Pneumatic tire with tread siping

A technology for sipes and tires, applied to tire treads/tread patterns, tire parts, vehicle parts, etc., can solve problems such as slowing down tread energy accumulation, sipe wear, and weakening the resistance of tread elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following text describes the best contemplated mode or implementation of the invention. The purpose of this description is to illustrate the general principles of the invention and should not be construed in a limiting sense. The scope of the invention is best determined by reference to the appended claims.

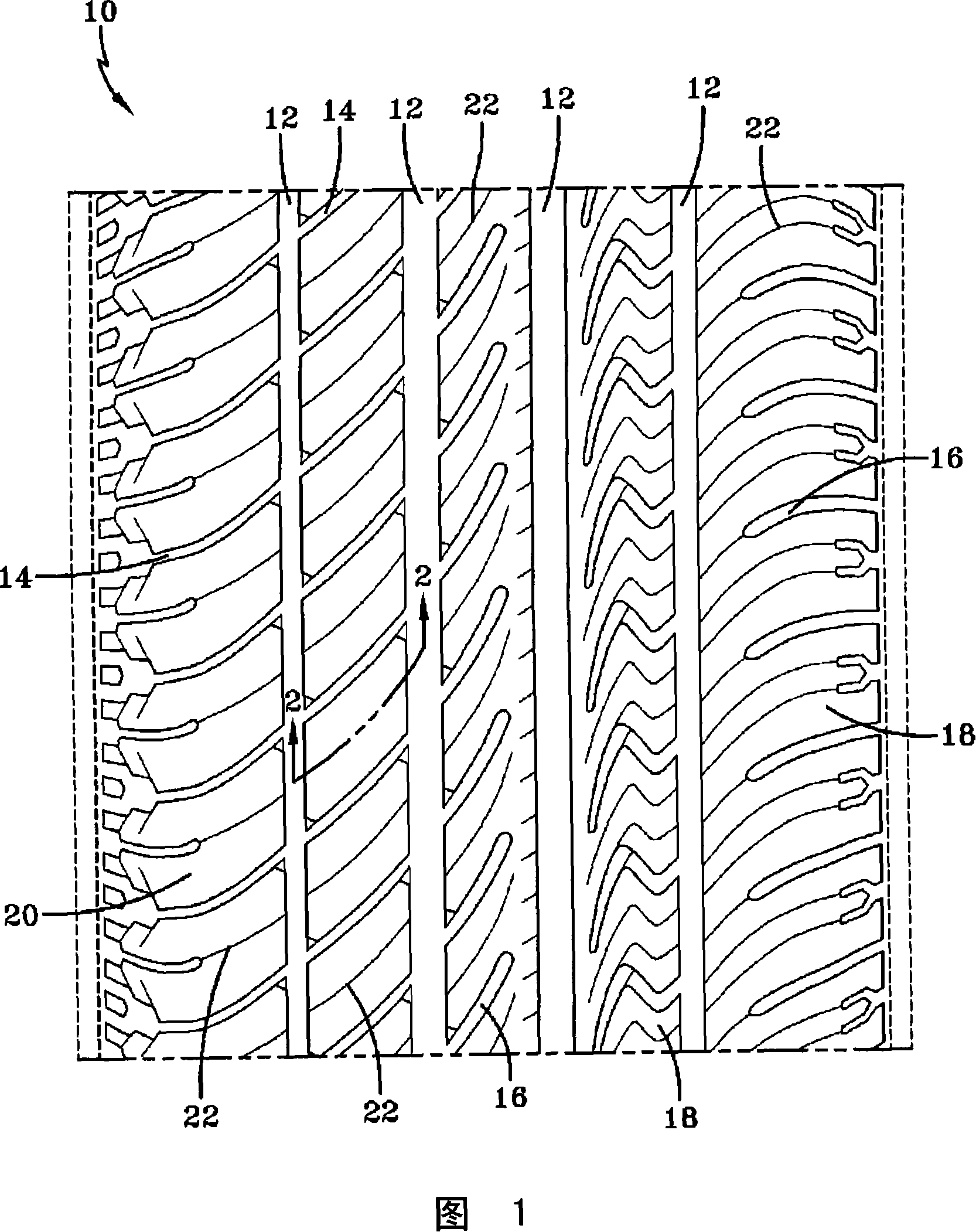

[0029] Figure 1 shows an exemplary tread 10 for a pneumatic tire. Tires using the tread shown may be of radial or bias configuration; more typically a radial configuration. The tire tread 10 has a plurality of circumferential grooves 12 and a plurality of transverse grooves 14 , 16 . These grooves 12 , 14 , 16 are combined differently from the plurality of tread elements 18 , 20 . Some of the transverse grooves 14 extend between the circumferential grooves 12 and some of the transverse grooves terminate inside the tread elements 18 , 20 forming blind grooves 16 . For the tread shown, there is at least one sipe inside each tread element 18, 20, either block-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com