Patents

Literature

241results about "Bicycle tyres" patented technology

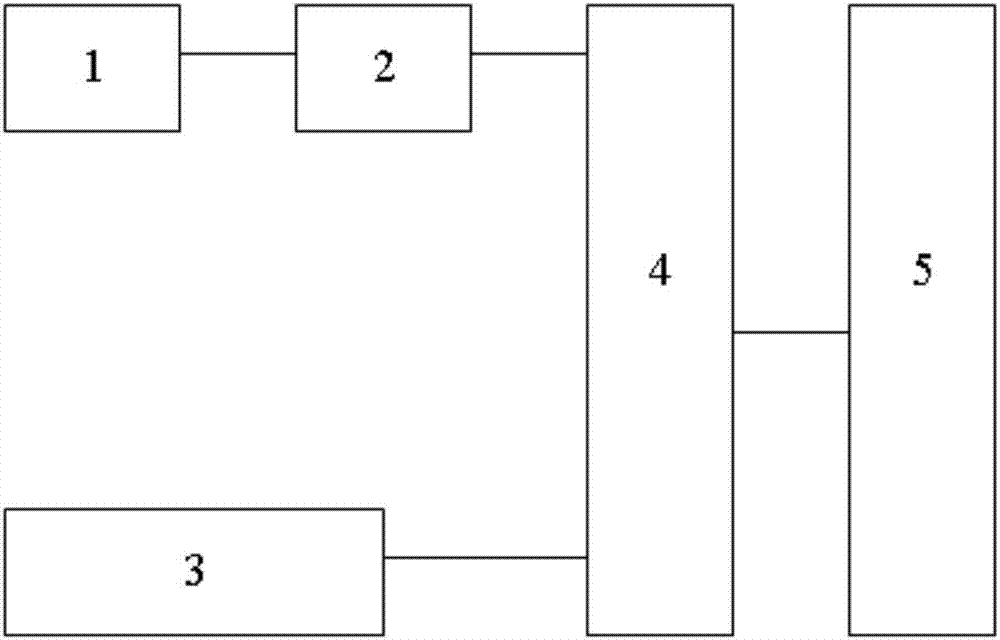

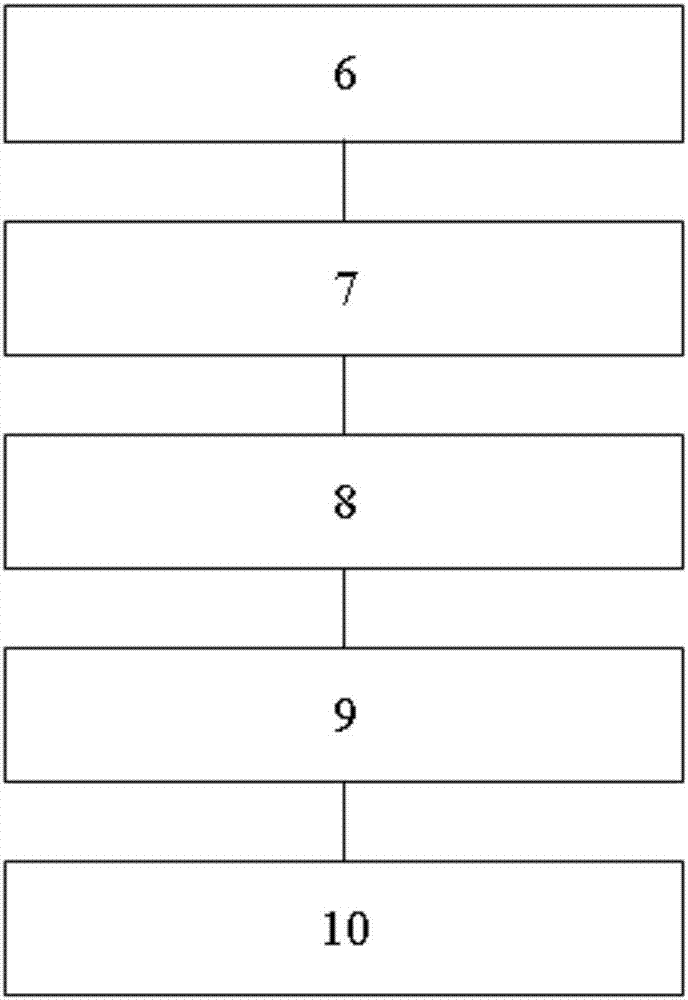

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

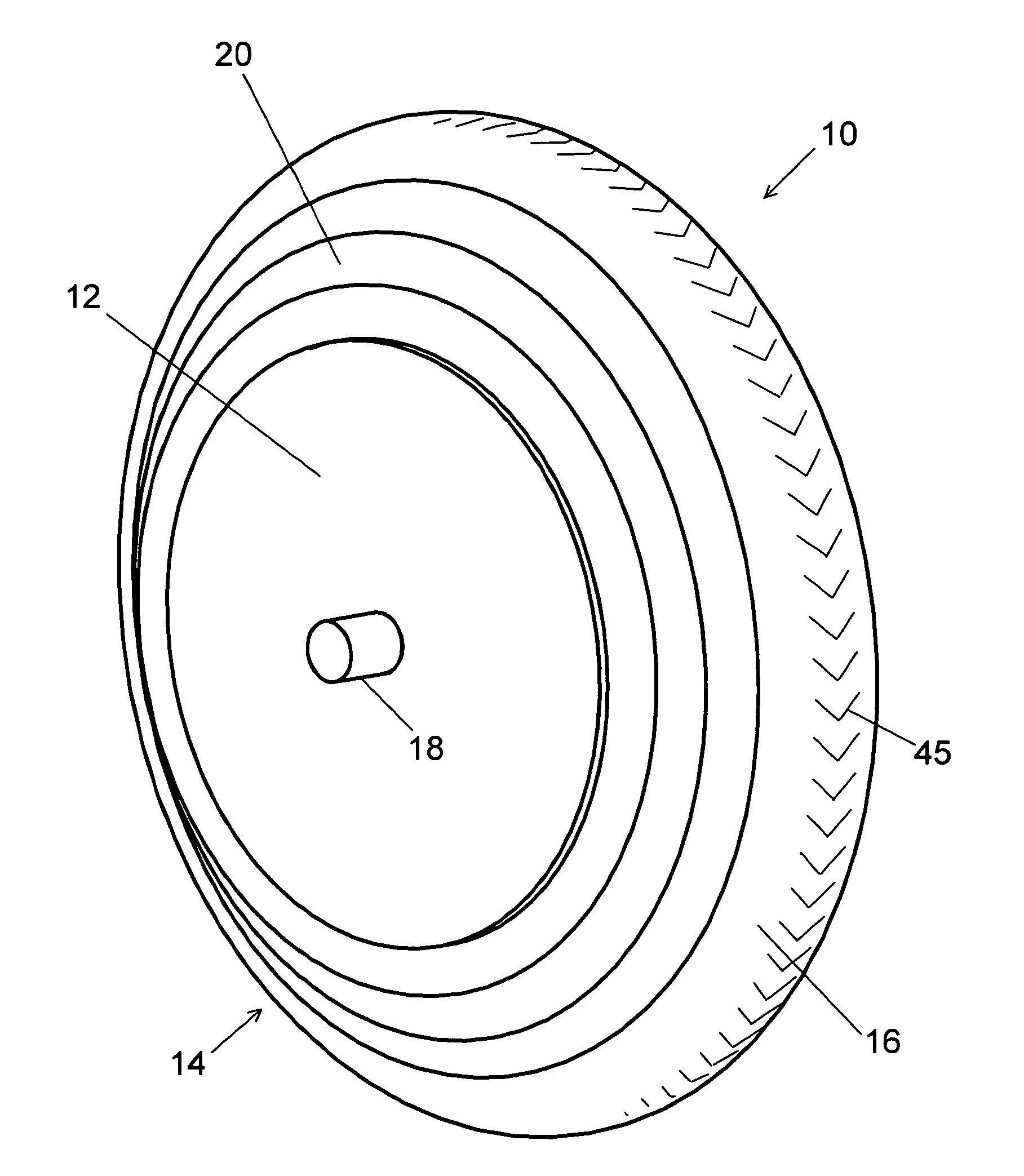

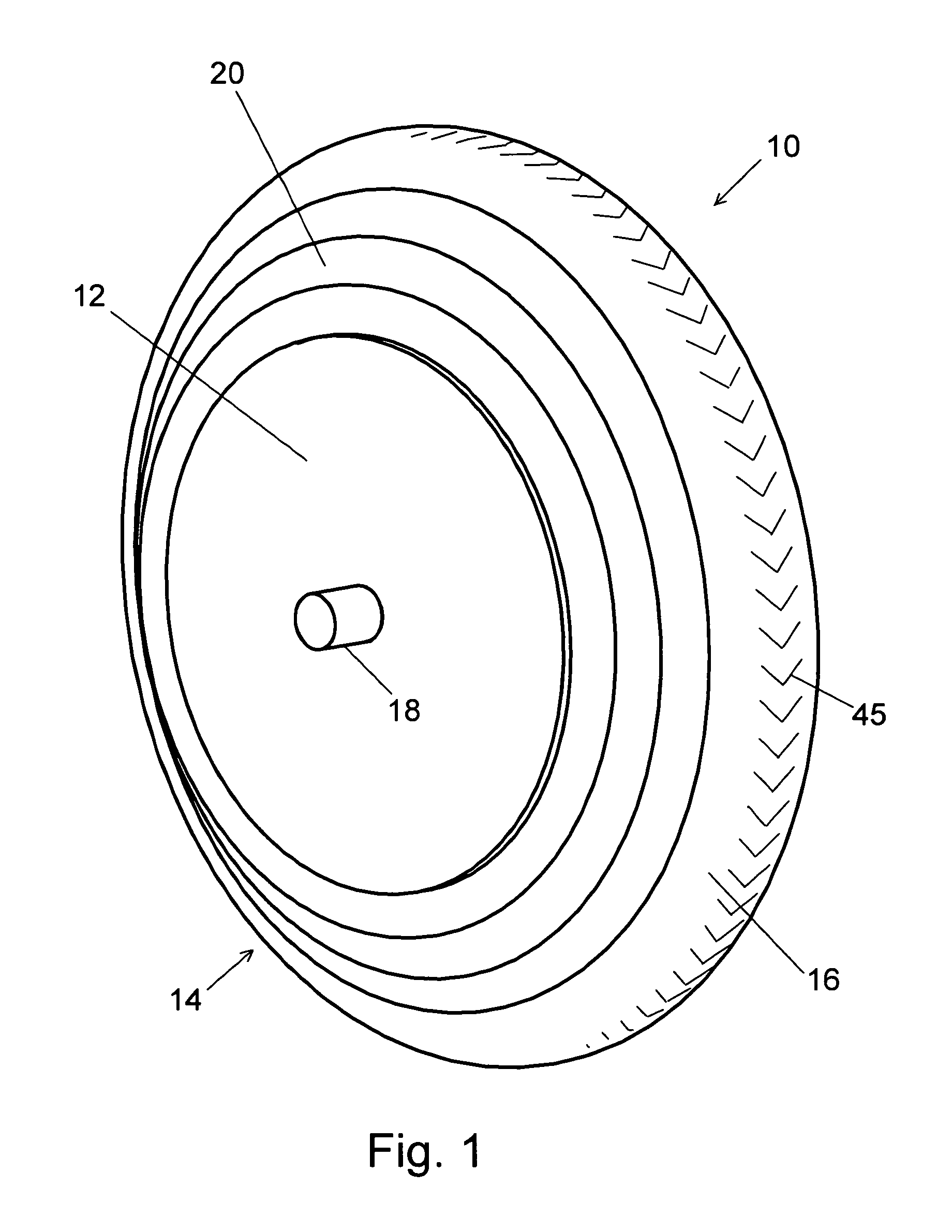

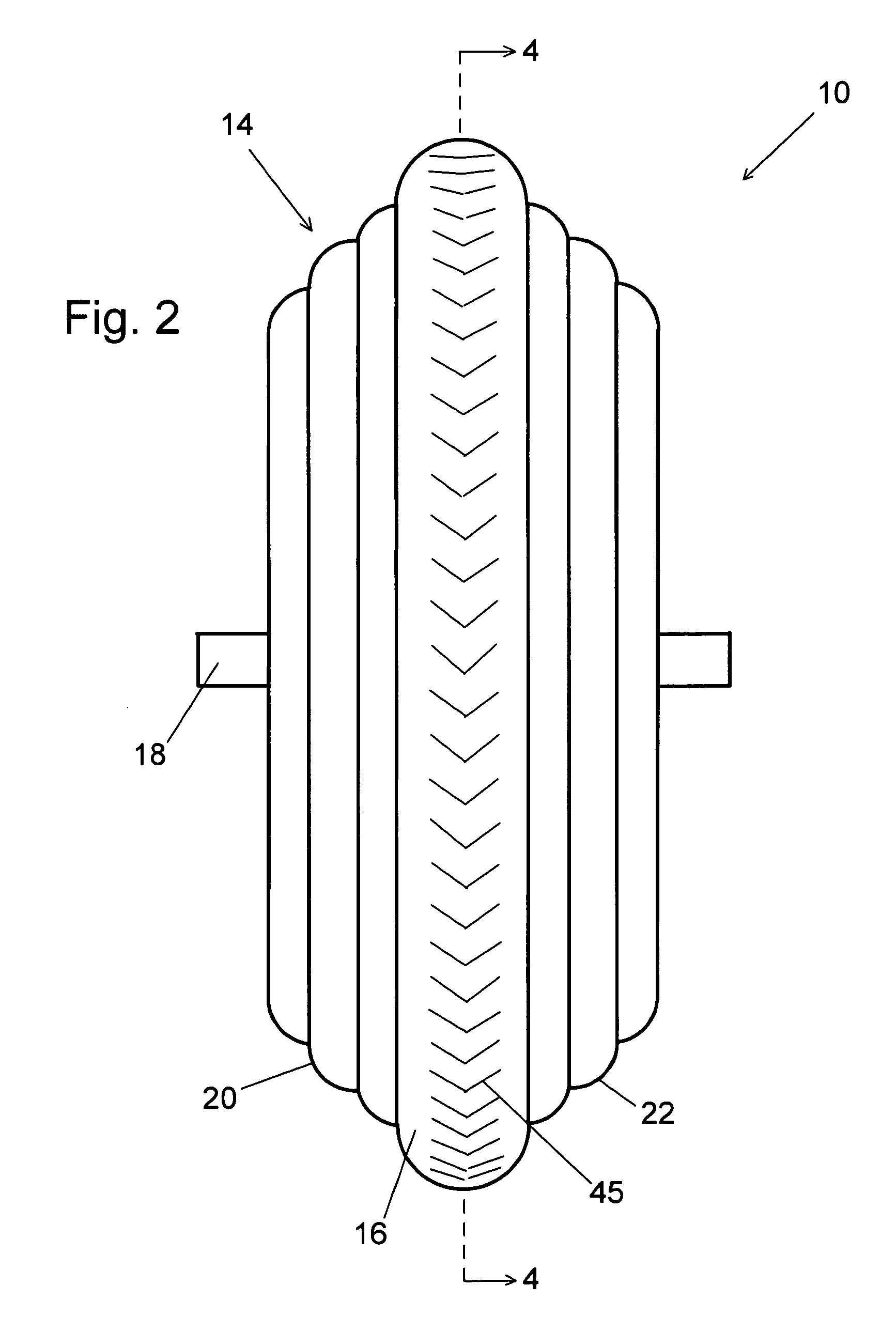

Modular Tire with Variable Tread Surfaces

InactiveUS20100200136A1Knob becomes largeBicycle tyresWith separate inflatable insertsMechanical engineeringTread

A new kind of tire utilizes a replaceable tread surface to enable variable tread characteristics determined by a removable riding surface. The tire body defines a slot that extends circumferentially around the tire and receives the removable riding surface. The removable riding surface is attached within the slot by attachment mechanisms. In other embodiments, the variable tread is accomplished via a removable sleeve that fits over the existing tire.

Owner:HAMILTON BRIAN H

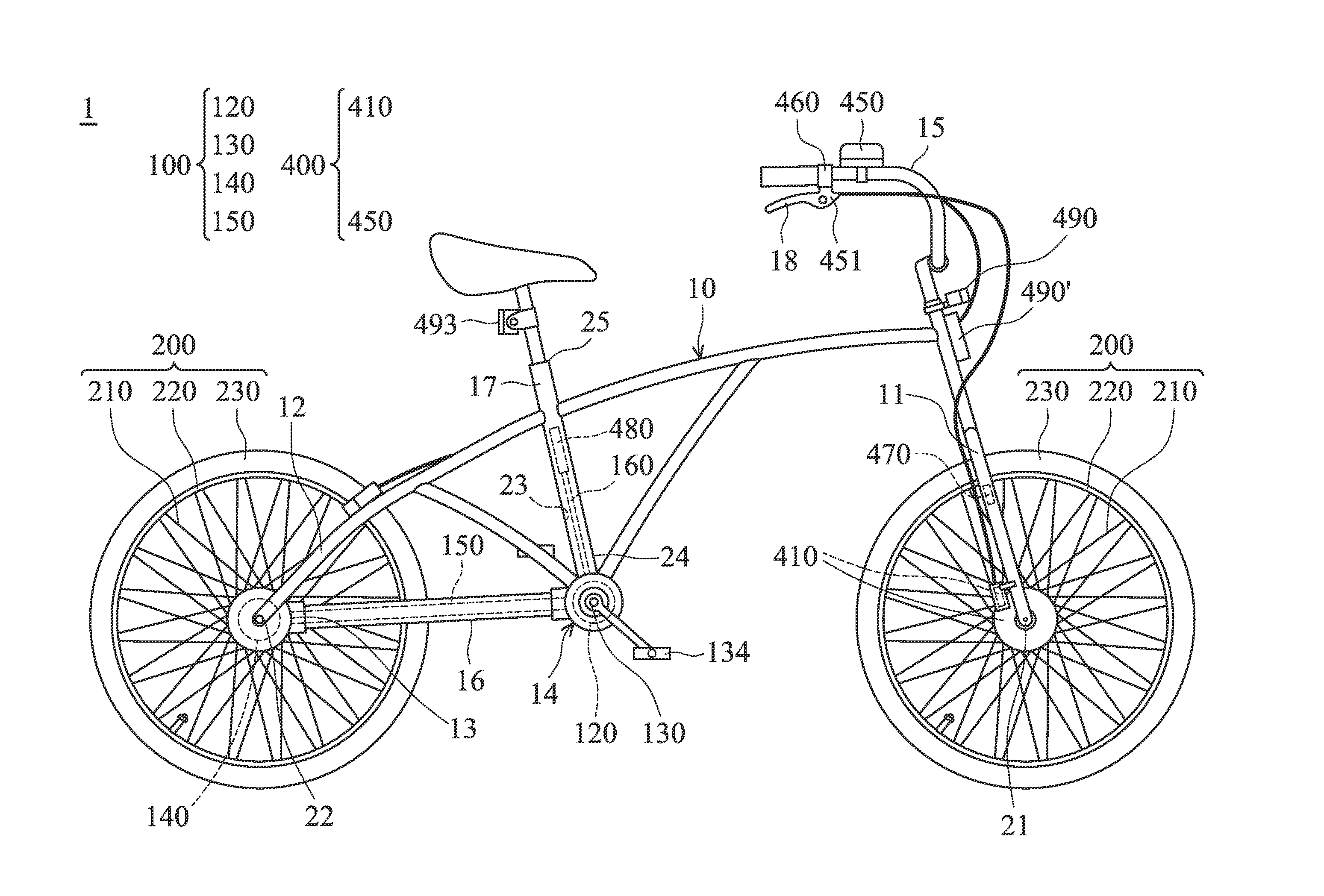

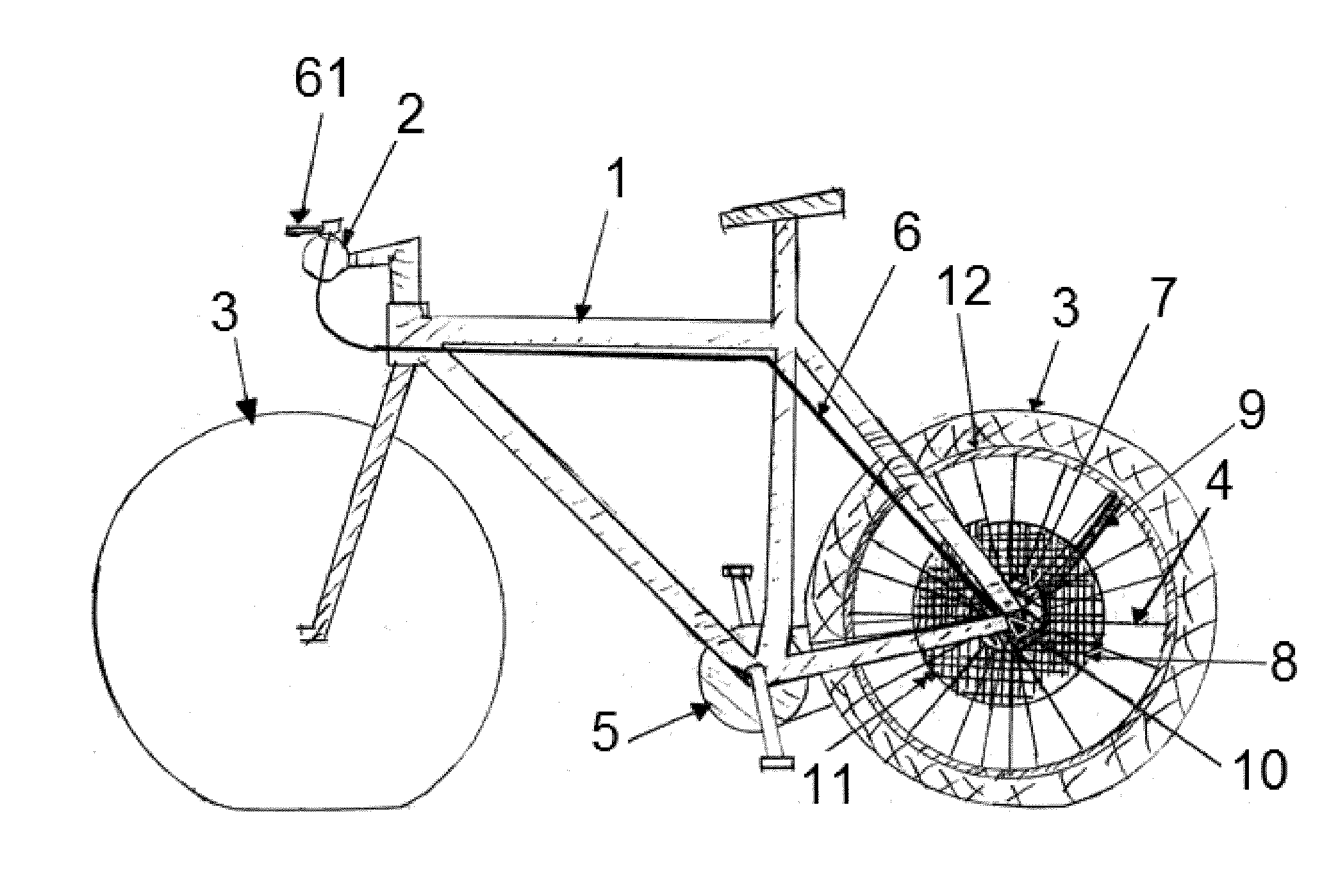

Green bike

ActiveUS20120086183A1Minimal forceSmooth effortElectric devicesBicycle tyresElectrical and Electronics engineering

Owner:KEN WENG DAH

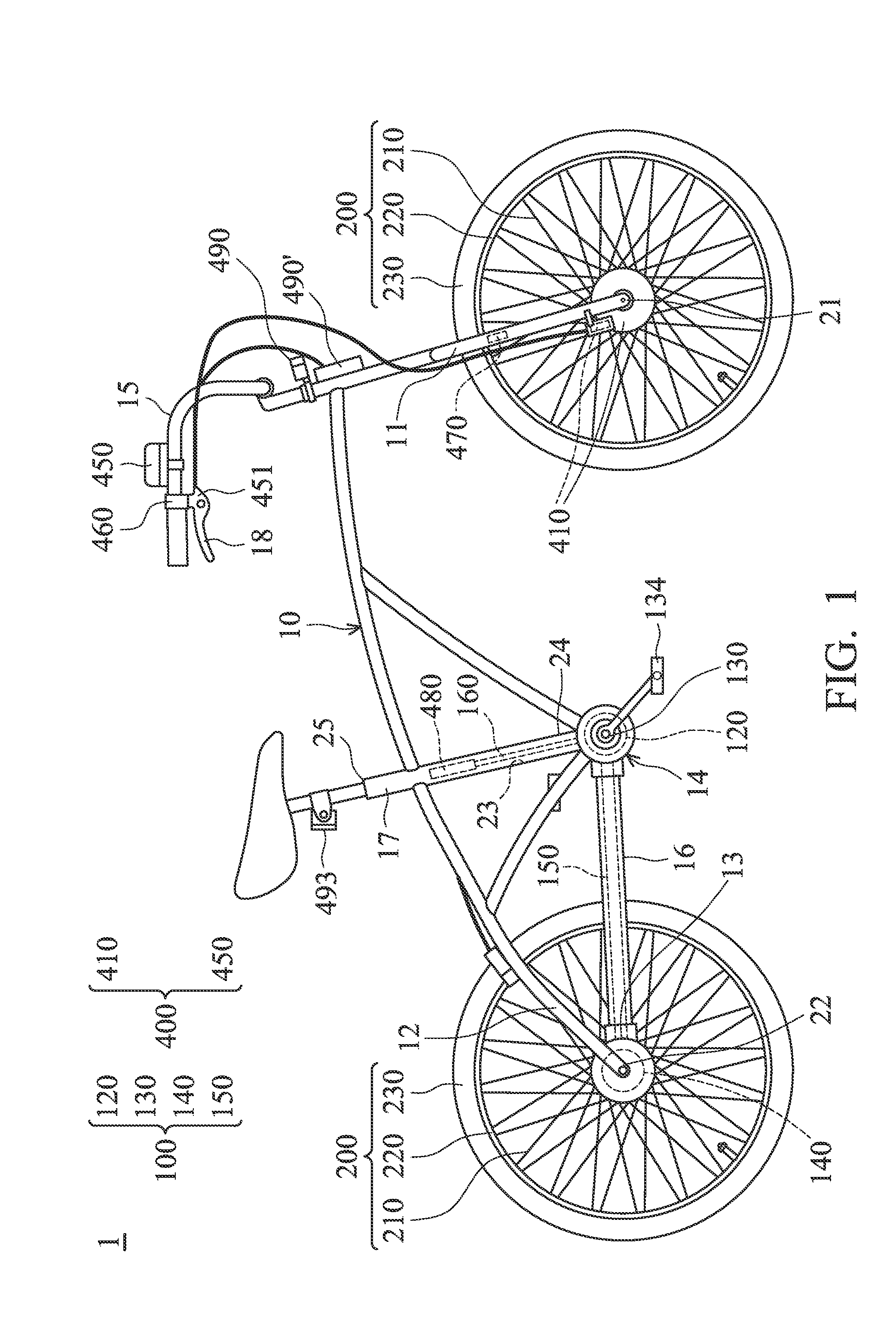

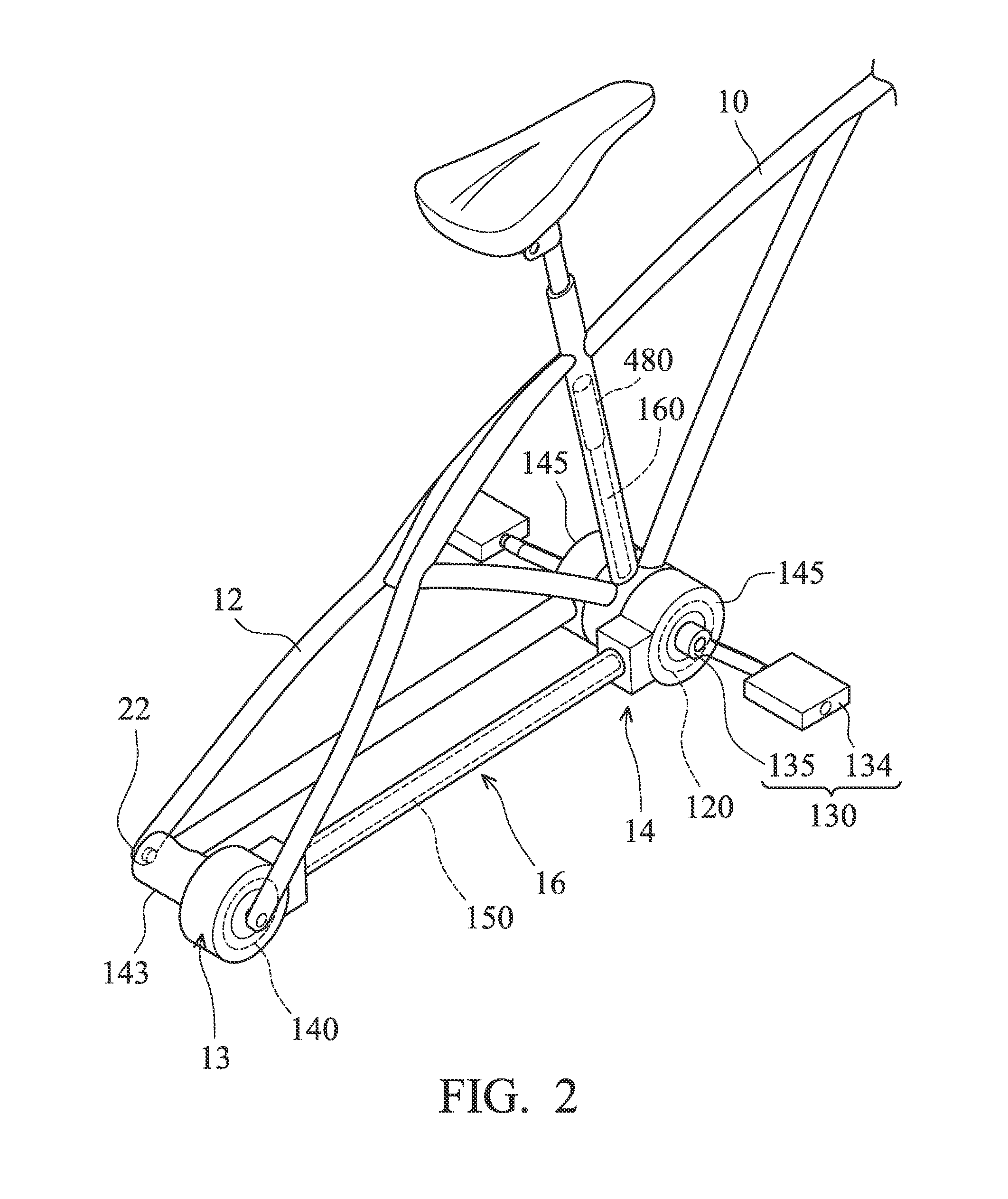

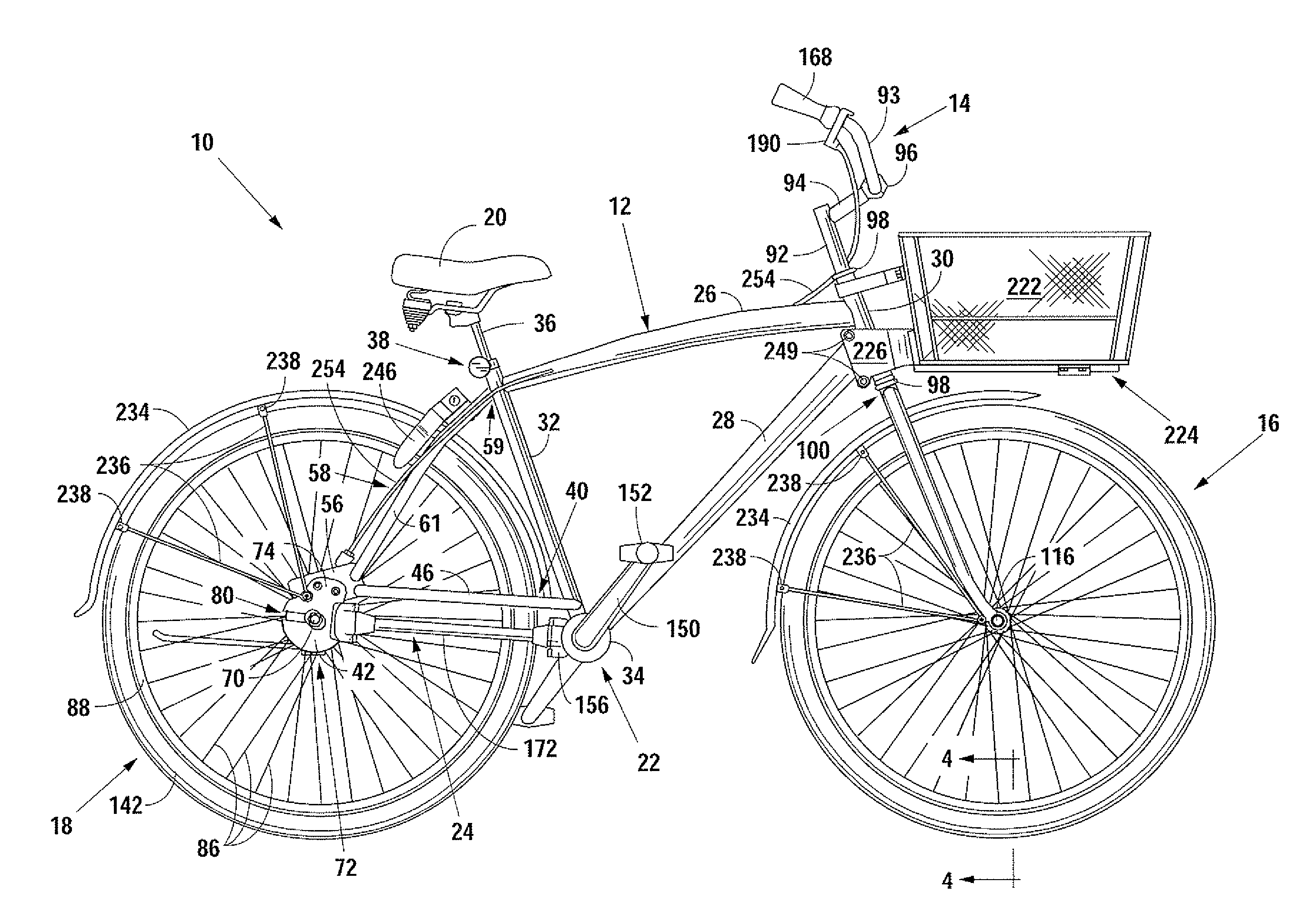

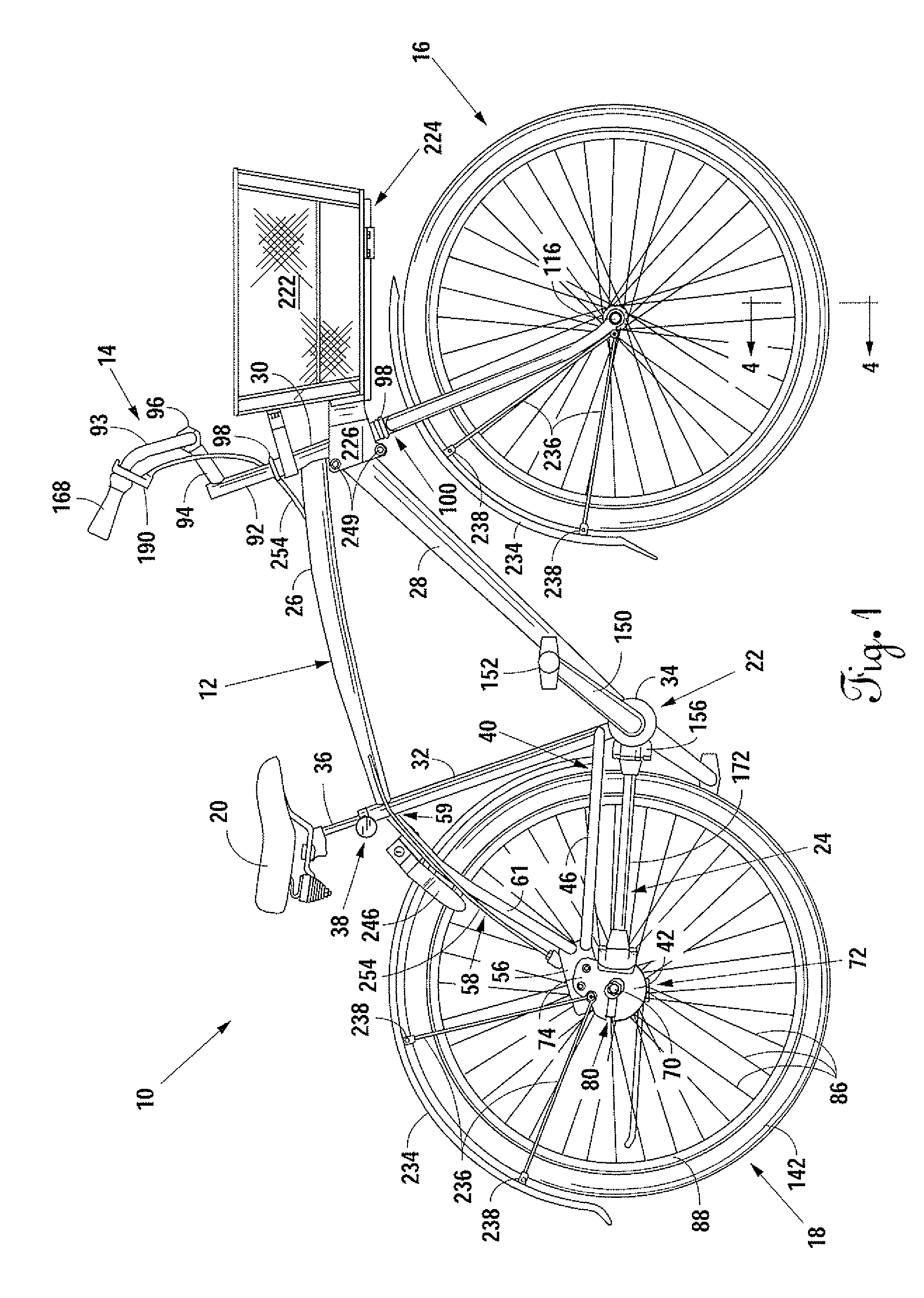

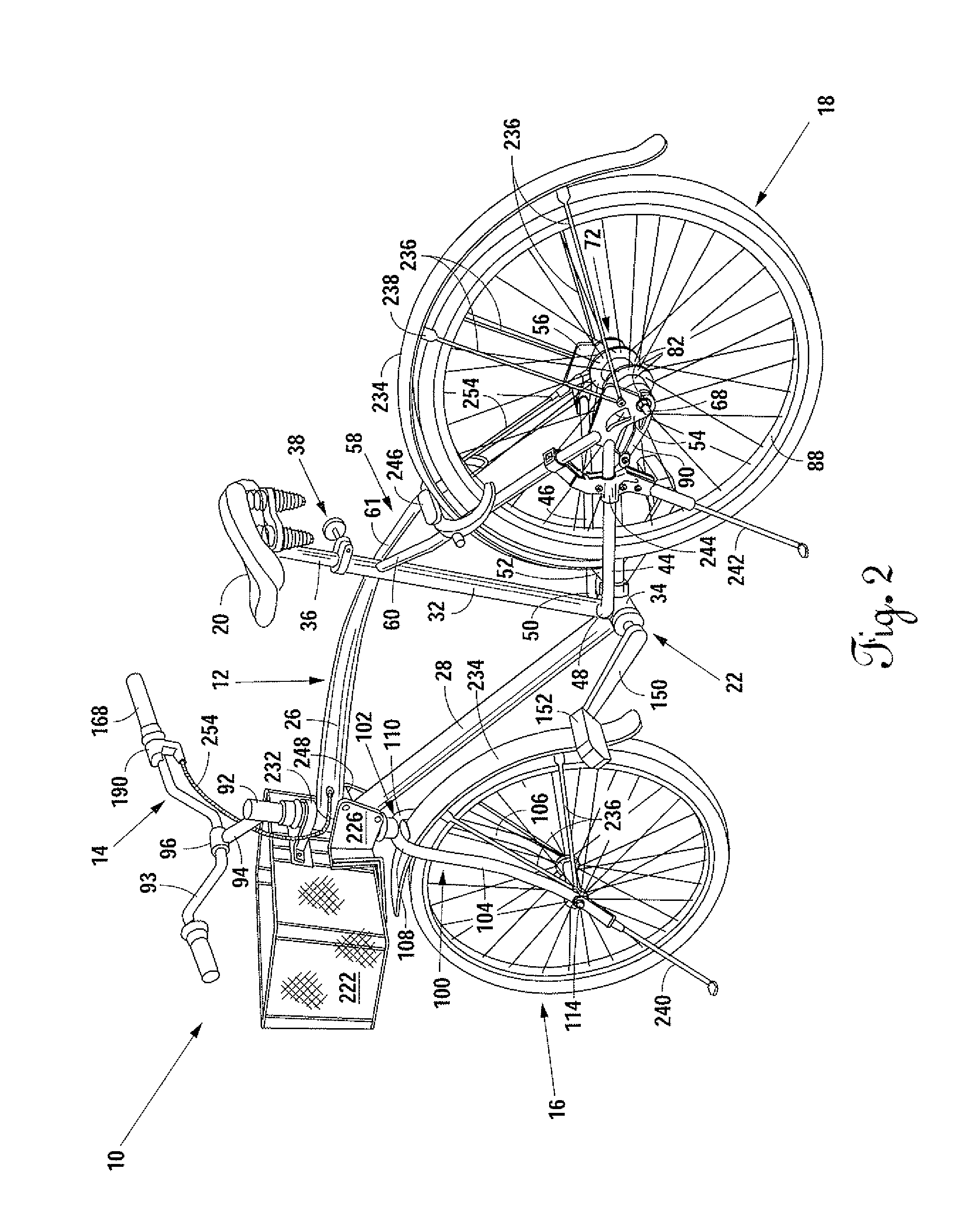

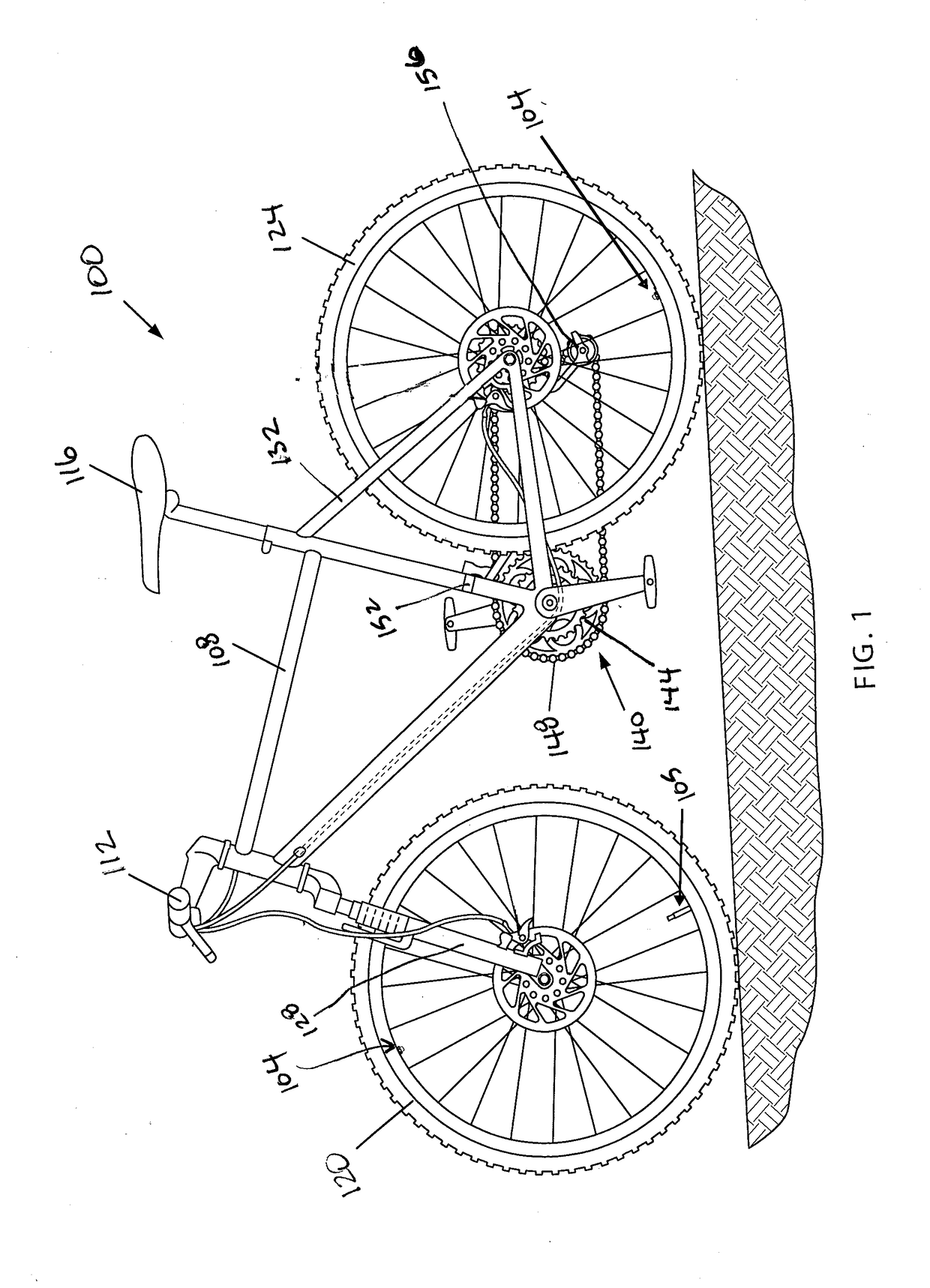

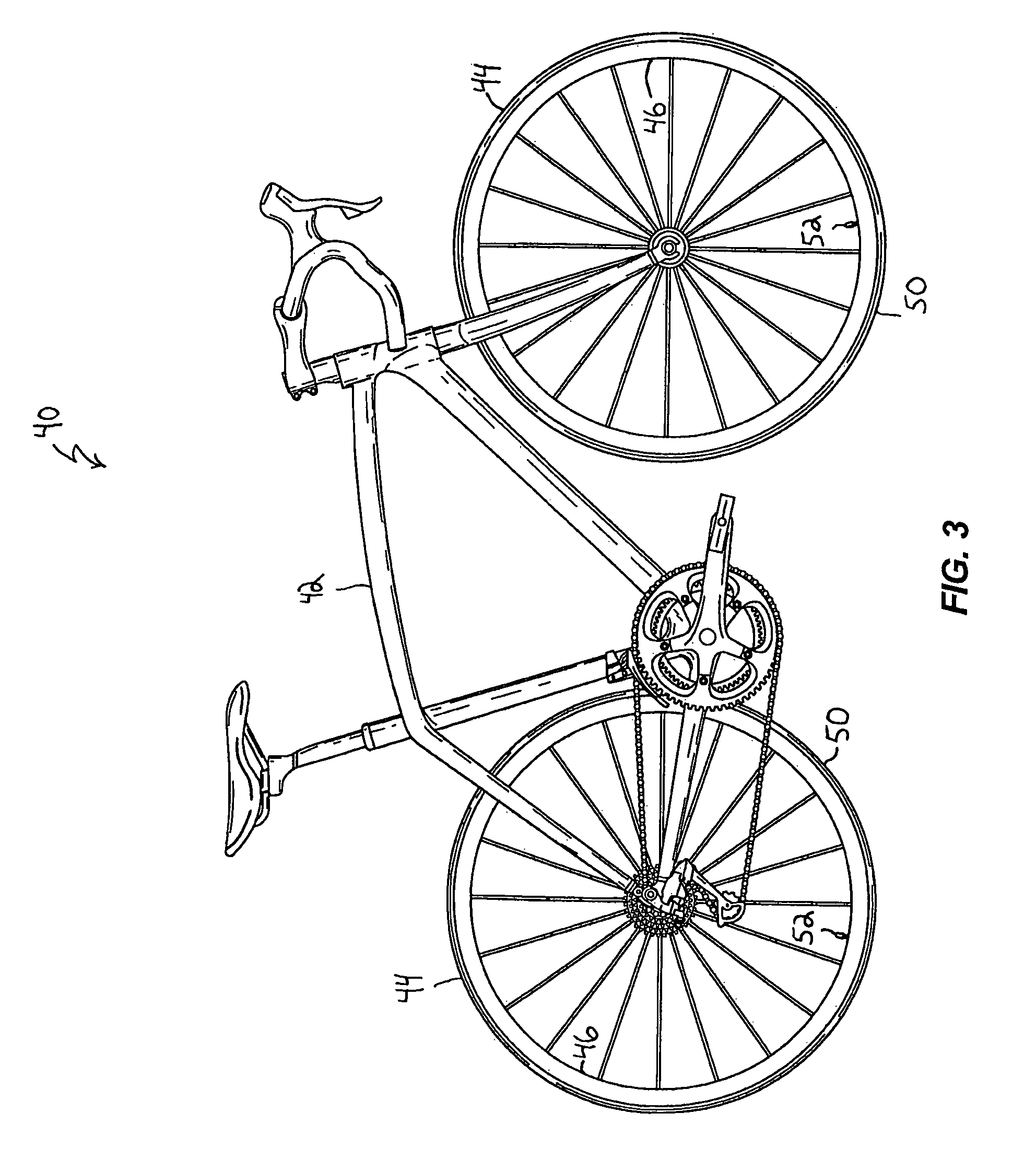

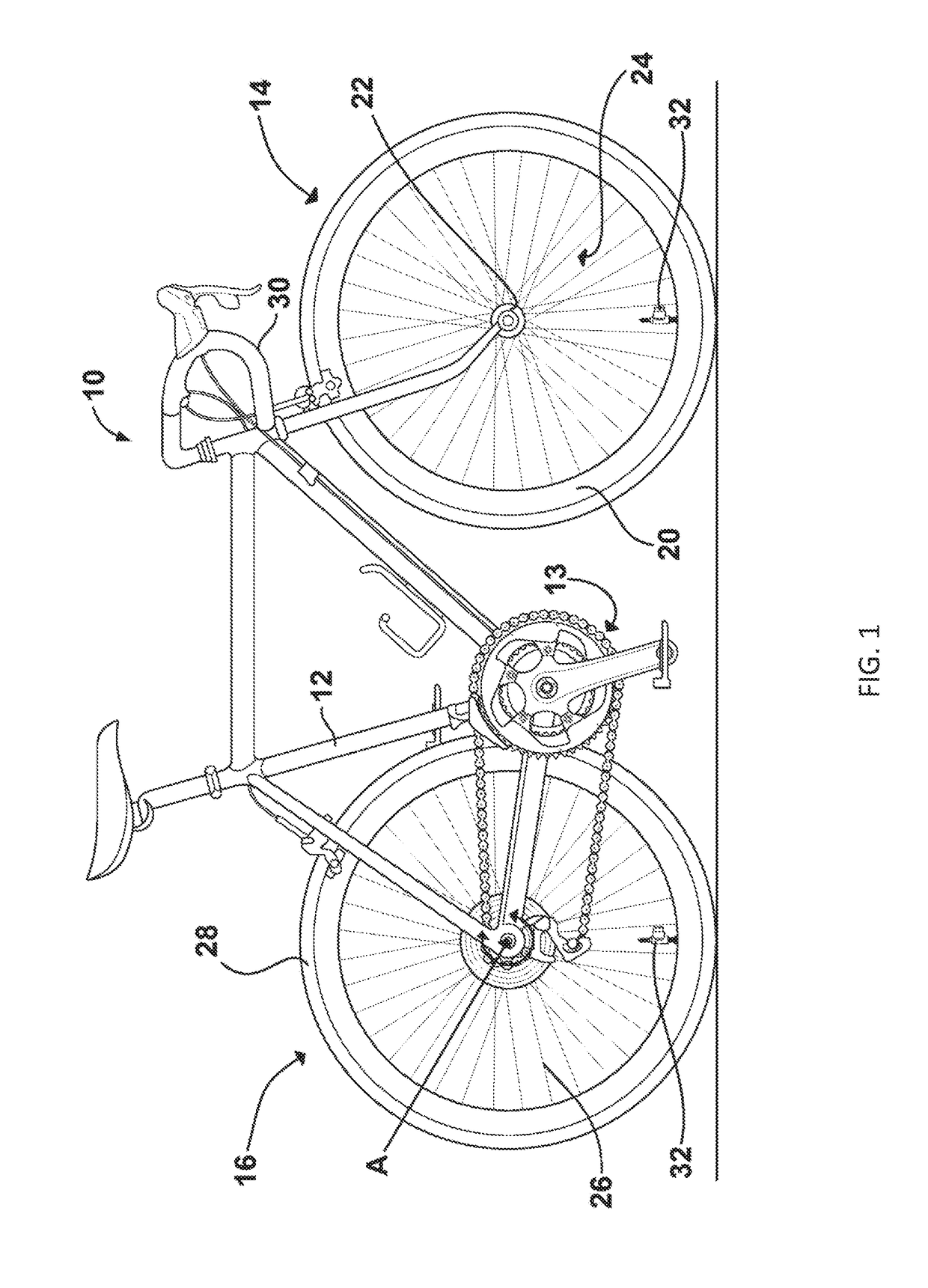

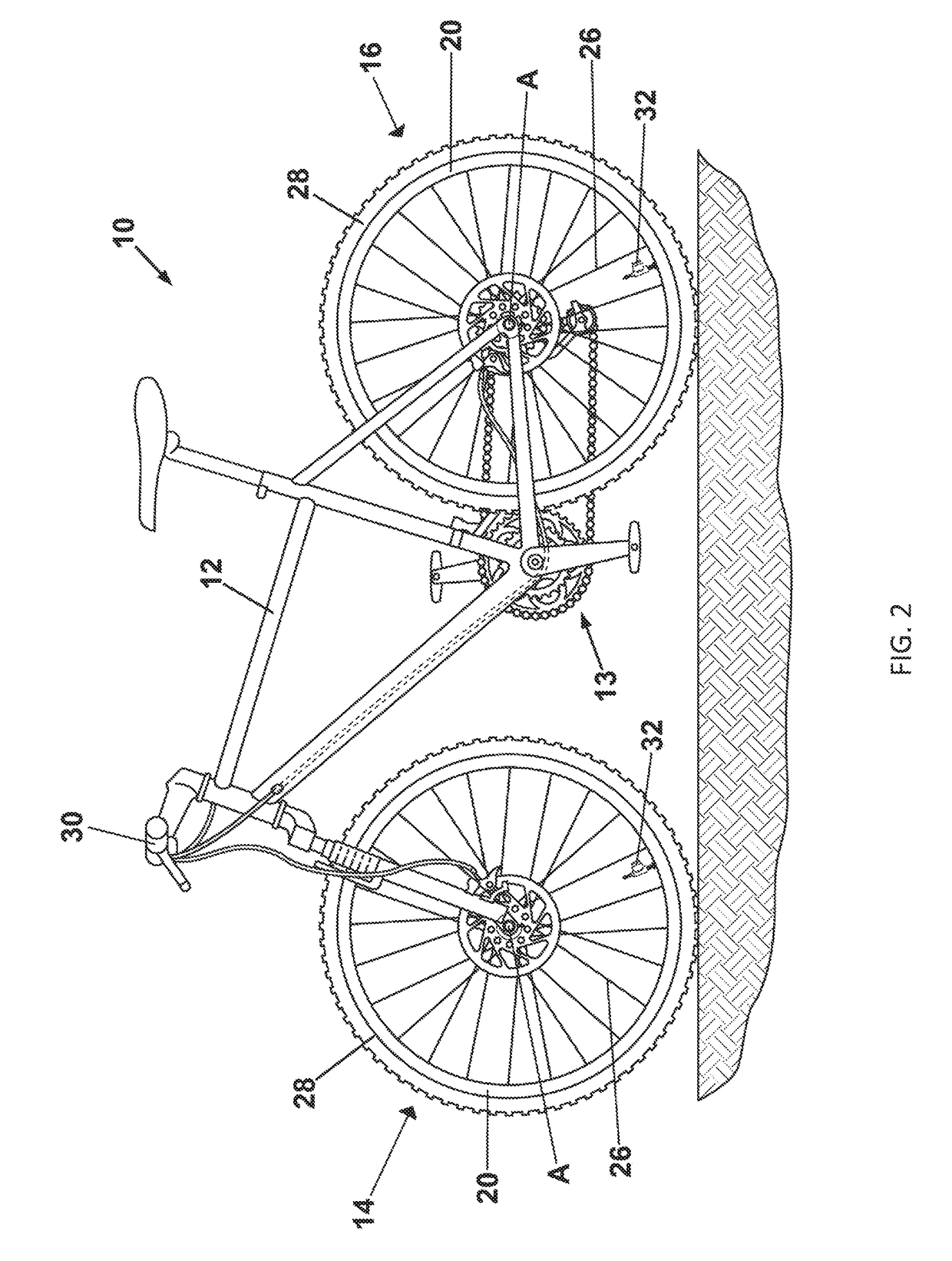

Airless, Chainless Bicycle

InactiveUS20100295264A1Easy to operateSmall loadPassenger cyclesChildren cyclesVehicle frameDrive shaft

A durable, airless, chainless bicycle multiple riders of differing heights is disclosed. The bicycle is propelled by a drive shaft instead of a chain, making the drive assembly more dependable. The tires are made from a solid material and cannot go flat. The frame and other components of the bicycle are either inherently rust resistant or are coated to increase their rust resistance. The bicycle also has a front basket that is mounted such that the basket does not turn when the front wheel turns. Finally, the bicycle has a seat adjustment mechanism which allows the seat height to be adjusted without tools.

Owner:DENAIS VINCE

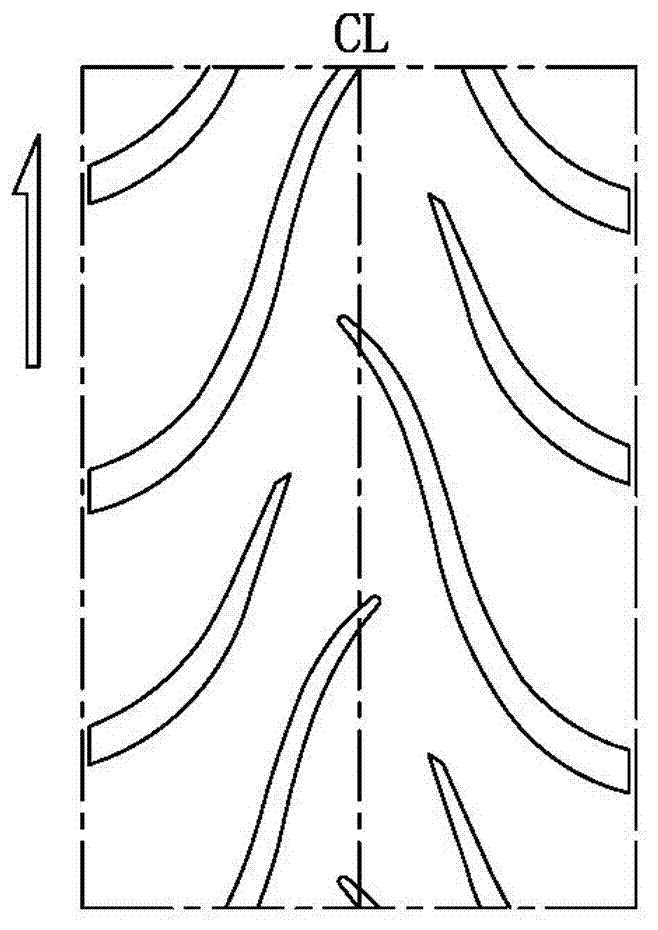

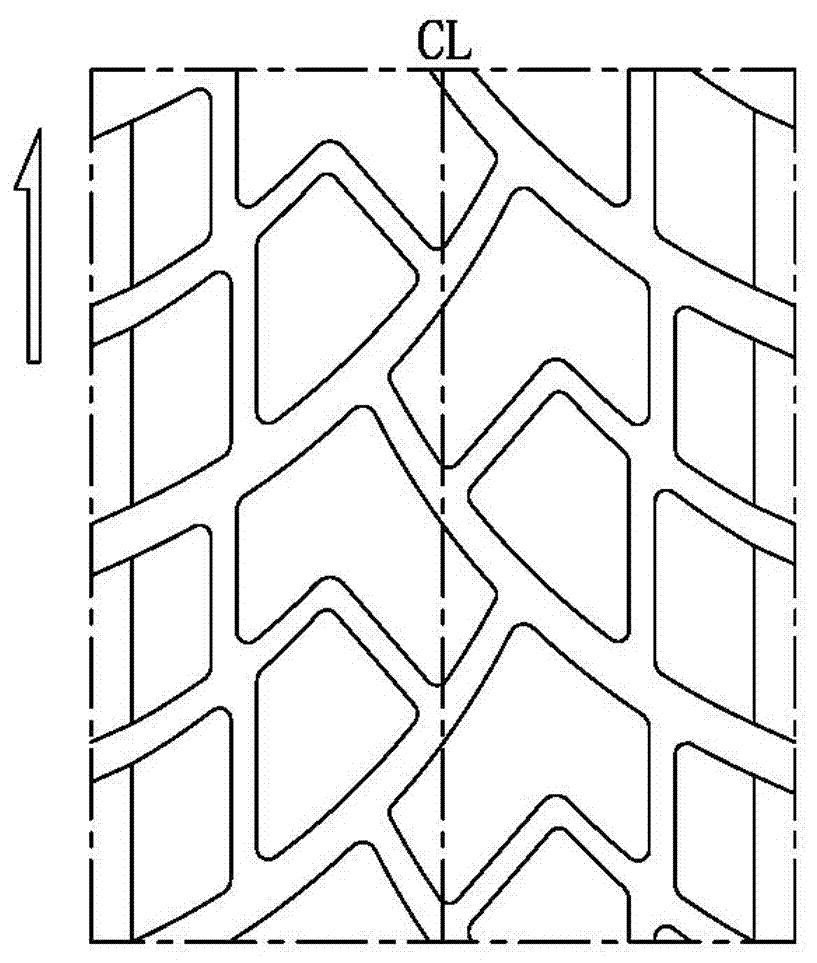

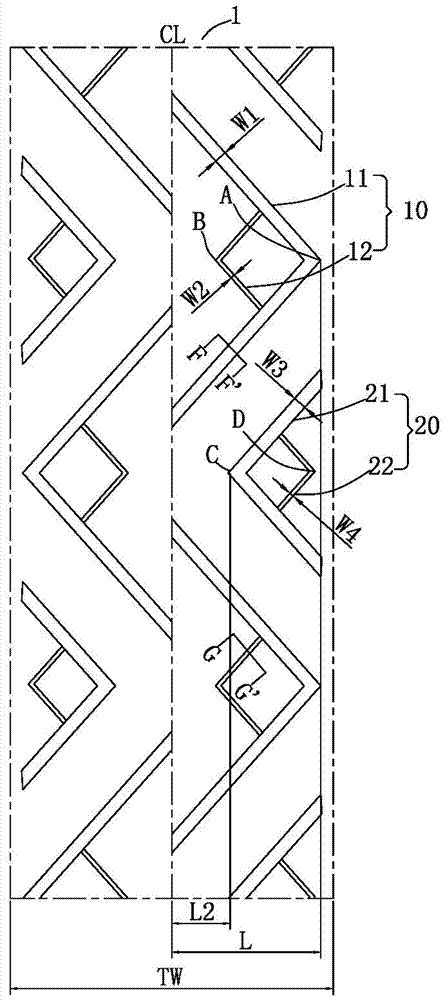

Tread pattern structure of pneumatic tires for two-wheelers

ActiveCN107415596AImprove traction performanceEnsure wear performanceBicycle tyresTyre tread bands/patternsStructural engineeringMechanical engineering

The invention discloses a tread pattern structure of pneumatic tires for two-wheelers. Each tire tread consists of a plurality of tread pattern units arranged alternately and symmetrically along the circumferential direction of the corresponding pneumatic tire, wherein each of the tread pattern units comprises a primary angle groove and a subsidiary angle groove; each primary angle groove extends from a tire equatorial plane towards a tire shoulder, and is formed by connecting a wide primary angle groove of which the opening faces the inside of the axial direction with a narrow primary tread of which the opening faces the outside of the axial direction; and each subsidiary angle groove is arranged between the two corresponding primary angle grooves of two tread pattern units adjacent to each other at the same side of the tire equatorial plane, and is formed by connecting a wide subsidiary angle groove of which the opening faces the outside of the axial direction with a narrow subsidiary tread of which the opening faces the inside of the axial direction. The openings of each primary angle groove and the corresponding subsidiary angle groove at the same side are alternately arranged in the opposite direction, so as to ensure good abrasion resistance performance and drainage performance of the tire tread and improve the traction performance of the tire tread of the pneumatic tires at the same time.

Owner:CHENG SHIN ZHANGZHOU RUBBER IND

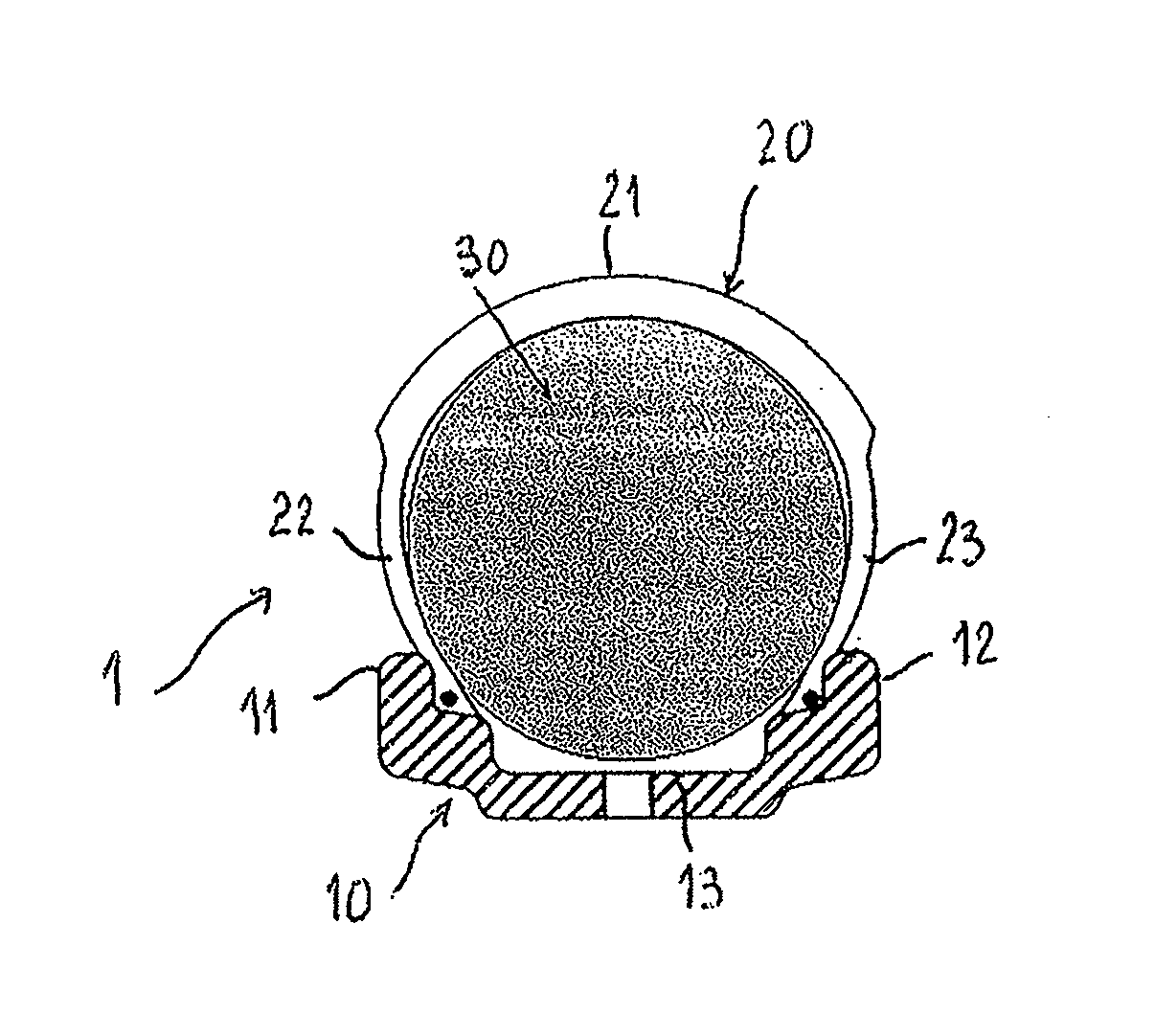

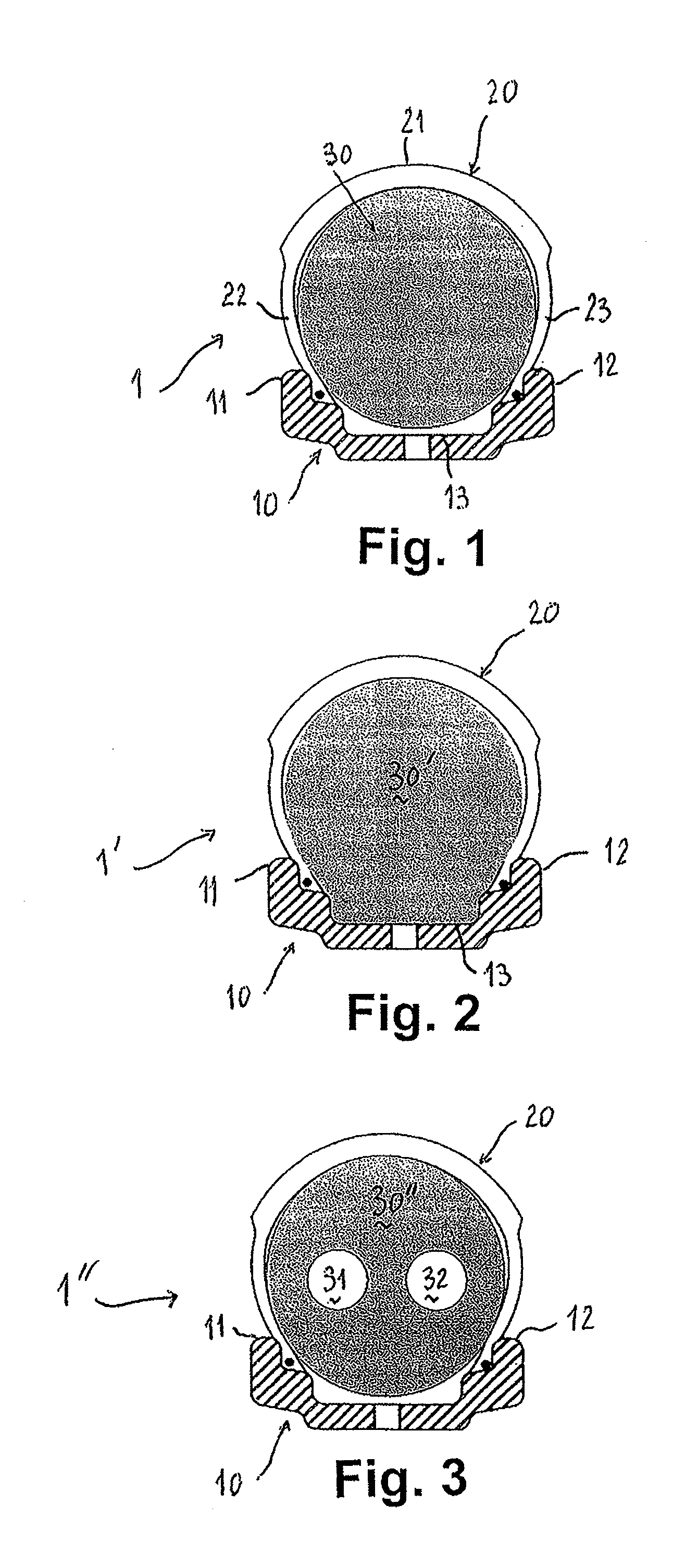

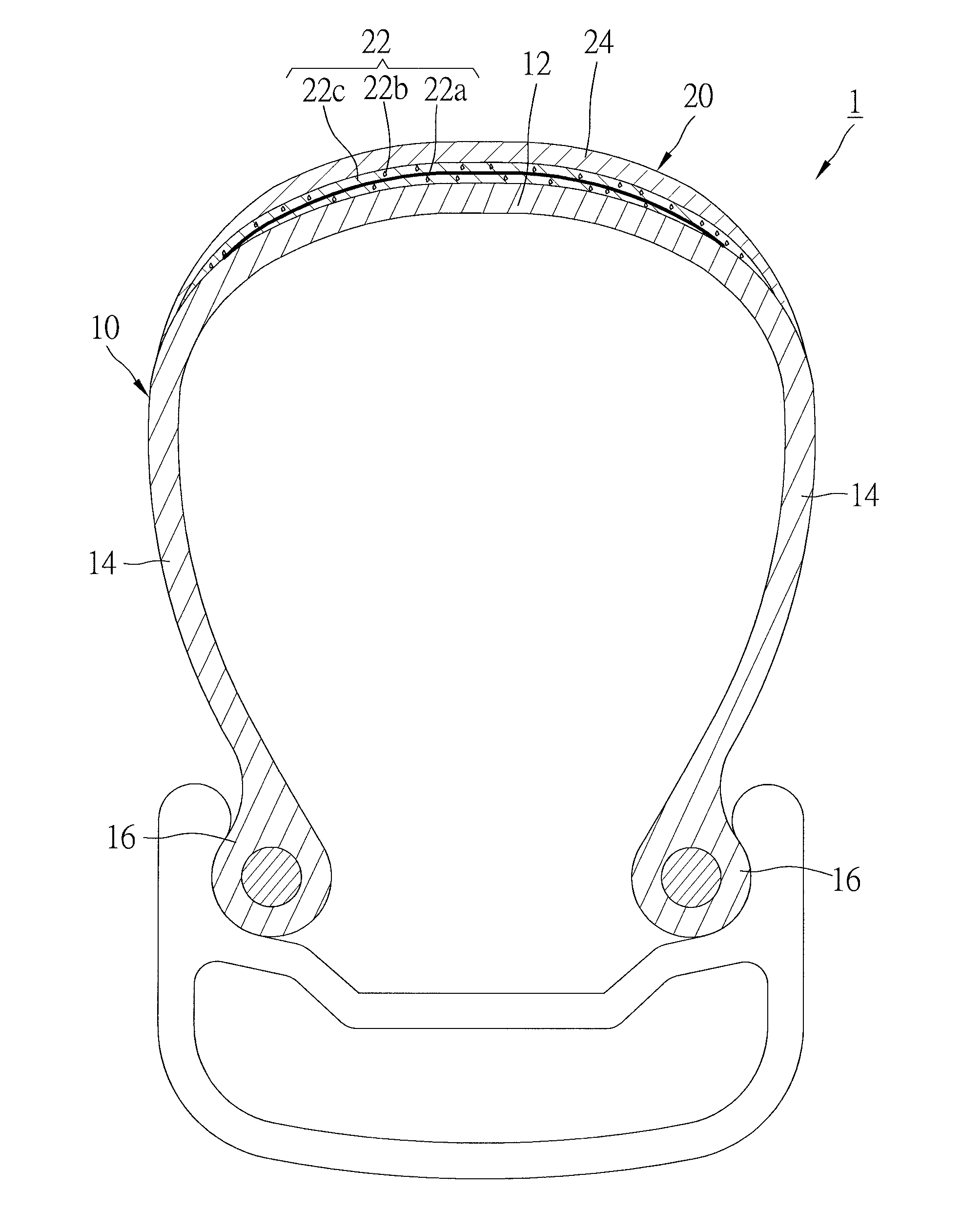

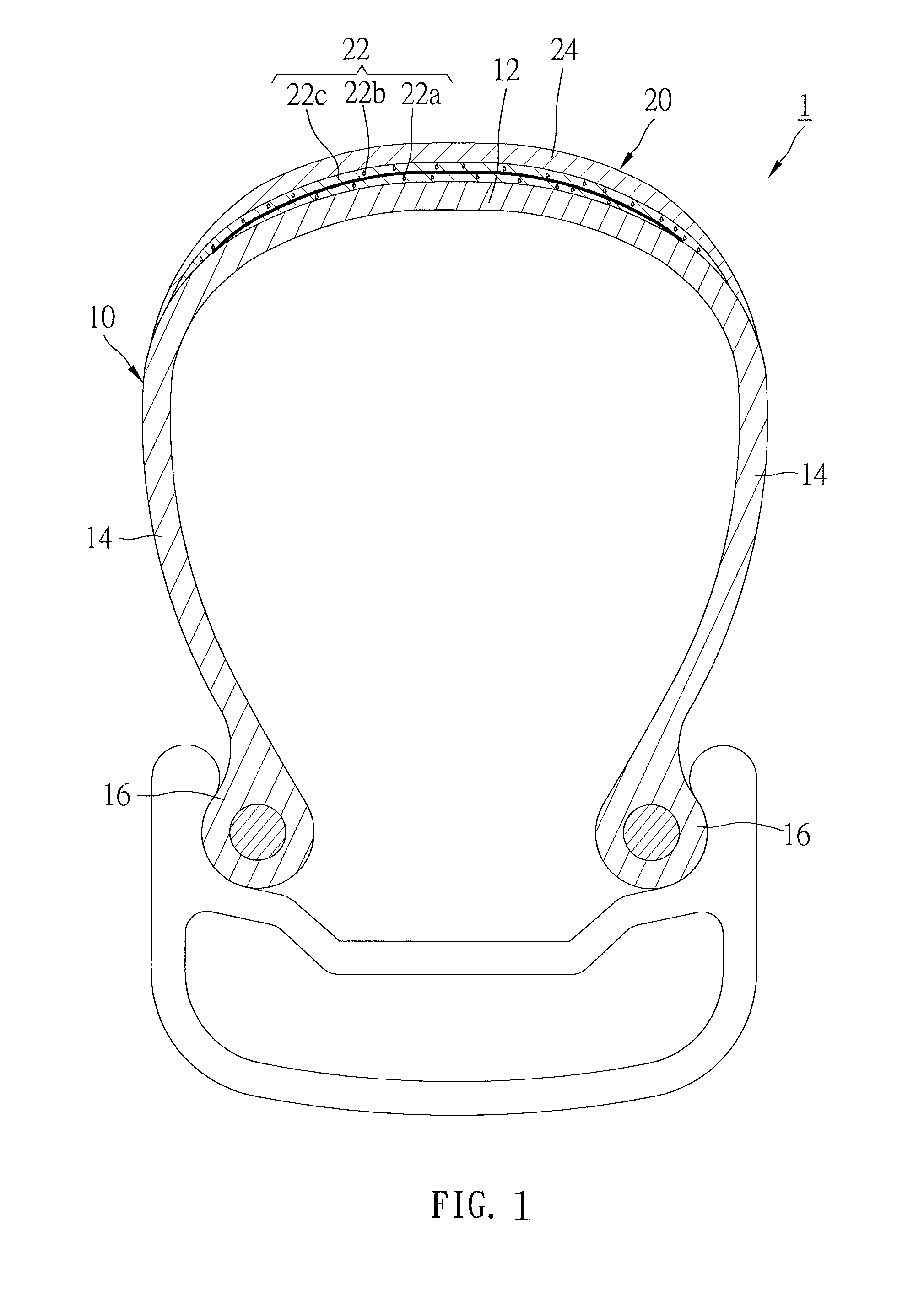

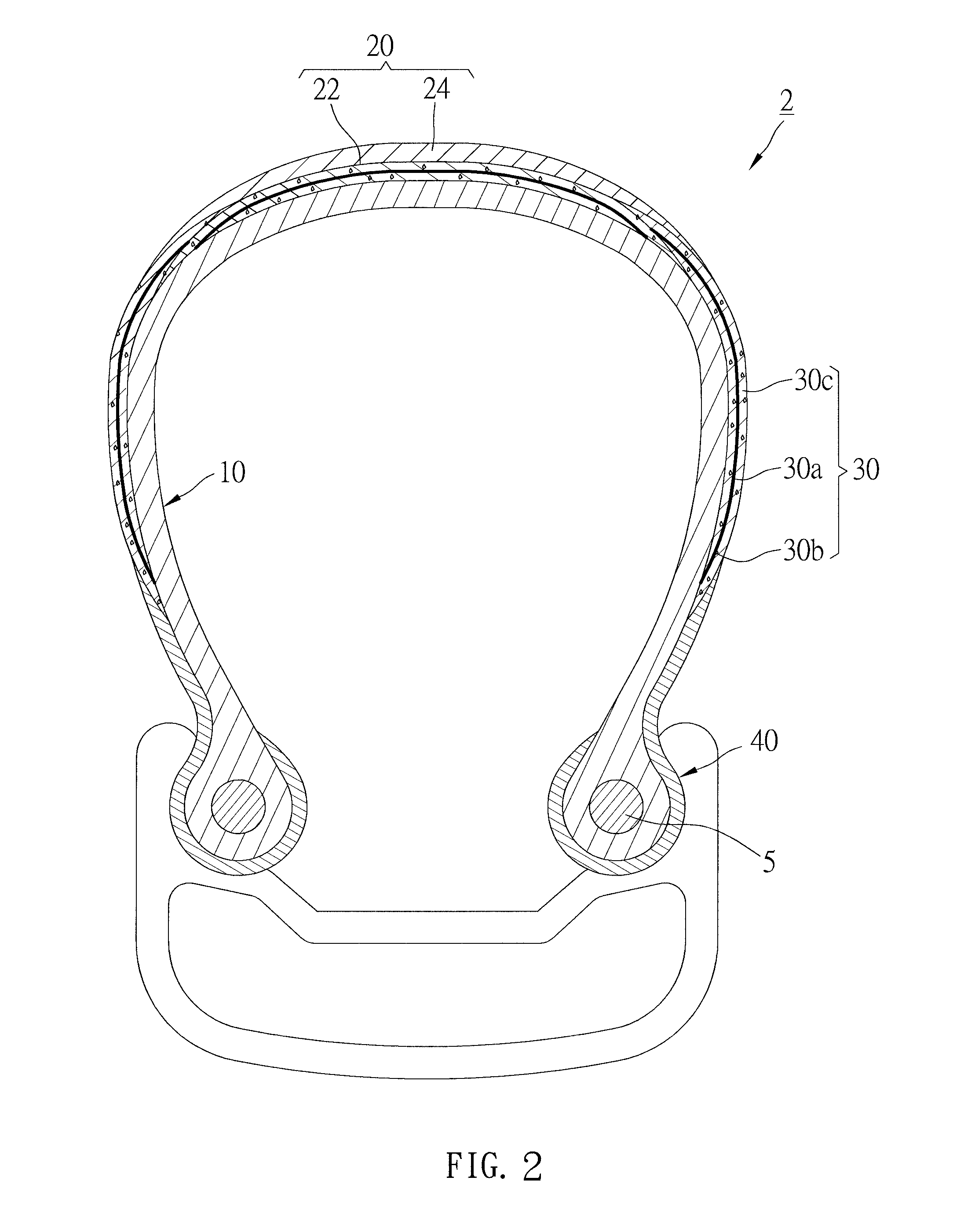

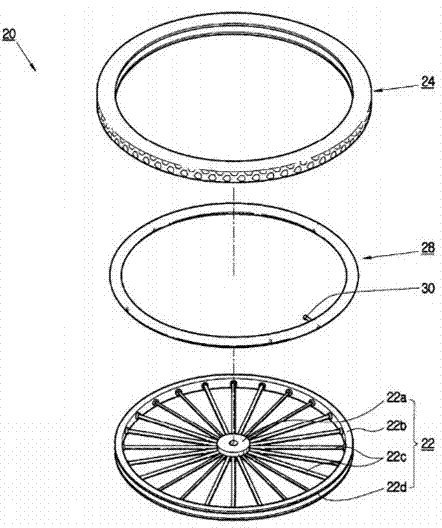

Puncture-Resistant Device for a Non-Pneumatic Mounted Assembly of a Two-Wheeled Vehicle, and This Mounted Assembly Incorporating Same

InactiveUS20110079336A1Minimizing densityBicycle tyresNon-inflatable tyresElastomerVolumetric Mass Density

The present invention relates to a puncture-resistant device for a non-pneumatic mounted assembly of a two-wheeled vehicle, in particular for a bicycle, and to such a mounted assembly incorporating this device. The invention applies to a mounted assembly with no inflation pressure, the tire of which is permanently supported by this puncture-resistant device.This puncture-resistant device (30) comprises an annular support (30), which is intended to be mounted between a rim (10) and a tire (20) of this mounted assembly (1) so as to permanently support this tire and which is constituted of a crosslinked rubber composition of cellular type having closed cells, the composition being based on at least one elastomer and comprising a reinforcing inorganic filler and at least one organic blowing agent.According to the invention, said composition comprises at least one active grade zinc oxide capable of activating the thermal decomposition of said blowing agent so as to stabilize the expansion of the support by giving it a minimized average density.

Owner:HUTCHINSON SA

Self-reinflating tire

Owner:CODA INNOVATIONS SRO

Flat resistant vehicular tire

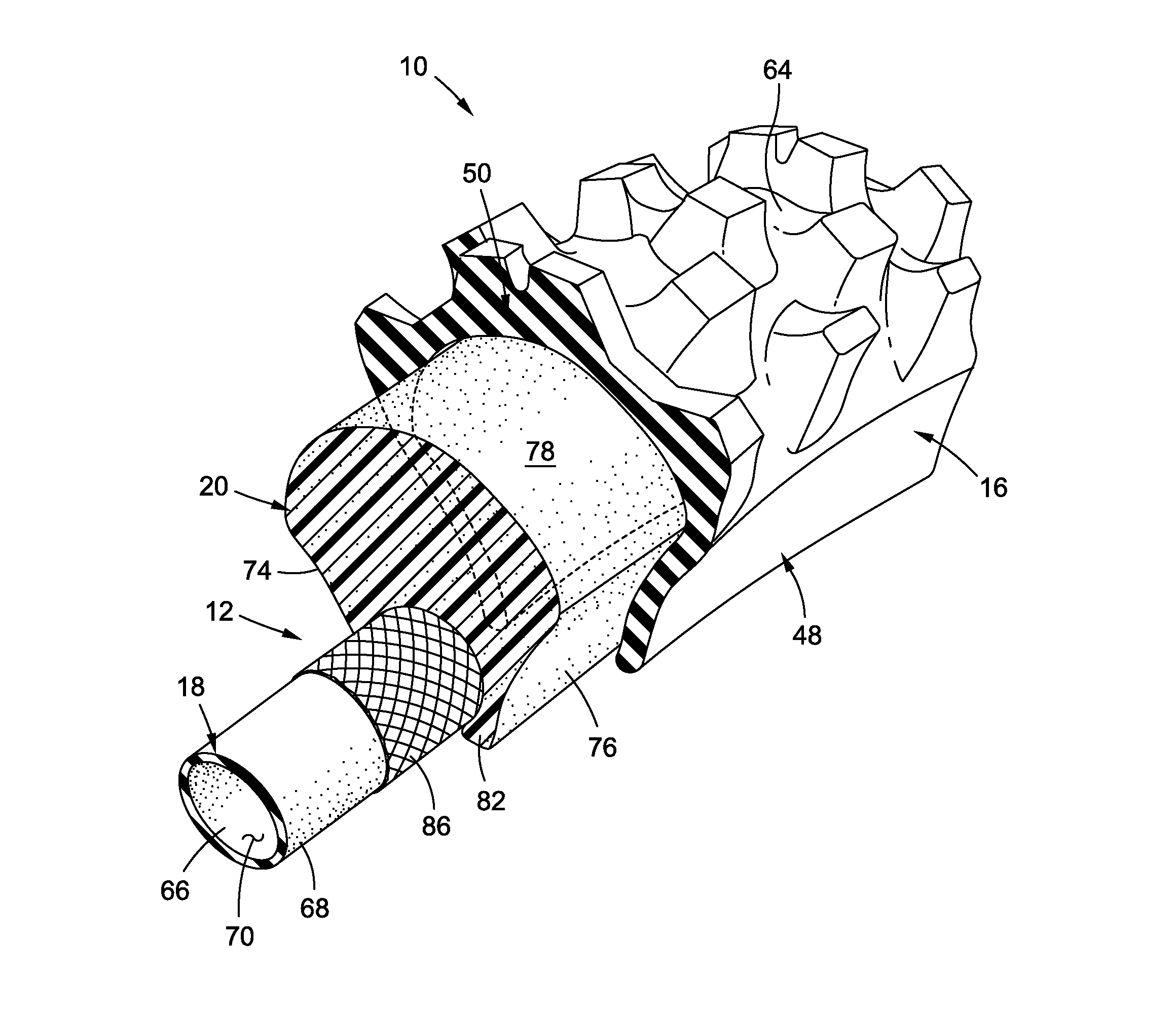

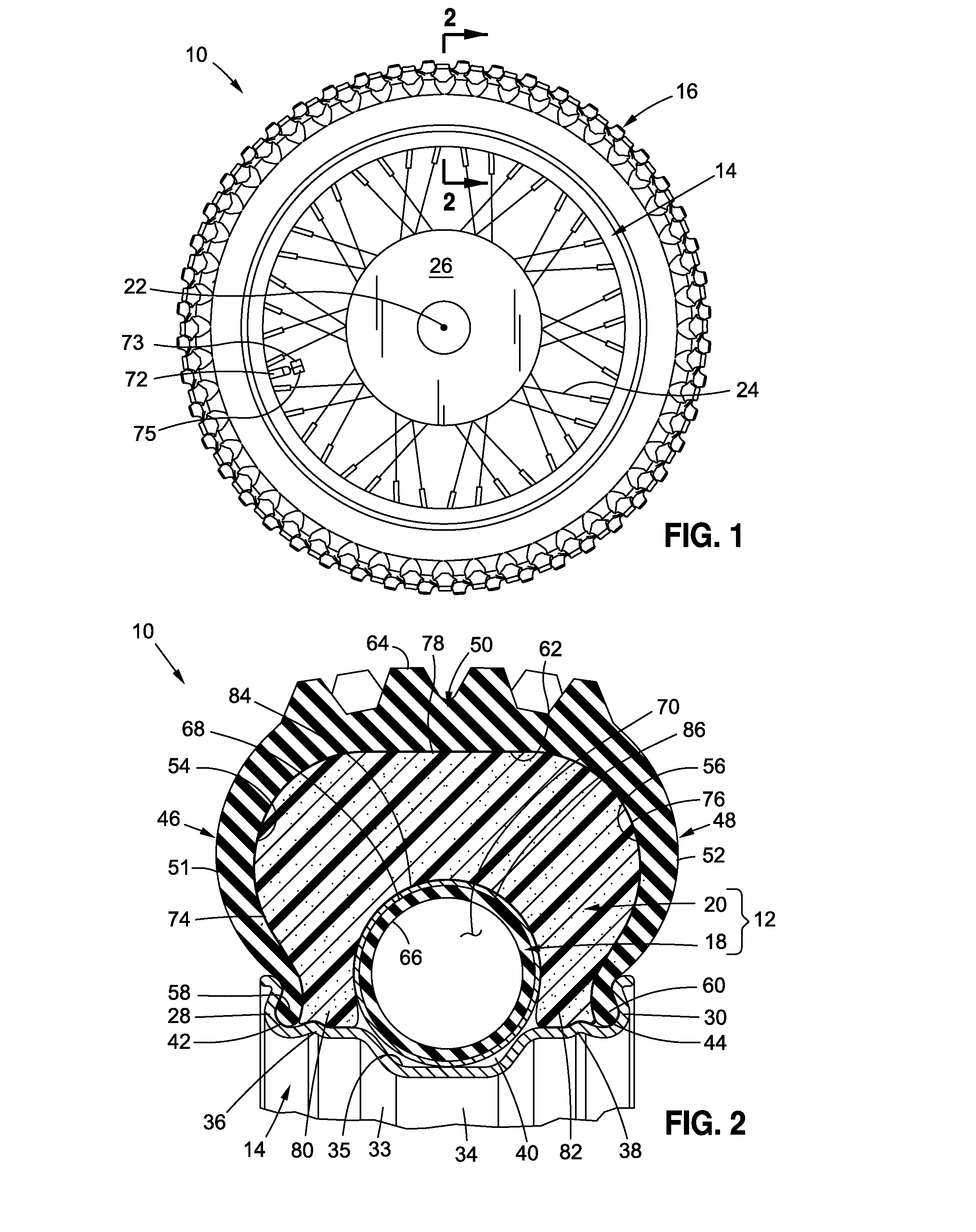

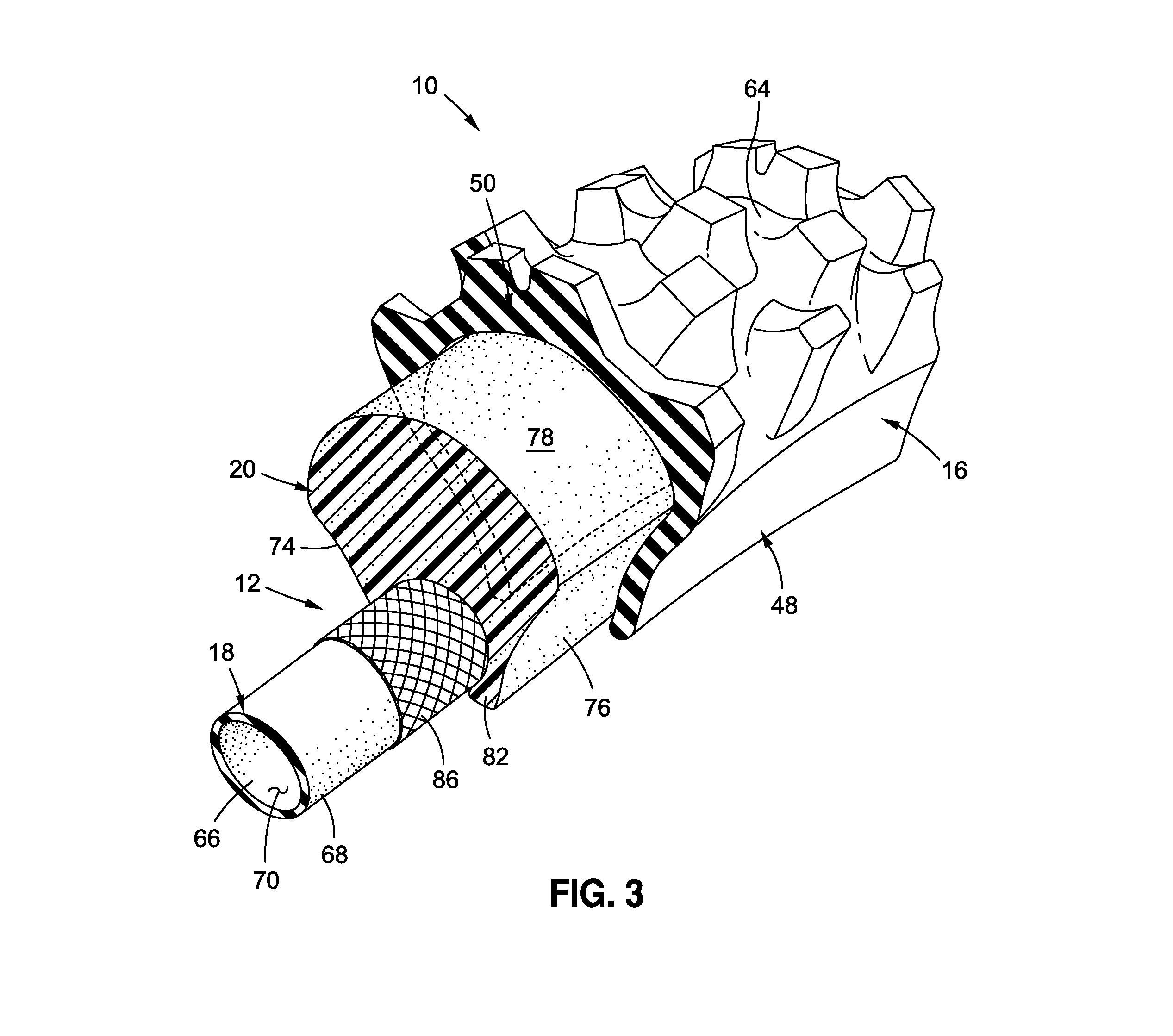

InactiveUS20170057286A1Easy to installBicycle tyresWith separate inflatable insertsTweelMechanical engineering

An insert specifically adapted for use with an off-road tire, such as an off-road tire of a motocross motorcycle, or an off-road bicycle. The insert includes an inflatable tube and a foam element which generally conforms to the contours of the off-road tire to provide support to the tire when the tube is inflated. The ability to deflate the insert facilitates installation of the insert between the wheel rim and off-road tire. When inflated, the insert occupies the space between the wheel rim and tire to support a load during use of the wheel.

Owner:SHAW RONALD D +1

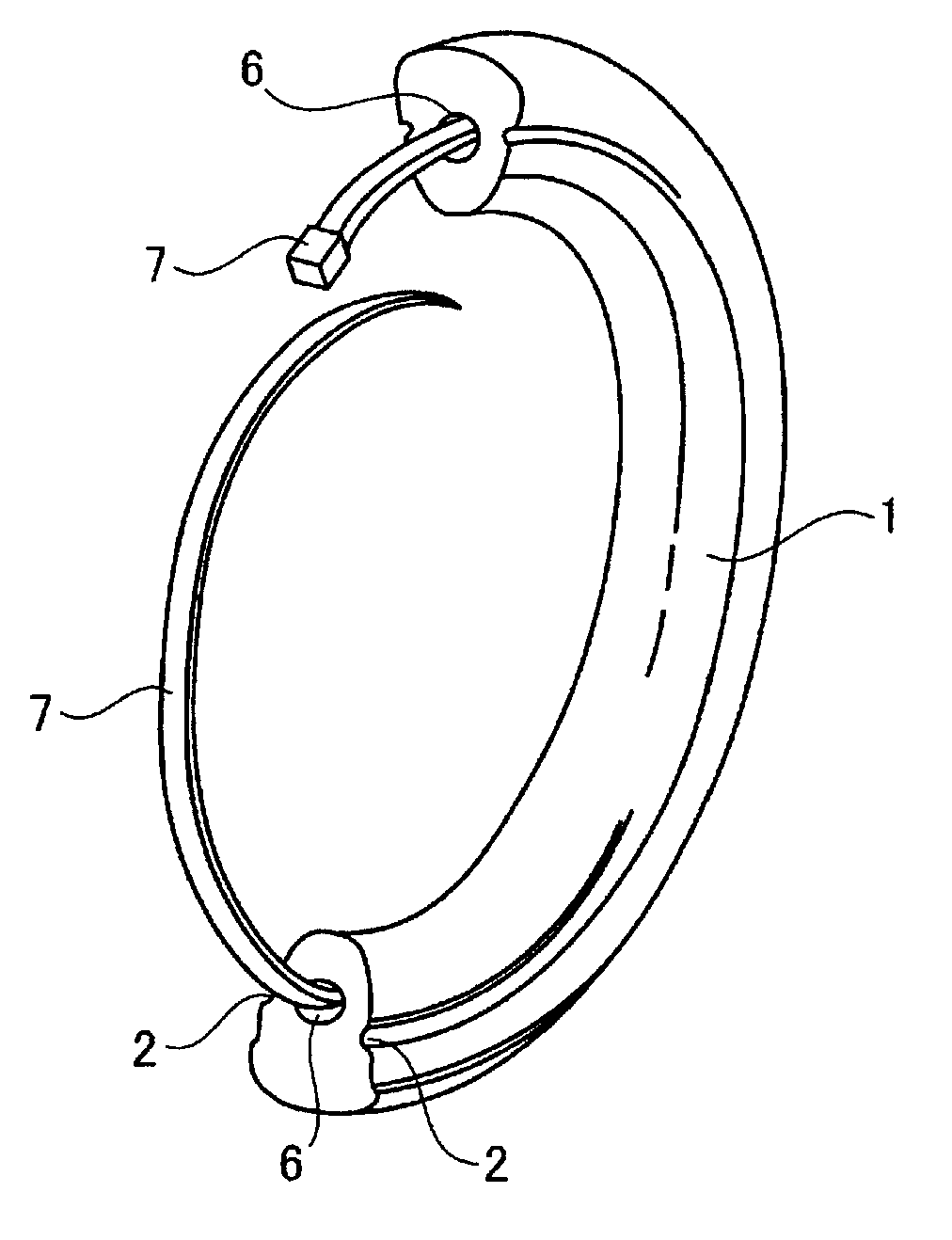

Non-pneumatic tire/wheel assembly

InactiveCN102712217AEasy to fixImprove workabilityBicycle tyresNon-inflatable tyresCross-linkElastomer

Disclosed is a non-pneumatic tire / wheel assembly including a tire body (1), at least part of which being composed of elastomer compound, and a wheel to which the tire body is assembled, which comprises a fastening member (7) embedded in the tire body (1) in the circumferential direction of the tire so as to fasten and fix the tire body (1) and the wheel together. Furthermore, the elastomer compound that composes at least the part of the tire body includes thermo-reversible cross-linking elastomer compound. With this structure, a non-pneumatic tire / wheel assembly for a light vehicle including a tire and a wheel that are firmly and reliably fixed to each other, and furthermore, allowing recycling of a tire body (material recycling) can be provided.

Owner:THE YOKOHAMA RUBBER CO LTD

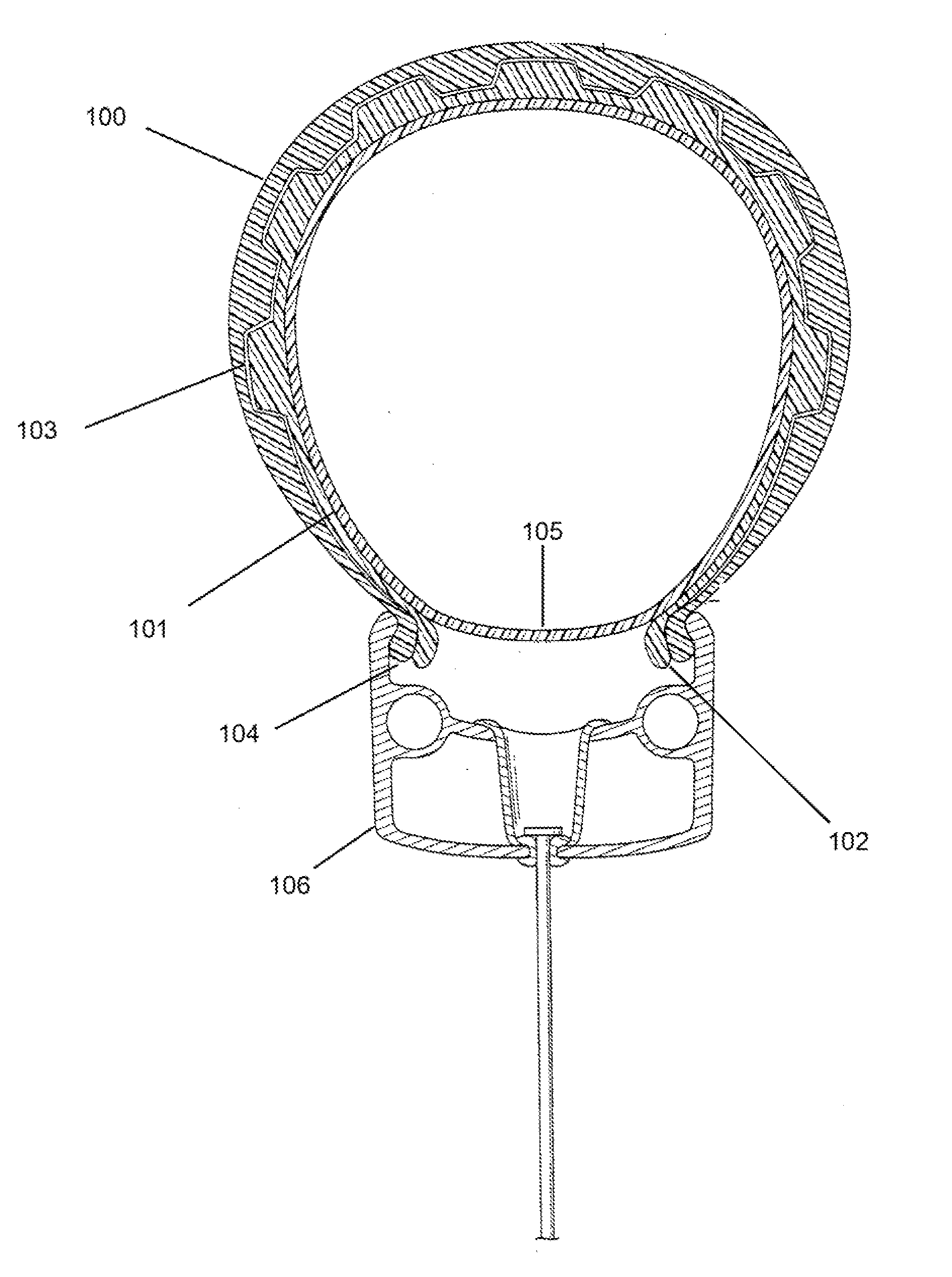

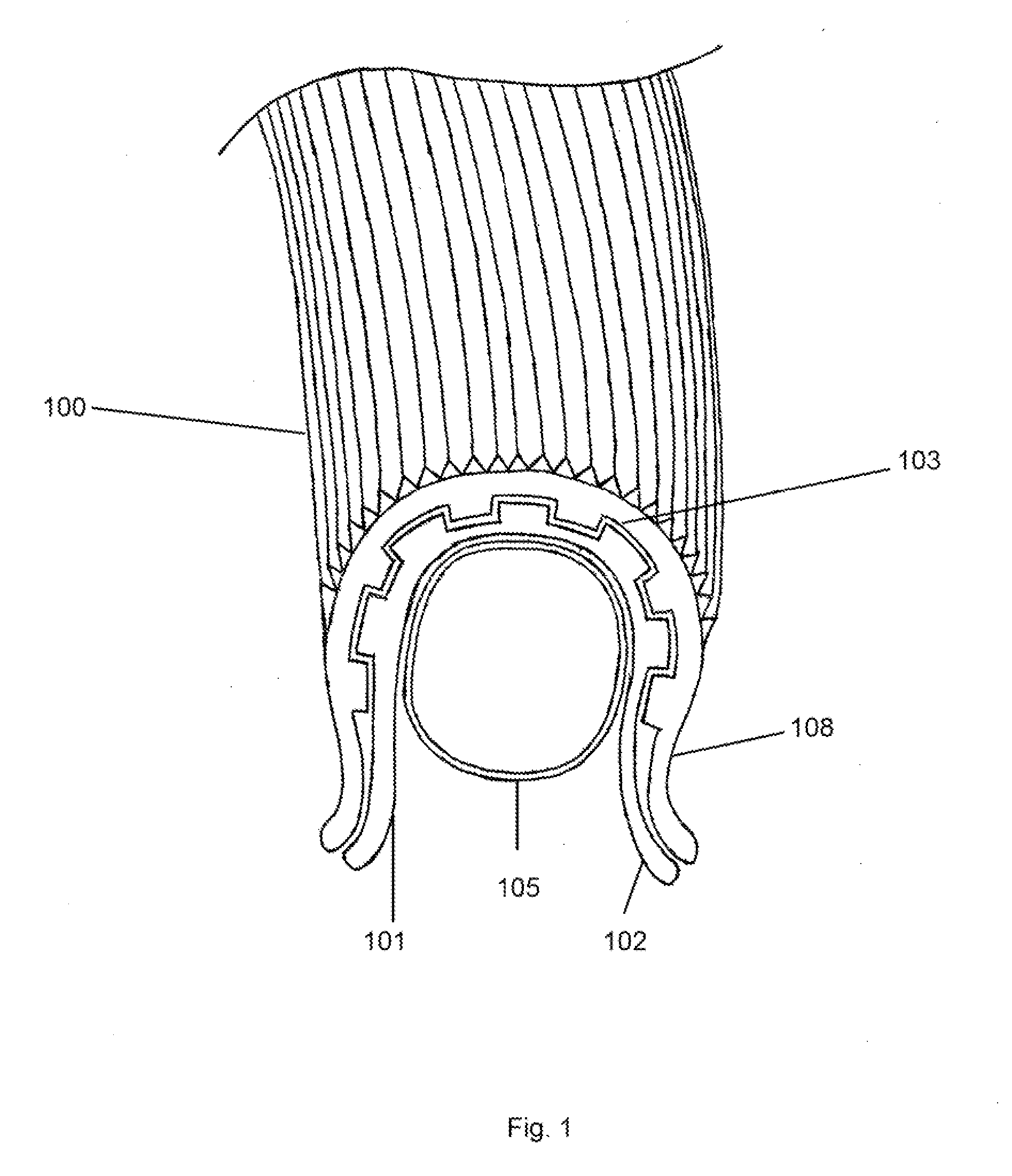

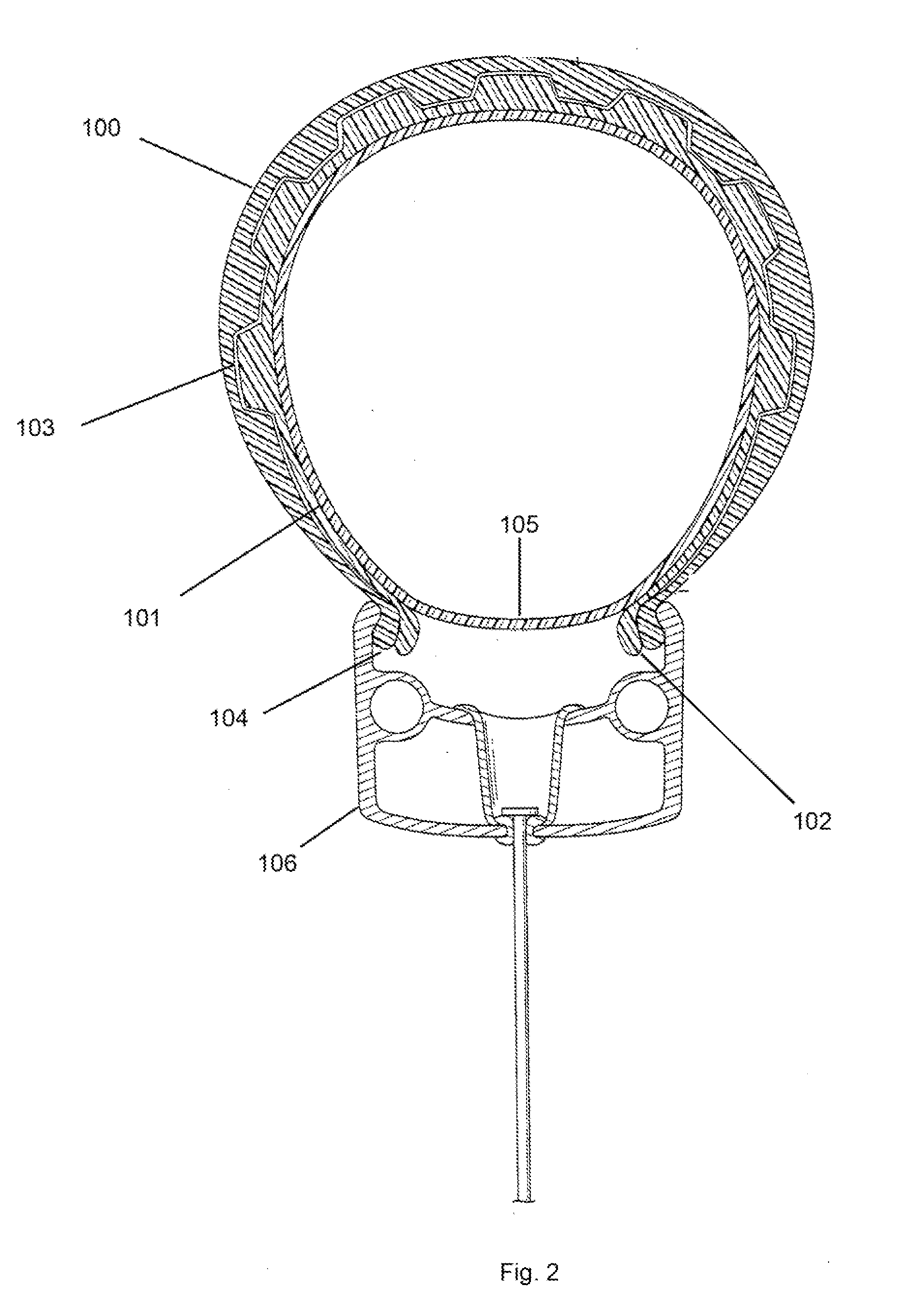

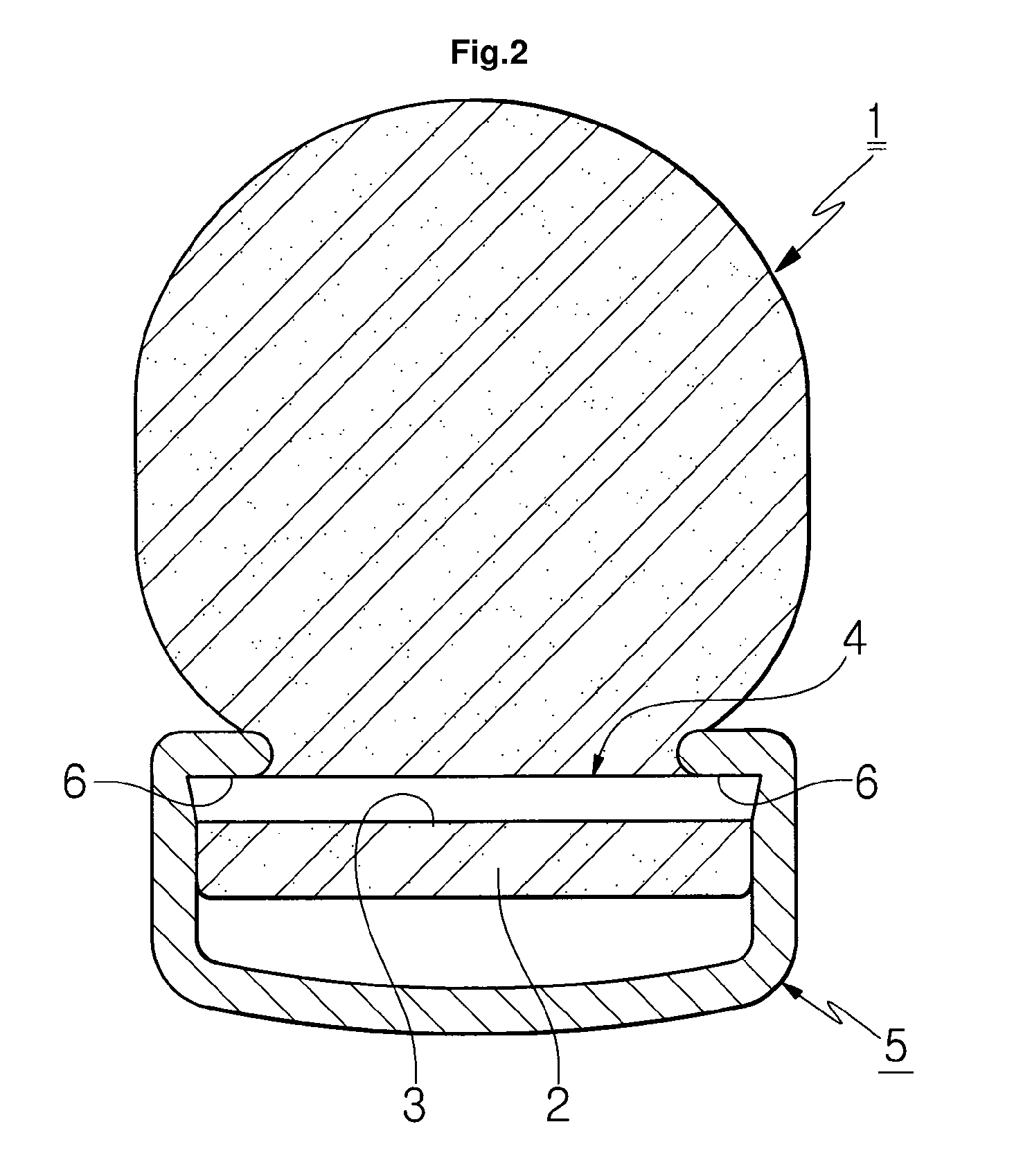

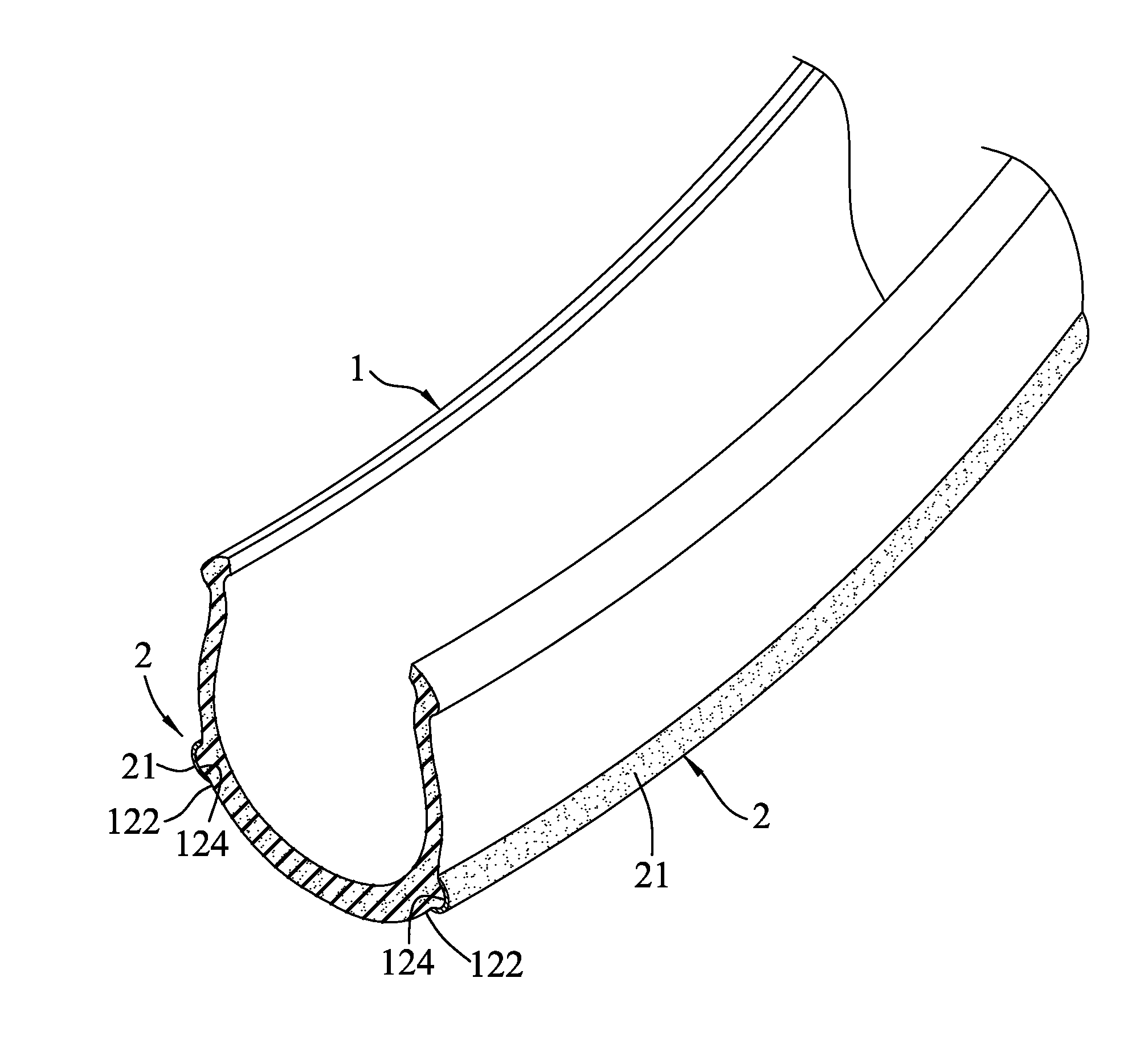

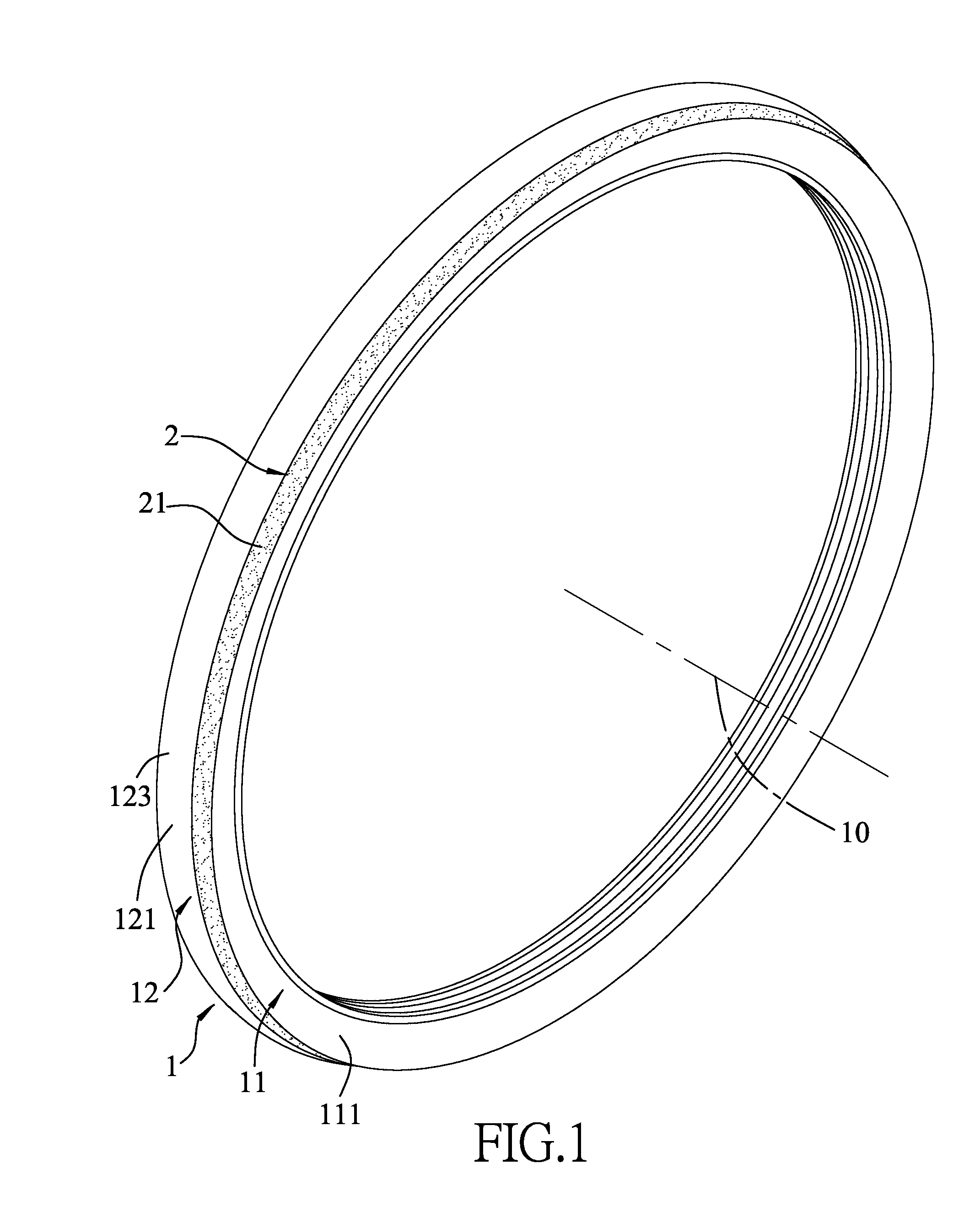

Bicycle tire

ActiveUS20120111468A1Reduce morbidityAvoid separationBicycle tyresWithout separate inflatable insertsCouplingEngineering

The present invention relates to a bicycle tire. More particularly, the bicycle tire is formed by foaming synthetic resin materials and is mounted to a rim of a bicycle, wherein the tire is prevented from being unexpectedly separated from the rim in use. That is, the bicycle tire formed by injection-foam molding is characterized in that: a rim coupling portion of the bicycle tire is formed with a plurality of coupling holes at predetermined intervals; and stoppers formed of synthetic resin materials are fixed in the coupling holes, stopped by annular holding protrusions when the tire is mounted to the bicycle rim, and formed of arch surfaces, horizontal surfaces and tilted both end surfaces so that the tilted both end surfaces are protruded when the stoppers are fixed to the coupling holes.

Owner:TANNUS CO LTD

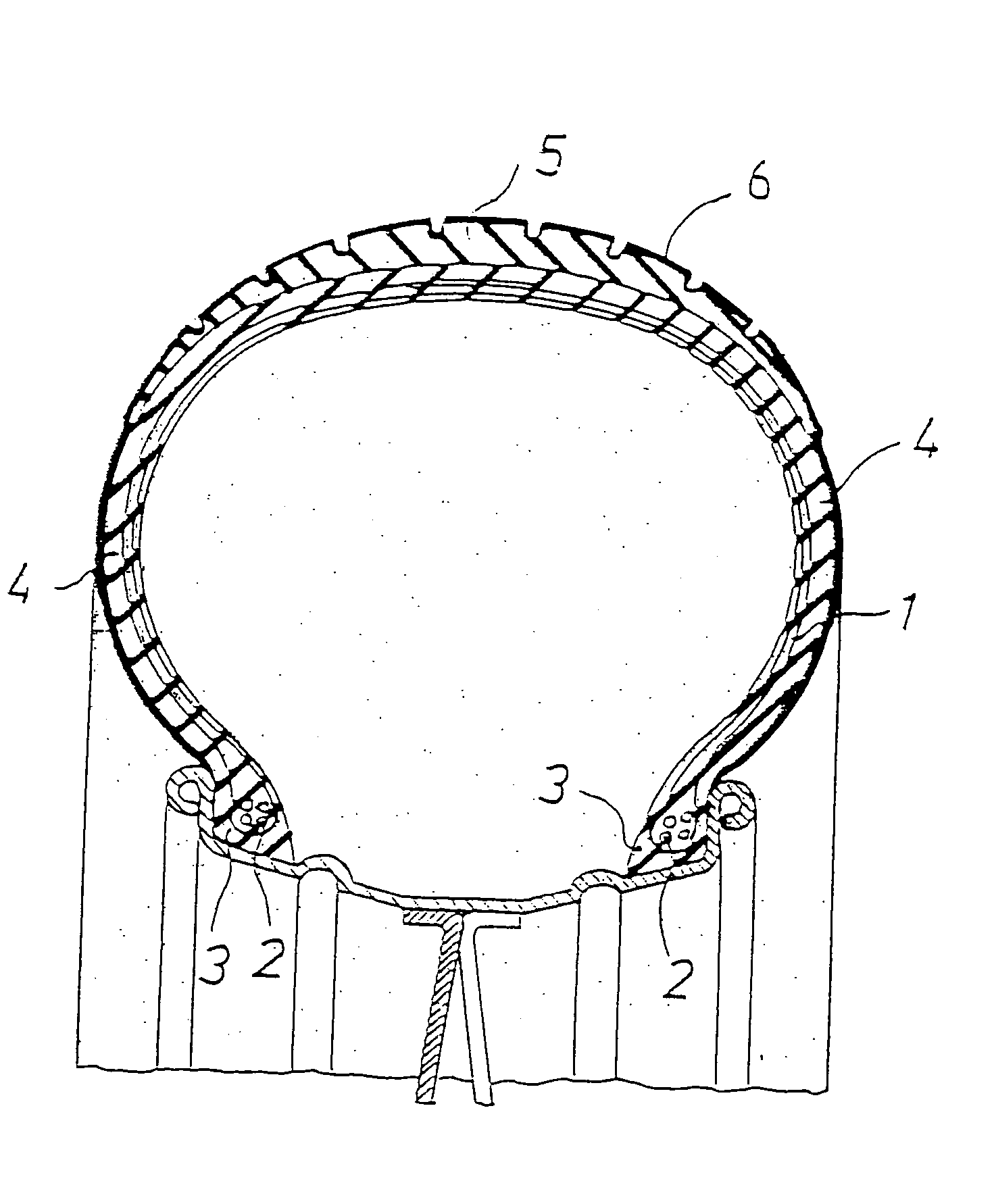

Pneumatic tire

Pneumatic tire, particularly a two-wheeler pneumatic tire, such as a bicycle tire, which includes at least one rubberized casing that is anchored in beads by wrapping bead cores. A tread is provided. An outer covering has a layer thickness of less than or equal to 0.5 mm. The outer covering has a high tear resistance and extends at least over the tread.

Owner:CONTINENTAL AG

Dynamic tire pressure regulator for bicycles

ActiveUS20170015148A1Not disrupt weight balanceBicycle tyresFlexible member pumpsRotary pumpWheel and axle

A wheel hub assembly of a bicycle wheel is disclosed that include a wheel axle, a rotary pump that may be composed of a pump housing, a pump rotor, a first fluid port configured for fluidly coupling to a pneumatic tire and a second fluid port configured for fluidly coupling to a fluid reservoir. The assembly allows for conveniently and efficiently modifying the tire pressure in bicycles at will while riding, in as many cycles as desired and without contaminating the air inside the tires.

Owner:VERSEC

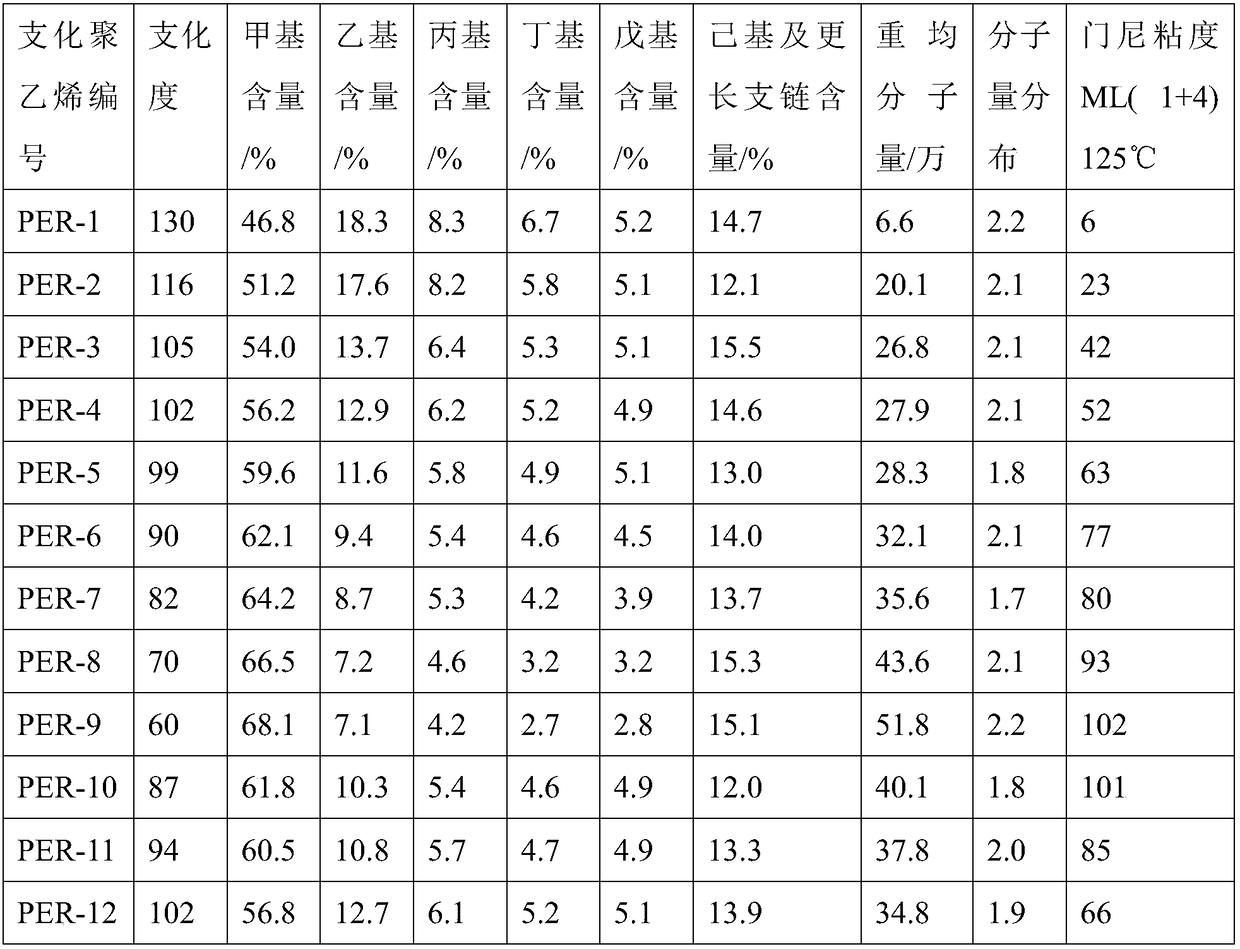

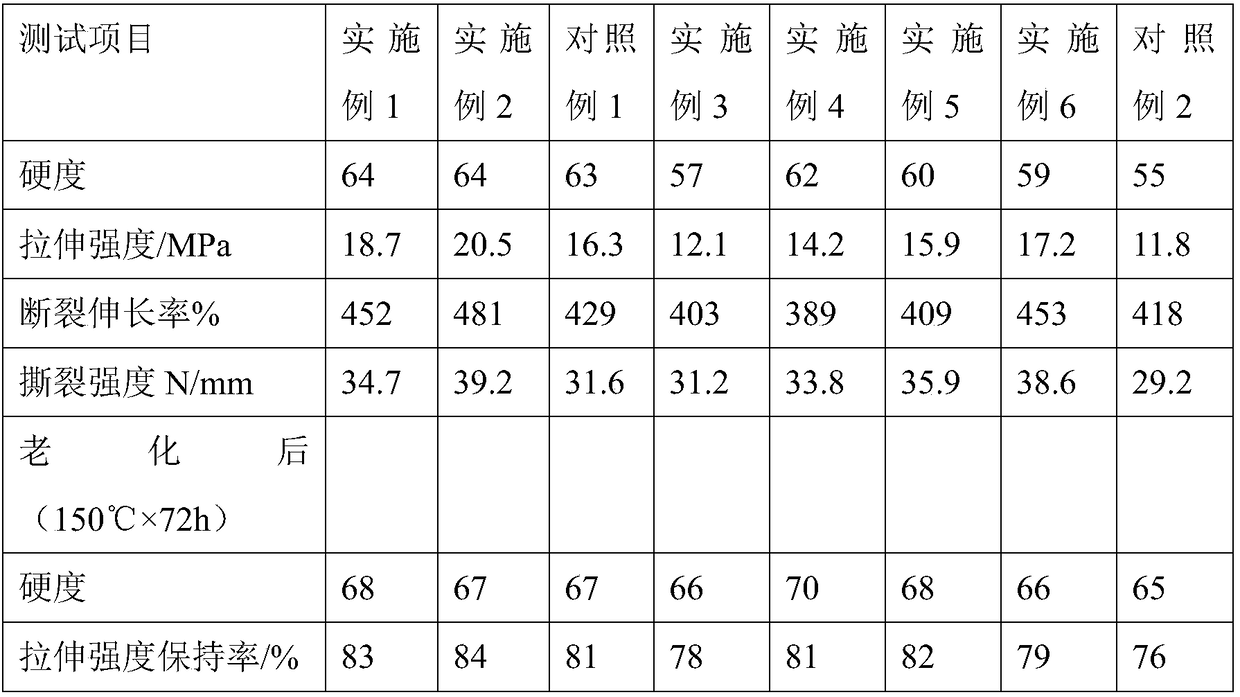

Rubber composition, processing method, rubber product adopting rubber composition and production method

ActiveCN108314850AImprove heat resistanceImprove stress resistanceRubber insulatorsAgricultural vehiclesCross-linkPolymer science

The invention discloses a rubber composition, a processing method, application of the rubber composition to a rubber product, and a production method of the rubber product. The rubber composition comprises a rubber matrix and necessary components, wherein the rubber matrix comprises the following components: being greater than 0 and smaller than or equal to 100 parts of branched polyethylene, greater than or equal to 0 and smaller than 100 parts of ethyene-propylene rubber and ethylene propylene terpolymer; the necessary components comprise the following components: 1.5 to 10 parts of a cross-linking agent, and 40 to 200 parts of a reinforcing filler; the reinforcing filler comprises 5 to 100 parts carbon black, and 5 to 60 parts of white carbon black, and can further comprise one or moreof calcium carbonate, talcum powder, calcined pottery clay, magnesium silicate and magnesium carbonate. The rubber composition is applied for the manufacture of the rubber product. The rubber productcomprises an insulating material for manufacturing high-strength cables and cords, a waterproof roll and a high temperature-resistance conveying belt. The rubber composition has the benefits that theyield and the tearing strength of the rubber product are improved, and the service performance of the rubber product is improved.

Owner:HANGZHOU XINGLU TECH CO LTD +1

High efficiency integrated automotive wheel

InactiveUS8020596B1Reduce energy lossSmall overall deformationWithout cord reinforcementBicycle tyresRoad surfaceElectric vehicle

The present device is an integrated automotive wheel for electric vehicles which substantially reduces energy loss due to tire flex and energy loss from a conventional drive train. The wheel includes an axle, a hub, two composite sidewalls, a low pressure inner chamber with shock absorbing hub protector, and at least one outer high pressure pneumatic chamber with tread. The hub can contain an electric hub motor which rotates the wheel, propelling the vehicle. The sidewalls include at least one pressurized chamber which position the outer tread ring and enable the wheel to simulate an energy efficient high pressure pneumatic wheel, experiencing little deformation when under smooth road conditions. When road conditions are rough, the sidewalls can temporarily buckle in response to the increased road forces, simulating a low pressure conventional tire having ample space for deformation, with suspension and shock absorption capability built in. The sidewalls and outer ring chamber can be filled with high pressure closed cell foam to prevent flats.

Owner:MORRISON GLENN ARTHUR

Tire

InactiveUS20130312883A1Improve airtightnessLight weightBicycle tyresNon-inflatable tyresEngineeringAir tightness

A tire includes a carcass and a tread member. The carcass has a tread portion, two sidewalls on opposite sides of the tread portion, and two beads on distal ends of the sidewalls. The tread member has a tread protective layer provided on an outer side of the tread portion of the carcass and a skin layer provided on the tread protective layer. In an embodiment the tire further includes a sidewall protective layer and a bead protective layer to protect the sidewalls and the beads of the carcass. The tire may have a good airtight condition and a light weight.

Owner:KENDA RUBBER INDUSTRIAL COMPANY

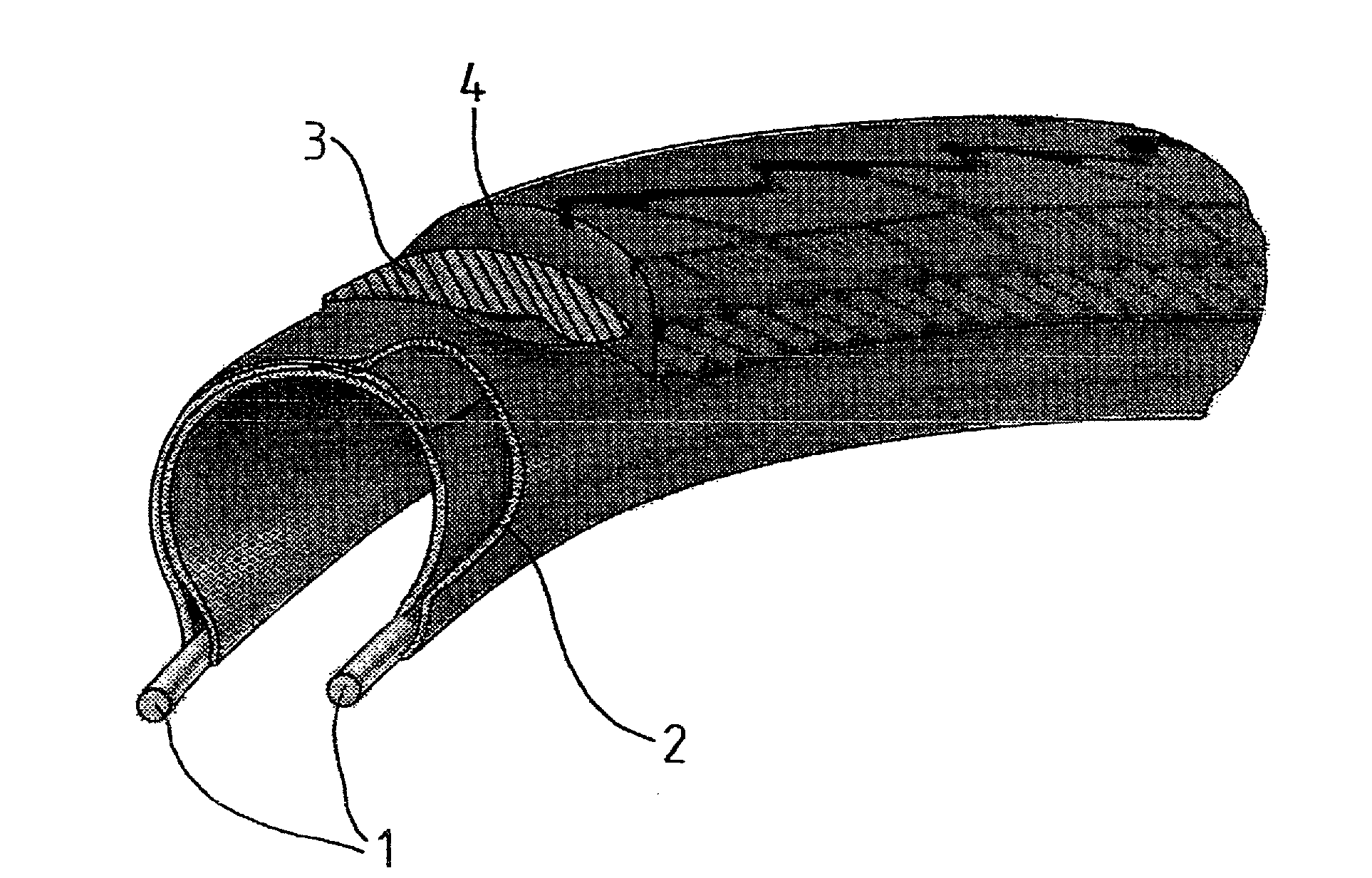

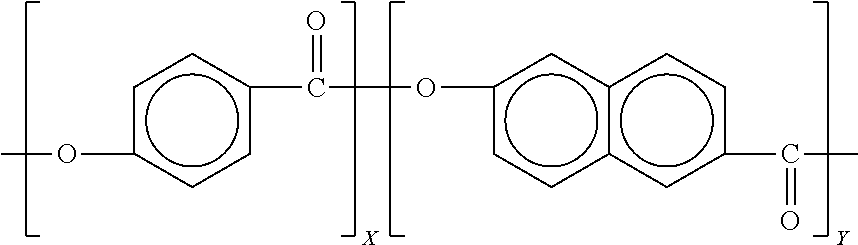

Bicycle tire with reinforcement layer

ActiveUS9016341B2Increase resistanceReduce weightBicycle tyresPneumatic tyre reinforcementsPolyesterLiquid crystal

Bicycle tires with at least one reinforcement layer that contains strength supports and that is arranged between carcass and tread rubber and / or between carcass layers below the tread rubber and / or within the tread rubber. For a high resistance to puncturing with low weight, the reinforcement layer contains multifilament threads of more than 30 polyester / polyarylate filaments, and the filaments are spun from molten liquid-crystal polymer.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

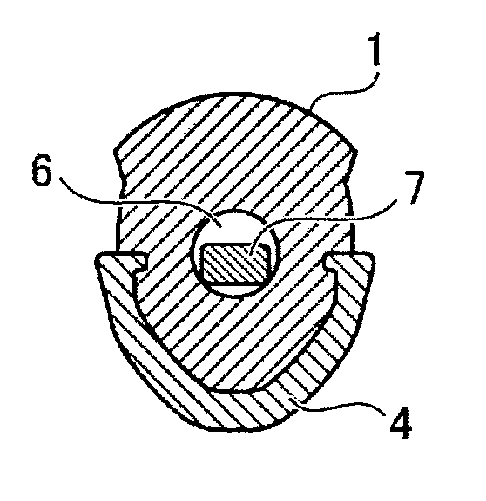

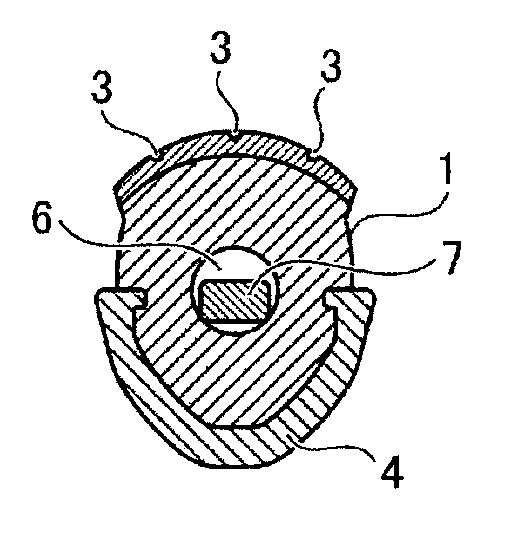

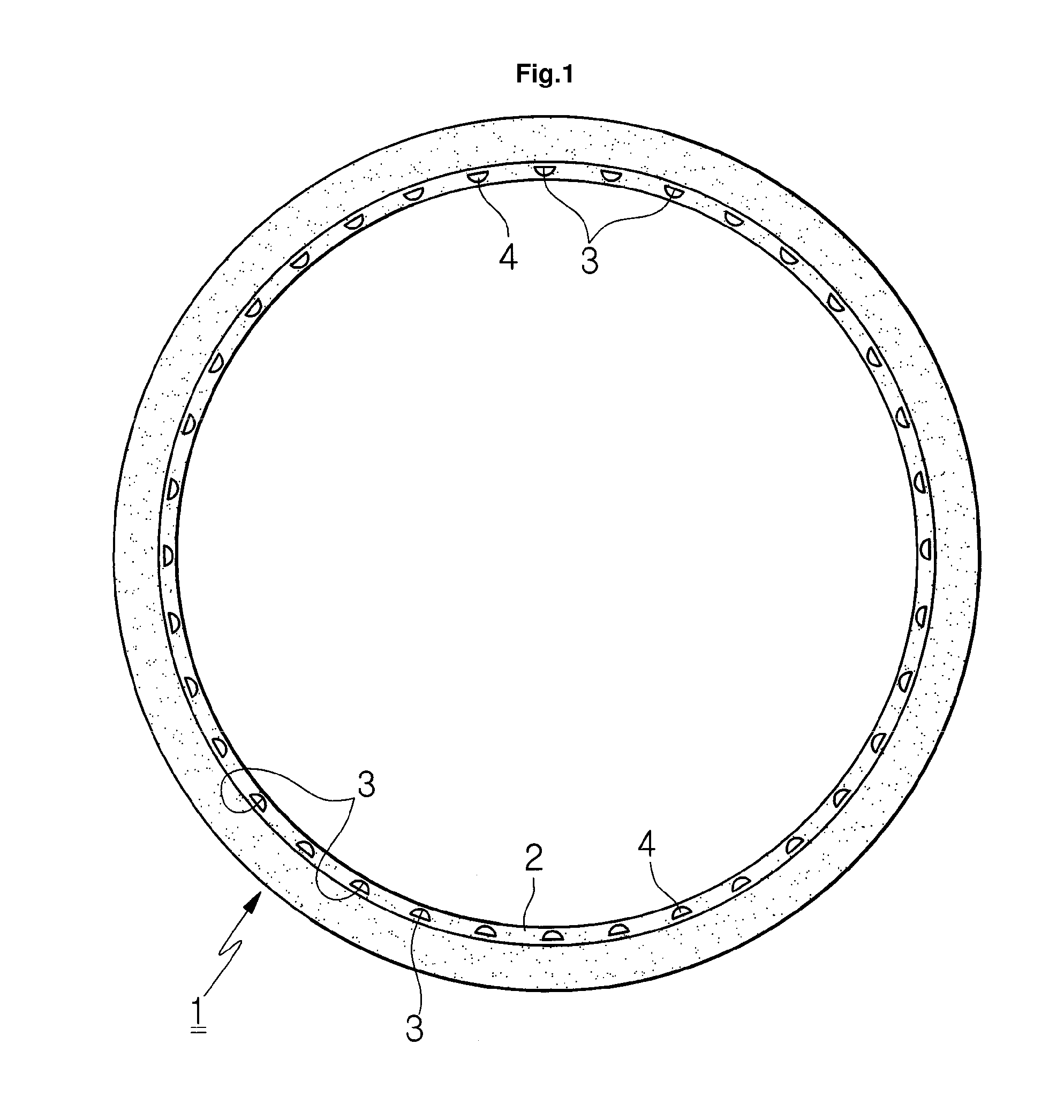

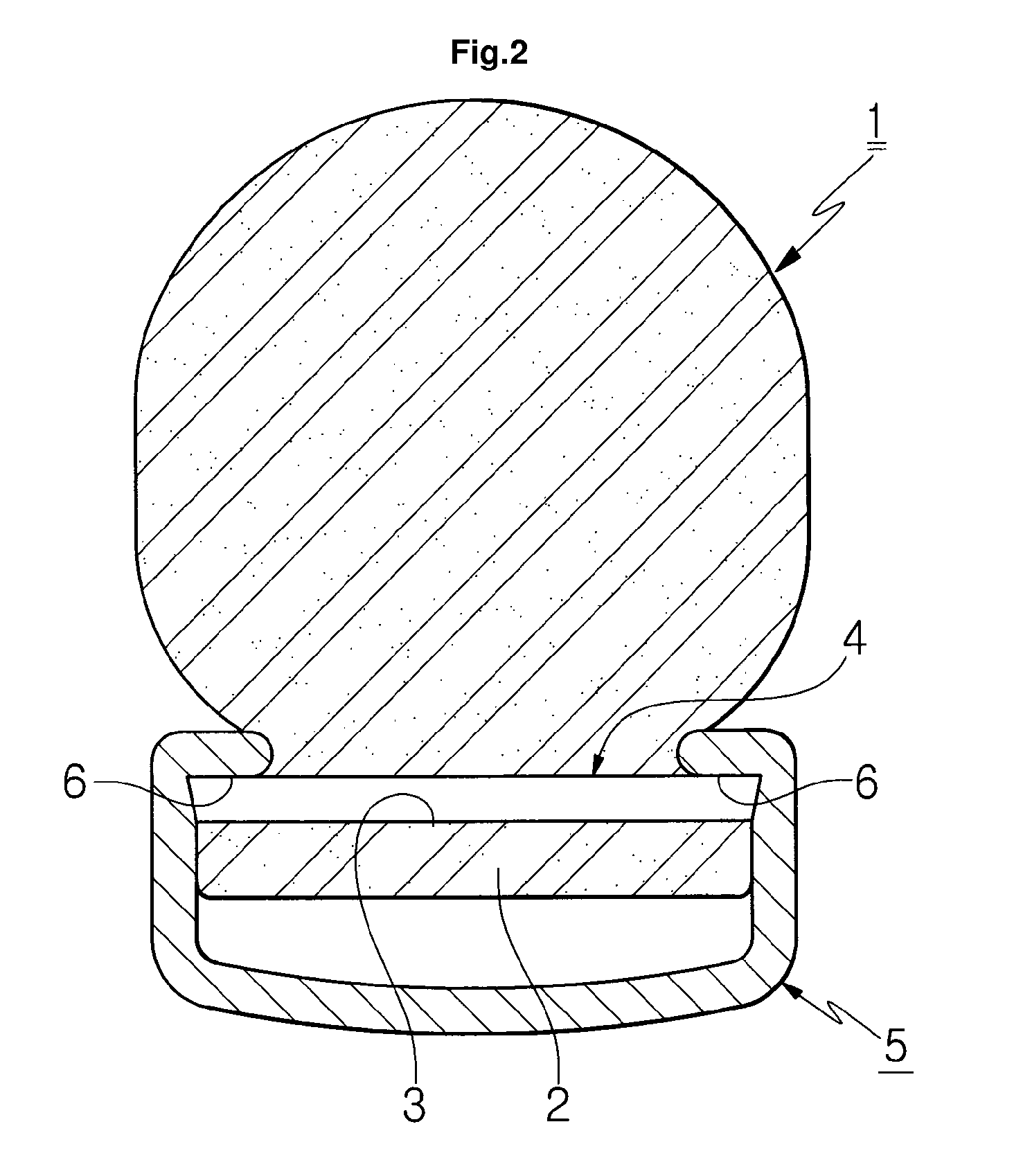

Bicycle tire

ActiveUS8770243B2Avoid separationDriving comfortBicycle tyresWithout separate inflatable insertsCouplingEngineering

The present invention relates to a bicycle tire. More particularly, the bicycle tire is formed by foaming synthetic resin materials and is mounted to a rim of a bicycle, wherein the tire is prevented from being unexpectedly separated from the rim in use. That is, the bicycle tire formed by injection-foam molding is characterized in that: a rim coupling portion of the bicycle tire is formed with a plurality of coupling holes at predetermined intervals; and stoppers formed of synthetic resin materials are fixed in the coupling holes, stopped by annular holding protrusions when the tire is mounted to the bicycle rim, and formed of arch surfaces, horizontal surfaces and tilted both end surfaces so that the tilted both end surfaces are protruded when the stoppers are fixed to the coupling holes.

Owner:TANNUS CO LTD

Bicycle tire tube and manufacture method thereof

ActiveCN102785534AEasy to installEasy to disassembleBicycle tyresWith separate inflatable insertsEngineeringMental detachment

Owner:JINZHOU XINXING RUBBER PRODN

Bicycle tire

InactiveUS20100230025A1Reduce the amount requiredReduce slippageBicycle tyresWithout separate inflatable insertsMechanical engineeringTread

A bicycle tire provides a first sidewall and a second sidewall each including an interior portion and an exterior portion. A rim attaching portion including a slipping reduction portion having an extended rim contact surface is connected to an inner circumference of each of the first sidewall and the second sidewall. A tire tread portion is connected to an outer circumference of the first sidewall and the second sidewall.

Owner:KAWAI SHUJI

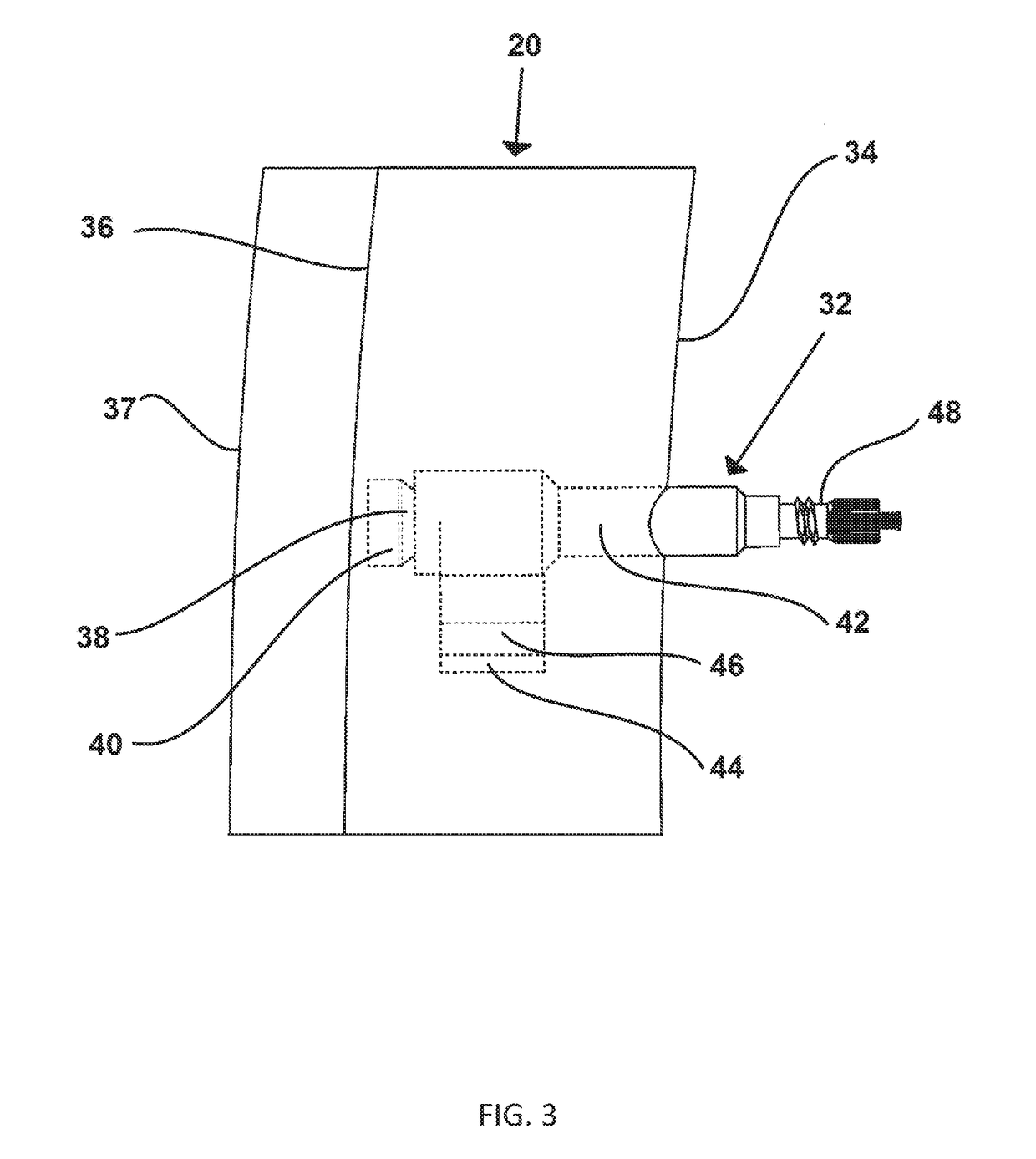

Pressure sensing assembly for a bicycle wheel

A pressure sensing assembly configured to be attached to a bicycle wheel having a tire and a rim mounted to the tire. The pressure sensing assembly includes a housing, a pressure transmitting member, a sensing chamber defined by the housing and the pressure transmitting member, and a sensing element. The pressure transmitting member is coupled the housing and has a central portion offset from the plane in a first direction. The sensing element is offset from the plane in a second direction opposite the first direction. The pressure transmitting member is configured to transmit a pressure in the tire to the sensing element via the sensing chamber.

Owner:SRAM CORPORATION

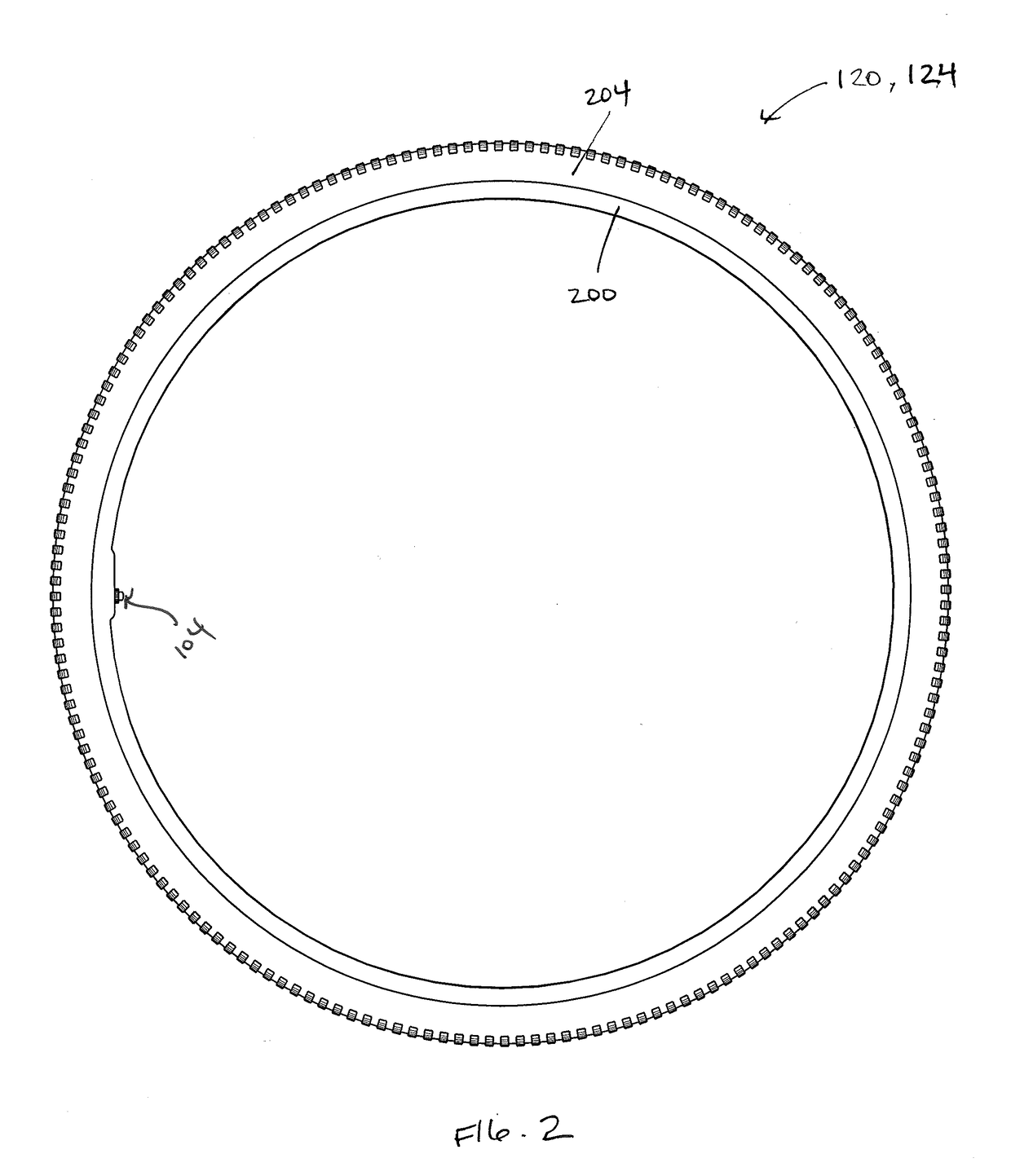

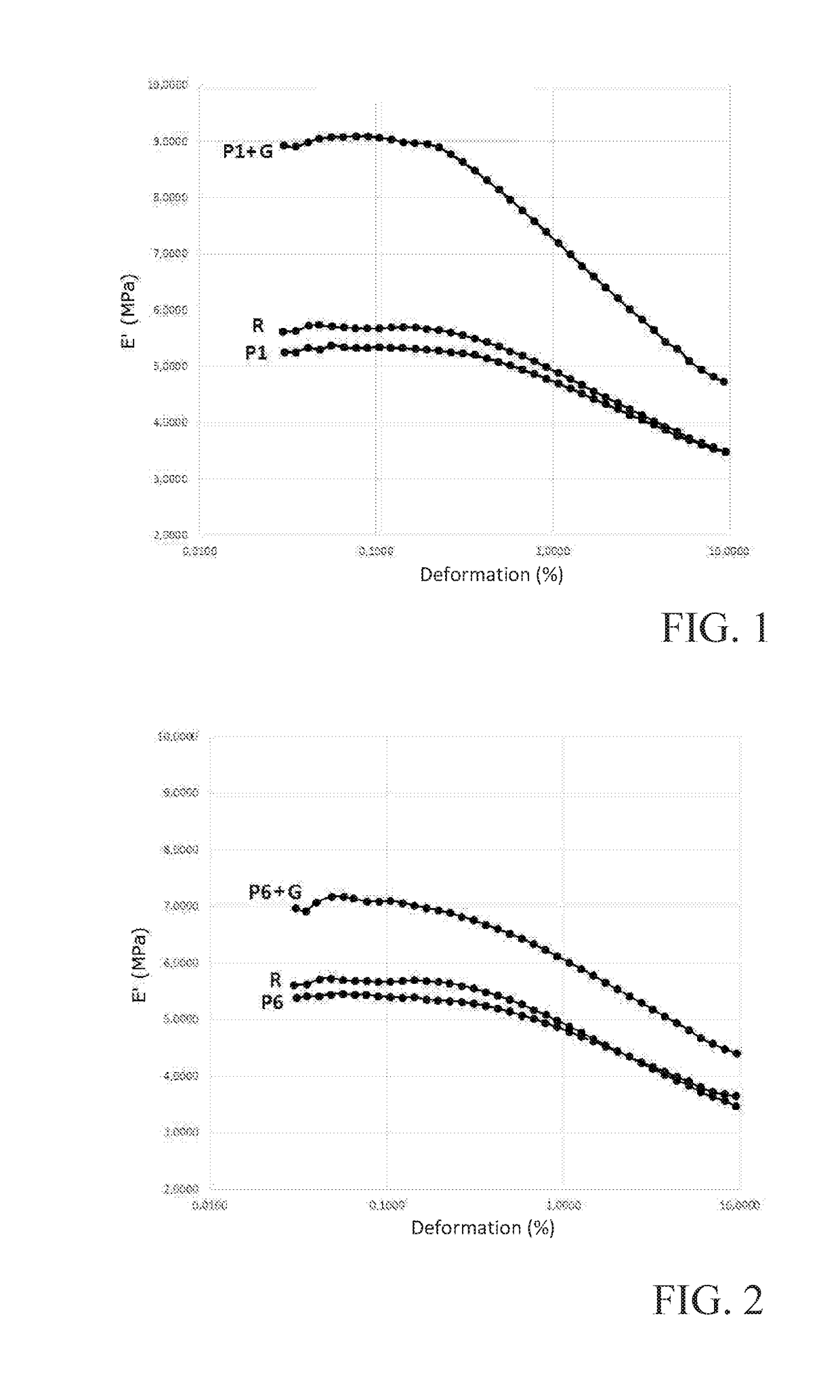

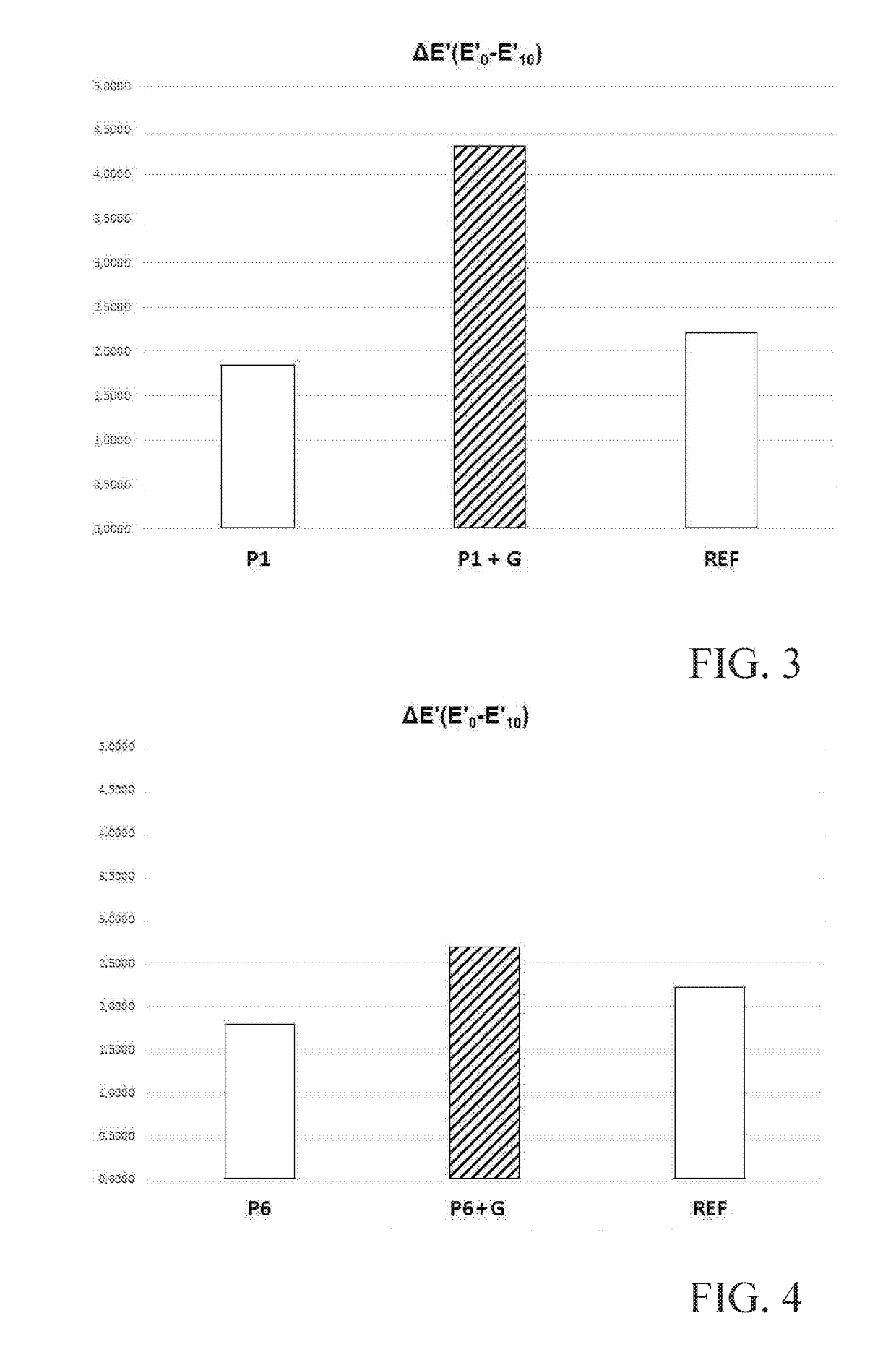

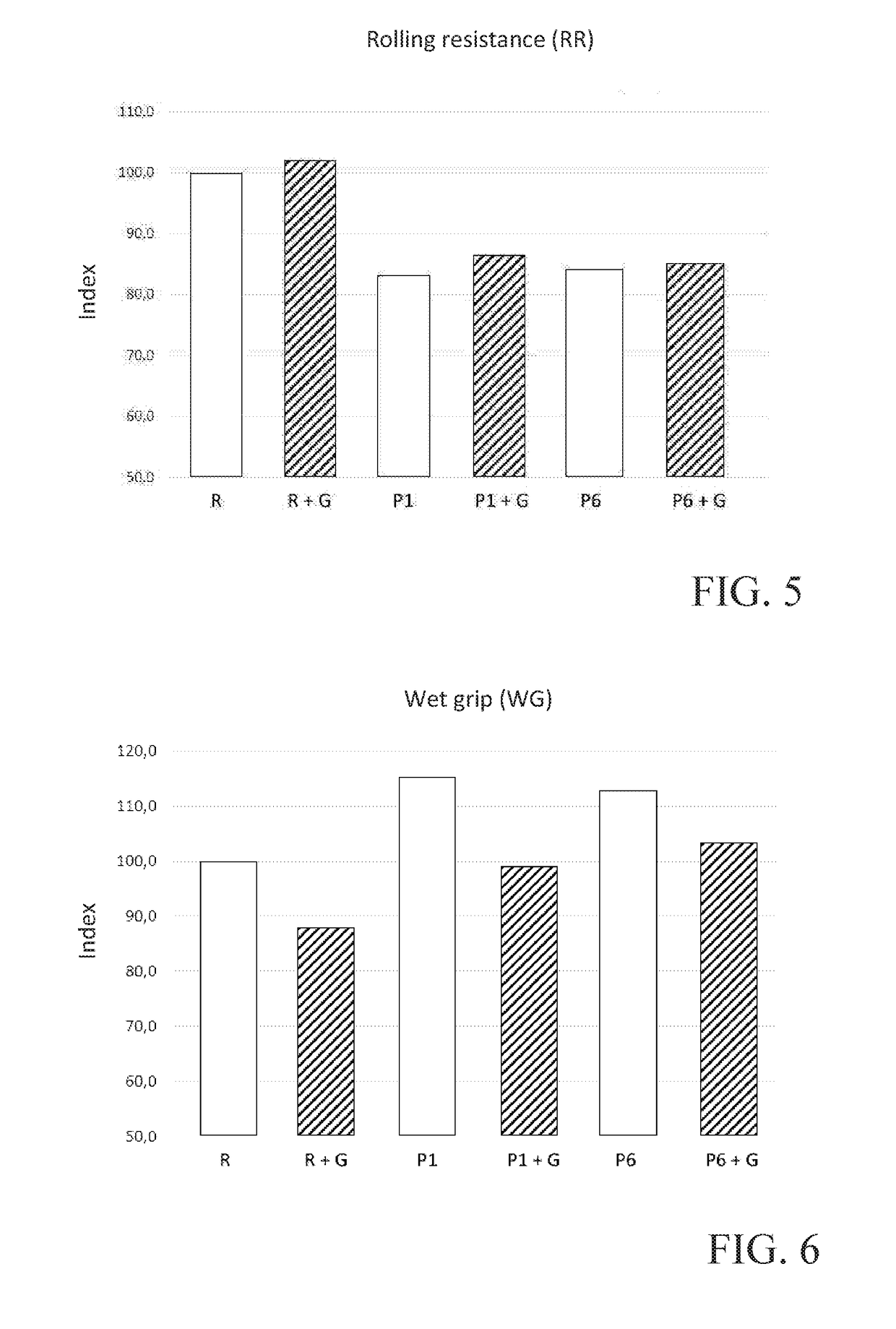

Elastomeric composition comprising graphene and tire components comprising said composition

ActiveUS20180215904A1Improve propertiesImprove balanceBicycle tyresInflatable tyresElastomerGraphene

Elastomeric composition for producing tire components comprising, based upon parts by weight per 100 parts by weight of rubber (phr):(A) 100 phr of a blend of rubber comprising at least 20% by weight of an isoprene polymer;(B) from 0 to 30 phr of silica;(C) from 0 to 50 phr of amorphous carbon black;(D) from 1 to 40 phr of graphene,wherein the graphene consists of graphene nanoplatelets, wherein at least 90% have a lateral size (x, y) from 50 to 50000 nm and a thickness (z) from 0.34 to 50 nm, wherein the lateral size is always greater than the thickness (x, y>z), and wherein the C / O ratio is ≥100:1.

Owner:DIRECTA PLUS

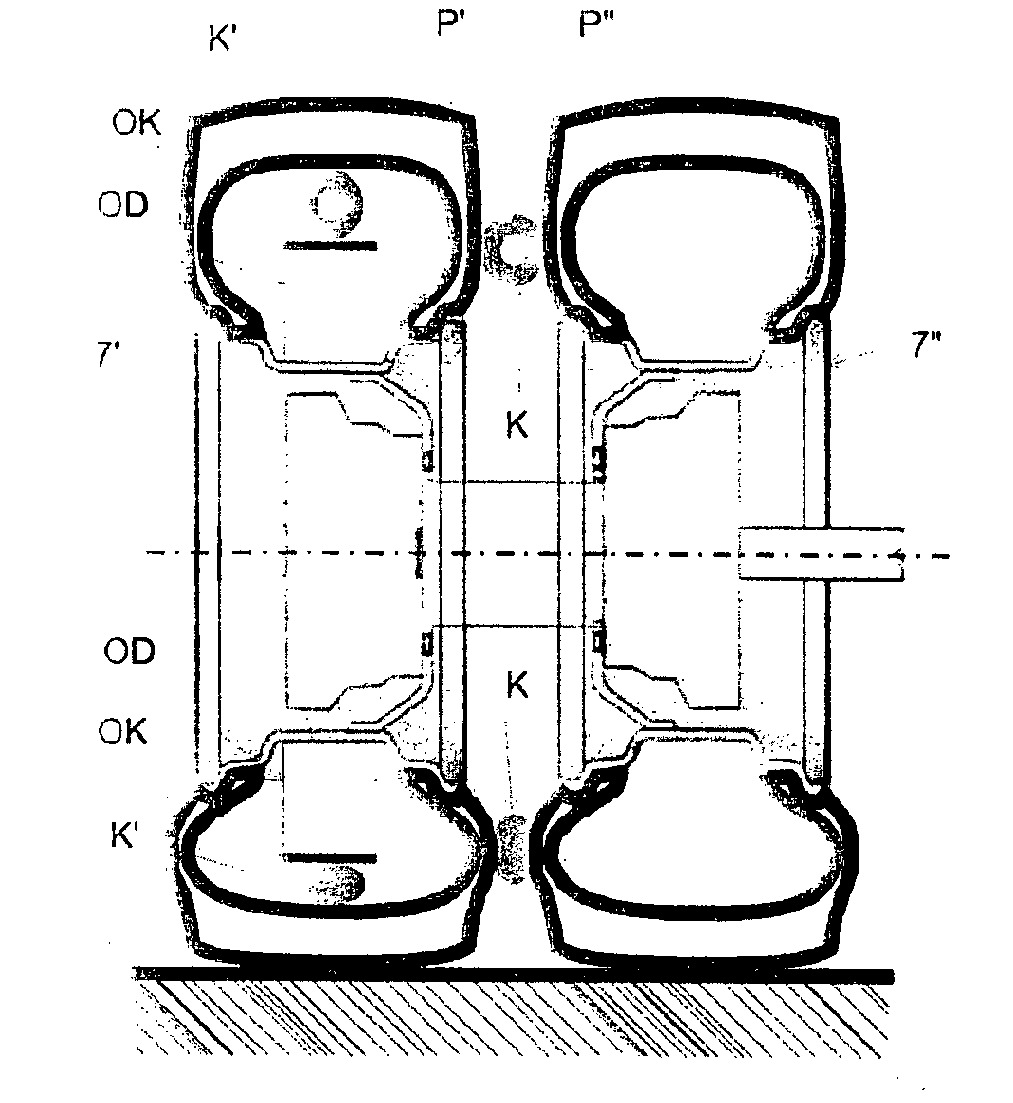

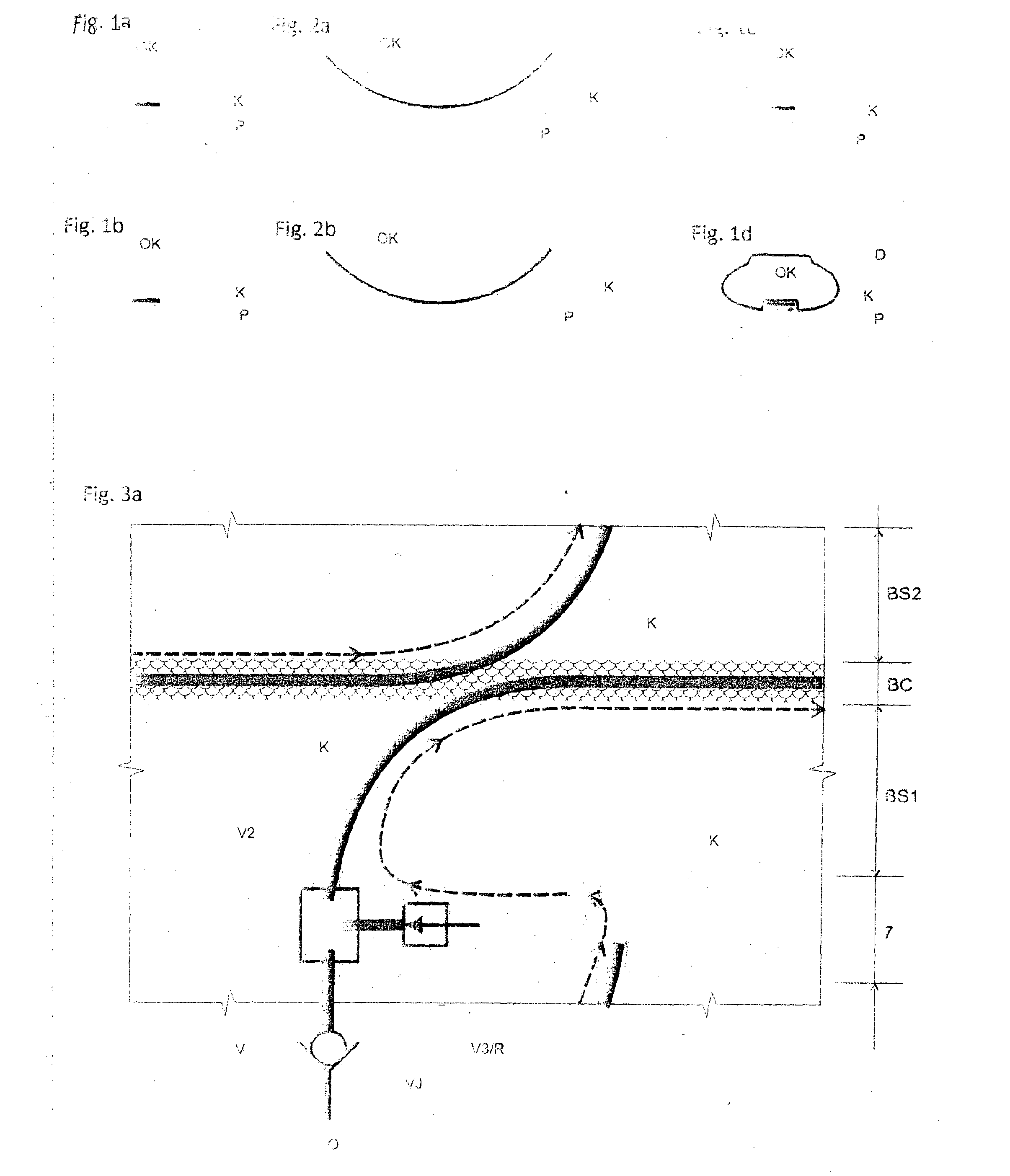

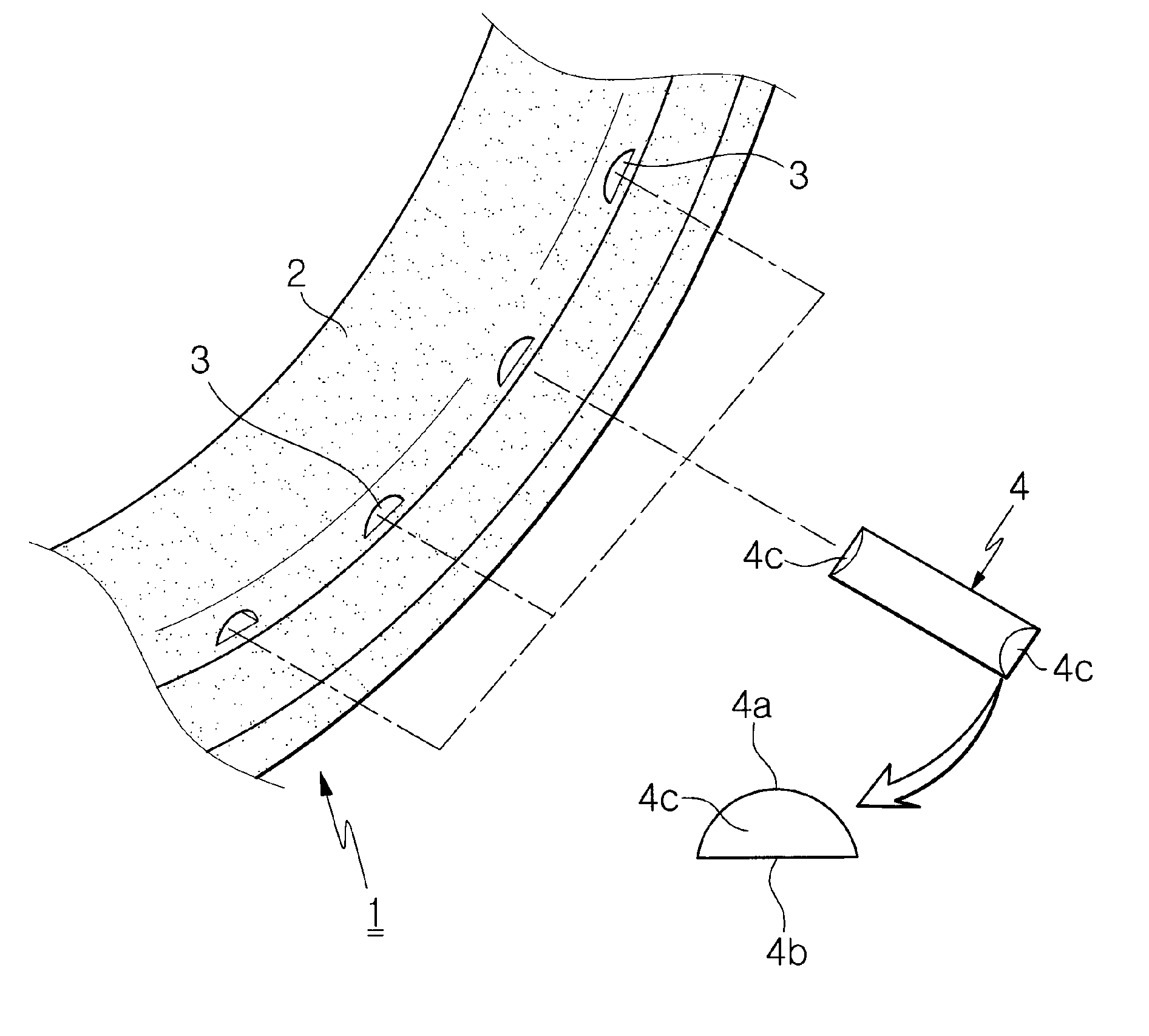

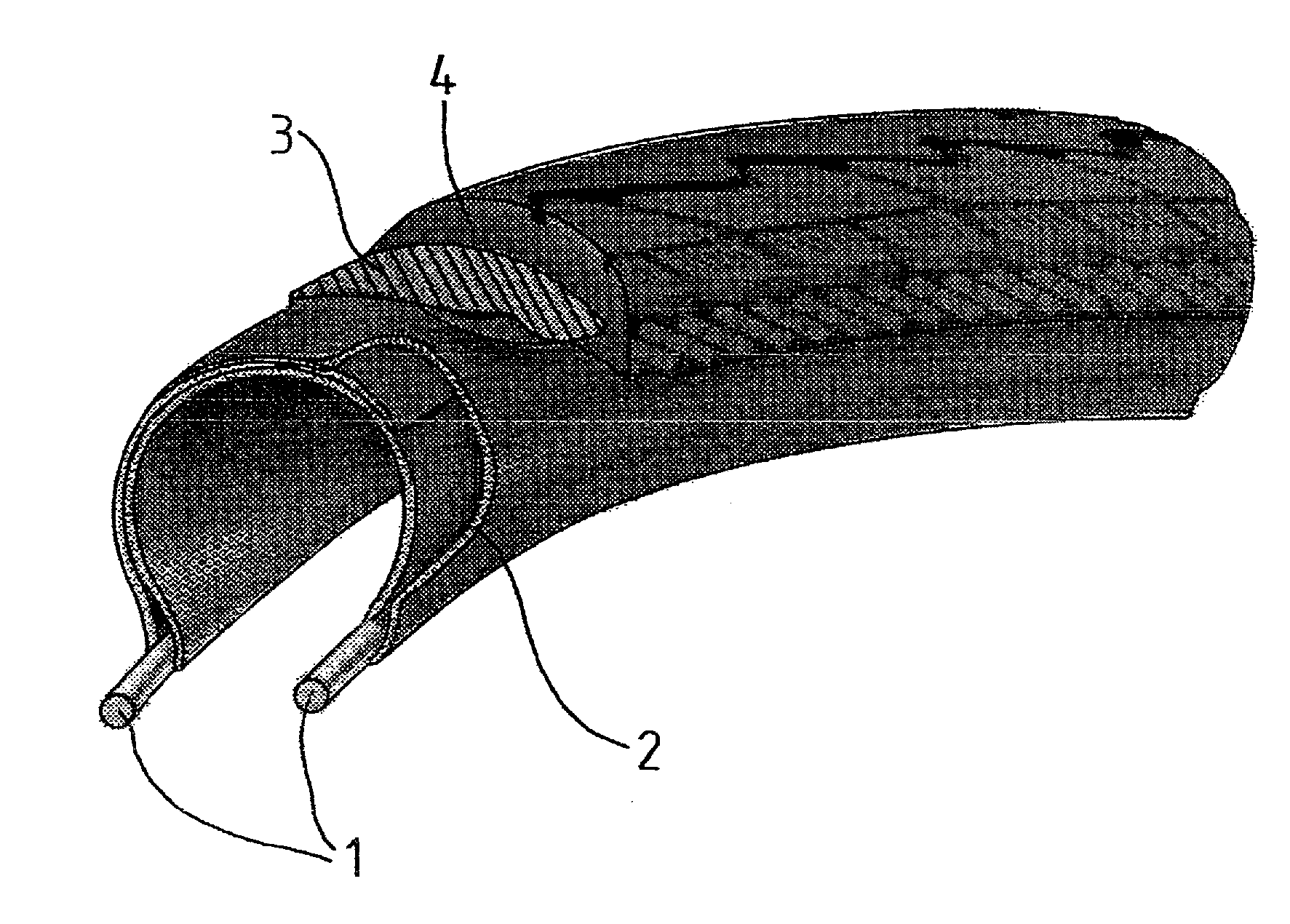

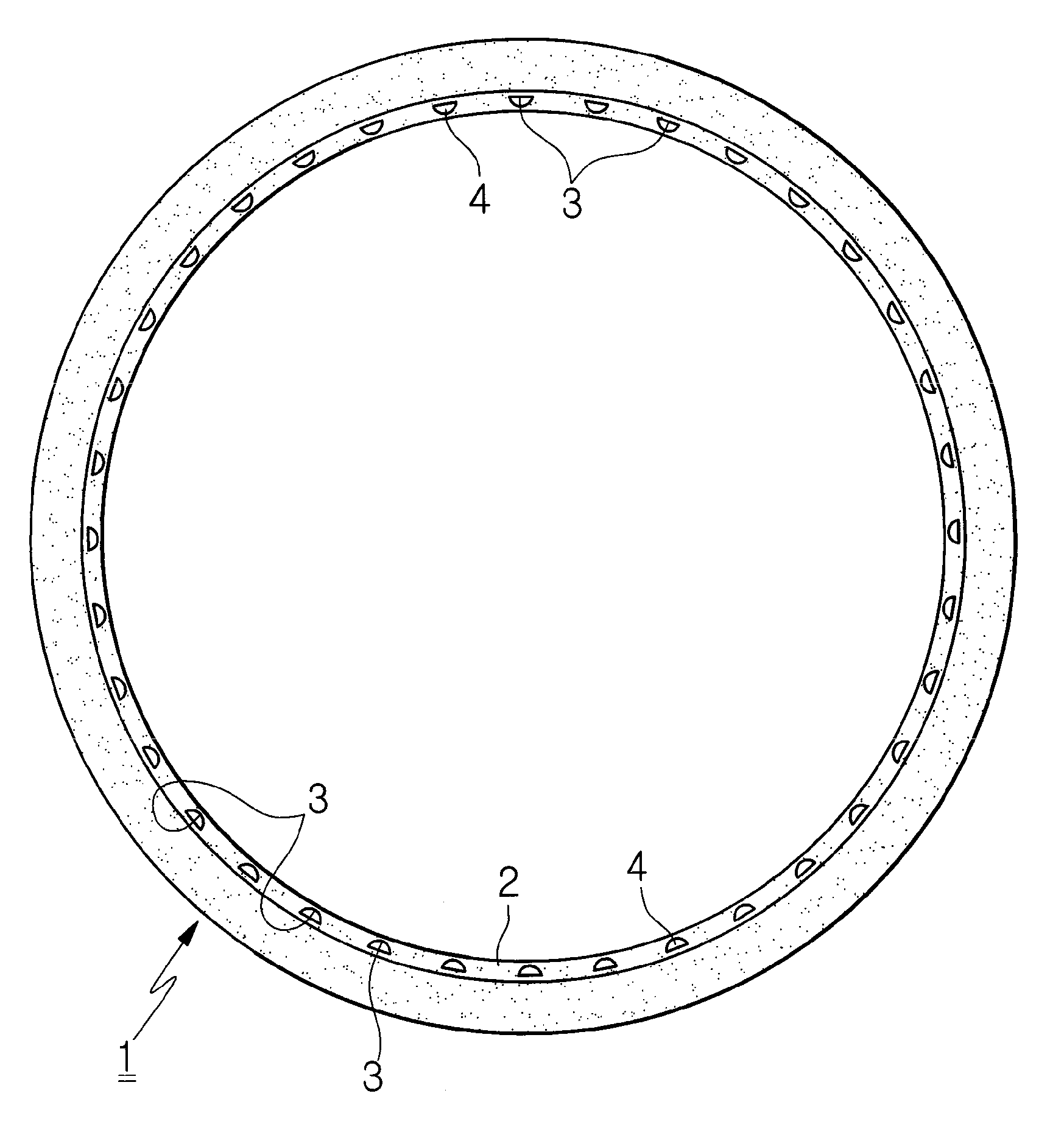

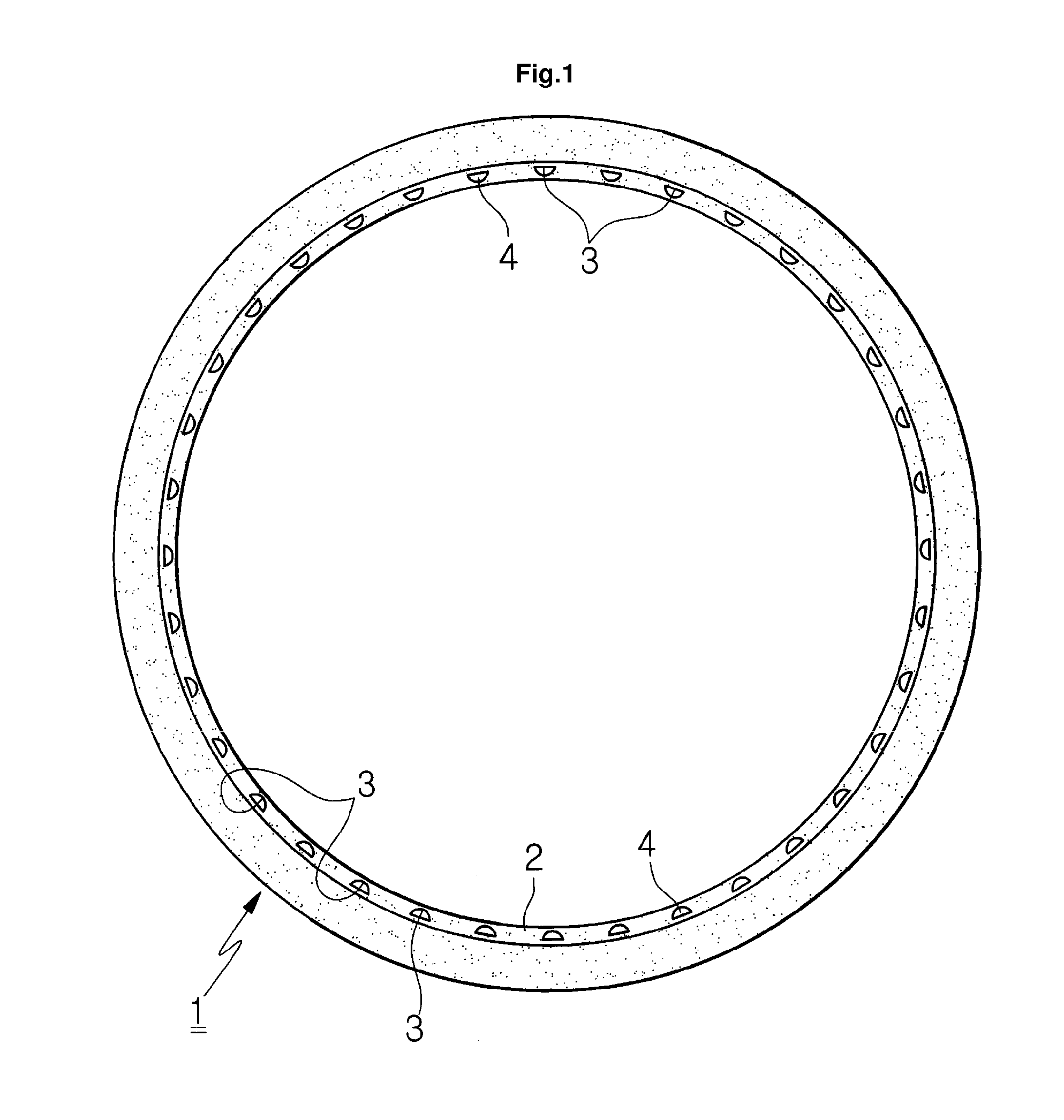

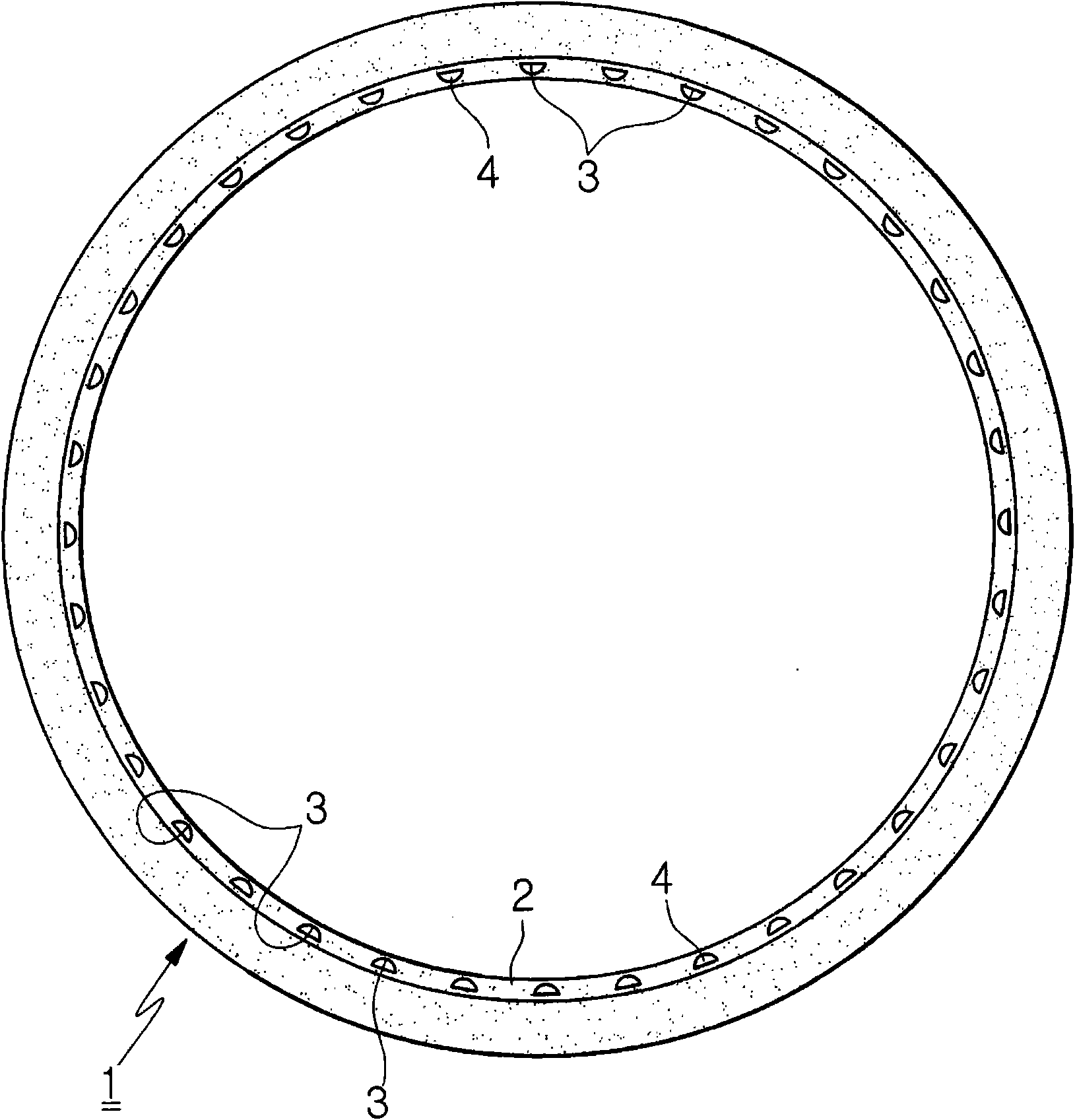

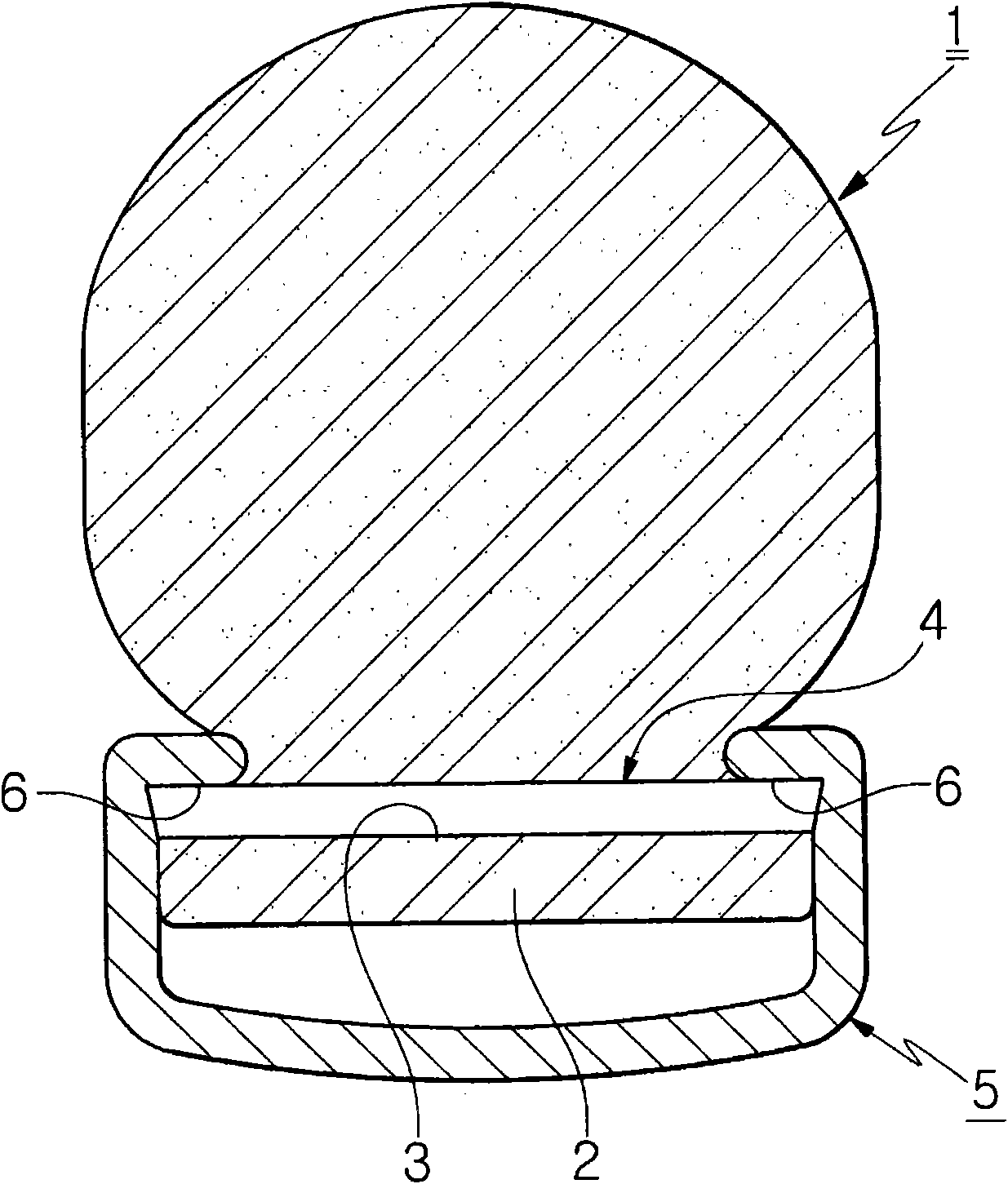

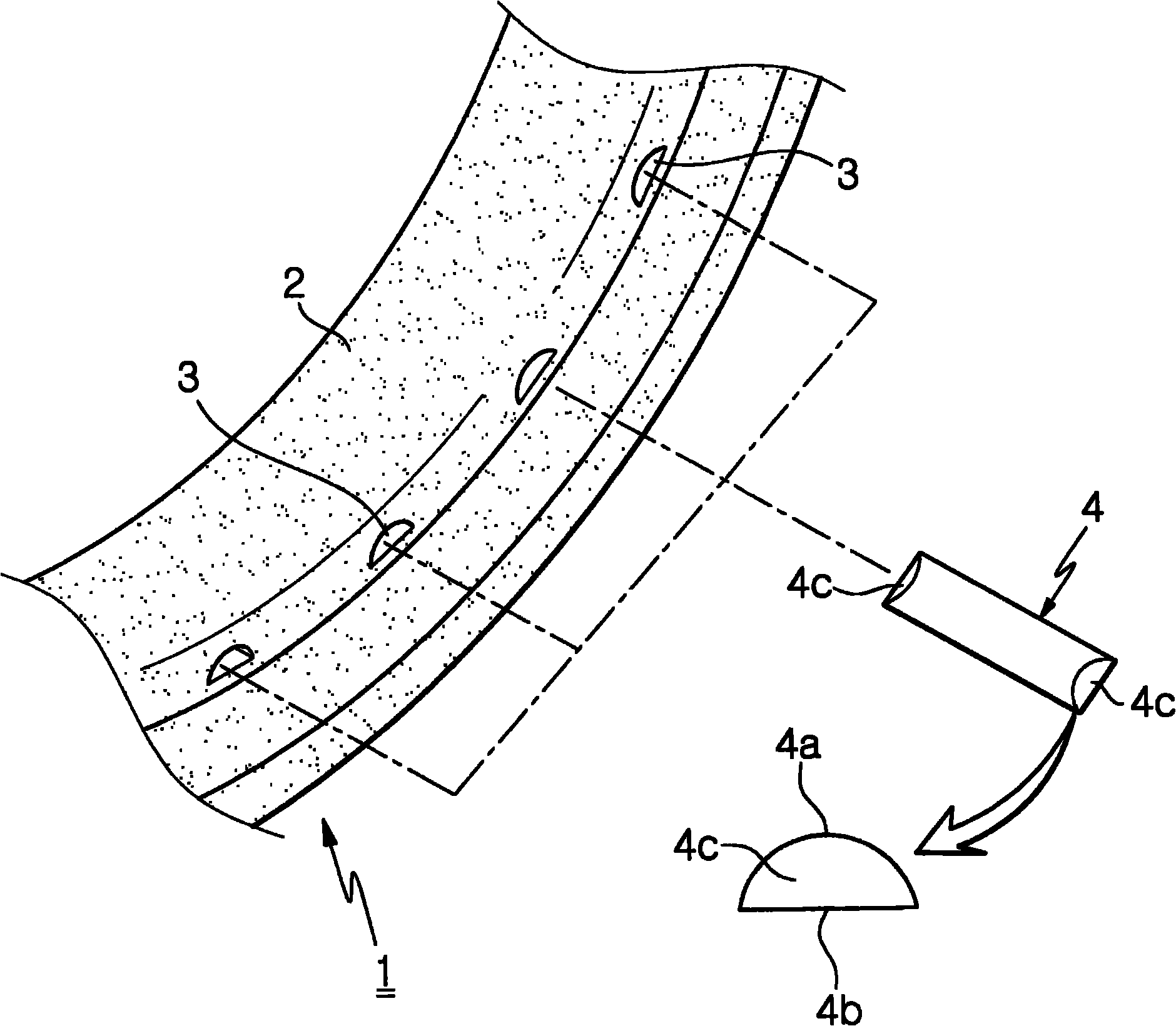

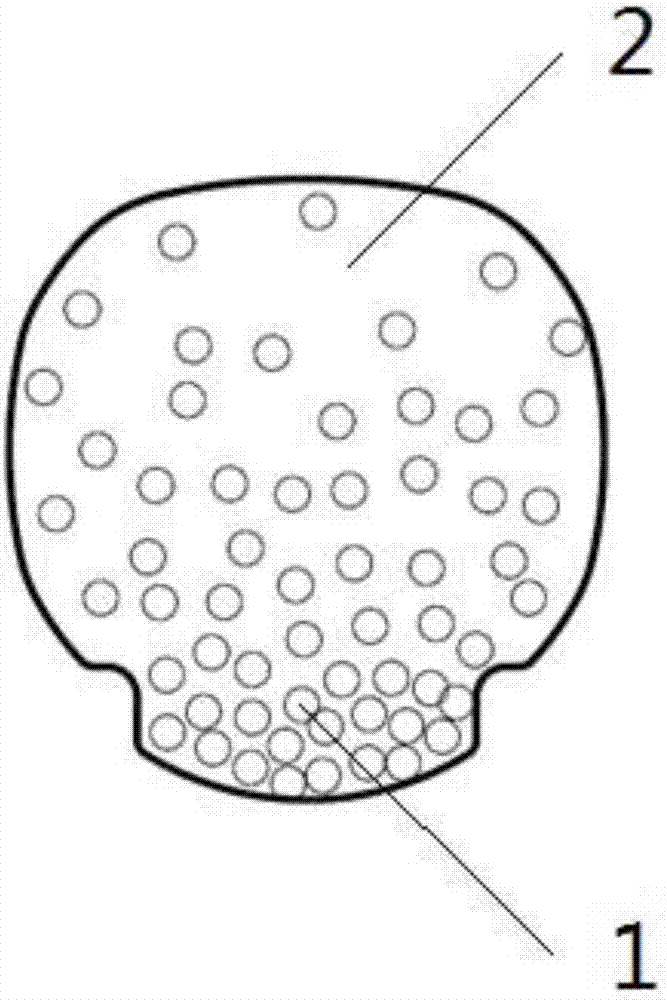

Bicycle tire

ActiveCN102026831AInhibit sheddingRandom fall offBicycle tyresNon-inflatable tyresCouplingSynthetic resin

The present invention relates to a bicycle tire. More particularly, the bicycle tire is formed by foaming synthetic resin materials and is mounted to a rim of a bicycle, wherein the tire is prevented from being unexpectedly separated from the rim in use. That is, the bicycle tire (1) formed by injection-foam molding is characterized in that: a rim coupling portion (2) of the bicycle tire (1) is formed with a plurality of coupling holes (3) at predetermined intervals; and stoppers (4) formed of synthetic resin materials are fixed in the coupling holes (3), stopped by annular holding protrusions (6) when the tire (1) is mounted to the bicycle rim (5), and formed of arch surfaces (4a), horizontal surfaces (4b) and tilted both end surfaces (4c) so that the tilted both end surfaces (4c) are protruded when the stoppers (4) are fixed to the coupling holes (3). According to the bicycle tire of the present invention, the plurality of stoppers is maintained to be held by the annular holding protrusions when the tire is mounted to the bicycle rim. Therefore, the tire can be prevented from being unexpectedly separated from the rim by an impact and the like applied from the outside, thereby reducing the incidence of safety accidents during riding of the bicycle.

Owner:TANNUS CO LTD

Automatic unlocking system for shared bike

ActiveCN107203926ABicycle tyresIndividual entry/exit registersComputer graphics (images)Single vehicle

The invention relates to an automatic unlocking system for a shared bike. The automatic unlocking system comprises an image acquisition device, an image recognition device, a local storage device, an image matching device and an electric control lock device, wherein the image acquisition device is used for acquiring high-definition image data of riding users to obtain and output high-definition user images; the image recognition device is used for segmenting face patterns of the users from the high-definition user images; the local storage device pre-stores pre-shot images of excellent riding users on all levels; the image matching device performs matching on the face patterns of the users one by one with the pre-shot images of the excellent riding users on all levels, and an excellent user presence signal is output once matching succeeds; the electric control lock device is used for unlocking the shared bike automatically for the corresponding riding user when the excellent user presence signal is received. The shared bike unlocking efficiency can be increased with adoption of the automatic unlocking system.

Owner:MENGCHENG COUNTY HONGWEN INFORMATION TECH CO LTD

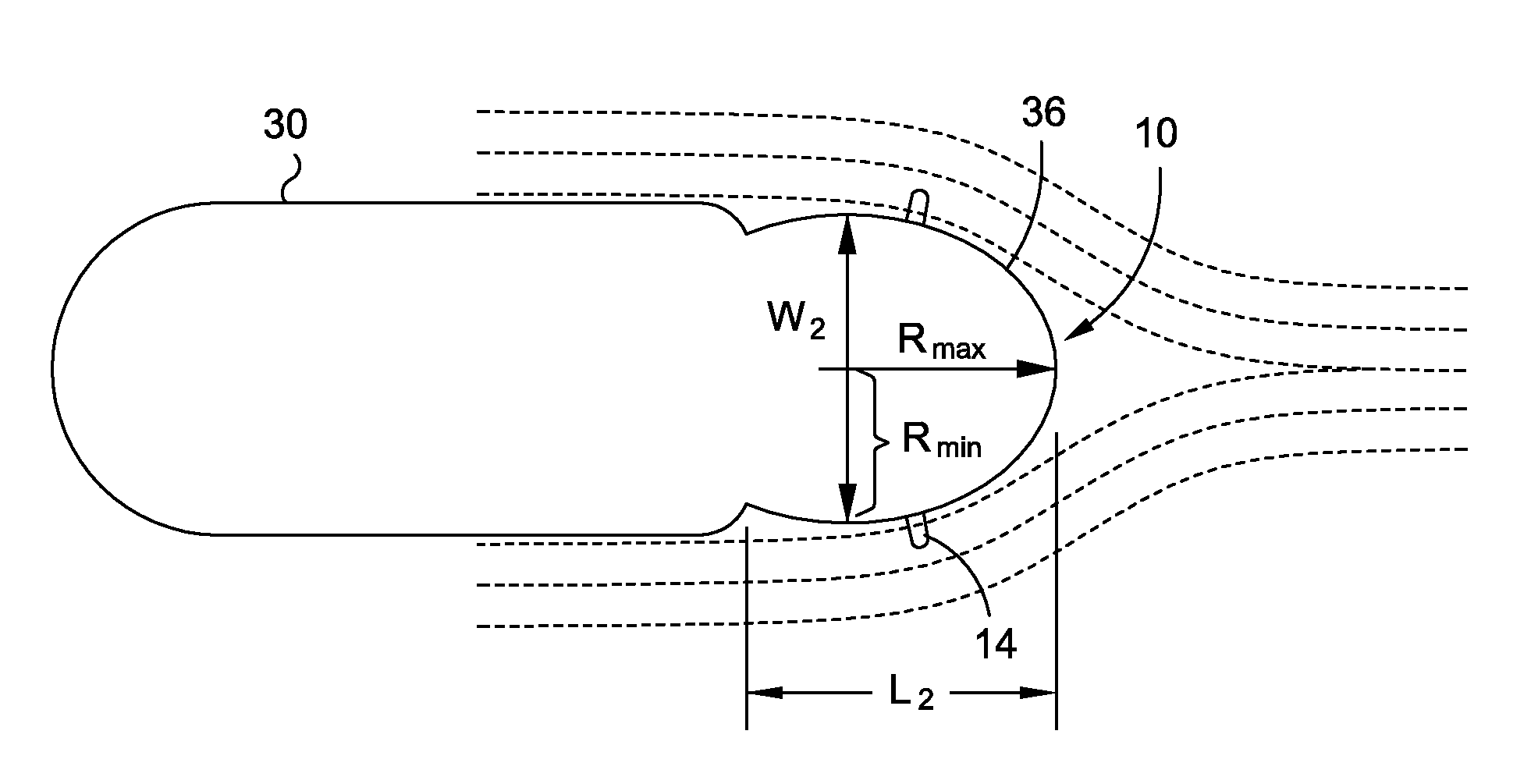

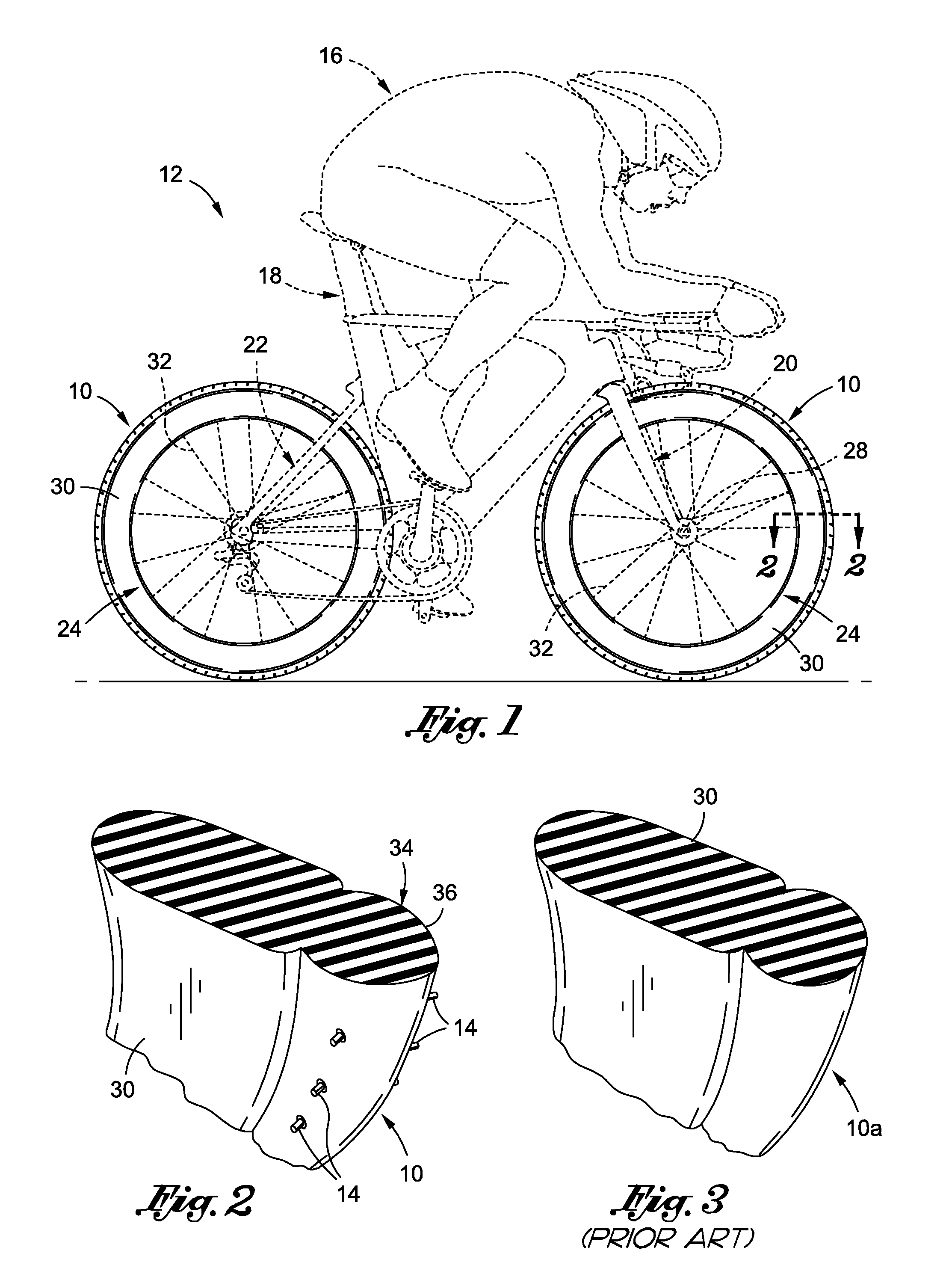

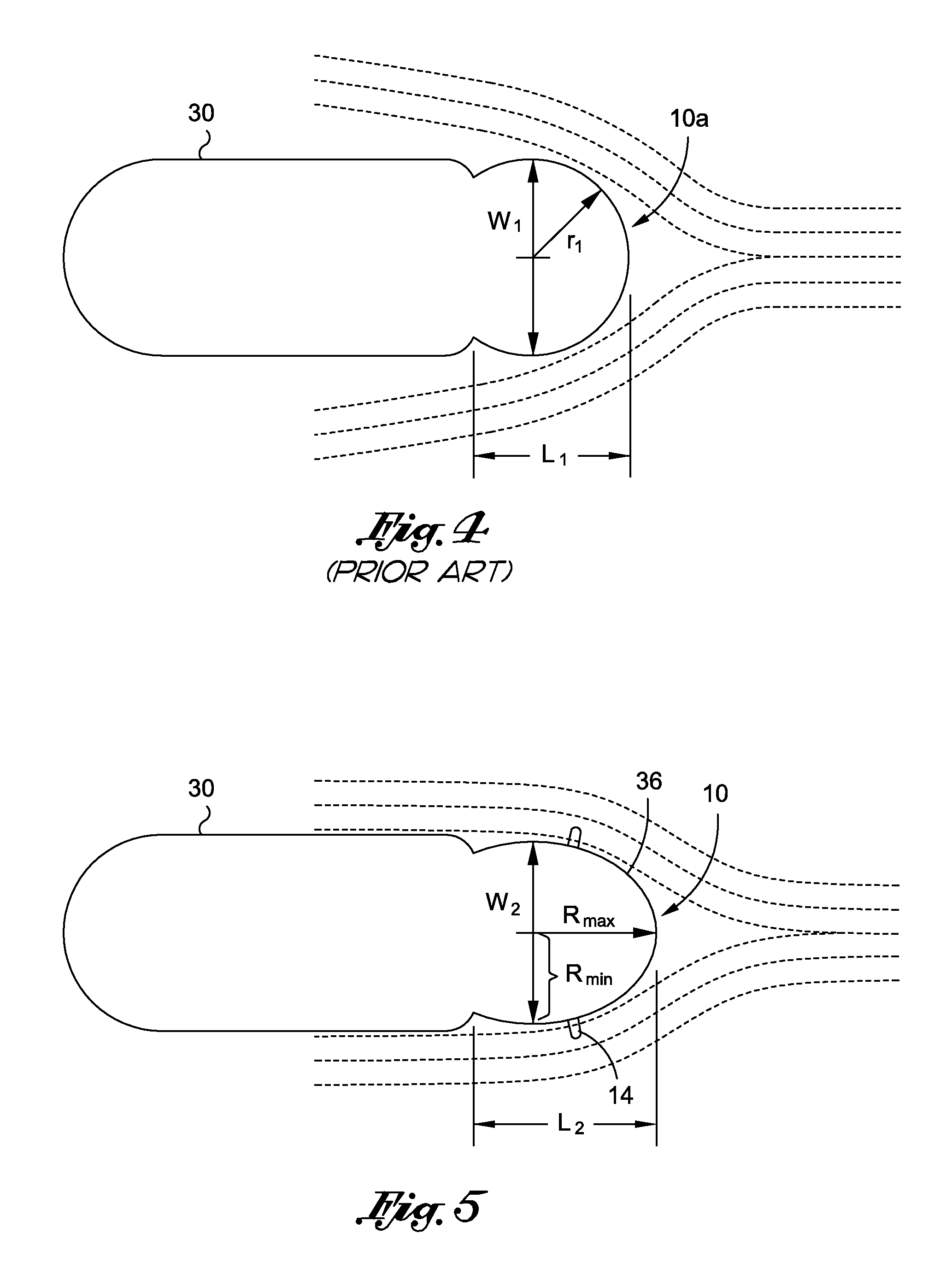

Aerodynamic bicycle tire

InactiveUS20140069562A1Improving aerodynamic qualityMinimize disruptionBicycle tyresInflatable tyresEllipseClosed loop

Provided is a bicycle tire for use with a bicycle wheel. The bicycle tire includes a tire body defining a closed loop and being configured to be engagable with the bicycle wheel. The tire body defines an outer periphery and includes an exposed portion extending radially outward from the bicycle wheel when engaged therewith. The exposed portion is externally configured to define a partial, non-circular ellipse in a cross sectional plane perpendicular to the tangent of the outer periphery. The partial ellipse includes a closed end portion at the outer periphery and an open end portion adjacent the bicycle wheel. A plurality of nubs is attached to the tire body, with the nubs being configured to remain attached thereto during the life of the bicycle tire. The nubs are sized and configured to enhance the aerodynamics of the bicycle tire as the tire rotates and translates through a fluid.

Owner:FELT RACING

PU solid bicycle tire containing ETPU foaming particles and manufacturing method of PU solid bicycle tire

ActiveCN107443644AIncrease elasticityReduce weightBicycle tyresNon-inflatable tyresSingle vehicleCentrifugal force

The invention discloses a PU solid bicycle tire containing ETPU foaming particles and a manufacturing method of the PU solid bicycle tire. The manufacturing method comprises the following steps: using existing production equipment for producing the PU solid bicycle tire for production, and adding the ETPU foaming particles into a mold in advance, wherein the volume of the ETPU foaming particles is 15% to 20% of the total volume of the mold; pouring raw materials for synthesizing PU into the mold through a casting machine; during centrifugal pouring, controlling the rotating speed of a centrifugal mold to be 850 to 1000 r / min; and during pouring, under the effect of centrifugal force, gathering the ETPU foaming particles with relatively small density towards the inner ring part of the tire, wherein relatively few ETPU foaming particles are arranged at the outer ring part of the tire, and micro foaming PU is mainly arranged at the outer ring part of the tire. The PU solid bicycle tire has the advantages that the elasticity and riding comfort level are greatly improved, and the elasticity is increased by 20% to 30%; the weight of the solid bicycle tire is reduced, and the weight of each tire is reduced by about 1 kg; and existing production equipment for polyurethane solid bicycle tires can be used for processing, so that the cost is not obviously increased.

Owner:SHANGHAI WINNER ENG

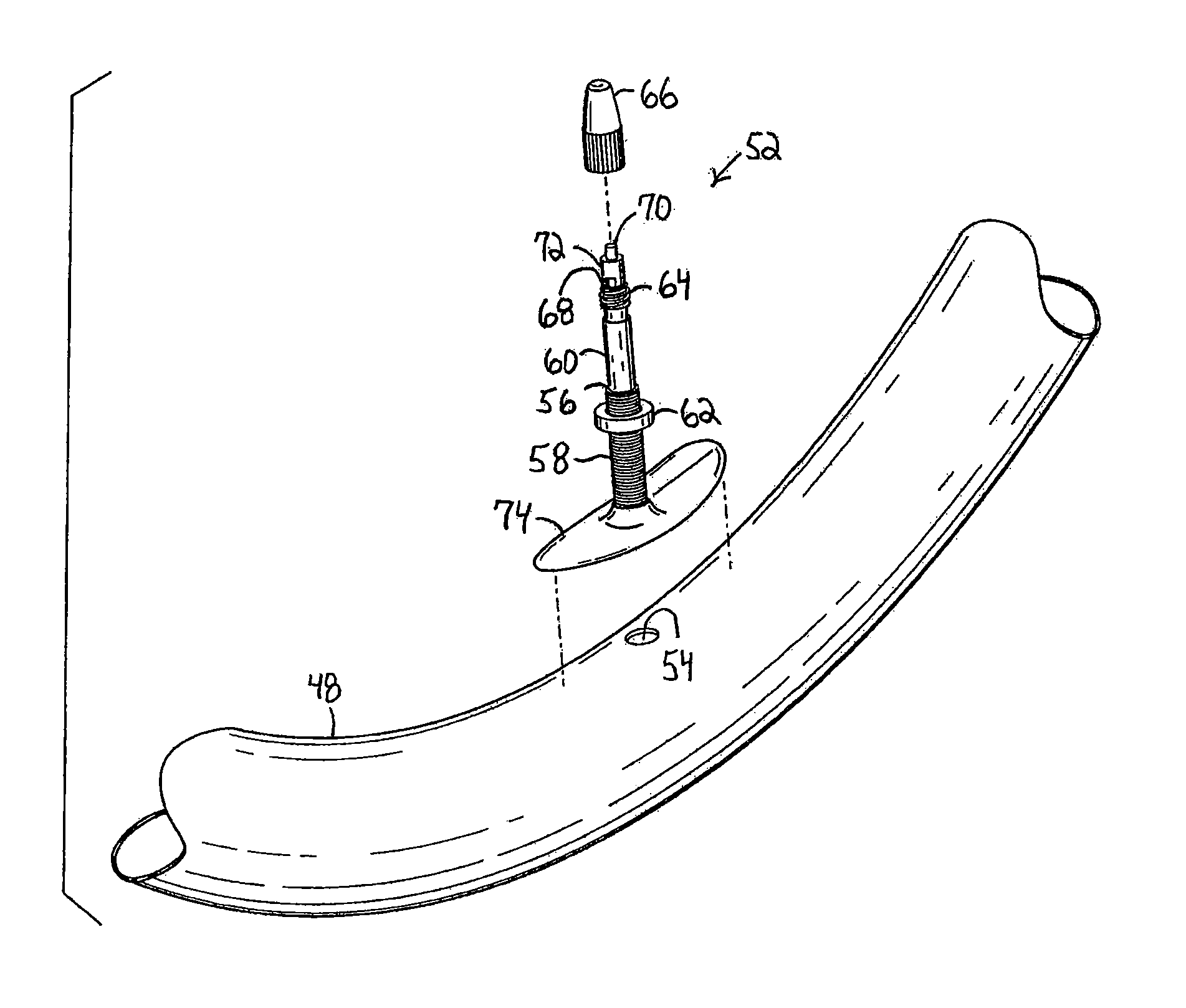

Inner-tube assembly for bicycle wheel

ActiveUS8122927B2Reduce generationGood adhesionBicycle tyresWith separate inflatable insertsMechanical engineeringAspect ratio

An inner-tube assembly that includes an inner-tube and a valve assembly. The valve assembly is configured to facilitate the inflation of the inner-tube, and the valve assembly includes a valve core and a valve housing. The valve housing has a lower portion coupled to the inner-tube and an opposite upper portion. At least part of an exterior surface of the lower portion is threaded and at least part of an exterior surface of the upper portion is unthreaded. In another aspect, the inner-tube assembly includes the inner-tube and a valve assembly. An attachment member couples the valve assembly to the inner-tube. The attachment member has a length and a width defining an aspect ratio of width / length, and the aspect ratio is less than about 0.50.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

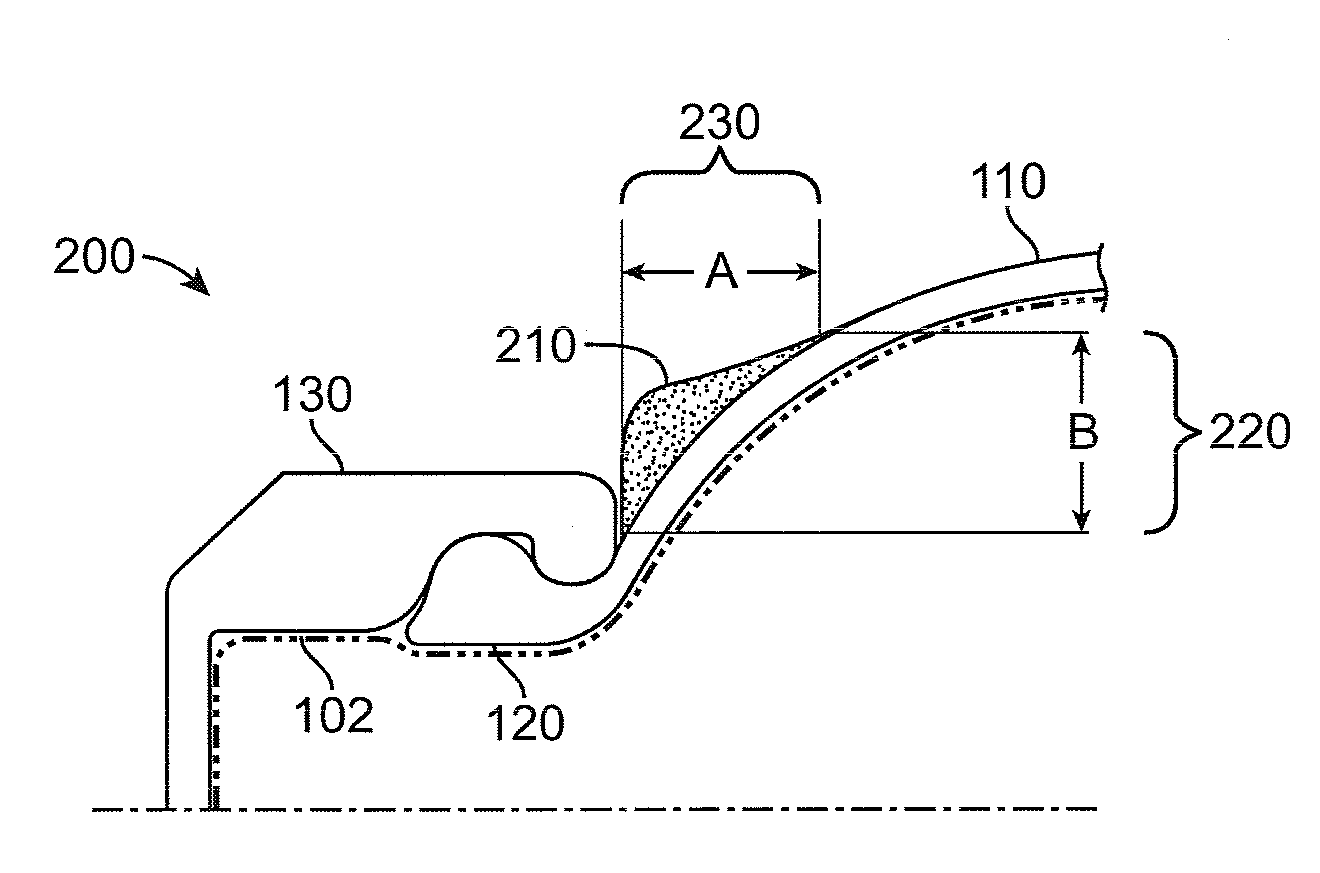

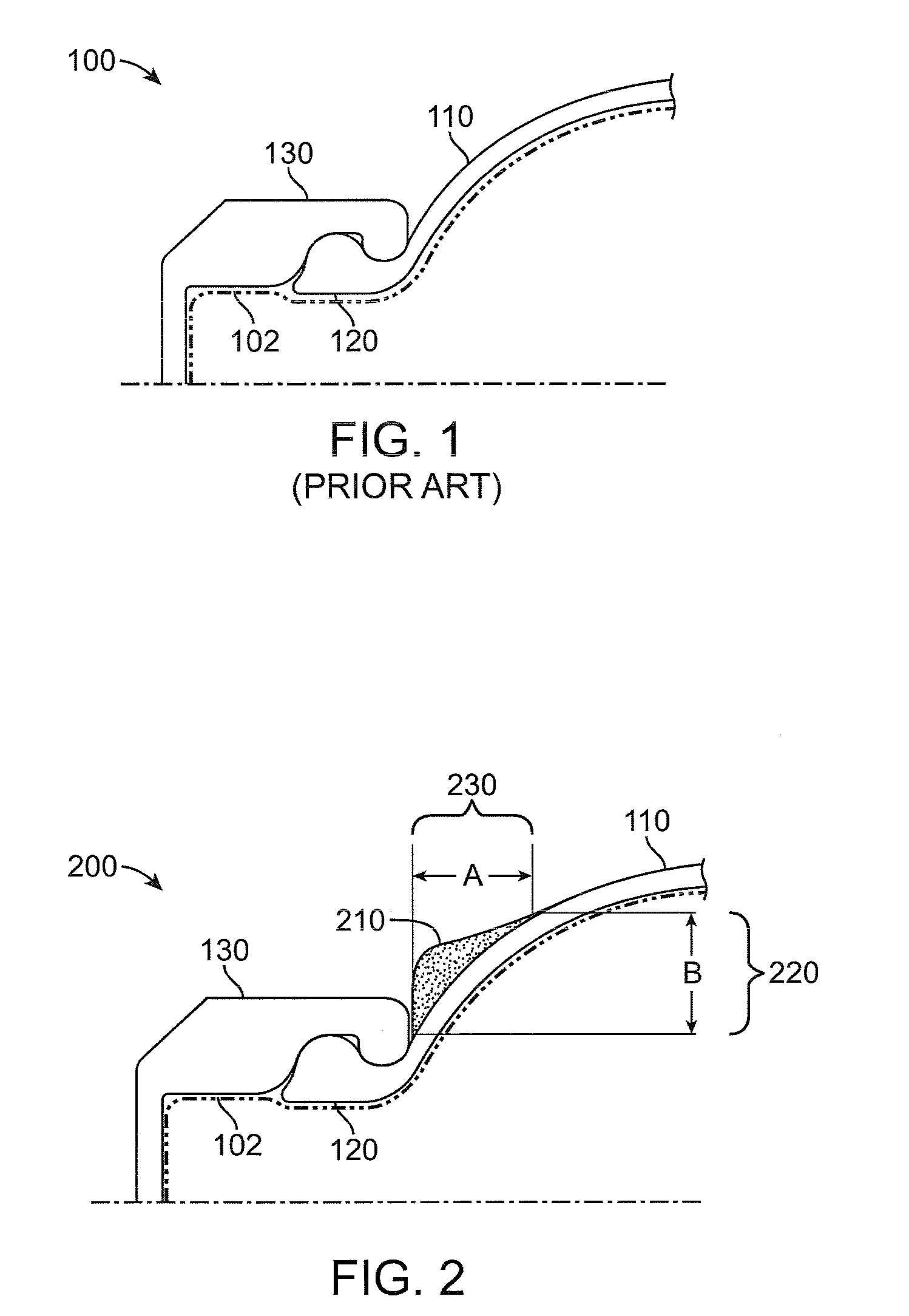

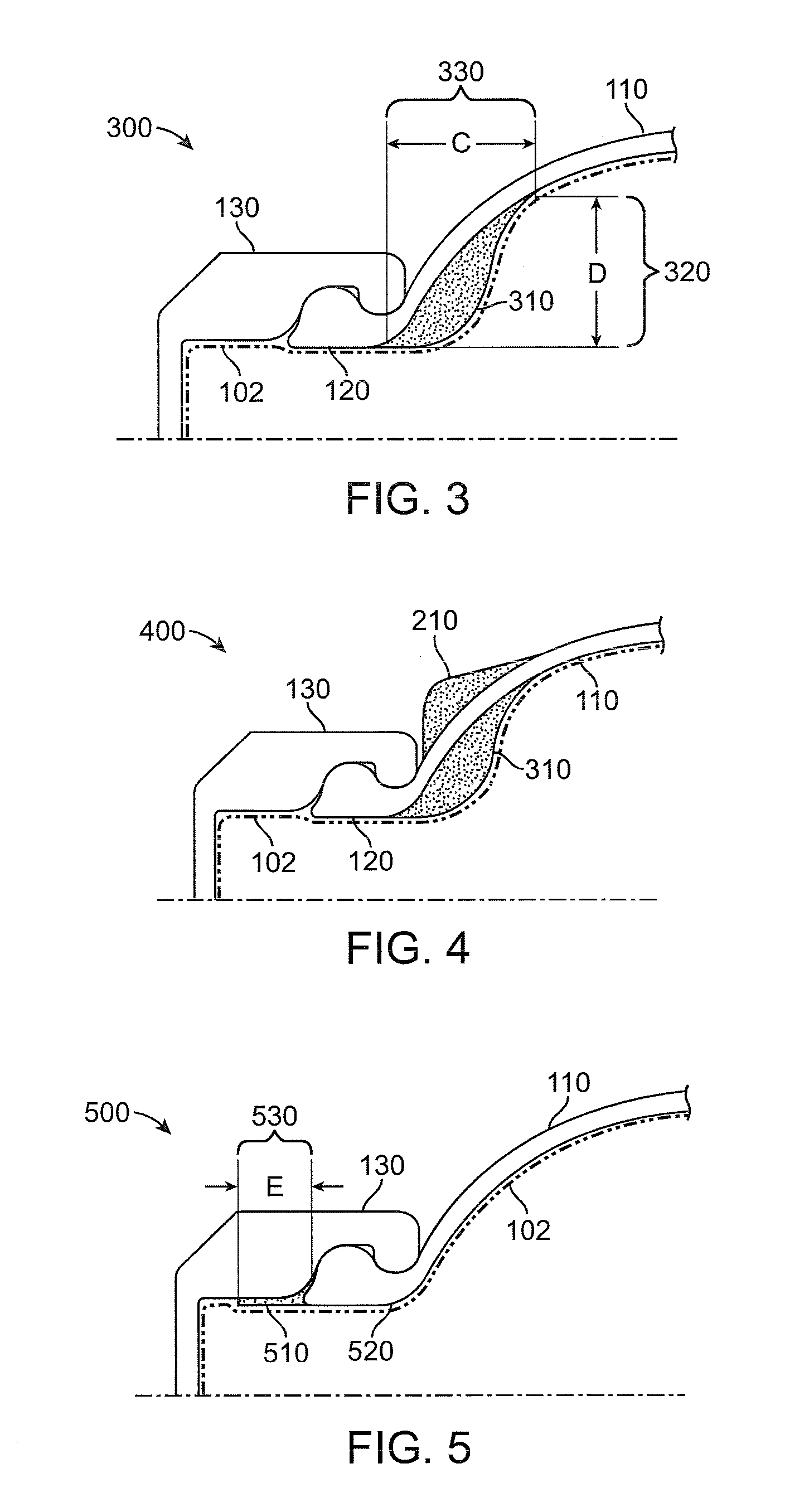

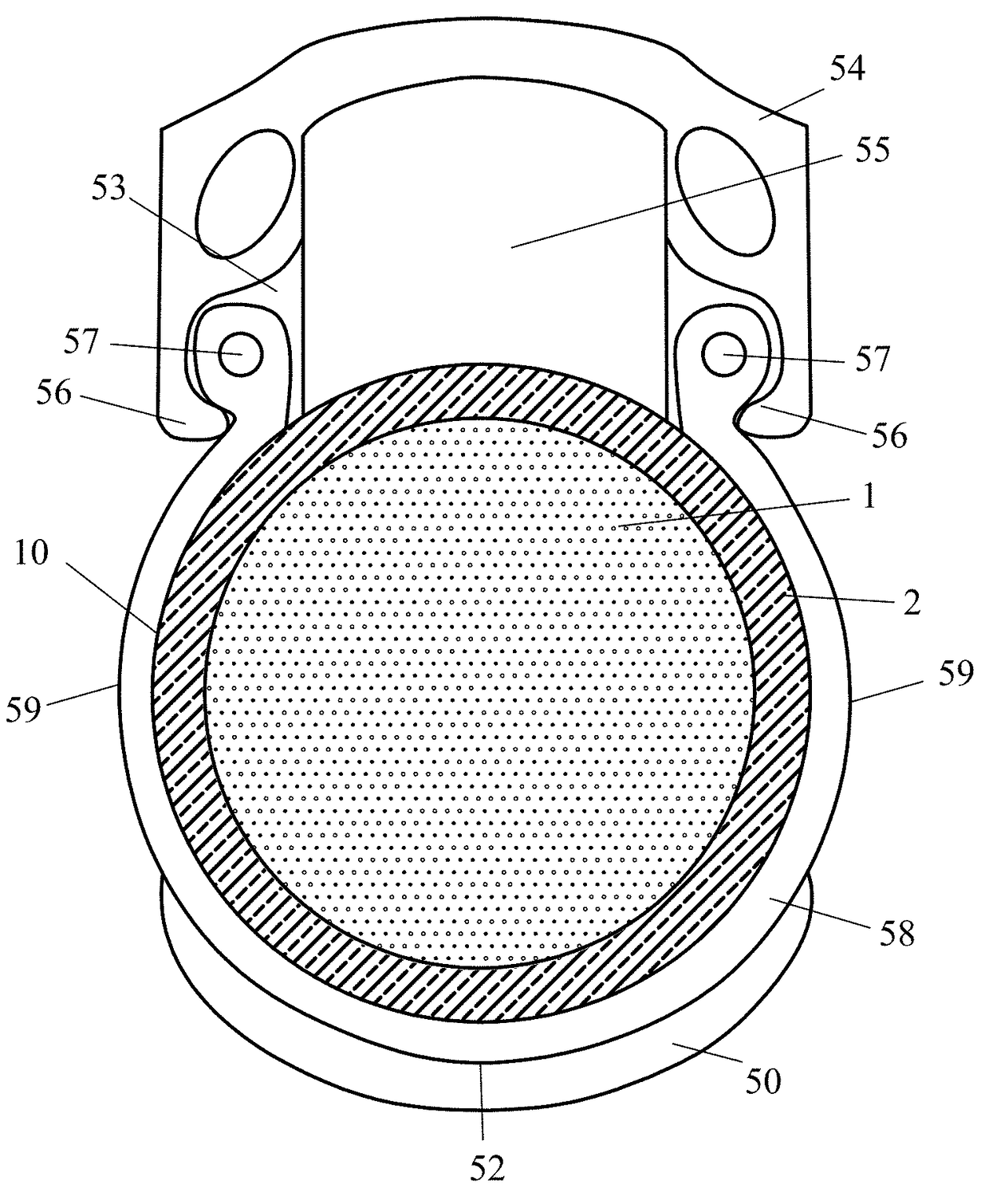

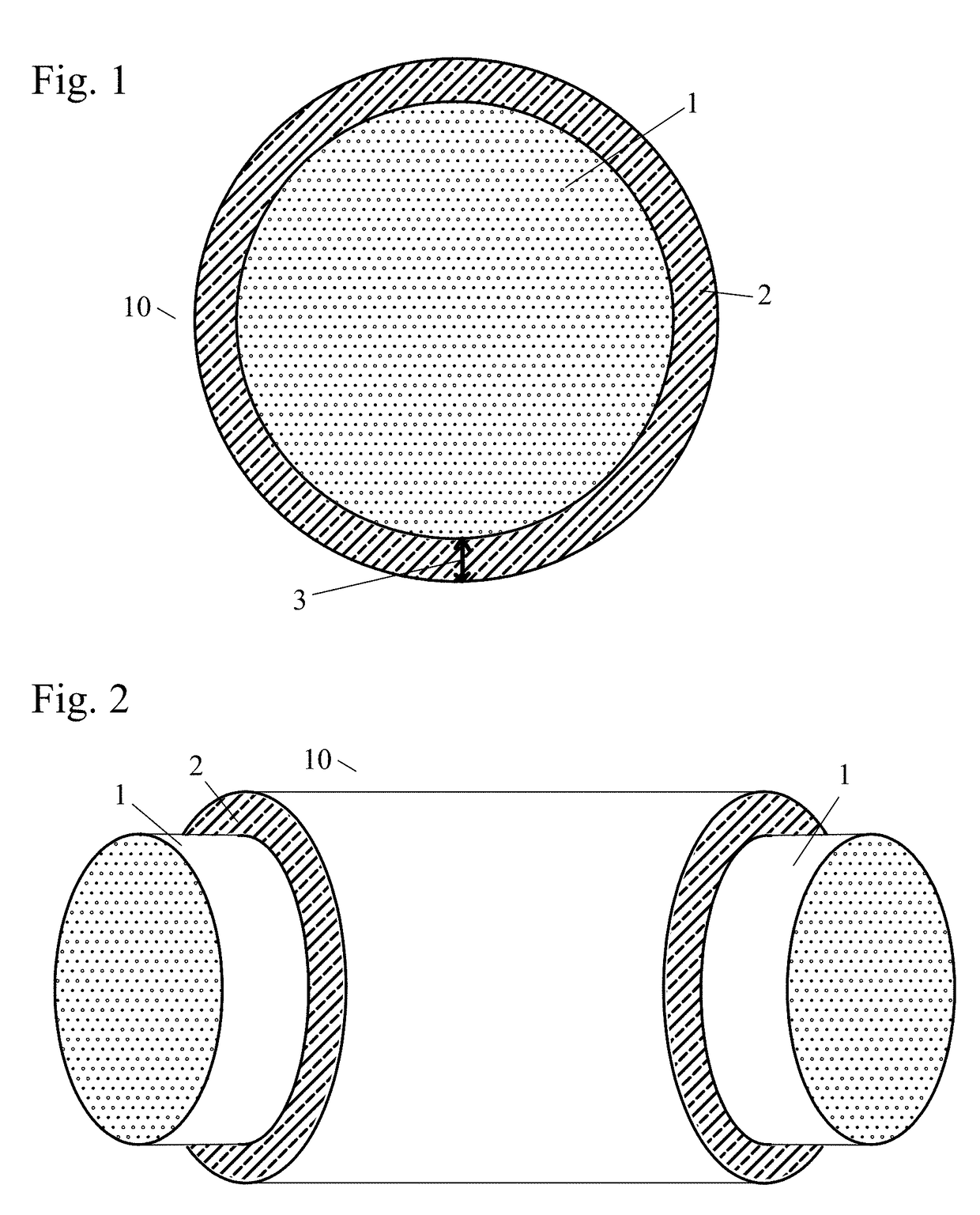

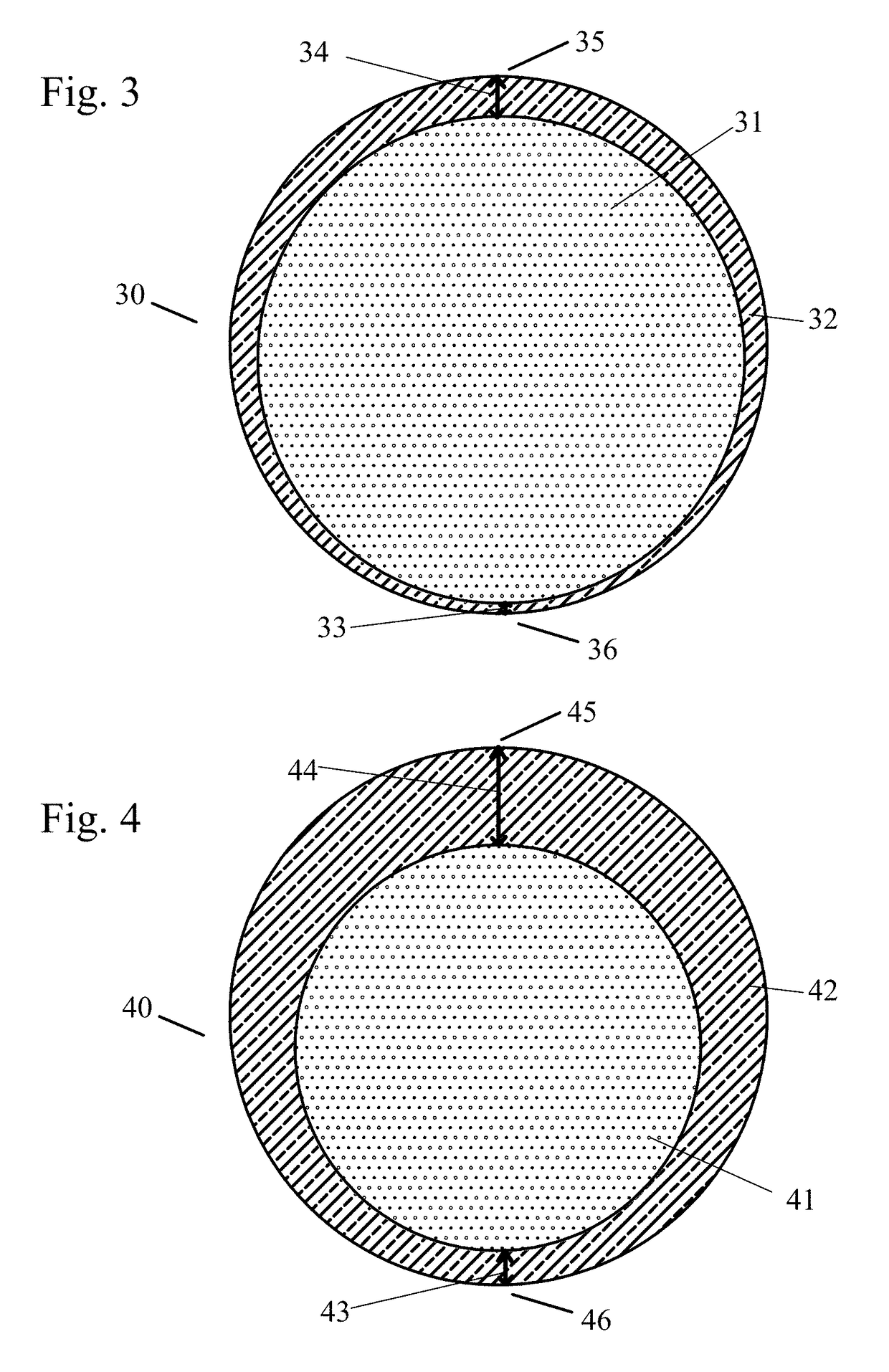

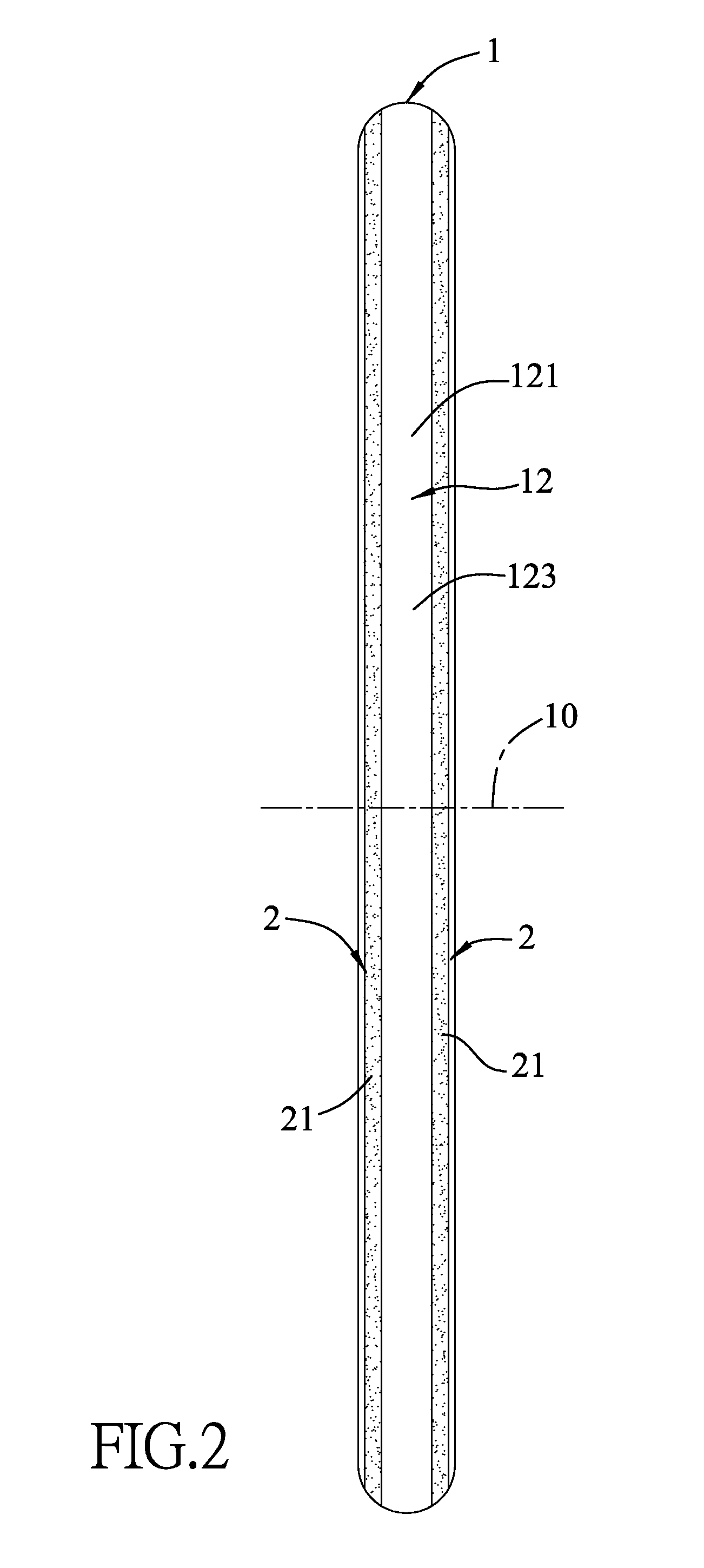

Multiple Layer Foam Insert for Tires

ActiveUS20170297375A1Preserving performance weightLoss is particularly problematicBicycle tyresNon-inflatable tyresEngineeringAtmospheric pressure

A multiple layer foam insert replacement for a pneumatic inner tube for a tire. The multiple layer foam insert emulates the effect of air pressure, across a range of pressures, while still approaching the weight of the air filled tube. Through the use of different density materials and the orientation and thickness of such materials, the desirable characteristics of the pneumatic tube structure and performance can be emulated to a high degree. This multiple layer foam insert can be produced in varying levels of quality and function through the method of extrusion of foam materials in different sizes and layering.

Owner:PETERMAN MARK H

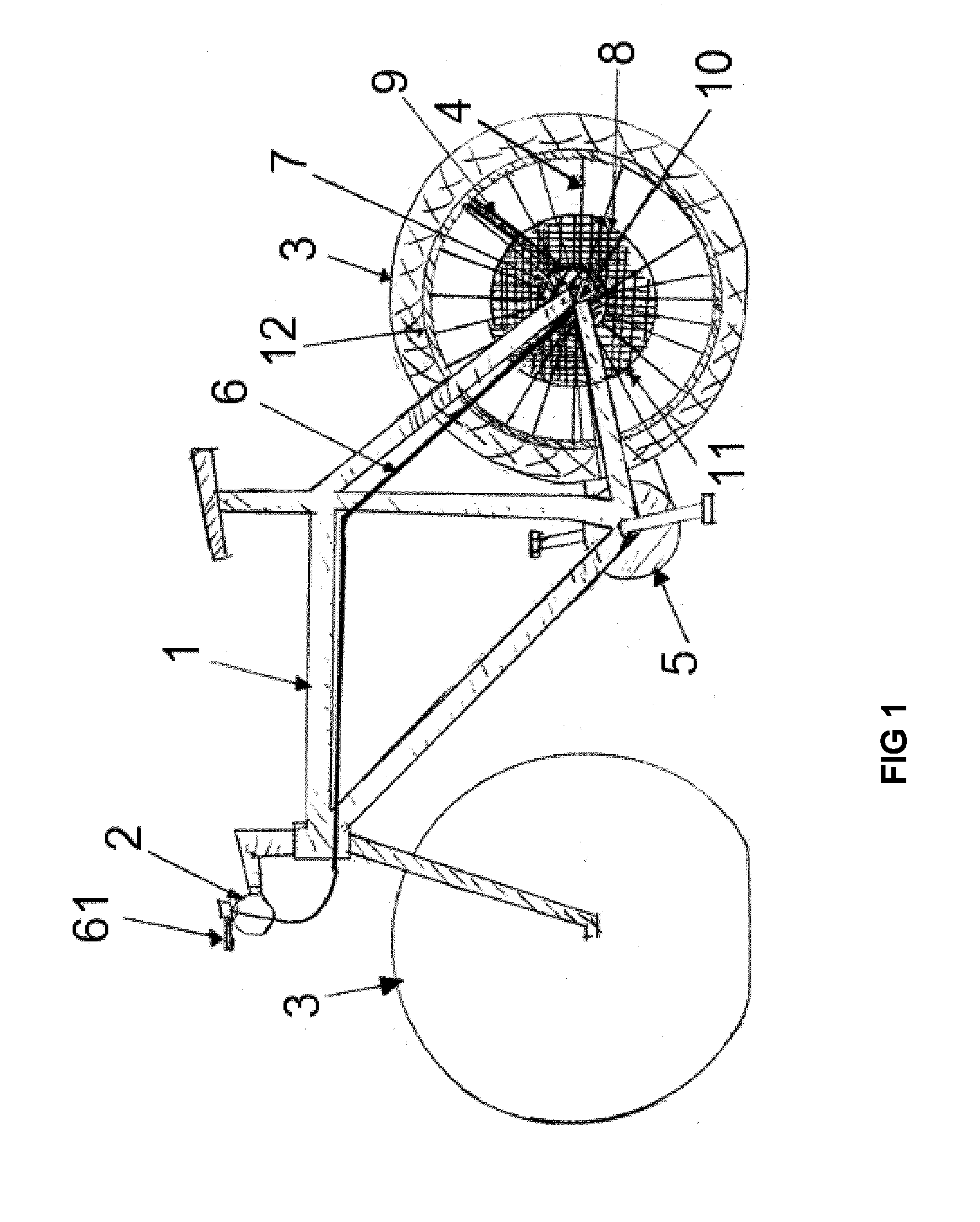

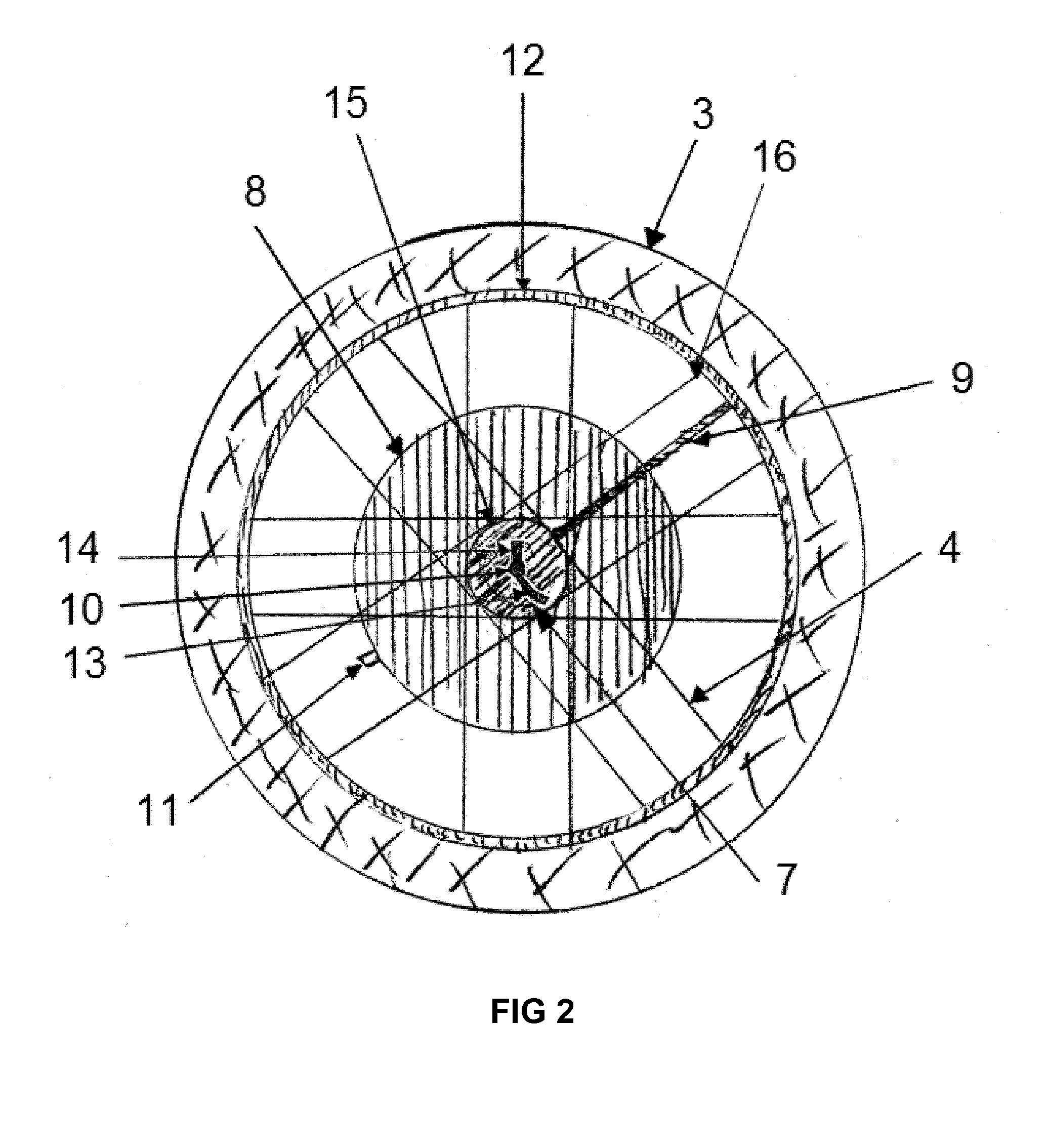

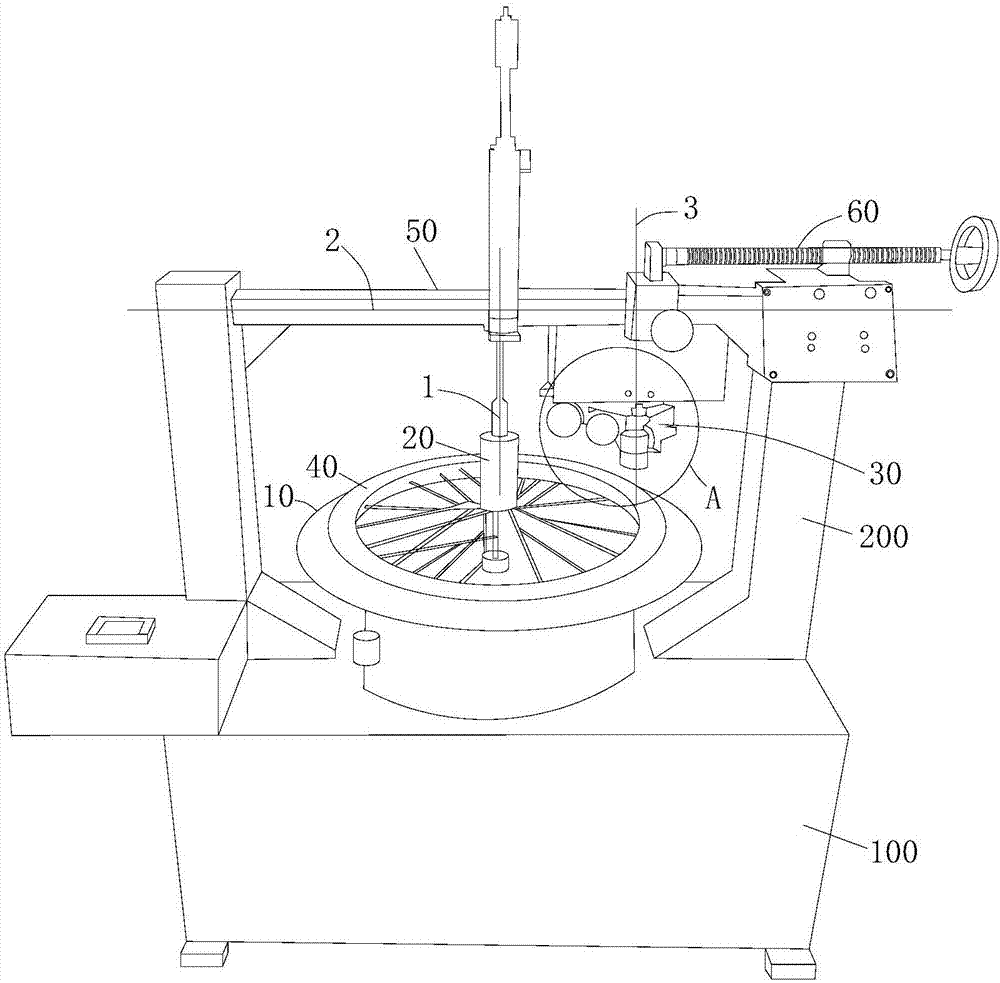

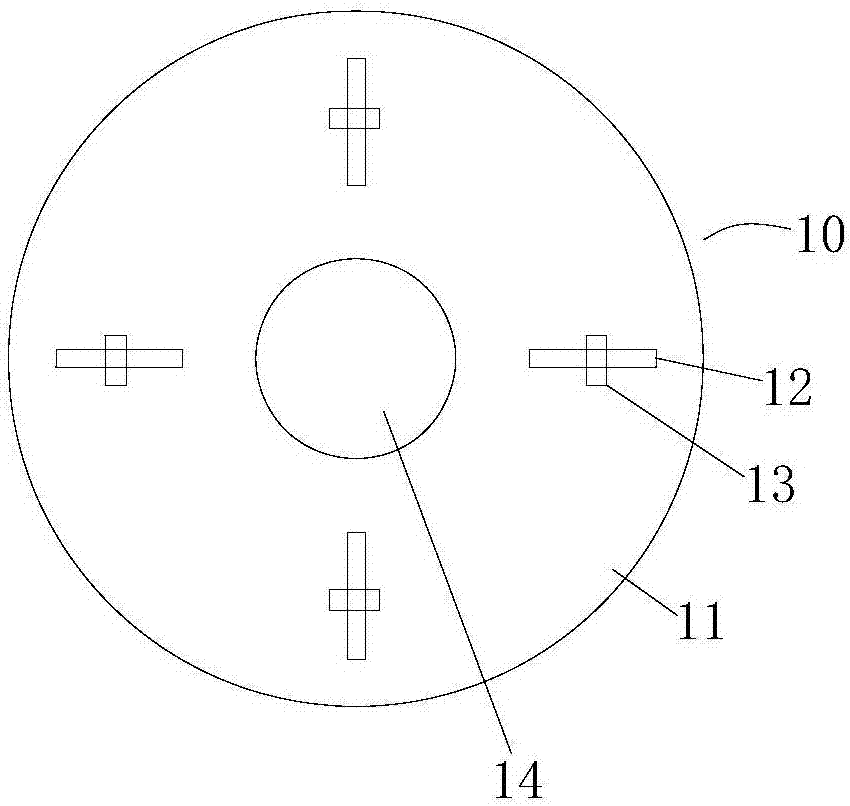

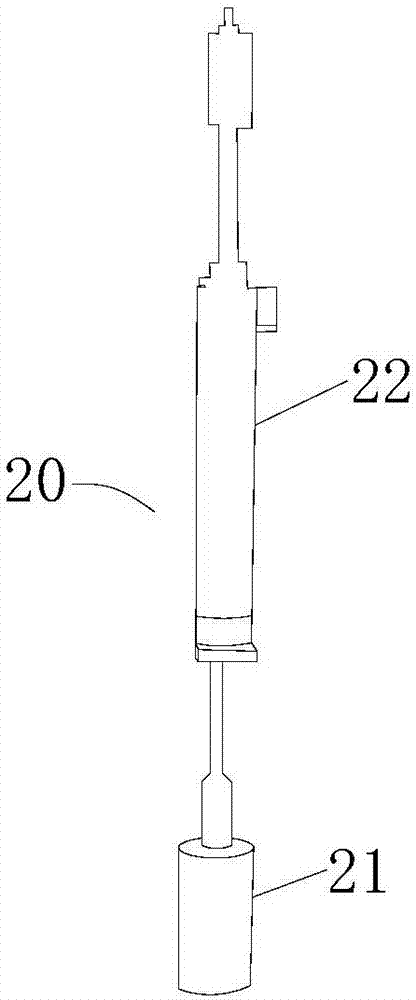

Tire installing machine suitable for bicycle wheel

InactiveCN107128135AEffective distanceEffectively extend the wheel distanceBicycle tyresBicyclesMechanical engineeringVertical axis

The invention discloses a tire installing machine suitable for a bicycle wheel. The tire installing machine comprises a wheel set rotary disk, a pressing and sleeving device and a wheel expanding device, wherein the wheel set rotary disk can rotate around a first vertical axis (1), the pressing and sleeving device can go up or down along the first vertical axis (1), and the wheel expanding device can go up or down along a second vertical axis (3); the wheel expanding device comprises a pressing wheel and an expanding wheel. The tire installing machine disclosed by the invention can be used for automatically install a non-pneumatic tire into a bicycle wheel rim, and is convenient to operate, and the efficiency is high.

Owner:叶凯旋 +1

Pressure measuring device

ActiveUS20190001765A1Measurement of fluid loss/gain rateBicycle tyresPressure measurementEngineering

A pressure measuring device for a bicycle has a housing that includes a pressure chamber. The pressure chamber has a valve disposed in a first opening and a second opening into or out of a tire assembly volume of a tire assembly. A sense element is in pressure communication with the pressure chamber along a flow path between the first and second openings.

Owner:SRAM CORPORATION

Safety warning tire

A safety warning tire for a vehicle includes: a tire body and at least one warning unit. The tire body has an annular tread portion adapted to contact a road surface, and two annular sidewalls respectively connected to two opposite sides of the annular tread portion. The annular tread portion has a tread surface. The tread surface has an annular contact surface region adapted to contact the road surface, and two annular non-contact surface regions respectively connected to two opposite sides of the annular contact surface region. The at least one warning unit is disposed on one of the annular non-contact surface regions and outer surfaces of the two annular sidewalls, and includes an annular coating layer that extends annularly along a circumference of the tire body.

Owner:SUNTOP ENTERPRISE

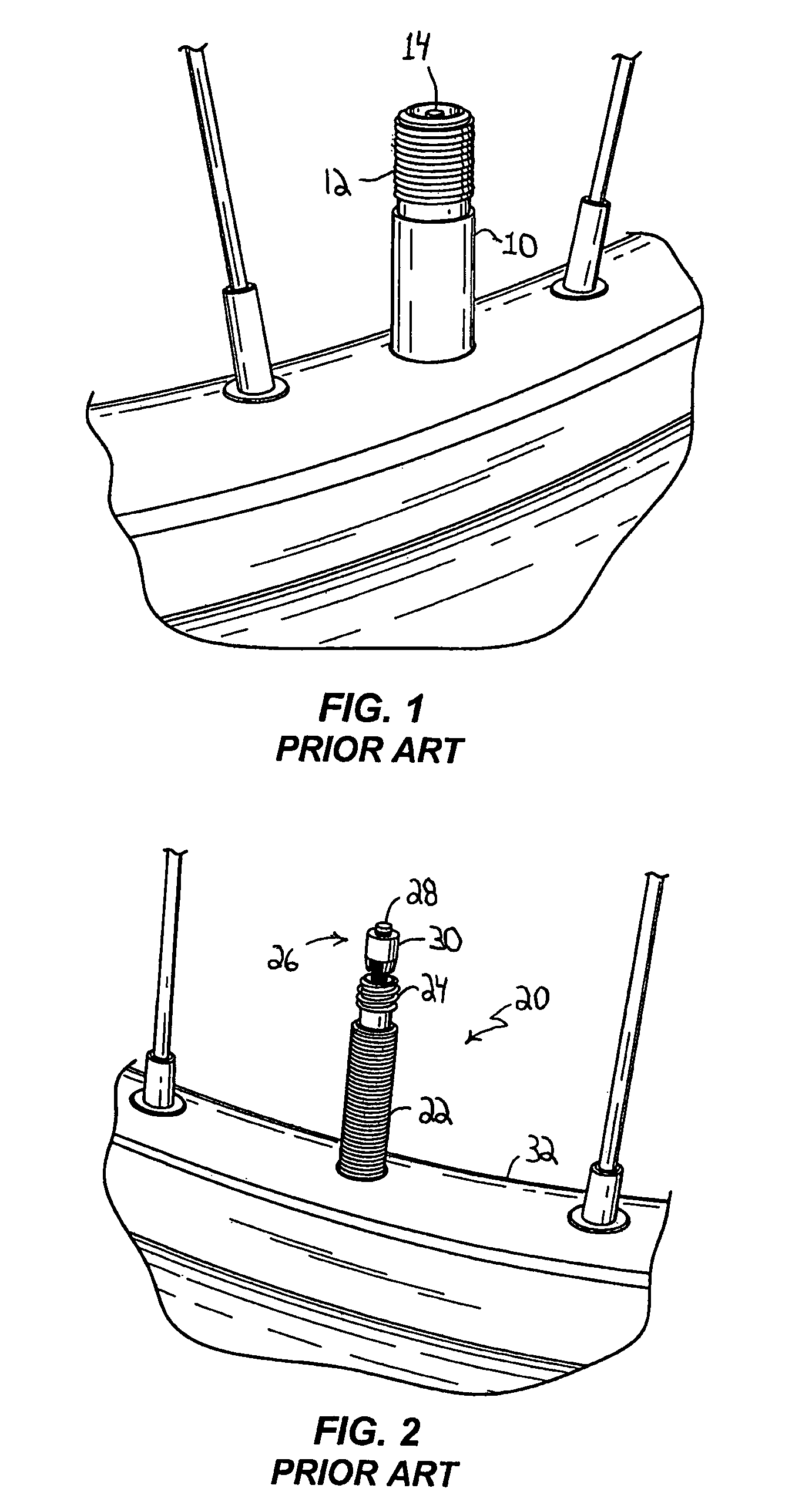

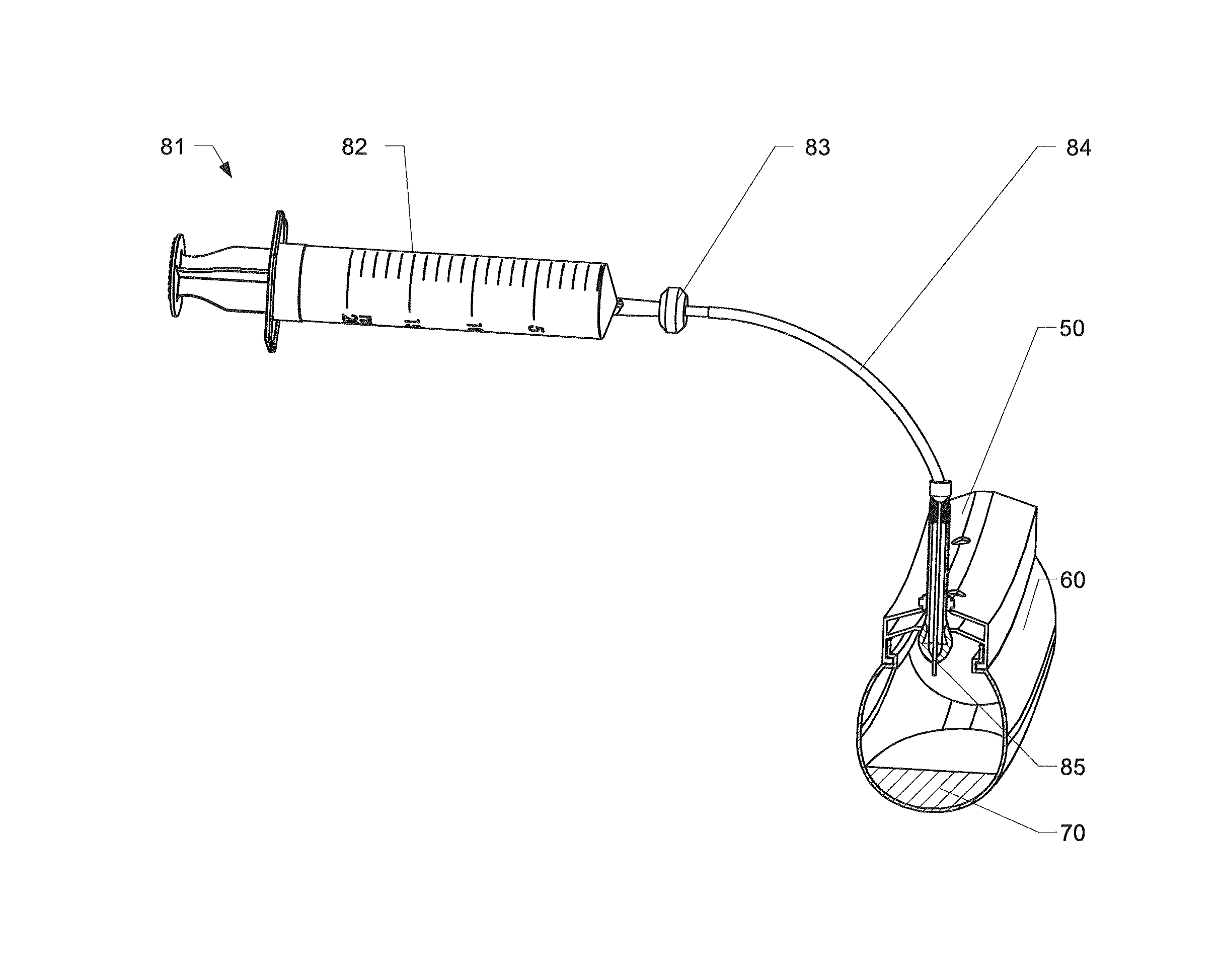

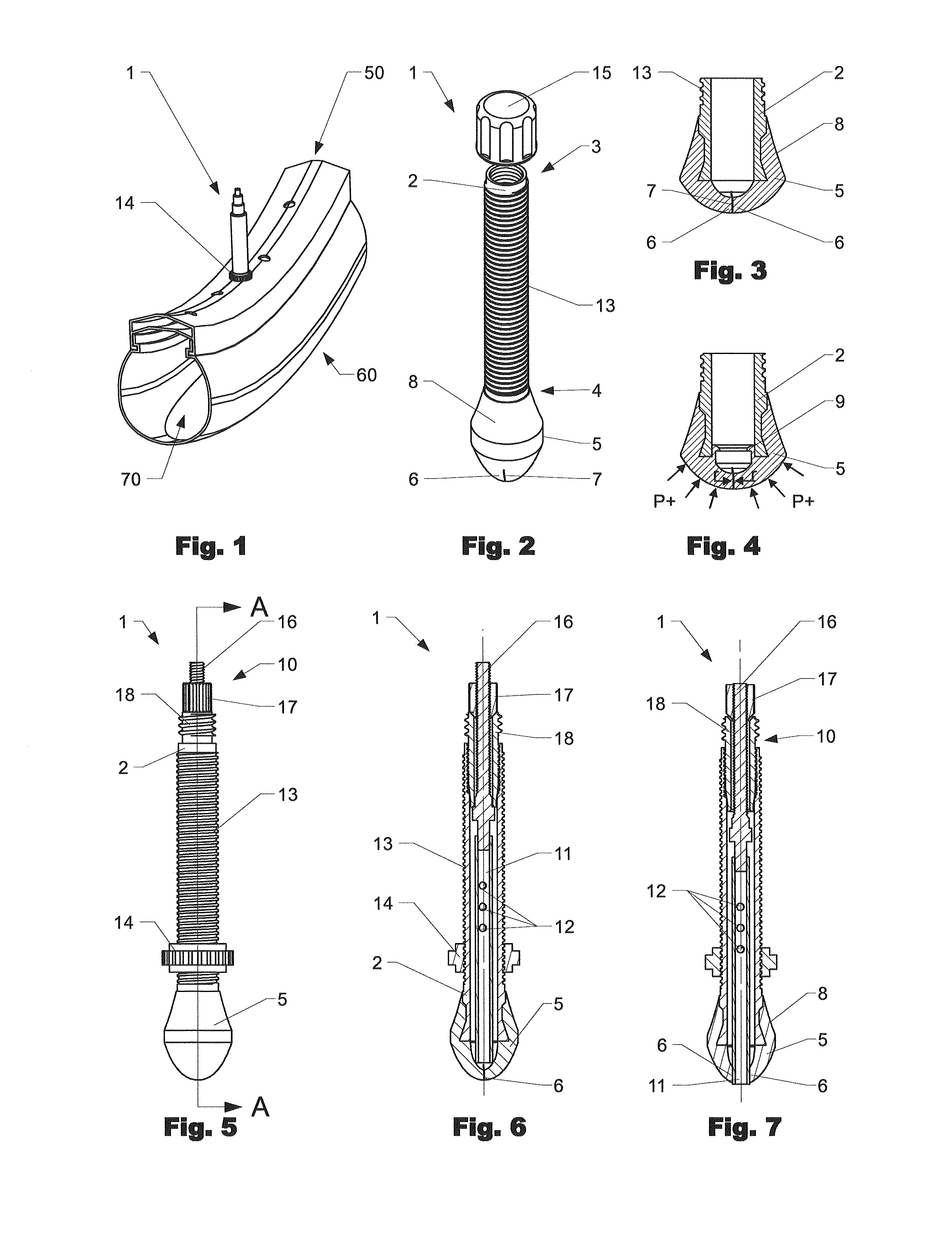

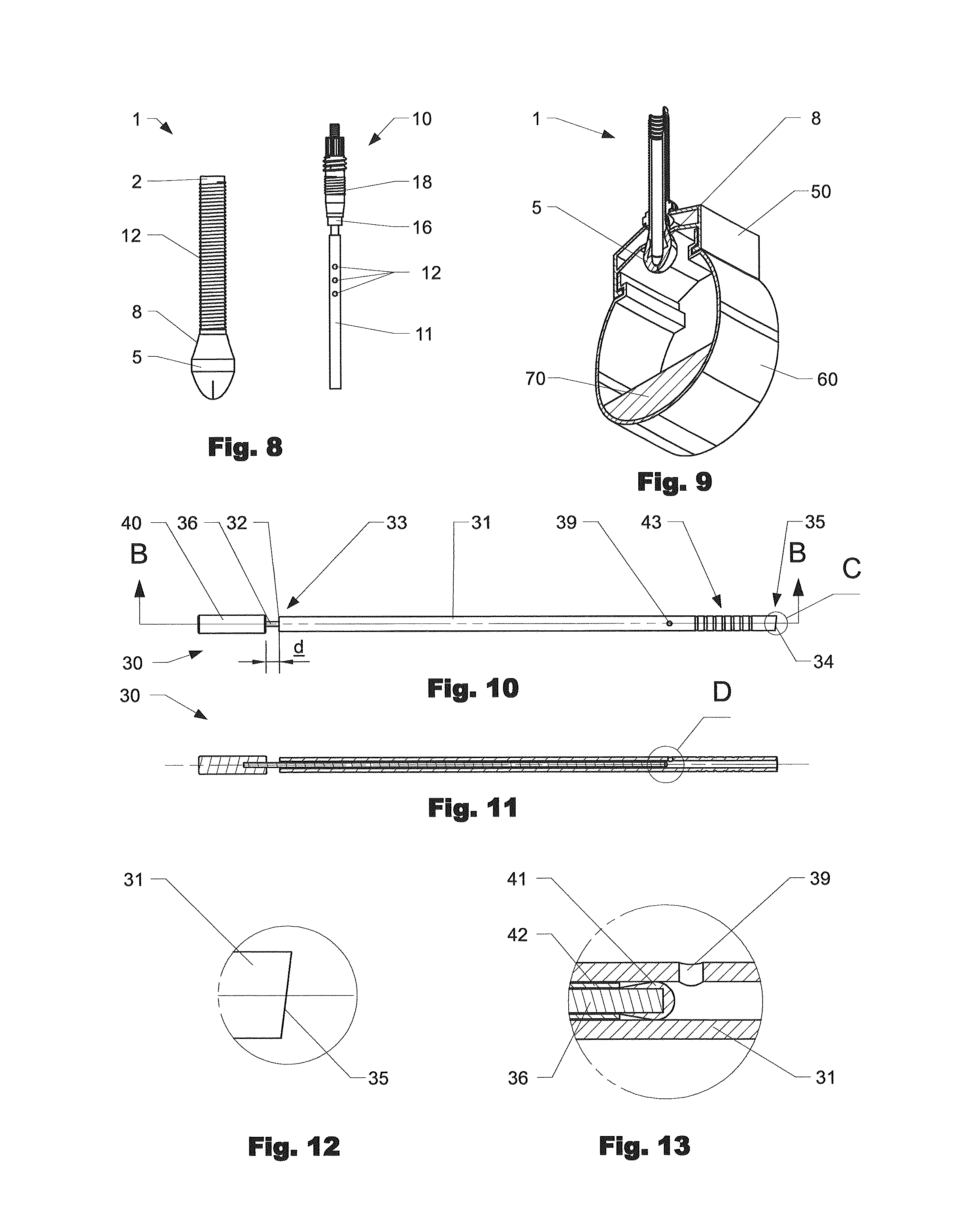

Valve for tubeless tires

InactiveUS20170057309A1Easily and precisely testedPromote resultsBicycle tyresWithout separate inflatable insertsTubeless tireEngineering

The invention is directed to a valve stem system (1) for tubeless wheels. The valve stem system (1) includes a valve stem body (2) with a first end (3) and a second end (4), wherein the second end (4) is located in a tire / rim-volume when mounted at the wheel. A first valve element (5) is arranged at the second end (4) of the valve stem body (2). The first valve element (5) is a self-sealing one-way valve. The invention further concerns a probe (30) for a valve stem system, a method to test the amount of sealant in a wheel and a refilling assembly (80) for a wheel.

Owner:SPORT COMPONENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com