Tire/wheel assembly and tread ring

A technology for assemblies and tread rings, applied to tire treads/tread patterns, pneumatic tires, tire parts, etc., can solve problems such as gas reduction, achieve the effects of suppressing deformation, improving driving performance, and suppressing tire blowouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

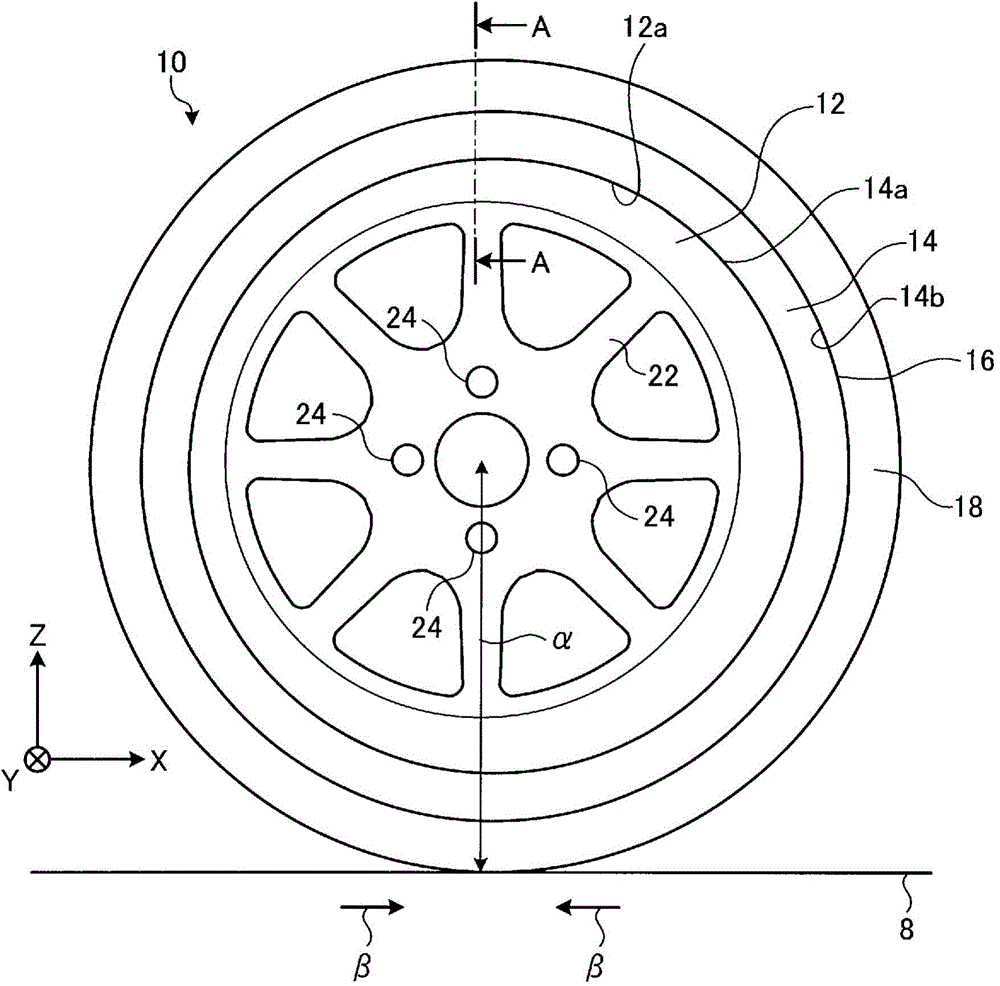

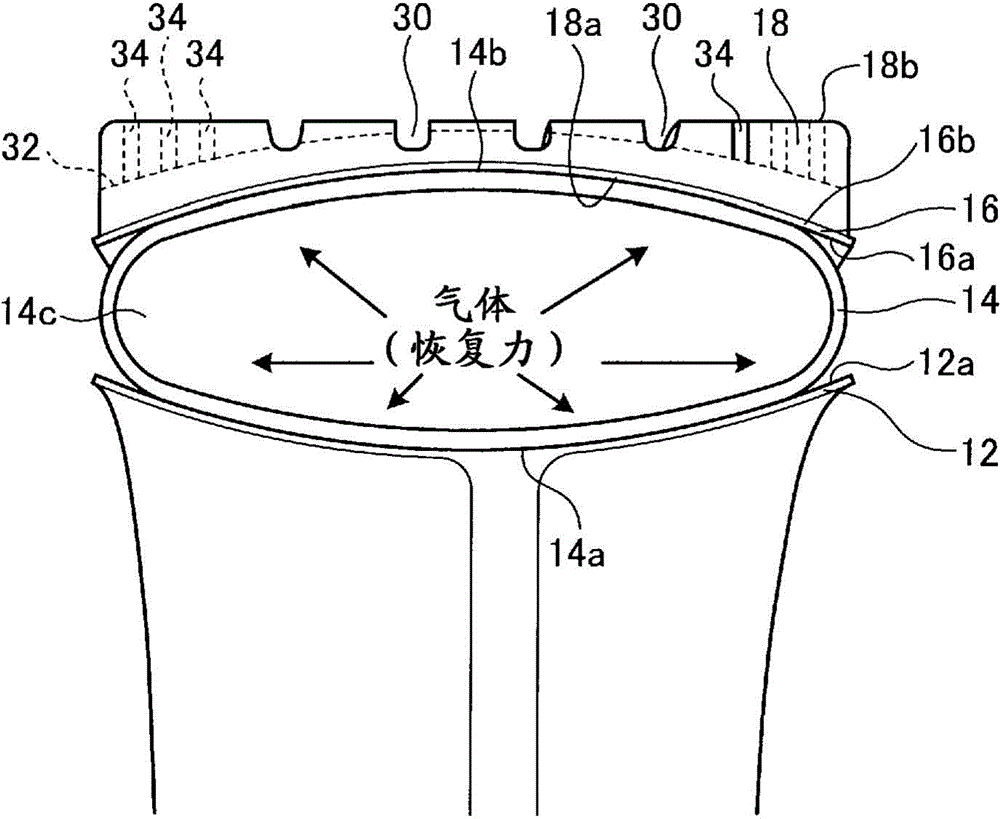

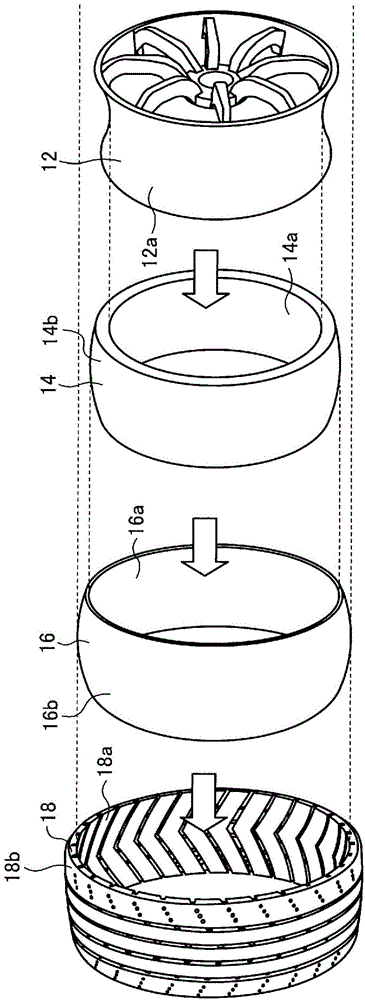

[0052] figure 1 It is a side view showing the schematic structure of an example of the tire / wheel assembly of this embodiment. figure 2 Yes figure 1 The A-A line sectional view in. image 3 Yes figure 1 An exploded perspective view of the tire / wheel assembly shown. Here, the A-A line sectional view is a meridian sectional view of the tire / wheel assembly. The meridian cross section is a cross section when the tire / wheel assembly 10 is cut on a plane parallel to and including the rotation axis of the tire / wheel assembly 10 . In the meridian section, since the tire / wheel assembly 10 is axisymmetric with respect to the rotation axis, the symmetrical side is shown in the present embodiment.

[0053] The tire / wheel assembly 10 rotates around a center axis (Y axis) as a rotation axis. The Y axis is the central axis of the tire / wheel assembly 10 and is the axis of rotation of the tire / wheel assembly 10 . Let the axis perpendicular to the Y-axis, which is the central axis (rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com