Material strip granulation production process and material strip traction equipment used in material strip granulation production process

A traction equipment and production process technology, applied in the field of strip production equipment, can solve problems such as uneconomical use, inconvenience for winding or cutting, and different traction forces, and achieves a high degree of intelligence, automation, and work efficiency. And high quality, anti-offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

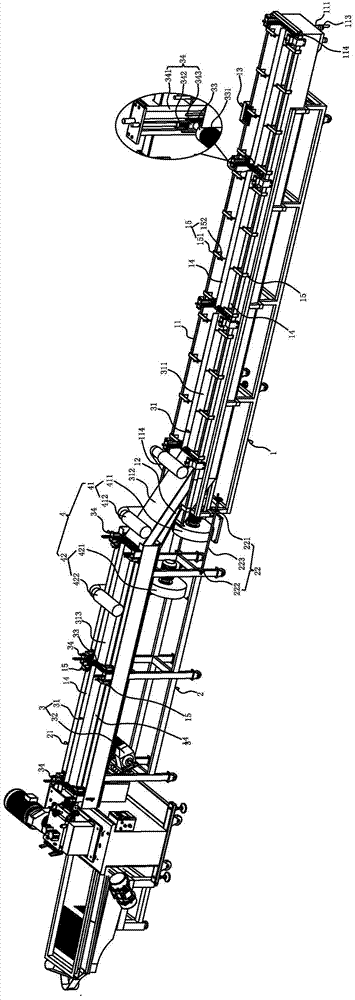

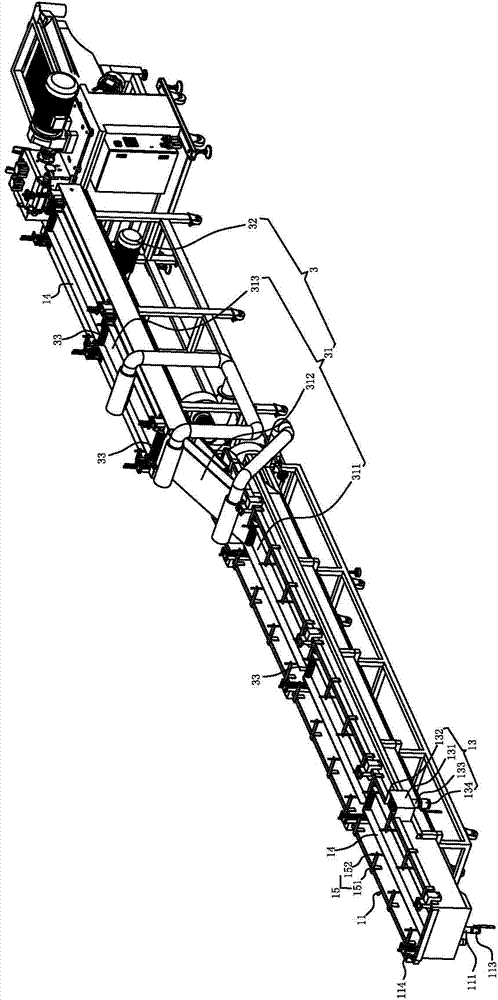

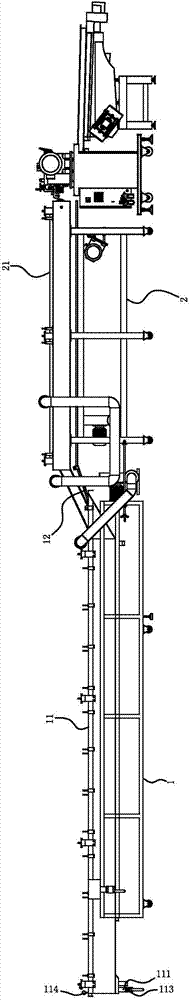

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0024] A kind of strip pelletizing production process, it comprises the following steps:

[0025] Step 1: Place the plastic raw material in the strip extruder, which heats and melts the plastic raw material, and extrudes multiple plastic strips at one time.

[0026] Step 2: The extruded plastic strips are sent to the cooling water tank of the strip traction equipment, the water in the cooling water tank cools the plastic strips, and the first section of the conveyor belt in the cooling water tank cooperates with the rollers to continuously clamp Tight plastic strips for delivery.

[0027] Step 3: The plastic strip is conveyed to the second conveying track in the inclined state in the strip traction equipment, and the plastic strip is air-dried through the air-drying device, wherein the generated water is installed on the second The water pan unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com