Tread pattern structure of pneumatic tires for two-wheelers

A tread pattern and pneumatic tire technology, applied to tire tread/tread pattern, bicycle tires, two-wheeled bicycles, etc., can solve the problems of low groove edge composition, large tire tread pattern, poor wear performance, etc. , to achieve the effect of ensuring wear performance and drainage performance and improving traction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

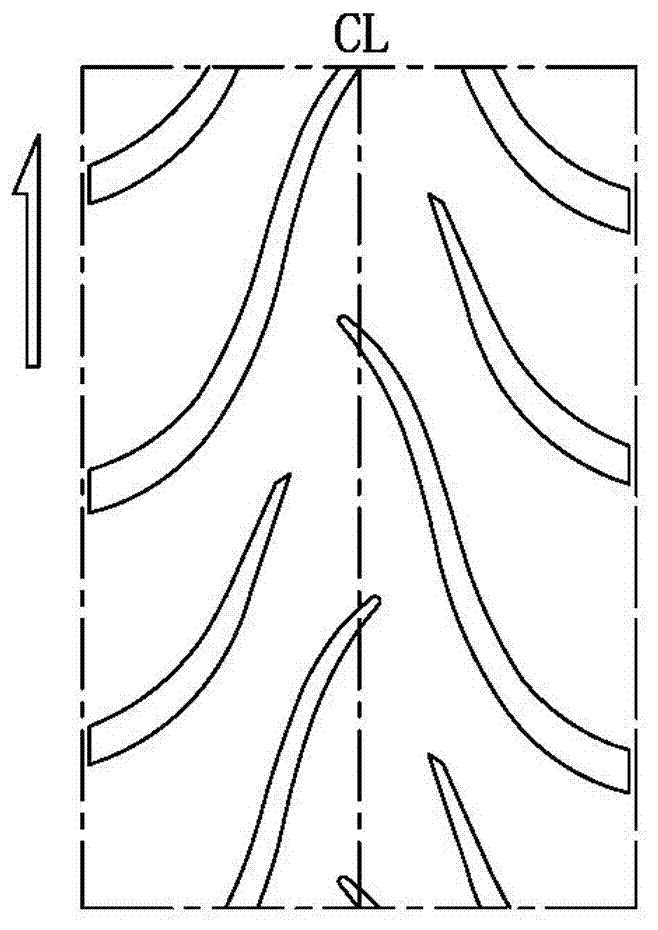

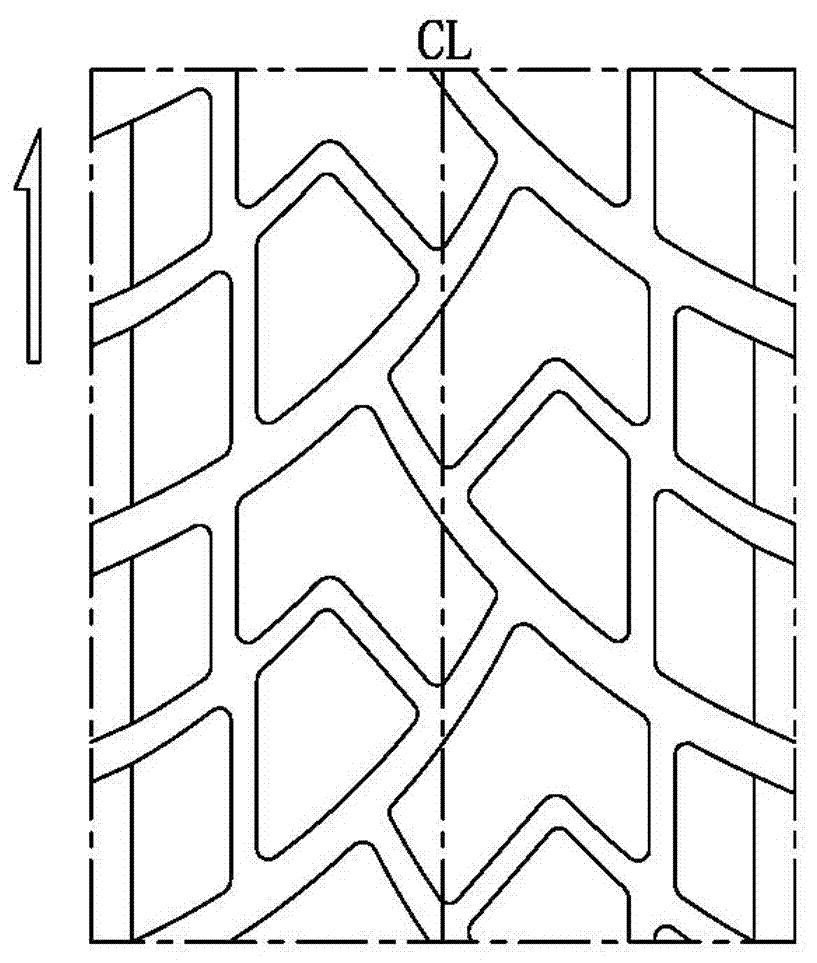

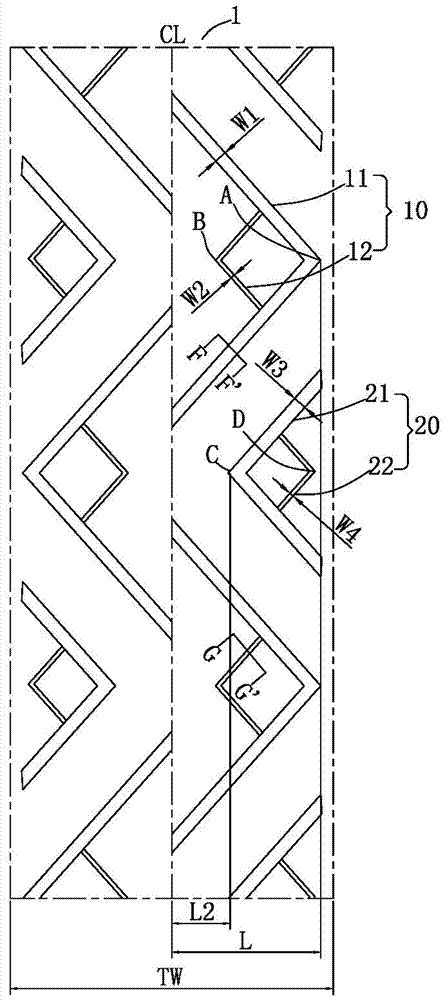

[0025] like Figure 3 to Figure 9 As shown, the present invention discloses a tread pattern structure of a pneumatic tire for two-wheeled vehicles, wherein the lateral direction is the tire axial direction, the vertical direction is the tire circumferential direction, and CL is the equatorial plane.

[0026] like Figure 3 to Figure 8 As shown in the figure, the tire tread 1 is composed of several groove units arranged symmetrically and staggered along the tire circumferential direction. In order to improve the traction performance of the tire tread, the protagonist groove 10 extends from the equatorial plane to the shoulder, and is formed by connecting a wide protagonist groove 11 with an opening toward the axial inner side and a narrow protagonist groove 12 with an opening toward the axial outer side. , the secondary angle groove 20 is arranged between the primary groove 10 on the same side of the tread equatorial plane and the primary groove 10 of another adjacent pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com