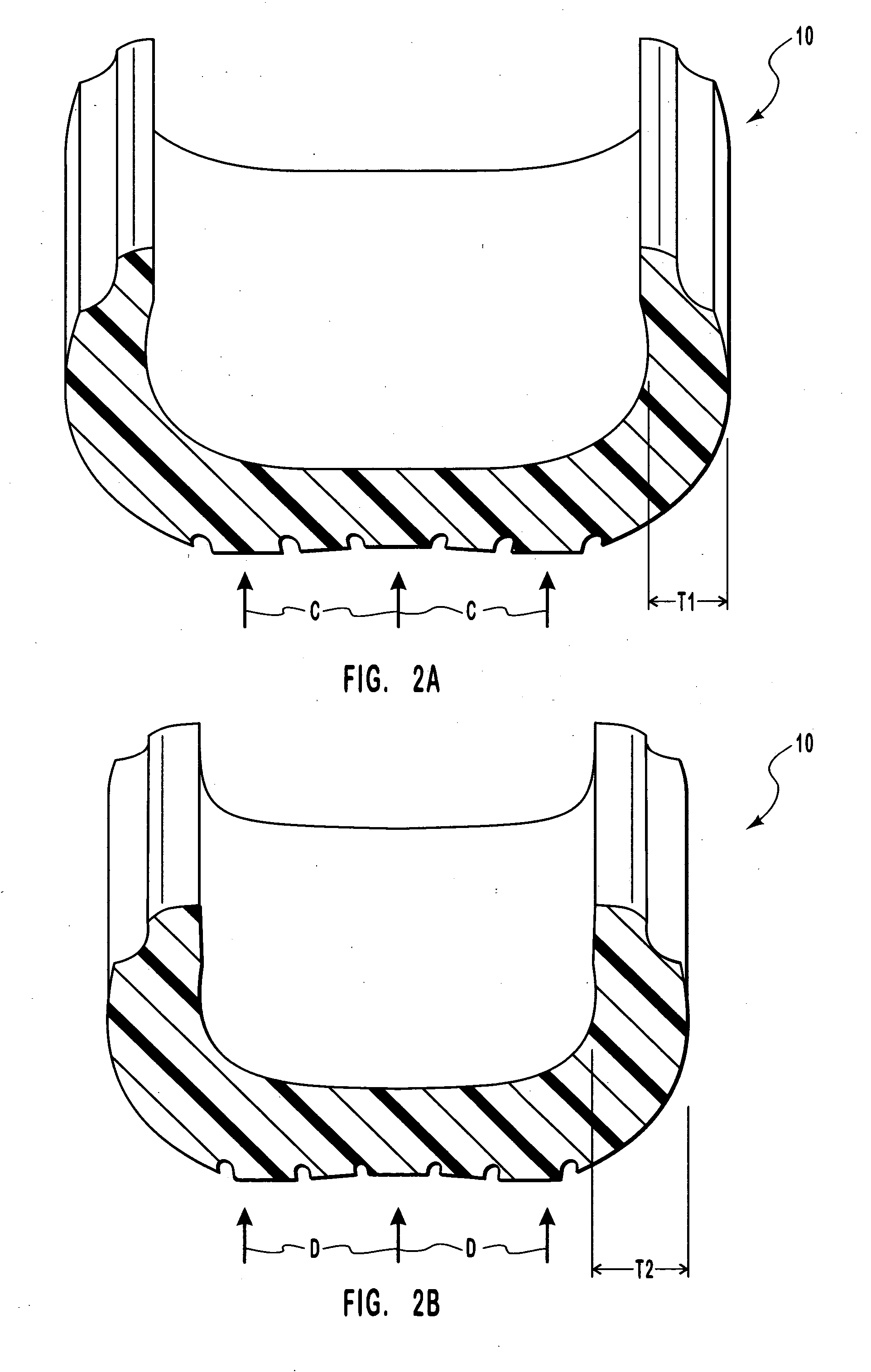

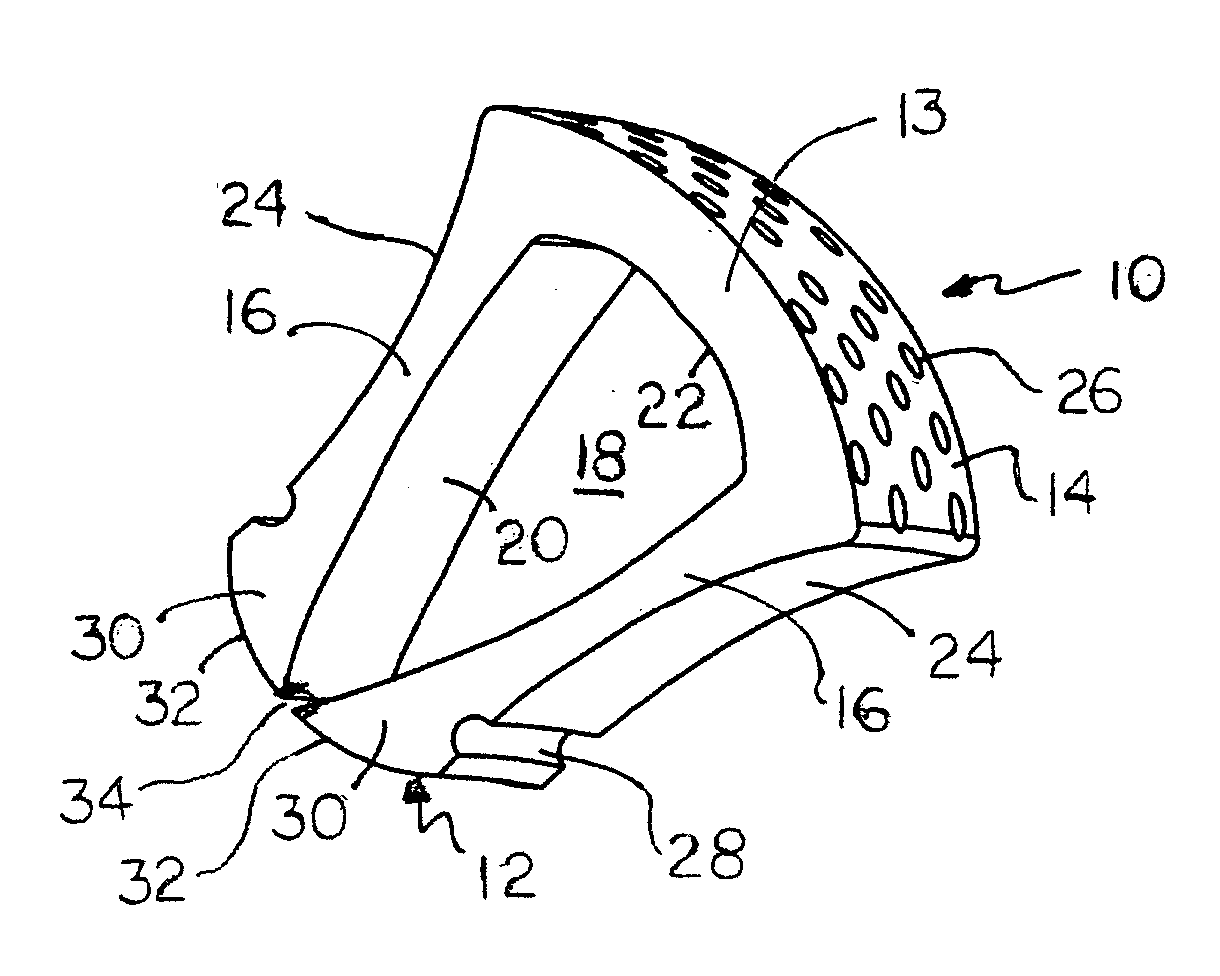

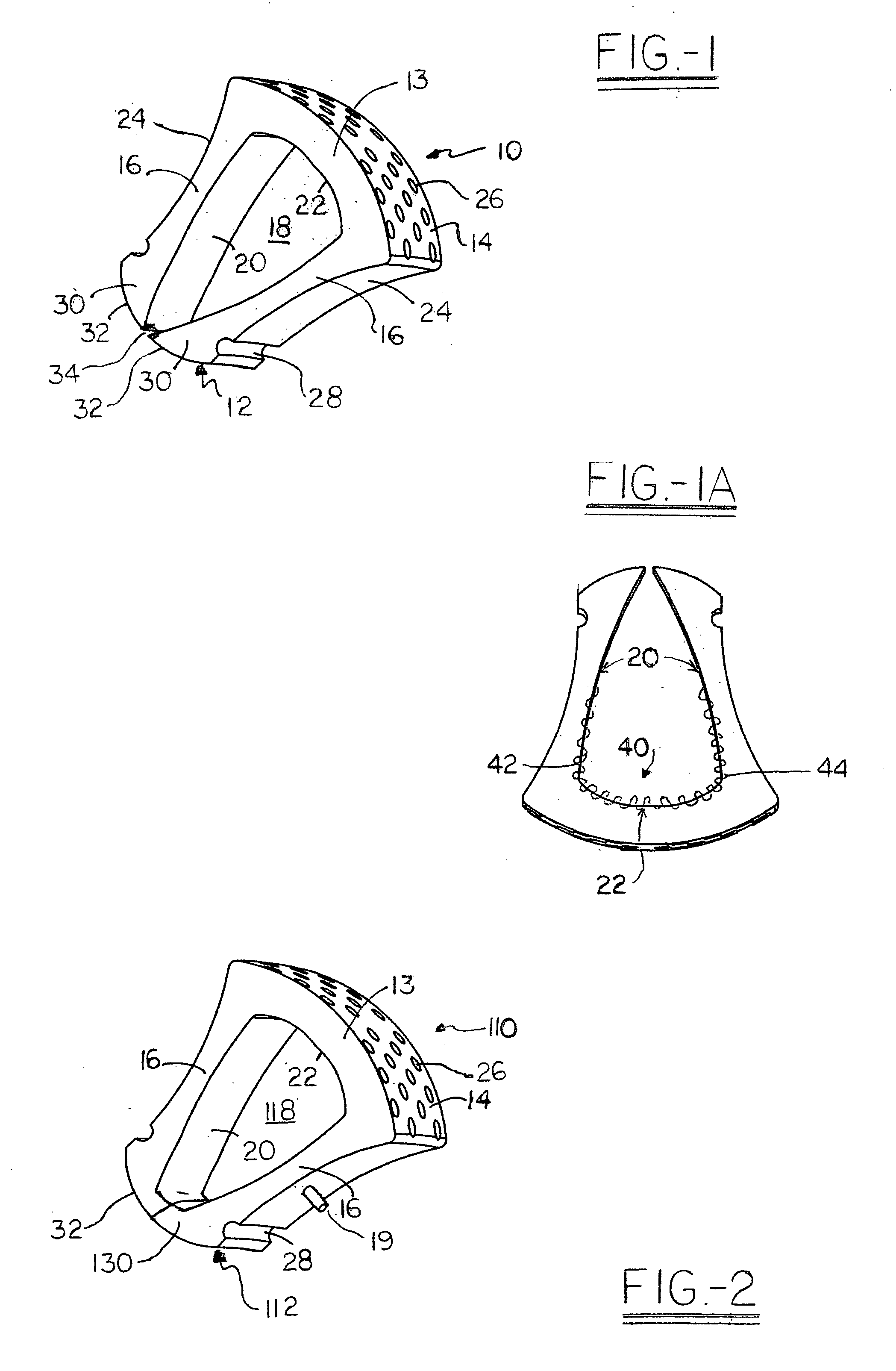

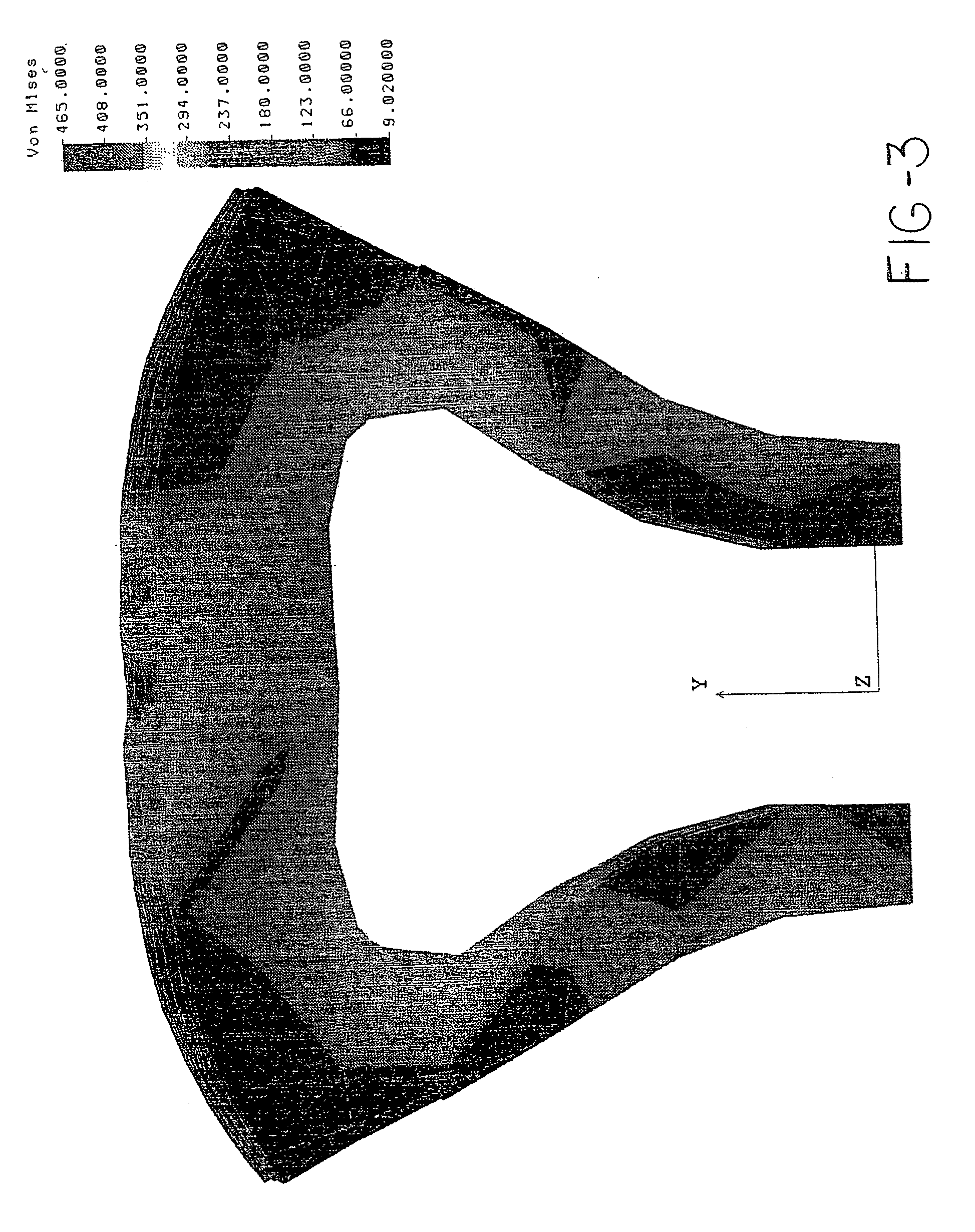

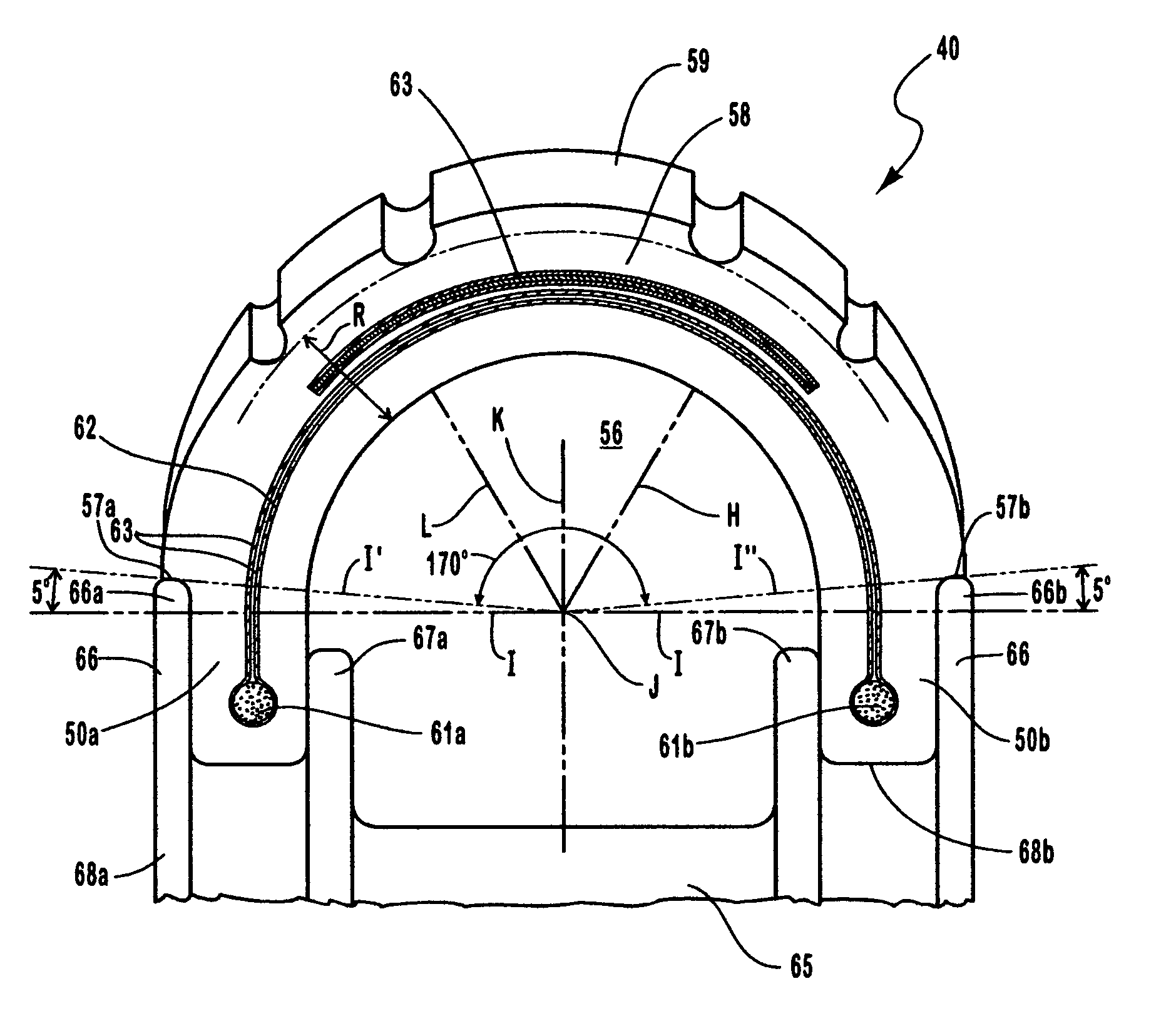

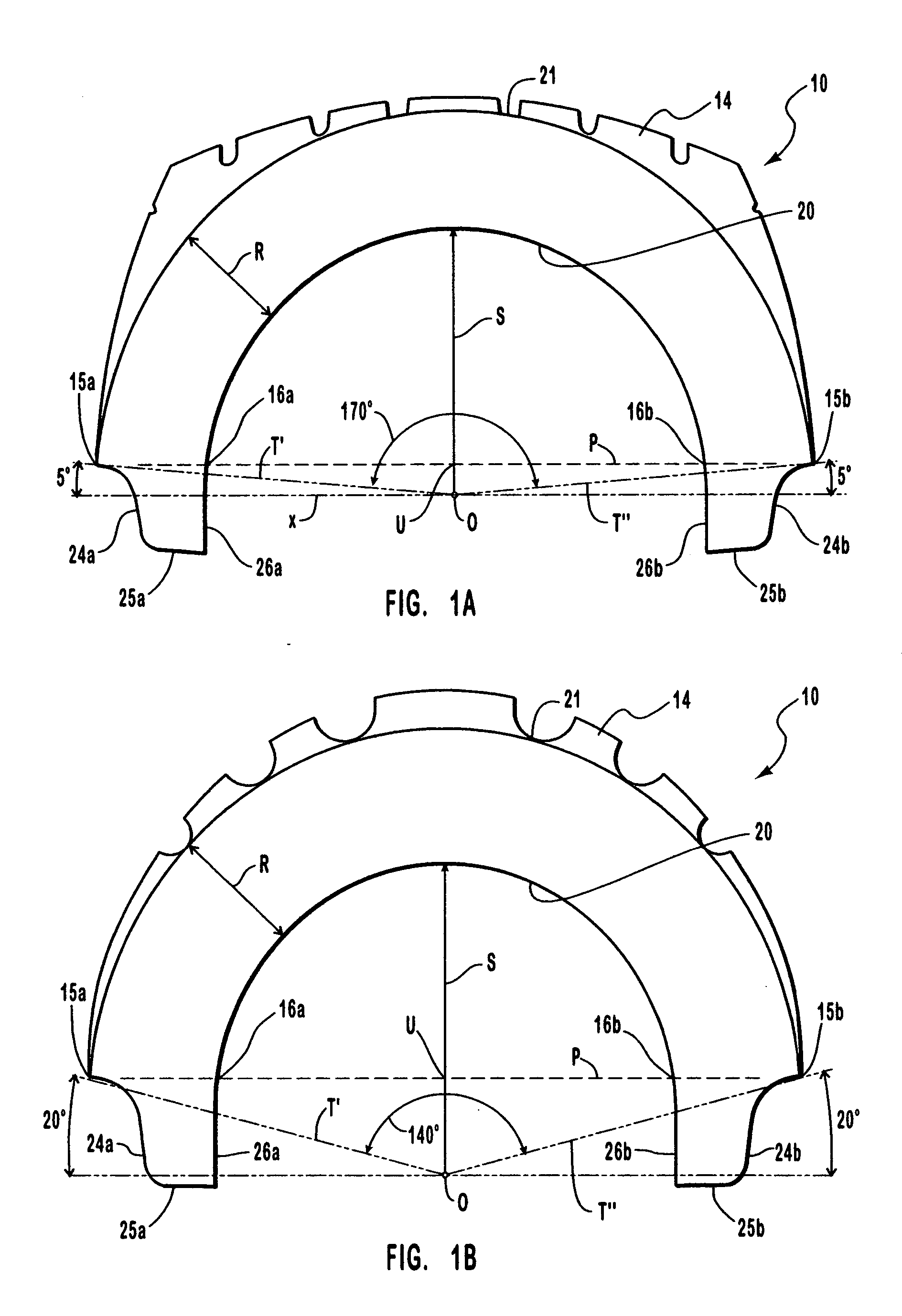

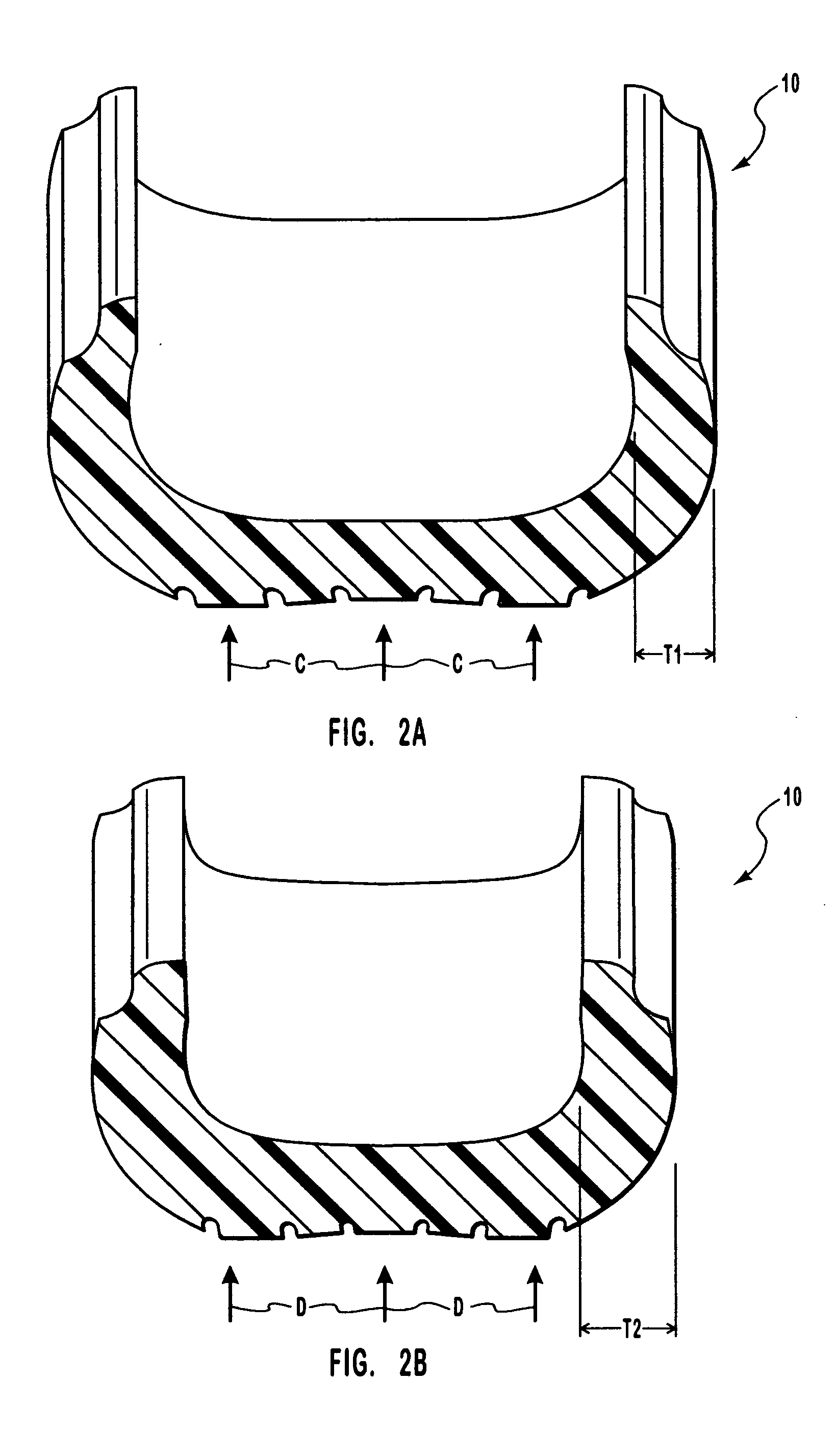

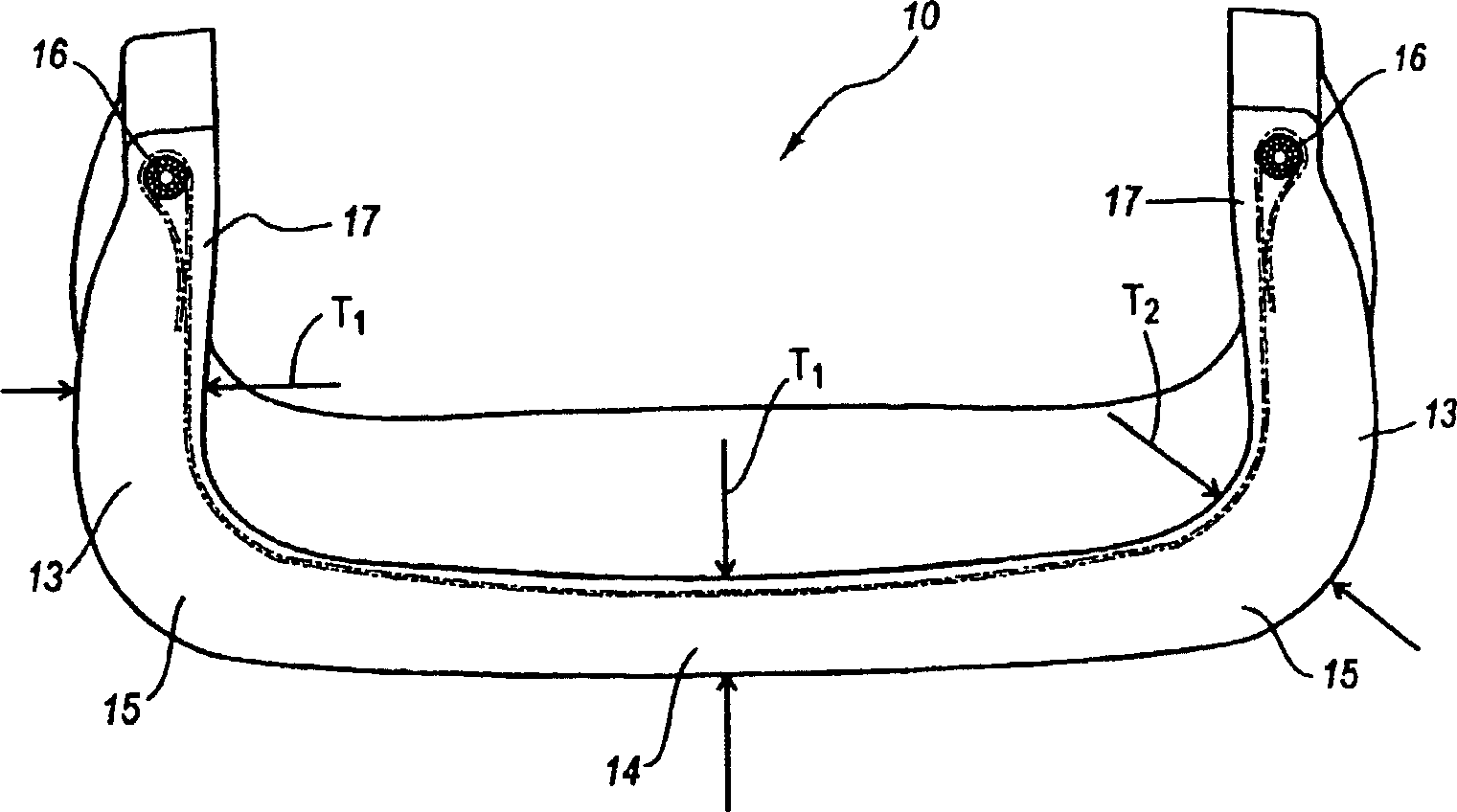

InactiveUS20080105350A1Safe loadingAdd supportWithout cord reinforcementNon-inflatable tyresAeroelasticityEngineering

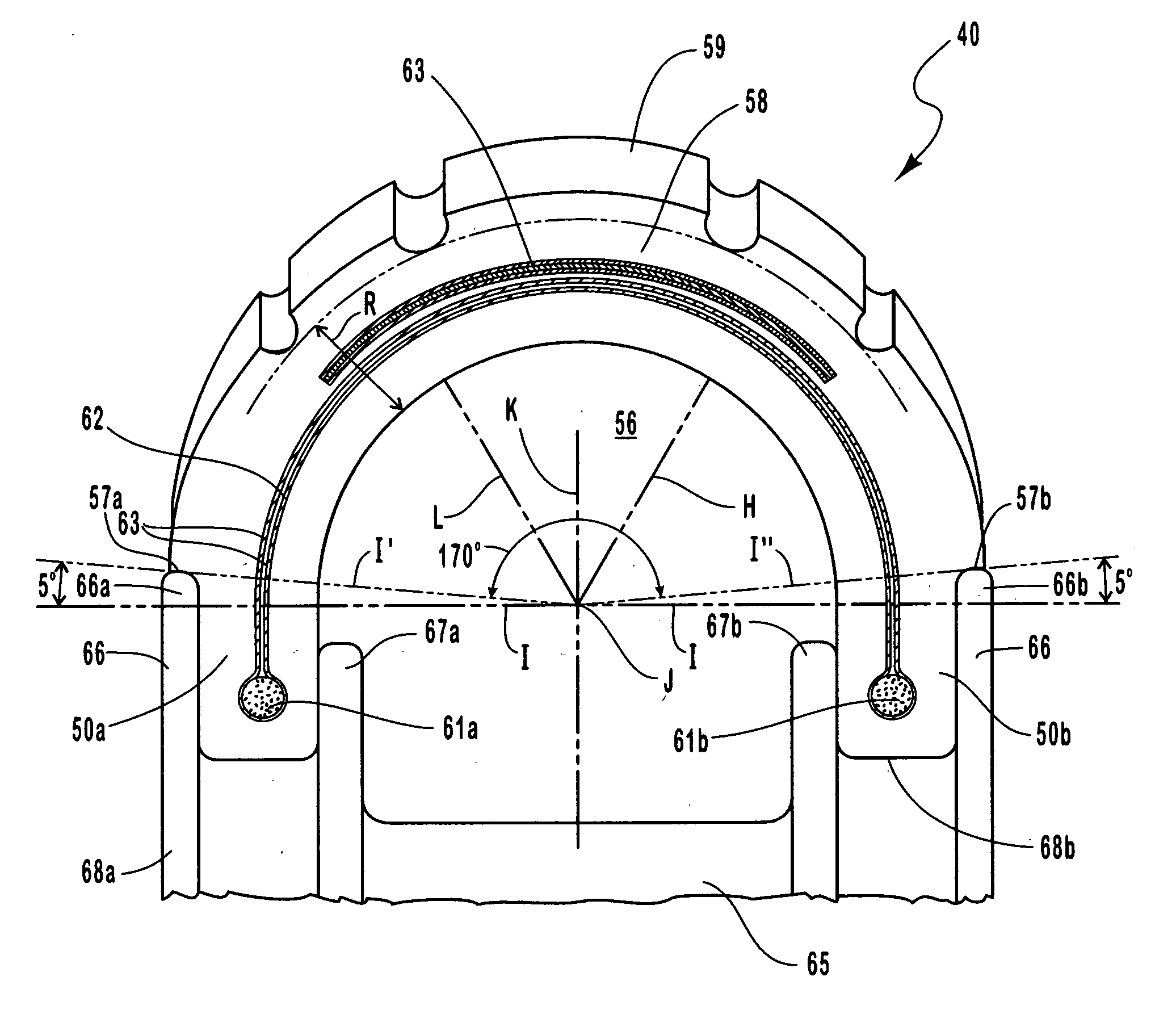

An elastomeric tire for mounting onto a rim that is manufactured by casting or molding methods to include an exterior arch shaped cavity that is centered under and is below the tire tread to have at least one hundred forty (140) degrees and not more than one hundred seventy (170) degrees of arc from one tire rim mounting contact point, around the tire to another tire rim mounting contact point, and with the cavity arch duplicated around the tire interior. A uniform tire wall thickness is provided that is selected for a particular anticipated load as the tire will carry, with the tire side wall ends each maintained at one the rim opposing ends, supporting the load carried by the tire in compression, and with the tire, at atmospheric pressure, providing ride and wear characteristics that are comparable to a pressurized pneumatic tire carrying a like load, and which tire of the invention interior arch-shaped cavity can be pressurized to add to its inherent load supporting character to safely support even greater loads.

Owner:STEINKE RICHARD A

Tire

InactiveUS20160152079A1Increased durabilityWithout cord reinforcementTyresThermoplastic elastomerEngineering

A tire (10) including: a circular tire frame (17) formed from a resin material, and a reinforcing metal cord member (27) that is wound on an outer circumference of the tire frame (17), at least a portion of the reinforcing metal cord member (27) being covered, via an adhesion layer including a hot melt adhesive, with a covering composition that includes at least one thermoplastic material selected from the group consisting of a thermoplastic resin and a thermoplastic elastomer.

Owner:BRIDGESTONE CORP

Tire

InactiveUS20150053327A1Excellent adhesion durabilityIncreased durabilityWithout cord reinforcementSpecial tyresThermoplastic polyurethanePolystyrene

A tire including: a circular tire frame formed from a resin material; and a metal reinforcing cord member wound on an outer circumference of the tire frame, at least a portion of the metal reinforcing cord member being covered by a covering mixture including at least a thermoplastic resin and a specific elastomer selected from the group consisting of (1) to (3) below:(1) a thermoplastic polyurethane-based elastomer;(2) a thermoplastic polystyrene-based elastomer; and(3) a thermoplastic olefin-based elastomer including at least one selected from the group consisting of an acid-modified thermoplastic olefin-based elastomer having an elastic modulus of less than 140 MPa and a non-acid-modified thermoplastic olefin-based elastomer having an elastic modulus of less than 140 MPa.

Owner:BRIDGESTONE CORP

Tire

ActiveCN105142928AIncreased durabilityWithout cord reinforcementSpecial tyresThermoplastic elastomerEngineering

This tire (10) has: an annular tire frame body (17) formed from a resin material; and a reinforcing metal cord member (27) wound at the outer peripheral portion of the tire frame body (17). At least a portion of the reinforcing metal cord member (27) is, with an adhesive layer containing a solvent-based adhesive therebetween, covered by a covering composition containing at least one type of thermoplastic material selected from a thermoplastic resin and a thermoplastic elastomer.

Owner:BRIDGESTONE CORP

Anisotropic homogeneous elastomeric closed torus tire design & method of manufacture

InactiveUS20050072507A1Effective installationImprove tire performanceWithout cord reinforcementNon-inflatable tyresMechanical engineeringAnisotropy

Owner:CHROBAK DENNIS S +1

High efficiency integrated automotive wheel

InactiveUS8020596B1Reduce energy lossSmall overall deformationWithout cord reinforcementBicycle tyresRoad surfaceElectric vehicle

The present device is an integrated automotive wheel for electric vehicles which substantially reduces energy loss due to tire flex and energy loss from a conventional drive train. The wheel includes an axle, a hub, two composite sidewalls, a low pressure inner chamber with shock absorbing hub protector, and at least one outer high pressure pneumatic chamber with tread. The hub can contain an electric hub motor which rotates the wheel, propelling the vehicle. The sidewalls include at least one pressurized chamber which position the outer tread ring and enable the wheel to simulate an energy efficient high pressure pneumatic wheel, experiencing little deformation when under smooth road conditions. When road conditions are rough, the sidewalls can temporarily buckle in response to the increased road forces, simulating a low pressure conventional tire having ample space for deformation, with suspension and shock absorption capability built in. The sidewalls and outer ring chamber can be filled with high pressure closed cell foam to prevent flats.

Owner:MORRISON GLENN ARTHUR

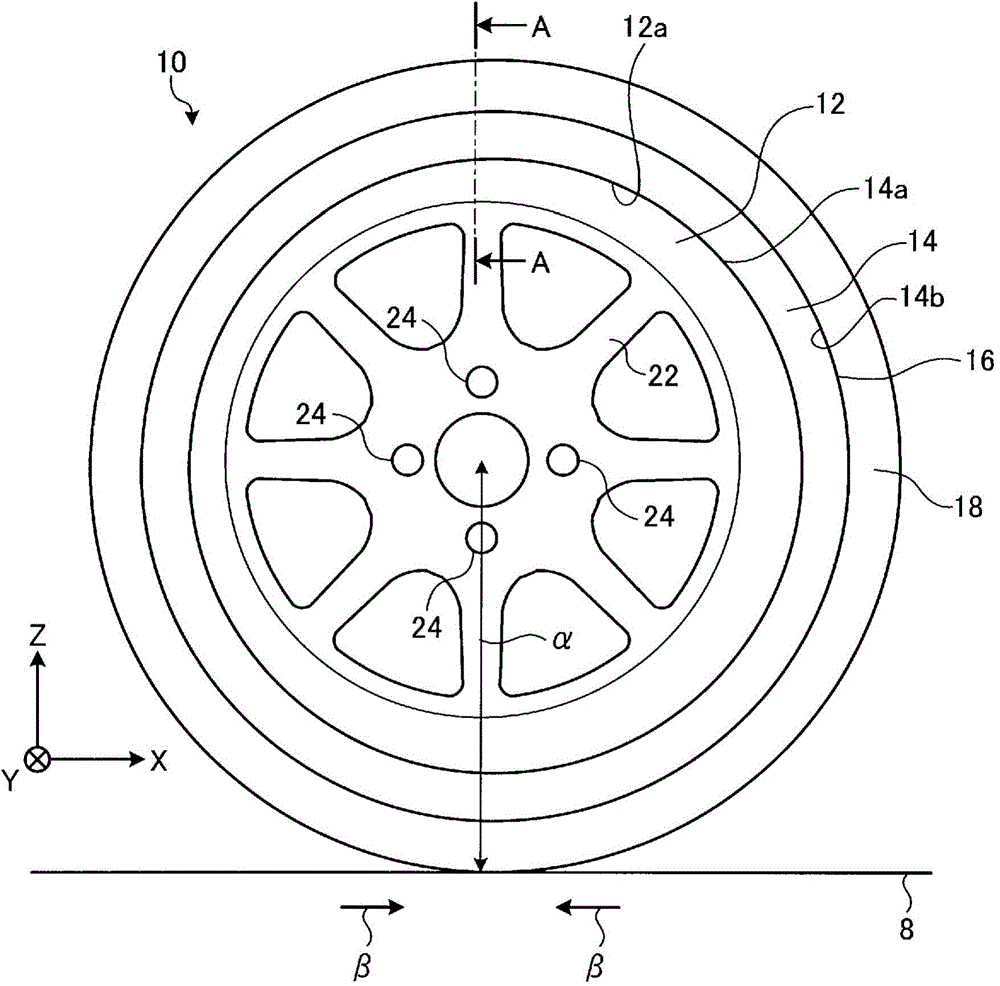

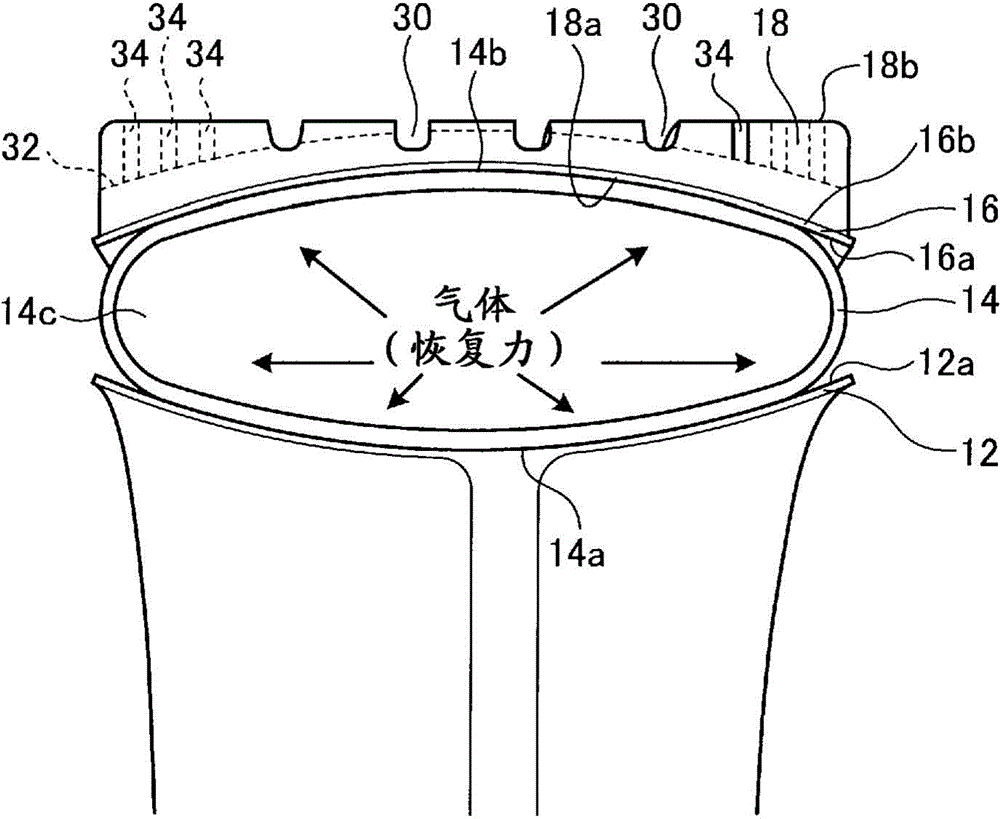

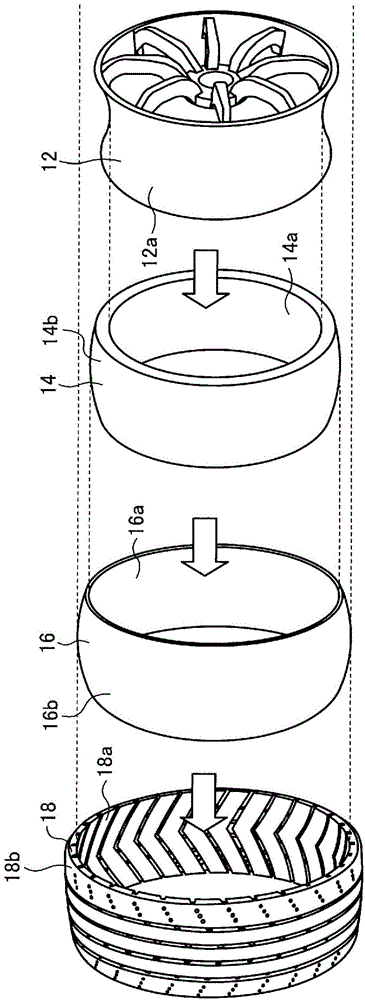

Tire/wheel assembly and tread ring

ActiveCN104884270ASuppress punctureAvoid deformationWithout cord reinforcementWith separate inflatable insertsRotational axisElastomer

The present invention addresses the problem of providing a novel tire / wheel assembly. The tire / wheel assembly has: a wheel coupled to a rotating shaft; an elastic tube arranged on the outside of the wheel in the radial direction and having air filled therein; a rigid protection ring arranged on the outside of the tube in the radial direction, separated from the wheel; and a tread ring arranged on the outside of the protection ring in the radial direction and such that the inner circumferential surface thereof is in contact with the outer circumferential surface of the protection ring.

Owner:THE YOKOHAMA RUBBER CO LTD

Tire

This tire has: a tire frame that is annular and is formed from a resin material; and a reinforcing metal cord member that is wound to the outer periphery of the tire frame. At least a portion of the reinforcing metal cord member is covered by a covering mixture containing at least a thermoplastic resin and a specific elastomer selected from the group consisting of the belowmentioned (1) to (3): (1) a polyurethane thermoplastic elastomer; (2) a polystyrene thermoplastic elastomer; and (3) an olefin thermoplastic elastomer containing at least one selected from the group consisting of an acid-modified olefin thermoplastic elastomer having a modulus of elasticity of less than 140 MPa and an acid-unmodified olefin thermoplastic elastomer having a modulus of elasticity of less than 140 MPa.

Owner:BRIDGESTONE CORP

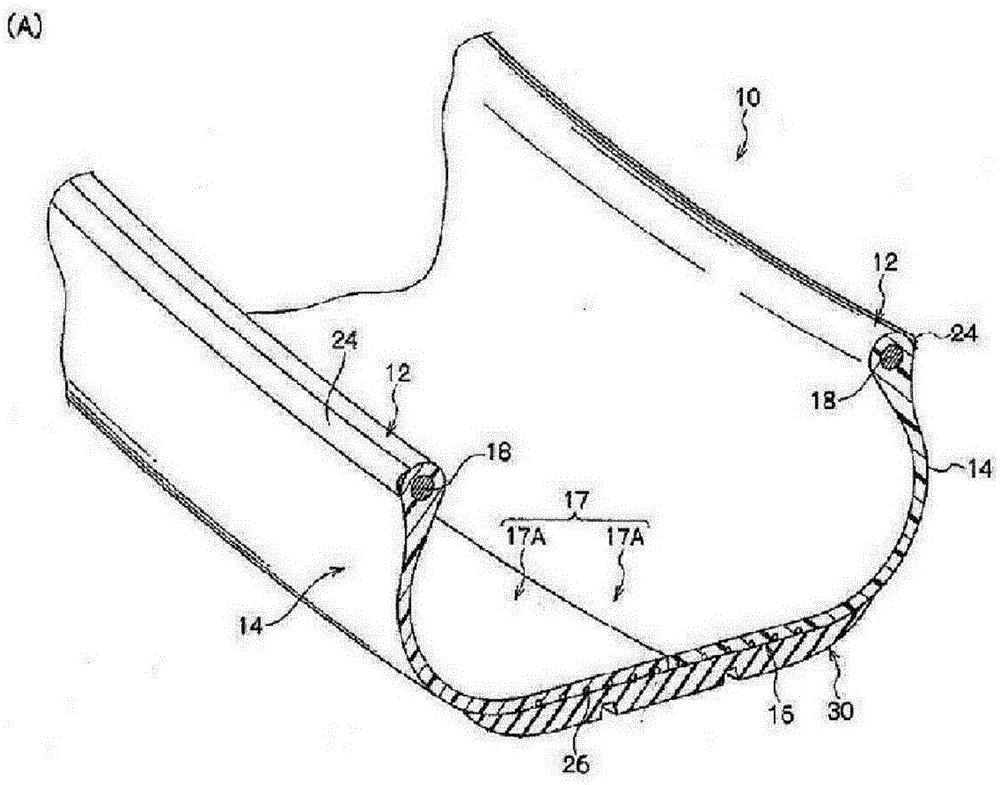

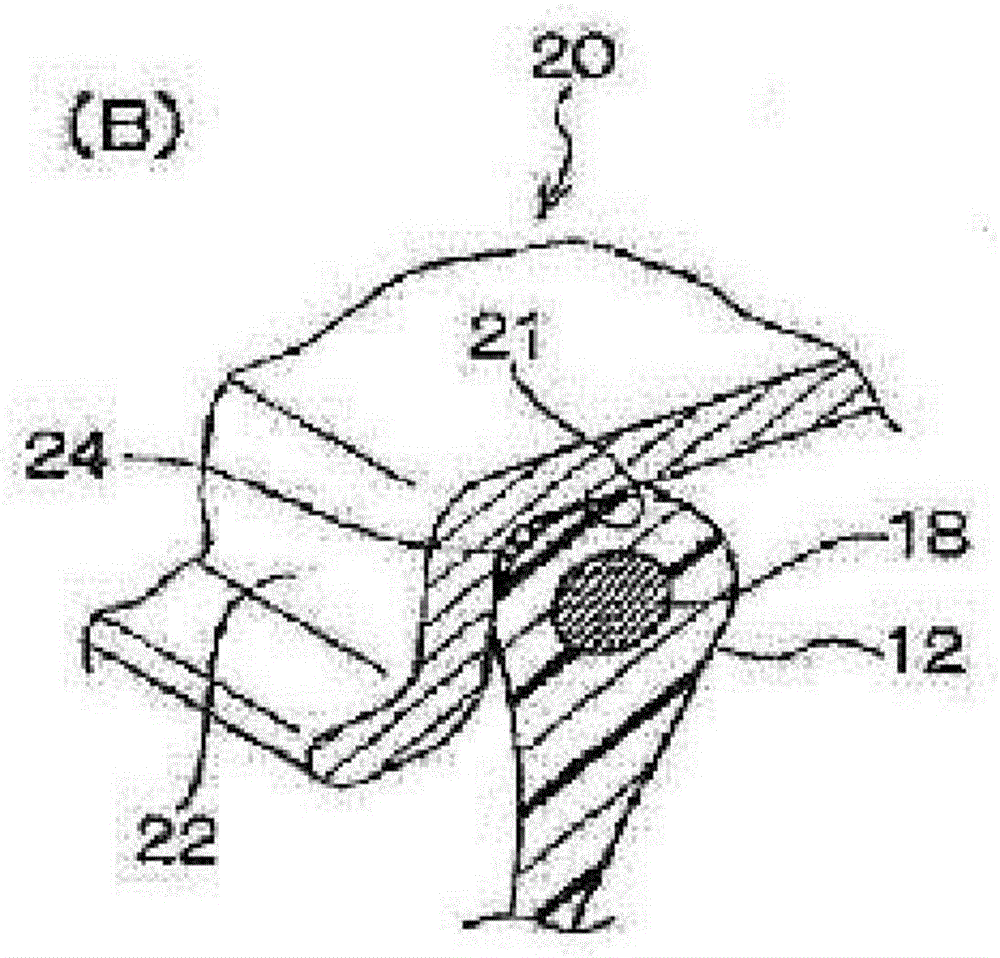

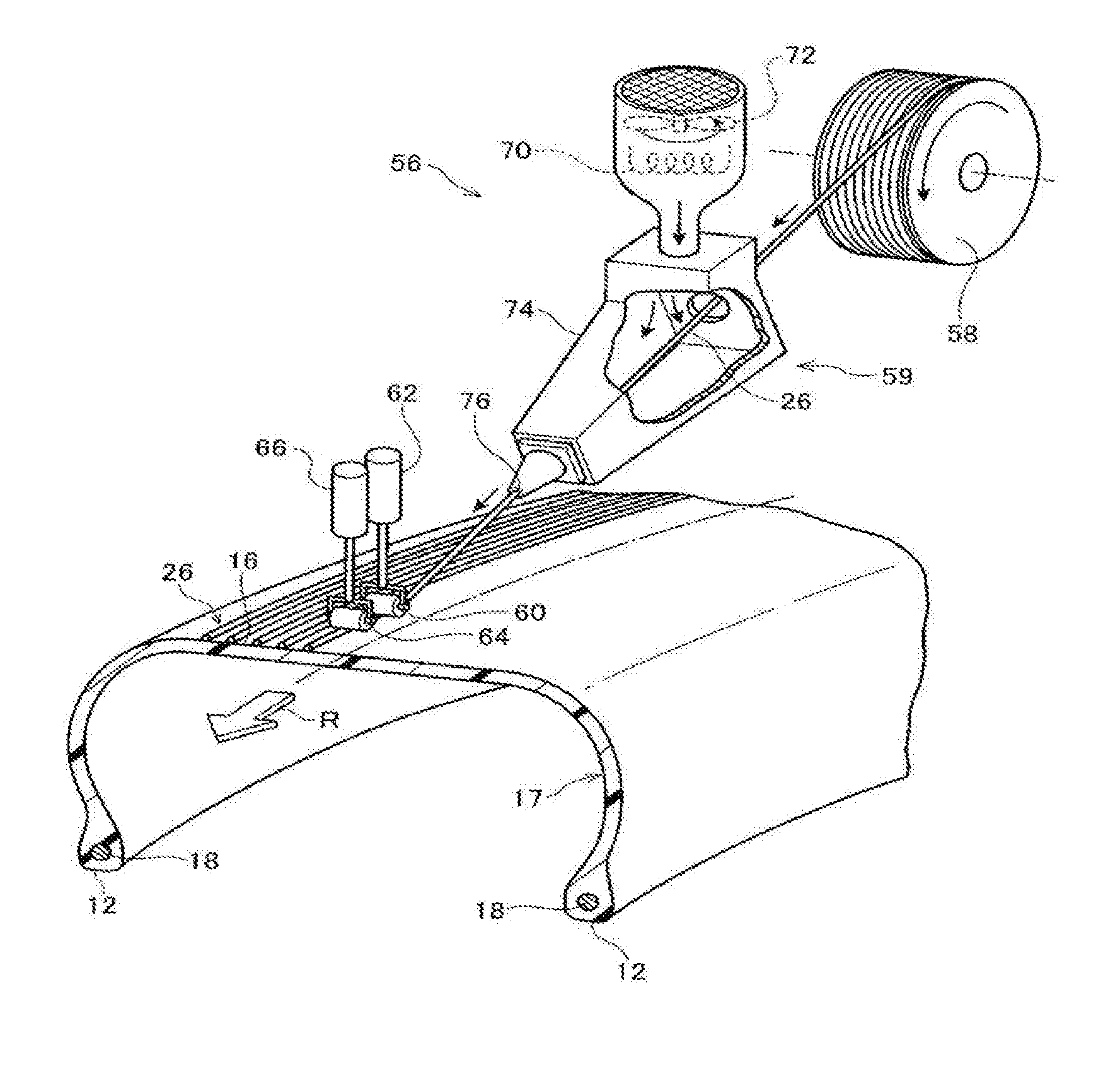

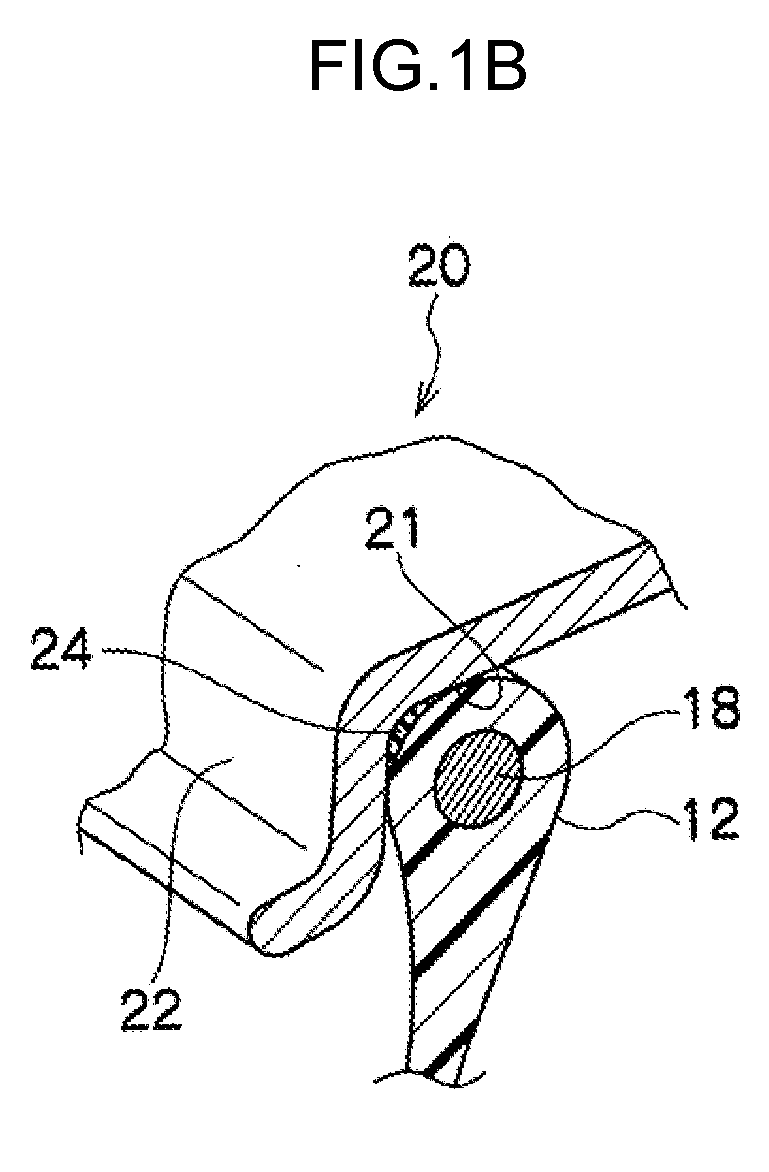

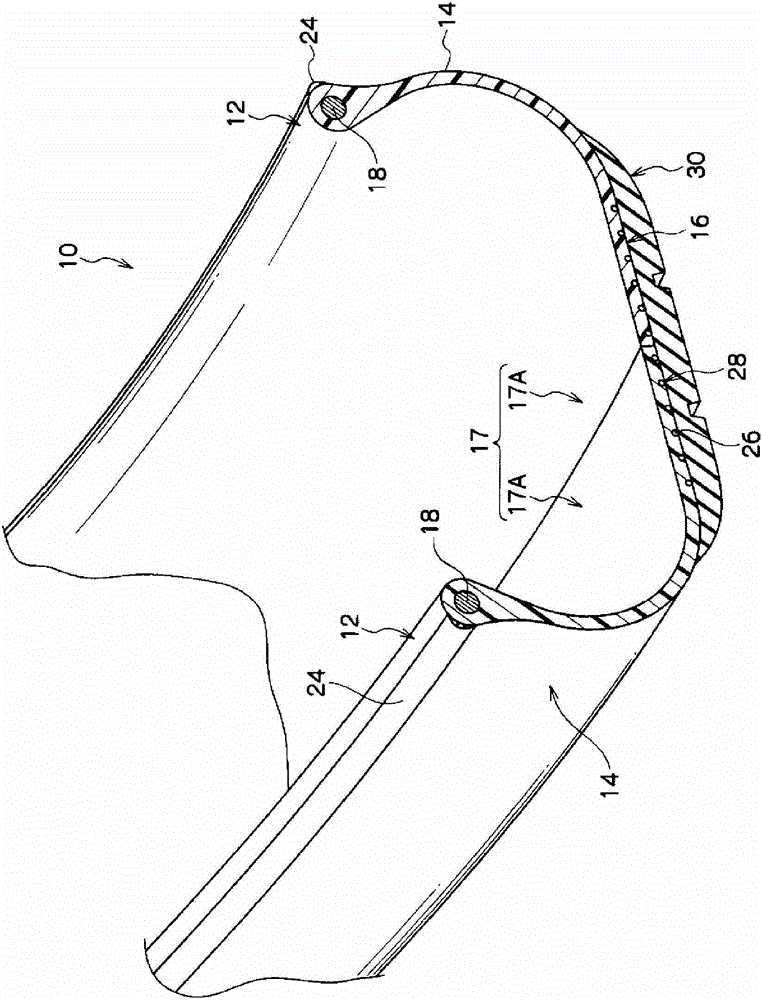

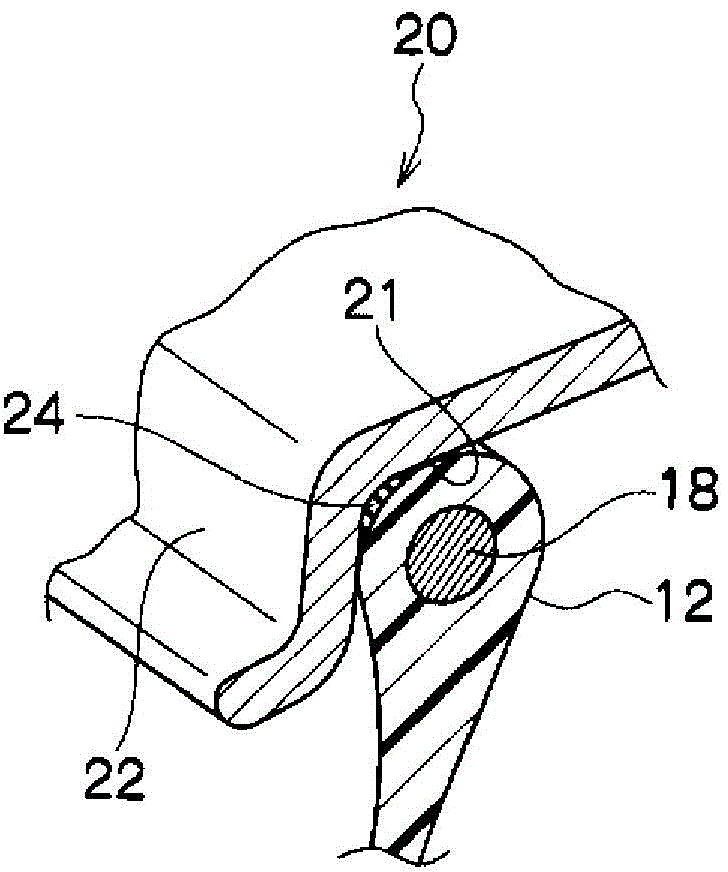

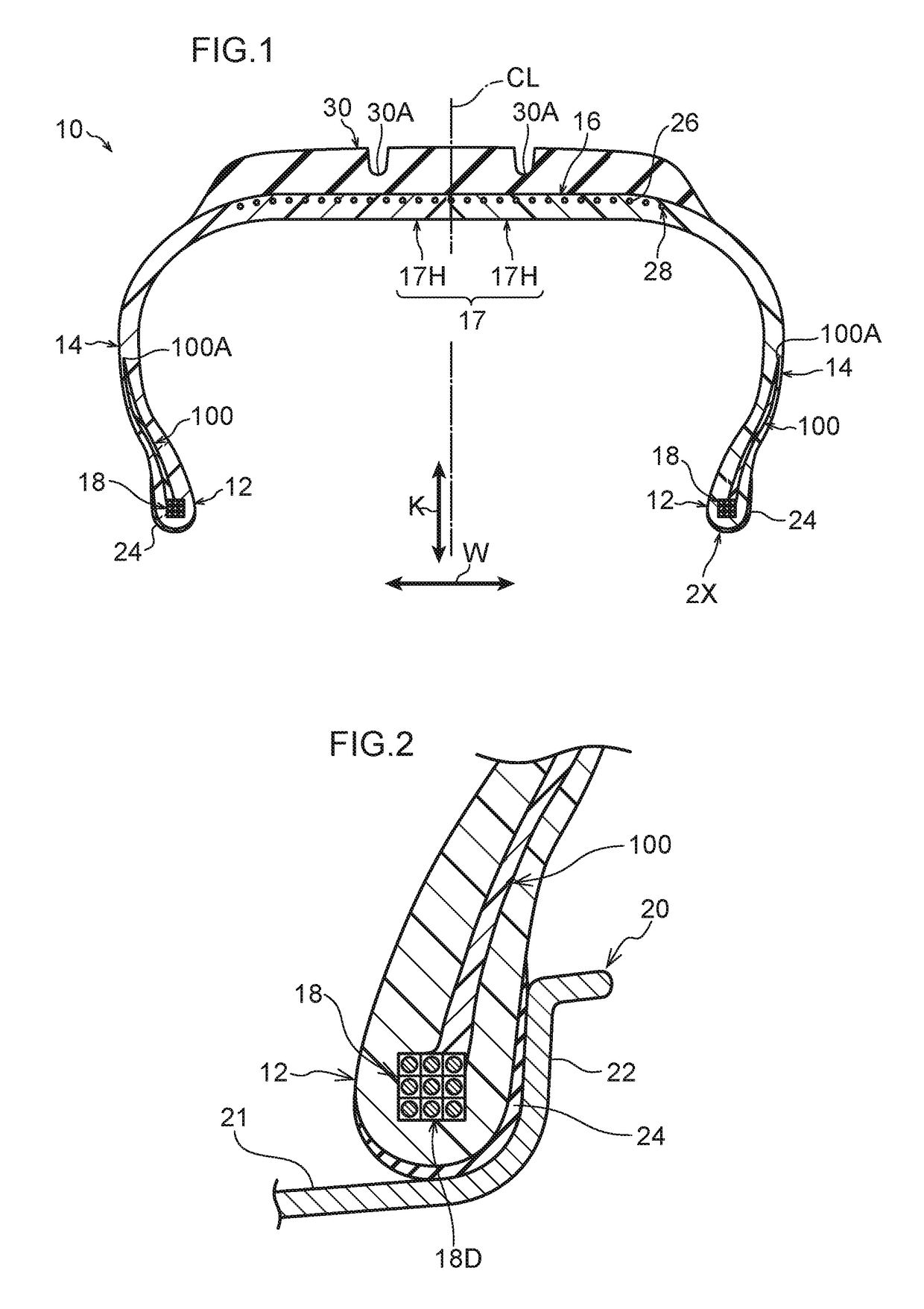

Tire and tire manufacturing method

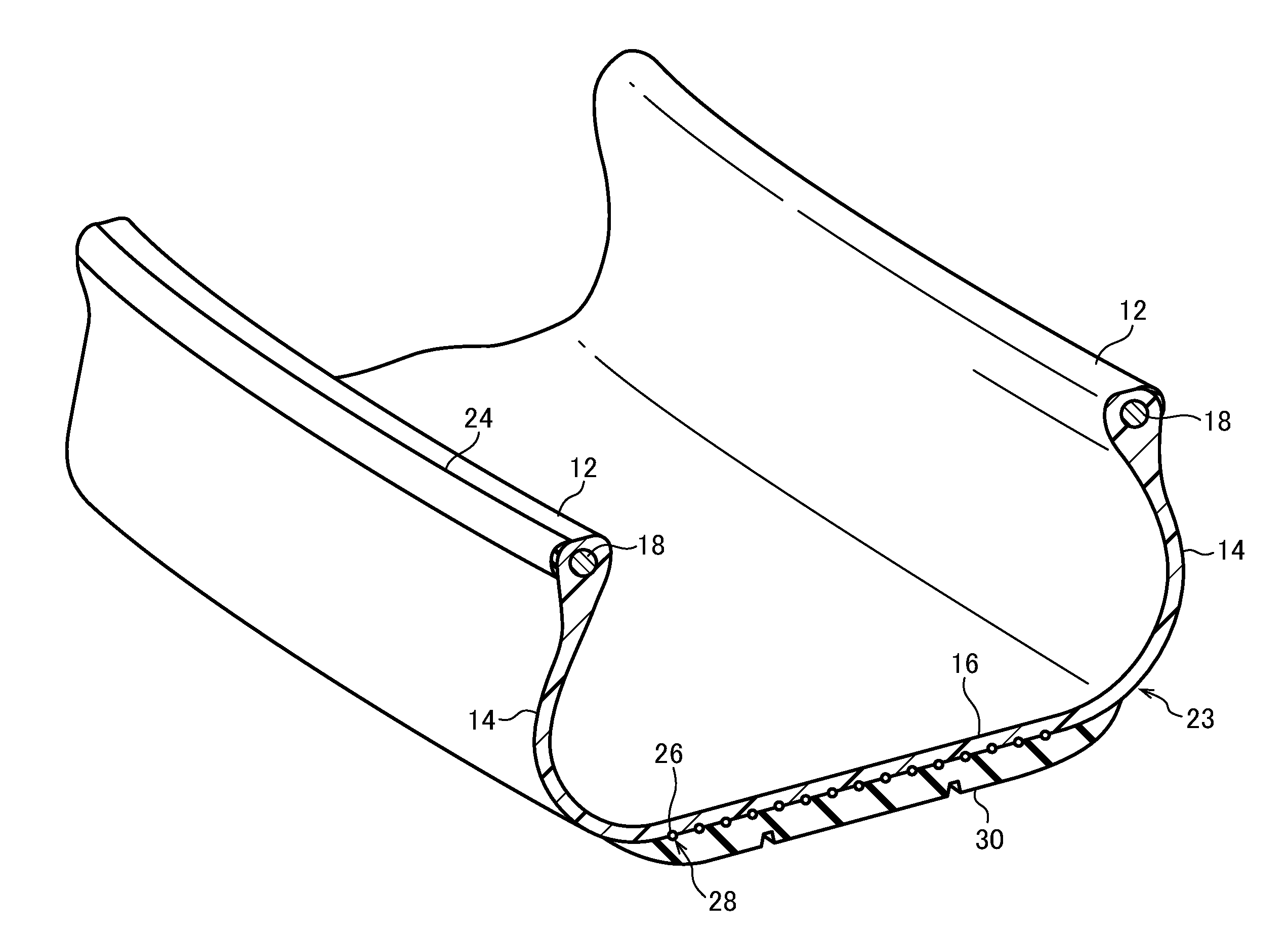

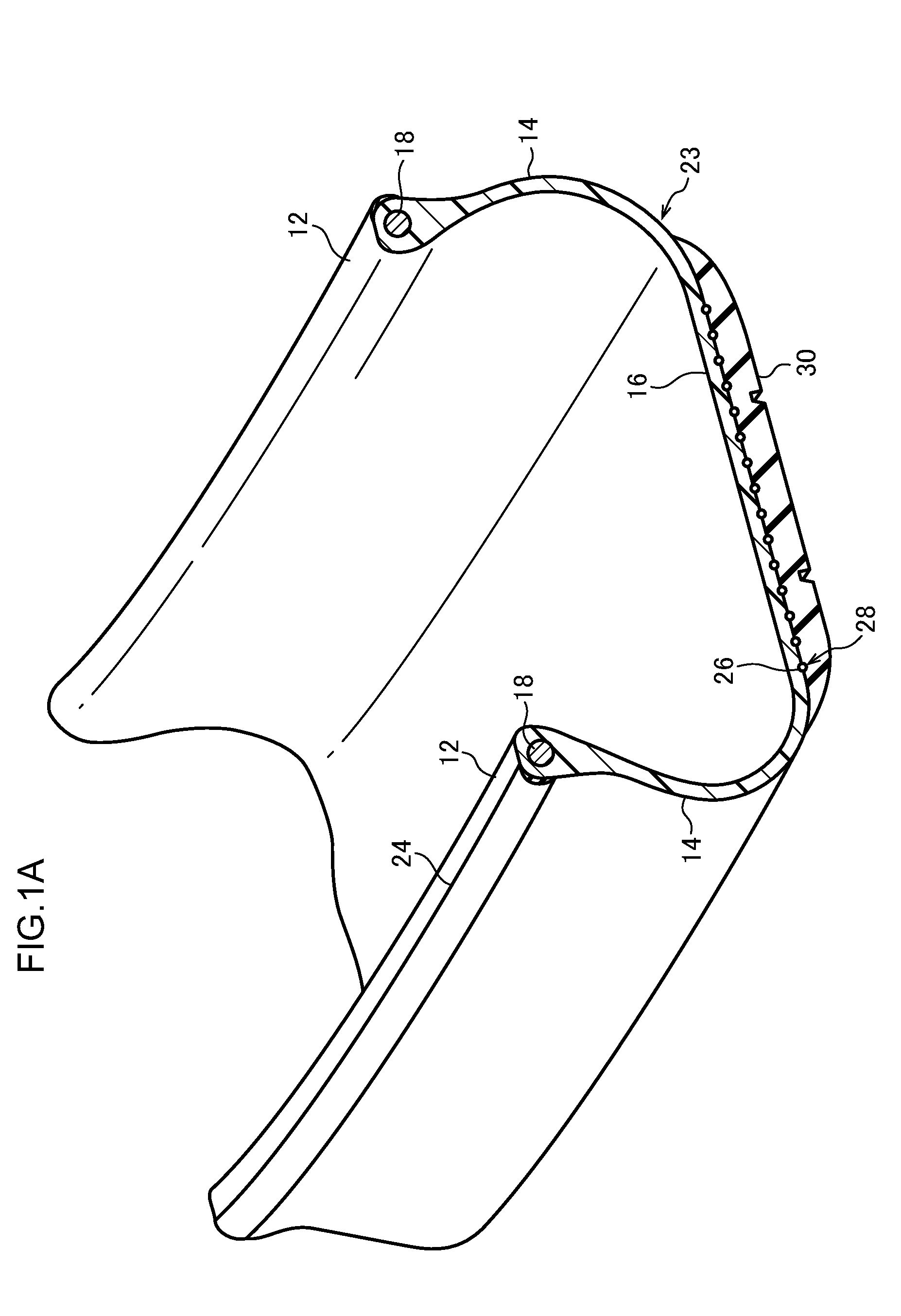

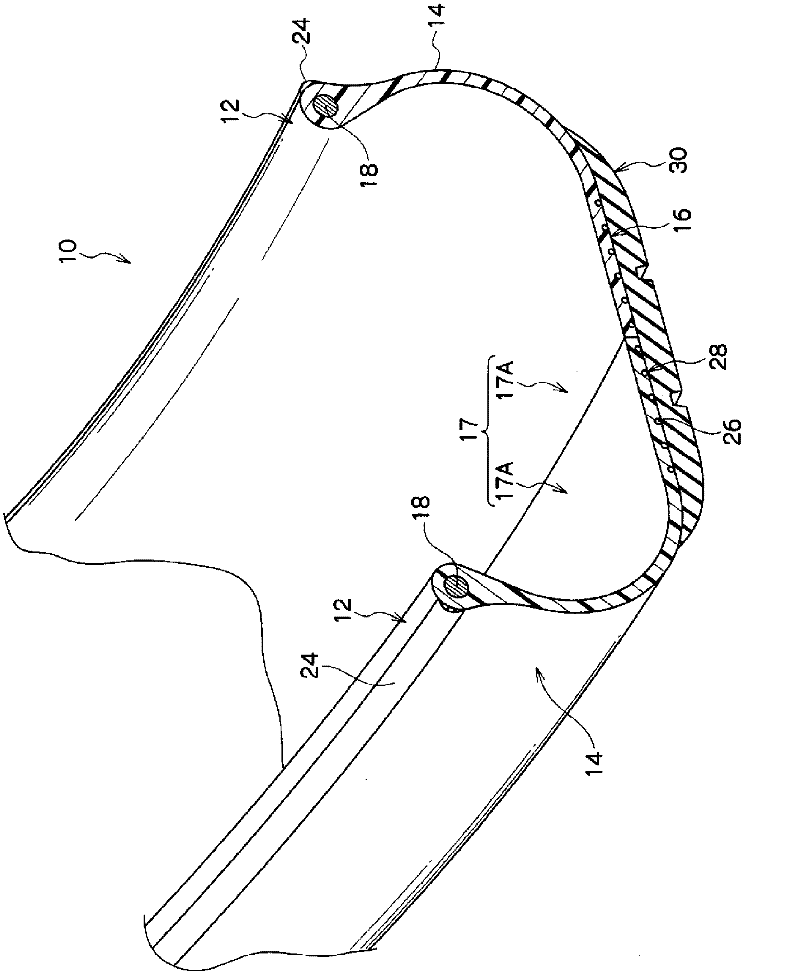

InactiveUS20120145301A1Improve joint strengthImprove performanceWithout cord reinforcementWith multiple inflatable chambersEngineeringUltimate tensile strength

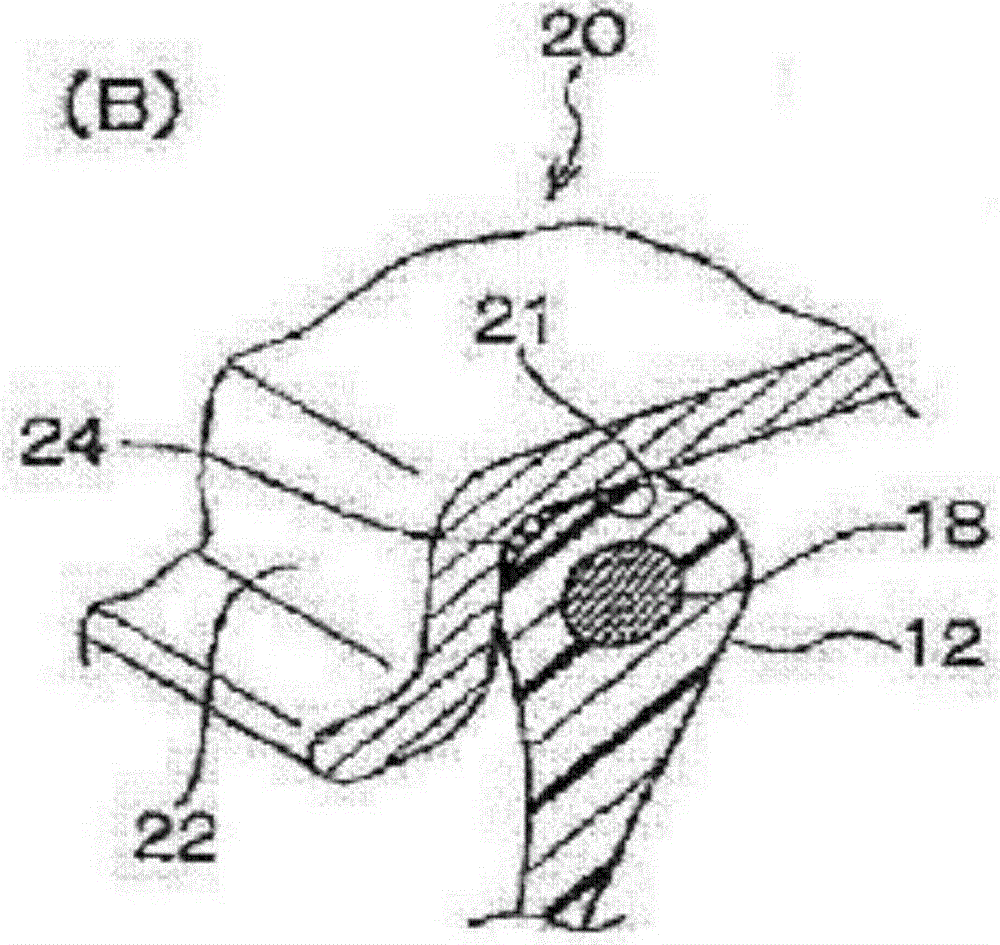

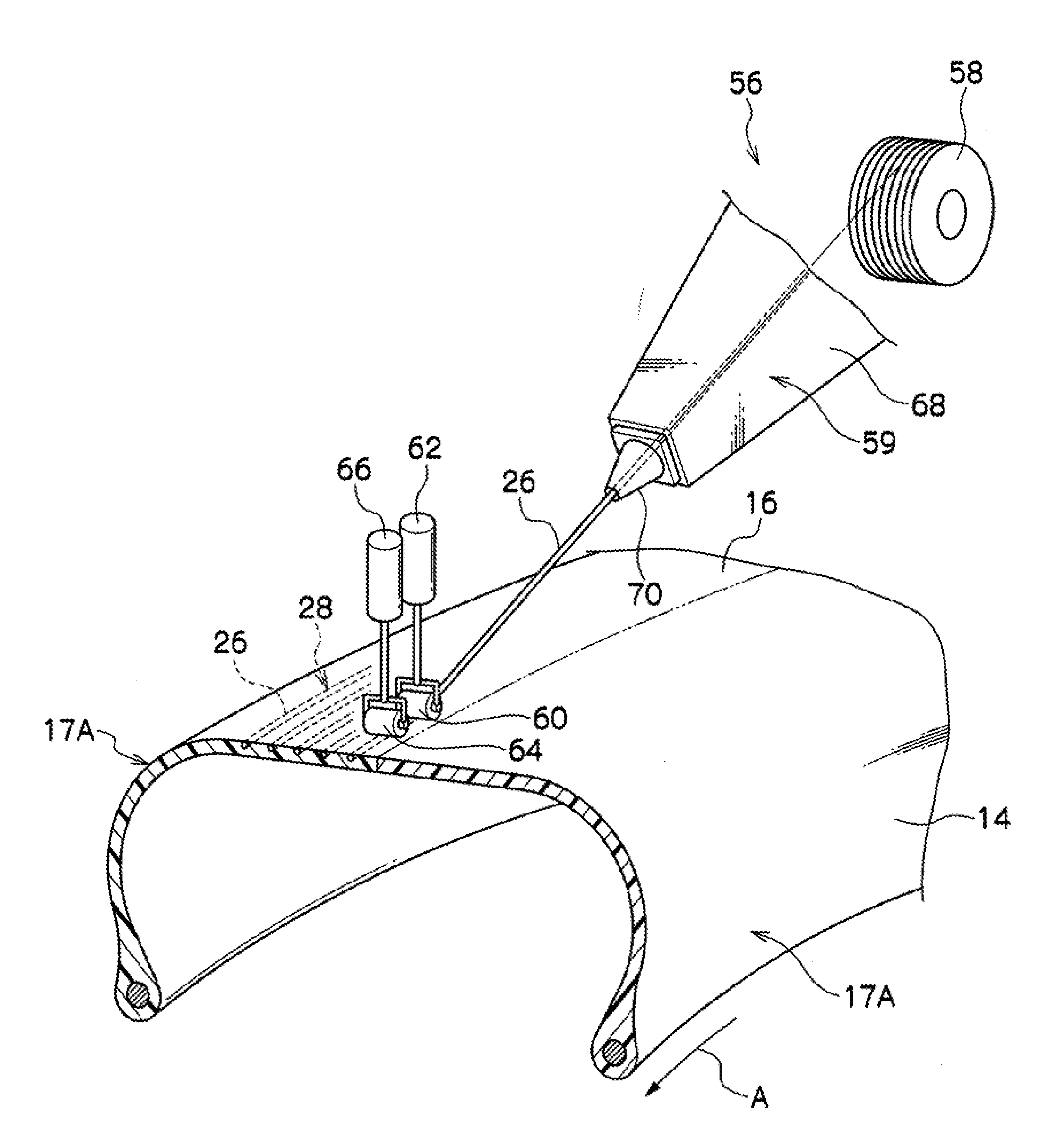

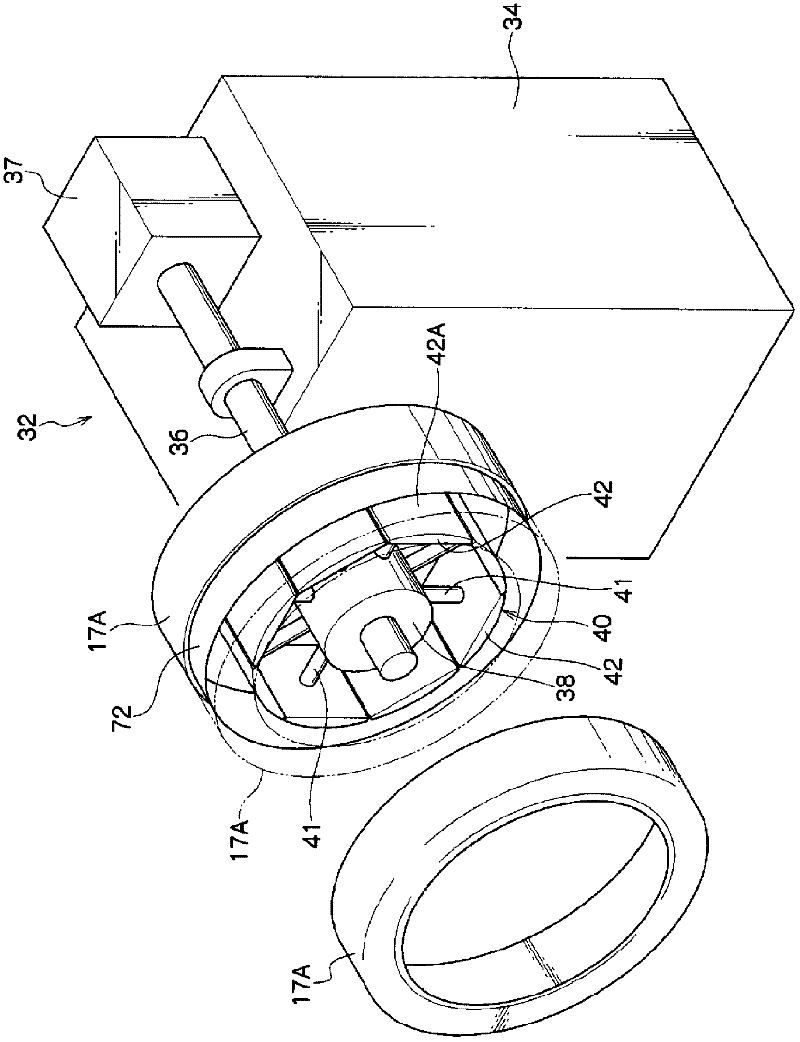

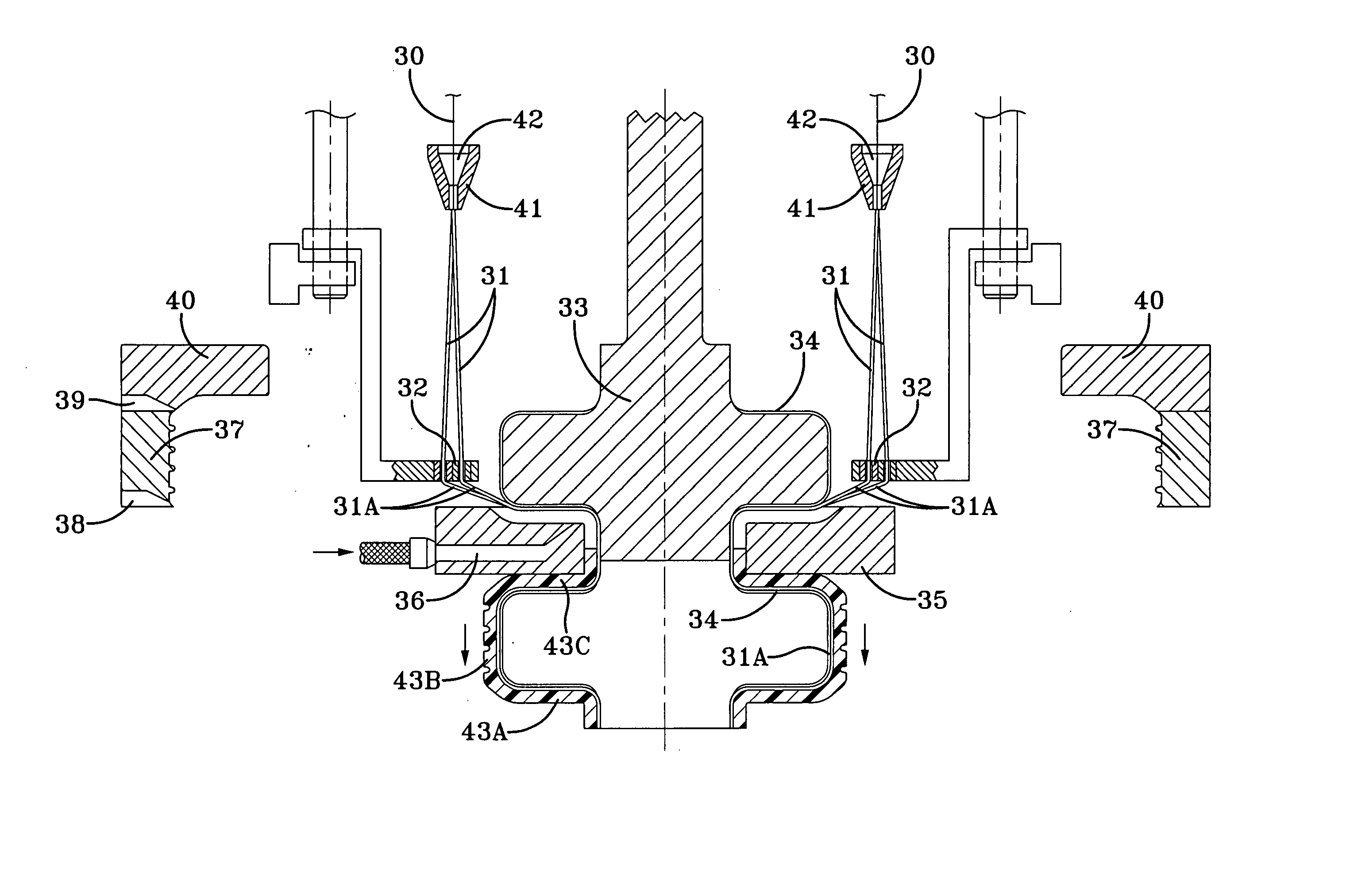

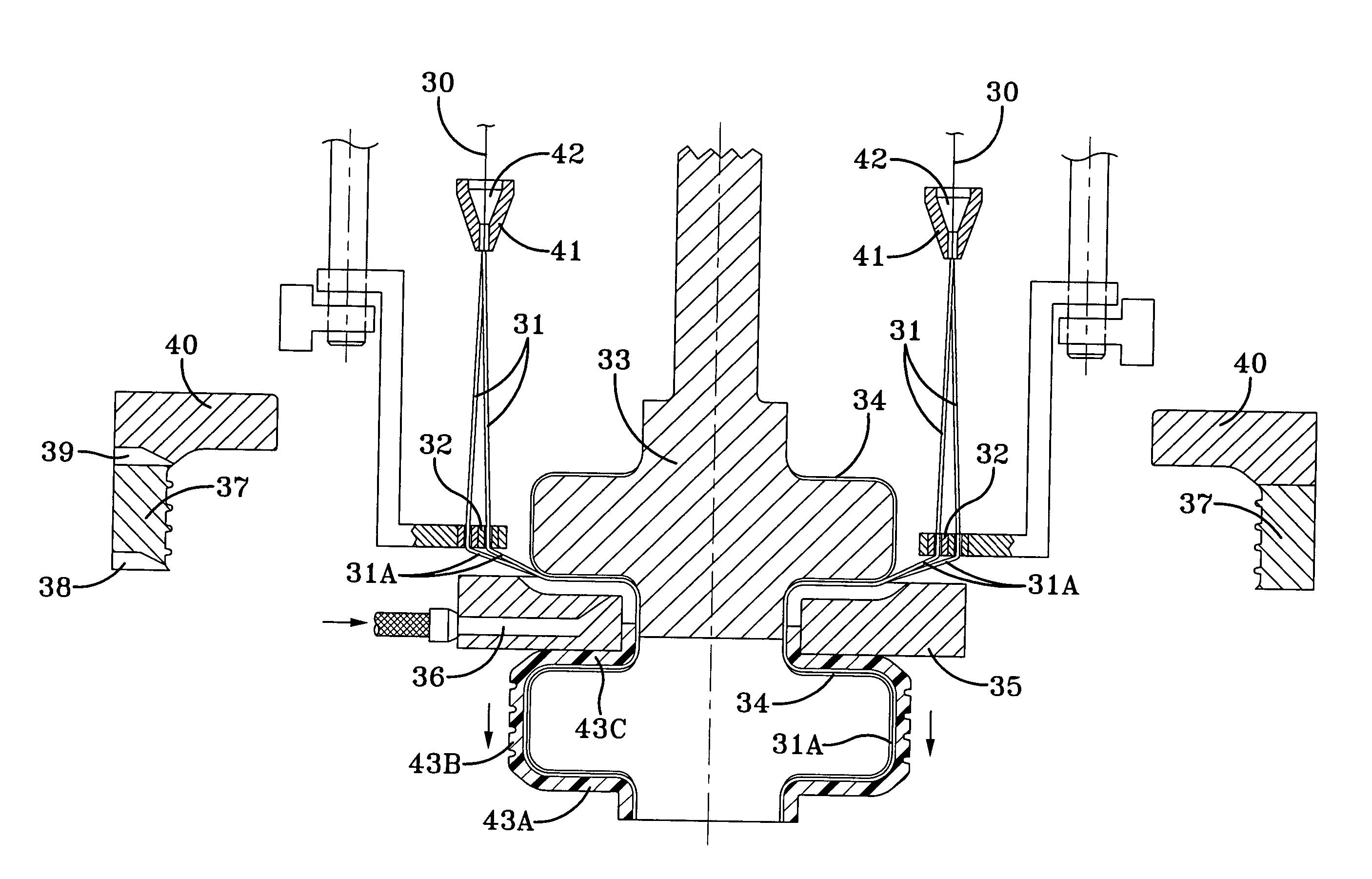

Sufficient strength of a joint portion is secured in a tire configured by joining together plural tire structuring members formed from a thermoplastic material.A welding thermoplastic material 43 that has been melted is extruded towards joining locations on two tire halves 17A formed from a first thermoplastic material that have been aligned so as to face each other and abut, such that the one tire half 17A and the other tire half 17A are welded together with the welding thermoplastic material 43. Degradation of the thermoplastic material forming the tire halves 17A is suppressed since the tire halves 17A are not themselves melted, and sufficient strength of the joint portion is secured.

Owner:BRIDGESTONE CORP

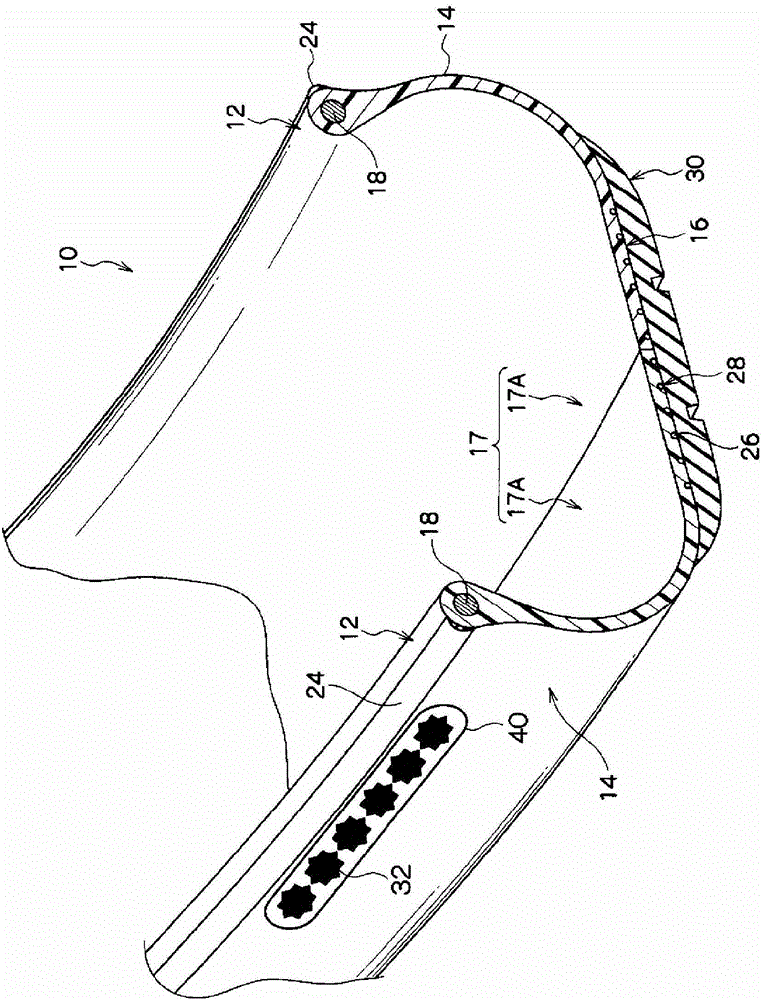

Tire and tire manufacturing method

ActiveUS20110297290A1High strengthEfficient preparationWithout cord reinforcementWith multiple inflatable chambersEngineeringUltimate tensile strength

A tire configured from joining together plural tire frame members formed from a thermoplastic material in which sufficient strength of the joint portion is secured. Two tire halves 17A formed from a first thermoplastic material are supported by a tire supporting section 40 so as to be aligned with each other and abutting, while rotating this configuration melted welding thermoplastic material 43 is extruded from a nozzle 46 towards the joining location, and the welding thermoplastic material 43 is pressed by a flattening roller 48. The one tire half 17A and the other tire half 17A are thereby welded together with the welding thermoplastic material 43. Since the tire halves 17A themselves are not melted, deterioration of the thermoplastic material forming the tire halves 17A is suppressed, and sufficient strength of the joint portion is secured.

Owner:BRIDGESTONE CORP

Air no air elastomeric tire

InactiveUS20050269005A1Improve carrying capacityUniform thicknessWithout cord reinforcementNon-inflatable tyresAeroelasticityEngineering

An elastomeric tire for mounting onto a rim that is manufactured by casting or molding methods to include an exterior arch shaped cavity that is centered under and is below the tire tread to have at least one hundred forty (140) degrees and not more than one hundred seventy (170) degrees of arc from one tire rim mounting contact point, around the tire to another tire rim mounting contact point, and with the cavity arch duplicated around the tire interior. A uniform tire wall thickness is provided that is selected for a particular anticipated load as the tire will carry, with the tire side wall ends each maintained at one the rim opposing ends, supporting the load carried by the tire in compression, and with the tire, at atmospheric pressure, providing ride and wear characteristics that are comparable to a pressurized pneumatic tire carrying a like load, and which tire of the invention interior arch-shaped cavity can be pressurized to add to its inherent load supporting character to safely support even greater loads.

Owner:STEINKE RICHARD A

Tire

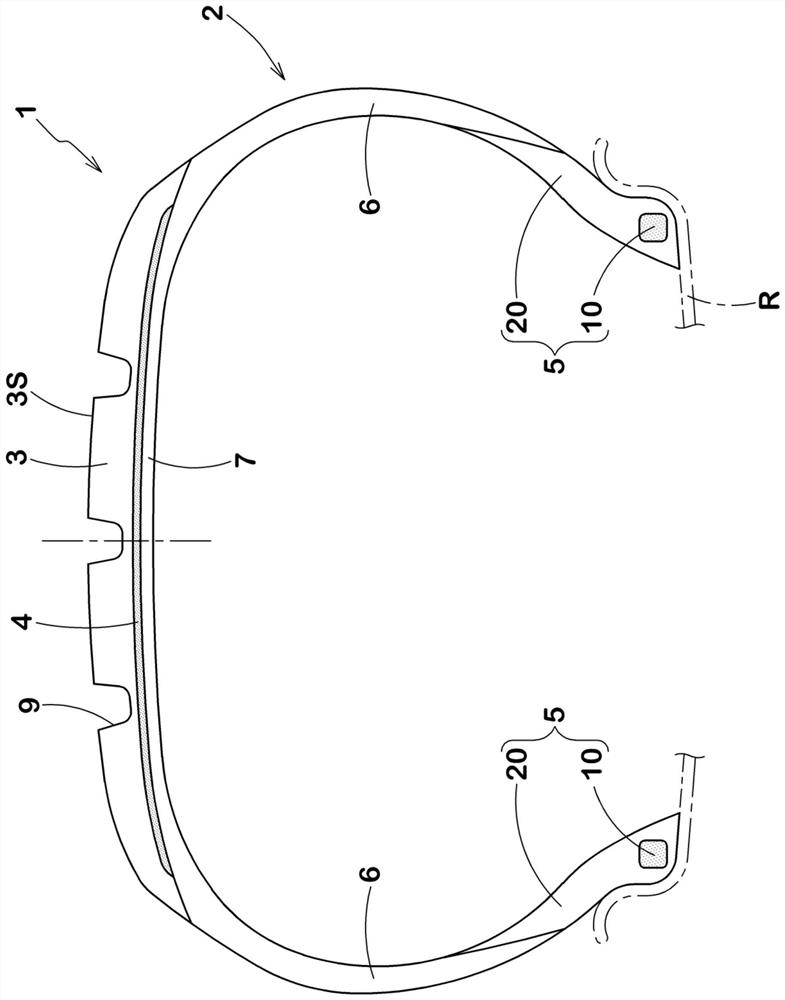

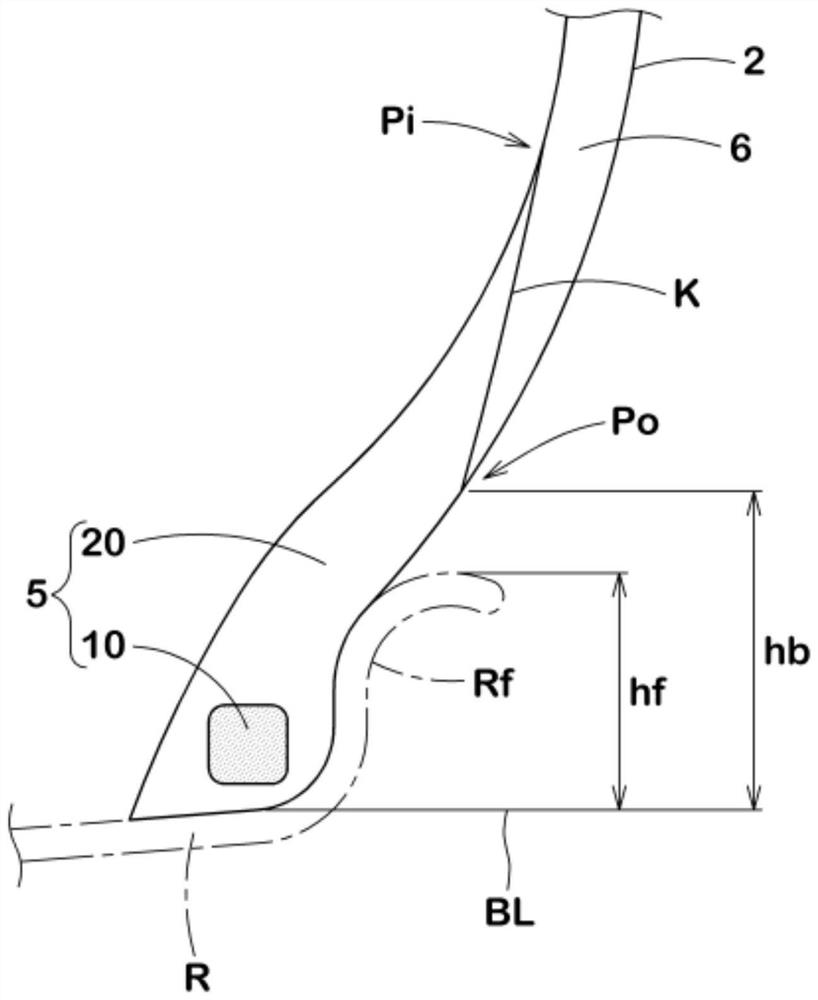

A tire includes: a tire frame member formed in a ring shape from a frame resin material, and including a pair of bead sections, a pair of side sections, and a crown section; a ring shaped bead core that is embedded in and joined to each of the bead sections, and that is formed by a single strand, or plurality of strands, of bead cord extending in the tire circumferential direction, and covered with, and joined to, a covering resin material; and an extension portion that extends from each of the bead cores in a direction that intersects with the tire circumferential direction when viewed from a tire side face, and that is joined to the tire frame member.

Owner:BRIDGESTONE CORP

Tire

InactiveUS20160075182A1Increased durabilityWithout cord reinforcementSpecial tyresAdhesiveThermoplastic elastomer

A tire (10) including: a circular tire frame (17) formed from a resin material; and a reinforcing metal cord member (27) that is wound on an outer circumference of the tire frame (17), at least a portion of the reinforcing metal cord member (27) being covered, via an adhesion layer including a solvent-based adhesive, with a covering composition that includes at least one thermoplastic material selected from the group consisting of a thermoplastic resin and a thermoplastic elastomer.

Owner:BRIDGESTONE CORP

Tire and tire manufacturing method

ActiveUS9440407B2Suppression problemIncreased durabilityWithout cord reinforcementWith separate inflatable insertsMechanical engineeringHelix

A tire includes a ring shaped tire case formed from a resin material, a reinforcement cord having a higher rigidity that that of the resin material, wound in a spiral shape on the outer peripheral section of the tire case and having at least a portion of the reinforcement cord embedded in and making close contact with the outer peripheral section of the tire case when viewed in a cross-section along the axial direction of the tire case and a tread provided on the radial direction outside of a reinforcement cord layer formed by the reinforcement cord.

Owner:BRIDGESTONE CORP

Tire

InactiveCN109195815AImprove fuel efficiencyImprove maneuverabilityWithout cord reinforcementSpecial tyresEngineeringRoad surface

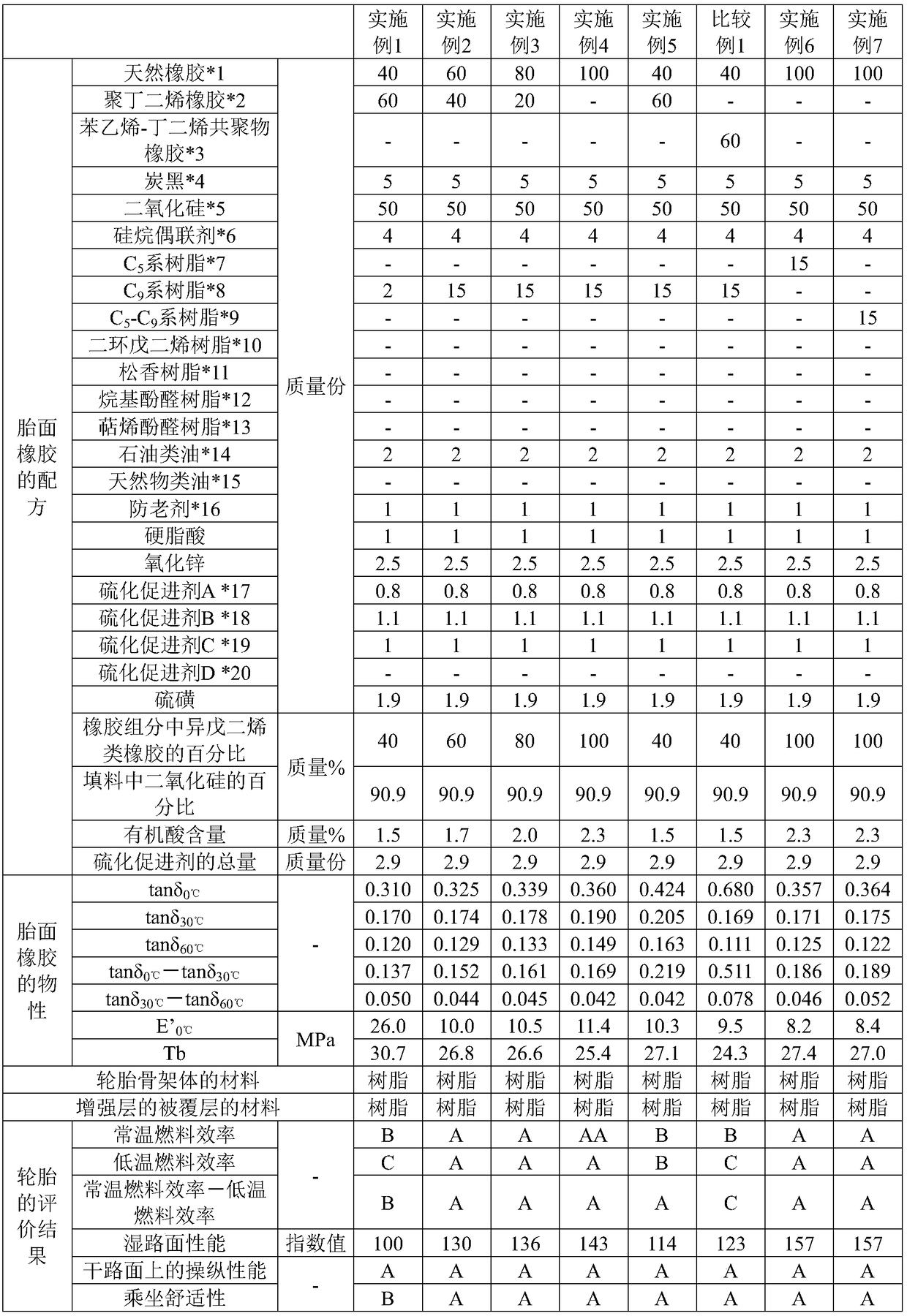

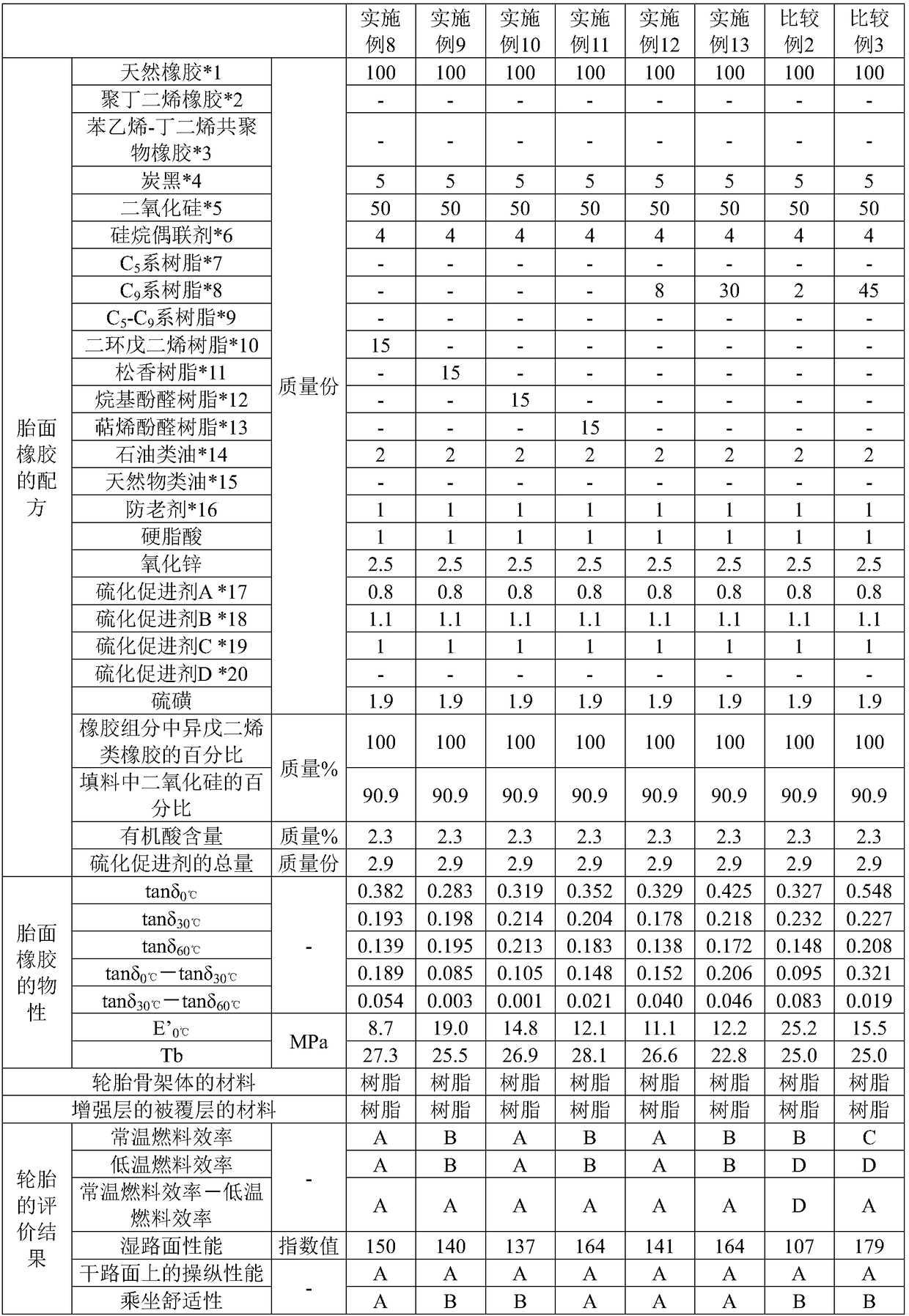

The present invention provides a tire that uses a resin material and still has improved ride comfort, improved dry handling performance, and favorable fuel consumption performance, without losing wetperformance. The tire is characterized by comprising an annular tire skeleton body (10); a reinforcing layer (20) that is provided to the outside of the tire skeleton body (10) in the radial directionof the tire; and tread rubber (30) that is provided to the outside of the reinforcing layer (20) in the radial direction of the tire. The reinforcing layer (20): is a resin composition that includes50-100 mass% of a resin material; and coats a reinforcing member (21). The storage modulus (E'0 DEG C) of the tread rubber 30 at 0DEG C and a strain of 1% is 30 MPa or lower, the loss tangent (tan delta 0 DEG C) thereof at 0DEG C and a strain of 1% is 0.5 or lower, and the value (tan delta 30 DEG C-tan delta 60 DEG C) of subtracting the loss tangent (tan delta 60 DEG C) thereof at 60DEG C and a strain of 1% from the loss tangent (tan delta 30 DEG C) thereof at 30DEG C and a strain of 1% is 0.08 or lower.

Owner:BRIDGESTONE CORP

Tire

ActiveUS20150053323A1Excellent adhesion durabilityIncreased durabilityWithout cord reinforcementSpecial tyresEngineering

A tire including a circular tire frame formed of a resin material, and a metal reinforcing cord member wound on the outer circumference of the tire frame, wherein at least a portion of the metal reinforcing cord member is covered by a covering mixture including at least an olefin-based thermoplastic resin and a thermoplastic resin other than the olefin-based thermoplastic resin.

Owner:BRIDGESTONE CORP

Tire and tire manufacturing method

ActiveCN102470697AFast curingSuppress buoyancyWithout cord reinforcementWith multiple inflatable chambersEngineeringUltimate tensile strength

The present invention provides a tire configured by joining together tire forming members consisting of a thermoplastic material, wherein the joined sections have sufficient strength. A molten thermoplastic material (43) for welding is extruded toward the portions to be joined of two half tire bodies (17A) which are butted against each other face to face and consist of a first thermoplastic material, and one half tire body (17A) and the other half tire body (17A) are welded together by the thermoplastic material (43) for welding. The half tire bodies (17A) are welded together without melting the half tire bodies (17A), and as a result, the thermoplastic material which forms the half tire bodies (17A) is prevented from degrading and the joined portions have sufficient strength.

Owner:BRIDGESTONE CORP

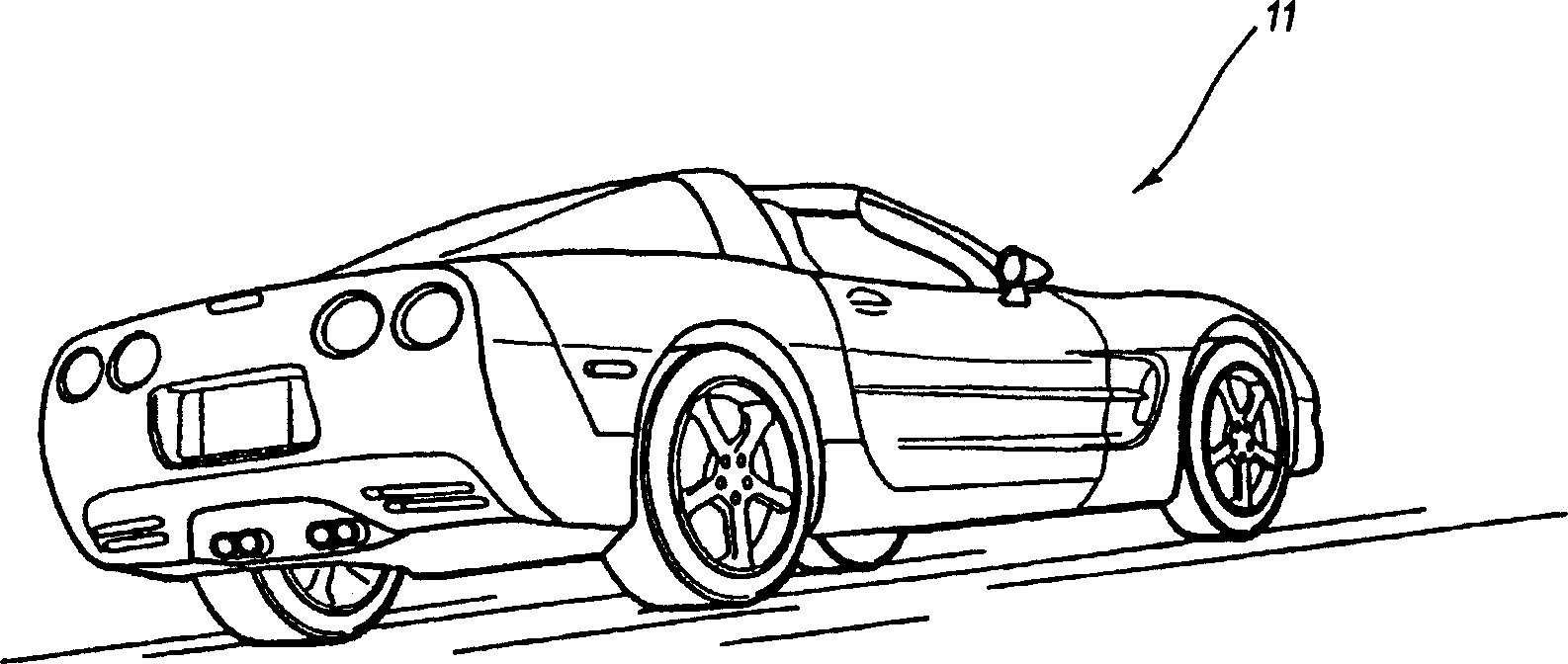

Manufacturing method for a reinforced liquid elastomer tire

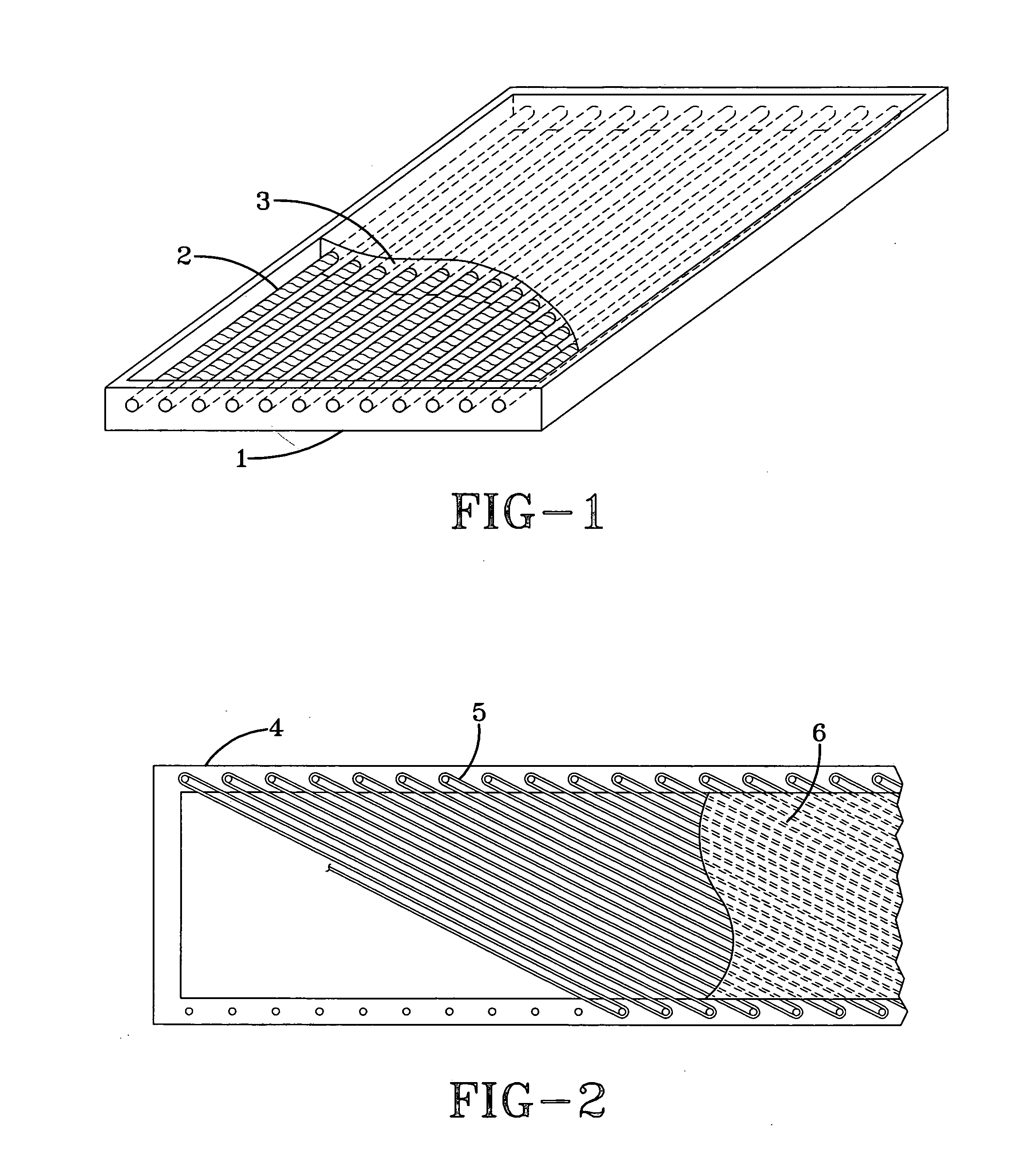

InactiveUS20060151916A1Improve interface adhesionReduce the possibilityWithout cord reinforcementTyresElastomerEngineering

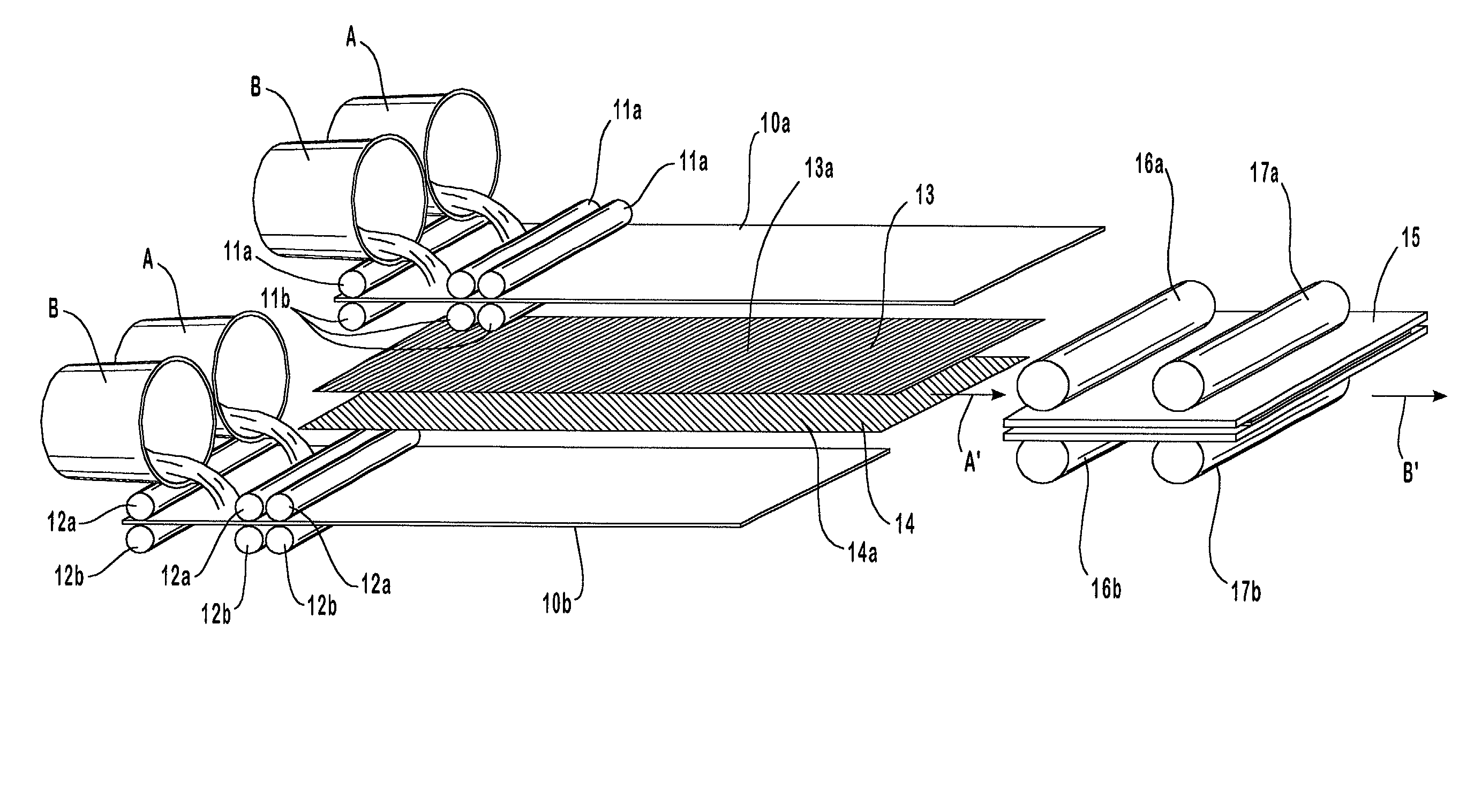

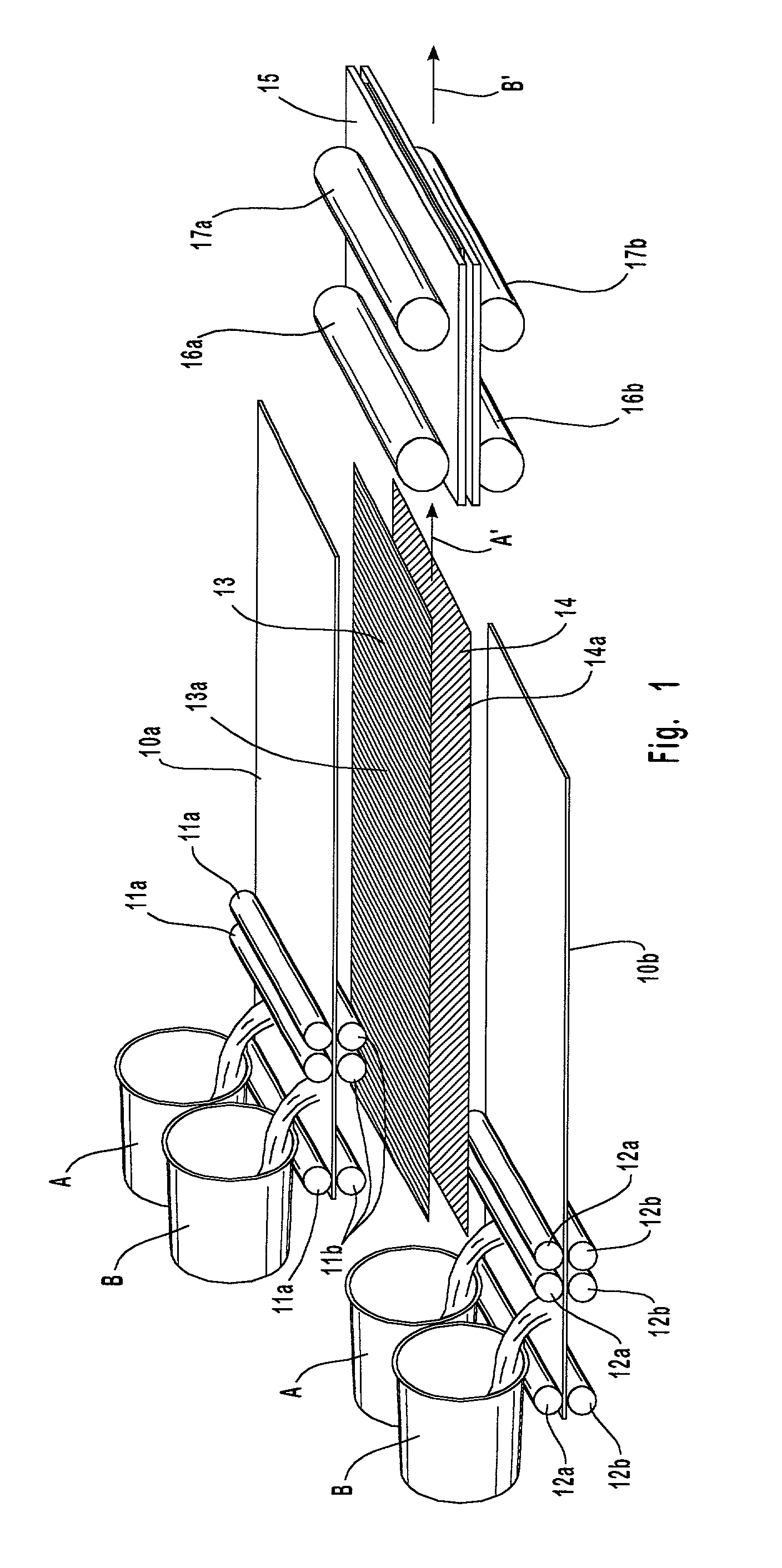

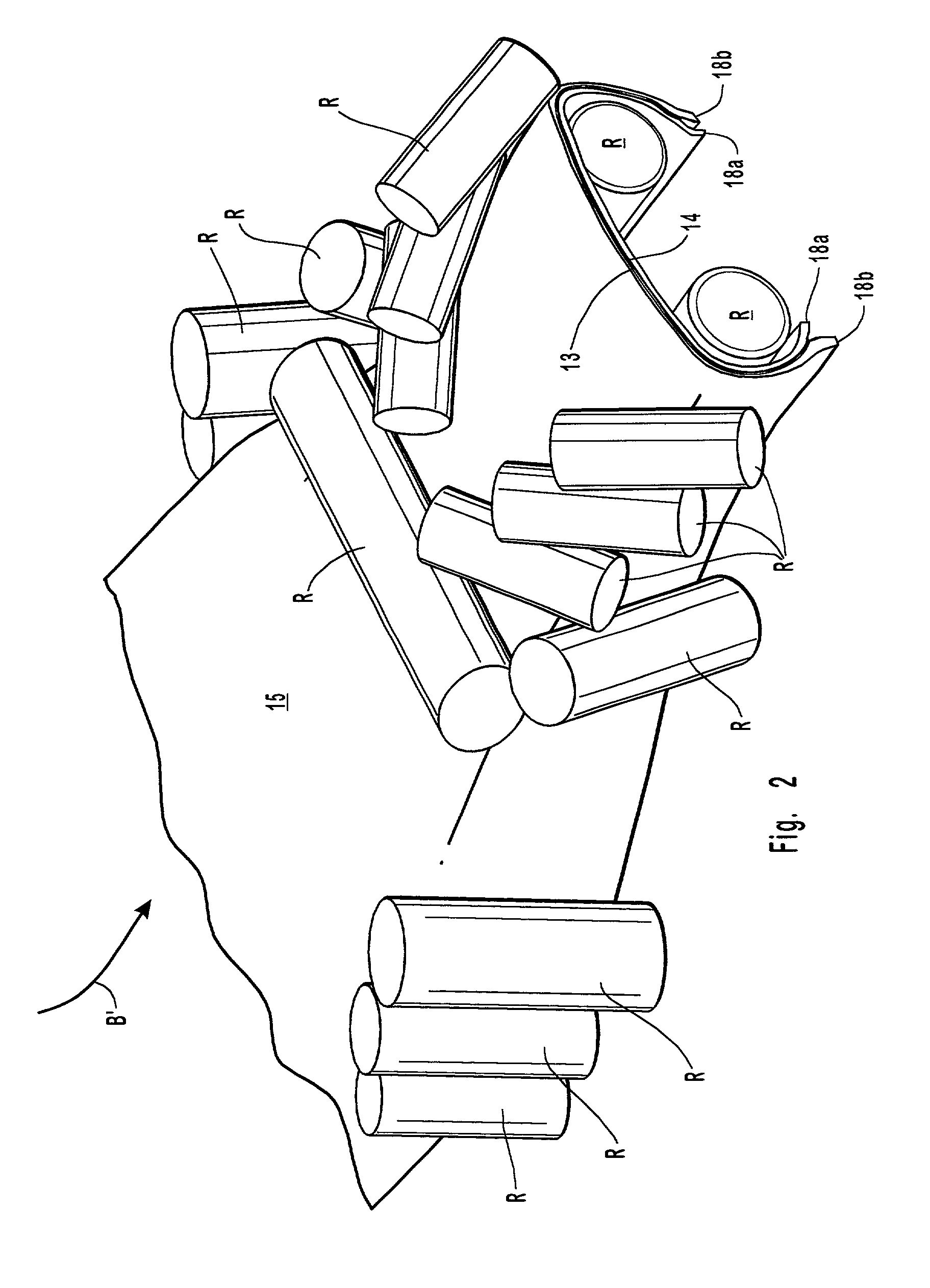

This invention pertains to a new method for manufacturing tires, an apparatus used with the new method and the article manufactured by the new method. The article is called the reinforced liquid elastomer tire (RLET). The method of manufacture includes placement of reinforcing materials inside a tire molding cavity and subsequently surrounding the reinforcement with a liquid elastomer which encapsulates the reinforcement and takes the outside shape of the tire mold. The liquid elastomer is solidified and the completed RLET is removed from the mold and ready for service.

Owner:VANNAN FREDERICK FORBES

Tire and tire manufacturing method

ActiveCN103338946AEasy to manufactureEfficient manufacturingWithout cord reinforcementTyresPigmentColoring agents

To easily manufacture a tire the color of which does not fade due to traveling, a tire case (17) which is a tire (10) structural member is formed by injection molding using a colored first thermoplastic material which contains a pigment. A tire the color of which does not fade due to traveling can be easily manufactured.

Owner:BRIDGESTONE CORP

Tire

ActiveCN108367595AExcellent rim fitImprove impact performanceWithout cord reinforcementNon-inflatable tyresThermoplastic elastomerPolyamide

Disclosed is a tire which is provided with: an annular tire carcass that contains a polyamide-based thermoplastic elastomer which has a hard segment and a soft segment and wherein the hard segment contains a copolymer of a dicarboxylic acid having 4 to 12 carbon atoms (inclusive) and a diamine having 4 to 12 carbon atoms (inclusive) and the soft segment contains a polyamine; and a reinforcing cordlayer that contains a reinforcing cord member which is wound around an outer circumferential part of the tire carcass in the tire circumferential direction at an average interval of from 0.4 mm to 3.2 mm (inclusive) in the tire width direction.

Owner:BRIDGESTONE CORP

Reinforced liquid elastomer tire and manufacturing method and apparatus for manufacture

InactiveUS20050067078A1Improve interface adhesionReduce the possibilityWithout cord reinforcementTyresElastomerEngineering

This invention pertains to a new method for manufacturing tires, an apparatus used with the new method and the article manufactured by the new method. The article is called the reinforced liquid elastomer tire (RLET). The method of manufacture includes placement of reinforcing materials inside a tire molding cavity and subsequently surrounding the reinforcement with a liquid elastomer which encapsulates the reinforcement and takes the outside shape of the tire mold. The liquid elastomer is solidified and the completed RLET is removed from the mold and ready for service.

Owner:VANNAN FREDERICK FORBES

Elastomeric tire with arch shaped shoulders

InactiveCN1906045ASafe and reliable supportIncreasing the thicknessWithout cord reinforcementNon-inflatable tyresElastomerSpin casting

An elastomeric tire with arch shaped shoulders for mounting onto a rim that is manufactured by spin casting or molding methods that includes an annular cavity that is centered under the tire tread having equal thicknesses of side walls and an area under the tread whose slope outwardly into shoulder that the side walls upper ends intersect that have greater thickness and which side walls lower ends include beads that are each spaced a selected distance from the surfaces of the side wall ends that slope upwardly from inner to outer surfaces and with the tire preferably including plies that extend across the tire having ends that wrap around the beads and belts fitted around the tire circumference, above the plies, and including porous spacers fitted between the layers of plies and belts to pass a flow of the elastomeric material therethrough during tire formation.

Owner:理查德·A·施泰因克

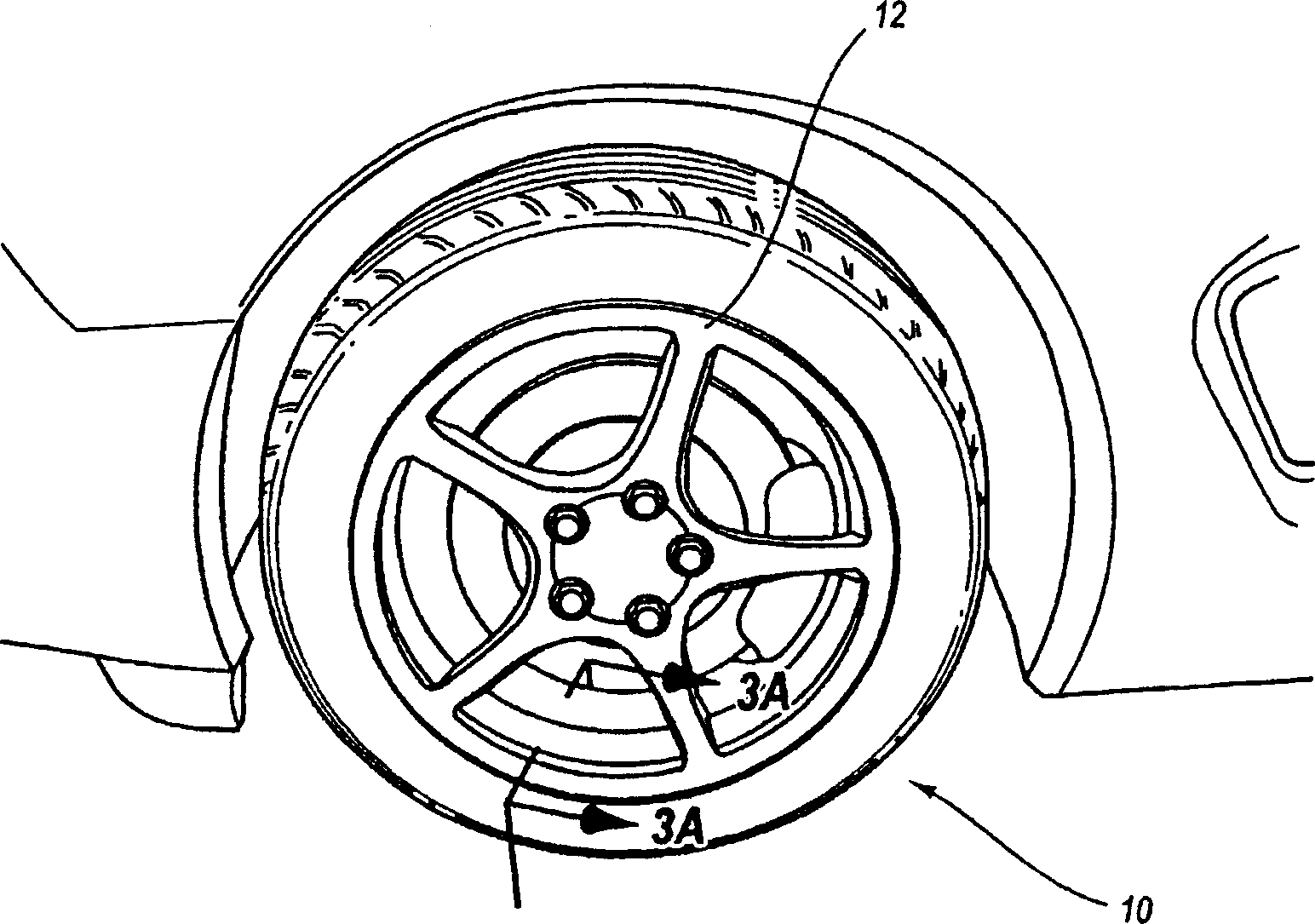

Steel-bone tire

InactiveCN101491998AWithout cord reinforcementPneumatic tyre reinforcementsState of artAtmospheric pressure

The invention relates to a steel rib tire, which overcomes the defects of easy pricking leak, easy tire burst, requirement of reaeration, non gunslinging resistance, complicated processing and high cost of the prior vehicle tires. The steel rib tire is characterized in that one end of a steel plate 3 is connected with a steel sheet ring 2, while the other end is connected to the inside of a tire ring 4; both ends of an annular hook slot ring 5 are connected to the inside of the tire ring 4 respectively; an annular rubber air holding ring 6 is connected to the inside of the annular hook slot ring 5; a pressing ring 7 is connected to the inside of the annular rubber air holding ring 6; and an inflating nozzle 8 is connected to the annular rubber air holding ring 6. The steel rib tire is arranged on the wheel rim of a vehicle, and can be used after being inflated with standard air pressure through the inflating nozzle 8. The steel rib tire has gunslinging resistance, and the problems of tire burst and pricking leak do not exist, so that the steel rib tire achieves no tire patching and tire pasting truly, and overcomes the defects of complicated processing, high cost, easy pricking, easy tire burst and gunslinging fear of the rubber tire. The steel rib tire fills a blank of the tire manufacturing industry, and provides reliable and safe technology for the safe running of the vehicles. The technology fills the blank of the prior art, and is suitable for processing the steel rib tires.

Owner:尹博功

Tire

A tire includes: a tire frame member formed in a ring shape from a frame resin material, and including a pair of bead sections, a pair of side sections, and a crown section; a ring shaped bead core that is embedded in and joined to each of the bead sections, and that is formed by a single strand, or plurality of strands, of bead cord extending in the tire circumferential direction, and covered with, and joined to, a covering resin material; and an extension portion that extends from each of the bead cores in a direction that intersects with the tire circumferential direction when viewed from a tire side face, and that is joined to the tire frame member.

Owner:BRIDGESTONE CORP

Pneumatic tire

ActiveCN113543989AIncreased durabilityImprove recycling effectWithout cord reinforcementTyre beadsTire beadEngineering

This pneumatic tire makes it possible to improve production efficiency while ensuring engagement with a rim, and to increase material recyclability. A pair of bead parts 5 are each configured by an annular bead core 10 comprising a thermoplastic resin, and a bead core coating part 20 comprising a thermoplastic resin.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com